Extrusion press

一种挤压机、挤压杆的技术,应用在金属挤压、压头/冲杆、金属加工设备等方向,能够解决精度及能量效率差、调整麻烦、环境不良影响等问题,达到提高生产效率、作业环境改善、运转效率好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

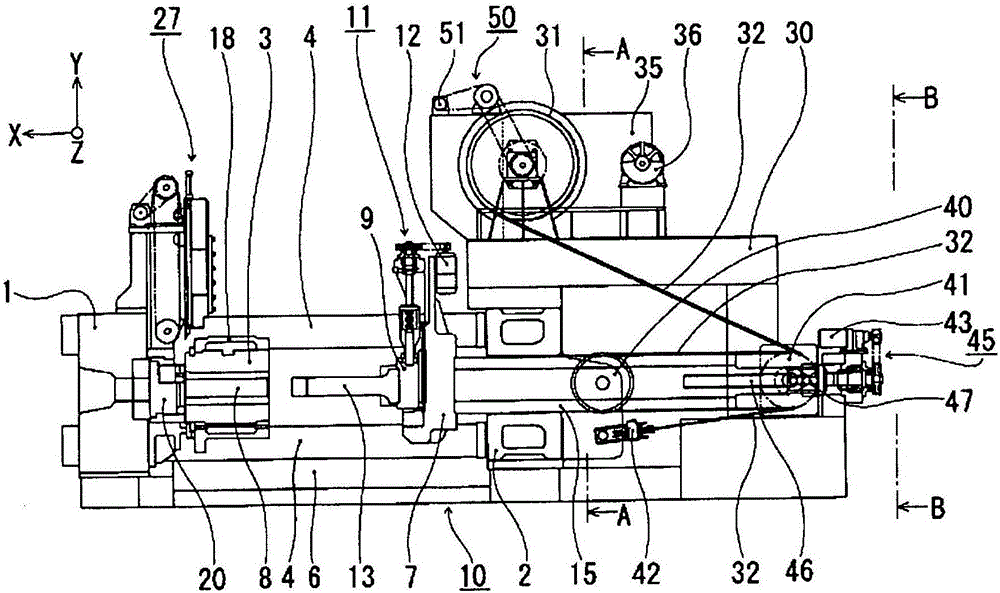

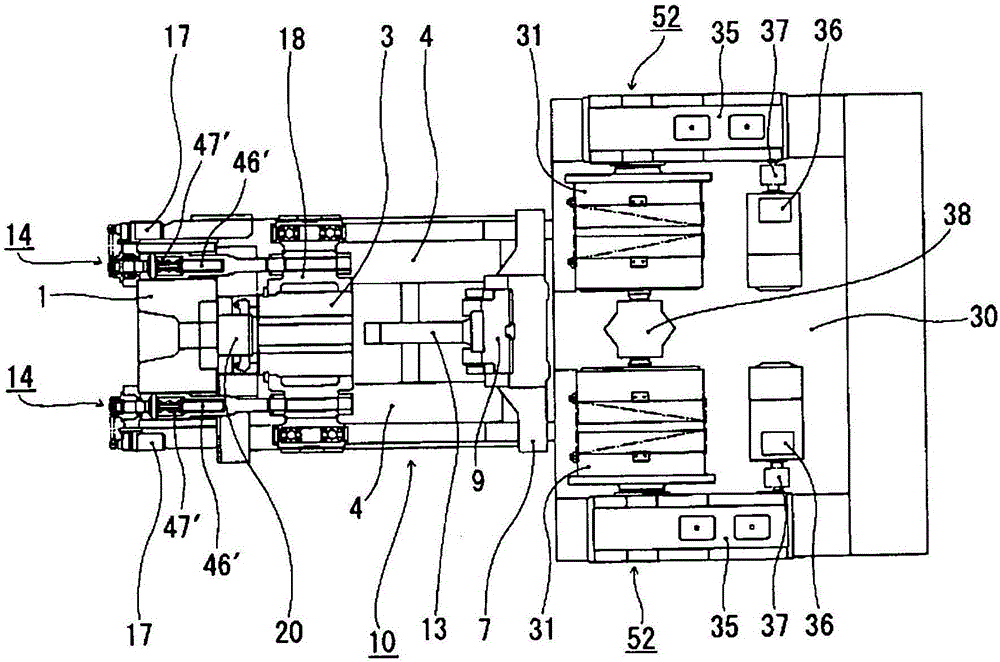

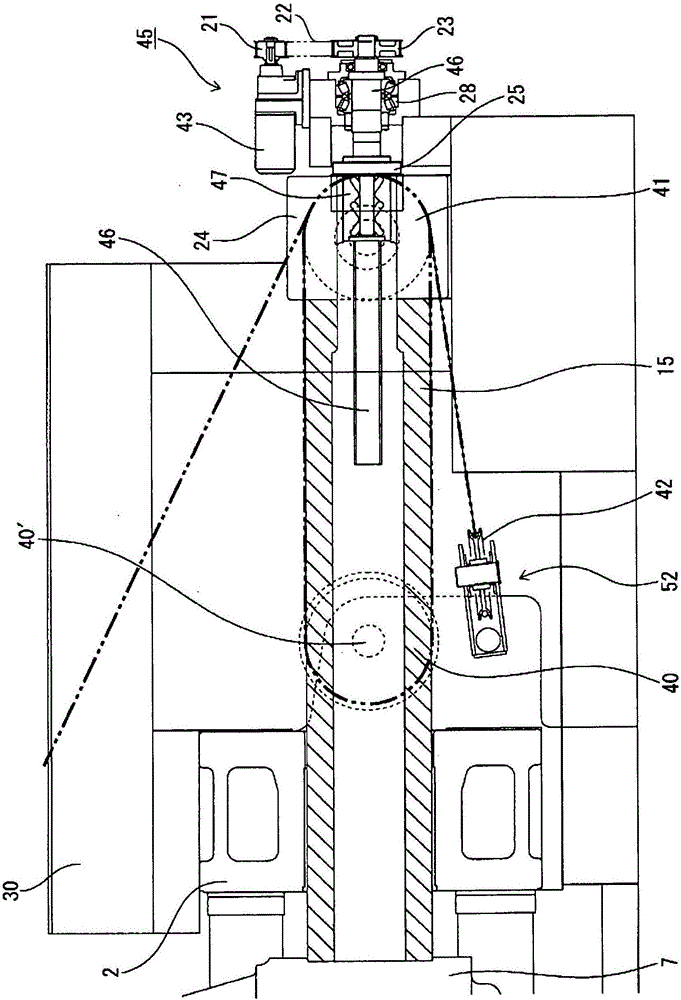

[0046] Figure 1-8 A first embodiment of the extruder of the present invention (a rod-slide extruder) is shown diagrammatically. figure 1 It is a side view showing the schematic structure of the extrusion machine of 1st Embodiment. figure 2is viewed from above figure 1 top view of the device. image 3 yes figure 1 A partial enlargement of the . Figure 4 From figure 1 A cross-sectional view viewed along line A-A. Figure 5 From figure 1 The side view of the BB line observation. Figure 6 is a rear view viewed from the rear.

[0047] The extruder of the present invention is provided with an electric extrusion drive device that converts rotary motion into linear motion. The extrusion machine of the present invention pushes the extrusion rod by the extrusion force generated by the electric extrusion driving device, pressurizes the billet usually at about 400-500°C, and extrudes a product of a predetermined shape through a die.

[0048] First refer to figure 1 and 2 ,...

no. 2 approach

[0078] use Figures 9 to 11 A second embodiment will be described. In the second embodiment, a case will be described in which there are four press drive devices 52 .

[0079] In addition to the two extrusion drive devices of the electric extrusion machine, two additional extrusion drive devices (four in total) were arranged and connected in series by two. The fixed pressing plate 2 and the fixed pressing plate 21 are composed of Figure 11 Four connecting rods 58 are shown connected. exist Figure 11 Among them, there are four connecting rods 58, but the number can be more.

[0080] In addition, pressing one end of the moving member 15 ( Figure 9 The left side) is the crosshead 7, the other end ( Figure 9 The right side) is fixed to the moving pulley 48 of extrusion driving device 53. The moving pulley 41 of the pressing driving device 52 is connected to the middle of the pressing moving member 15 . In addition, in the extrusion machine of this embodiment, the extru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com