Transmission with torque control mechanism

A torque control and transmission technology, applied in clutches, mechanical equipment, automatic clutches, etc., can solve the problems of high manufacturing cost, hidden safety hazards, complex structure, etc., to avoid failure or performance degradation and ensure safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

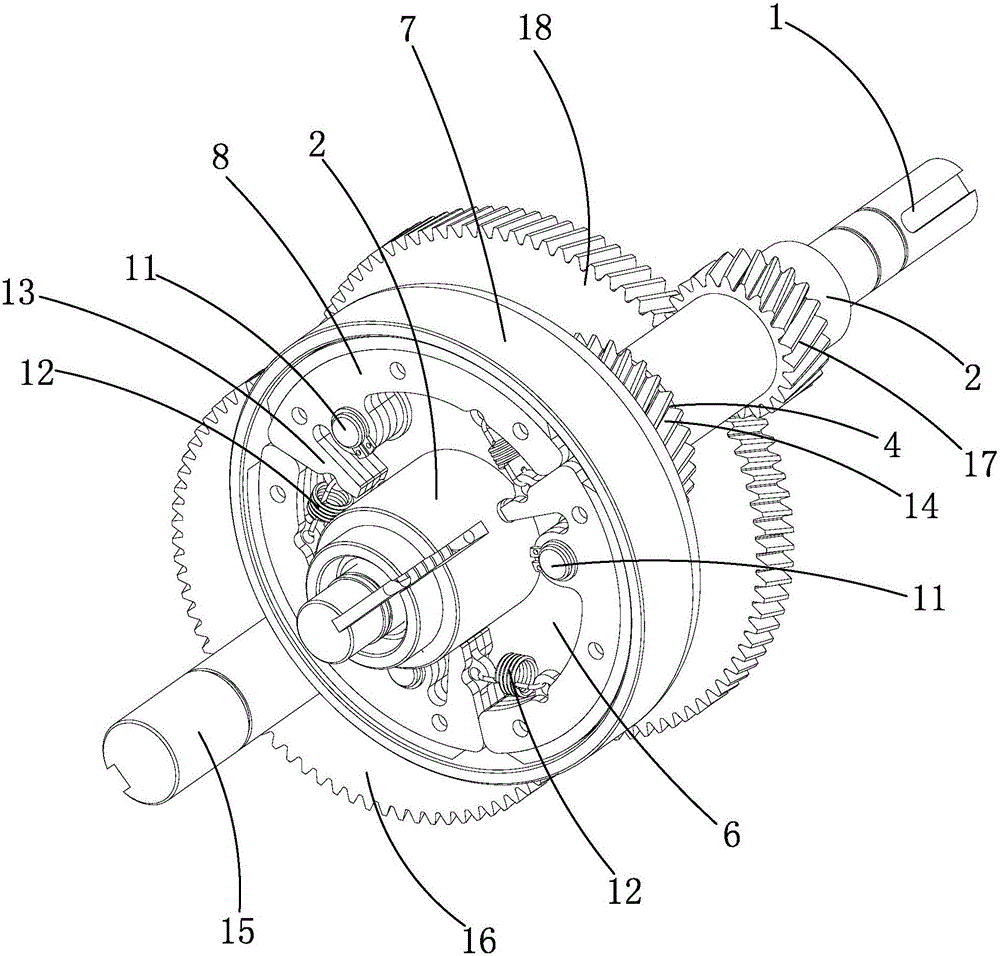

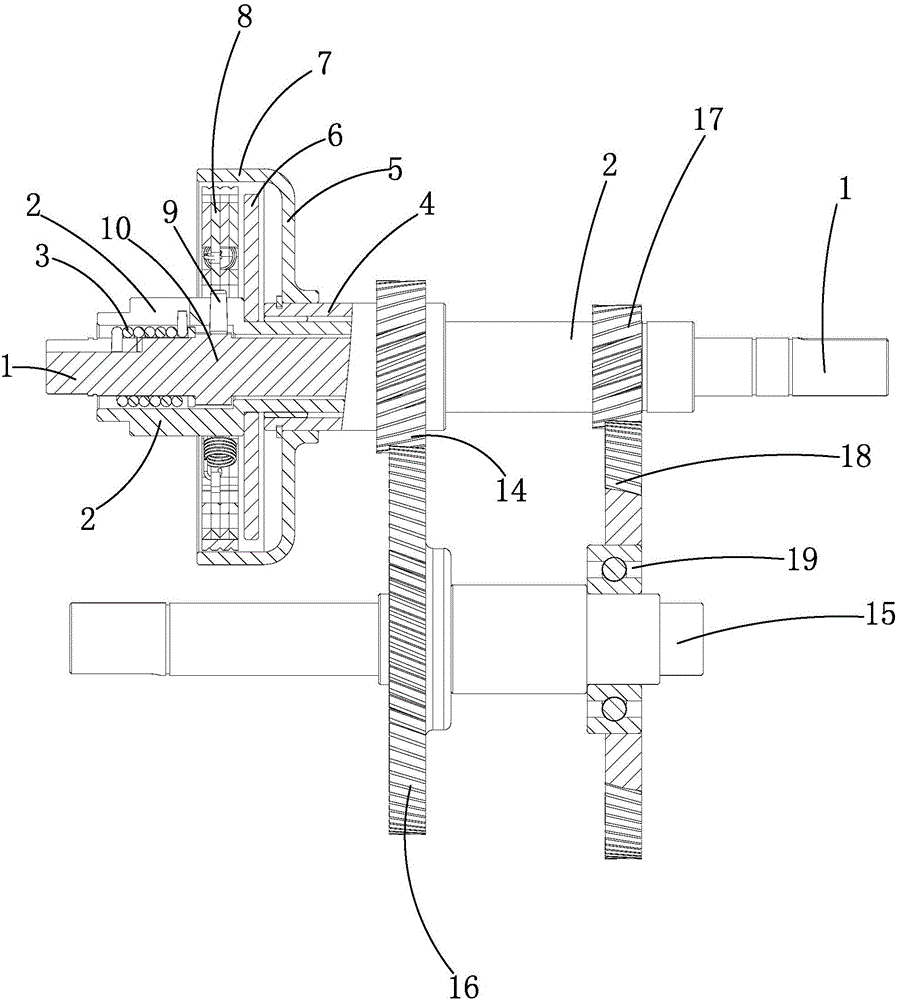

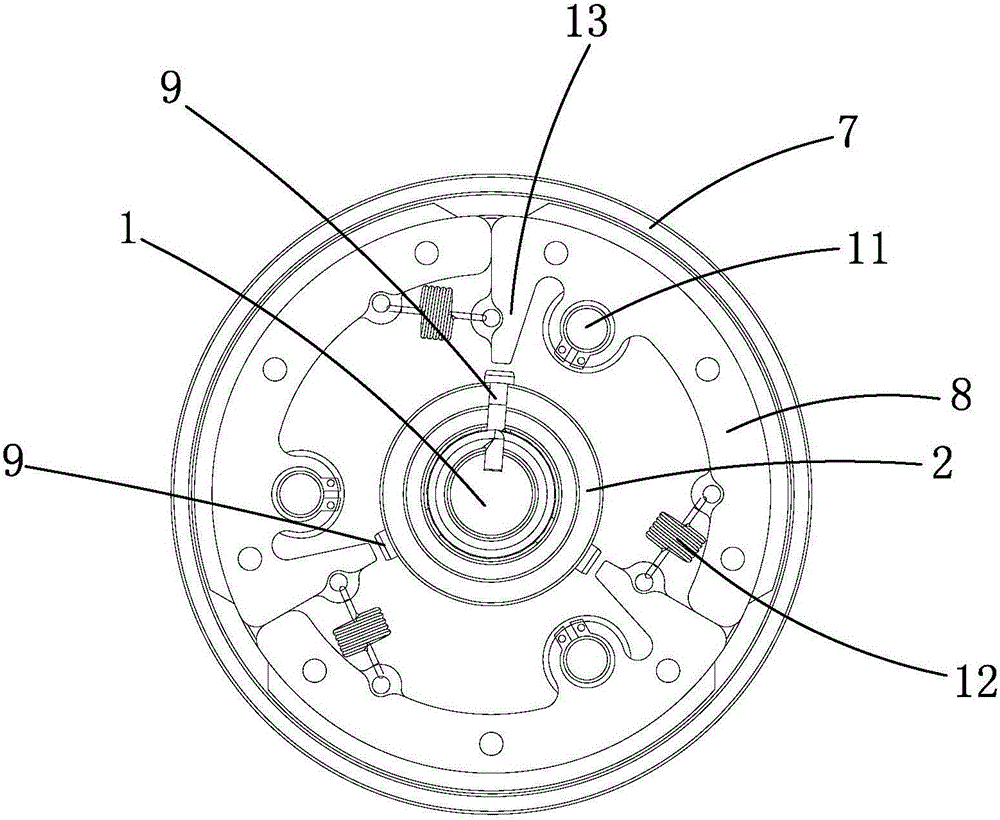

[0022] The substantive features of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0023] Such as figure 1 , 2 A transmission with a torque control mechanism is shown, including an input shaft 1, an output shaft 15, and a clutch mechanism that controls the disconnection of the input shaft 1 and the output shaft 15. The shaft 15 is linked, and the transmission is provided with a torque control mechanism. The torque control mechanism includes an inner drive sleeve 2 rotatably set on the input shaft 1, an elastic element 3 set on the input shaft 1 and a set The clutch control assembly on the inner drive sleeve 2, the inner drive sleeve 2 is rotatably fitted with an outer drive sleeve 4, and the inner drive sleeve 2 is connected to the outer drive sleeve 4 through the clutch mechanism. To switch between the linked state and the disconnected state, the elastic element 3 is deformed due to the torque d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com