Cranking-caused vibration suppressing apparatus and method for internal combustion engine

a technology of internal combustion engine and apparatus, which is applied in the direction of engine starters, electric control, machines/engines, etc., can solve the problems of small output torque and great output torque of motors, and achieve the suppression of engine vibrations, small output torque, and great output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]In the following description and the accompanying drawings, the present invention will be described in more detail in terms of exemplary preferred embodiments.

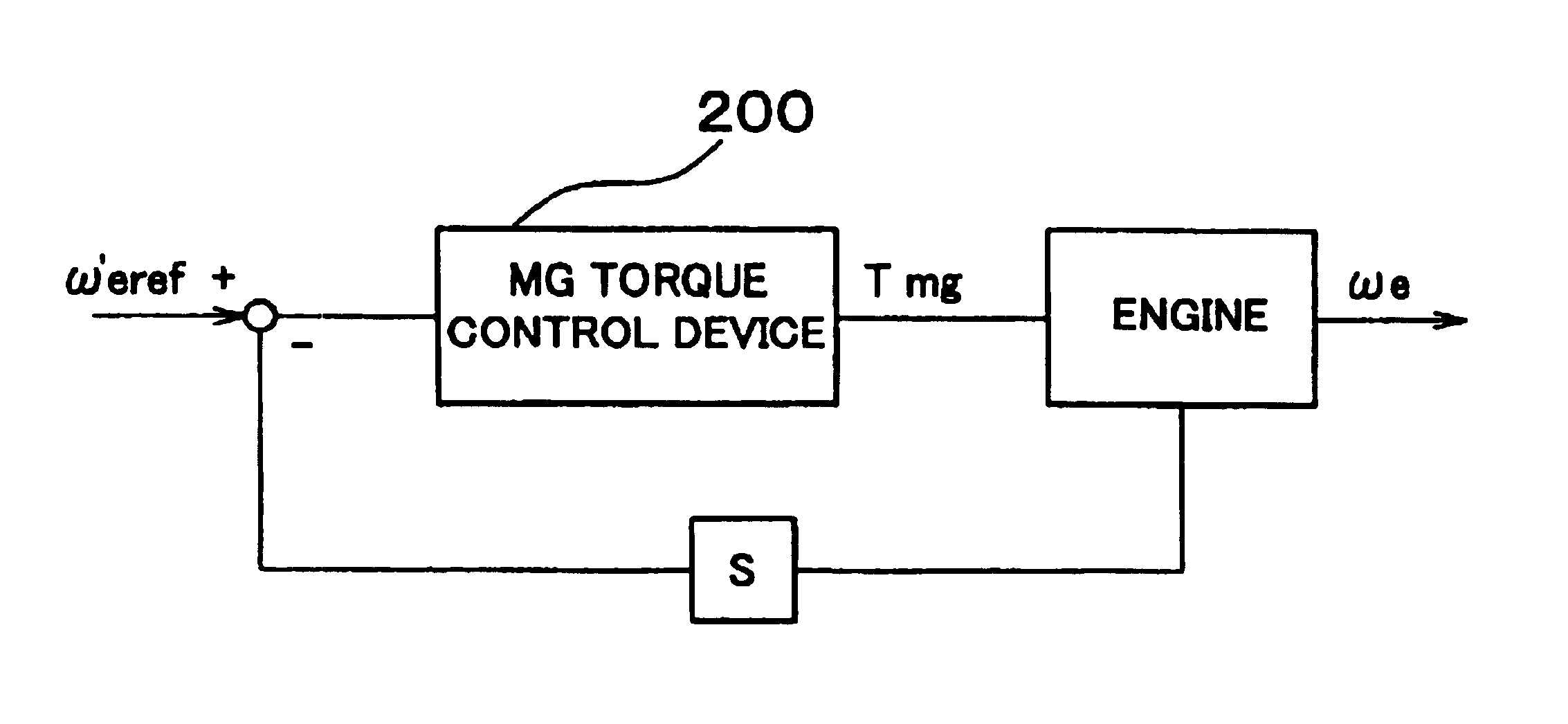

[0020]FIG. 2 is a diagram illustrating a power system of a hybrid vehicle to which a vibration suppressing apparatus in accordance with the invention is applied. A reciprocating piston engine 10, that is, a type of internal combustion engine, drives wheels (not shown) via an output shaft of the engine 10, and also drives an air conditioner 20, a power steering pump (PS pump) 30 and a water pump 50, via an endless belt 80 that is disposed and turned around the output shaft of the engine 10, the air conditioner 20, the power steering pump 30, a tensioner 40, the water pump 50, a motor-generator (MG) 60 and an idler 70. When a battery device (not shown) is to be charged, the motor-generator 60 is operated as a generator. The motor-generator 60 also may operate as an electric motor. When the engine 10 is to be started, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com