Mechanical friction and hydraulic transmission collection type stepless speed change device

A continuously variable transmission, mechanical friction technology, applied in the direction of friction transmission, transmission, fluid transmission, etc., can solve the problems of high manufacturing cost, low output speed, complex structure of variable oil pump and variable hydraulic motor, etc. The effect of large adjustment range, large output torque and small speed adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

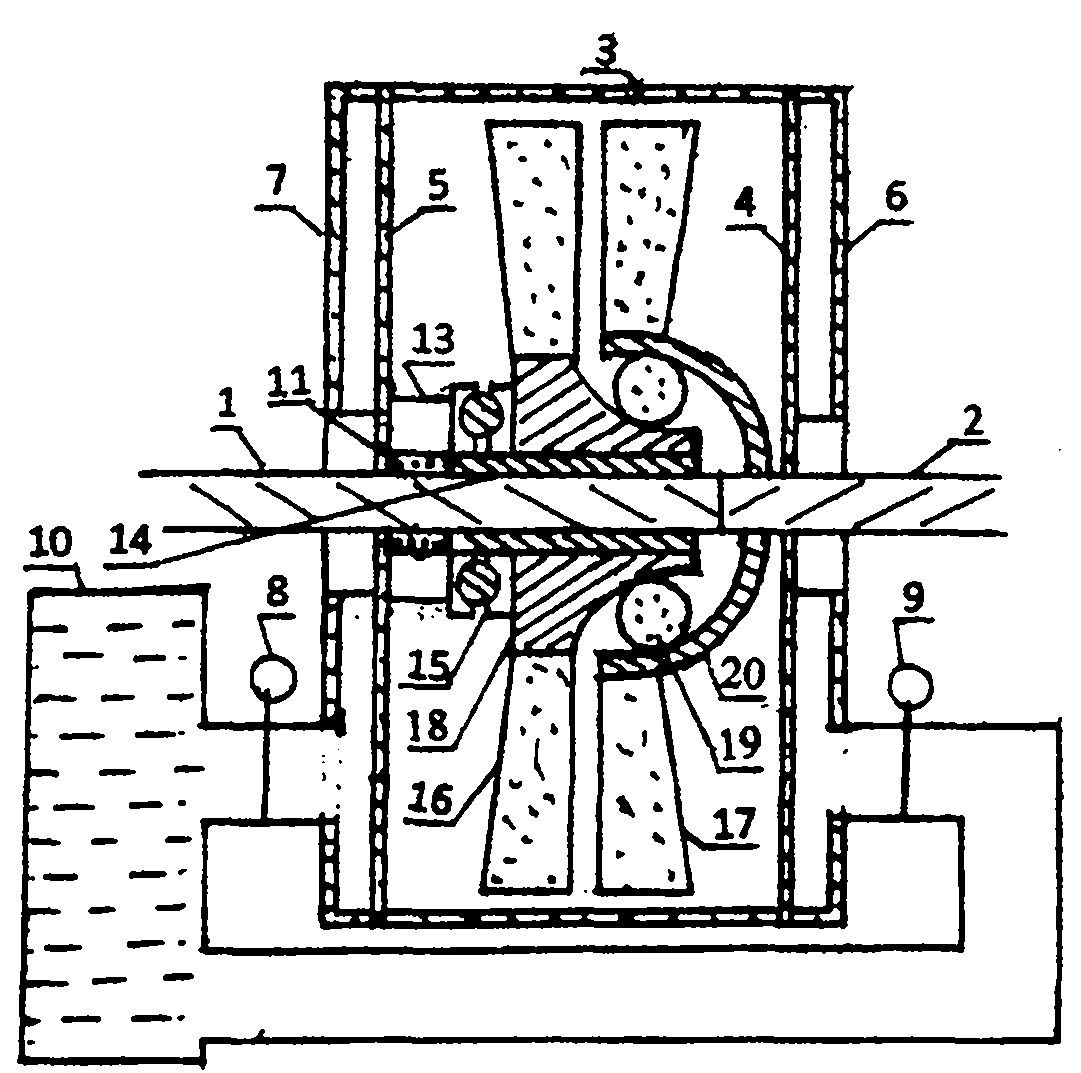

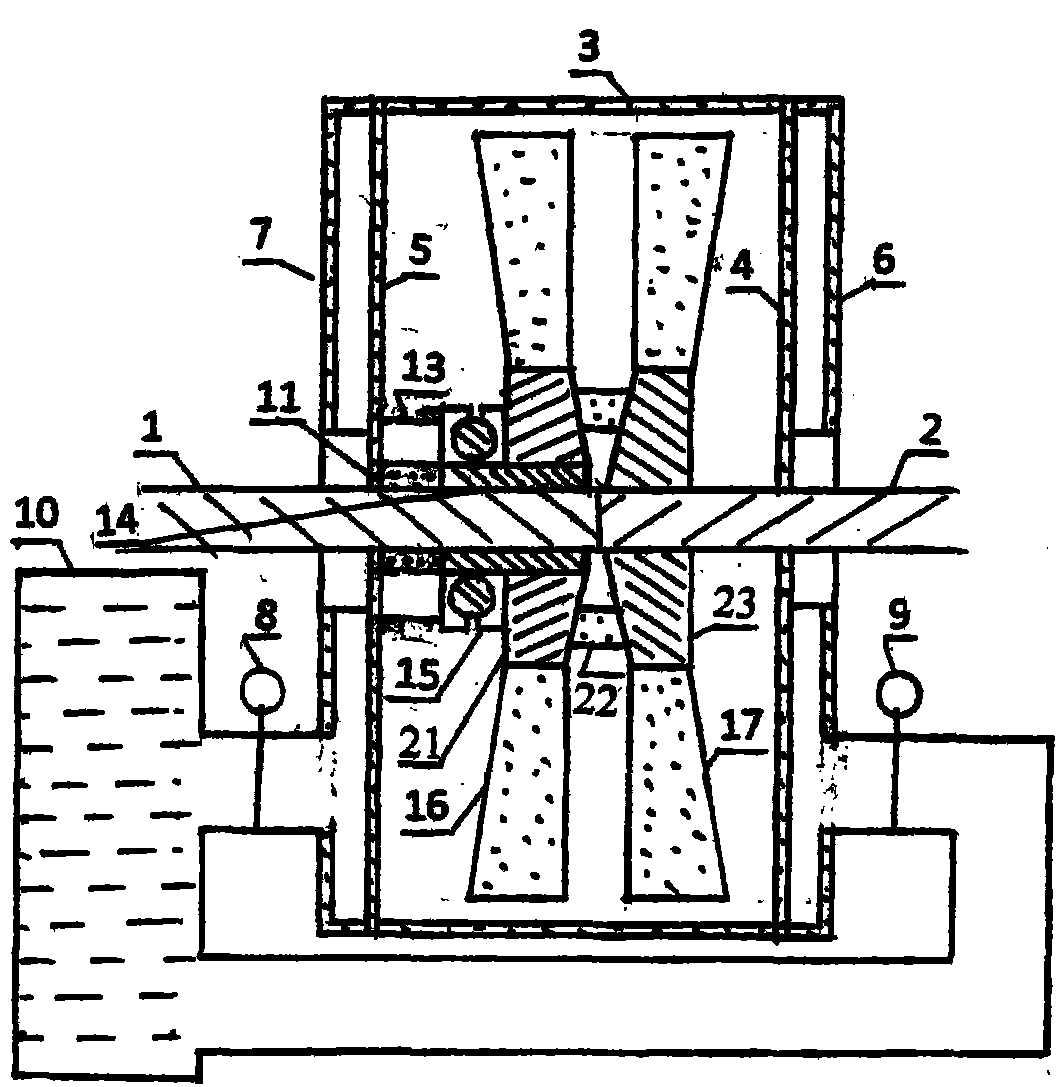

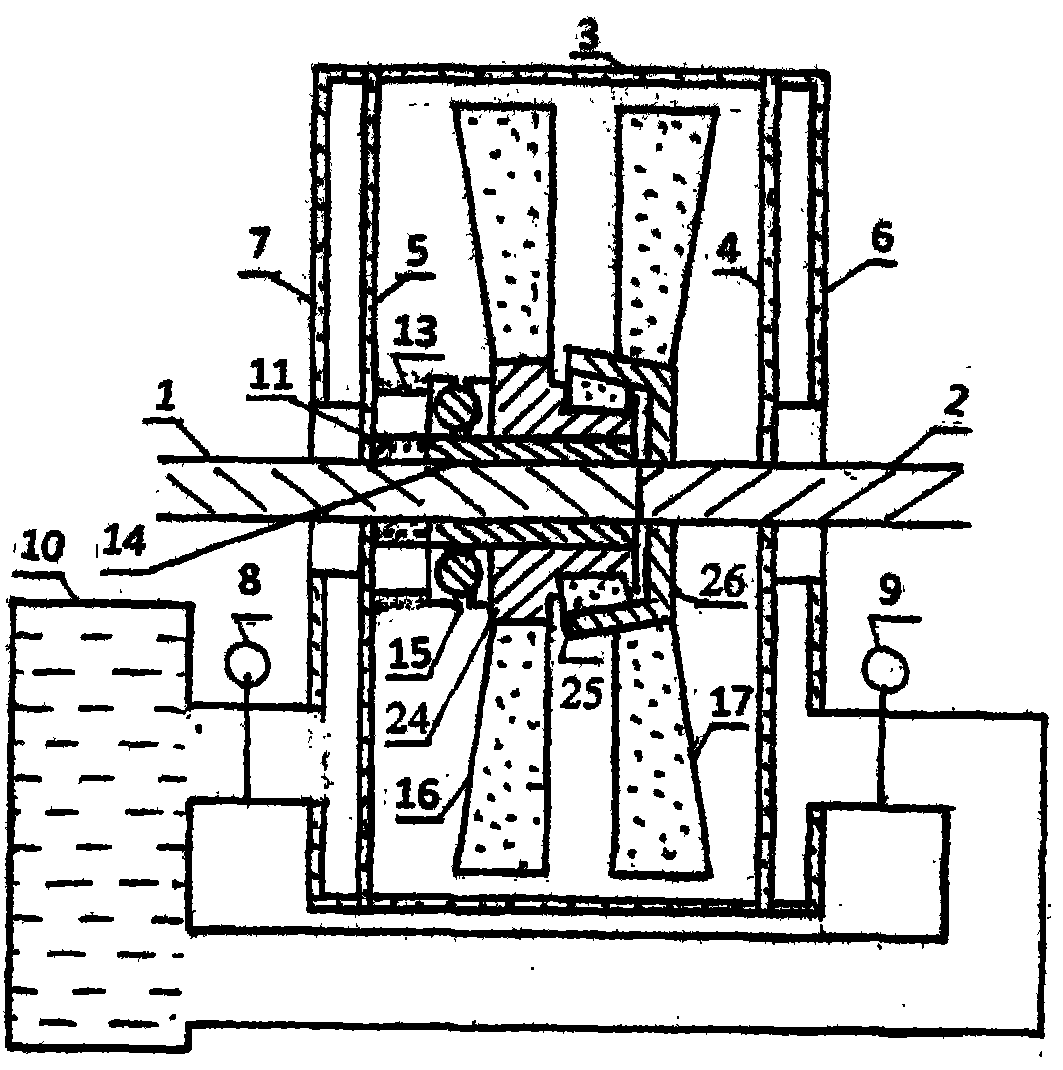

[0020] figure 1 , figure 2 , image 3 and Figure 4 As shown, the mechanical friction and hydraulic transmission integrated type continuously variable transmission device of the present invention is mainly composed of input shaft 1, output shaft 2, casing 3, front end cover 4, rear end cover 5 and mechanical friction continuously variable transmission components. The return spring sleeve 11 is on the input shaft 1 in the shell 3, and the sleeve 14 is sleeved on the input shaft 1 in front of the return spring 11 through a spline. The front end of the return spring 11 is fixed on the rear end of the sleeve pipe 14, and the rear end of the return spring 11 is fixed on the inner side of the rear end cover 5. The input friction parts for mechanical friction stepless transmission are installed on the front section of the casing 14, and the pressure bearing 15 is installed on the rear section of the casing 14, that is, the tight ring of the pressure bearing 15 is in the front, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com