Dual-stator multi-degree-of-freedom motor

A technology of electric motors and degrees of freedom, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problem of small output torque of multi-degree-of-freedom motors, to make up for insufficient output torque, increase output torque, and improve output efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

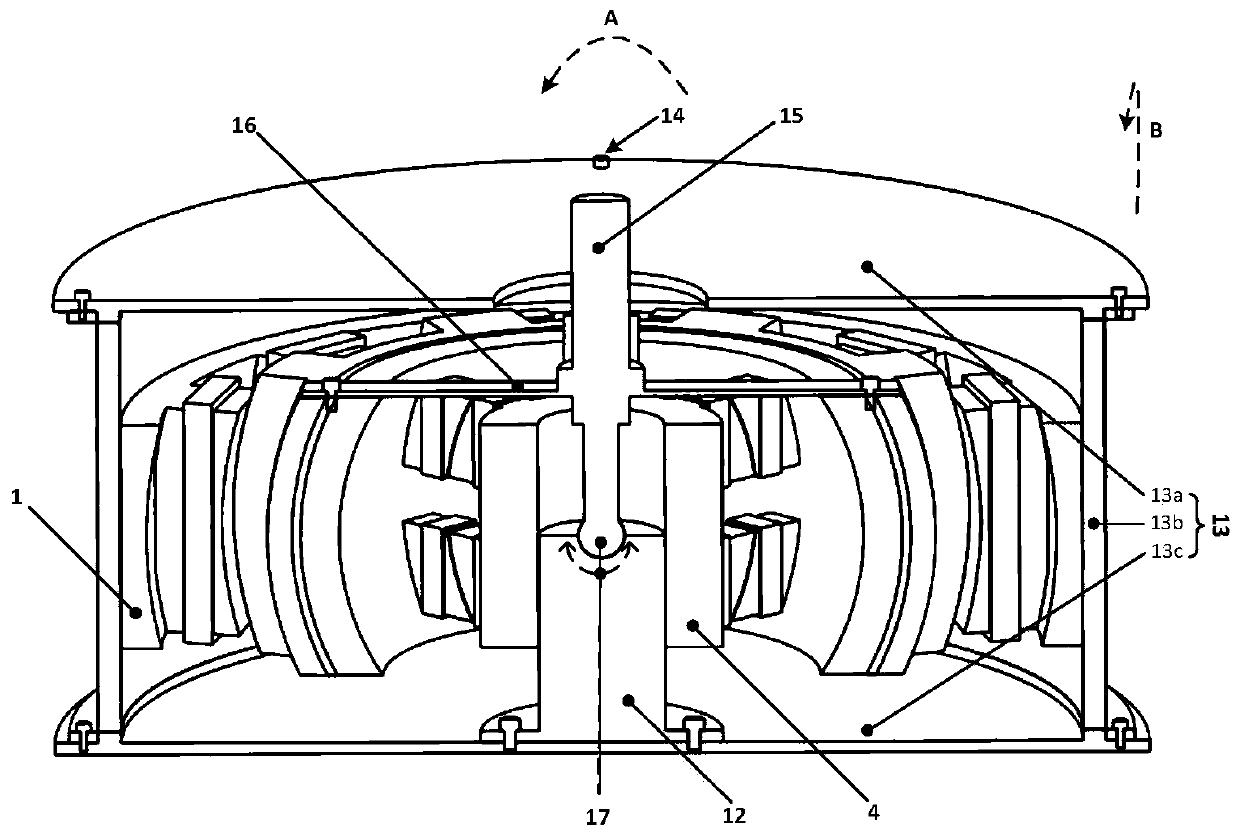

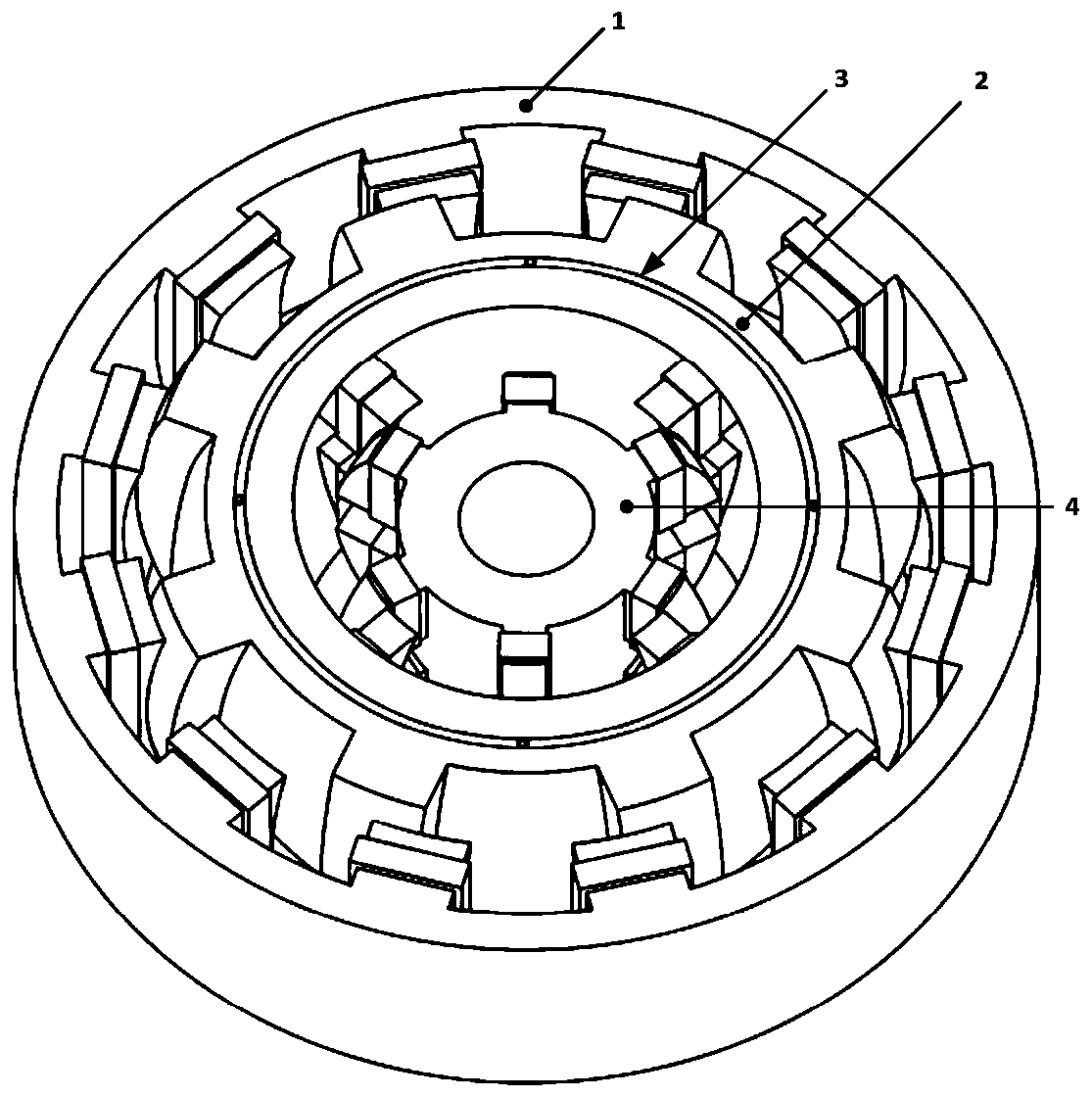

[0030] The accompanying drawings are only used to illustrate examples, and should not be construed as limitations on this patent; in order to better illustrate this embodiment, some components in the accompanying drawings may be omitted, enlarged or reduced. Omissions, enlargements or reductions where present are understandable. Below in conjunction with accompanying drawing, this patent is described in detail.

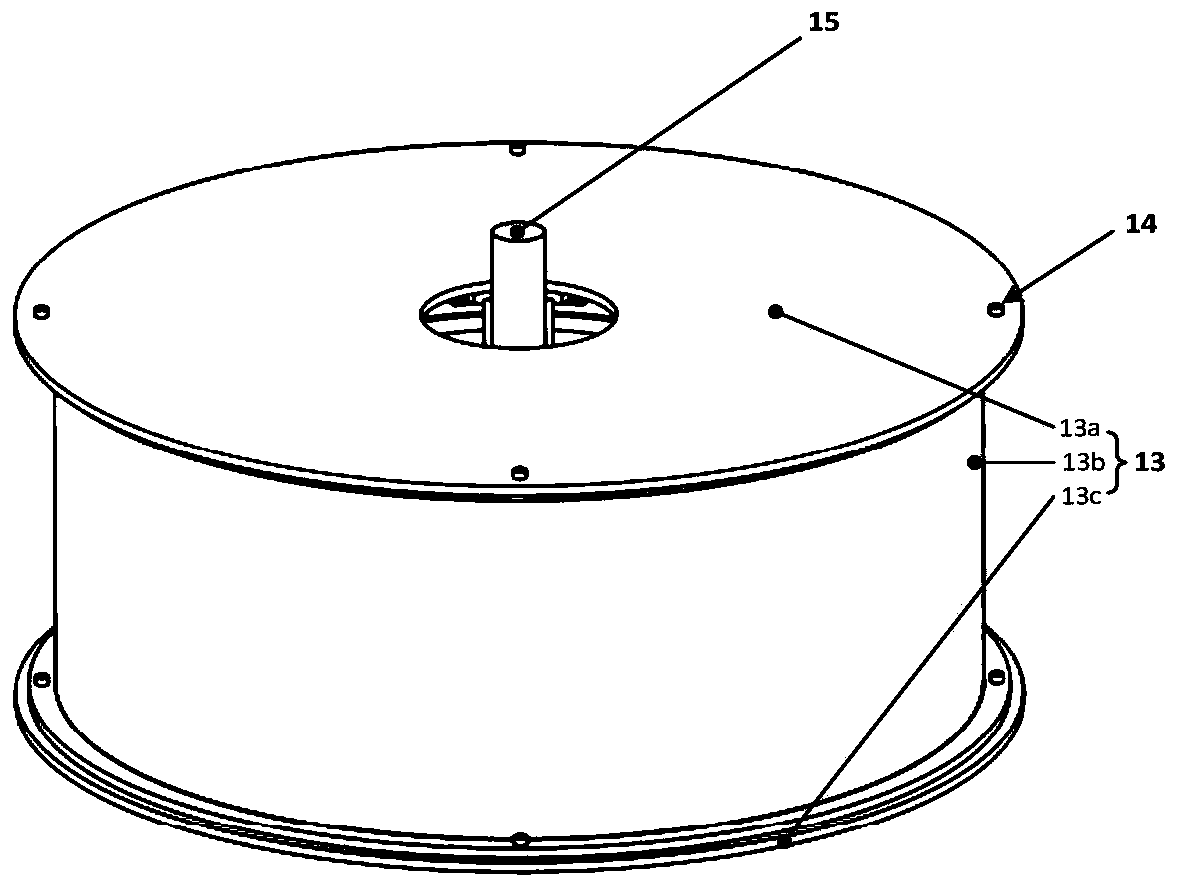

[0031] As a specific embodiment of the present invention. The technical scheme adopted in the present invention is: a double-stator multi-degree-of-freedom motor, comprising a motor housing 13 and an outer stator 1, characterized in that it also includes a rotor 2 and an inner stator 4, and the rotor 2 is located between the outer stator 1 and the inner stator 4 Between the inner and outer sides of the rotor 2, a magnetic isolation plate 3 is embedded to separate the magnetic circuits on the inner and outer sides of the rotor 2; the outer stator 1, the inner side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com