Patents

Literature

46results about How to "Guaranteed output torque" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

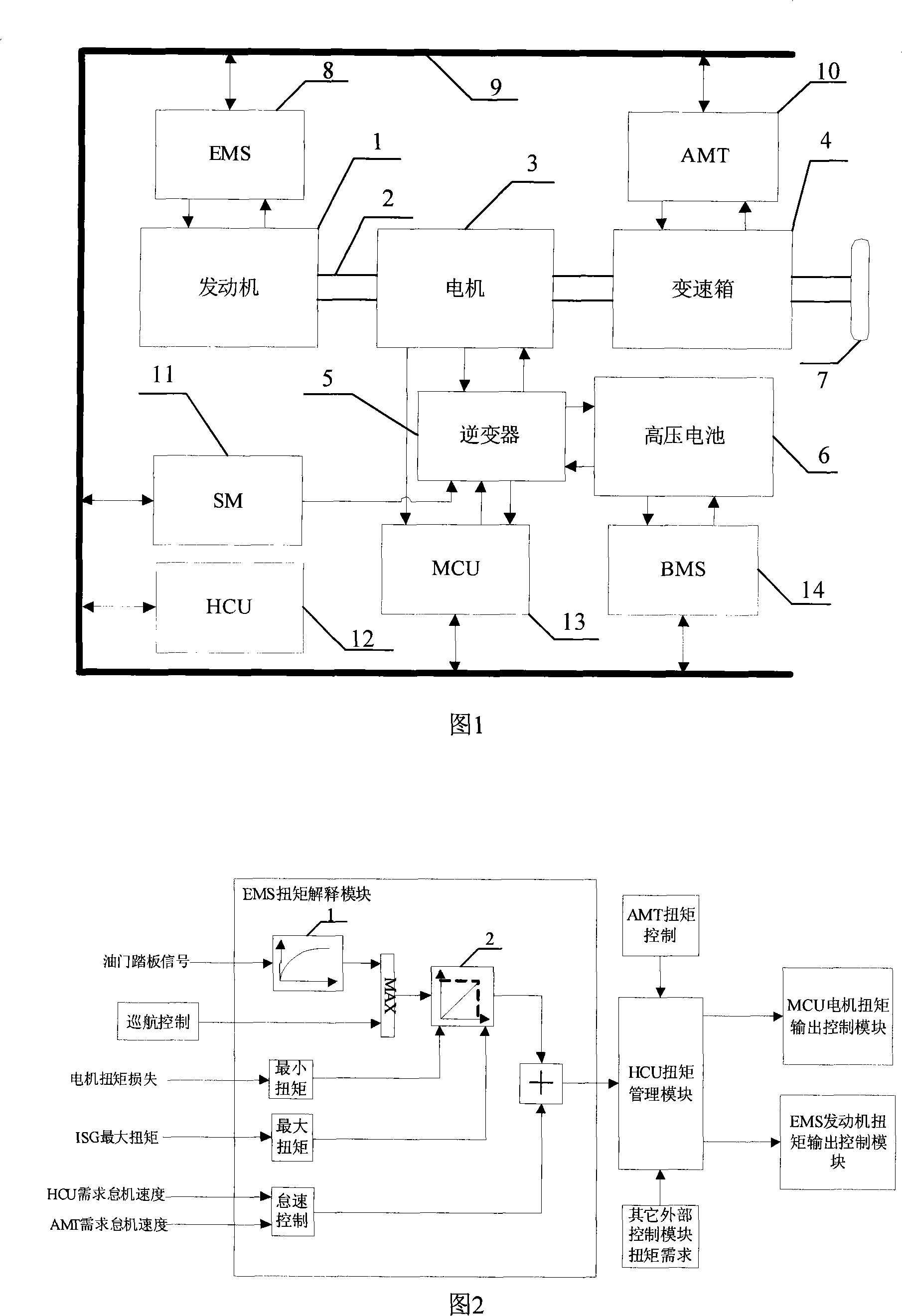

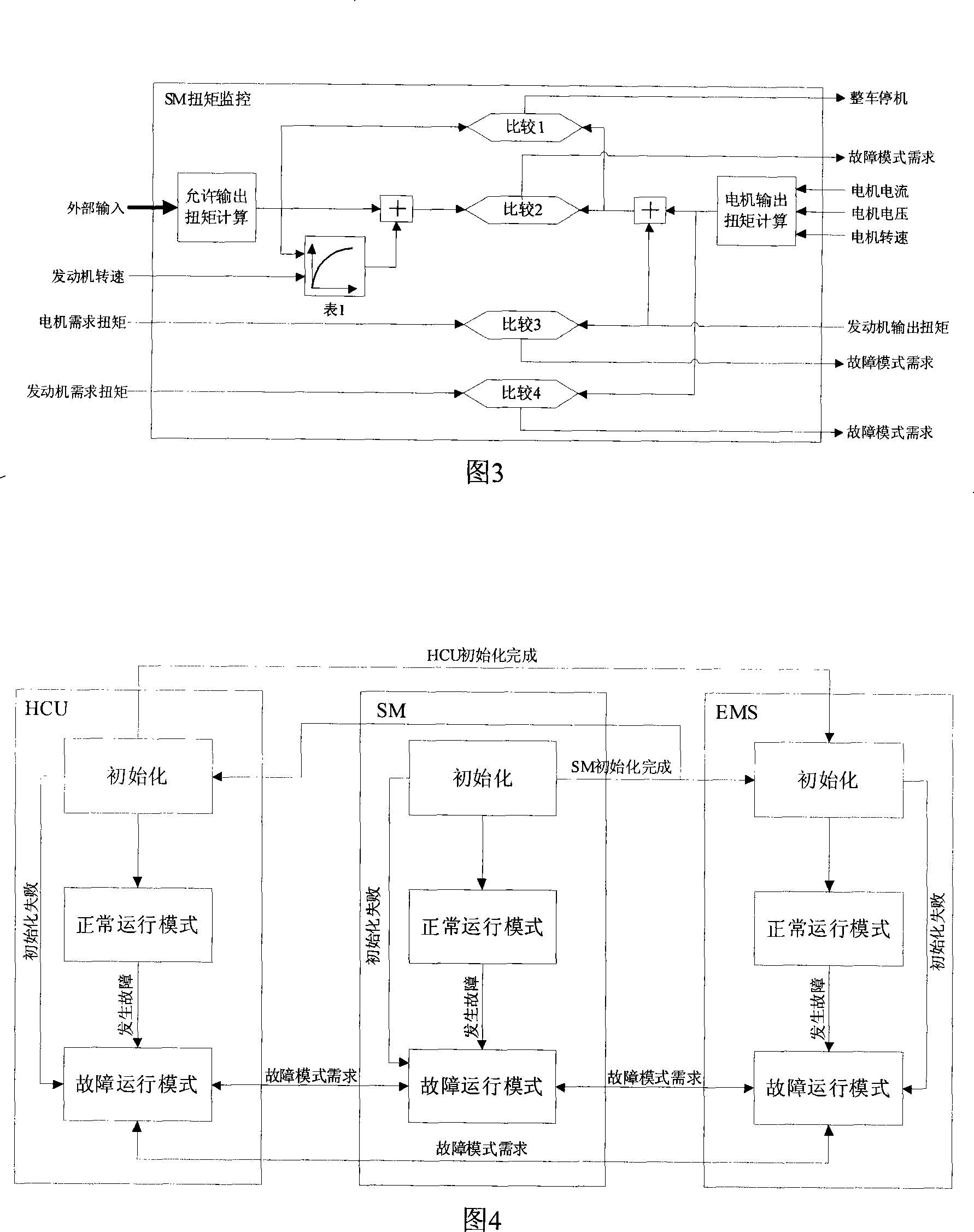

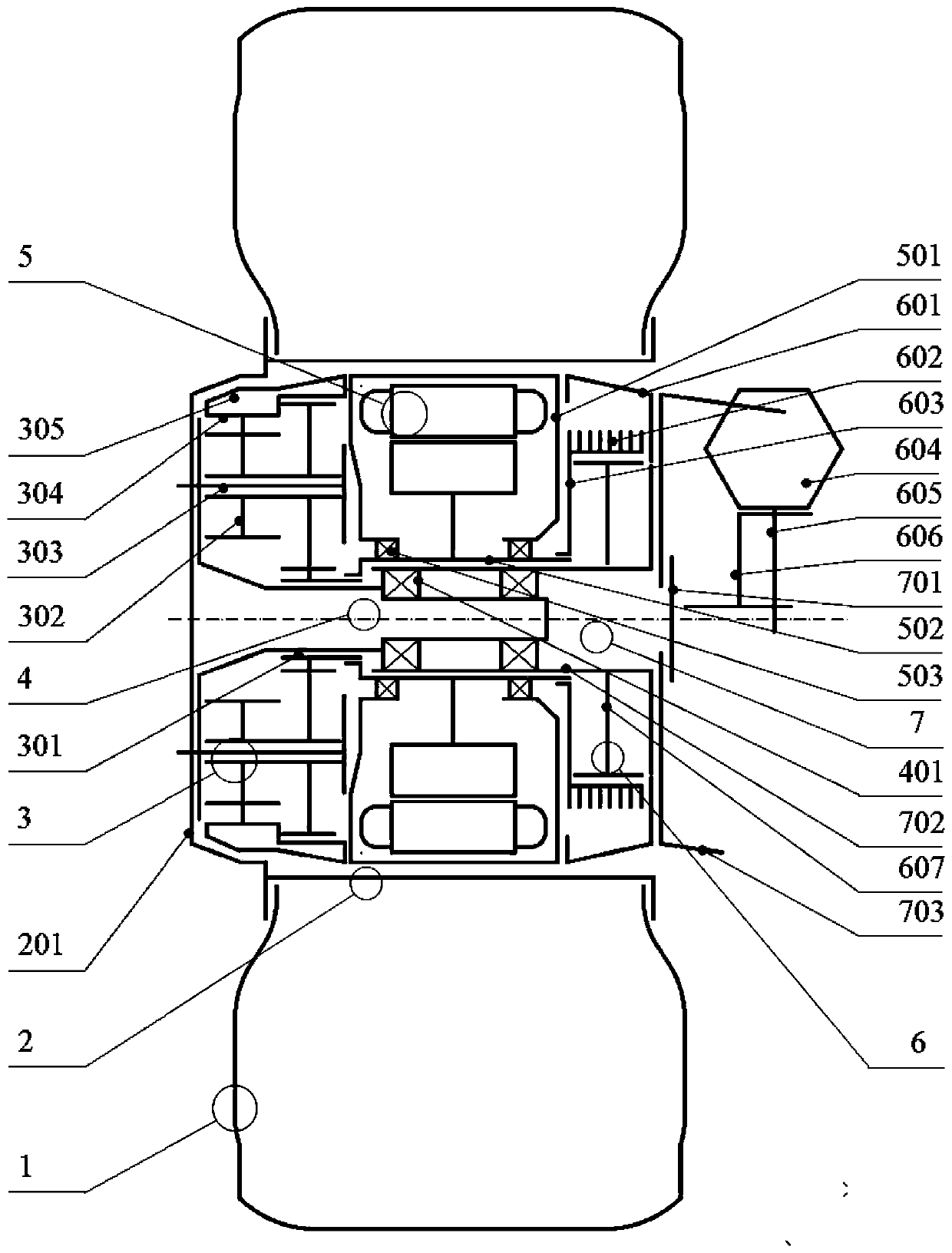

A monitoring system of mixing dynamical vehicle torsional moment

ActiveCN101157360AGuaranteed correctnessMonitor carefullyHybrid vehiclesHybrid systemElectric machine

The invention describes a safety monitoring system and a monitoring method for the torque output by a power assembly of a hybrid vehicle. The safety monitoring system and the monitoring method can be used for preventing the entire output torque from increasing and reducing accidently to provide relatively reliable protection for every module in the hybrid system, thereby ensuring the safety performance of the hybrid system. The torque monitoring of the safety monitoring system relates to three main controllers, including a hybrid control unit, an engine management system and the hybrid safety monitoring system, and respectively monitors the real output torque of the entire vehicle, a motor and the engine; the system can monitor the entire torque in normal mode and failure mode; the monitoring in normal mode can ensure the accurate explain of the entire real output torque; while the monitoring in failure mode can limit the entire real entire output torque.

Owner:CHERY AUTOMOBILE CO LTD

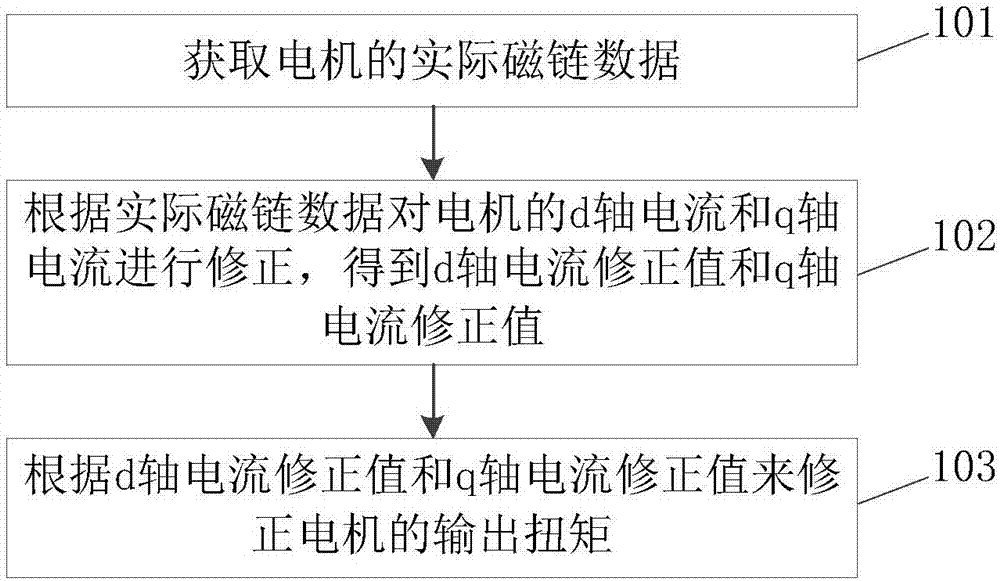

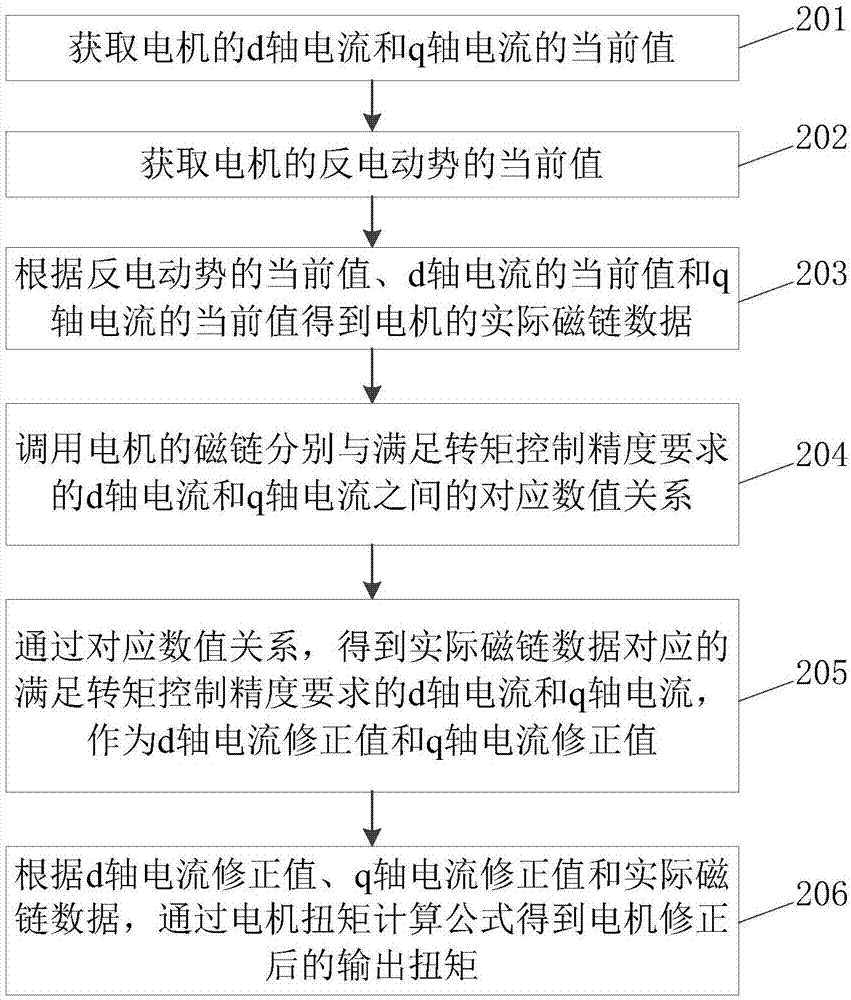

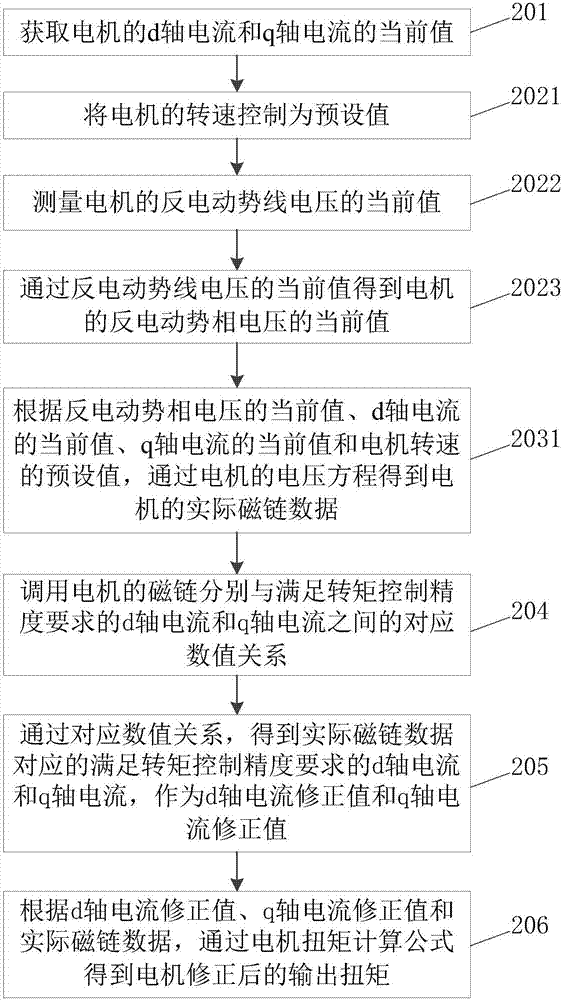

Motor torque correction method and device, motor and vehicle

InactiveCN107508503AGuaranteed torqueGuaranteed output torqueSpeed controllerVector control systemsUltrasound attenuationPermanent magnet synchronous motor

The present invention provides a motor torque correction method and device, a motor and a vehicle, and relates to the automobile technology field. It is realized that a permanent magnet synchronous motor still can ensure that the motor outputs torque satisfying demands after attenuation. The main technical scheme of the invention is a motor torque correction method. The method comprises: obtaining the real flux linkage data of a motor; performing correction of d-axis current and q-axis current of the motor according to the real flux linkage data to obtain a d-axis current correction value and a q-axis current correction value; and correcting the output torque of the motor according to the d-axis current correction value and the q-axis current correction value. The motor torque correction method is mainly used for correction of the output torque of the motor to allow the motor to output the torque satisfying demands.

Owner:BEIJING CHJ AUTOMOTIVE TECH CO LTD

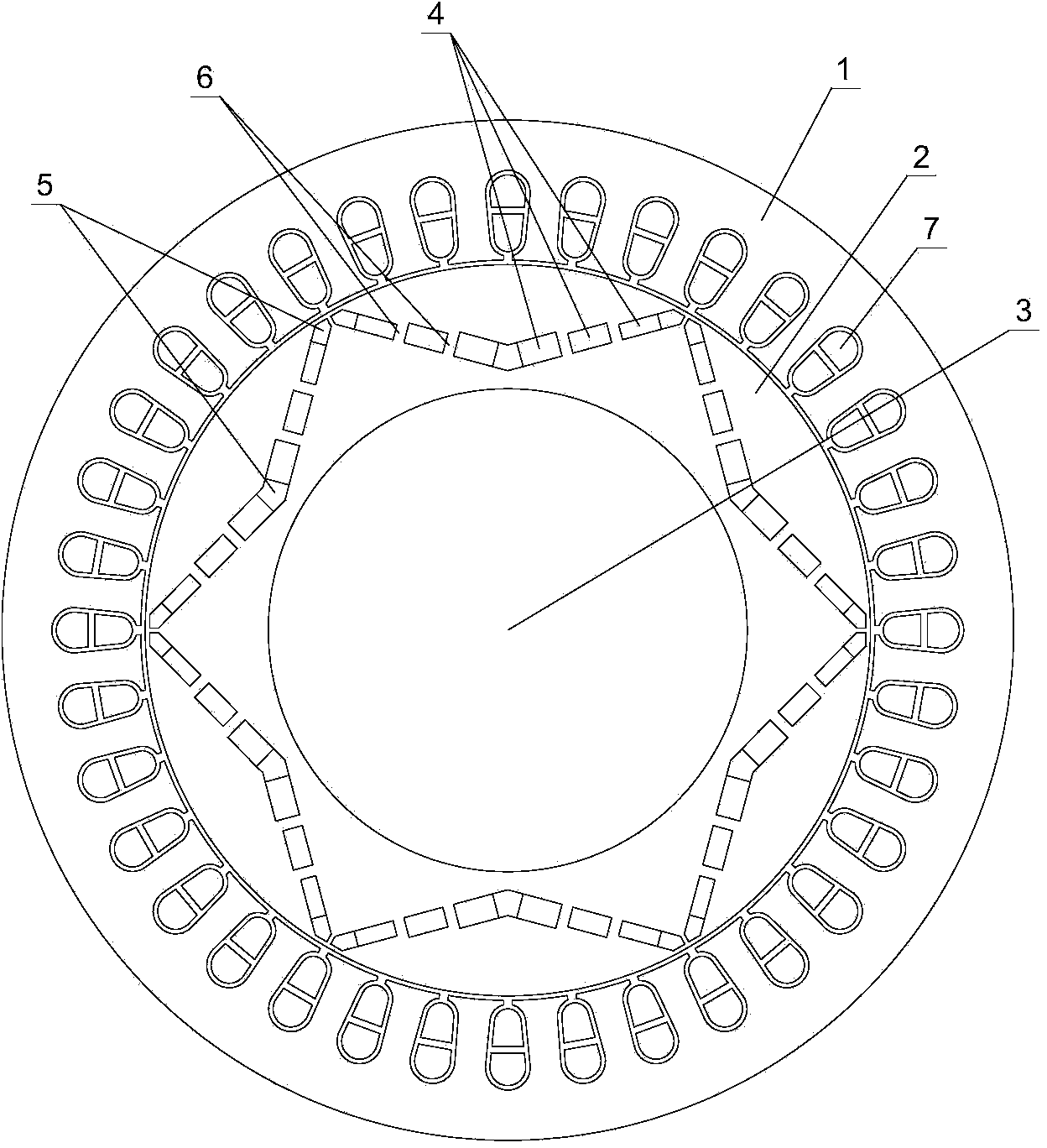

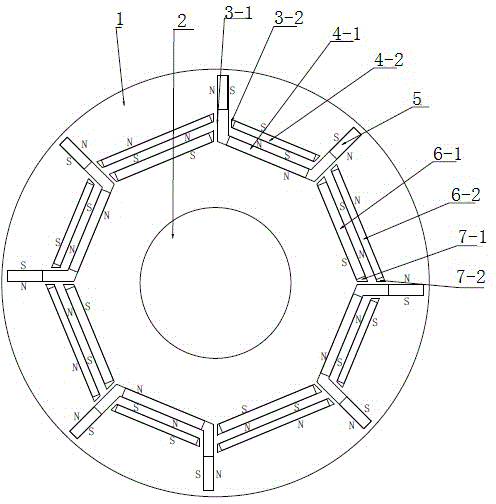

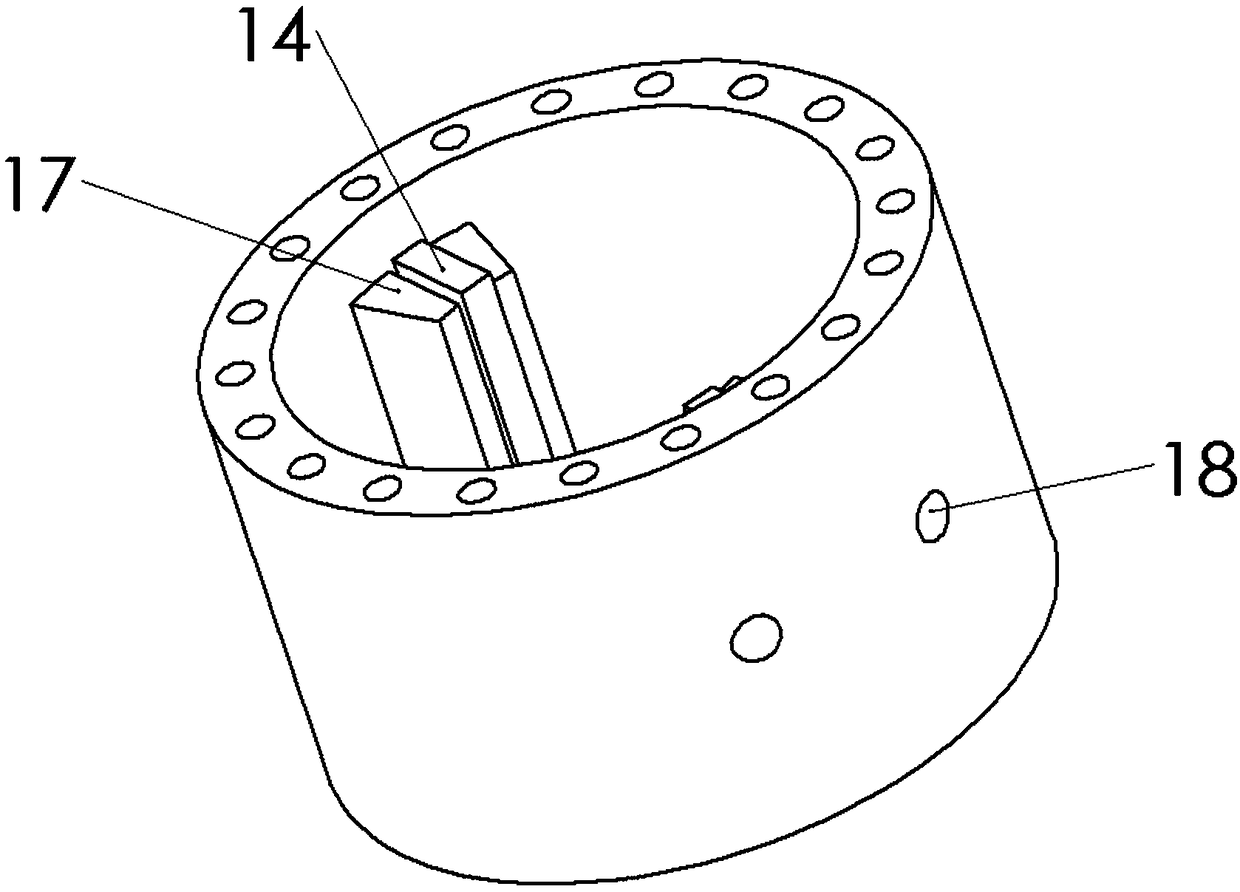

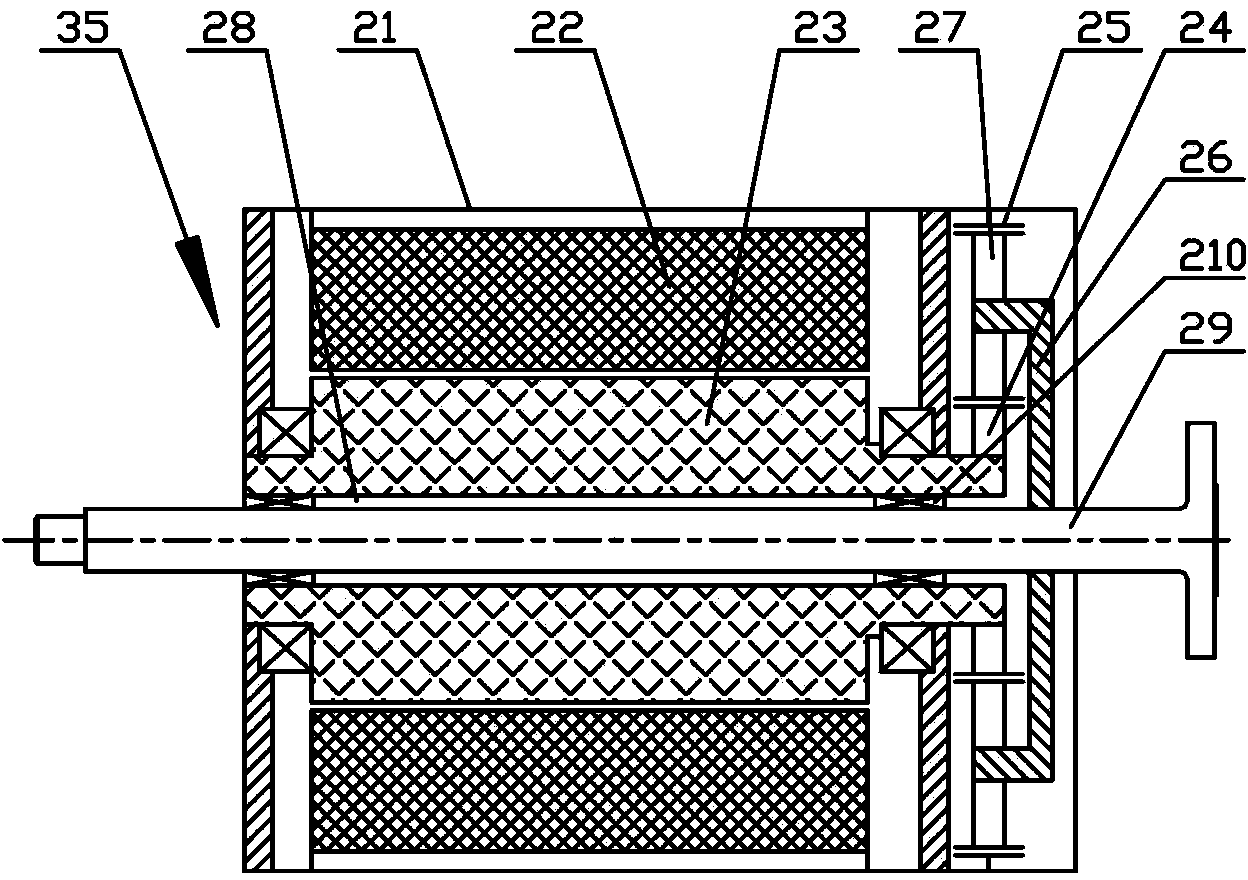

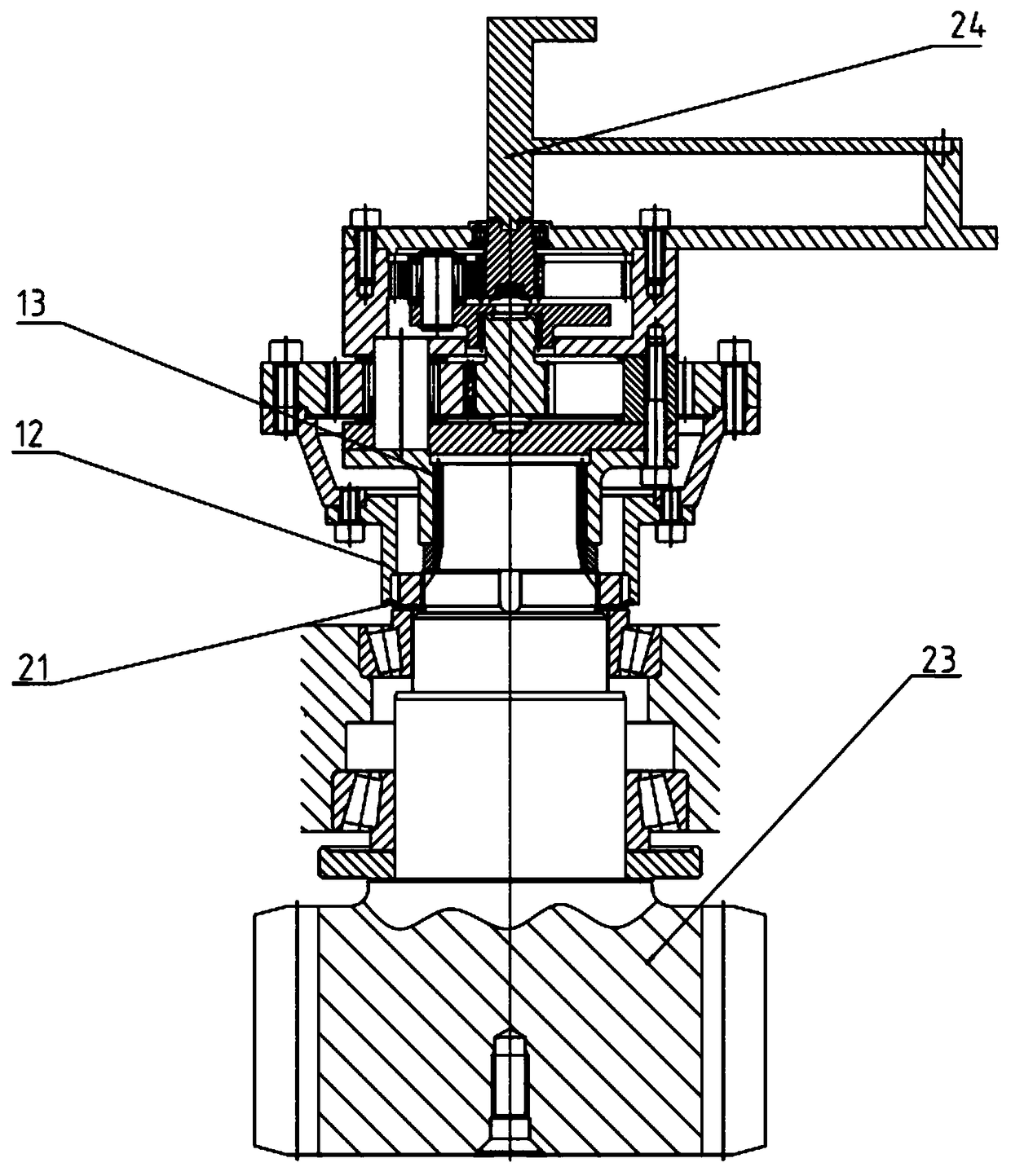

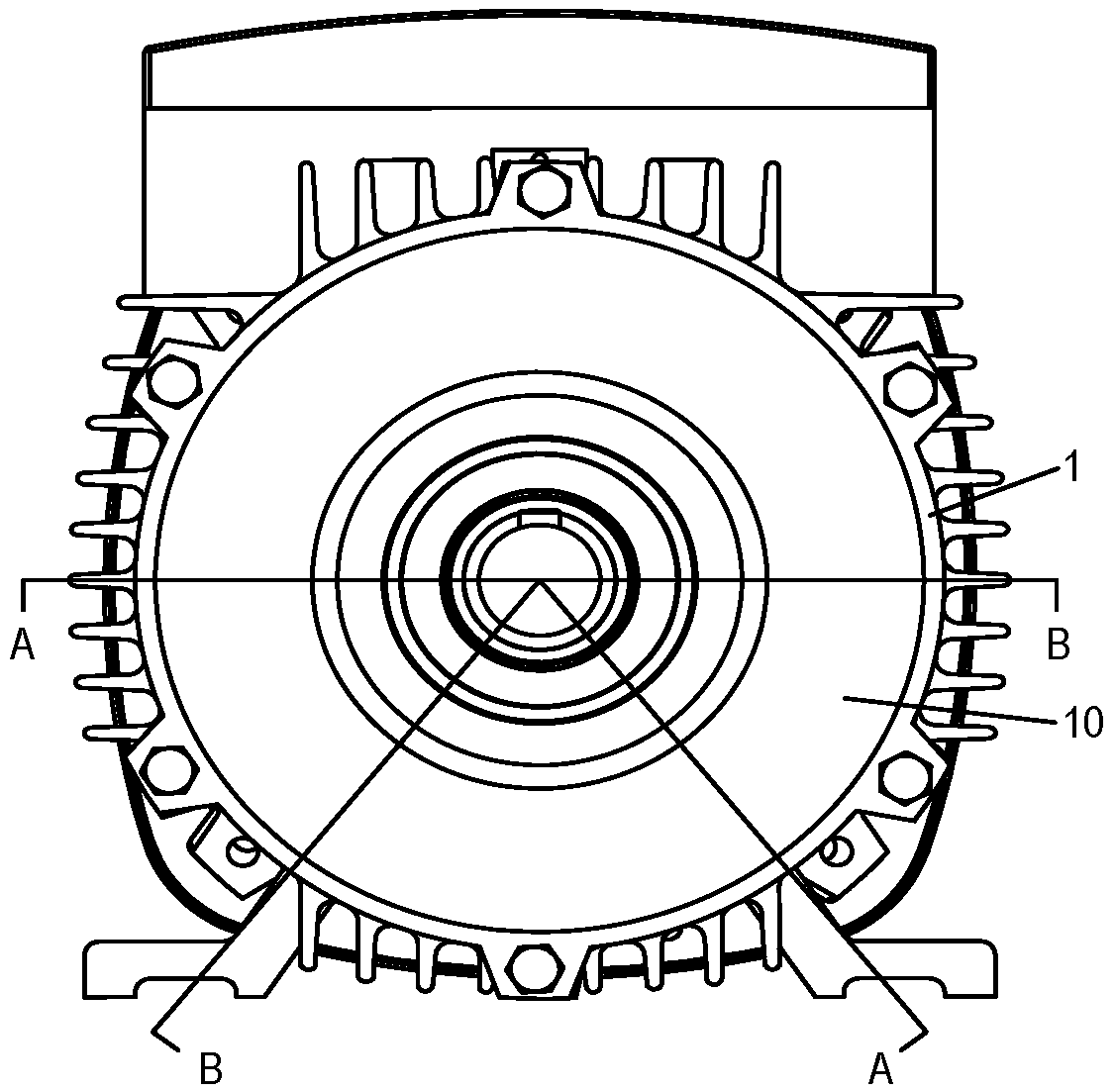

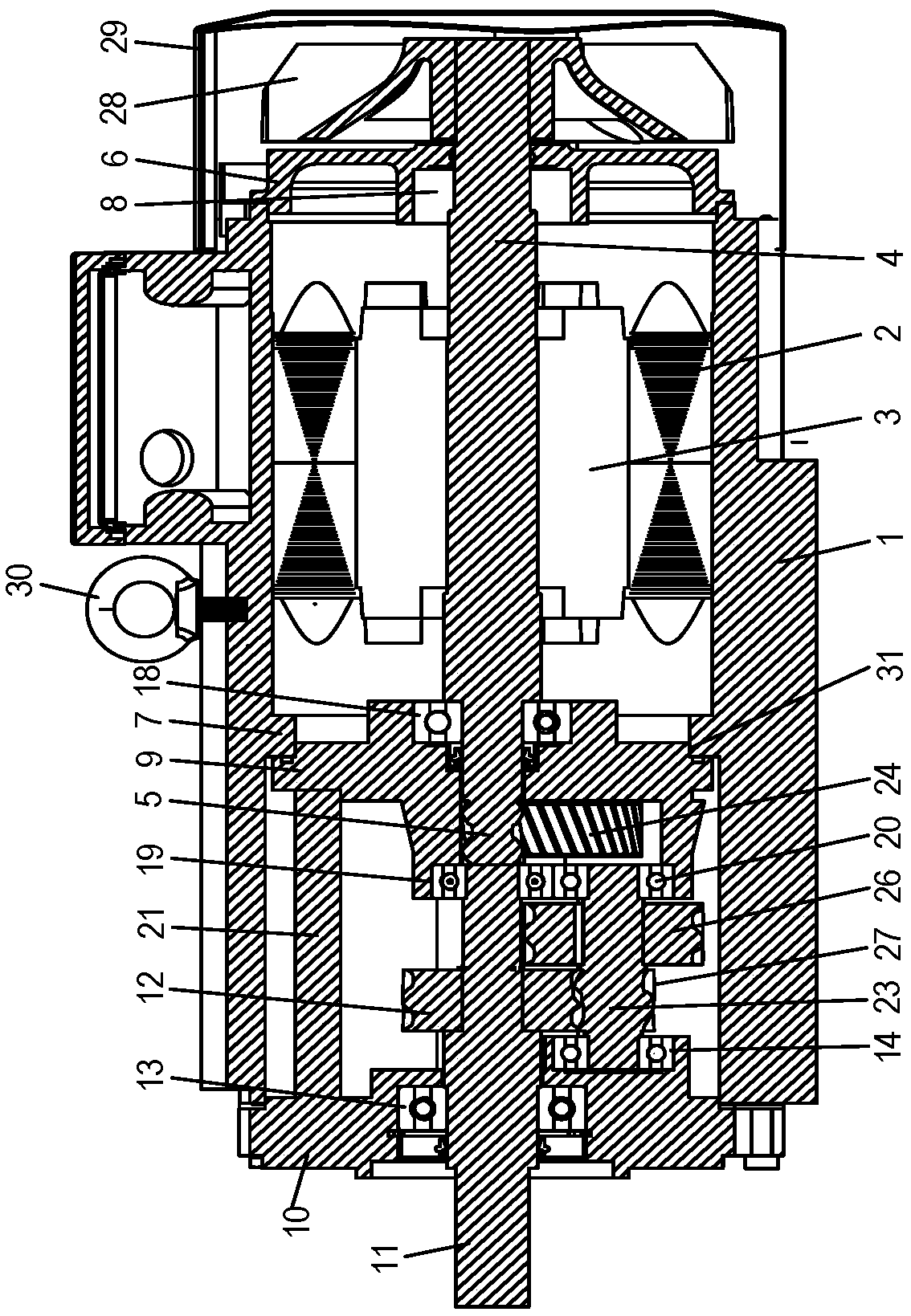

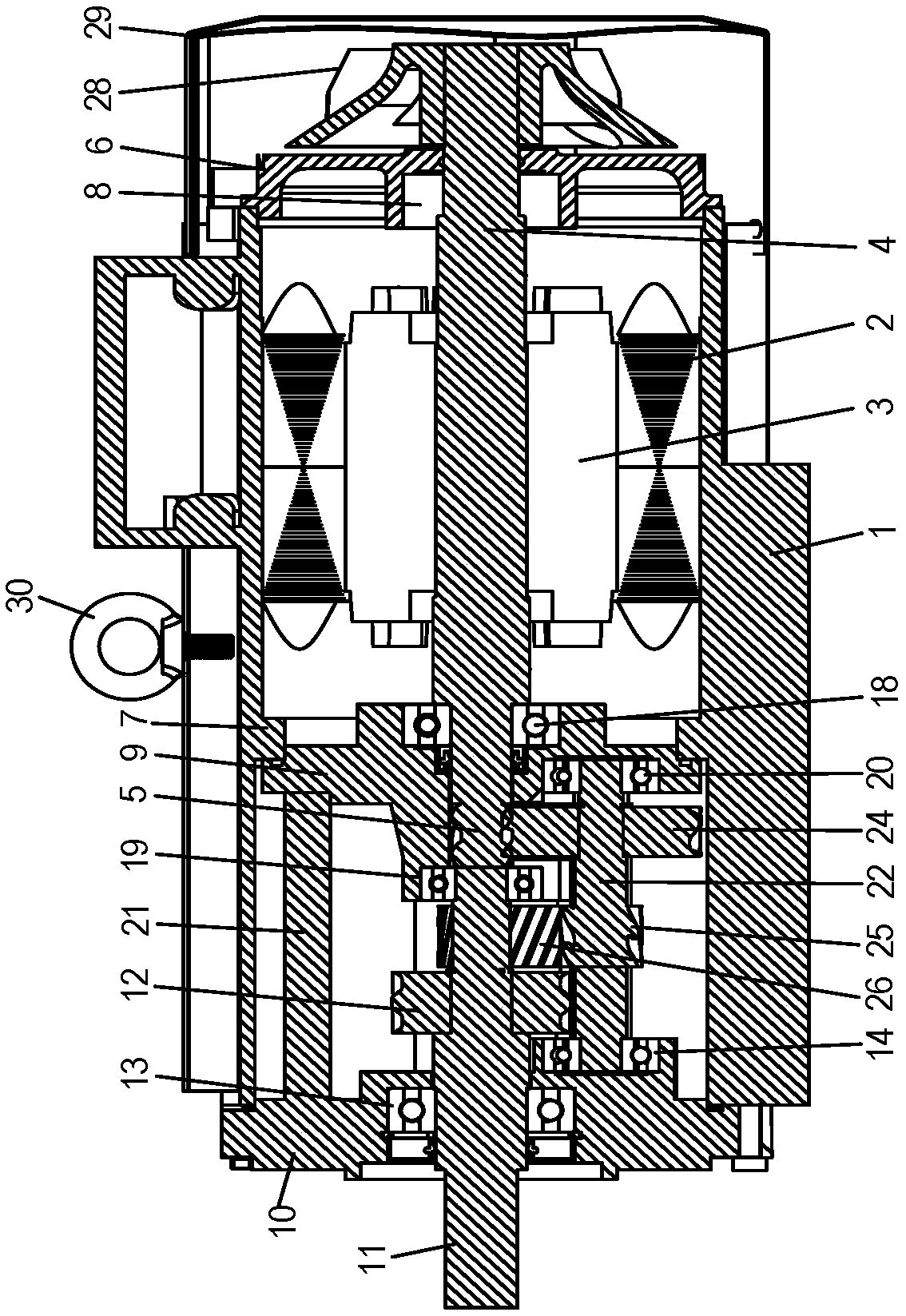

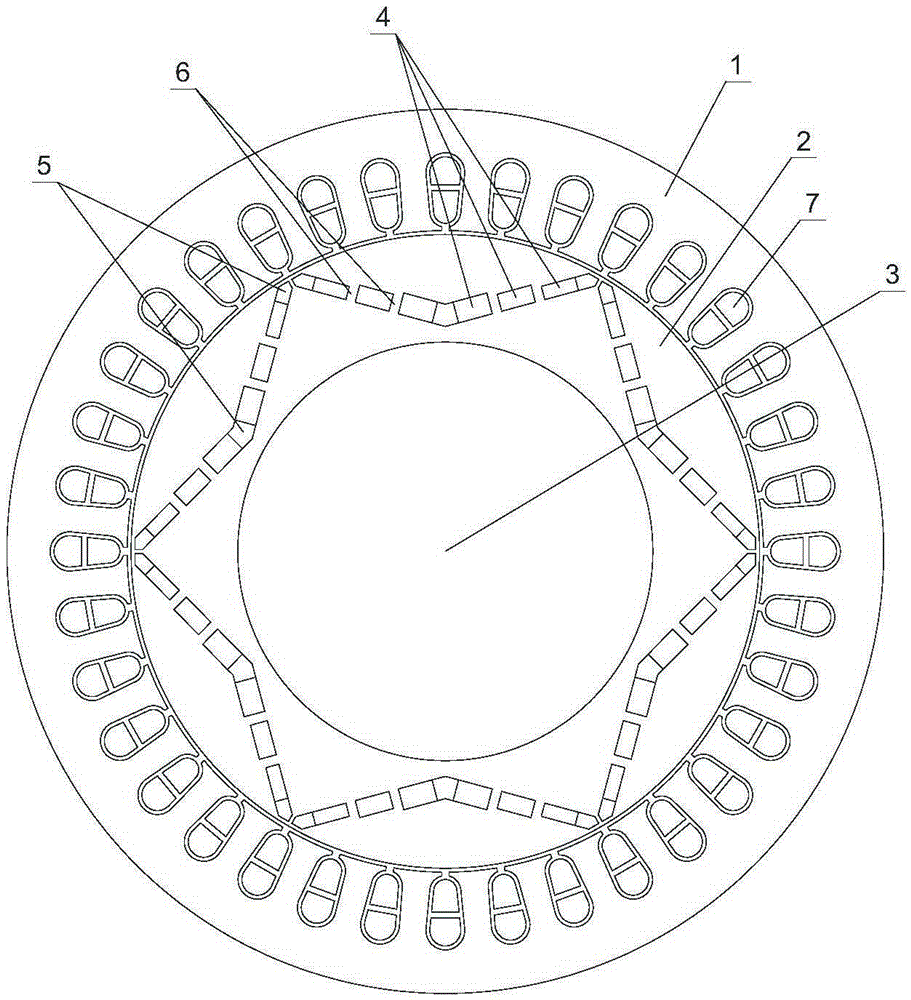

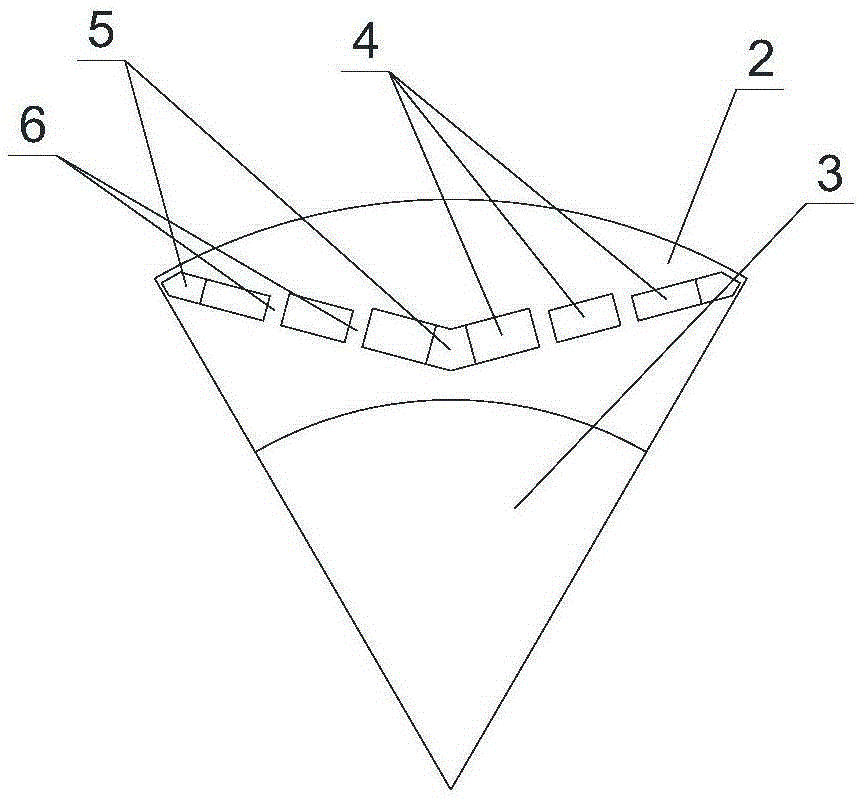

Built-in permanent magnet synchronous motor used for high-speed electric spindle

ActiveCN103956843AFlux Leakage GuaranteeFlux leakage increasesMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsLow speedConstant power

The invention relates to a built-in permanent magnet synchronous motor used for a high-speed electric spindle. The built-in permanent magnet synchronous motor comprises a stator iron core, a rotor iron core, a rotation shaft, magnetic steel and stator three-phase symmetrical windings. The built-in permanent magnet synchronous motor is characterized in that the magnetic steel is V-shaped magnetic steel which is evenly inlaid in the circumferential direction and radially magnetized; the V-shaped magnetic steel comprises a plurality of permanent magnets, a plurality of magnetic insulation bridges and a plurality of magnetic bridges; the permanent magnets are arranged on the two sides of the V-shaped magnetic steel, the magnetic bridges are arranged between the adjacent permanent magnets and the magnetic insulation bridges are arranged at the top ends of the V-shaped edges on the two sides and the bottom ends of the V-shaped magnetic steel. The built-in permanent magnet synchronous motor used for the high-speed electric spindle has the advantages that the motor has the high-torque running performance achieved during low-speed running, and has a wide weak magnetic speed raising range at the constant power section above base speed; during constant-power high-speed running, the leakage flux of the permanent magnets is high and the weak magnetic speed raising capacity is high; during non-load running, the leakage flux of the motor is low and the output torque is high; the segmented unequal-thickness magnetic steel enables gap flux densities of the motor to be distributed similar to a sine, therefore, the torque pulsation is low, the control precision is high and the permanent magnets of the motor are not prone to excitation loss.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

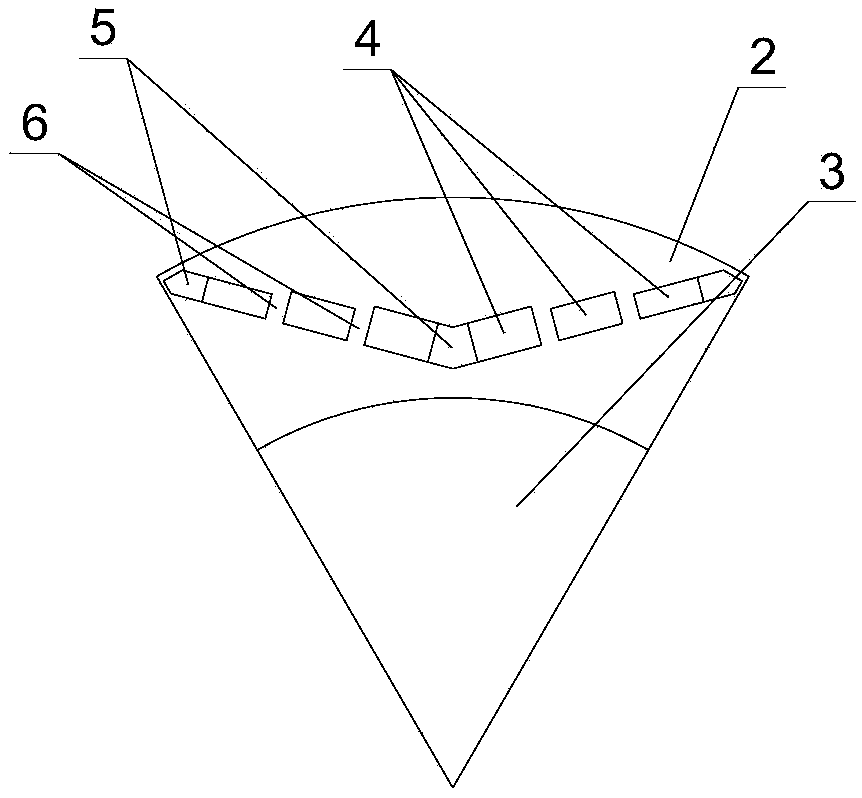

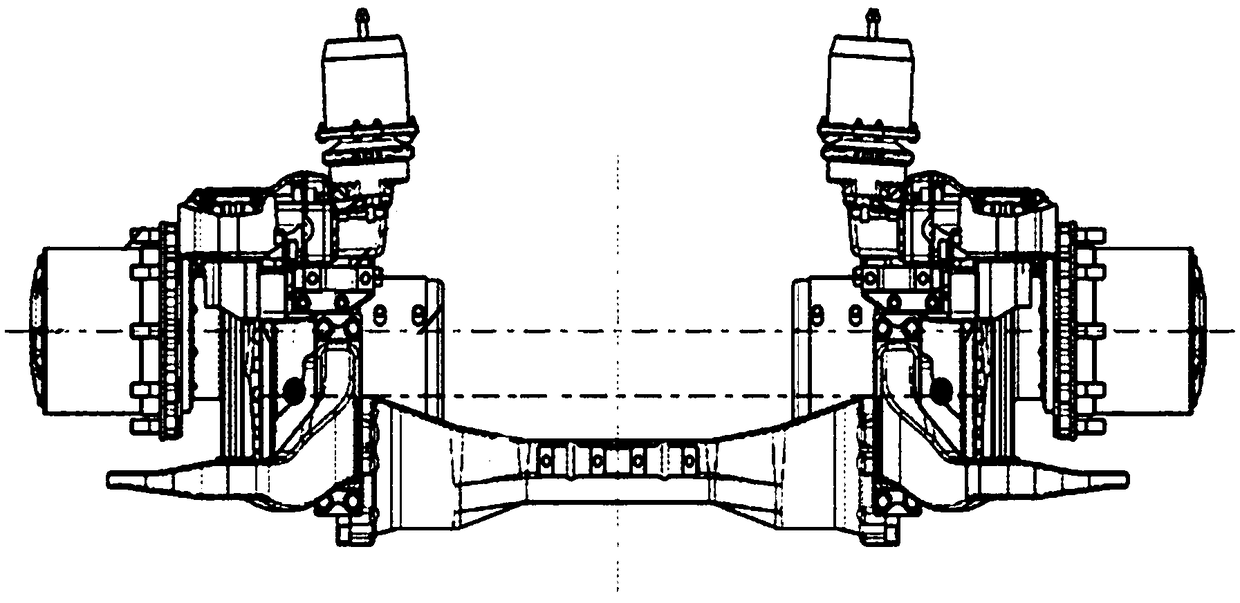

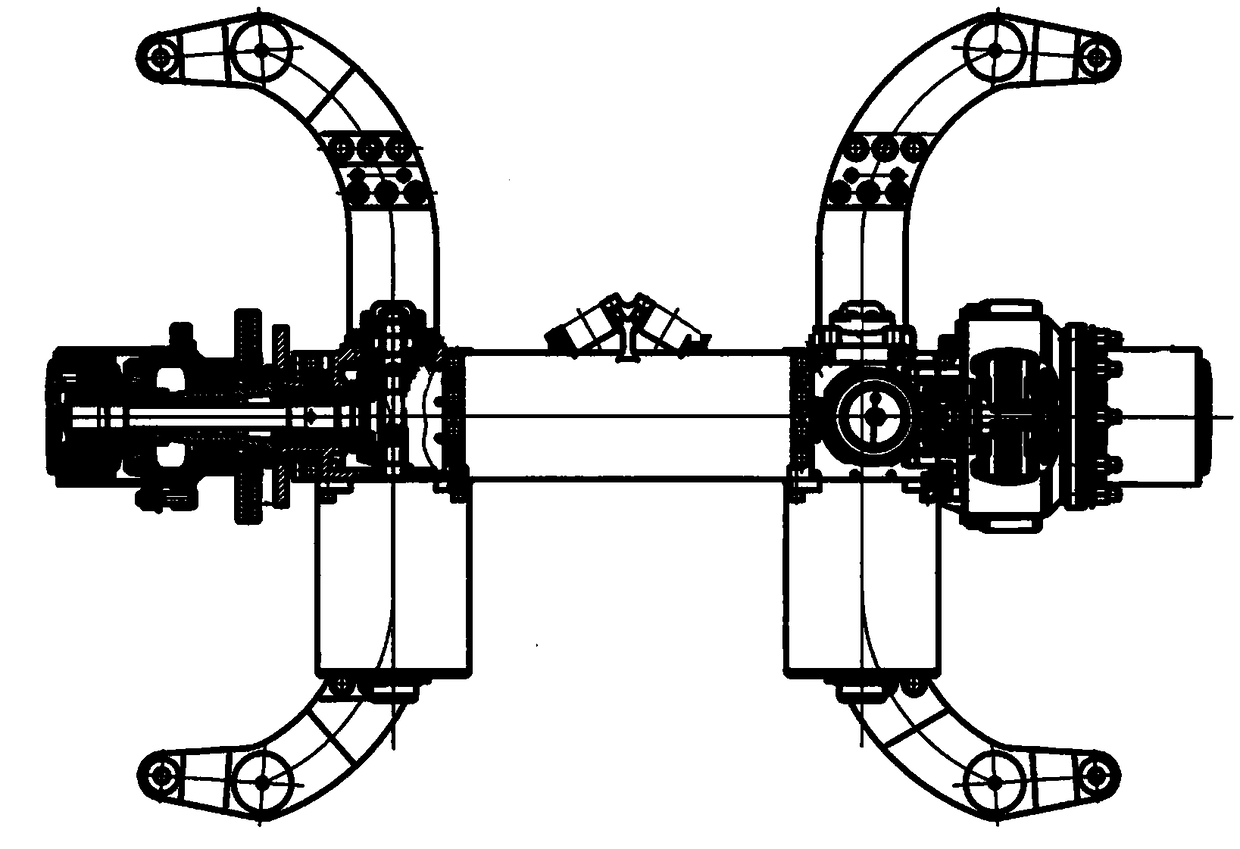

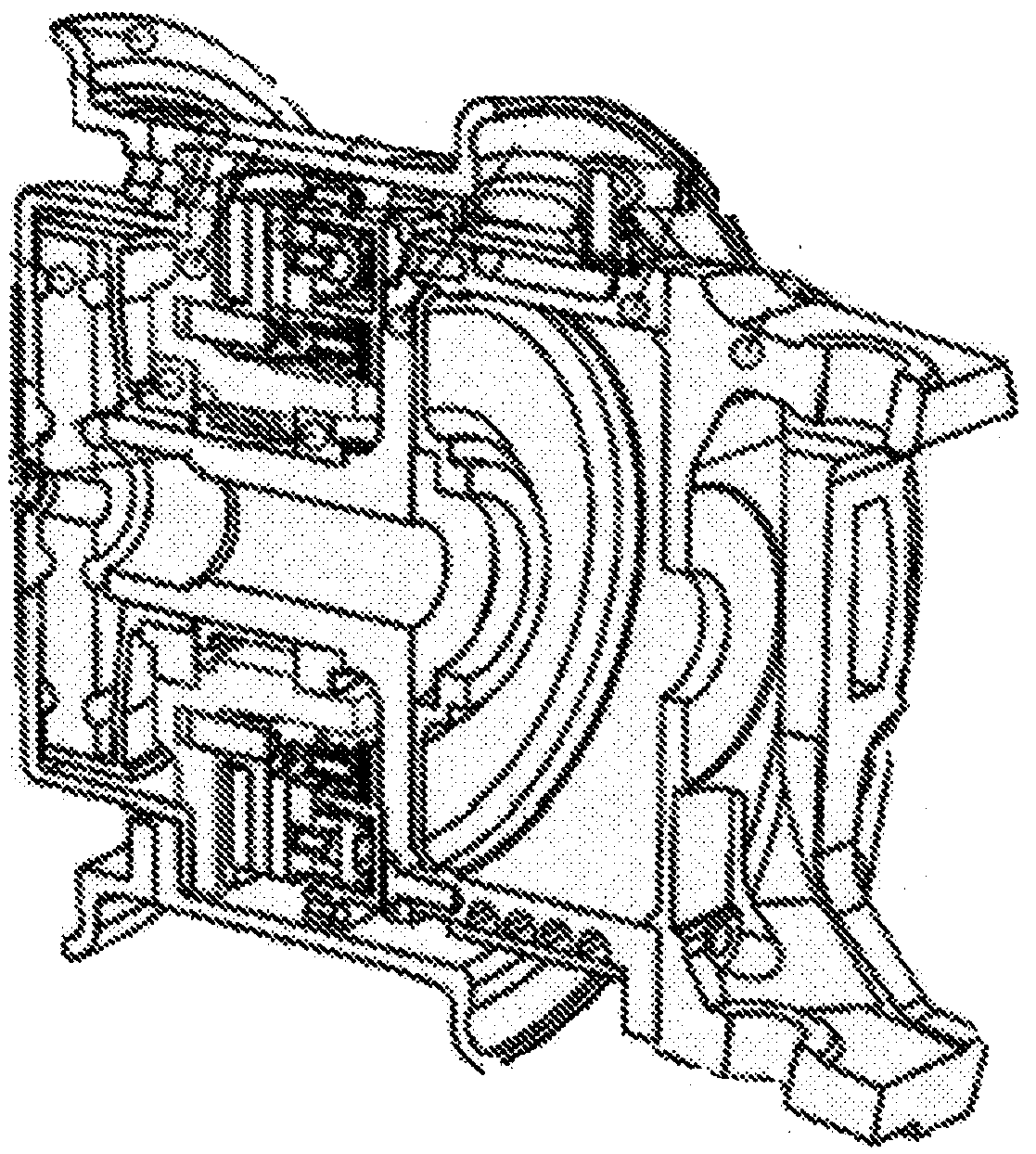

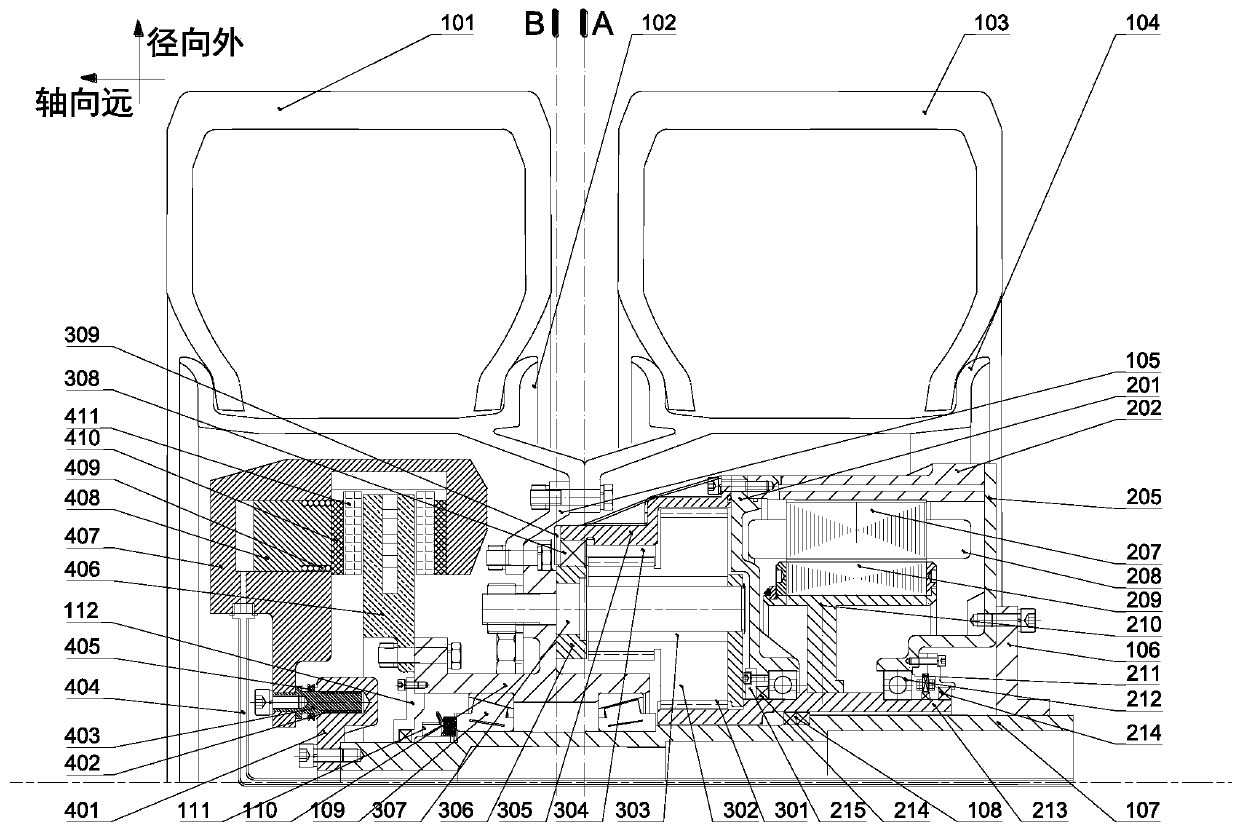

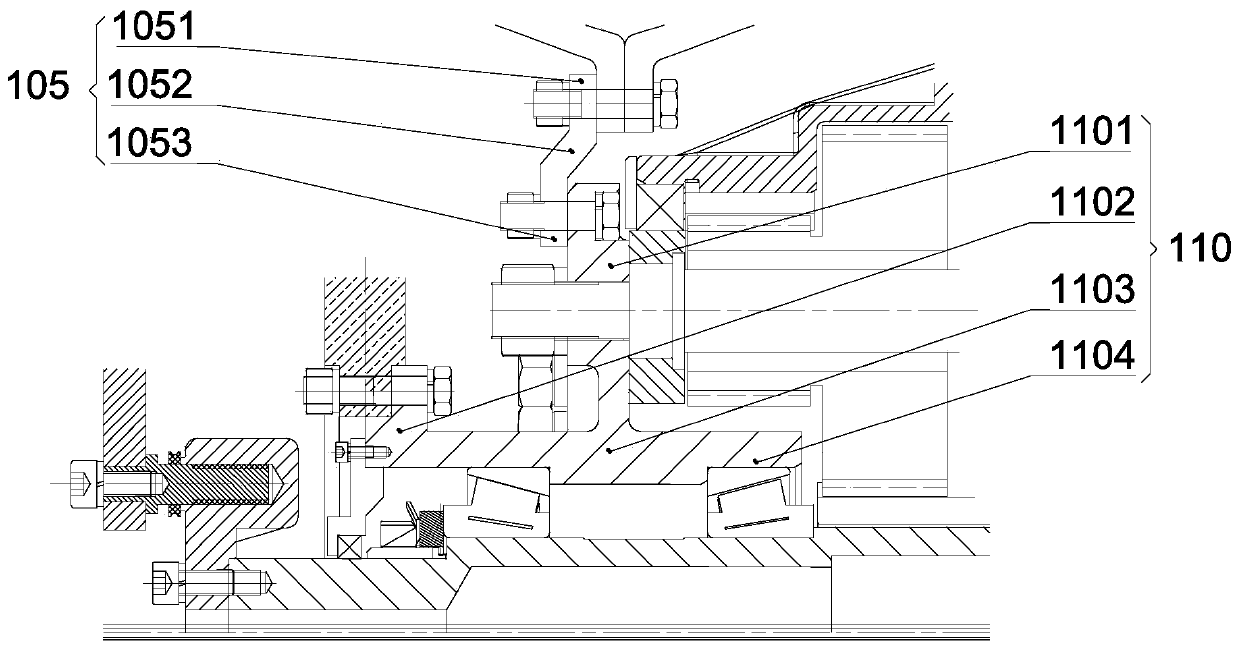

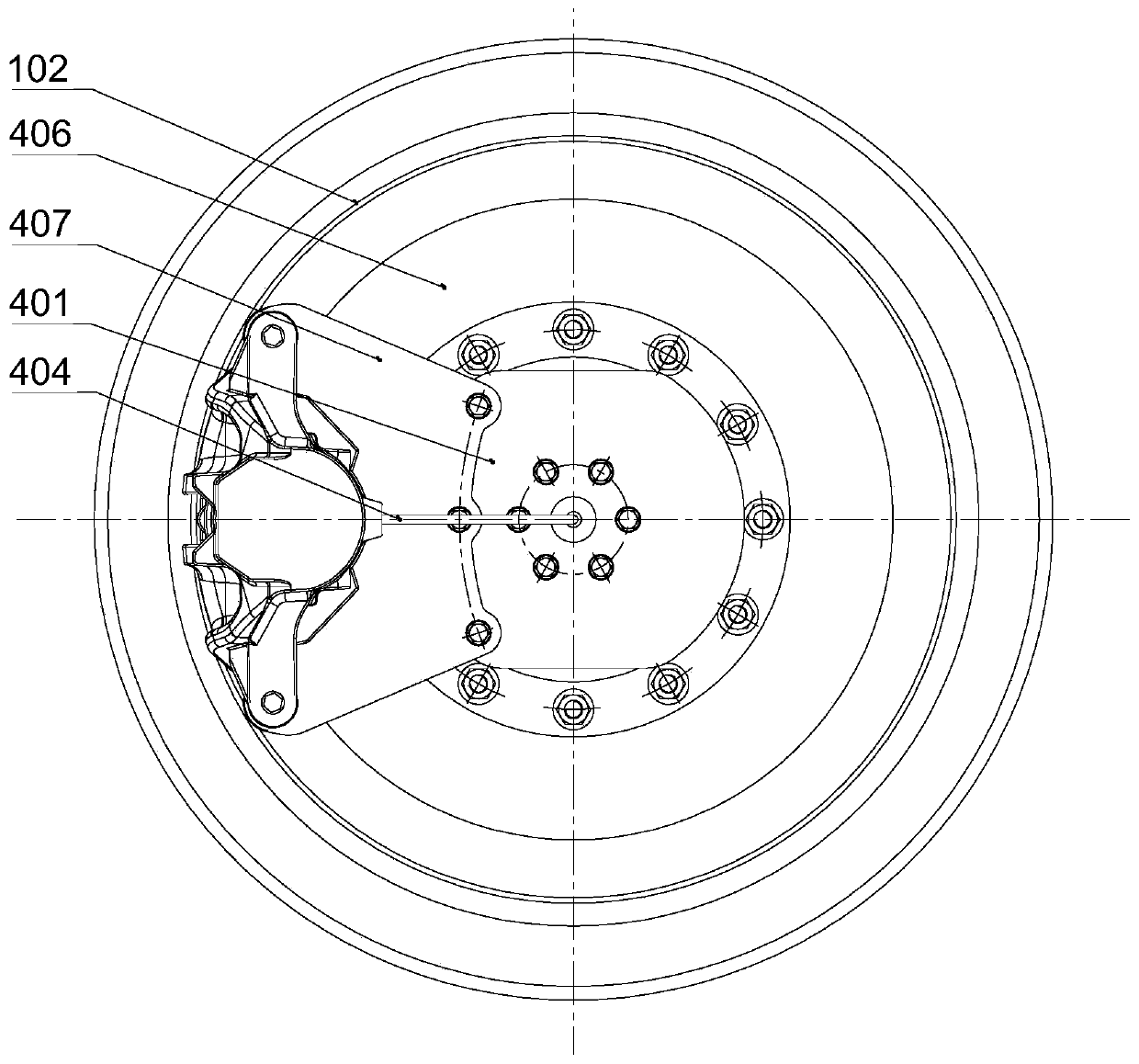

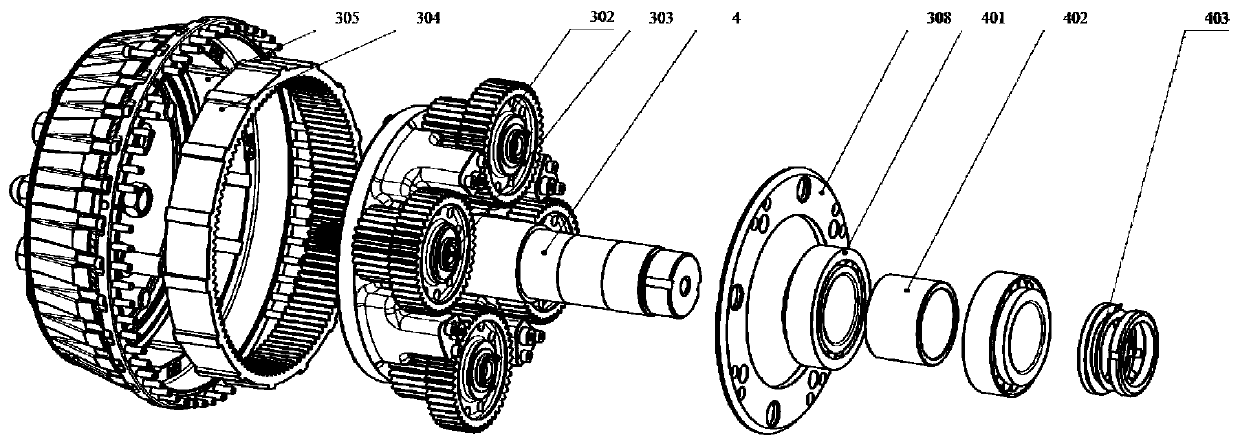

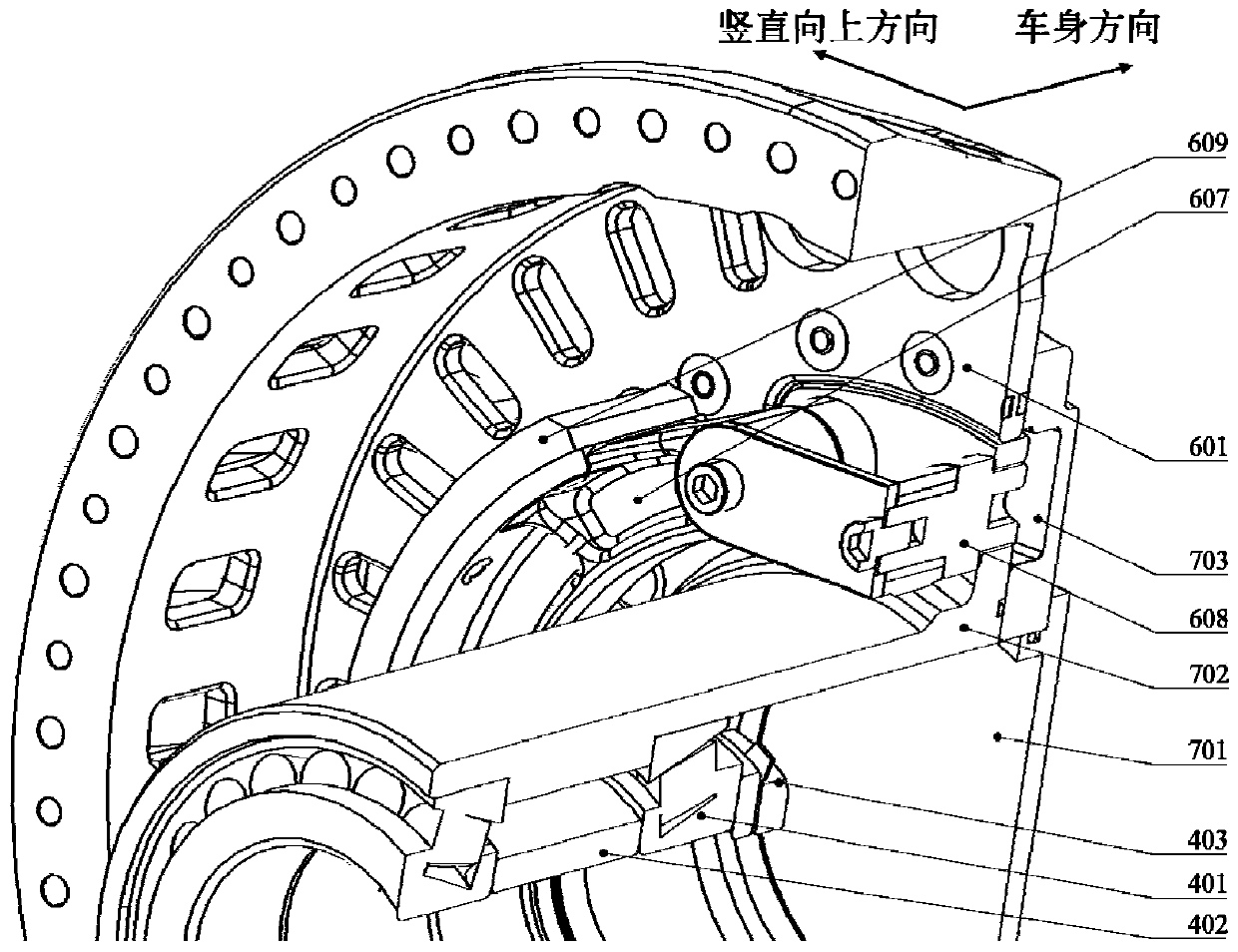

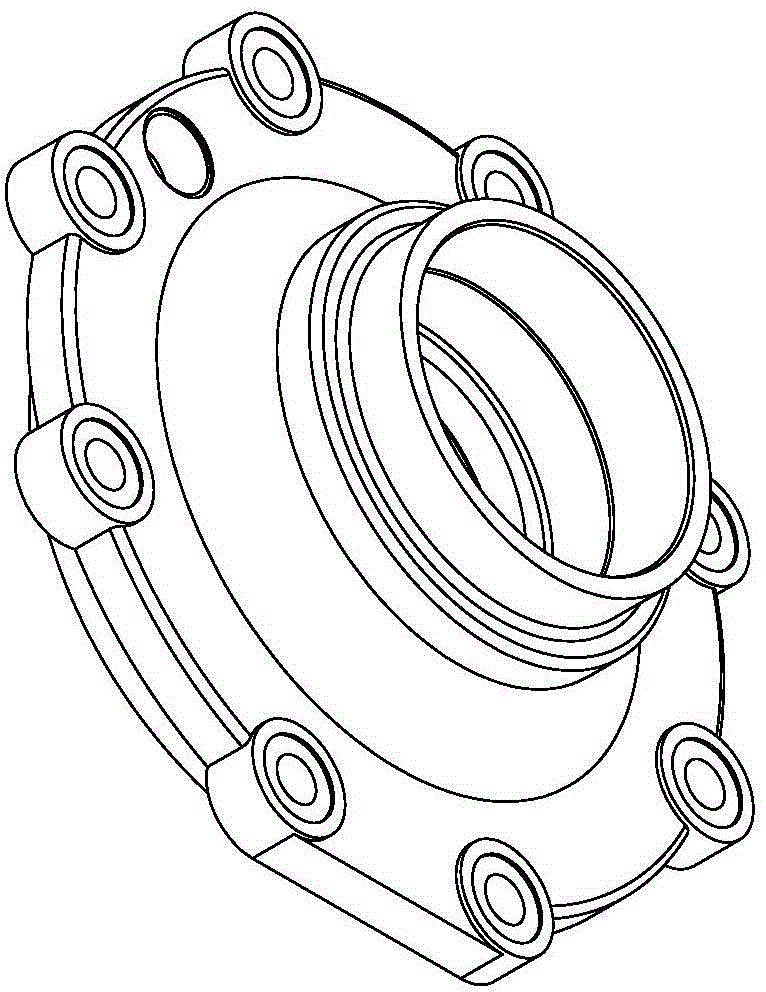

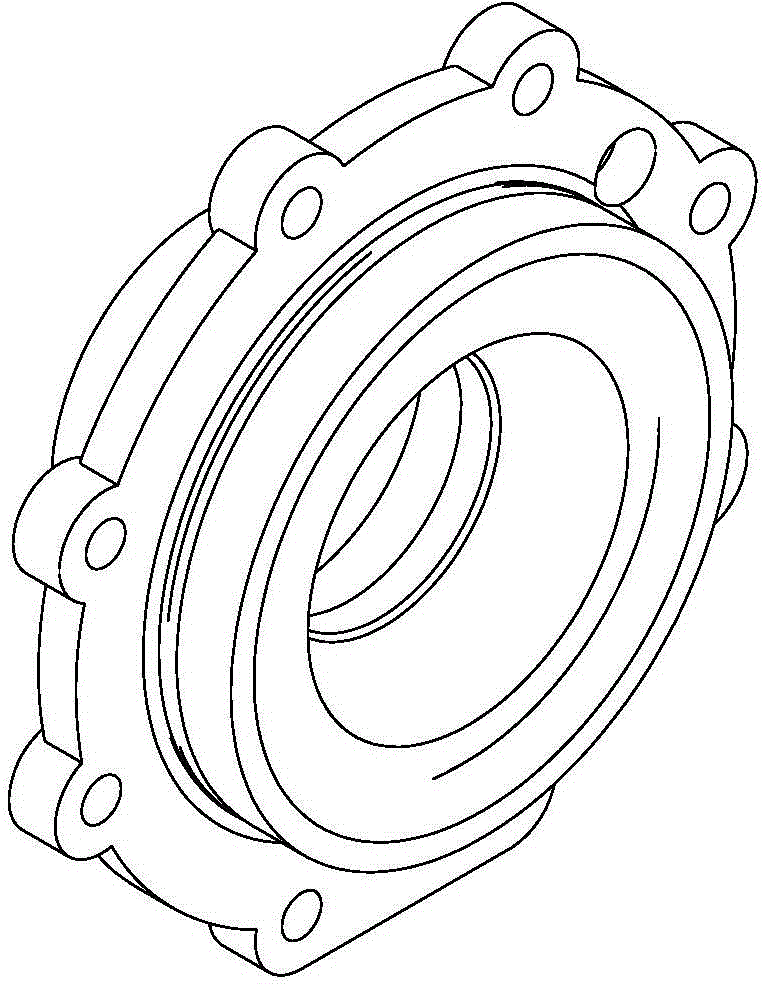

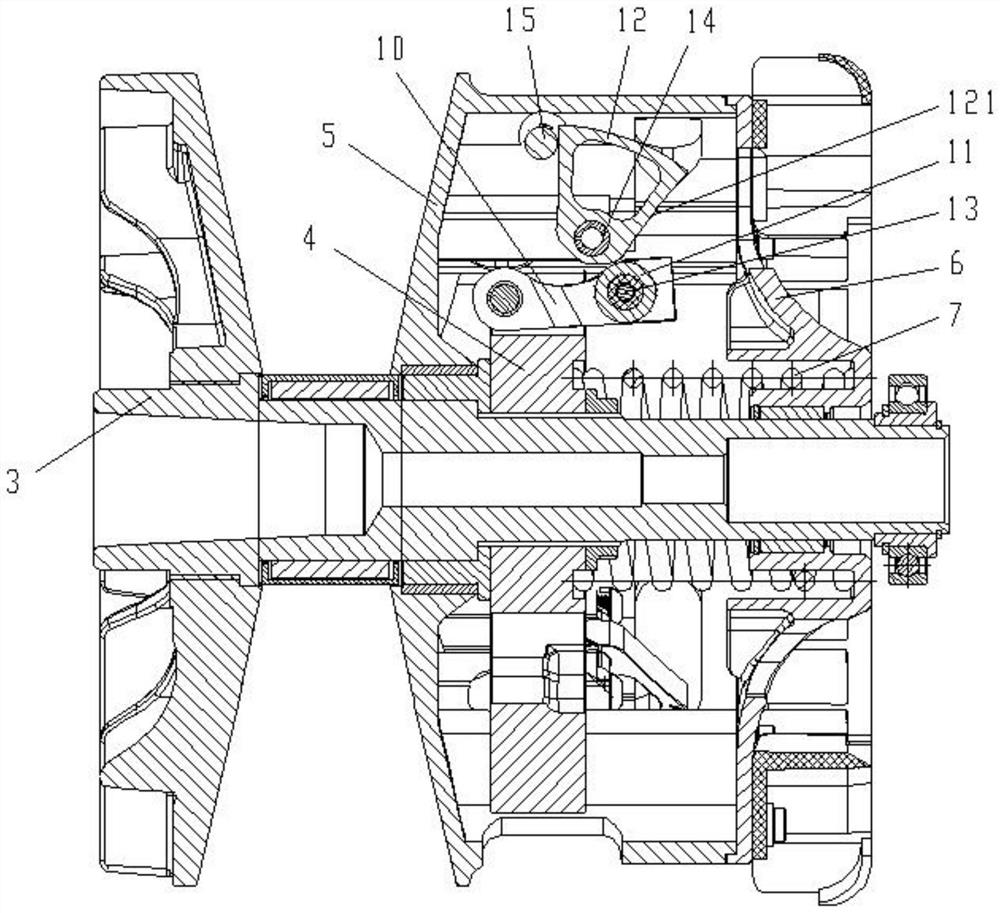

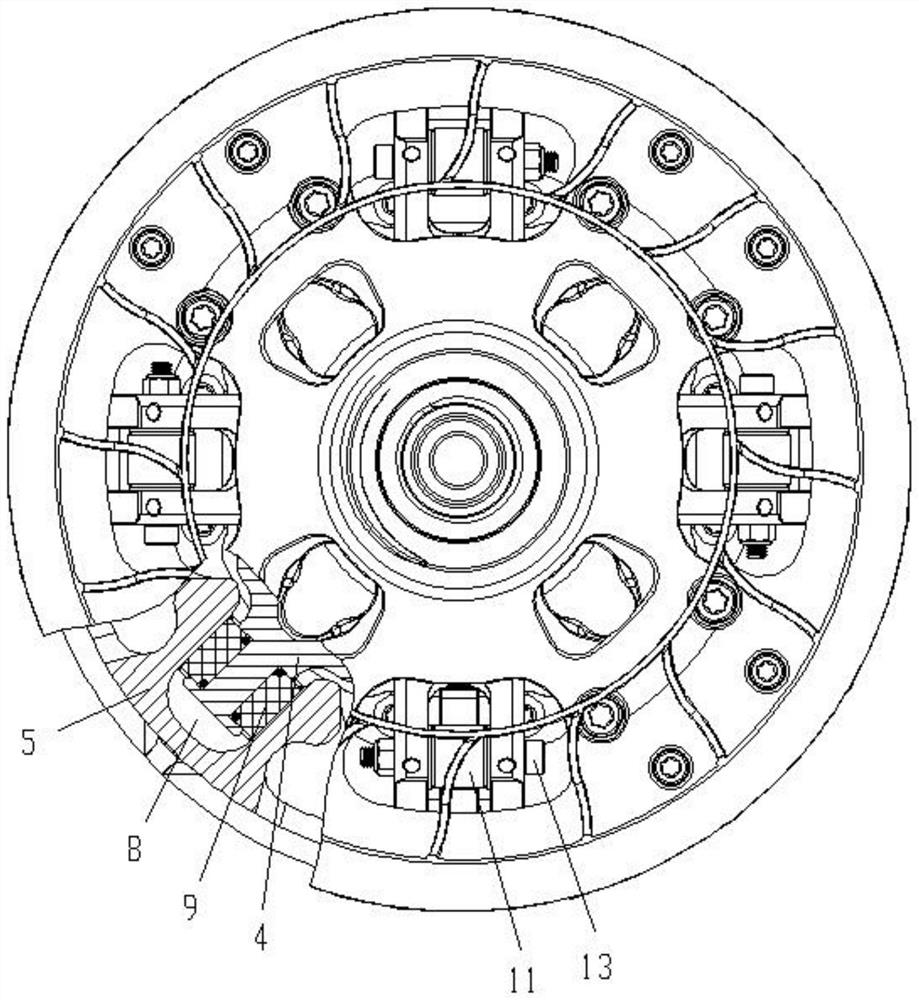

Electric wheel assembly, axle and vehicle suitable for twin tires and loading wheels

ActiveCN109130839AAxial dimension shortCost controlBraking element arrangementsBrake coolingReduction driveGear wheel

The invention discloses an electric wheel assembly, axle and vehicle suitable for twin-tire parallel loading wheels. The electric wheel assembly comprises wheels and a support shaft assembly, an innerrotor hub motor, a planetary gear reducer and a braking system. A planet carrier is connected with a wheel hub, the wheel hub connects a spoke and a wheel rim, a wheel support shaft passes through arotor sleeve, and hub bearings are arranged on the wheel support shaft to support the wheel hub and the whole wheel. The sun gear at one end of the rotor sleeve of the inner rotor hub motor is the power input of the planetary gear reducer, and the planet carrier is the power output. The planetary gear of planetary gear reducer adopts tower gear to realize larger transmission ratio under smaller axial length. The brake system adopts drum brake, the brake drum is connected with the rotor sleeve, and the braking force is amplified through the planetary gear reducer, which can reduce the braking force required by the brake system, and the electric motor can provide the electric braking force when braking. The electric wheel assembly can be used for the non-independent suspension of the commercial vehicle, and the cooling lubrication mode of the integrated cooling lubrication can be adopted to improve the performance.

Owner:南京清研易为新能源动力有限责任公司

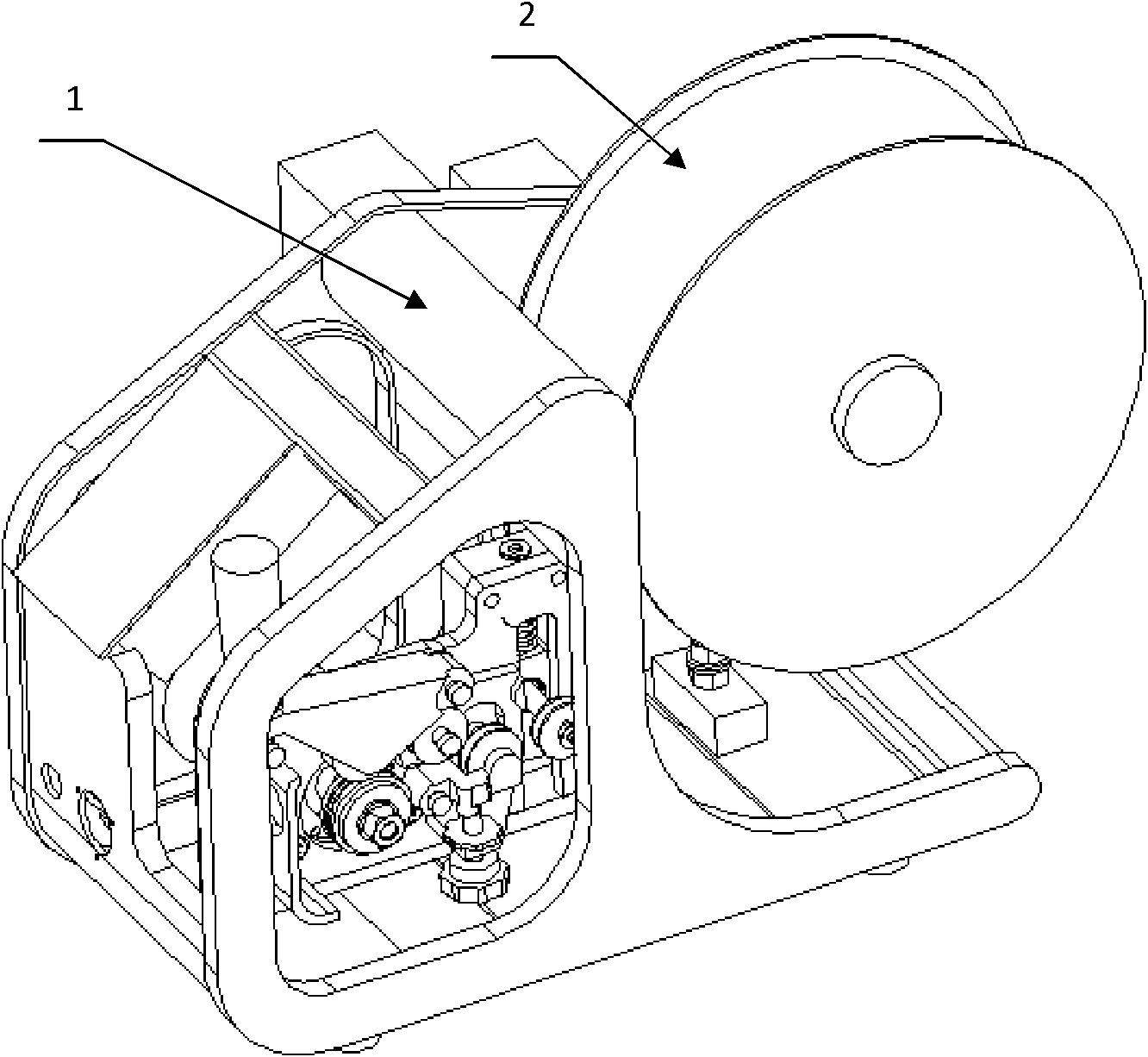

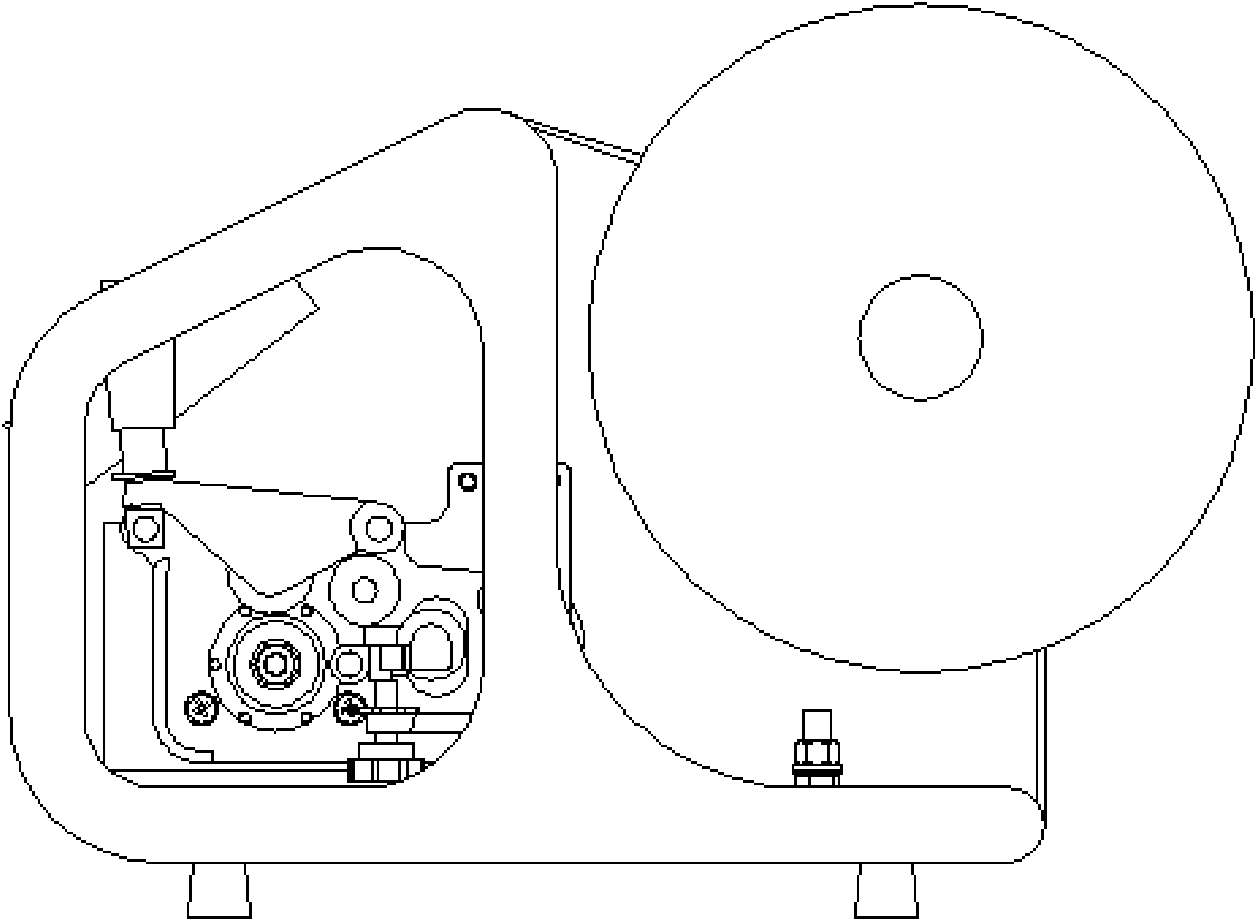

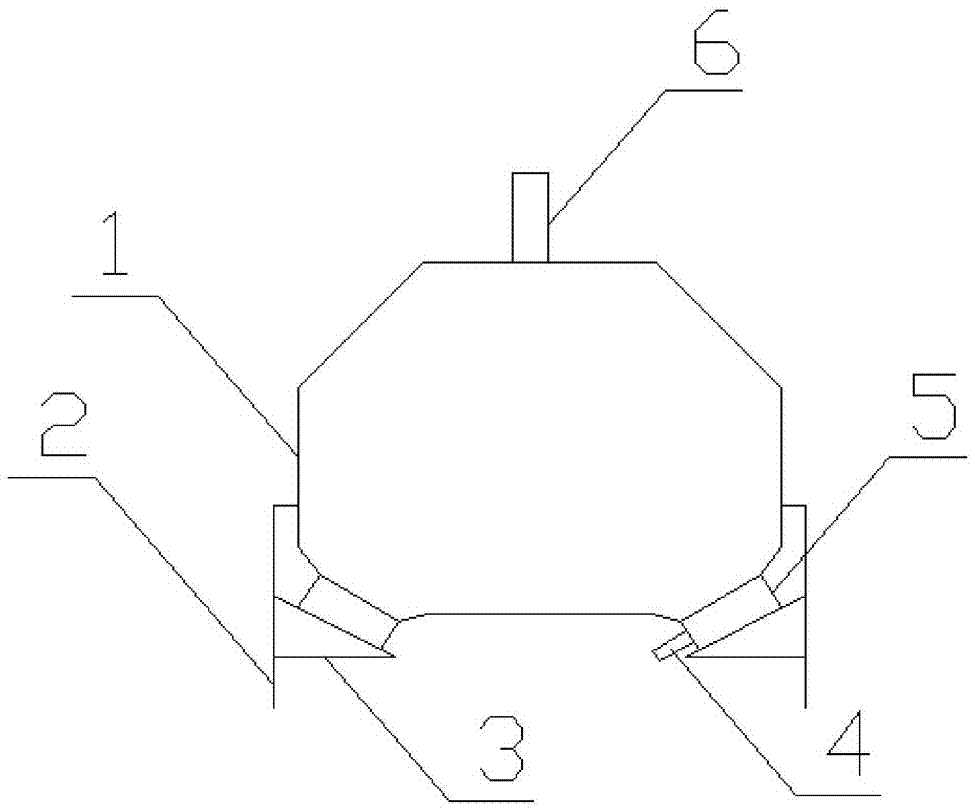

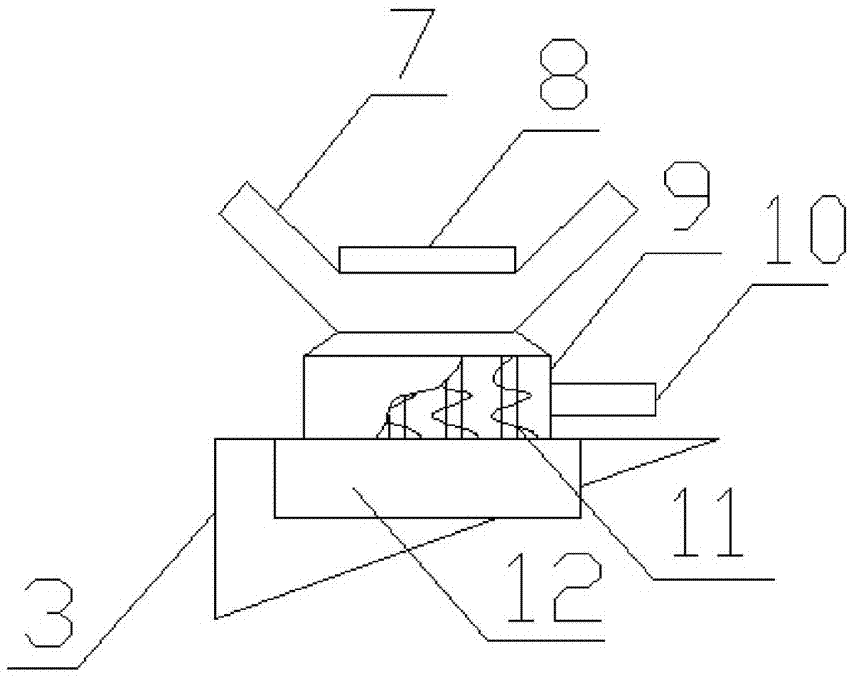

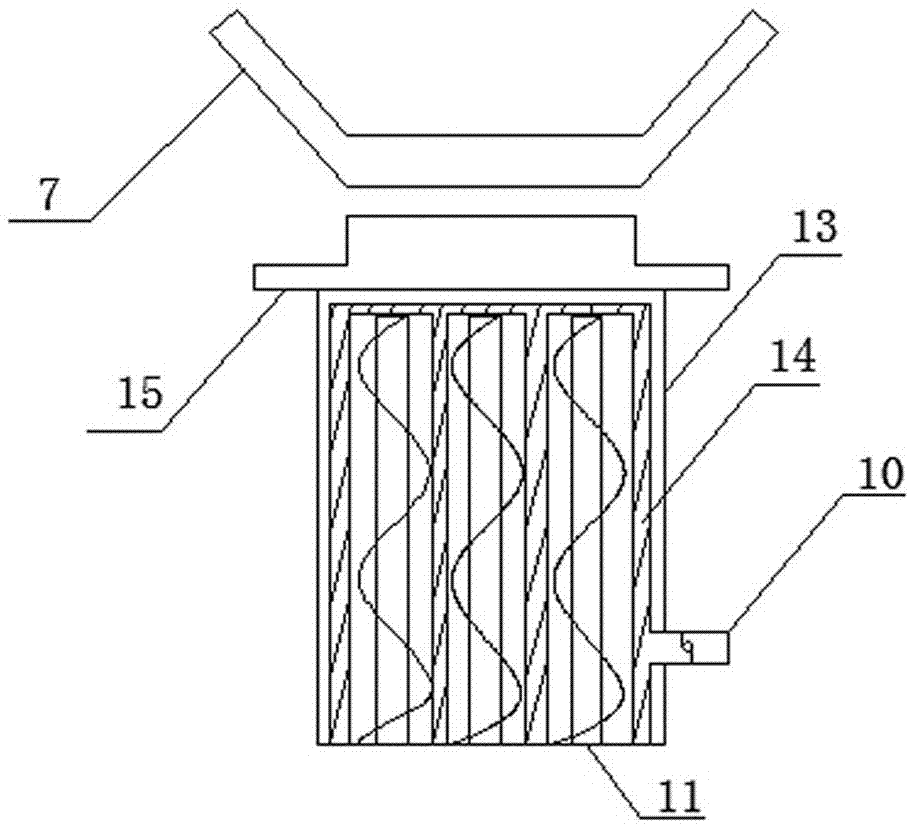

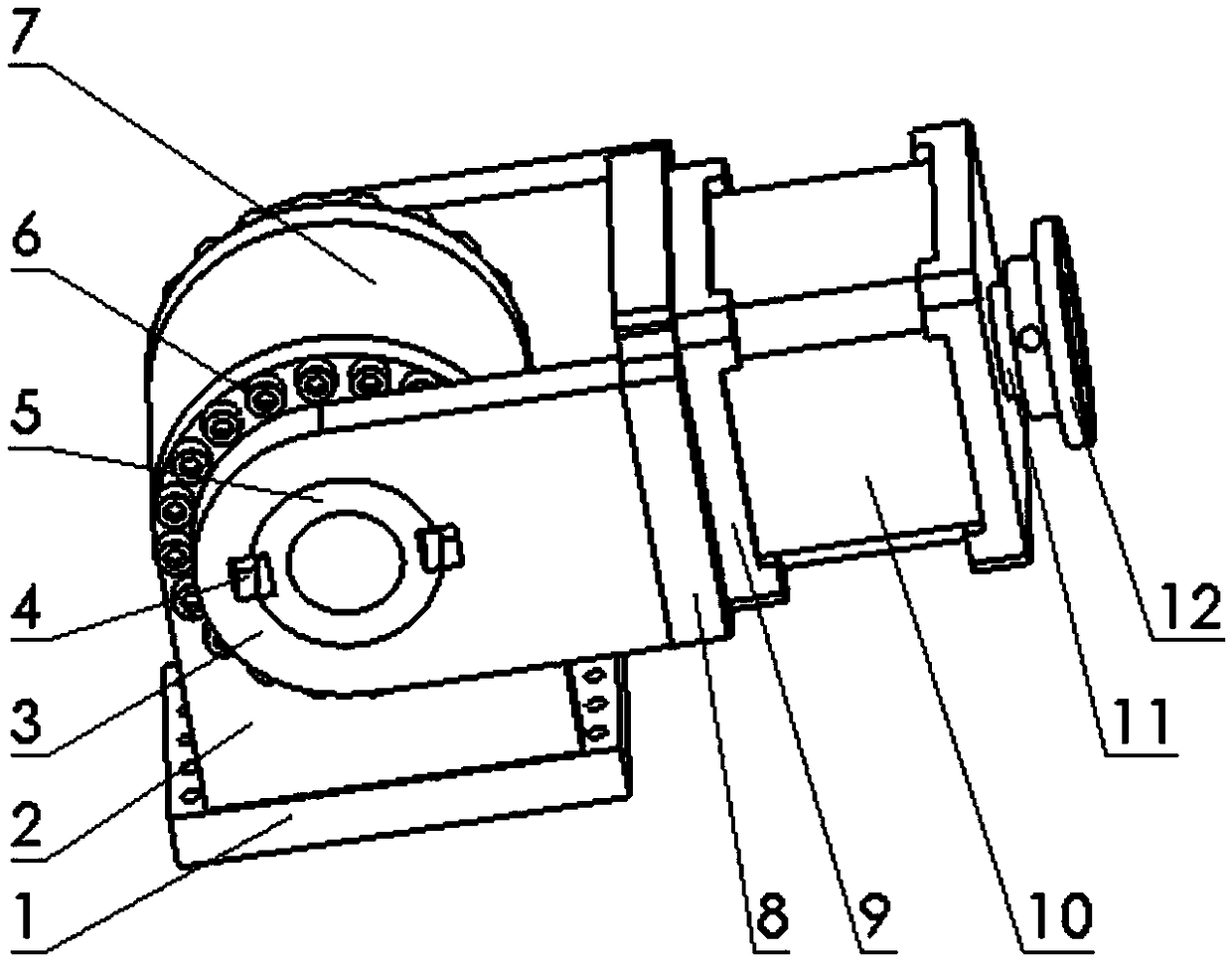

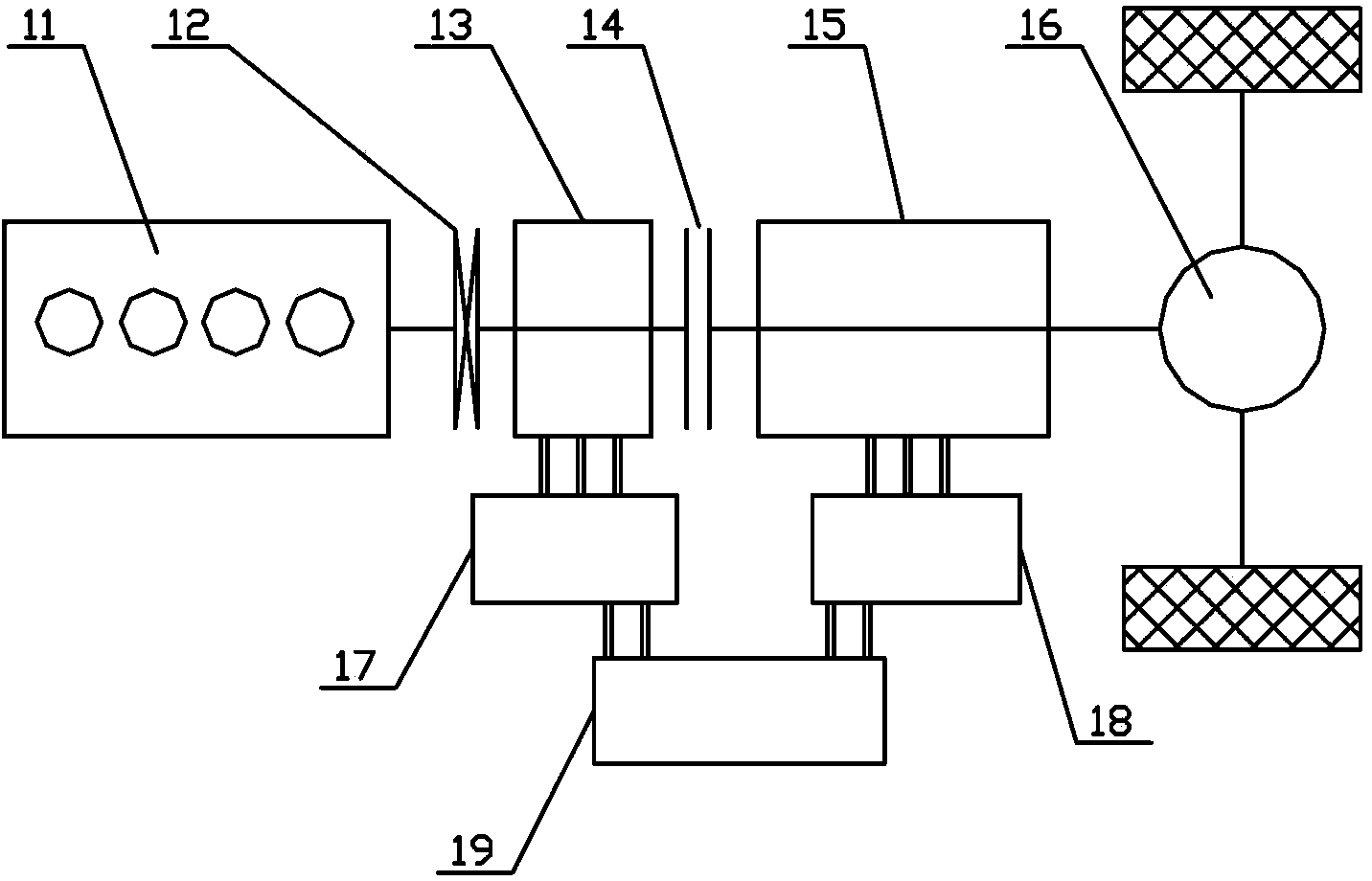

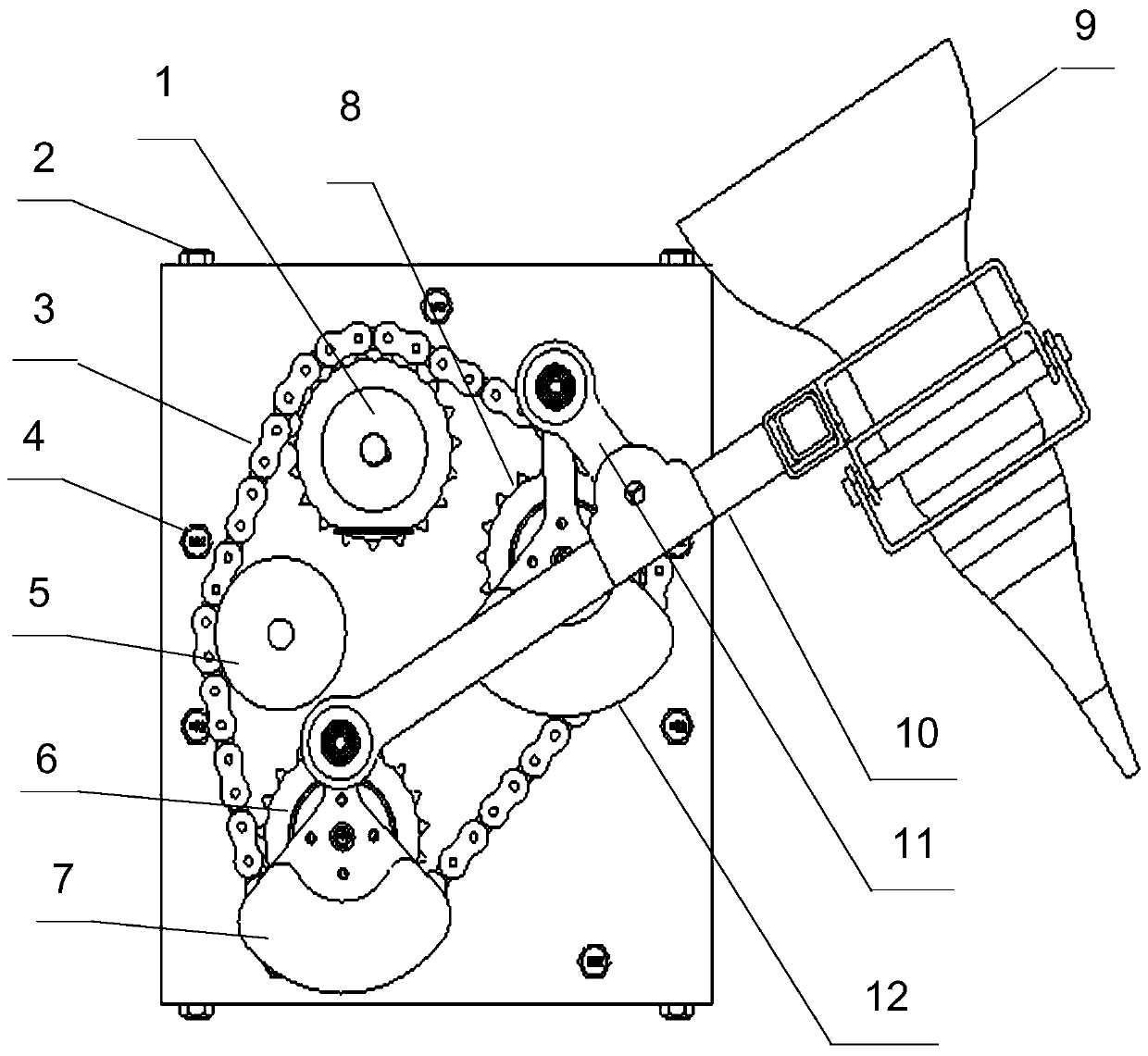

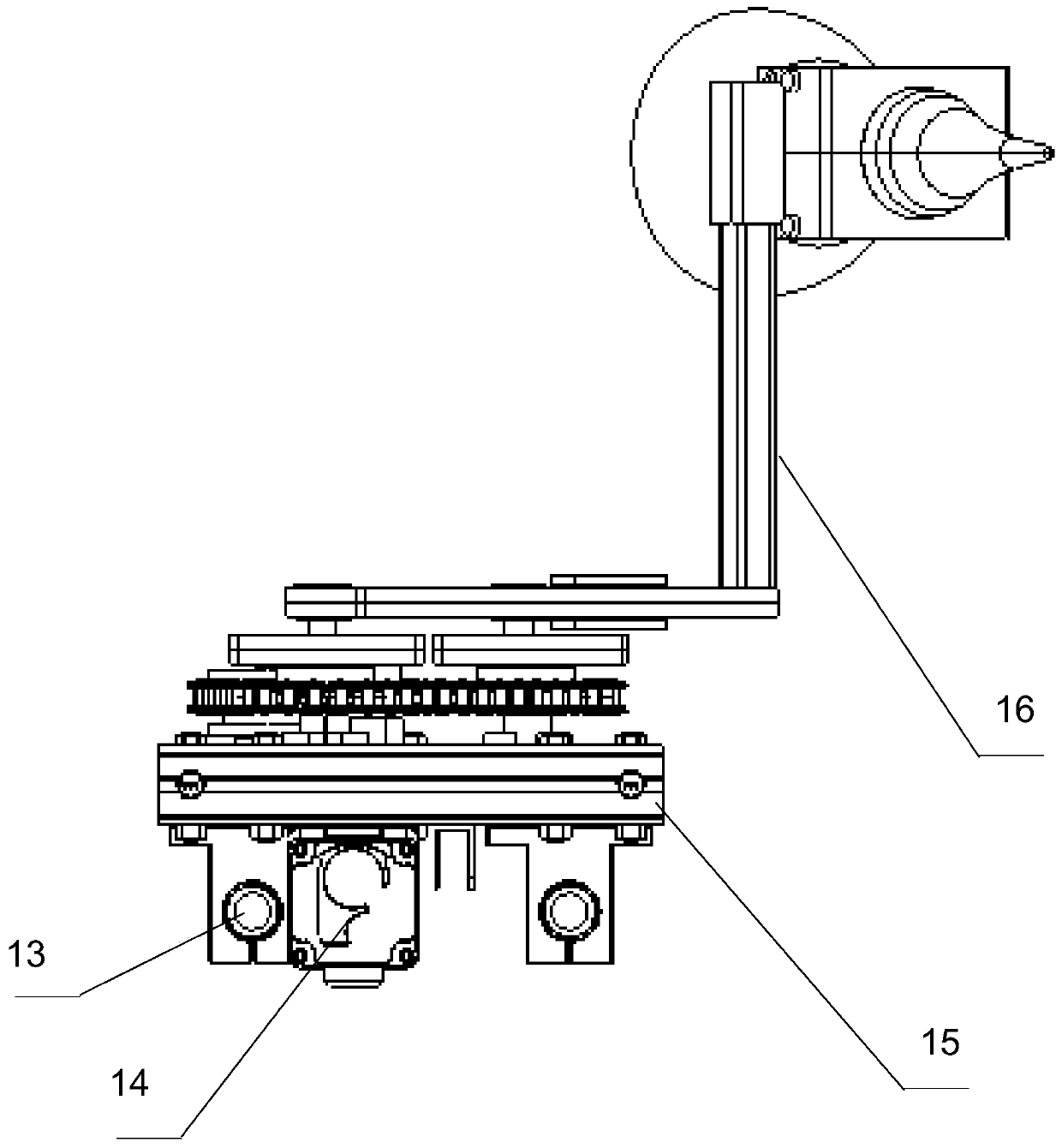

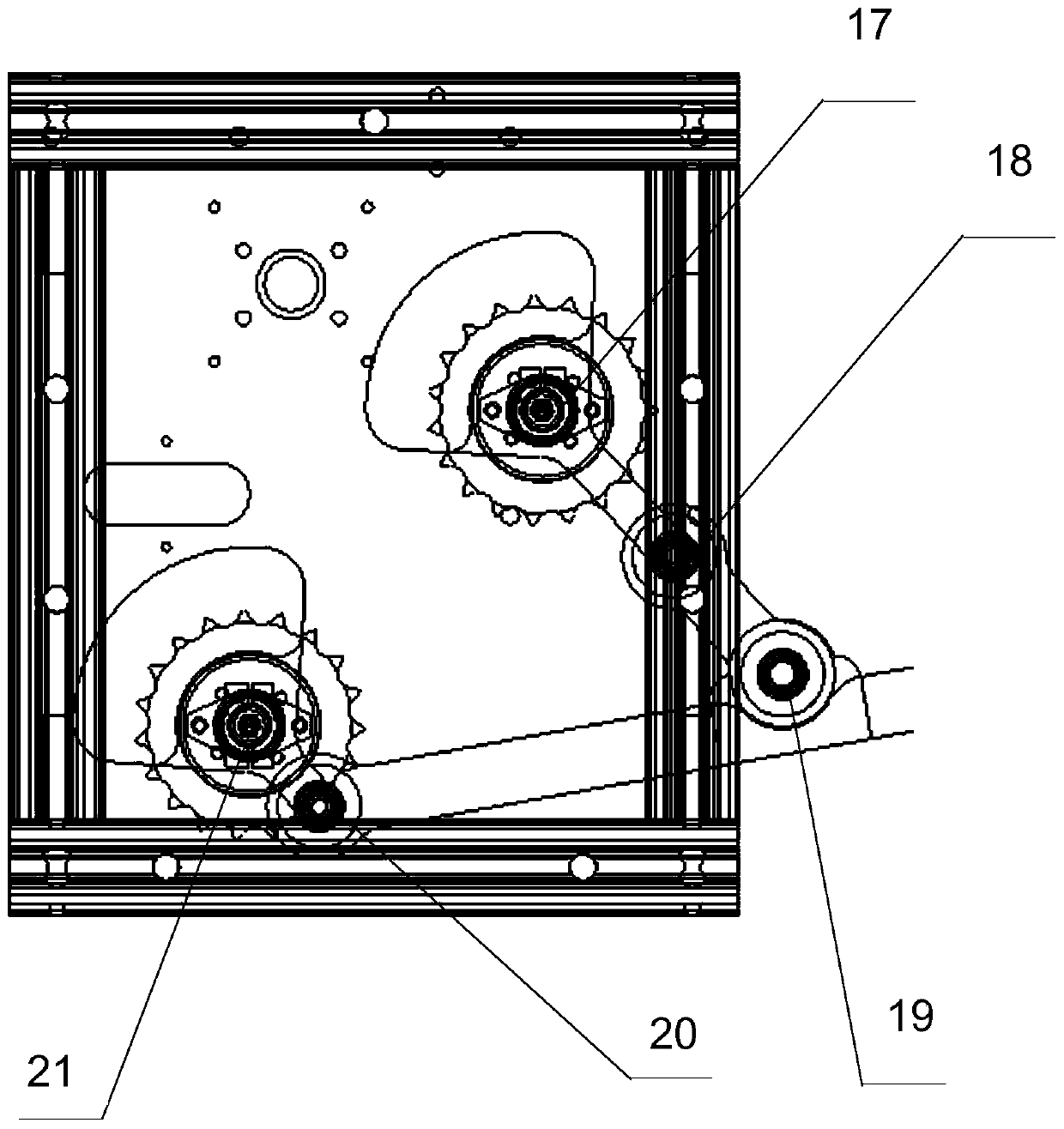

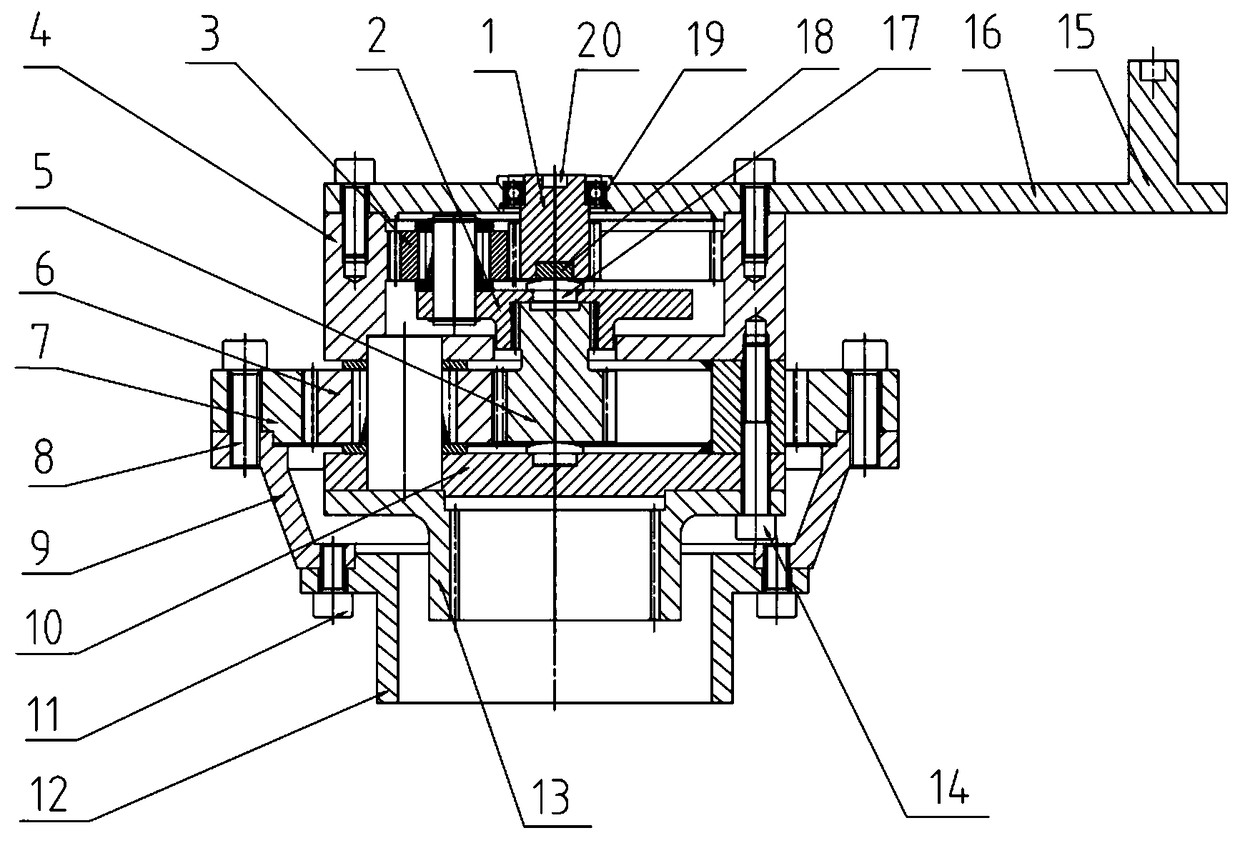

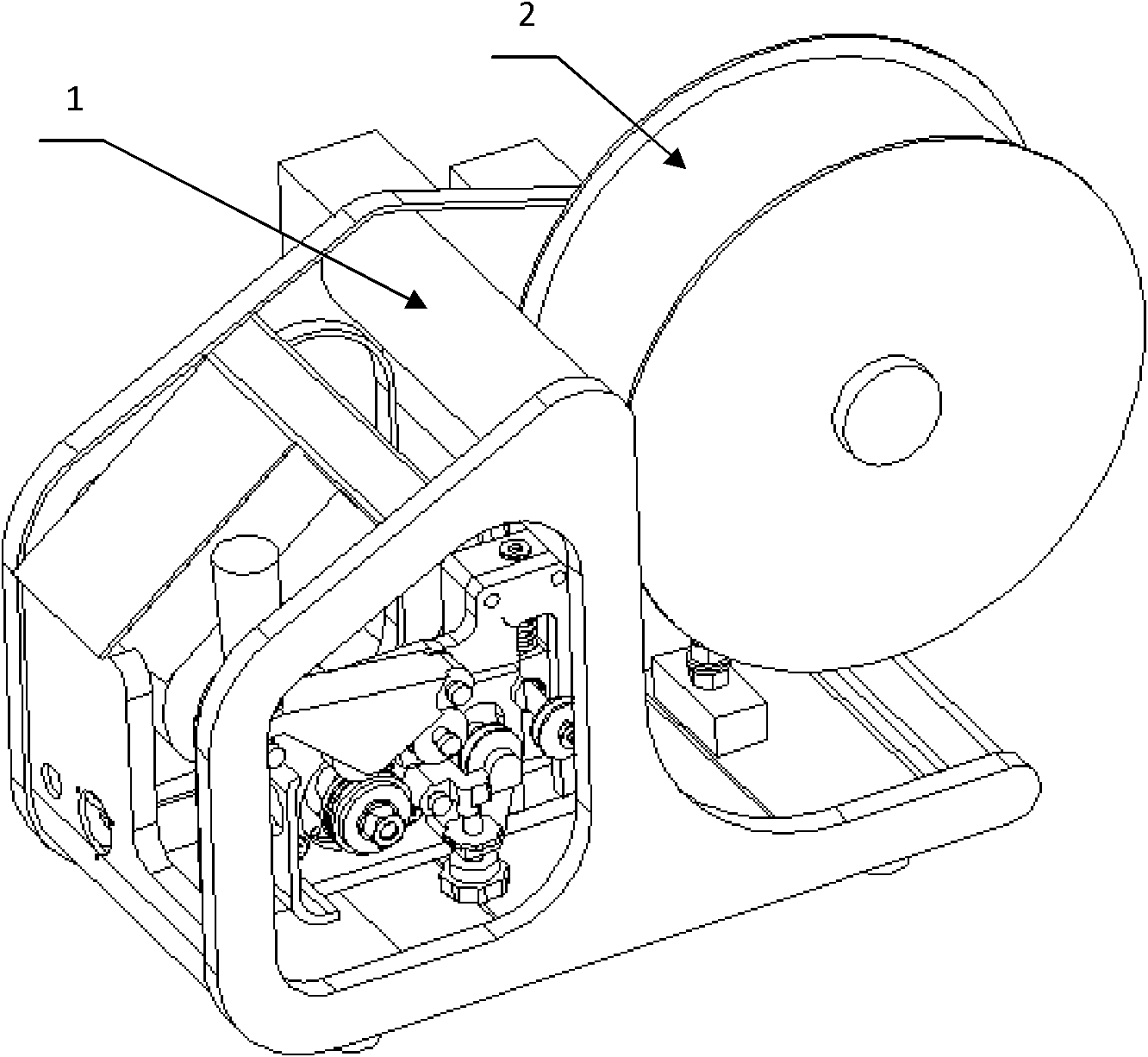

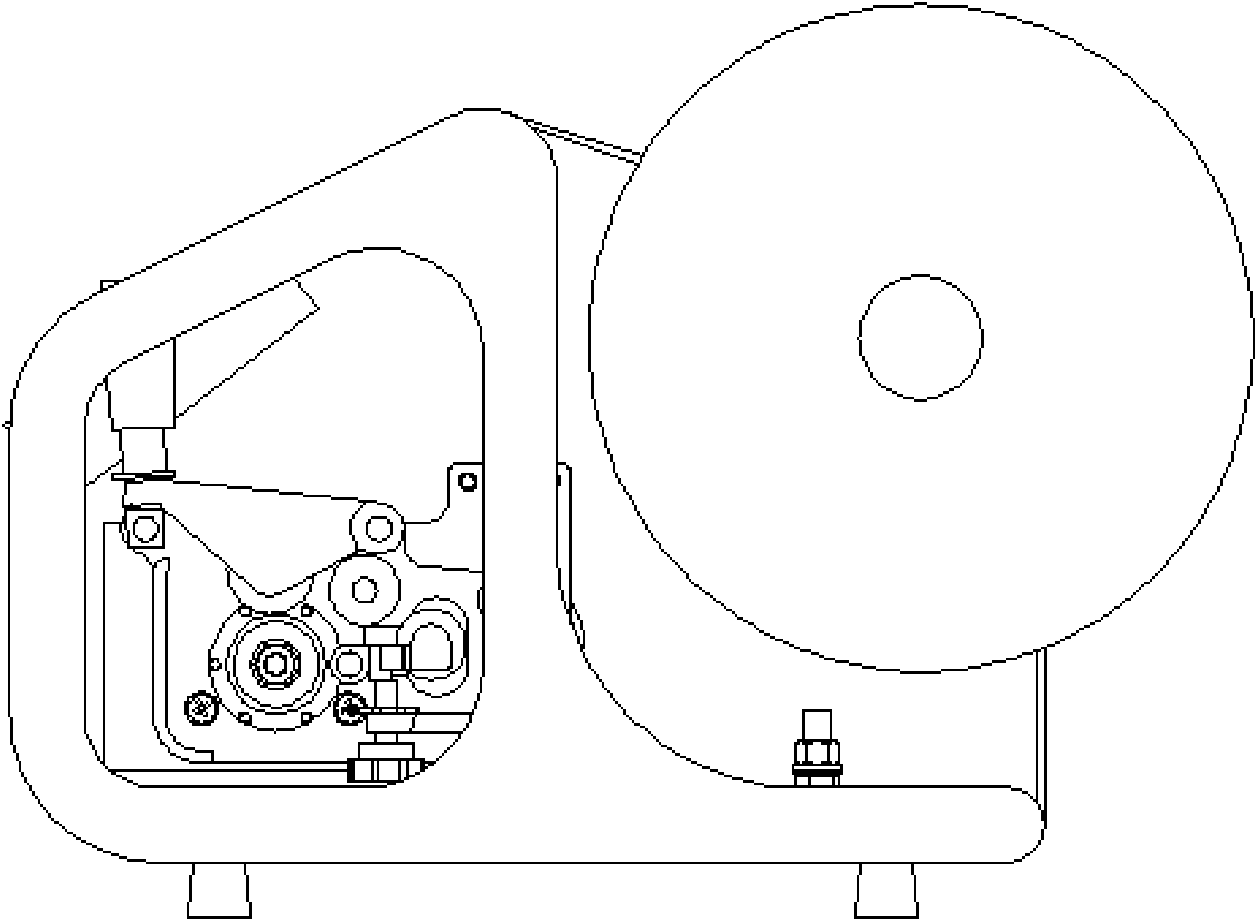

Intelligent wire feeding machine

InactiveCN102465292AStable outputGuaranteed output torqueMetallic material coating processesLaser beam welding apparatusLaser processingControl system

The invention relates to an intelligent wire feeding machine. The machine comprises a frame, a wire welding disc, a wire feeding device and a control mechanism. The machine is characterized in that: the tail part of the frame is provided with a wire welding disc shaft; the wire feeding device fixed by bolts is arranged on a bottom plate below the frame; the side surface of the frame is provided with a supporting plate for fixation; the wire feeding device comprises a servo motor, a harmonic reducer, a panel, a wire feeding wheel, regulating wheels, a thumb wheel, a compression rod, a wheel bracket panel, a connecting rod, bearings, an encoder, a compression spring, a spring core shaft, a shaft sleeve, a sliding body, and a sliding body cover; the control mechanism is that: an embedded computer system is arranged in the intelligent wire feeding machine. According to the present invention, the servo control technology and the harmonic reducer are adopted, such that the operating stability of the welding wire at the low speed is effective controlled; the elastic floating device and the encoder are added, such that the control system is improved, the terminal close loop of the welding wire output movement is achieved, the wire feeding speed is real-timely monitored, and the damage probability of the laser processing workpiece due to the machine problem is reduced to the minimum.

Owner:鞍山大陆激光技术有限公司

Heavy-load electric wheel

PendingCN111361358AAxial dimension shortCost controlBraking element arrangementsMagnetic circuit rotating partsReduction driveGear wheel

The invention discloses a heavy-load electric wheel, and belongs to the field of electric vehicle power devices. A brake, a planetary gear reducer and a hub motor are sequentially arranged on the outer side of a supporting shaft from the distant to the near; the outer side of a hub is connected with a spoke mounting plane of a rim through a spoke, and the hub is mounted on the outer side of the supporting shaft through a pair of hub bearings; a brake caliper support in the brake is installed outside the distal facet of the wheel supporting shaft through a bolt, and a brake disc is installed ona brake disc installation flange of the hub; a hub part of the hub motor rotor support is sleeved on the rotor shaft; and a sun gear in the planetary gear reducer is disposed outside the distal end side of the rotor shaft. The axial size of the whole electric wheel assembly is short, and the hub motor, the planetary gear reducer and the brake are all arranged in the space defined by the rim on the inner side and the outer side of the electric wheel assembly, so that the electric wheel assembly can be suitable for common commercial vehicle double-tire parallel loading wheels.

Owner:南京清研易为新能源动力有限责任公司

System for optimizing commercial vehicle engine vibration performance

ActiveCN107187308AReal-time monitoring of vibration transmissionReduce vibrationSustainable transportationJet propulsion mountingMicrocontrollerVehicle frame

The invention provides a system for optimizing the commercial vehicle engine vibration performance. The system comprises suspension cushions, vibration sensors, cylinder pressure sensors, an alerter, a combination instrument, a single chip microcomputer, an adjusting switch, a vacuum pump and a driving motor; the suspension cushions are thickness-changeable suspension cushions and are installed at the joint of an engine and a frame; the vibration sensors are installed on the four suspension cushions in front and at back of the engine and flywheels, the cylinder pressure sensors are installed on all cylinders of the engine, and each thickness-changeable suspension cushion is composed of an upper connecting support, a middle adjusting part and a lower connecting support, wherein the middle adjusting part is composed of a metal flange, a damping spring, an air bag and a vacuum valve; the single chip microcomputer is arranged in a vehicle body, the alerter, the combination instrument and the adjusting switch are installed in a cab, and the single chip microcomputer can communicate with the engine ECU. Accordingly, vibration transmission generated by the engine can be monitored in real time, and when vibration exceeds a set value, vibration of the engine is reduced.

Owner:湖北三环汽车有限公司

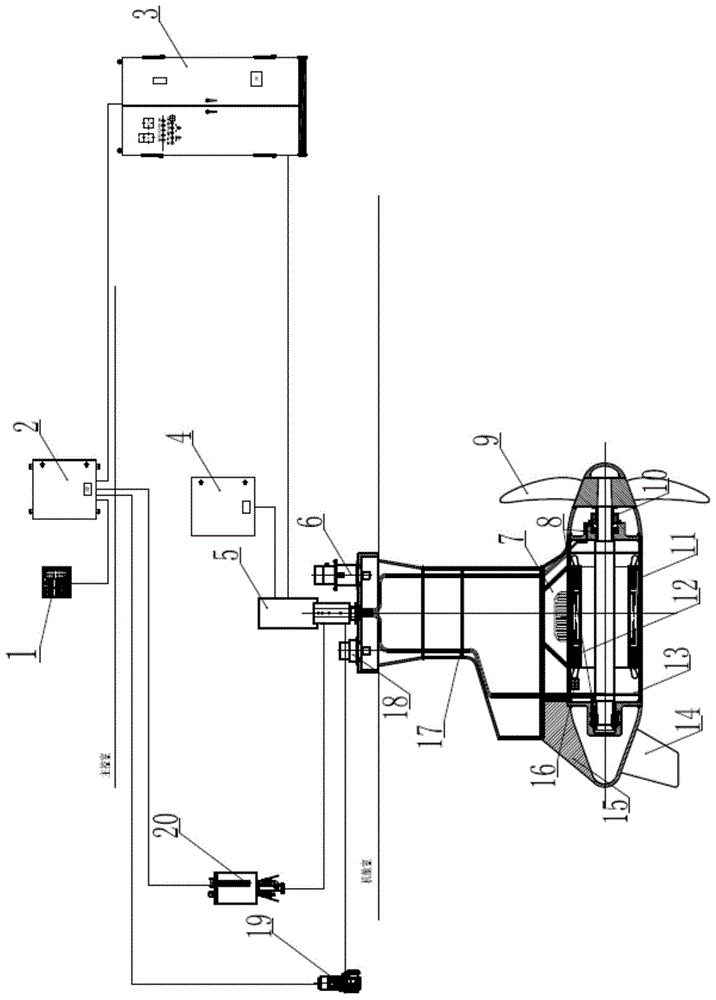

Pull type full-rotation electric power pod propelling system for ship

InactiveCN106240779AReduce vibrationSave spacePropulsion power plantsOutboard propulsion unitsControl vectorElectric machinery

The invention relates to the field of ship propelling systems and discloses a pull type full-rotation electric power pod propelling system for a ship. The pull type full-rotation electric power pod propelling system comprises a streamlined pod shell arranged outside a ship body. A fixed-pitch propeller is arranged at the front end of the outer part of the pod shell and is of a pull type structure. A main propelling motor with the speed under frequency control is arranged in the pod shell, and a shaft of the main propelling motor is directly connected with the propeller. The upper end of the pod shell is connected with a rudder shifting system. The pod shell can horizontally rotate within 360 degrees along the axis of a pod, and vector control is achieved through the rudder shifting system. The main propelling motor is installed in the streamlined pod, and the motor shaft is used for directly driving the propeller so that the integral propelling efficiency can be improved, the vibration of the ship body can be reduced, control can be flexible, and the cabin space can be saved.

Owner:CNR SHIP & MARINE ENG DEV CO LTD

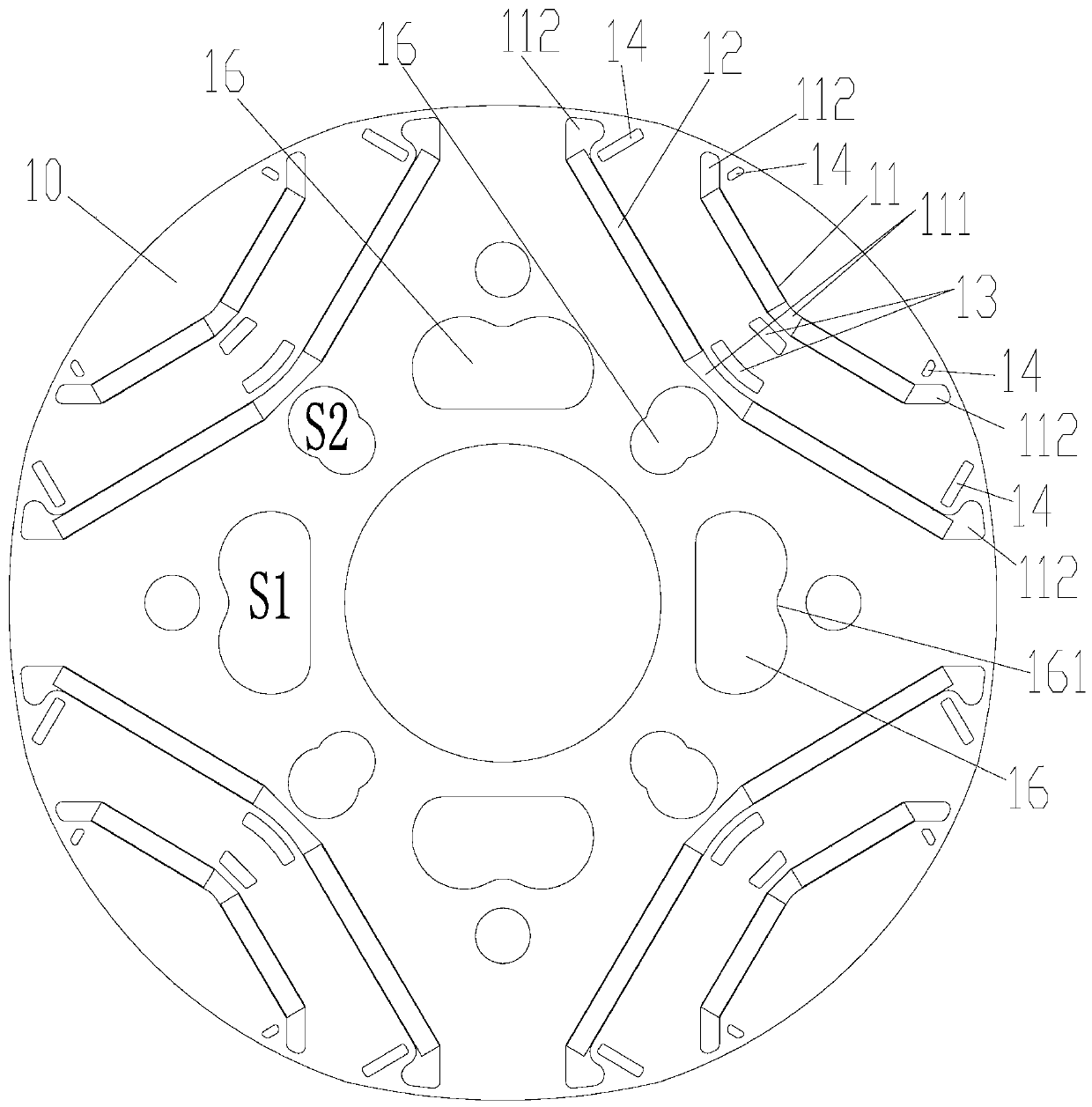

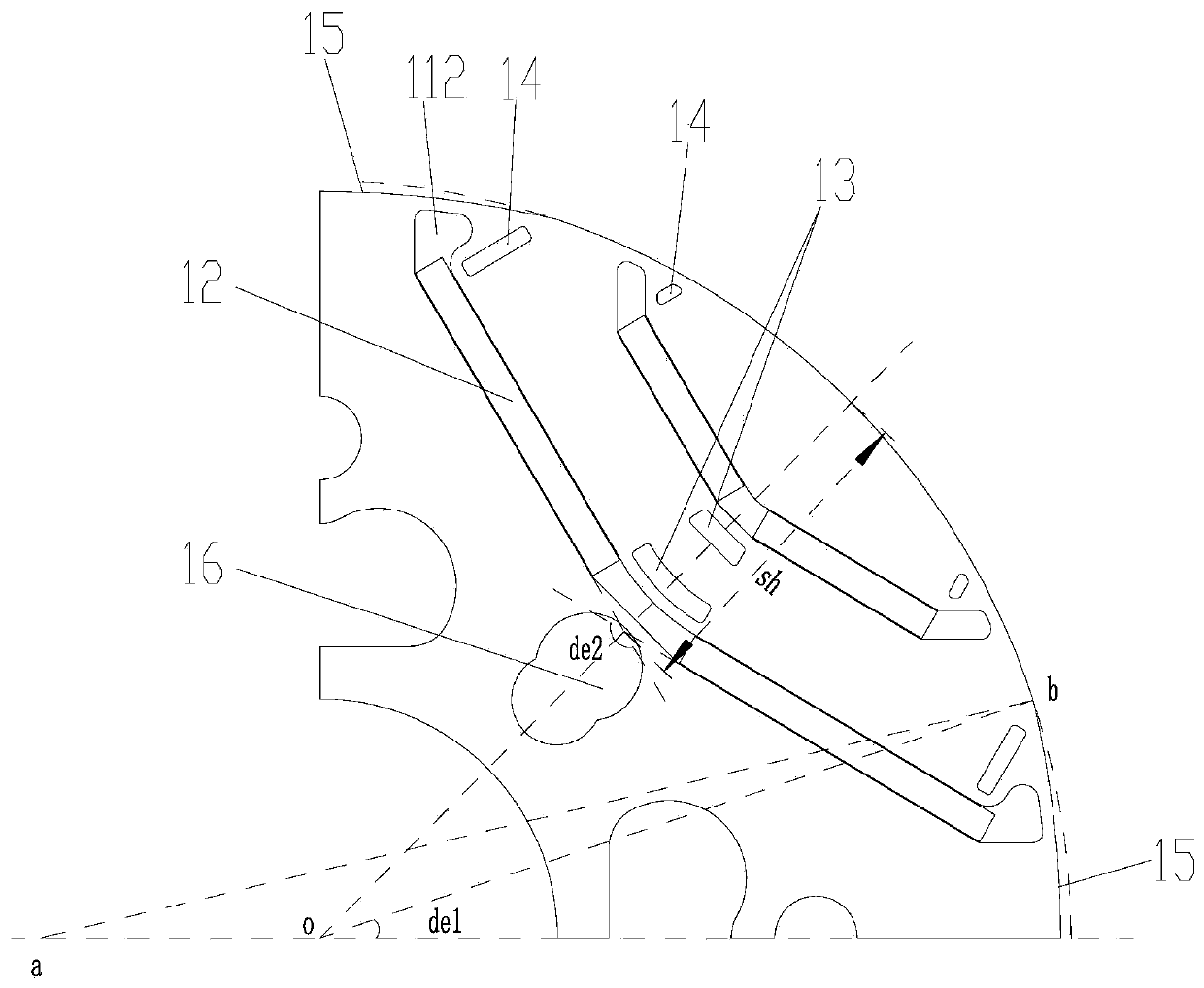

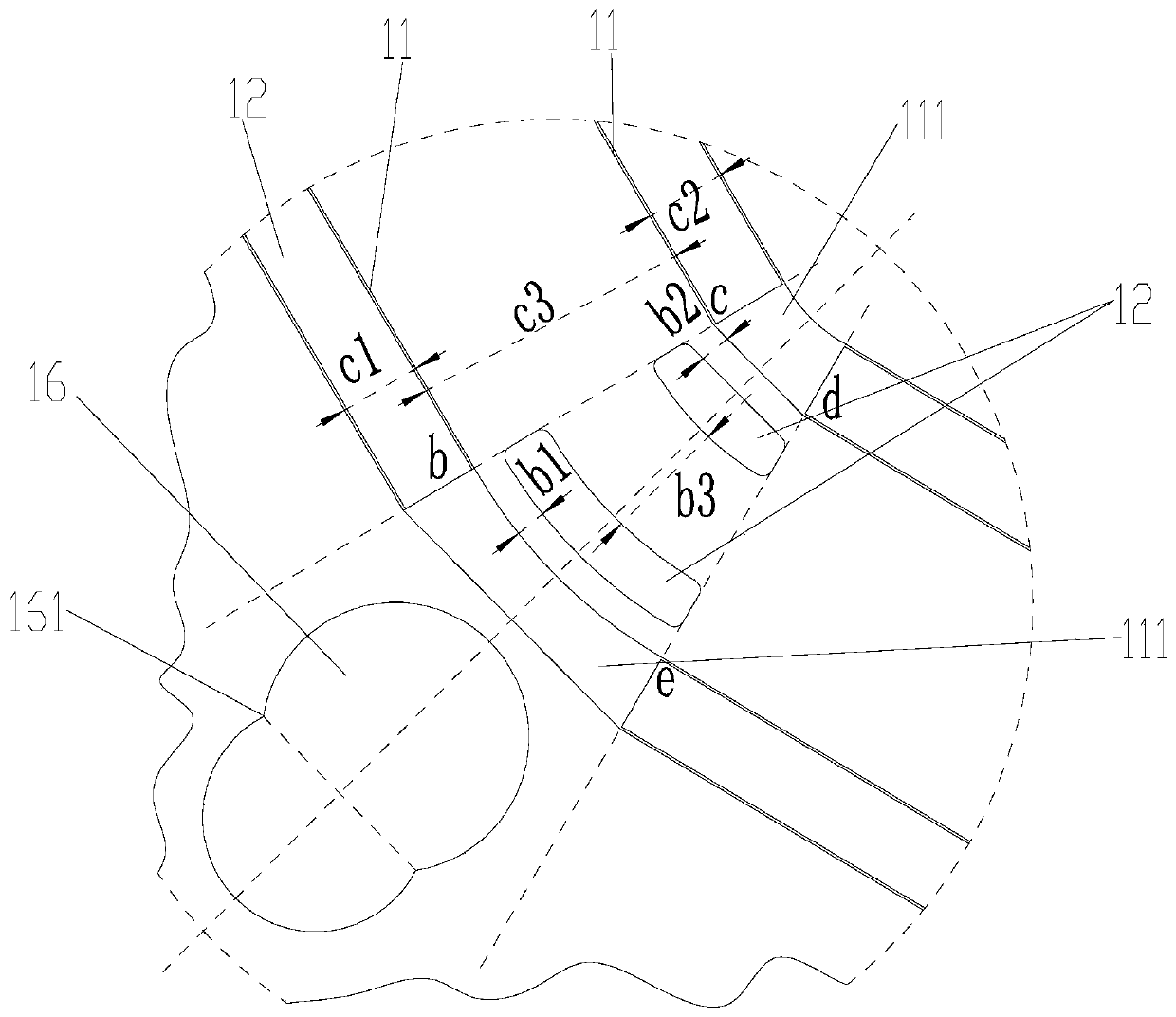

Motor rotor, motor and compressor

PendingCN110011444AAdd branchReduce short-circuit fluxAC motor controlMagnetic circuit rotating partsMagnetic barrierElectric machine

The invention provides a motor rotor, a motor and a compressor. The motor rotor includes a rotor body, wherein a plurality of poles are disposed on the rotor body in a circumferential direction; eachof the poles includes two magnetic steel slots spaced apart in the radial direction of the rotor body and permanent magnets embedded in the magnetic steel slots; and at least one magnetic barrier structure is arranged between the two magnetic steel slots of each pole. The reactance of the quadrature-axis magnetic circuit of the motor rotor can be controlled within a reasonable range so as to ensure that the motor rotor has a certain output torque, reduce the output torque ripple and the radial electromagnetic force, improve a cogging effect, and reduce the electromagnetic excitation force andelectromagnetic noise caused thereby.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

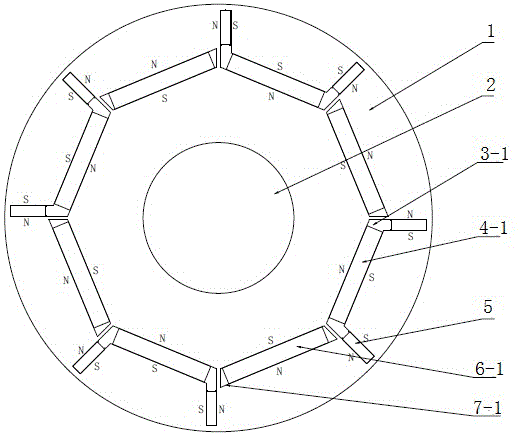

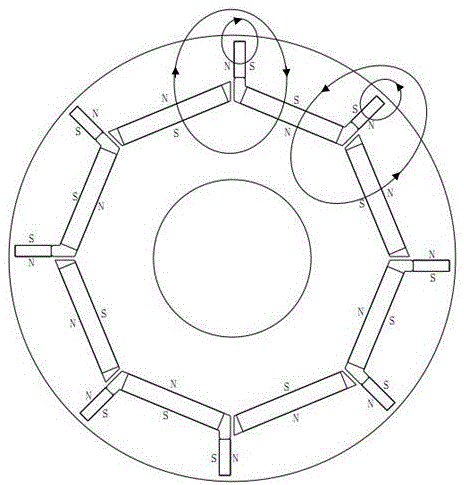

Rotor of rotating motor

InactiveCN104659940AGuaranteed output torqueReduce usageMagnetic circuit rotating partsElectric machineMagnetic reluctance

The invention discloses a rotor of a rotating motor. The rotor comprises a rotating shaft and a rotor core, wherein a plurality of pieces of neodymium iron boron magnetic steel are uniformly embedded in the rotor core in tangential directions; a piece of ferrite magnetic steel is embedded between two adjacent pieces of neodymium iron boron magnetic steel in a radial direction; two adjacent pieces of neodymium iron boron magnetic steel are arranged in an N-N opposite manner; two adjacent pieces of ferrite magnetic steel are arranged in an N-S separating manner. The rotor has the benefits that the ferrite magnetic steel and reluctance torque are sufficiently utilized, so that the consumption of the neodymium iron boron magnetic steel can be greatly reduced under the premise that motor output torque is guaranteed. Therefore, the cost of a permanent magnet motor can be reduced.

Owner:澳特卡新能源科技(上海)有限公司

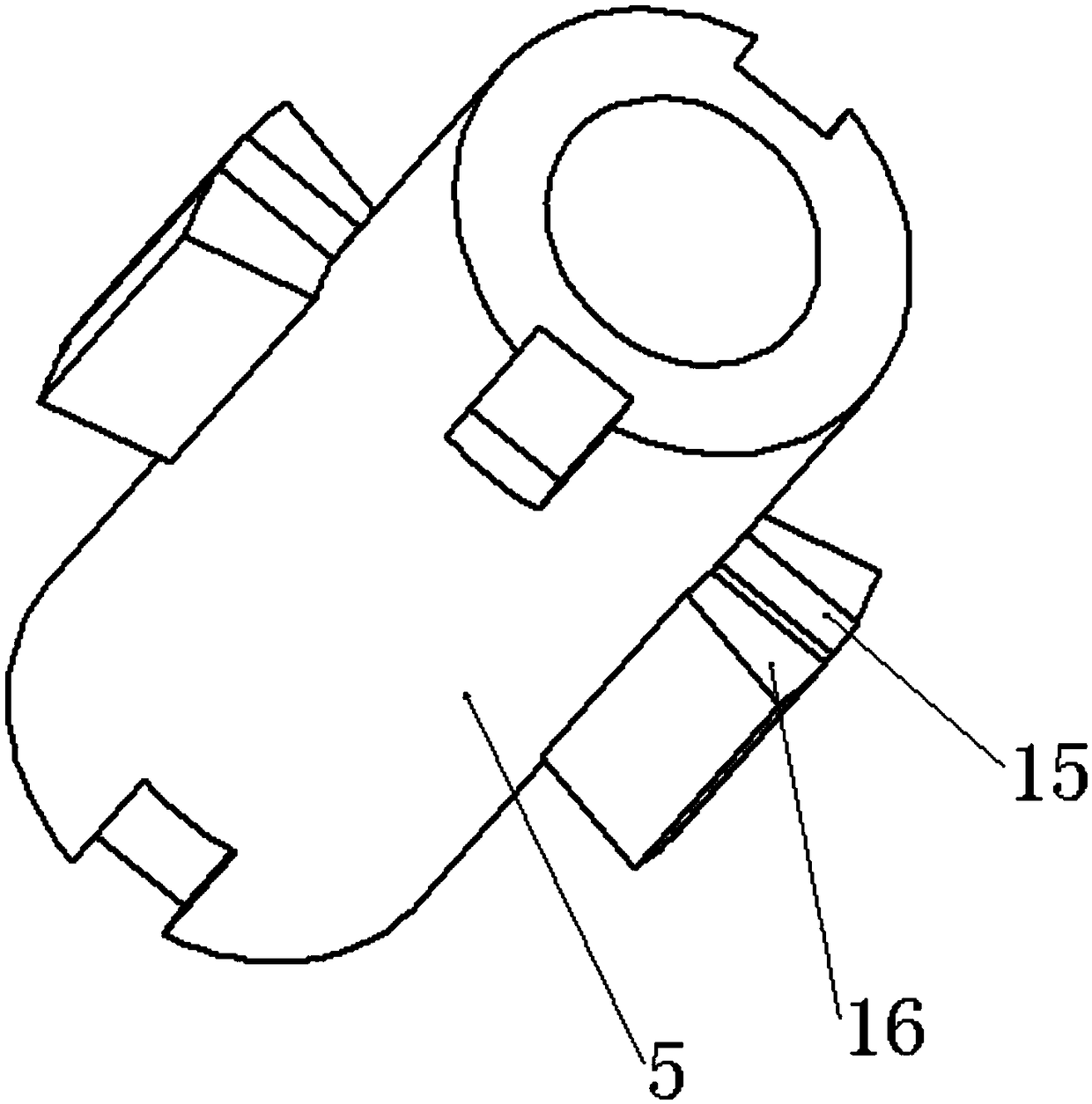

Novel mechanical arm joint

The invention discloses a novel mechanical arm joint. The novel mechanical arm joint comprises a swinging oil cylinder driving device and a servo motor driving device, wherein two cylinder body bladesupports which are symmetrically distributed are arranged on the inner wall of a cylinder body of the swing oil cylinder driving device, the cylinder body blade supports are used for installing cylinder body blades, two rotor blade supports which are symmetrically distributed are arranged on the side wall of a swing cylinder rotor, and the rotor blade supports are used for installing the swing cylinder rotor blades, the swing cylinder rotor is installed in the cylinder body, and the two cover plates which are packaged on the two sides of the cylinder body are fixedly supported, the cover plates on the two sides of the cylinder body are installed on a cover plate connecting plate; a servo motor driving device is provided with two motor end covers which are fixedly installed on the two sidesof a servo motor body correspondingly, the servo motor body is connected with a motor output shaft, and an output shaft end flange plate is installed at one end, far away from the servo motor body, of the motor output shaft; and one end, far away from the motor output shaft, of the servo motor driving device is installed at the two ends of the swing cylinder rotor through two force arm rods. According to the arm joint, large torque and large output torque can be borne, and meanwhile, a relatively good swinging angle can be achieved.

Owner:WUHAN UNIV OF SCI & TECH

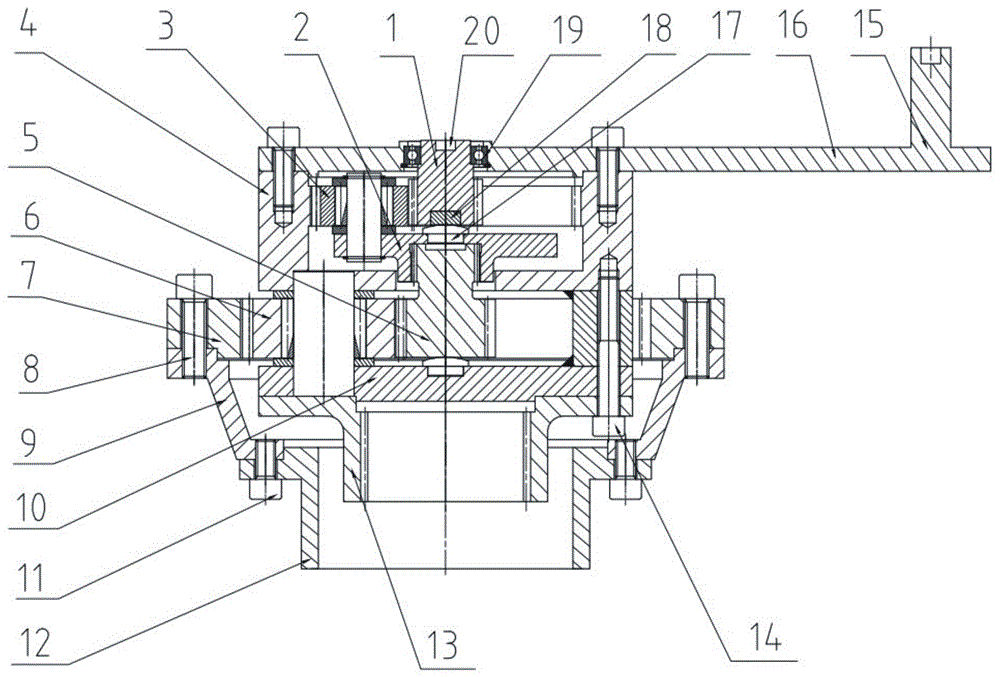

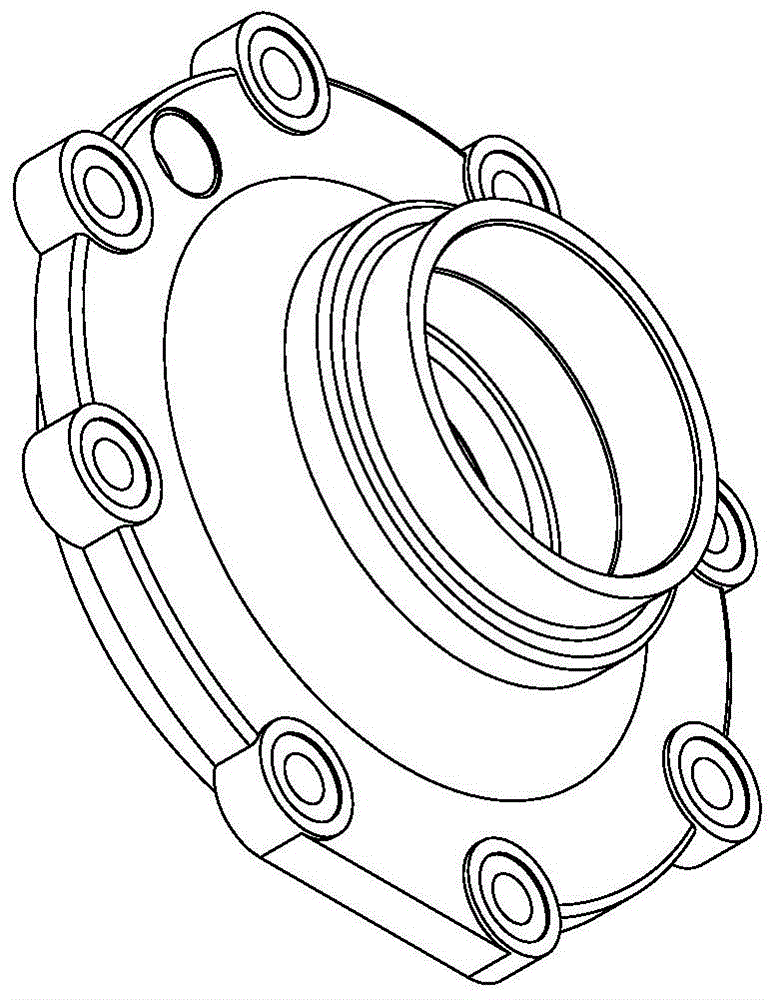

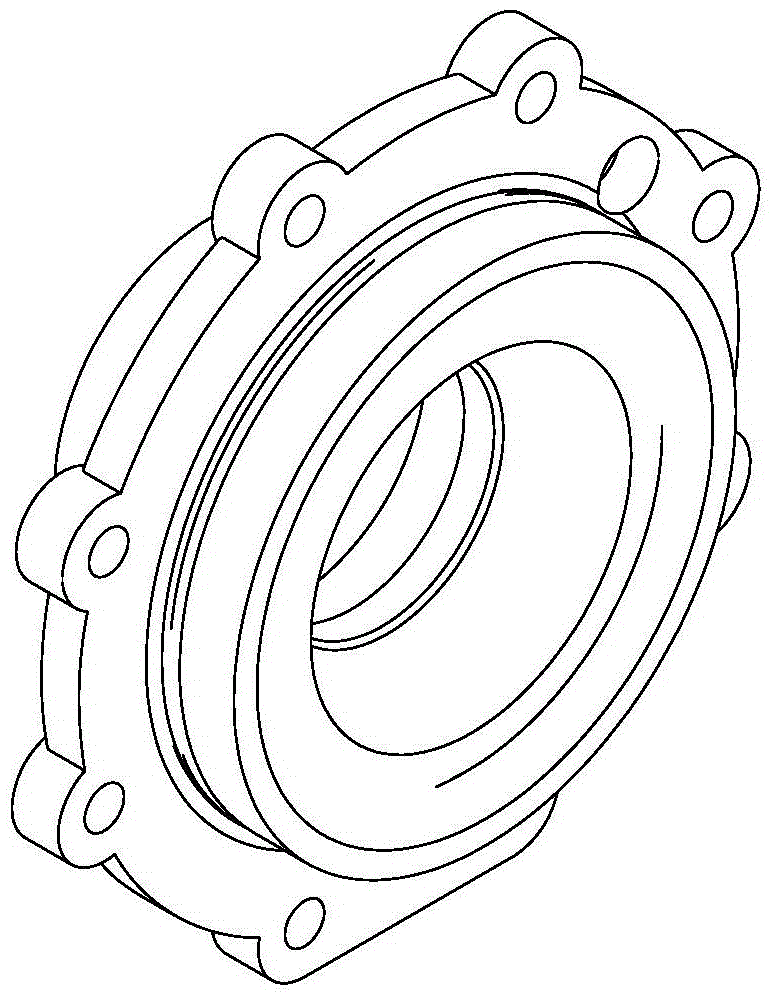

Round nut tightening device

ActiveCN105922181AEffective fasteningLarge output torqueWrenchesScrewdriversEngineeringControl theory

Owner:YINCHUAN WEILI REDUCER MACHINERY

Electric wheel assembly adopting drum brake

PendingCN109823163AReasonable locationEasy to carryBraking element arrangementsMotor depositionTowerMechanical engineering

The invention discloses an electric wheel assembly adopting a drum brake, which comprises a tire, a wheel rim, a wheel hub, a steering knuckle assembly, a drum brake, an inner rotor hub motor and a planetary gear reducer. The input of the planetary gear speed reducer is a sun gear, and the output of the planetary gear speed reducer is a planetary carrier; the planetary carrier is integrally integrated on the wheel hub and is connected with the wheel rim, and the tower gear adopted by the planetary gear of the planetary gear speed reducer achieves larger transmission ratio under the condition of smaller axial length. The inner rotor hub motor is arranged between the planetary gear reducer and the drum brake, power is transmitted to the sun gear through a hollow rotor sleeve, the other end of the rotor sleeve is connected with a brake drum of the drum brake, braking force of the brake is amplified through the planetary gear reducer, braking force required to be provided by a braking system can be reduced, and the motor can provide electric braking force during braking. The steering knuckle assembly and the wheel hub penetrate through the centers of the inner rotor hub motor and the drum brake, and a wheel hub bearing is arranged between the steering knuckle sleeve and the wheel hub.

Owner:南京清研易为新能源动力有限责任公司

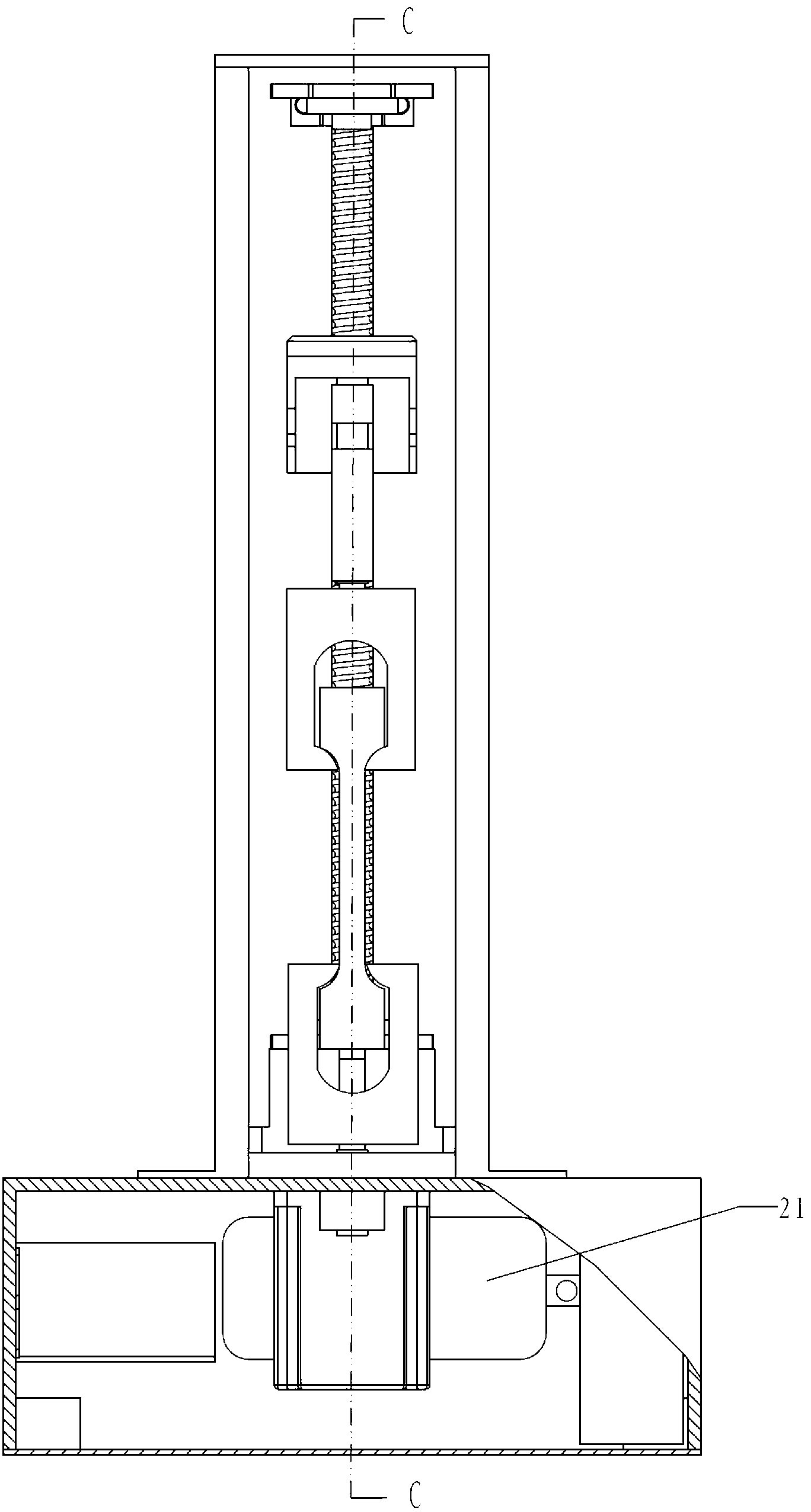

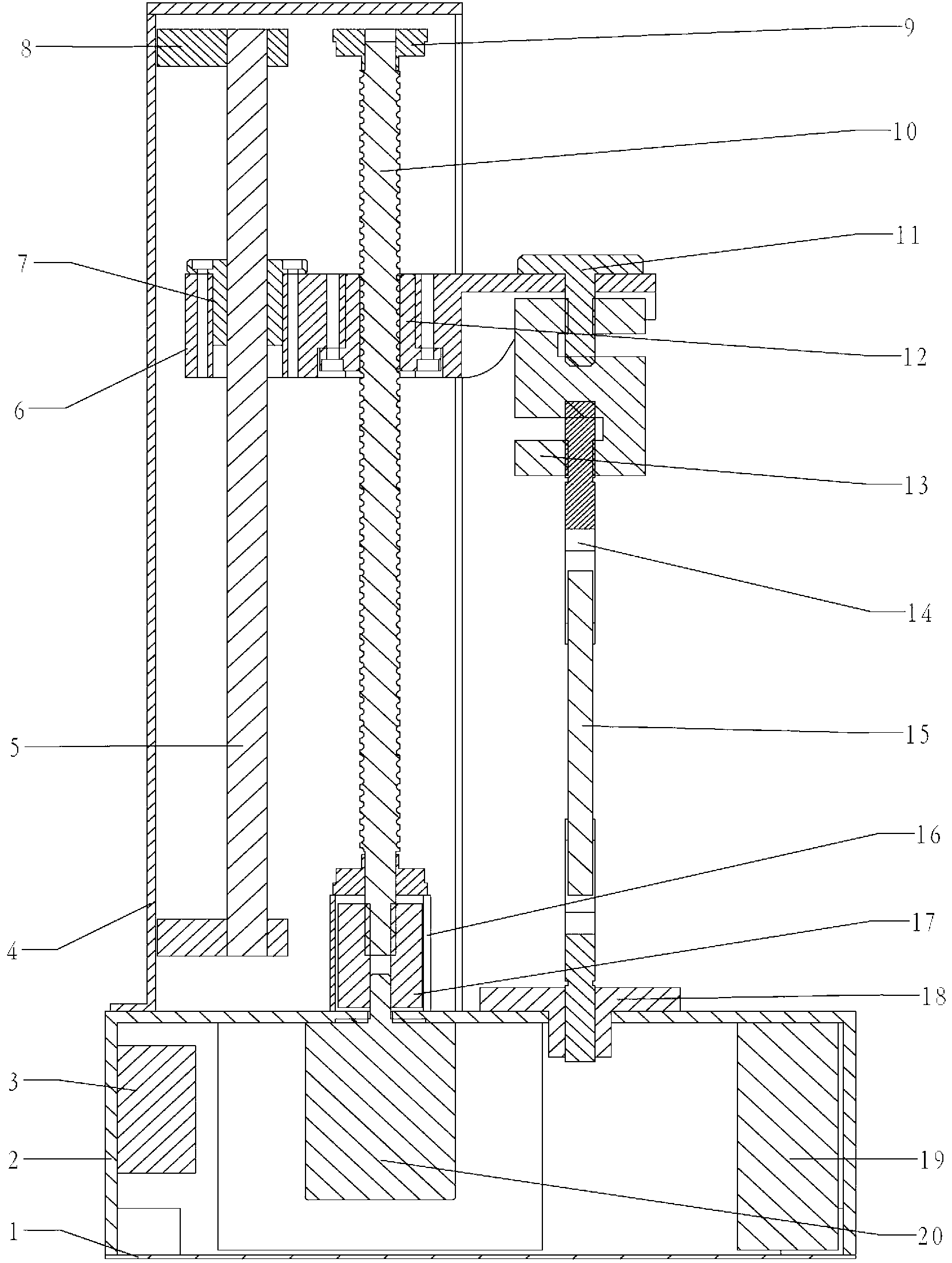

Macromolecular material tensile testing device

InactiveCN103245568AReduce mistakesGuaranteed output torqueMaterial strength using tensile/compressive forcesOptical axisBall screw

The invention relates to a macromolecular material tensile testing device. The macromolecular material tensile testing device comprises a bottom plate, a base, a driver, an upright post, a cross beam, a bearing seat, a ball screw, a force transmission fixed part, a pressure sensor, a clamping apparatus, a testing piece, a clamp sleeve and a patch board, and is characterized by further comprising an optical axis rod, a smooth flange plate, an optical axis bracket, a screw flange plate, a tension groove boss, a coupler, a voltage stabilizer and a stepper motor with an encoder, wherein the upright post is of a one-piece box type and is vertically arranged on the base; the driver is a subdividing driver; the stepper motor with the encoder is connected with the bottom end of the ball screw through the coupler; the tail end of the cross beam is connected with the optical axis rod through the mode that the smooth flange plate is sleeved in a hole, the optical axis rod is connected with the optical axis bracket in a sleeve manner, and the optical axis bracket is fixed on the side surface of the upright post. The macromolecular material tensile testing device has obvious advantages of high precision and high reliability, and great reduction of the volume and manufacturing cost of the equipment.

Owner:NANJING UNIV OF SCI & TECH

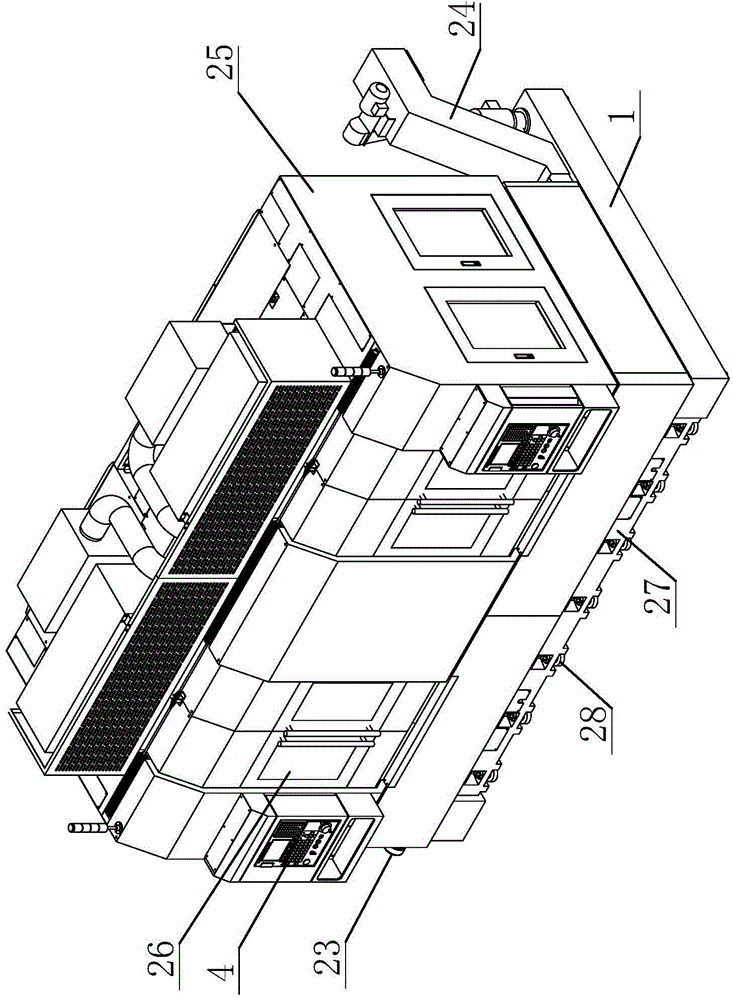

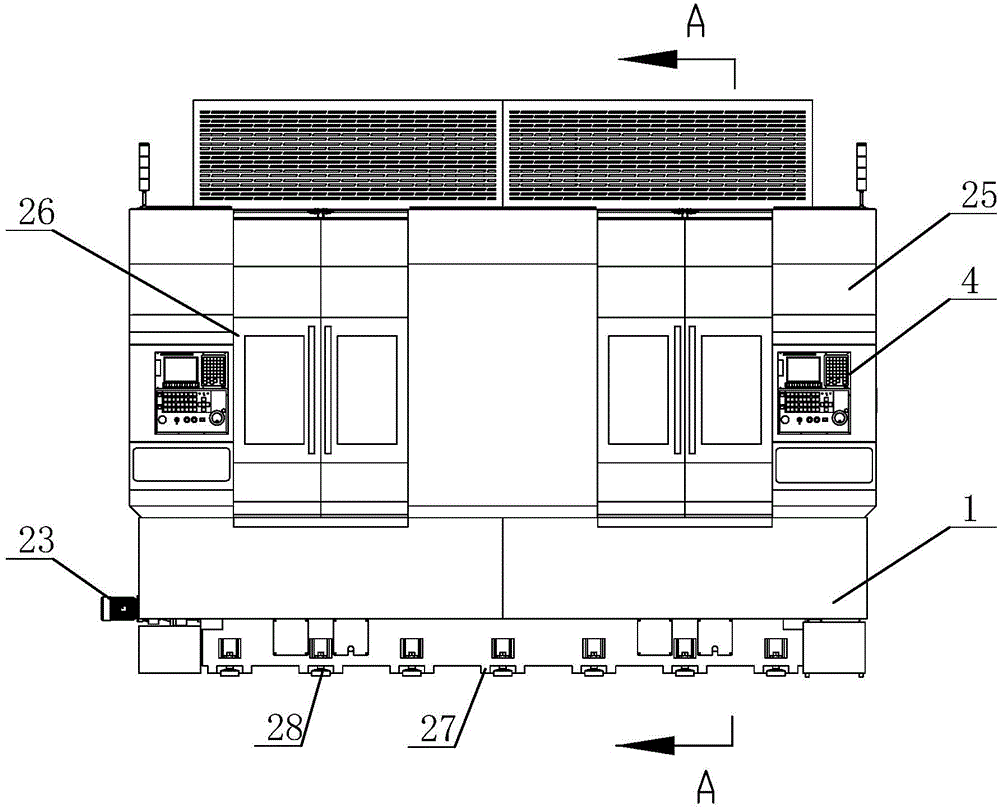

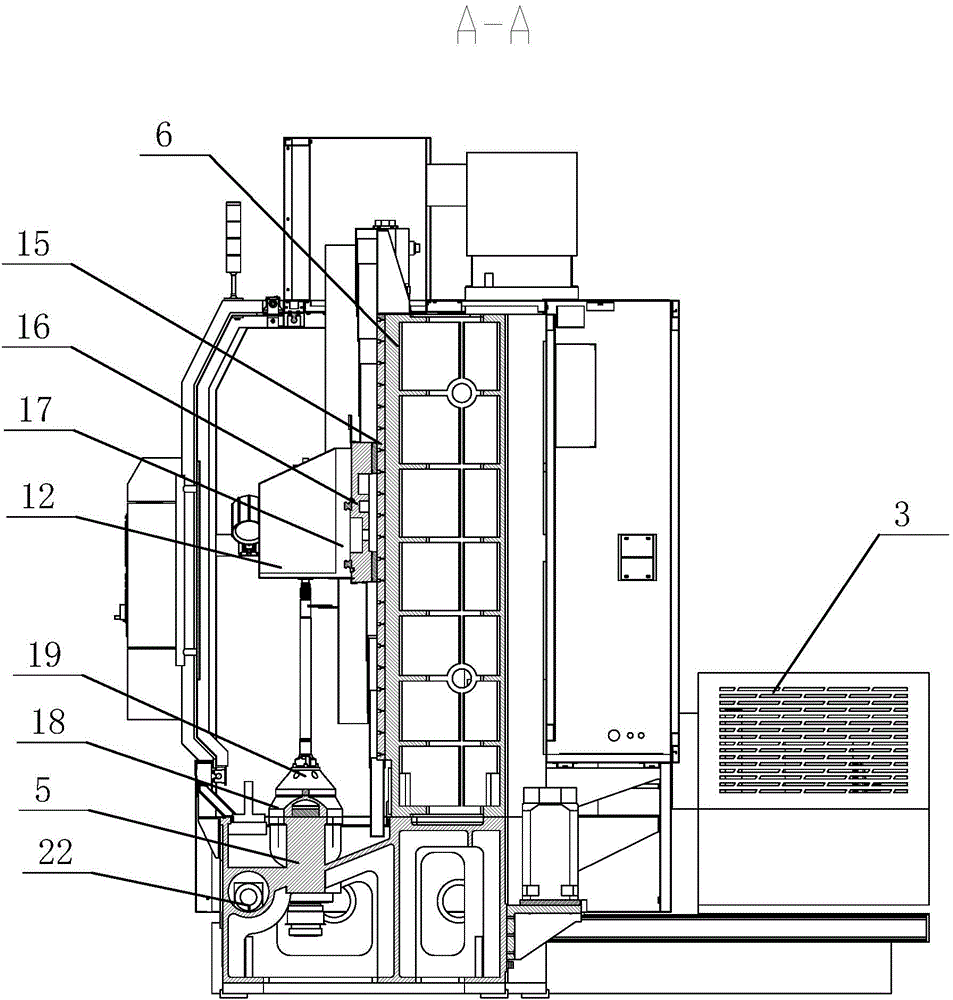

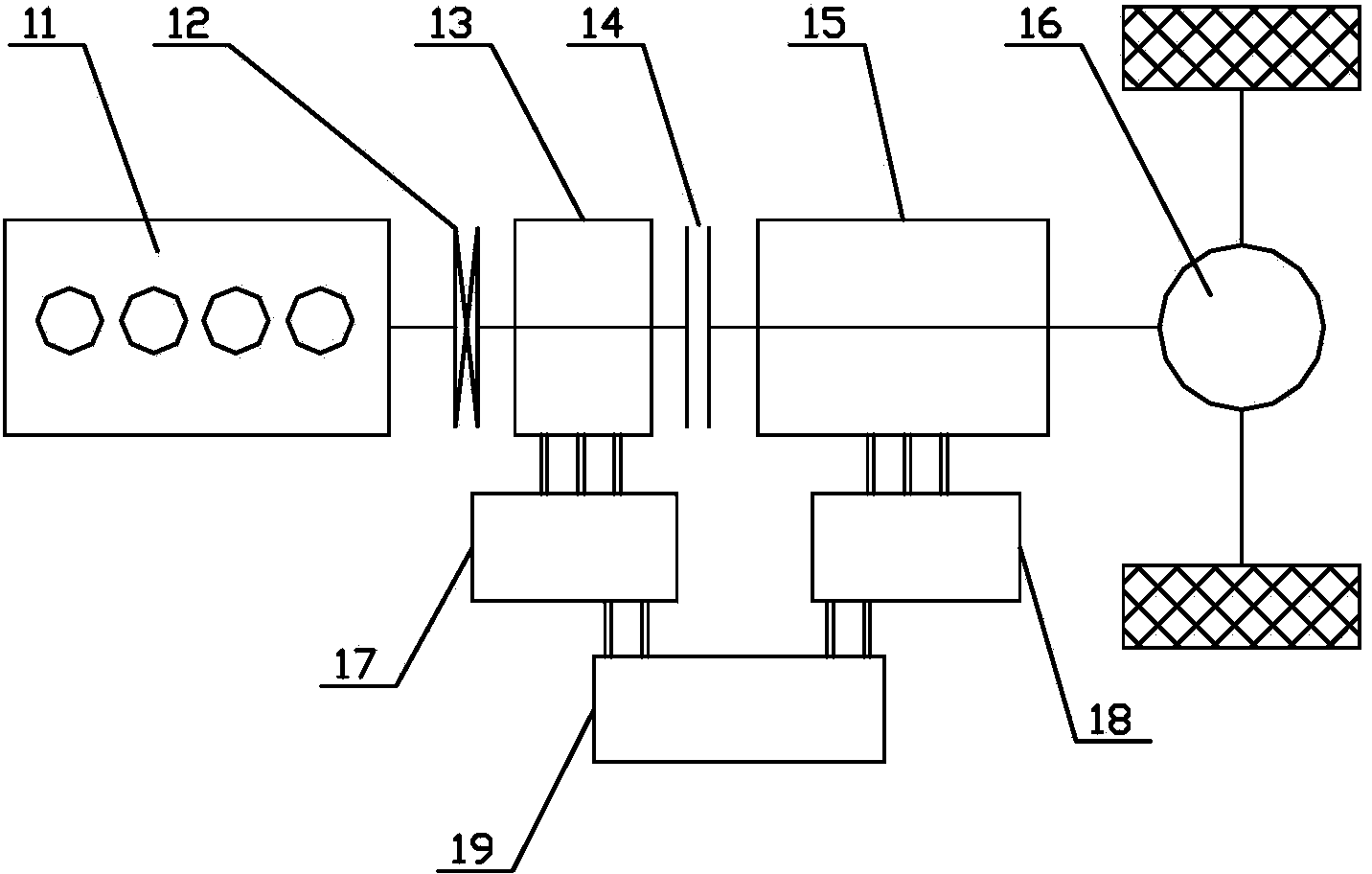

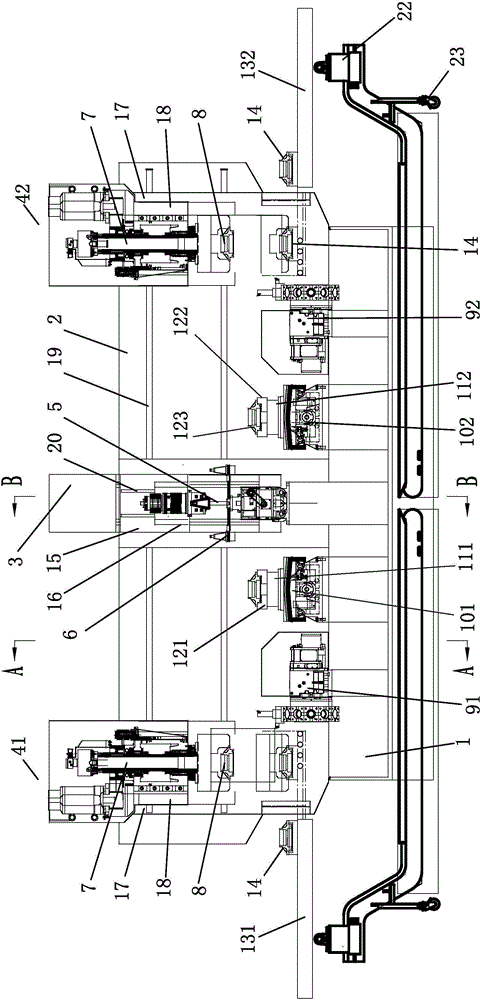

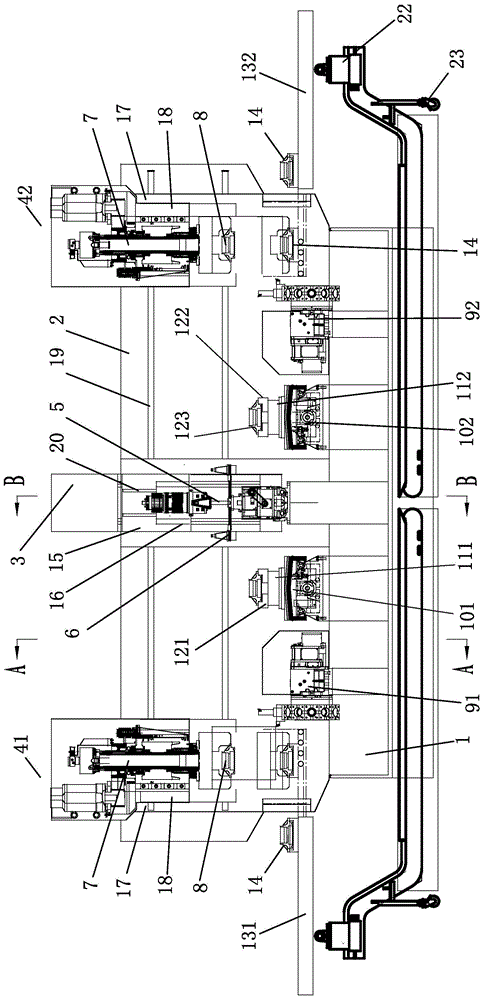

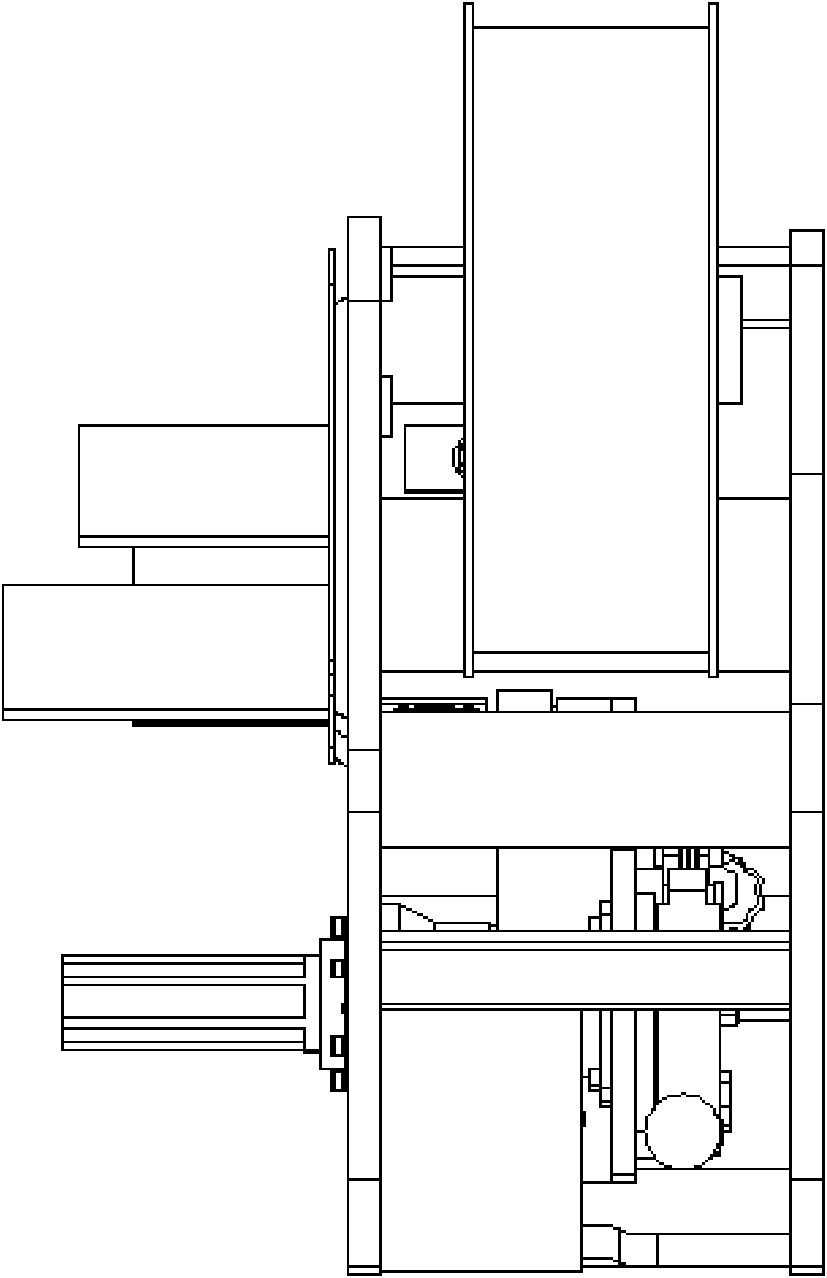

Multi-spindle numerical control vertical type special lathe

ActiveCN104801727AReduce manufacturing costLabor savingCamsAutomatic/semiautomatic turning machinesNumerical controlEngineering

The invention relates to a multi-spindle numerical control vertical type special lathe, which comprises a base, wherein a processing mechanism is arranged on the base and comprises two vertical spindle units, the two spindle units are closely arranged along the transverse direction, a vertical column is arranged at the back side of each spindle unit, a vertical tail seat unit and two feeding units are arranged on each vertical column, and the two feeding units are respectively arranged at the two transverse sides of the corresponding tail seat unit; each tail seat unit comprises a first slide device, a tail seat is arranged on each first slide device, and two vertical tail seat sleeve cylinders are arranged at the lower part of each tail seat, are positioned above spindles, and are correspondingly arranged; each feeding unit comprises a second slide device and a transverse movement device, each transverse movement device is arranged on the corresponding second slide device, a knife holder is arranged on each transverse movement device, each first slide device and each second slide device can be moved on the corresponding vertical column along the vertical direction, and each transverse movement device is moved on the corresponding second slide device along the transverse direction. The multi-spindle numerical control vertical type special lathe has the advantages that multiple different types of camshaft parts can be simultaneously processed, and the production efficiency is high; the whole land occupation area of the equipment is small.

Owner:JINAN FIRST MACHINE TOOL GROUP

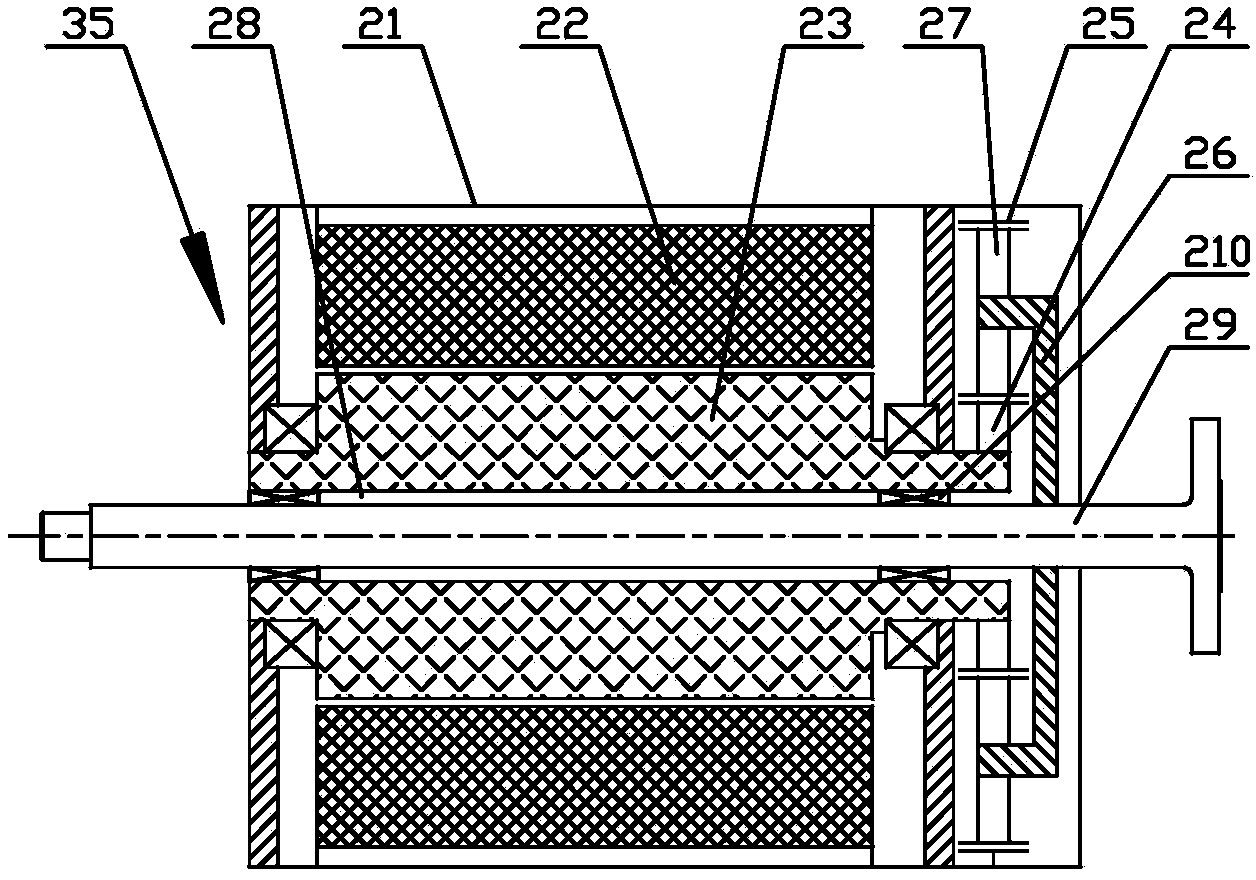

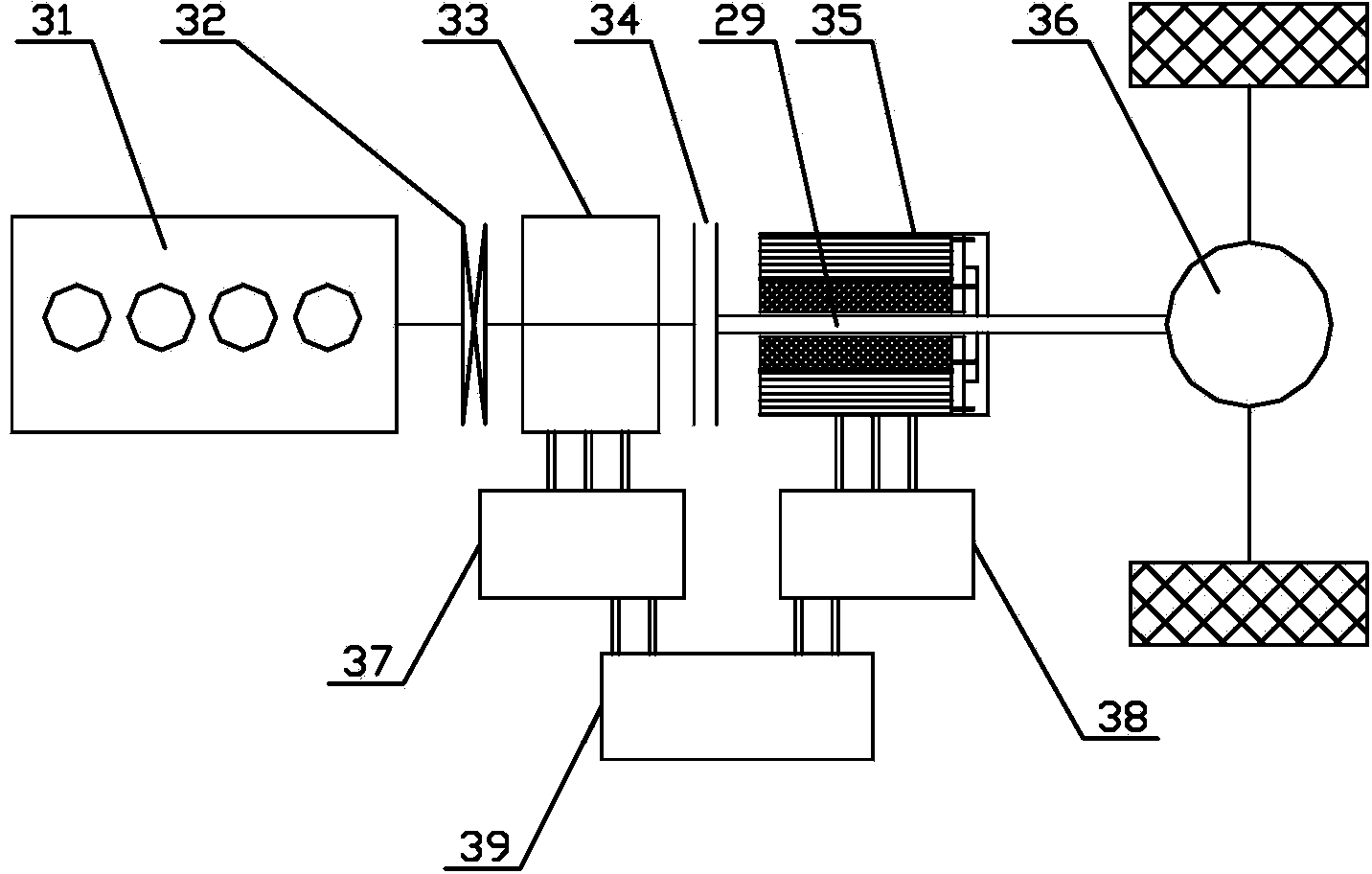

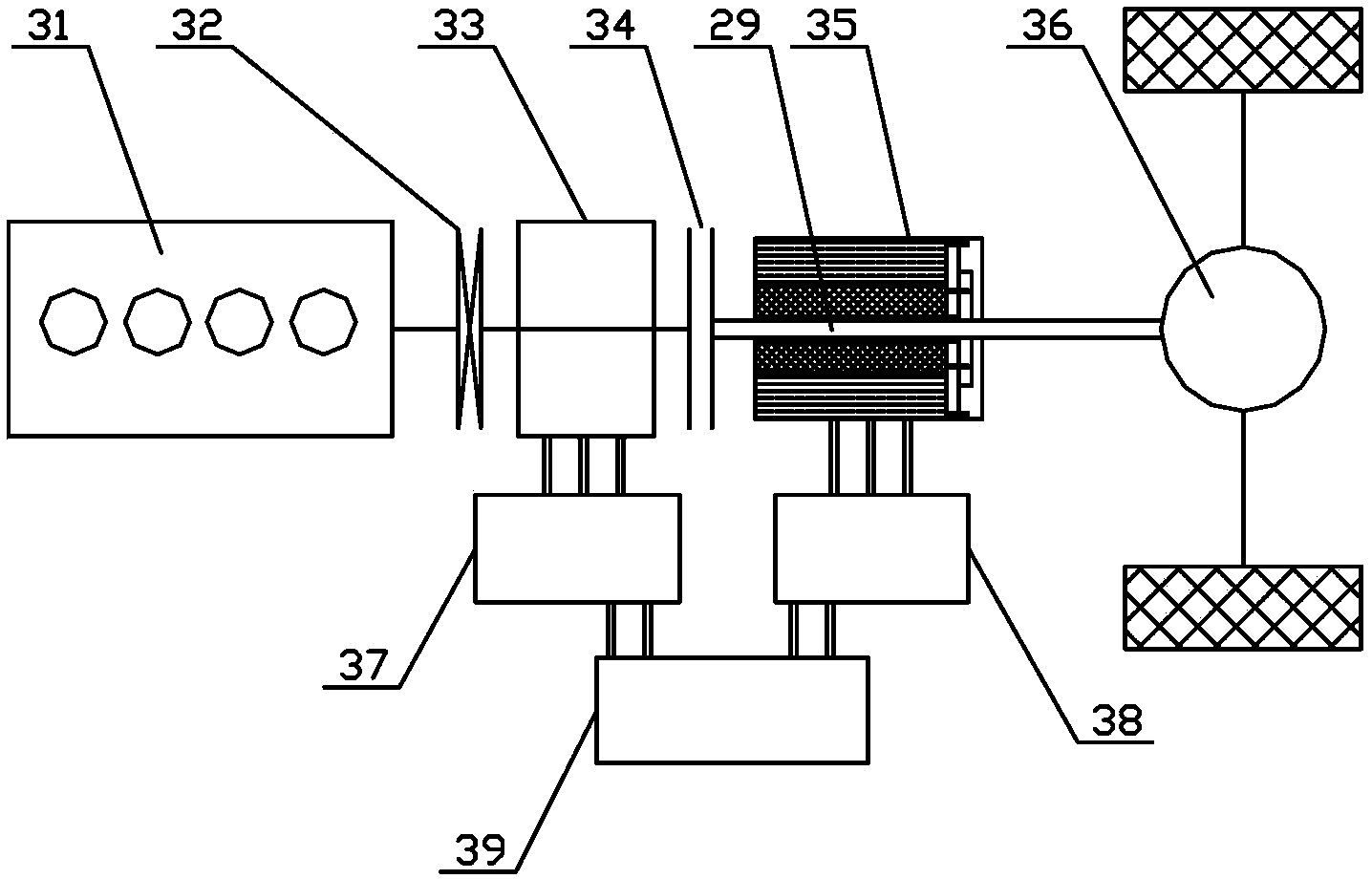

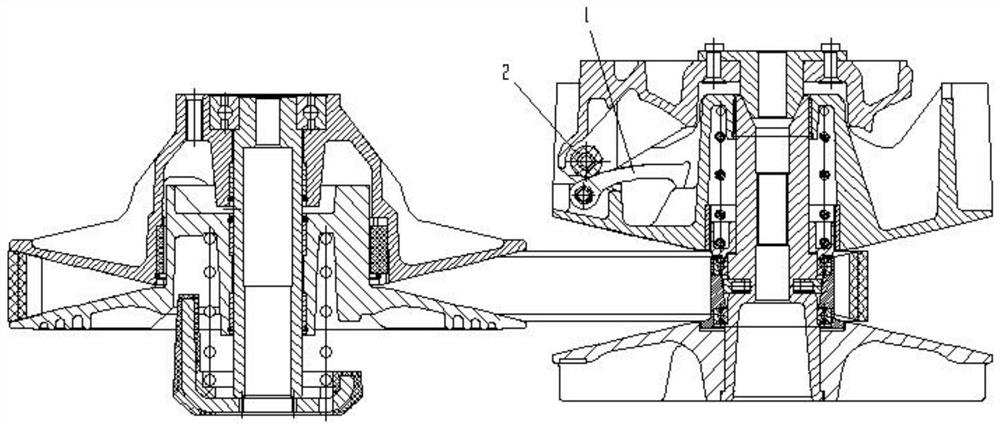

Driving motor and series-parallel hybrid power systems

InactiveCN103481764ASmall sizeReduce weightGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingElectric machineGear wheel

The invention provides a driving motor which comprises a shell, a stator and a rotor. The stator and the rotor are arranged in the shell; a sun gear is fixedly sleeved on an output shaft of the rotor, an inner gear ring is fixedly connected into the shell, and both the sun gear and the inner gear ring are meshed with a planet gear mounted on a planet carrier; a through hole is axially formed in the middle of the rotor, and a rotatable output connecting shaft is arranged in the through hole; the planet carrier is fixedly mounted at an output end of the output connecting shaft. Output torque of the output shaft of the rotor can be reduced to the greatest extent while the requirement on high output torque can be met by the output connecting shaft of the driving motor, so that the size of the stator and the size of the rotor of the driving motor can be greatly reduced, the size and the weight of the driving motor can be greatly decreased, the driving motor is convenient to mount and use, and the service range of the driving motor is greatly increased. The invention further provides two series-parallel hybrid power systems. The driving motor and the series-parallel hybrid power systems have advantages that the integral sizes and the integral weights of the series-parallel hybrid power systems are greatly reduced, and the universality of the series-parallel hybrid power systems is improved.

Owner:HUNAN CSR TIMES ELECTRIC VEHICLE

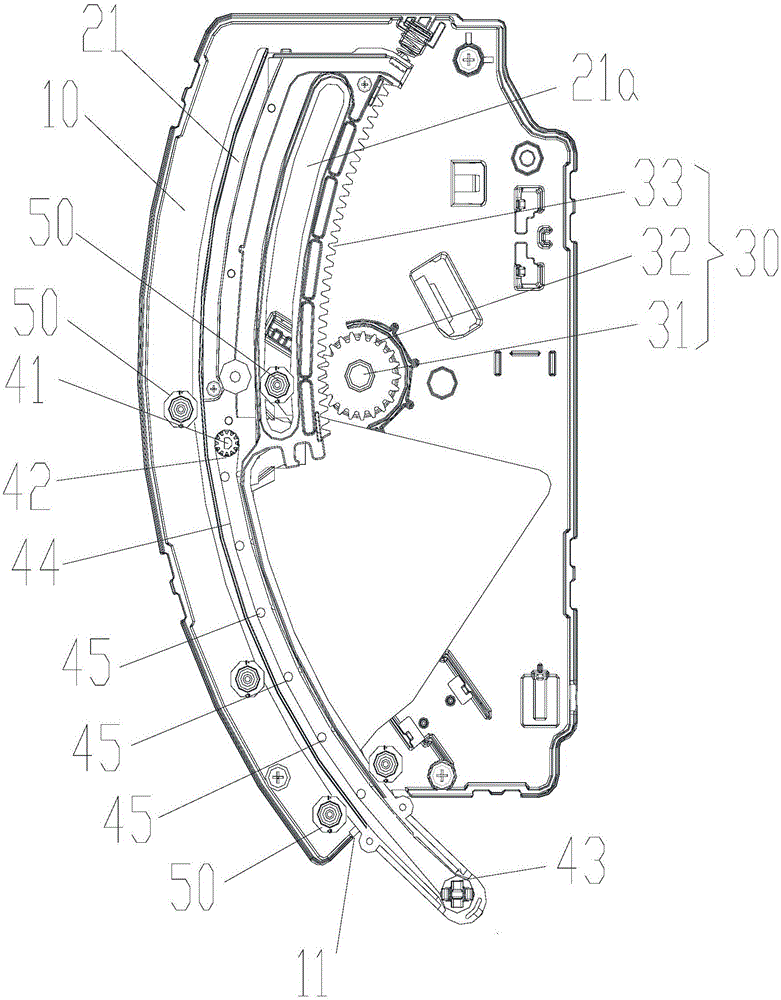

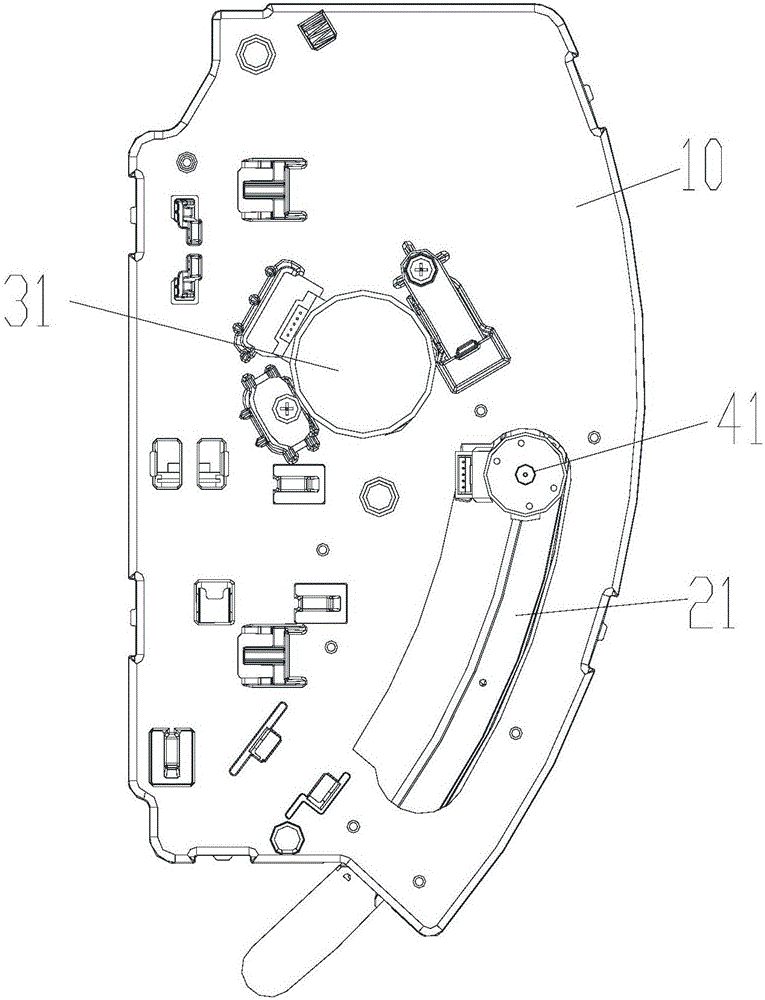

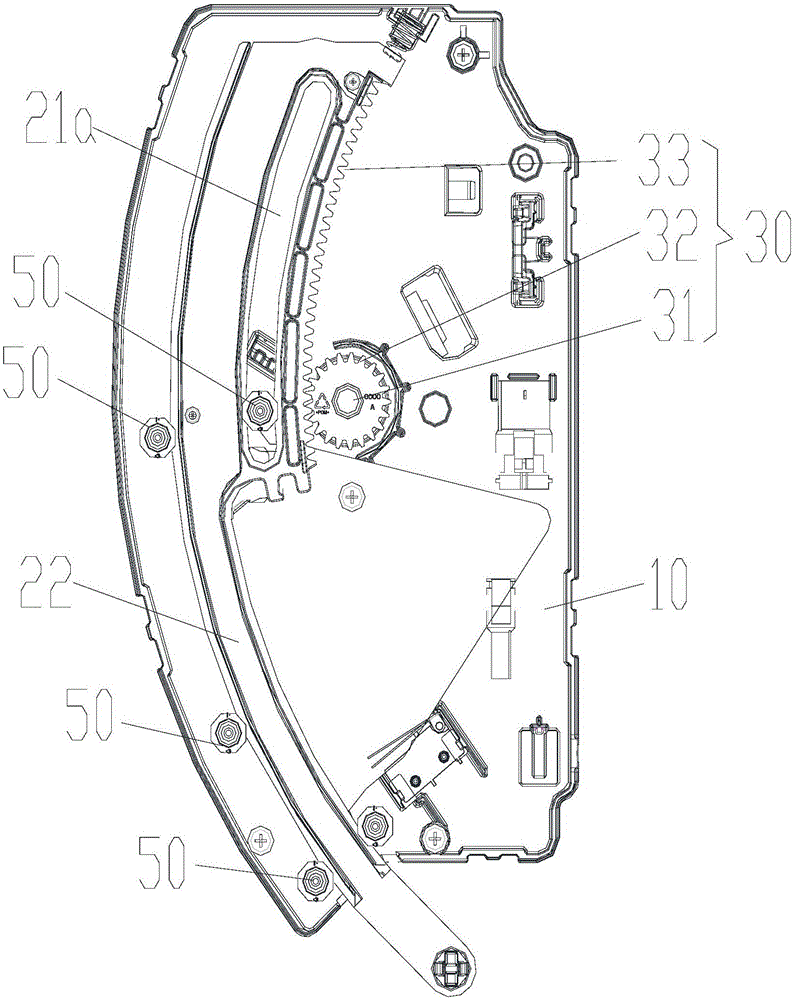

Air deflector driving device, indoor air conditioner and air conditioner

InactiveCN106642621AFix oversizeNo need to reduce sizeLighting and heating apparatusAir conditioning systemsEngineeringConveyor belt

The invention provides an air deflector driving device, an indoor air conditioner and an air conditioner. The air deflector driving device comprises a box, a connecting rod component, a first driving mechanism, and a swing flap component; an outlet is formed in one side of the box; the connecting rod component is movably arranged in the box, the connecting rod component comprises a first end and a second end which are oppositely arranged, the first end of the connecting rod component stretches out or draws back from the outlet, and the first end of the connecting rod component is connected with an air deflector; the first driving mechanism is in driving connection with the second end of the connecting rod component, and the first driving mechanism drives the air deflector to move through the connecting rod component; the swing flap component is arranged on the connecting rod component and comprises a second driving mechanism and a conveyor belt component, one end of the conveyor belt component is in driving connection with the second driving mechanism, the other end of the conveyor belt component is connected with the air deflector, and the second driving mechanism drives the air deflector to rotate through the conveyor belt component. According to the technical scheme, the problem that in the prior art, the size of the joint of a push-out movement mechanism and the air deflector is too large can be solved.

Owner:GREE ELECTRIC APPLIANCES INC

Double-handstand turning center lathe

ActiveCN104815993AShort processing timeIncrease productivityAutomatic/semiautomatic turning machinesSlide plateOptimal matching

The invention discloses a double-handstand turning center lathe. The double-handstand turning center lathe comprises a bed base; the bed base is provided with a standing column; the standing column is provided with a standing column guide rail; the standing column guide rail is connected with the lathe and a left-right handstand turning center; the lathe comprises a lathe carriage, a lathe sliding plate, a left work bench, and a right work bench; the lathe carriage is matched with the lathe sliding plate; the lathe sliding plate is provided with a lathe main shaft; a lathe tool changer at the front side of the lower part of the lathe main shaft is connected with the base; the left-right handstand turning center comprises a handstand turning center carriage, a handstand turning center sliding plate, and a handstand turning center main shaft; the lower part of the handstand turning center main shaft is connected with a handstand chuck; the base between the lathe main shaft and the handstand turning center main shaft is provided with a work bench base; the work bench is provided with a left clamping fixture; and the bed base is provided with a turning head. The double-handstand turning center lathe is capable of achieving the optimal matching of the turning and lathe time during the processing of the disc parts, saving the labor, reducing the manufacturing cost, and ensuring the precision and quality of the part production, the whole processing time is the shortest, and the production efficiency is high.

Owner:JINAN FIRST MACHINE TOOL GROUP

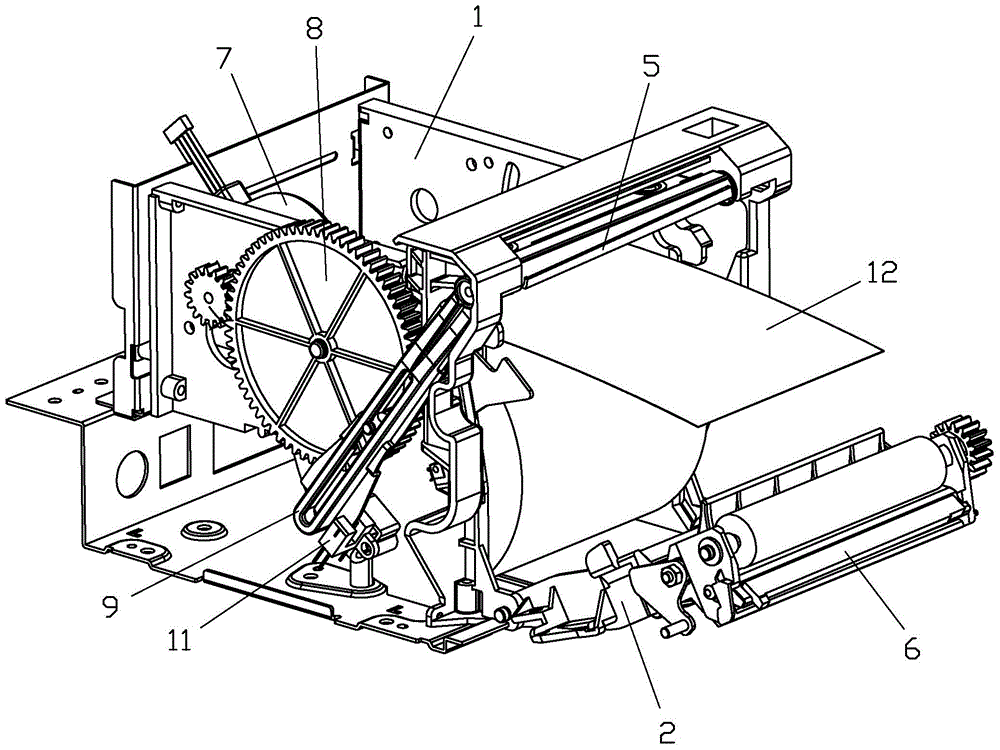

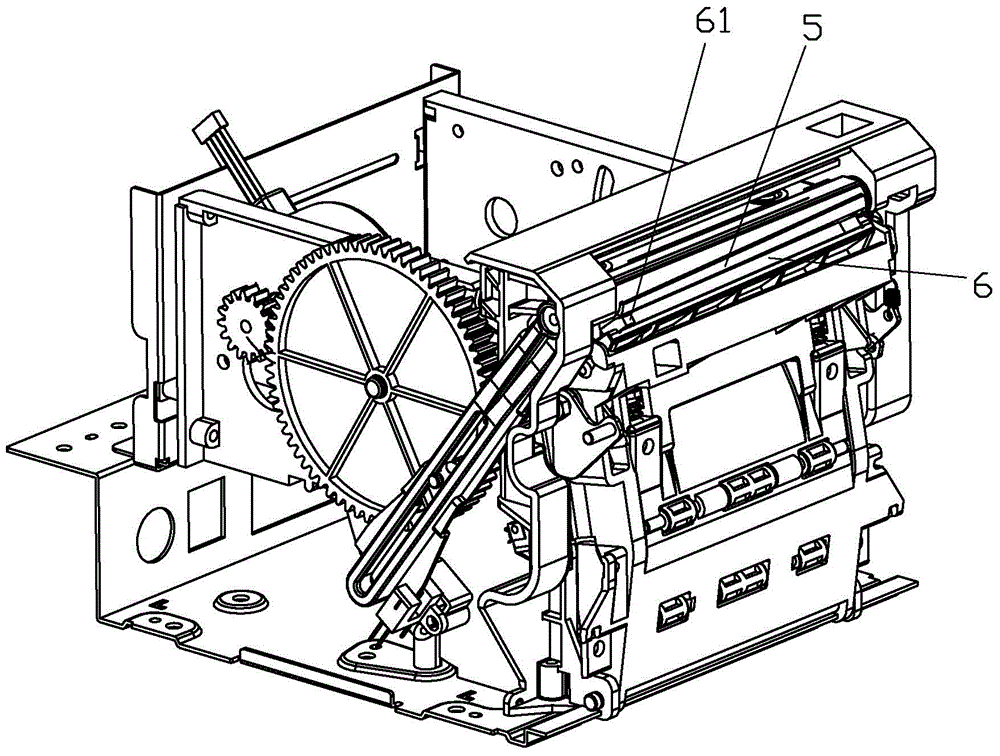

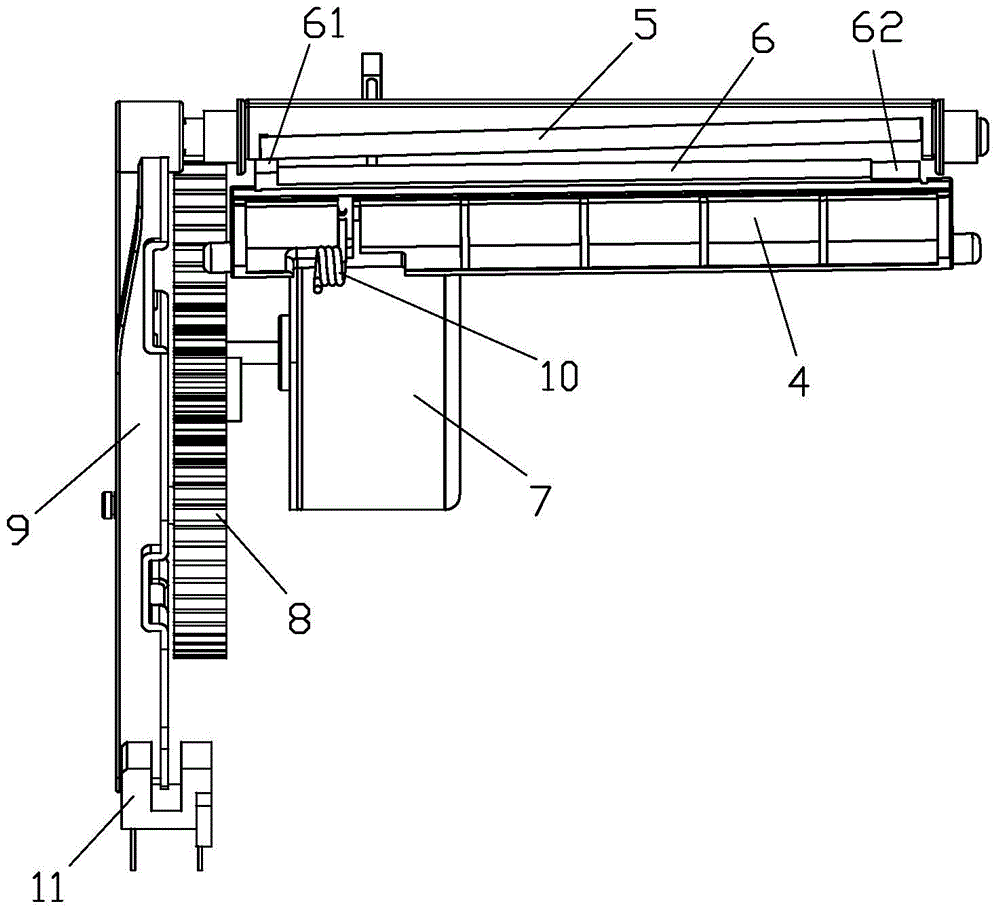

Printer with built-in hob paper cutting device

InactiveCN104859317AExtended service lifeReduce frictionOther printing apparatusGear driveGear wheel

The invention discloses a printer with a built-in hob paper cutting device. The printer includes a machine core assembly and a paper feeding roller fixing frame assembly which are pivoted with a moving blade fixing frame and a fixed blade fixing frame respectively; the moving blade fixing frame and the fixed blade fixing frame are provided with a moving blade and a fixed blade respectively; the machine core assembly is provided with a stepping motor and a cutter gear driven by the stepping motor; the cutter gear is connected with a cutter driving arm which is driven by the cutter gear so as to swing in a reciprocating manner; one end of the cutter driving arm is fixedly connected with the moving blade fixing frame so as to drive the moving blade to move in a reciprocating manner; the fixed blade is provided with a guide arm used for guiding the moving blade; the paper feeding roller fixing frame assembly is provided with a torsional spring used for driving the fixed blade to rotate towards the moving blade; the two cutting edges of the moving blade and the fixed blade are arranged obliquely in a manner that the closer the two cutting edges are to the guide arm, the smaller the interval between the cutting edges is; and the cutting edge of the moving blade is a plane curve. The printer of the invention is simple and compact in structure. The appearance design and miniaturization design of the printer can be benefitted, and the service life of the paper cutting device is long.

Owner:KONG YUE ELECTRONICS & INFORMATION IND XIN HUI

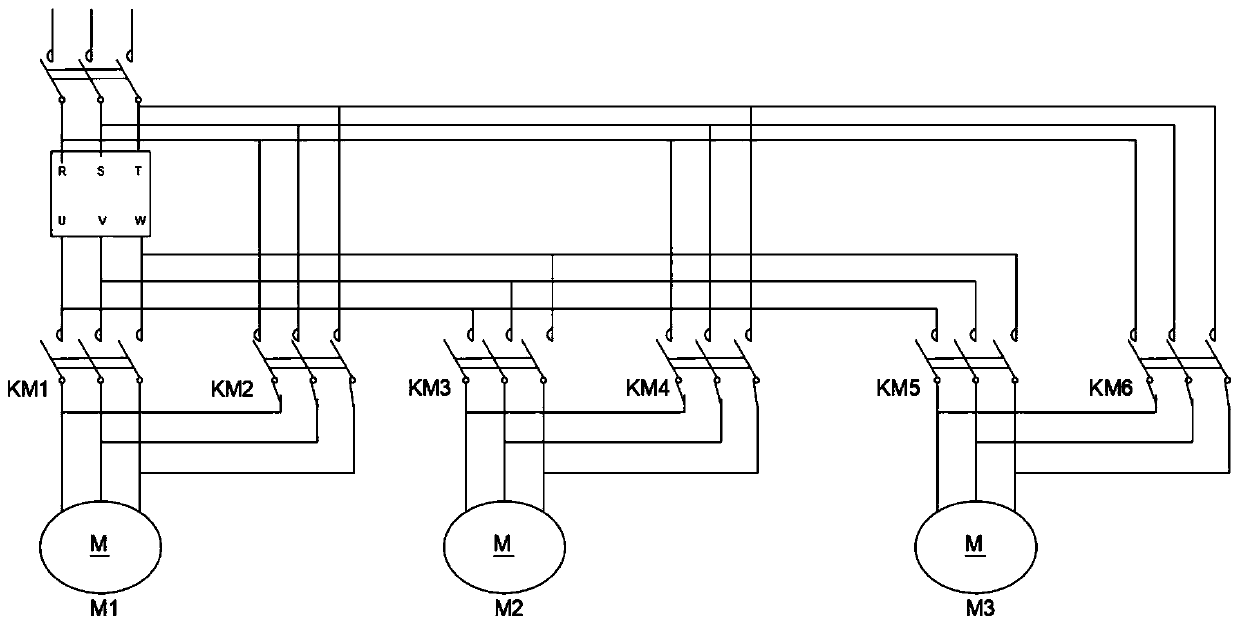

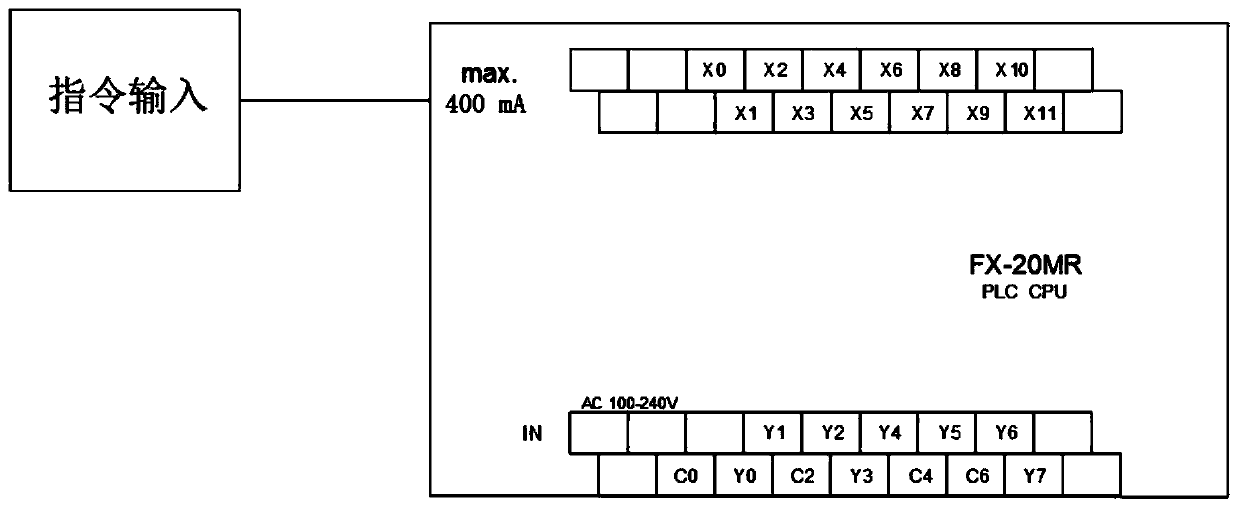

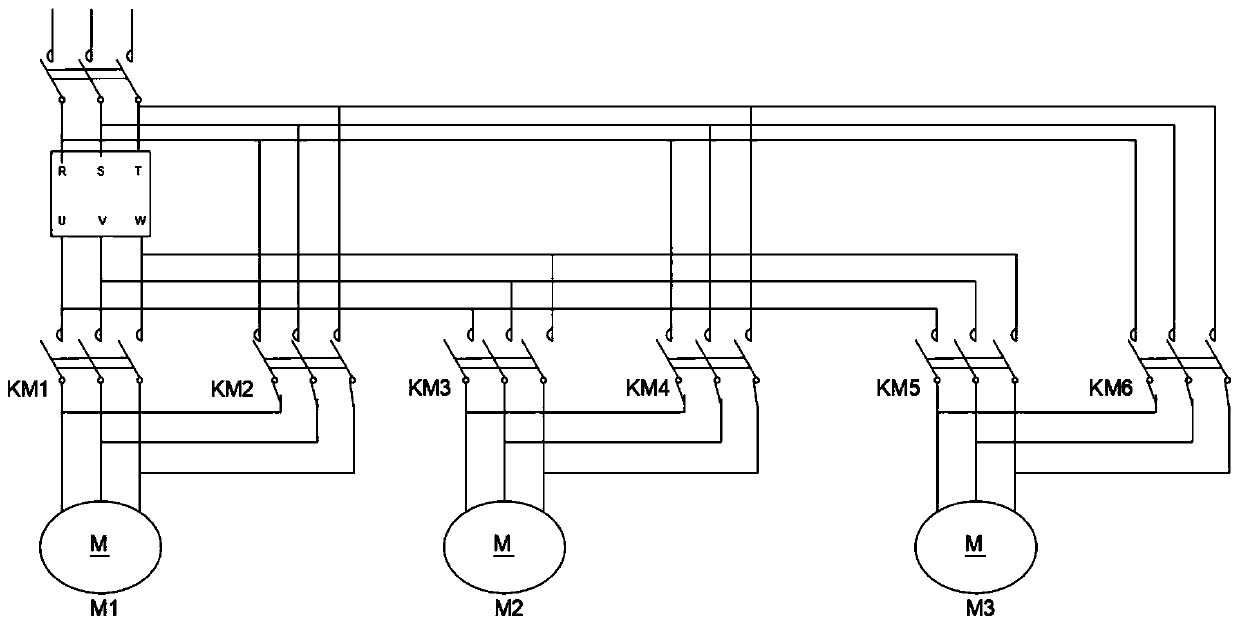

Method for controlling frequency converter to start plurality of large motors by using PLC

InactiveCN111162695AGuaranteed magnetic fluxGuaranteed output torqueMultiple dynamo-motor startersFrequency changerElectric machine

The invention relates to the field of motor control, in particular to a method for controlling a frequency converter to start multiple large motors through a PLC. The method for controlling one frequency converter to start a plurality of large motors by using the PLC comprises the following operation steps of: 1, controlling a single motor to start, and then randomly starting the next motor; according to the invention, only one frequency converter is used, and single gradual starting is limited by a PLC program; after the PLC receives the starting instruction, the Y1 acts to start the KM1 andthe Y0 acts to start a frequency converter; when the frequency reaches 50.5 HZ, the auxiliary relay of the frequency converter outputs a passive switch signal to switch on x0, and the PLC stops the output of the y0 and the y1, Y2 starts KM2 after short time delay, the motor is started and operated at power frequency, the next motor can be started, and the like, so that the problems of simple structure, high failure rate, low automation degree, inconvenience in control and high investment cost of conventional starting of a self-coupling, a star-delta and a soft starter which are used at presentare solved.

Owner:湖北冠驰智慧科技有限公司

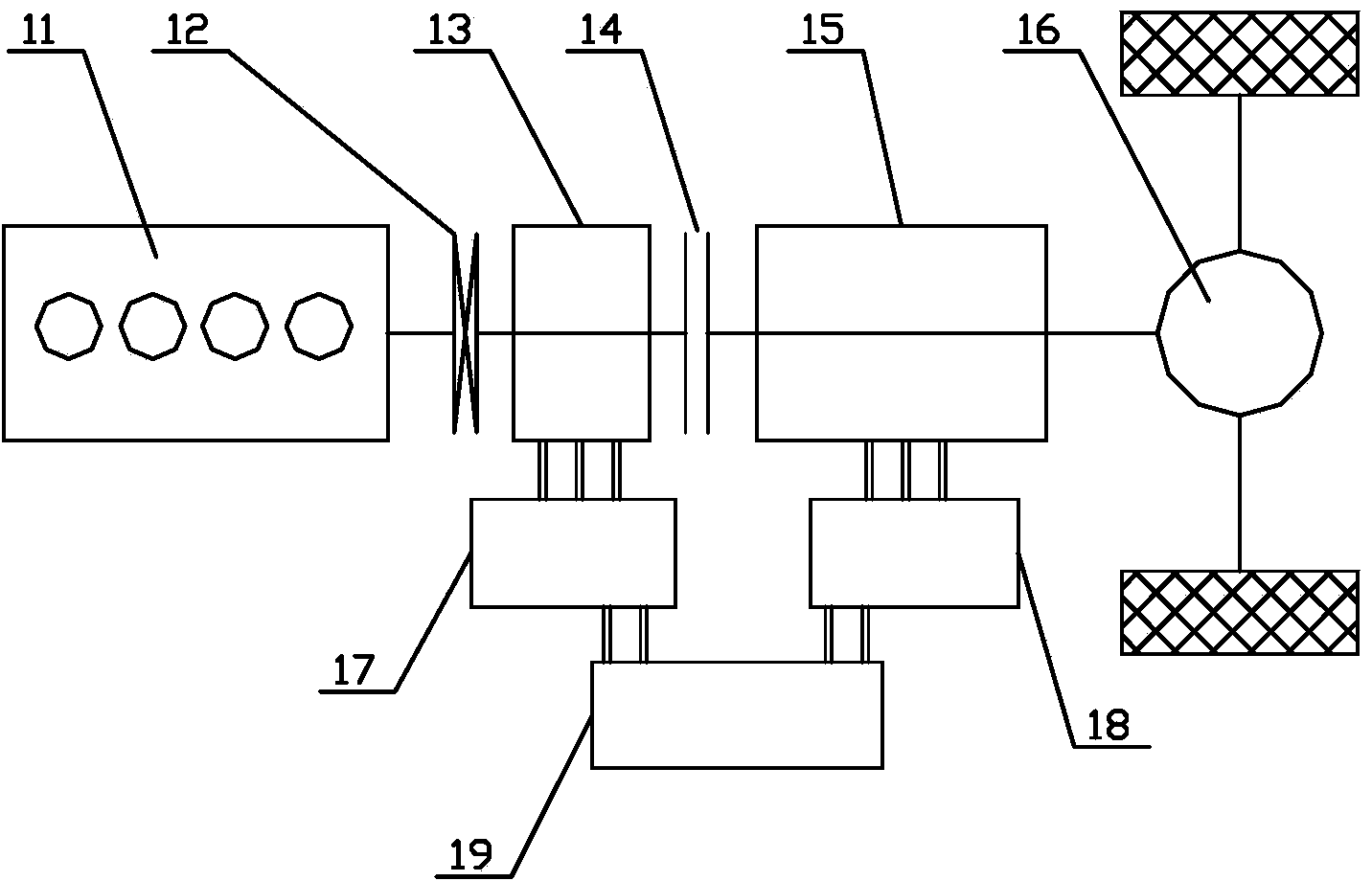

Drive motor and series-parallel type hybrid power systems

InactiveCN103490554ASmall sizeReduce weightGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingDrive motorControl theory

The invention provides a drive motor. The drive motor comprises a shell body, a stator and a rotor. The stator and the rotor are arranged in the shell body. An output shaft of the rotor is fixedly connected with a sun gear in a sleeved mode. The shell body is fixedly connected with a planet carrier provided with a planet gear. The planet gear is respectively connected with the toothed end of the sun gear and the toothed end of an inner ring gear. A through hole is formed in the middle of the rotor along the axial direction. An output connecting shaft capable of rotating is arranged in the through hole. The non-toothed end of the inner ring gear is fixedly connected with the output end of the output connecting shaft. According to the drive motor, the output connecting shaft is made to have large output torque and reduce, to the greatest extent, the output torque of the output shaft of the rotor at the same time, so that the stator and the rotor of the drive motor are made to be greatly reduced in size, the size and the weight of the drive motor itself are made to be greatly reduced, the drive motor is made to be installed and utilized more conveniently, and the utilization range of the drive motor is expanded. The invention further provides two kinds of series-parallel type hybrid power systems which are made to be greatly reduced in overall size and weight and are improved in universality.

Owner:HUNAN CSR TIMES ELECTRIC VEHICLE

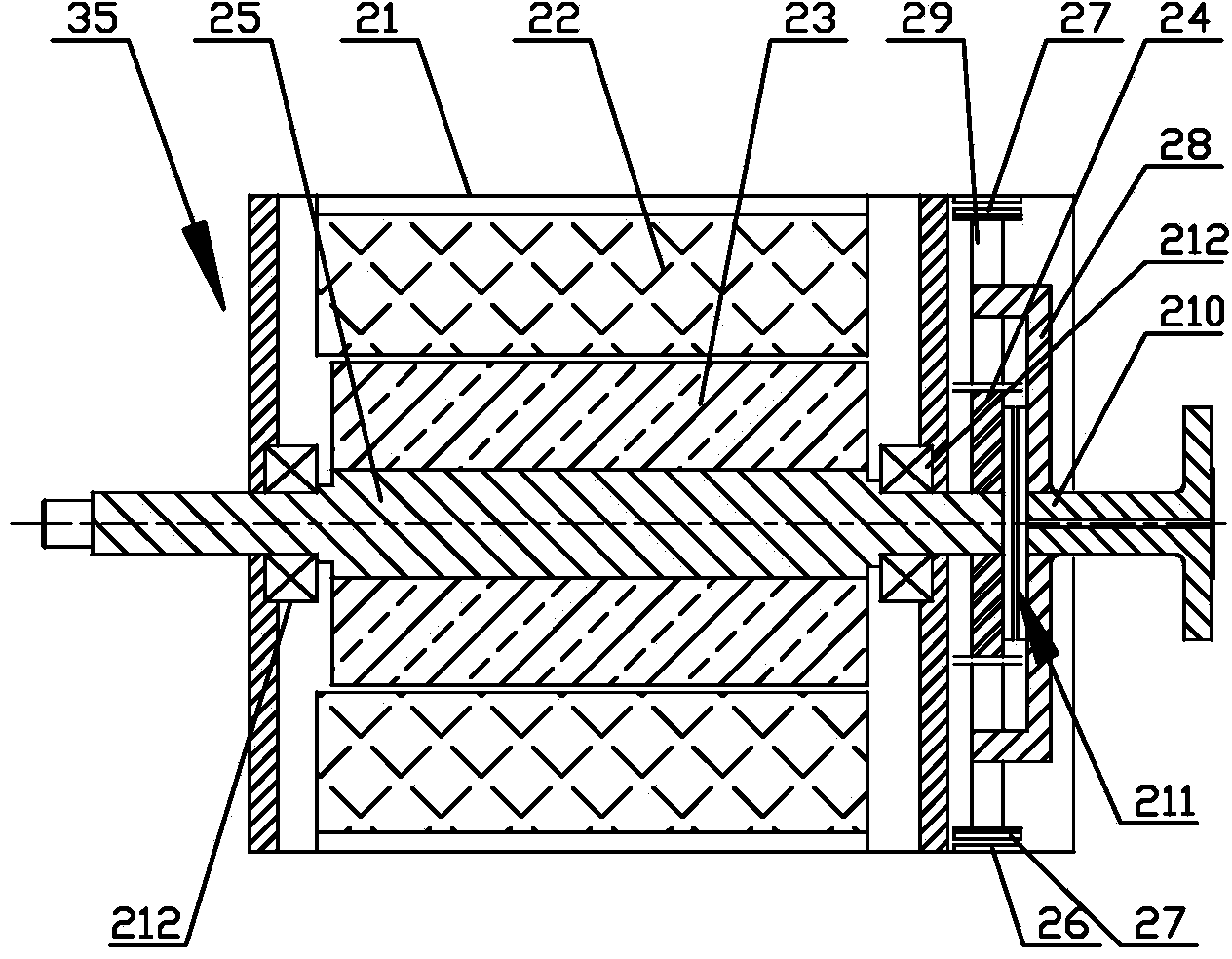

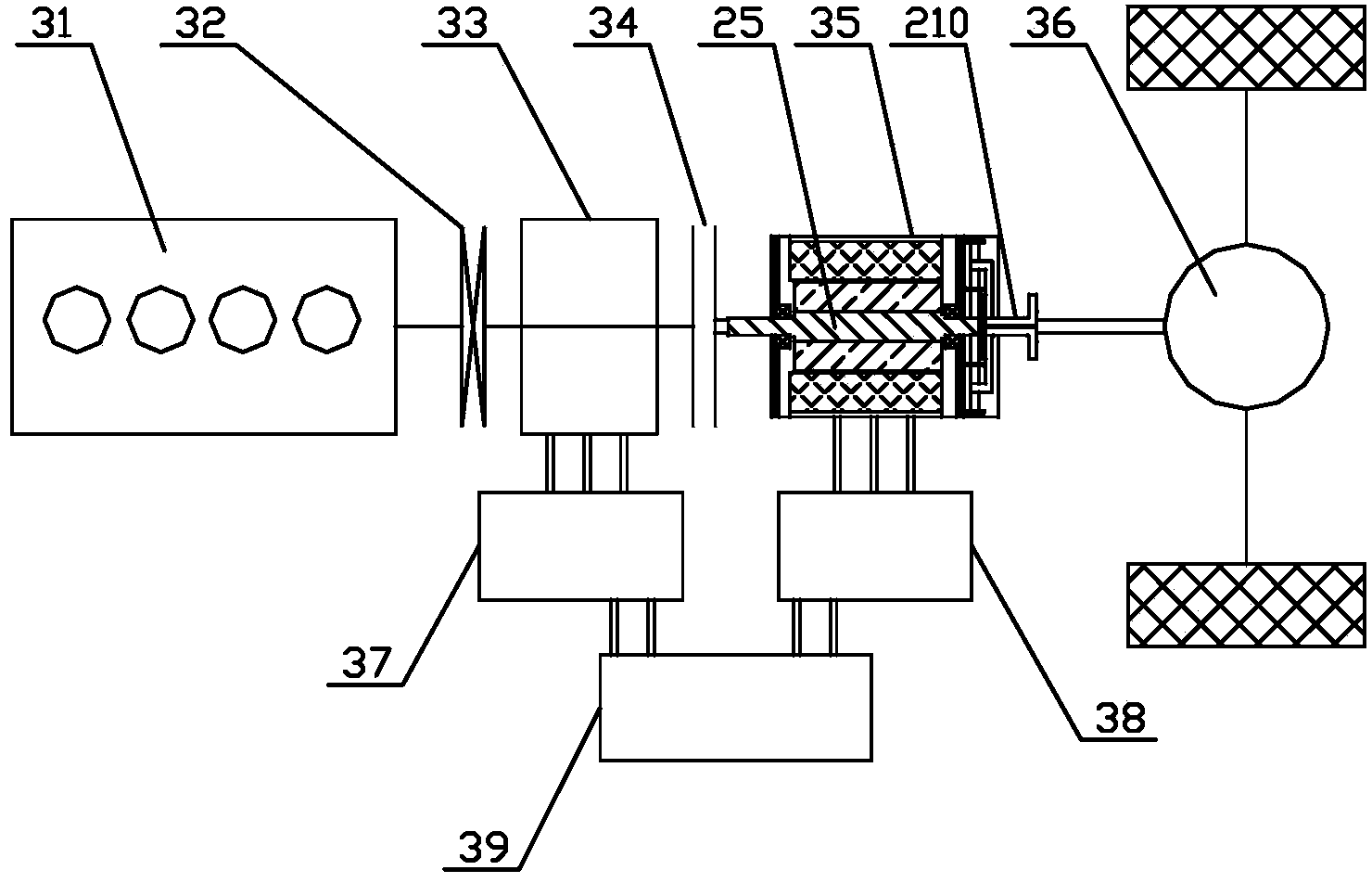

Driving motor and series-parallel hybrid power system

ActiveCN103647367ASmall sizeReduce weightGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingEngineeringDrive motor

The invention provides a driving motor. The driving motor comprises a casing and a stator and a rotor which are arranged inside the casing; a rotor spindle which is used for fixing a sun gear in a sleeve mode is formed in the middle of the rotor along the axial direction; an internal ring gear is installed inside the casing through a first brake; the sun gear and the internal ring gear are meshed with a planetary gear which is installed on a planetary frame; the middle of the planetary frame is fixedly connected with an output connecting shaft which is arranged along the axial direction; a second brake is arranged between the planetary frame and the sun gear. According to the driving motor, output torque of an output shaft of the rotor is reduced under the premise that the series-parallel hybrid power system normally operates and meanwhile the output connecting shaft satisfies larger output torque, so that the size of the driving motor and the stator and the rotor inside the driving motor is greatly reduced and meanwhile the driving motor is convenient to install and use. The invention also provides two series-parallel hybrid power systems which enable the integral size and weight of the series-parallel hybrid power system to be greatly reduced and the universality to be improved.

Owner:CHANGSHA CRRC INTELLIGENT CONTROL & NEW ENERGY TECH CO LTD

Five-rod type planting mechanism applicable to electric drive transplanter in dry land

InactiveCN111010948AMinimize energy consumptionMaximize work efficiencyGeometric CADDesign optimisation/simulationAgricultural engineeringGenetics algorithms

The invention aims at the multi-objective parameter optimization problem of coordinated optimization of controlled characteristic parameters and agronomic requirement parameters of a double-crank five-connecting rod type planting mechanism of an electric drive transplanter in dry land, a closed vector equation is used to describe the motion characteristics of the mechanism, actual agronomic parameter requirements and other requirements during operation of a transplanter are transformed into constraint conditions, after weight distribution is performed through a matrix method, the controlled characteristic is obtained through combination and is used as an objective function, a genetic algorithm is used to optimize and determine the structural parameters of the mechanism, so that the controlled double-crank five-connecting rod planting mechanism is designed.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

A tightening device for round nuts

ActiveCN105922181BEffective fasteningLarge output torqueWrenchesScrewdriversControl theoryWheel and axle

Owner:YINCHUAN WEILI REDUCER MACHINERY

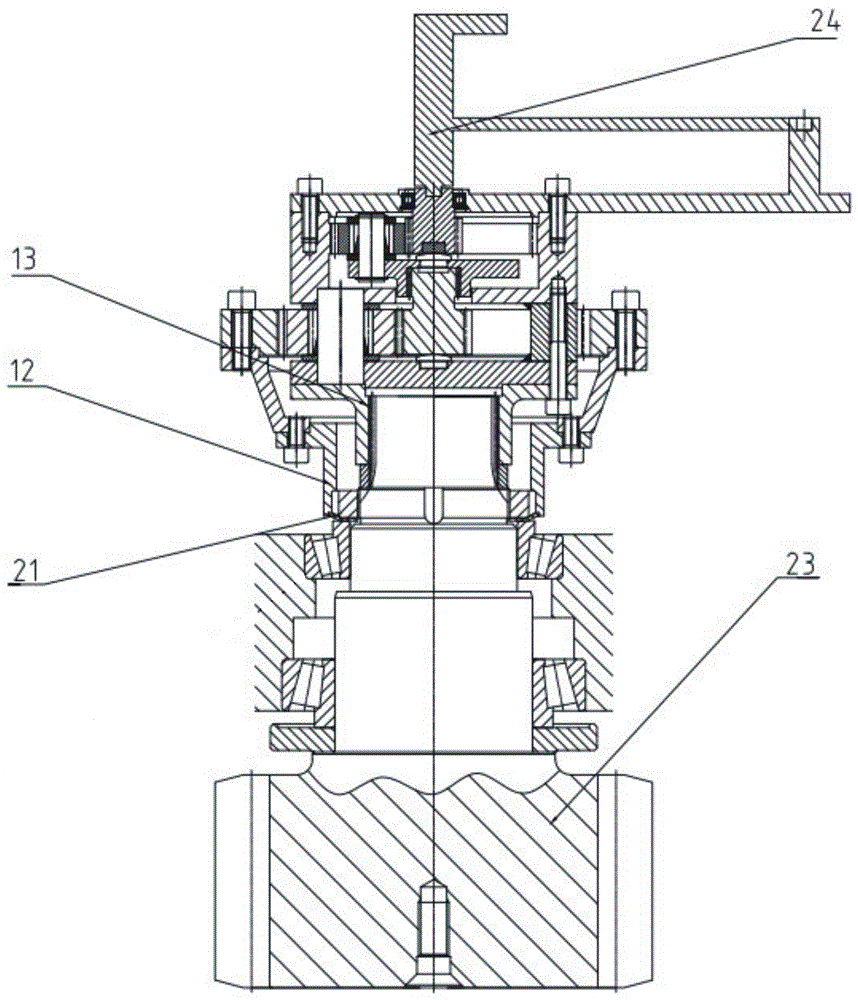

Front output overspeed ratio speed reduction large-torque motor

PendingCN110492670ALarge reduction ratioGuaranteed output torque and rigidity requiredMechanical energy handlingGear transmissionMotor shaft

The invention relates to a front output overspeed ratio speed reduction large-torque motor. The motor comprises a motor shell, a motor stator, a motor rotor, a motor shaft, a driving wheel and a rearend cover; the device further comprises a suspension torque flange, a power output flange, a power output shaft, a driven wheel and a multi-shaft linkage device. According to the technical scheme, a flange ring is arranged in the middle of a motor cavity; a multi-shaft helical gear transmission device and the motor form an all-in-one machine; the invention aims to solve the defects in the prior art, and provides an energy-saving and environment-friendly product which can effectively reduce a mechanical friction coefficient, increase the torque by several times to dozens of times on the basis of a standard motor, achieve the ultrahigh energy efficiency value in efficiency, and is high in space saving value, novel in appearance, high in protection grade and convenient to install.

Owner:ZHEJIANG DONGBA TRANSMISSION

Double Inverted Turning Center Vertical Plus

ActiveCN104815993BShort processing timeIncrease productivityAutomatic/semiautomatic turning machinesSlide plateOptimal matching

The invention discloses a double-handstand turning center lathe. The double-handstand turning center lathe comprises a bed base; the bed base is provided with a standing column; the standing column is provided with a standing column guide rail; the standing column guide rail is connected with the lathe and a left-right handstand turning center; the lathe comprises a lathe carriage, a lathe sliding plate, a left work bench, and a right work bench; the lathe carriage is matched with the lathe sliding plate; the lathe sliding plate is provided with a lathe main shaft; a lathe tool changer at the front side of the lower part of the lathe main shaft is connected with the base; the left-right handstand turning center comprises a handstand turning center carriage, a handstand turning center sliding plate, and a handstand turning center main shaft; the lower part of the handstand turning center main shaft is connected with a handstand chuck; the base between the lathe main shaft and the handstand turning center main shaft is provided with a work bench base; the work bench is provided with a left clamping fixture; and the bed base is provided with a turning head. The double-handstand turning center lathe is capable of achieving the optimal matching of the turning and lathe time during the processing of the disc parts, saving the labor, reducing the manufacturing cost, and ensuring the precision and quality of the part production, the whole processing time is the shortest, and the production efficiency is high.

Owner:JINAN FIRST MACHINE TOOL GROUP

Continuously variable transmission with adjustable transmission ratio characteristic curve

PendingCN113685517AGuaranteed output torqueGuaranteed growthGearingPortable liftingStructural engineeringControl theory

The invention discloses a continuously variable transmission with an adjustable transmission ratio characteristic curve. The continuously variable transmission comprises a shaft sleeve, a spring seat, a moving wheel, a sliding cover and a spring, and further comprises a swing arm, a cylindrical roller, an inclined plane guide block and an eccentric bolt assembly; one end of the swing arm is hinged to the spring seat, and the other end of the swing arm is connected with the cylindrical roller; the inclined plane guide block is hinged to the moving wheel; the eccentric bolt assembly comprises an eccentric bolt and a nut; and one side of the inclined plane guide block abuts against an eccentric cylindrical section, and the other side of the inclined plane guide block is provided with a guide inclined plane abutting against the cylindrical roller. According to the continuously variable transmission with the adjustable transmission ratio characteristic curve, the transmission ratio characteristic curve of the transmission can be changed by adjusting the installation position of the eccentric bolt, and therefore the continuously variable transmission can better meet the driving requirements of vehicles in different areas.

Owner:CHONGQING CHANGXING IND

Intelligent wire feeding machine

InactiveCN102465292BStable outputGuaranteed output torqueMetallic material coating processesLow speedLaser processing

The invention relates to an intelligent wire feeding machine. The machine comprises a frame, a wire welding disc, a wire feeding device and a control mechanism. The machine is characterized in that: the tail part of the frame is provided with a wire welding disc shaft; the wire feeding device fixed by bolts is arranged on a bottom plate below the frame; the side surface of the frame is provided with a supporting plate for fixation; the wire feeding device comprises a servo motor, a harmonic reducer, a panel, a wire feeding wheel, regulating wheels, a thumb wheel, a compression rod, a wheel bracket panel, a connecting rod, bearings, an encoder, a compression spring, a spring core shaft, a shaft sleeve, a sliding body, and a sliding body cover; the control mechanism is that: an embedded computer system is arranged in the intelligent wire feeding machine. According to the present invention, the servo control technology and the harmonic reducer are adopted, such that the operating stability of the welding wire at the low speed is effective controlled; the elastic floating device and the encoder are added, such that the control system is improved, the terminal close loop of the welding wire output movement is achieved, the wire feeding speed is real-timely monitored, and the damage probability of the laser processing workpiece due to the machine problem is reduced to the minimum.

Owner:鞍山大陆激光技术有限公司

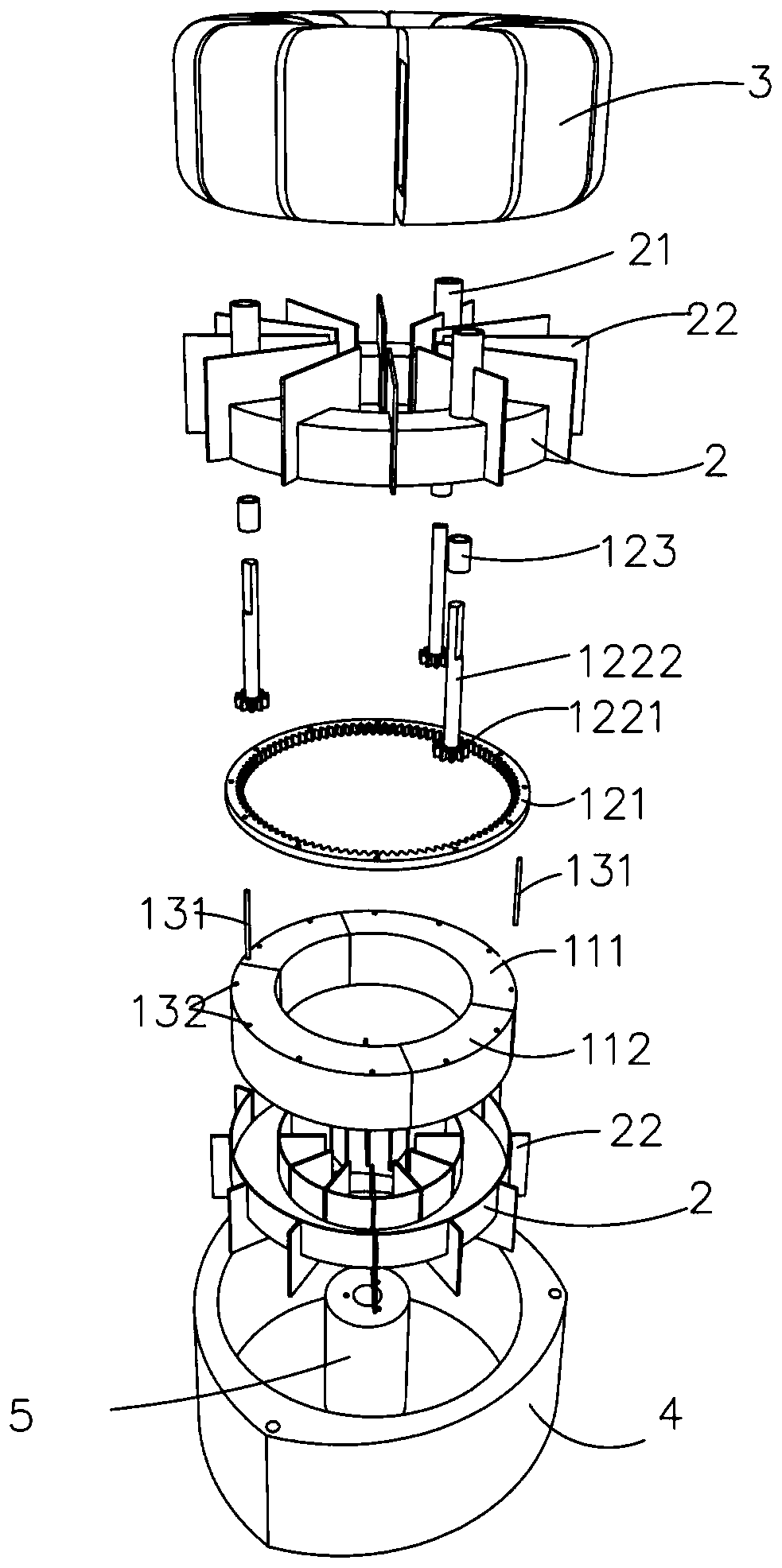

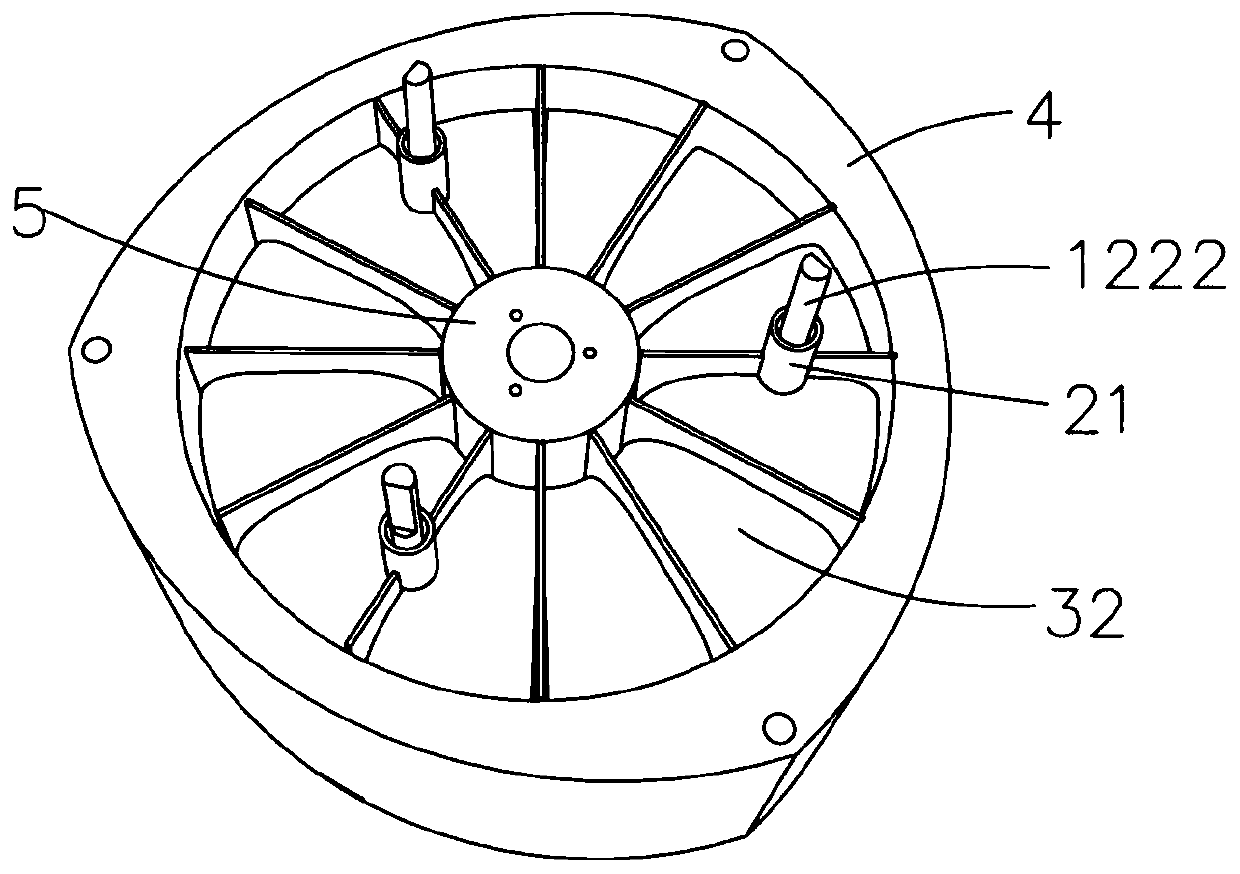

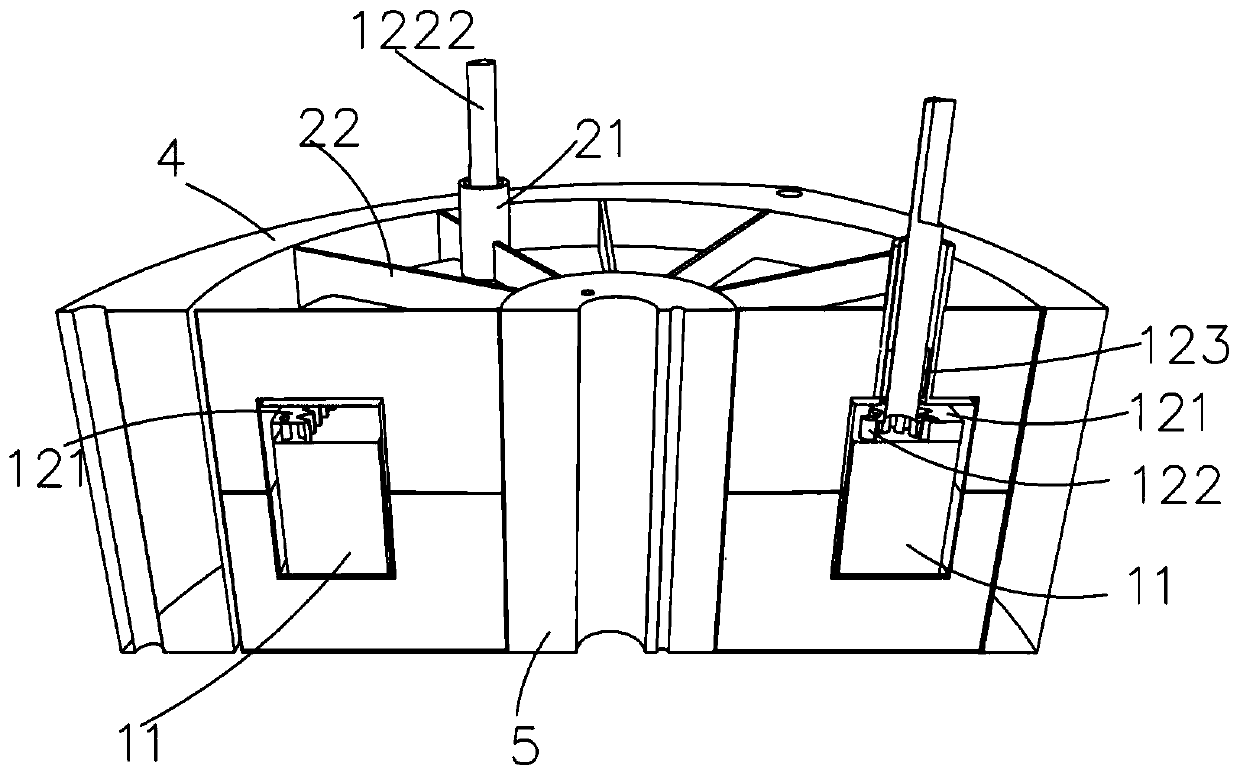

A High Power Density Reluctance Motor

ActiveCN107769411BReduce volumeImprove power densityMagnetic circuit rotating partsWindings conductor shape/form/constructionReluctance motorEngineering

The invention provides a high-power density reluctance motor. The high-power density reluctance motor comprises a rotor, a rotor shell and a winding, wherein the rotor is arranged in the rotor shell,the winding comprises a plurality of coils, the coils all are wound around the rotor shell, the rotor comprises a circular-annular rotor body and a gear group, the rotor shell is of a circular-annularstructure of a non-magnetic conduction material, the circular-annular rotor body is formed by alternatively arranging and connecting N tile-shaped silicon steel arc blocks and N non-magnetic conduction filling arc blocks, the gear group comprises an inner gear ring and a gear shaft, the inner gear ring is fixed on an end surface of the circular-annular rotor body, the inner gear ring and the circular-annular rotor body are concentrically arranged, a gear end of the gear shaft is engaged with the inner gear ring, a shaft end extends out of the rotor shell, and the tile-shaped silicon steel arcblock and the gear ring are fixedly connected to form a single-phase iron core. By the high-power density reluctance motor, the problem of low power density of an existing switched reluctance motor is solved; and meanwhile, by the structure, the system noise is also reduced.

Owner:抚顺三平科技开发有限公司

A built-in permanent magnet synchronous motor for high-speed electric spindle

ActiveCN103956843BFlux Leakage GuaranteeFlux leakage increasesMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsConstant powerLow speed

The invention relates to a built-in permanent magnet synchronous motor used for a high-speed electric spindle. The built-in permanent magnet synchronous motor comprises a stator iron core, a rotor iron core, a rotation shaft, magnetic steel and stator three-phase symmetrical windings. The built-in permanent magnet synchronous motor is characterized in that the magnetic steel is V-shaped magnetic steel which is evenly inlaid in the circumferential direction and radially magnetized; the V-shaped magnetic steel comprises a plurality of permanent magnets, a plurality of magnetic insulation bridges and a plurality of magnetic bridges; the permanent magnets are arranged on the two sides of the V-shaped magnetic steel, the magnetic bridges are arranged between the adjacent permanent magnets and the magnetic insulation bridges are arranged at the top ends of the V-shaped edges on the two sides and the bottom ends of the V-shaped magnetic steel. The built-in permanent magnet synchronous motor used for the high-speed electric spindle has the advantages that the motor has the high-torque running performance achieved during low-speed running, and has a wide weak magnetic speed raising range at the constant power section above base speed; during constant-power high-speed running, the leakage flux of the permanent magnets is high and the weak magnetic speed raising capacity is high; during non-load running, the leakage flux of the motor is low and the output torque is high; the segmented unequal-thickness magnetic steel enables gap flux densities of the motor to be distributed similar to a sine, therefore, the torque pulsation is low, the control precision is high and the permanent magnets of the motor are not prone to excitation loss.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com