Intelligent wire feeding machine

A wire feeder, intelligent technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of unstable low-speed operation, stuck, welding wire slippage, etc., to reduce welding wire fluctuation, ensure output torque, stable The effect of wire feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment and accompanying drawing, concrete technical scheme of the present invention will be further described:

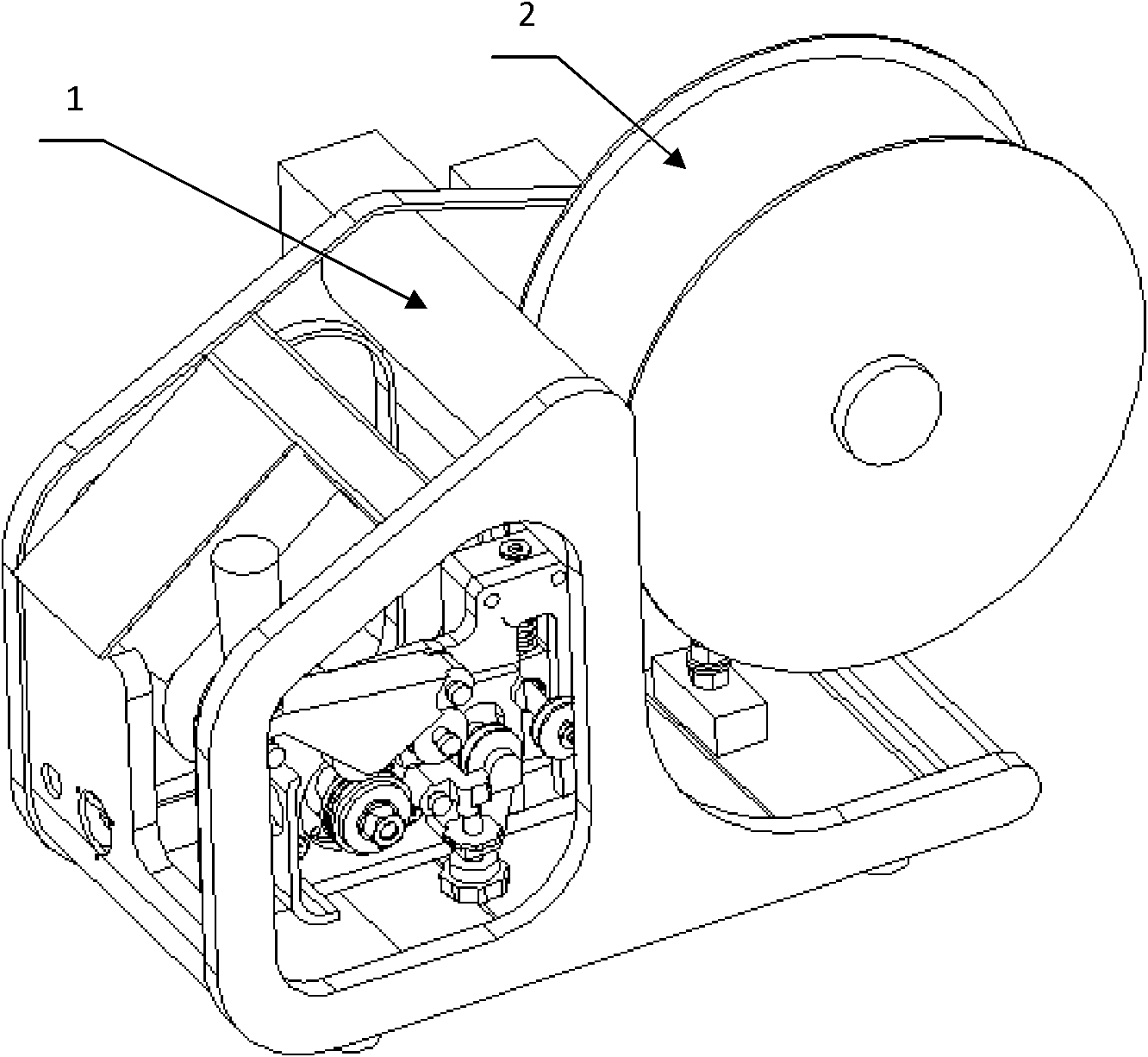

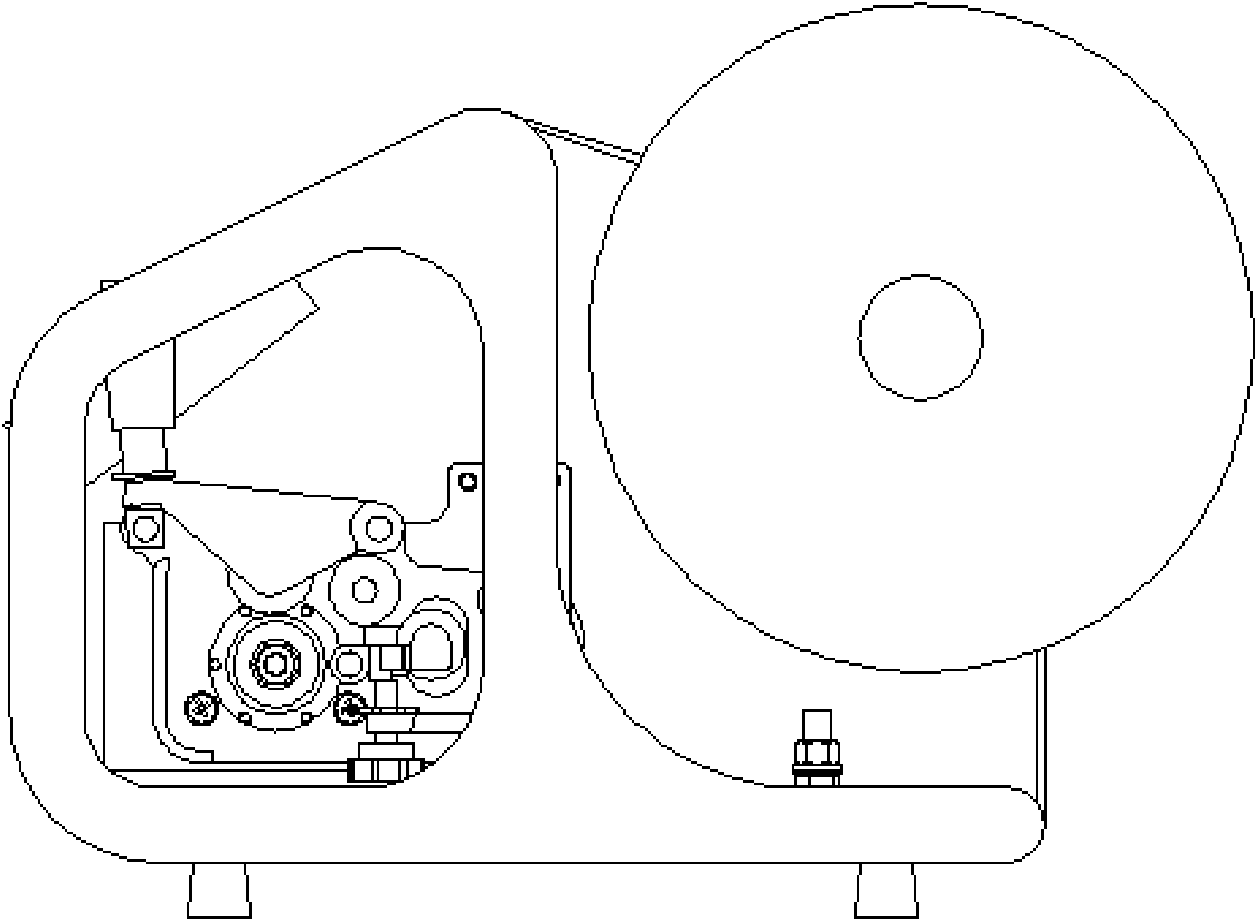

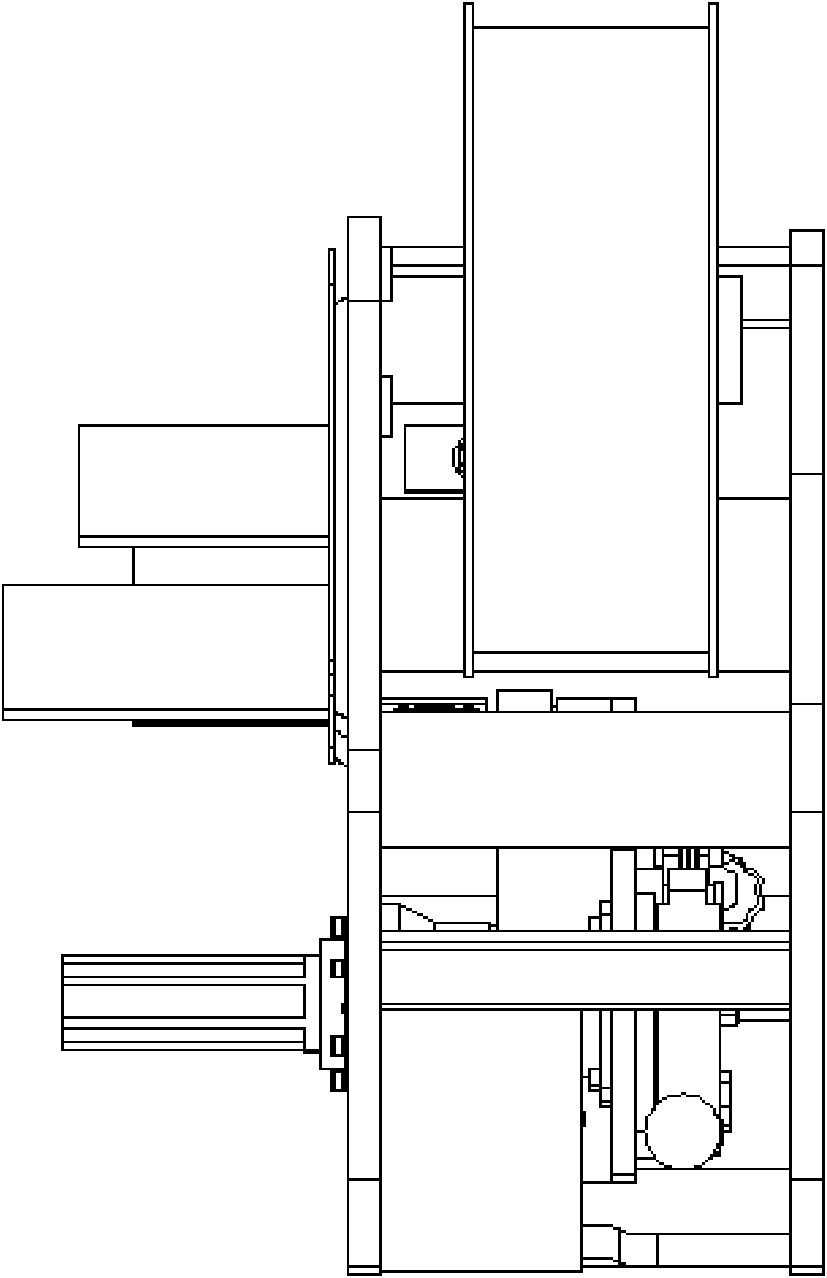

[0027] Such as Figure 1 to Figure 7 As shown, the intelligent wire feeder includes a frame, a welding wire reel, a wire feeding device, and a control mechanism. There are two holes at the bottom of the frame 1 to fix the wire feeding device on the bottom of the frame through screws and nuts, and the welding wire reel 2 is installed on the machine. on the spindle of Rack 1.

[0028] In the wire feeding device, the servo motor 14 is connected to the harmonic reducer 15 through a key; the wire feed wheel 5 is connected to the shaft end of the harmonic reducer 15 through a key and a nut; the harmonic reducer 15 is fixed to the panel 6 through screws; The wheel bracket panel 9 is fixed to the panel 6 by screws; the sliding body cover 11 is fixed to the panel 6 by screws; the adjustment wheel 7 is connected to the connecting rod 19 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com