Double-handstand turning center lathe

A turning center and vertical machining technology, applied in turning equipment, turning equipment, metal processing equipment, etc., can solve the problems of difficulty in ensuring coaxiality requirements and dimensional accuracy, large number of machine tools and operators, and long auxiliary time consumption. Achieve the effect of saving auxiliary loading and unloading time, saving human resources, improving precision and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

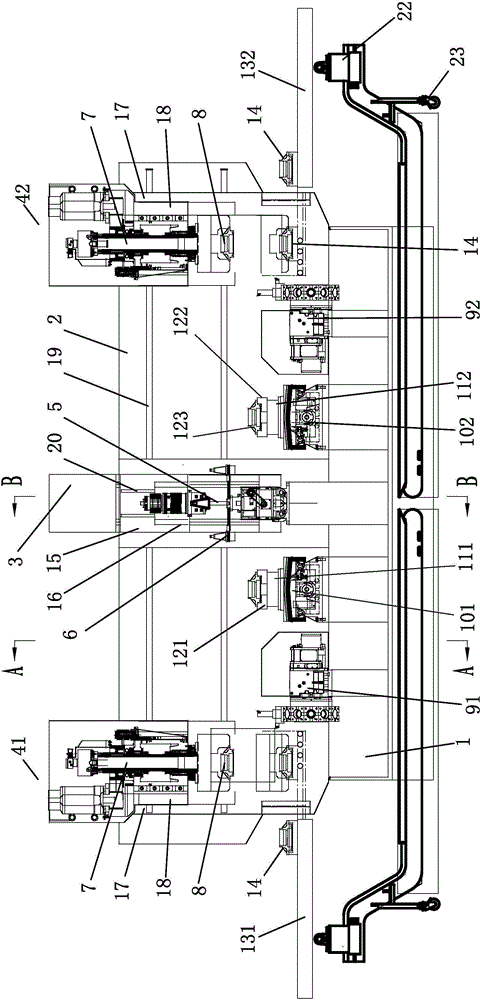

[0032] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

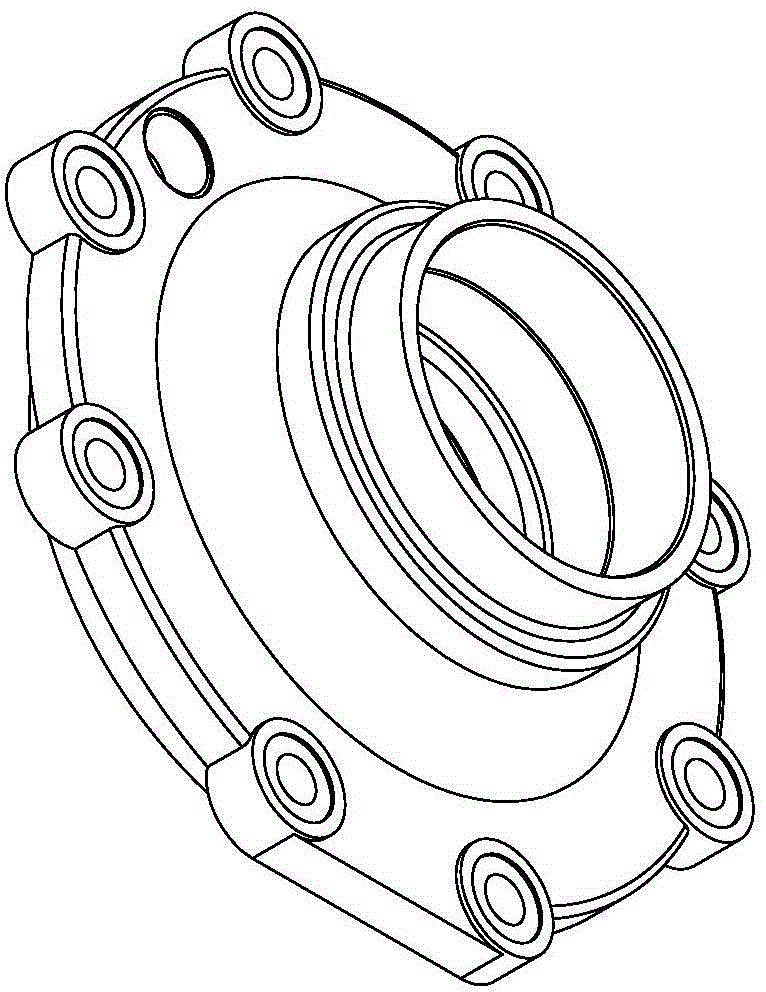

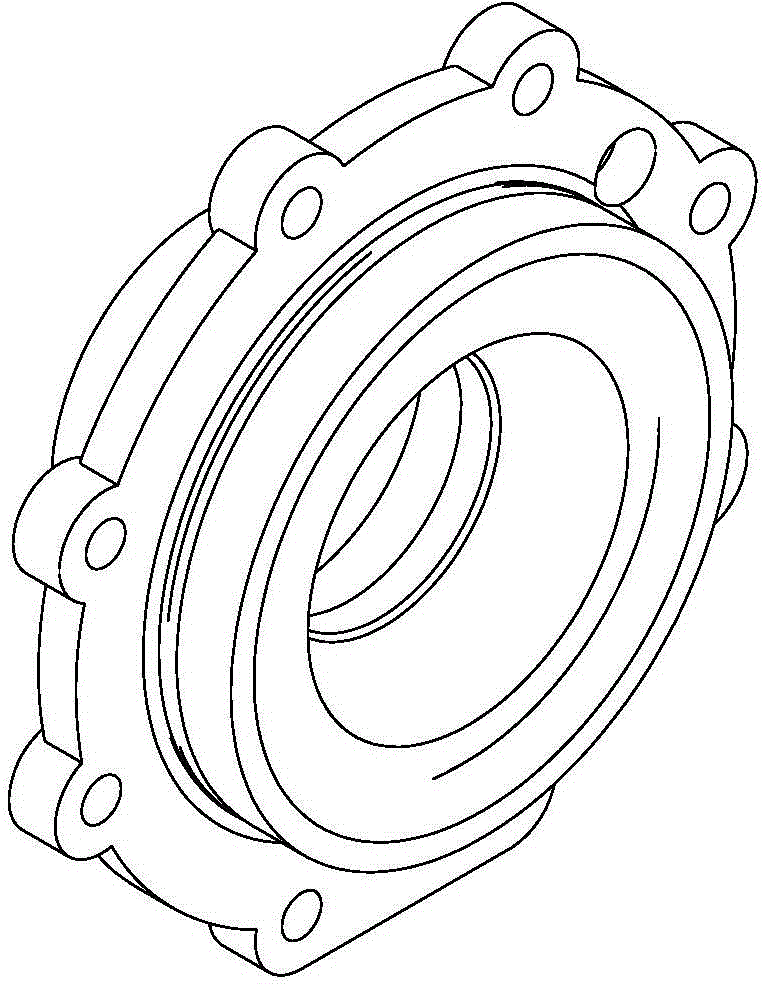

[0033] combine Figure 3 to Figure 5 , a kind of double inverted turning center is vertically added, comprises bed base 1, is provided with column 2 above the rear part of bed base 1, and the front end face of described column 2 is provided with horizontal column guide rail 19 in the left and right direction, namely X-axis direction, and column 2 An electrical box 21 is provided on the rear end, and a vertical machining center that moves horizontally and laterally along the column guide rail is provided in the middle of the horizontal column guide rail, referred to as the vertical machining center 3, and on both sides of the vertical column guide rail, there are respectively a set of vertical machining centers that move horizontally and laterally along the column guide rail. The inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com