Patents

Literature

94results about How to "Reduce clamping errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lathe turnover fixture

ActiveCN101700627AImprove automationAvoid pinchingPositioning apparatusMetal-working holdersEngineeringSliding contact

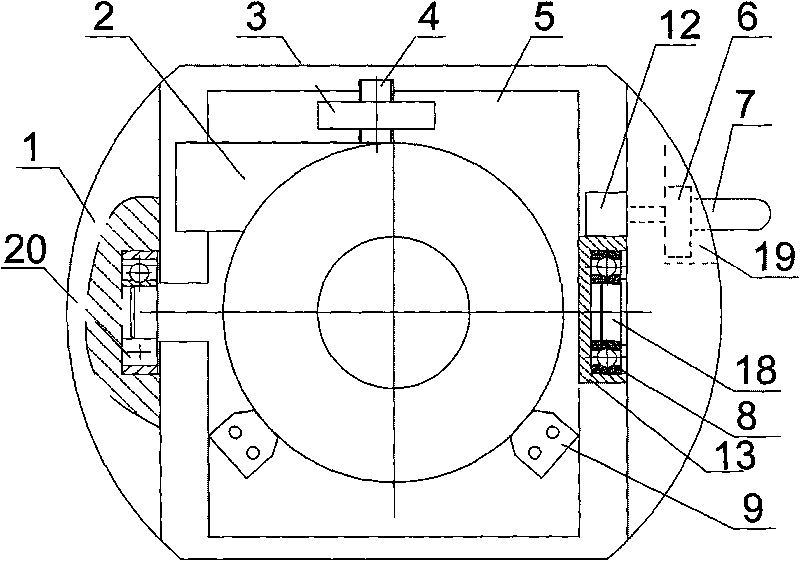

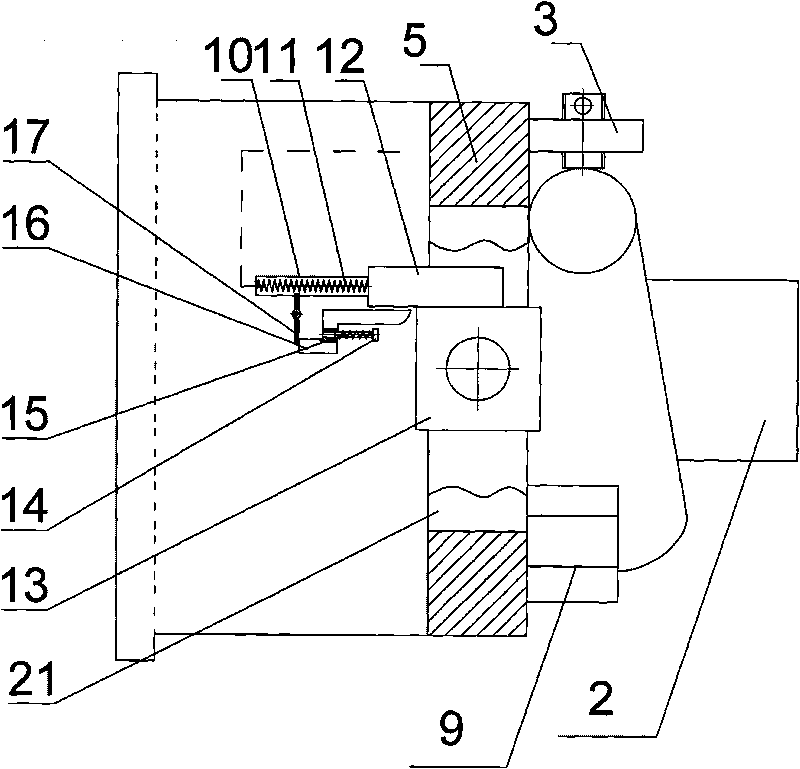

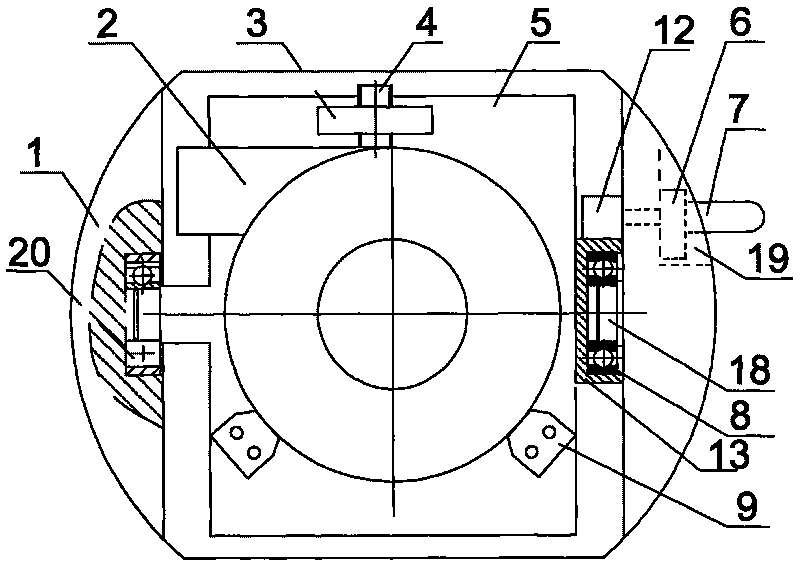

The invention relates to a fixture, particularly to a lathe turnover fixture. According to the technical scheme provided by the invention, the lathe turnover fixture comprises a fixture body; a first bearing is arranged at one end of the fixture body, a rectangular block is arranged at the other end of the fixture body, a second bearing is positioned in the rectangular block, a turnover plate body is arranged between the first bearing and the second bearing, a positioning block is arranged at one end of the turnover plate body, a workpiece clamping seat is arranged at the other end of the turnover plate body, and a clamping guide screw is arranged on the workpiece clamping seat; and a positioning groove is arranged on the fixture body, a sliding key block is arranged in the positioning groove, a sliding handle is arranged on the sliding key block, the sliding handle penetrates through the sliding key block and is fixedly connected with a rotating sliding block, the rotating sliding block and the rotating sliding block are in sliding contact, a guide rail is arranged at one end of the rotating sliding block, a rotating rod is arranged on the guide rail, a push rod is arranged between the rotating rod and the rectangular block, a push rod spring is arranged on the push rod, a spring seat is arranged at the end part of the push rod spring, and the spring seat is fixedly connected with the fixture body. The lathe turnover fixture has simple structure, convenient operation, capability of processing both surfaces of workpieces and high processing efficiency.

Owner:江苏智慧工场技术研究院有限公司

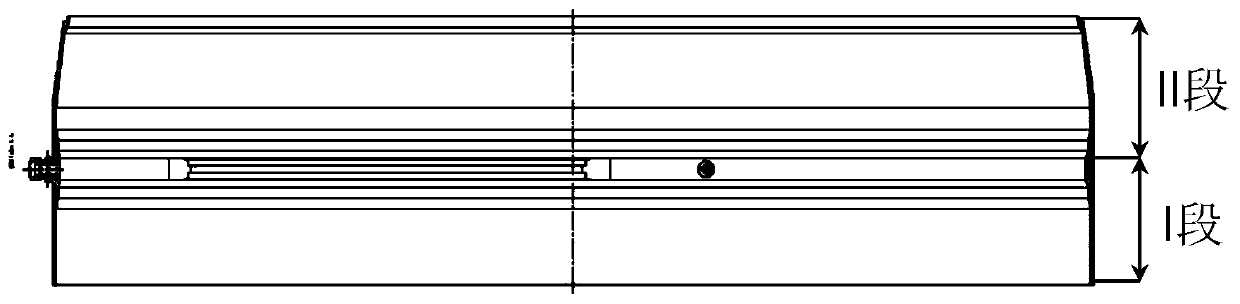

Overall manufacturing method for large-size thin-walled annular belt type oxygen-enhancing frame

ActiveCN111014668AFormed smallLess formingAdditive manufacturing apparatusFurnace typesLaser processingStress relieving

Disclosed is an overall manufacturing method for a large-size thin-walled annular belt type oxygen-enhancing frame. The overall manufacturing method comprises the following steps that a special substrate for laser melting deposition is designed; up-and-down segmentation is carried out along the wall thickness sudden changing portion of the oxygen-enhancing frame; a lower-segment part is formed byselecting a large-power large-scanning-speed laser melting deposition process parameter and a corresponding scanning strategy; laser machining program codes of all slice layers of the upper and lowersegments are obtained by utilizing slice software and are introduced into equipment to carry out laser melting deposition forming of the lower-segment portion first; stress relieving annealing is carried out after outward taking; then the lower segment end surface is taken as a substrate to complete deposition of the upper-segment portion, and heat treatment and machining are carried out to obtaina part under a final state. The overall manufacturing method solves the problems that a current forging and machining method is long in machining period, low in material utilization ratio and severein stress deformation, and the high-performance, small-deformation and small-allowance forming of the oxygen-enhancing frame part is realized.

Owner:XIAN SPACE ENGINE CO LTD

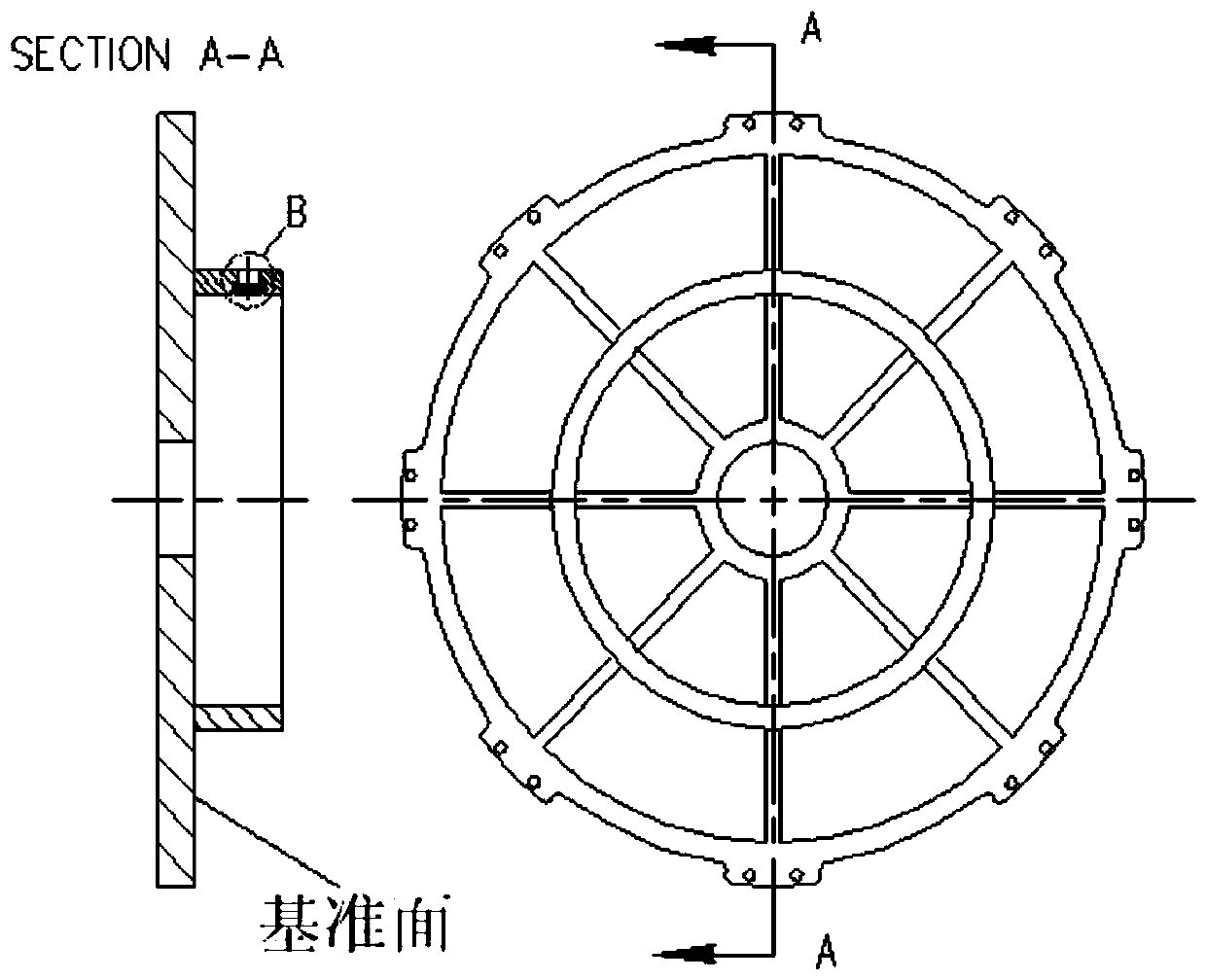

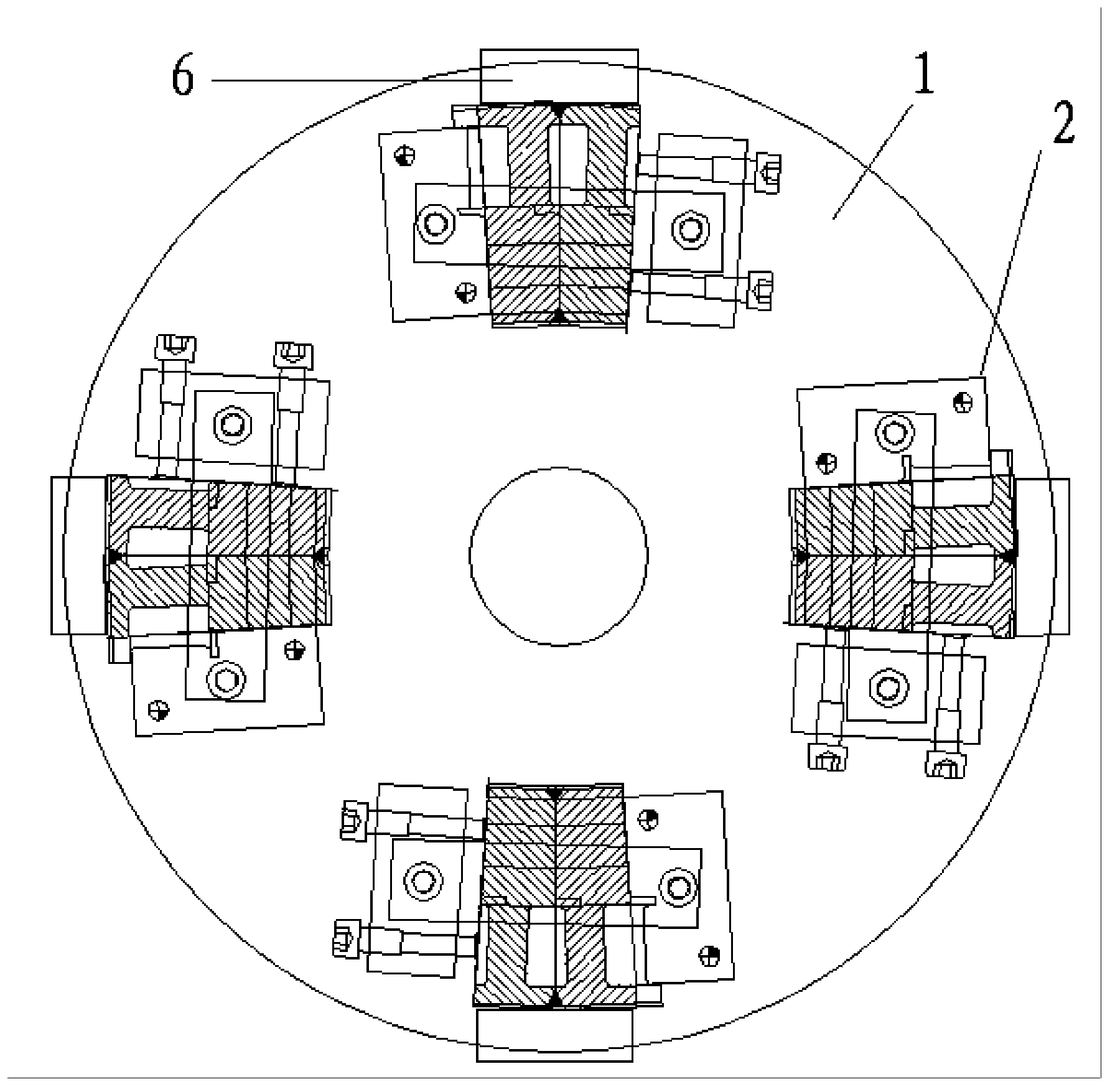

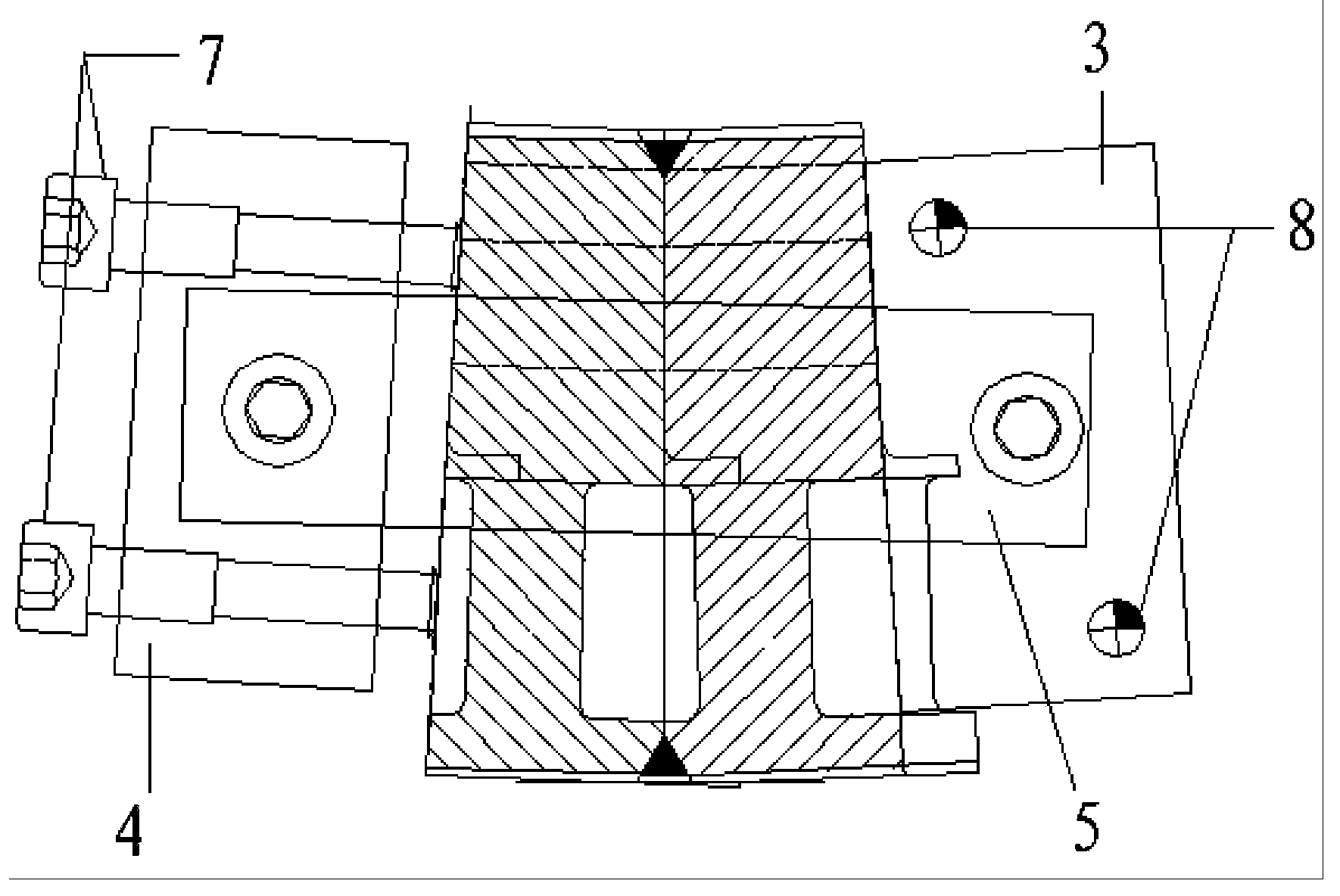

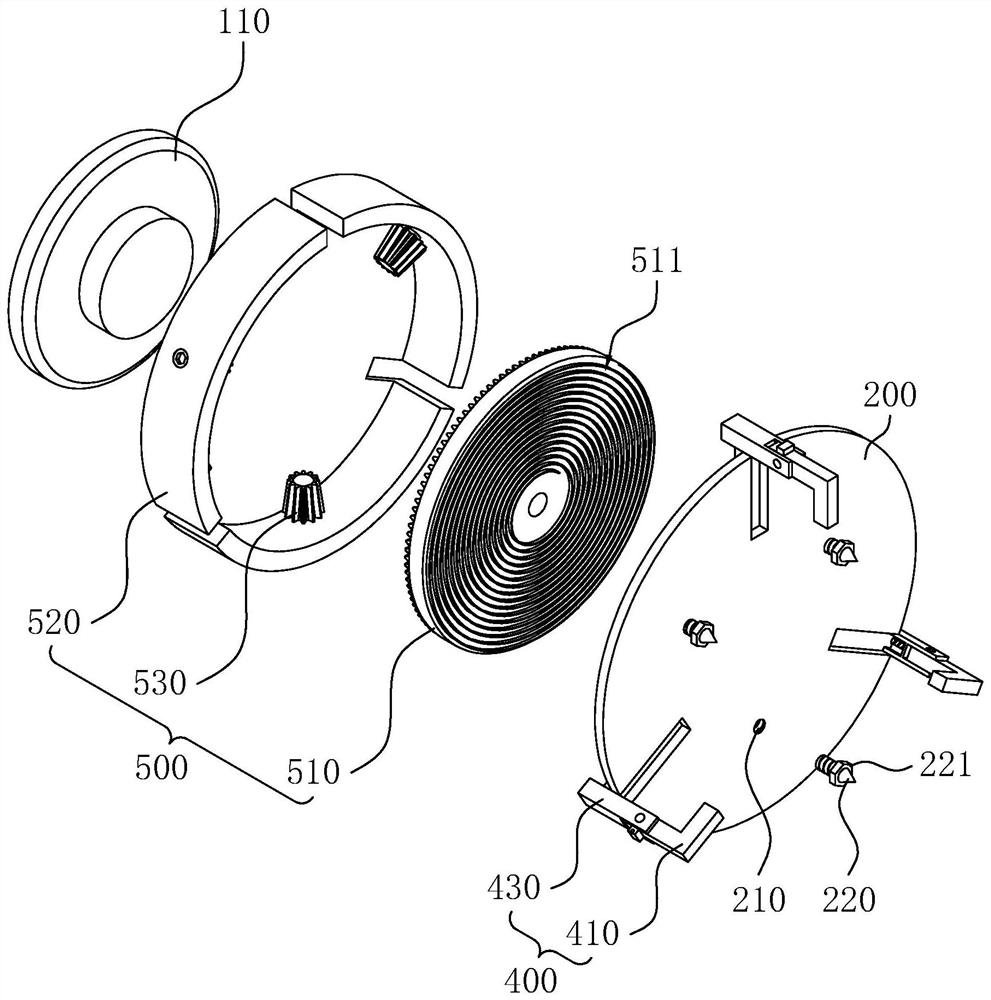

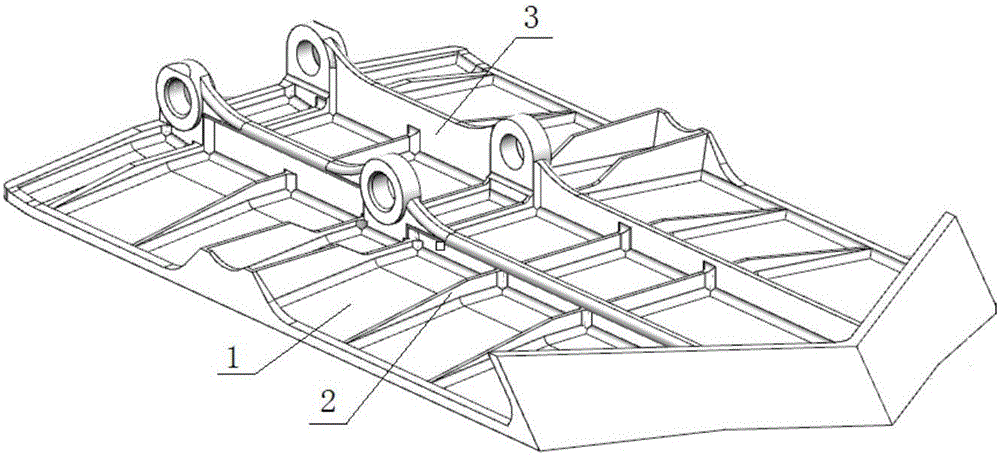

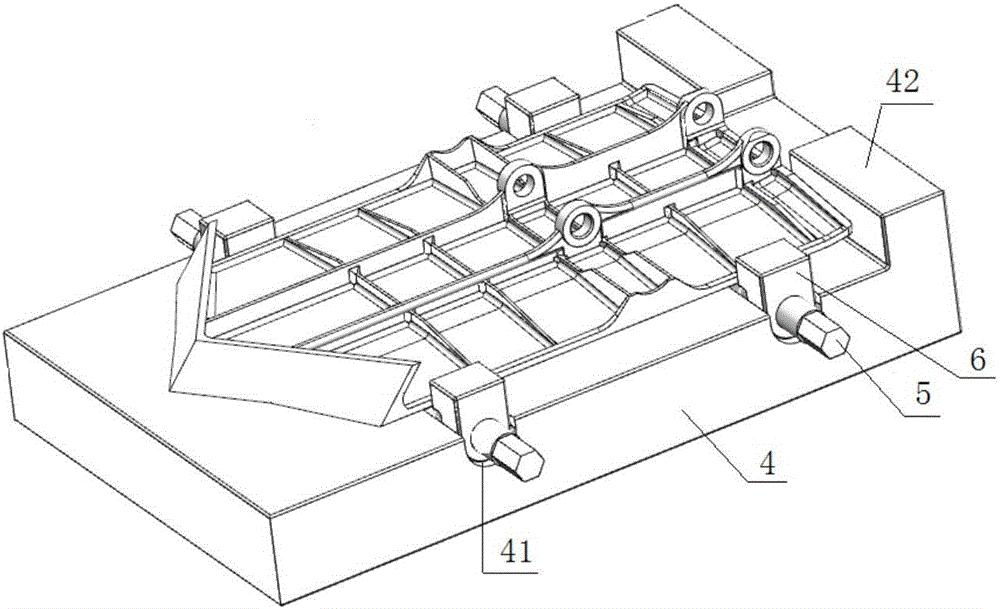

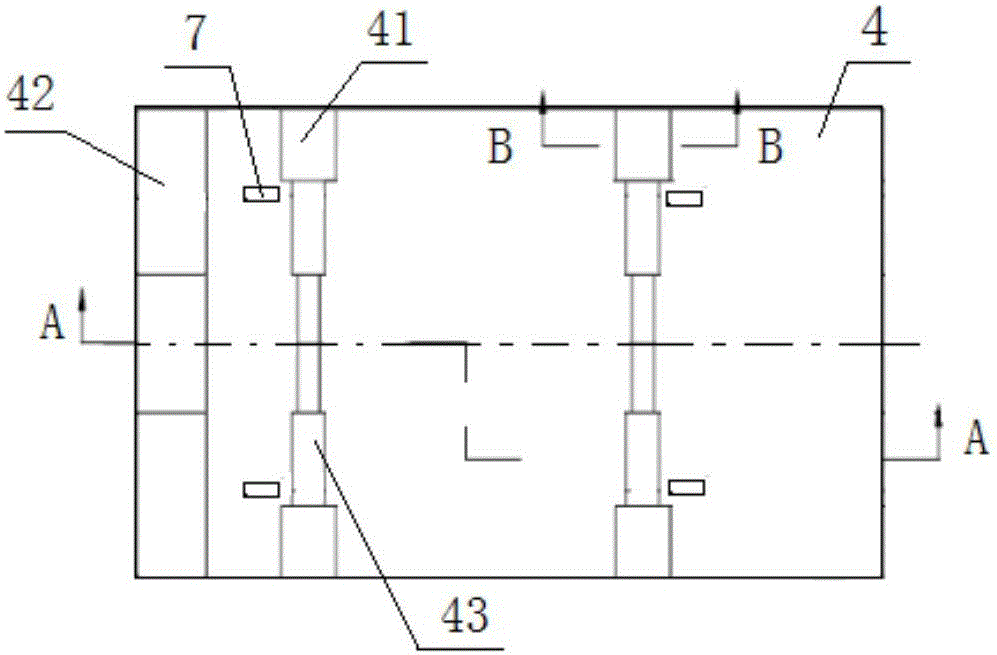

Group machining tooling and process for steam turbine blade multi-pass arc surface

ActiveCN103433511ARealize multi-arc machiningImprove consistencyPositioning apparatusTurning machinesCircular discSteam turbine blade

The invention discloses a group machining tooling and a group machining process for steam turbine blade multi-pass arc surfaces. The tooling consists of an arc machining and installation disc and a blade clamping part. The steam turbine blade multi-pass arc surfaces are machined and formed through group clamping of blades by using an ordinary vertical lathe for turning. The group machining tooling and the group machining process for steam turbine blade multi-pass arc surfaces have the advantages that the group machining is realized by using ordinary equipment and the tooling with a simple structure, the production efficiency is increased and the production cost is decreased.

Owner:常州市三维技术成套设备有限公司

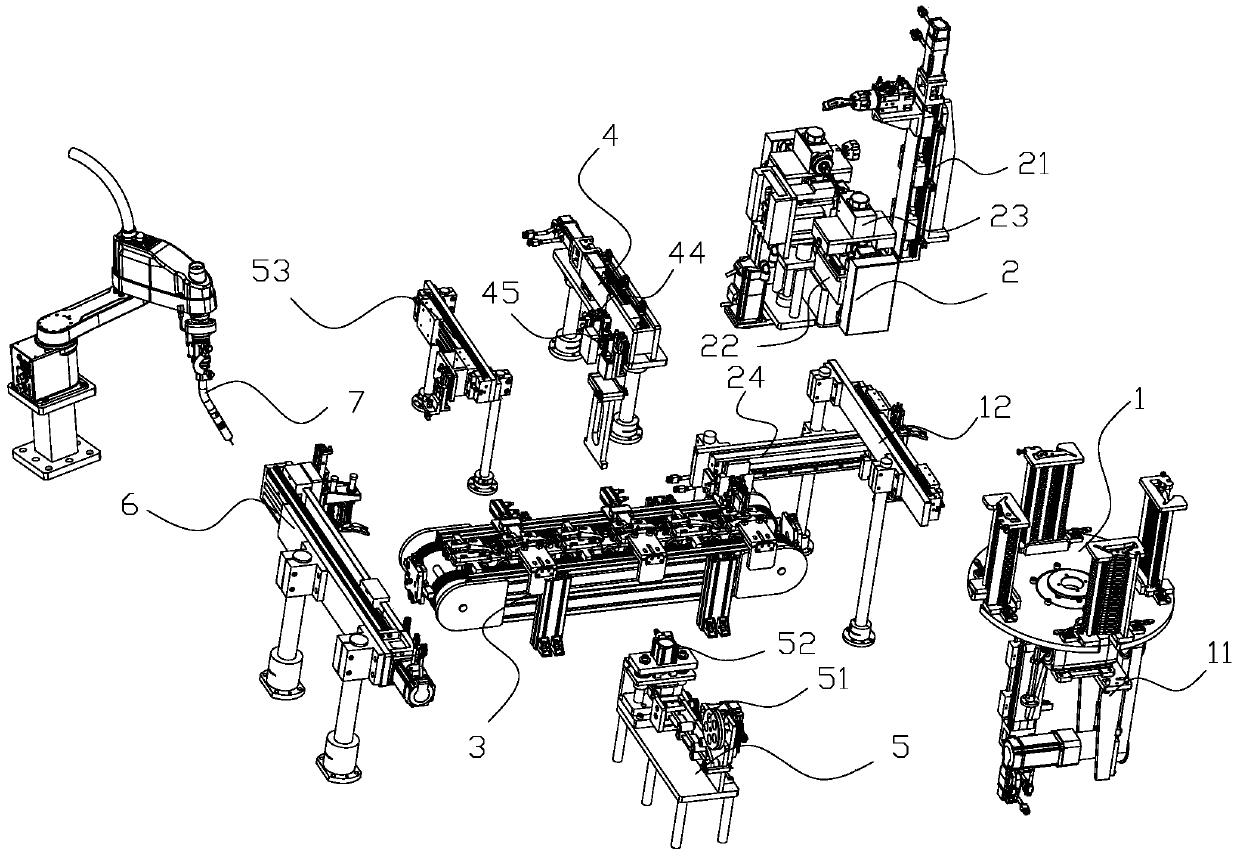

Contact synchronous belt conveying device of circuit breaker assembling equipment and method

InactiveCN111360311AEasy to fixSave spaceShearing machinesCleaning using toolsDrive shaftElectric machinery

The present invention relates to the technical field of circuit breaker production, and discloses a contact synchronous belt conveying device of circuit breaker assembling equipment and a method. Thecontact synchronous belt conveying device of the circuit breaker assembling equipment comprises a synchronous belt support, a synchronous belt motor, a synchronous belt driving shaft and a synchronousbelt driven shaft. The contact synchronous belt conveying device of the circuit breaker assembling equipment and the method have the advantages of improving the conveying efficiency of the synchronous belt, saving equipment space and improving the overall processing efficiency.

Owner:丁水珍

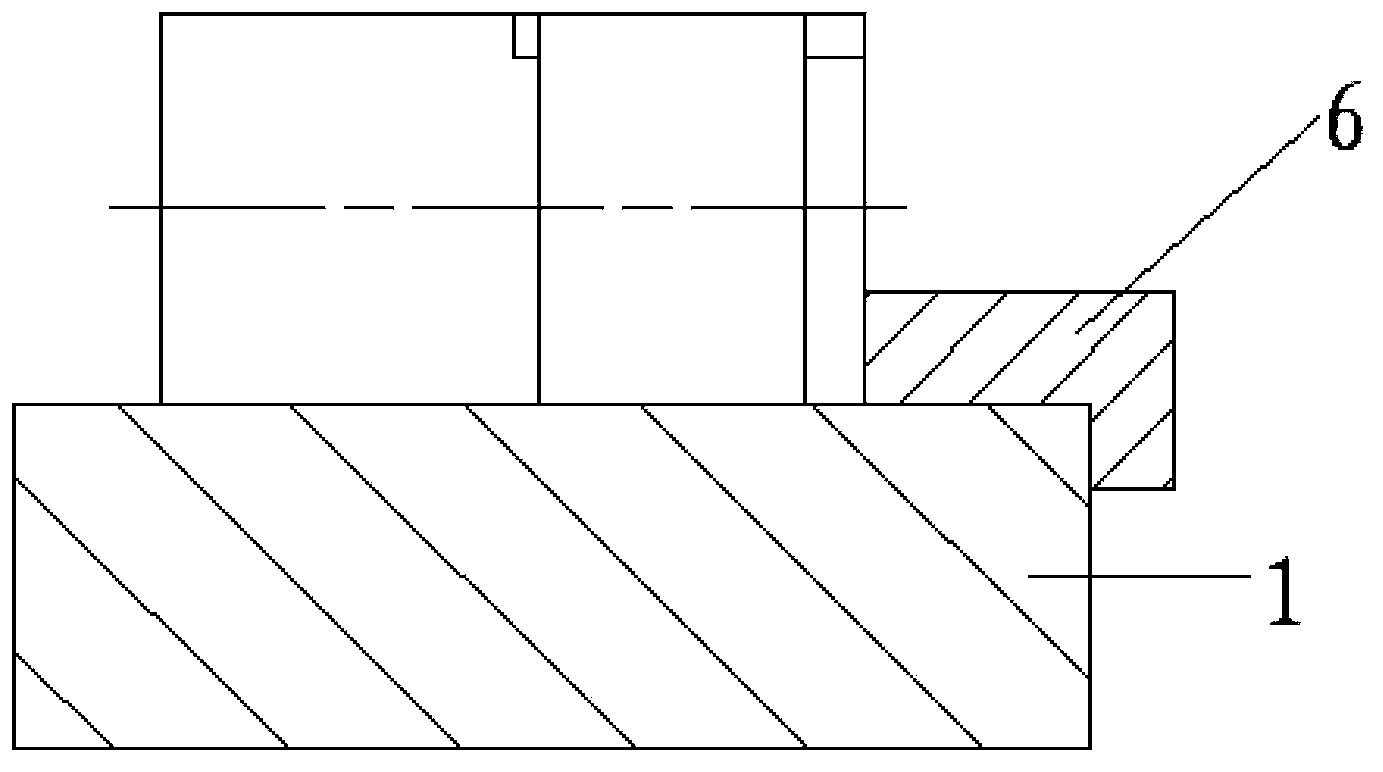

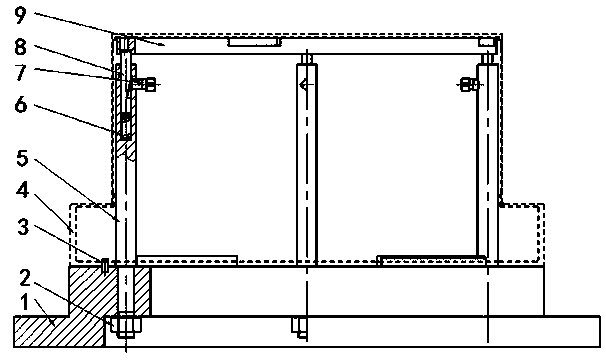

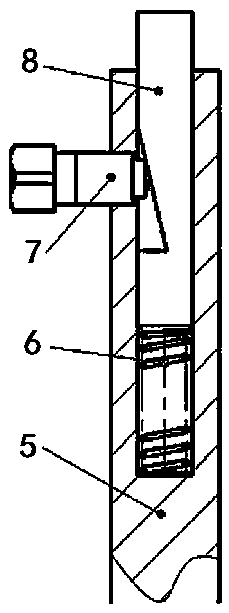

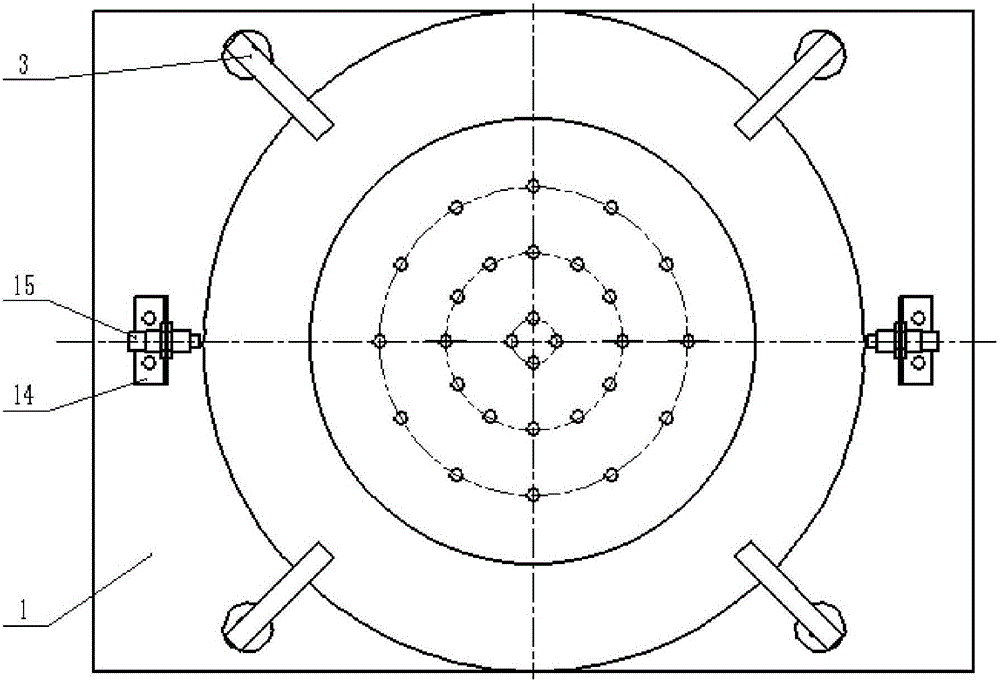

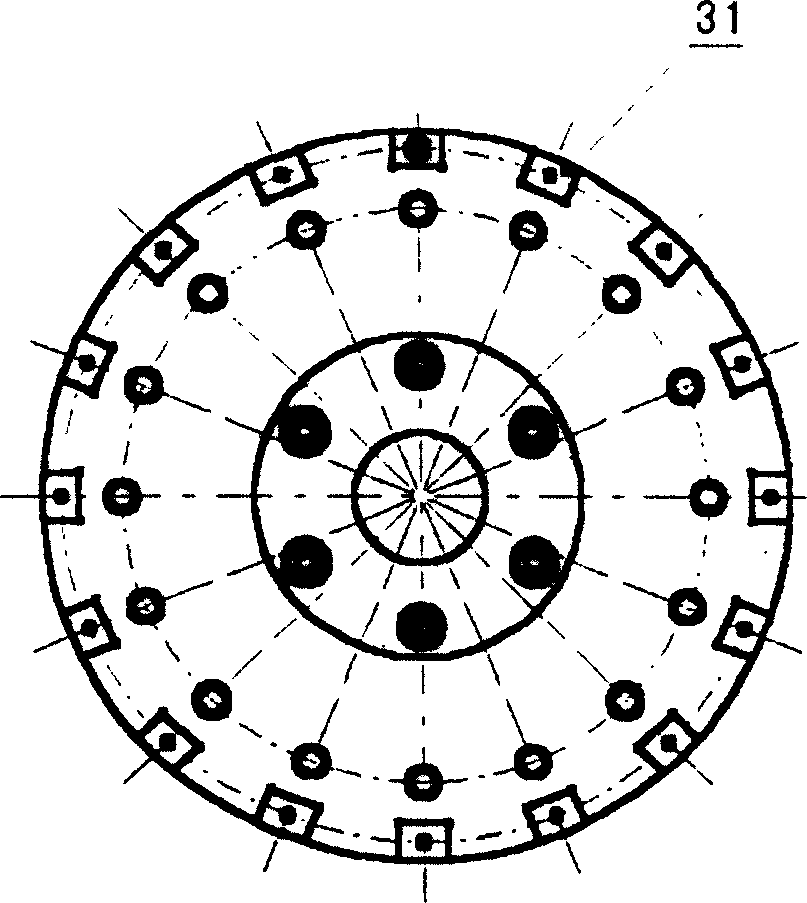

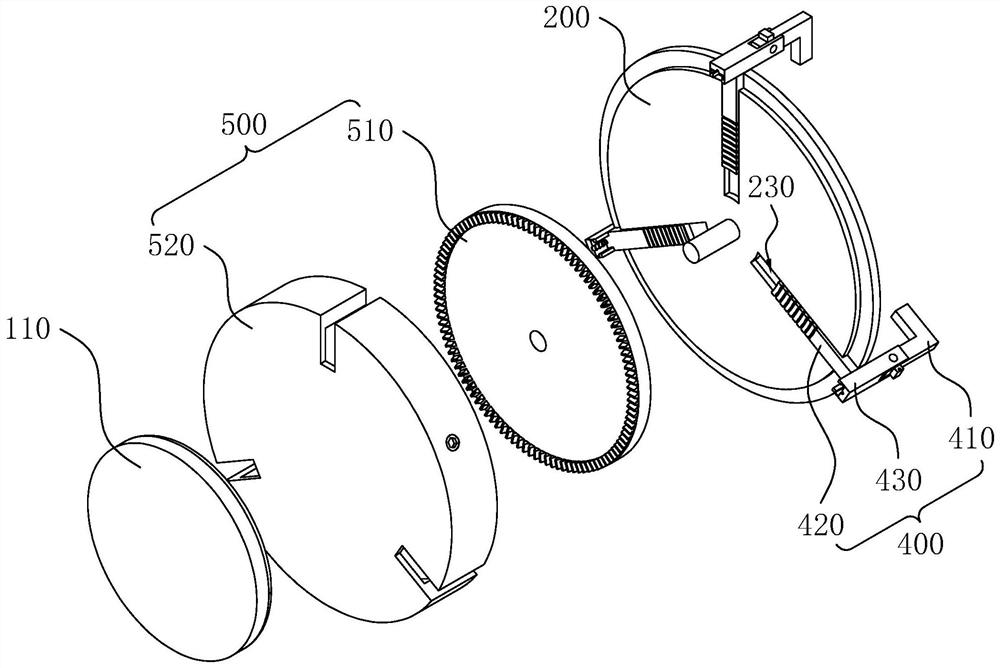

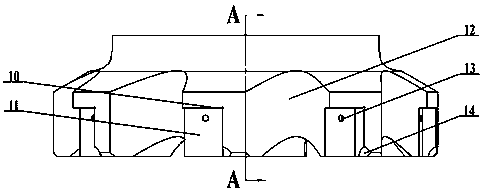

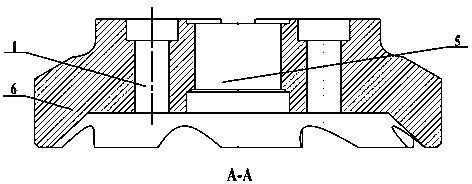

Thin-walled rotating member flange face drilling and milling fixture

ActiveCN108723814AReliable adjustmentReduce clamping errorsPositioning apparatusMetal-working holdersEngineeringSelf adaptive

The invention discloses a thin-walled rotating member flange face drilling and milling fixture. The thin-walled rotating member flange face drilling and milling fixture comprises a base, a plurality of support rods mounted on the base and a support ring mounted on the top ends of the multiple support rods. A self-adaptive height-adjusting structure for adjusting the supporting height and maintaining the height is arranged between the support ring and the support rods, so that the top surface of the support ring is tightly attached to the lower bottom surface of a ring flange of a thin-walled rotating member. The base is provided with a limiting structure for limiting the lower end position of the thin-walled rotating member, and the support ring is provided with an avoiding groove corresponding to a flange face notch to be processed of the thin-walled rotating member and die holes corresponding to hole series to be processed of the flange surface. The thin-walled rotating member flangeface drilling and milling fixture can design a reasonable fixture structure according to the processing characteristics of the flange face, and the operation of processing personnel is facilitated.

Owner:HUNAN UNIV

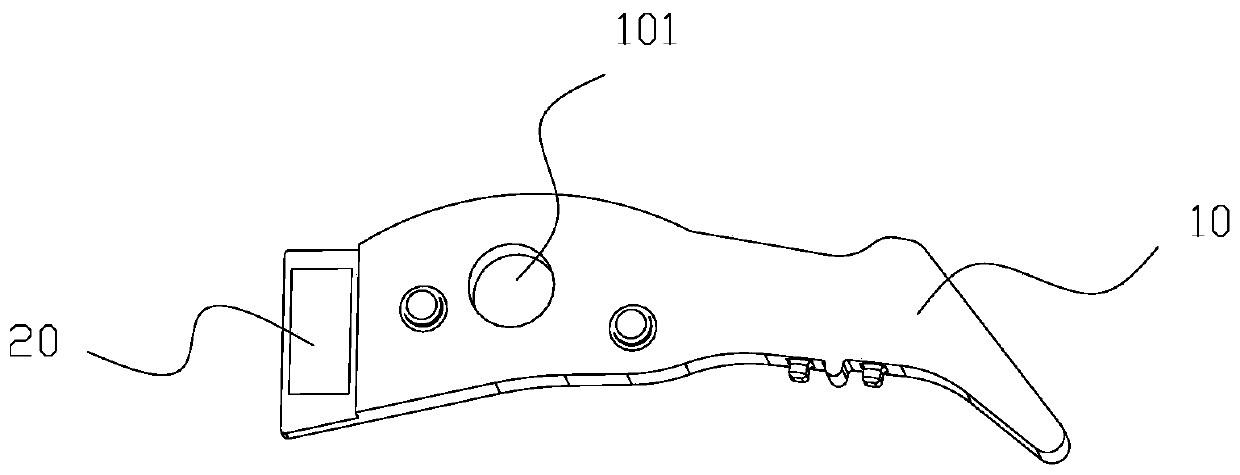

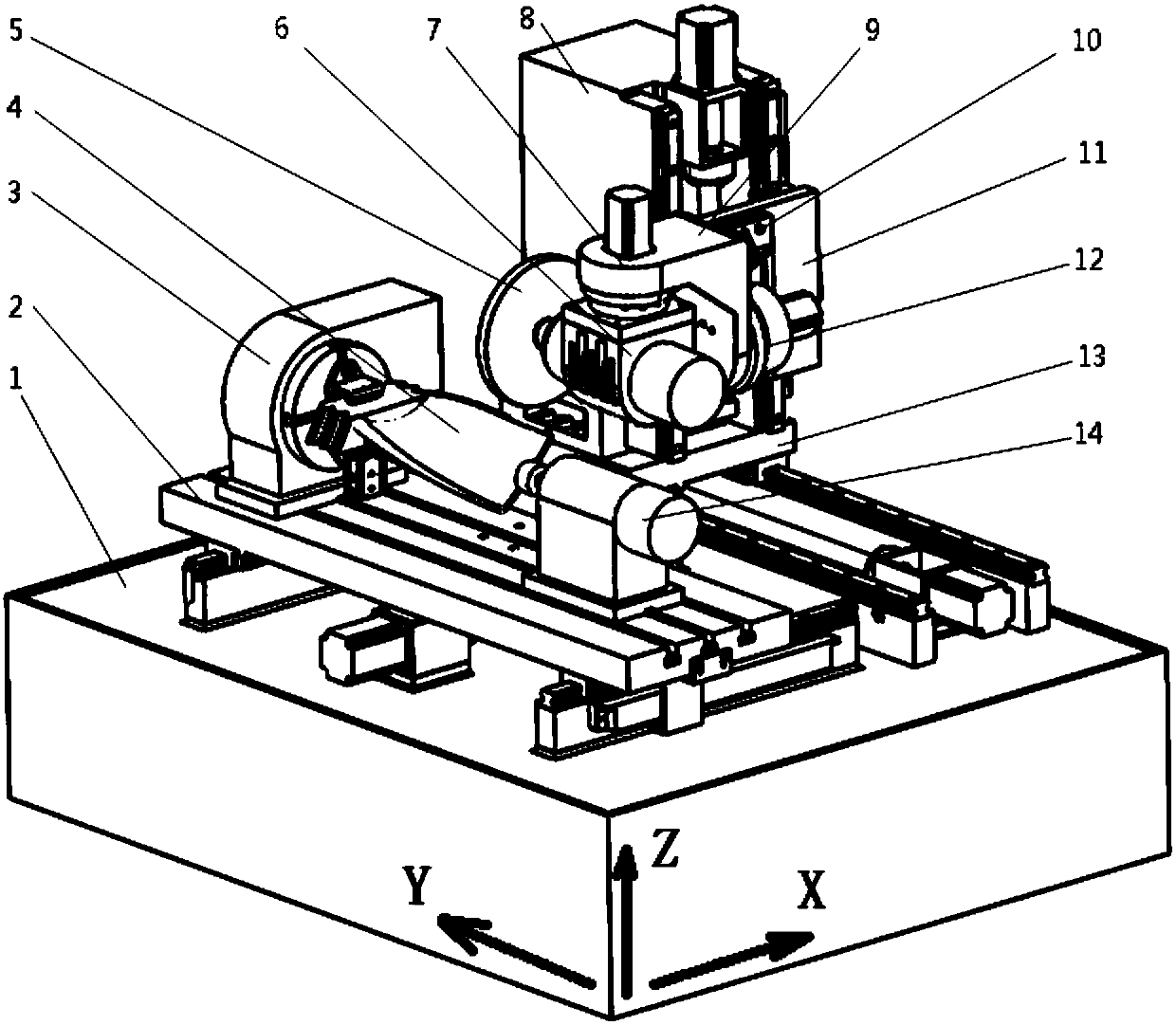

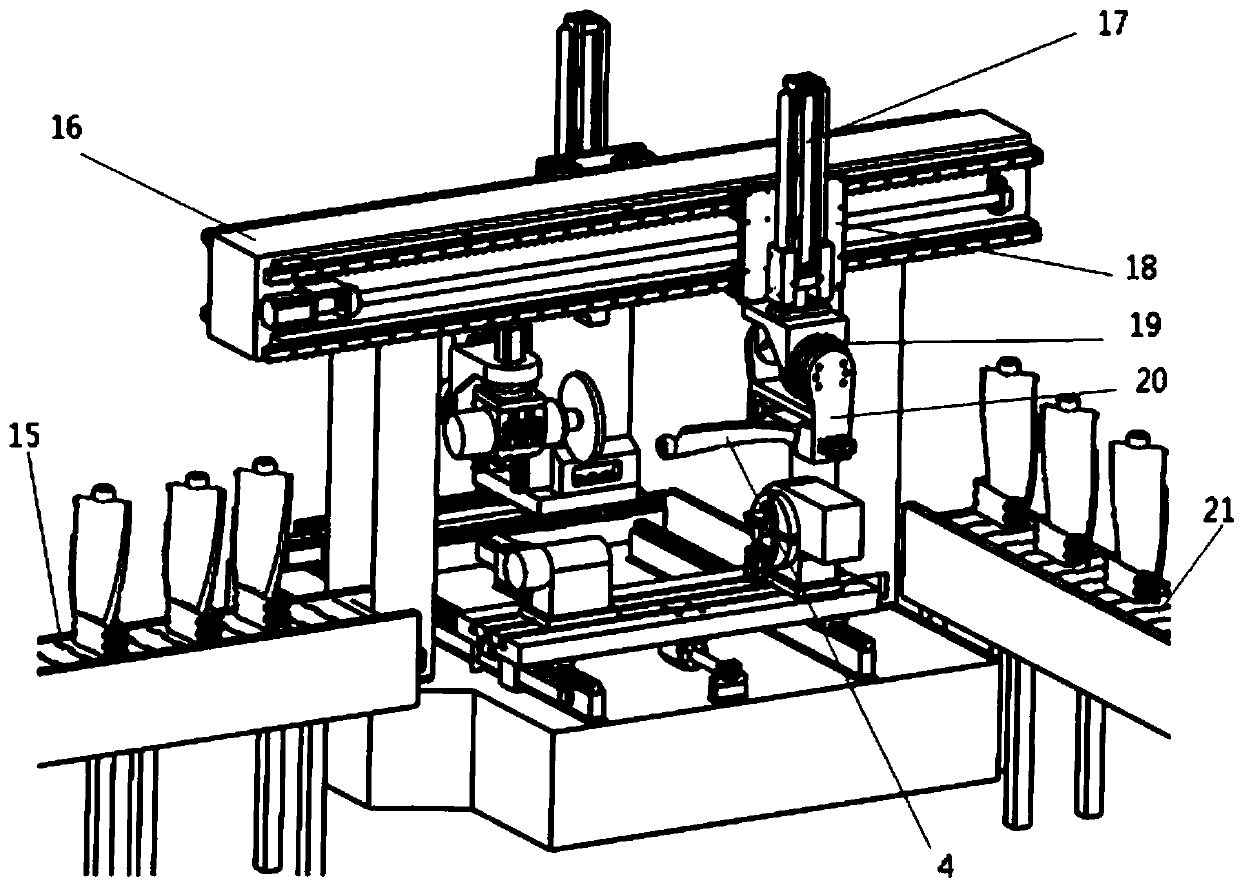

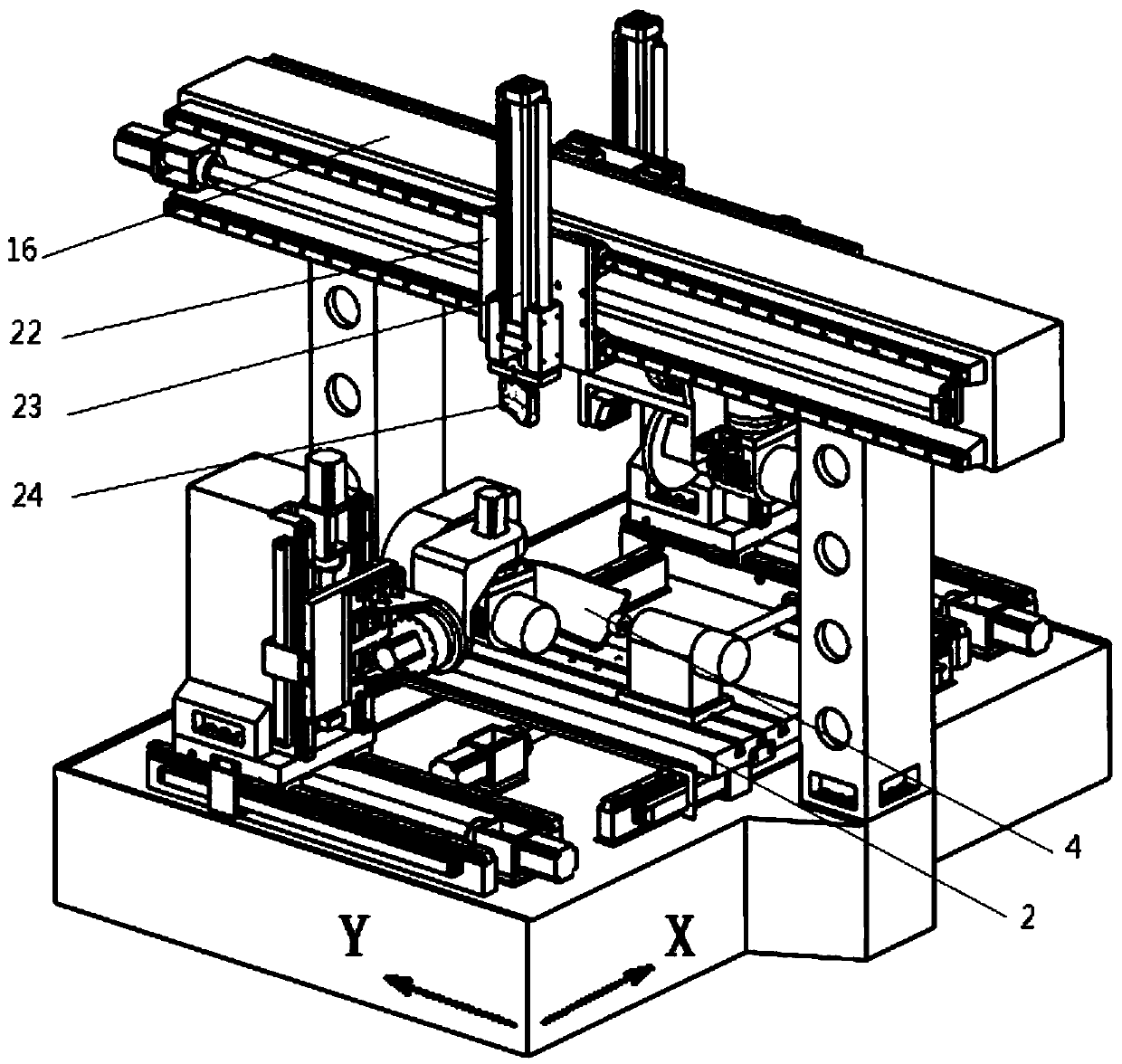

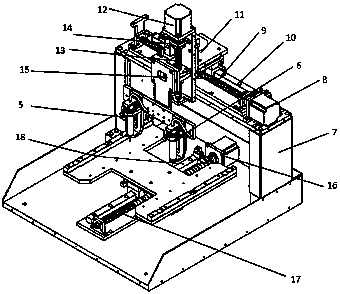

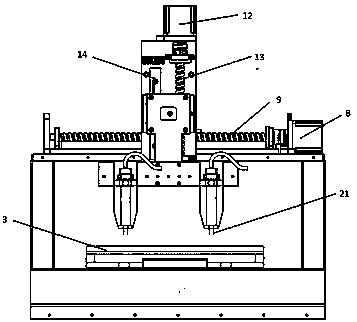

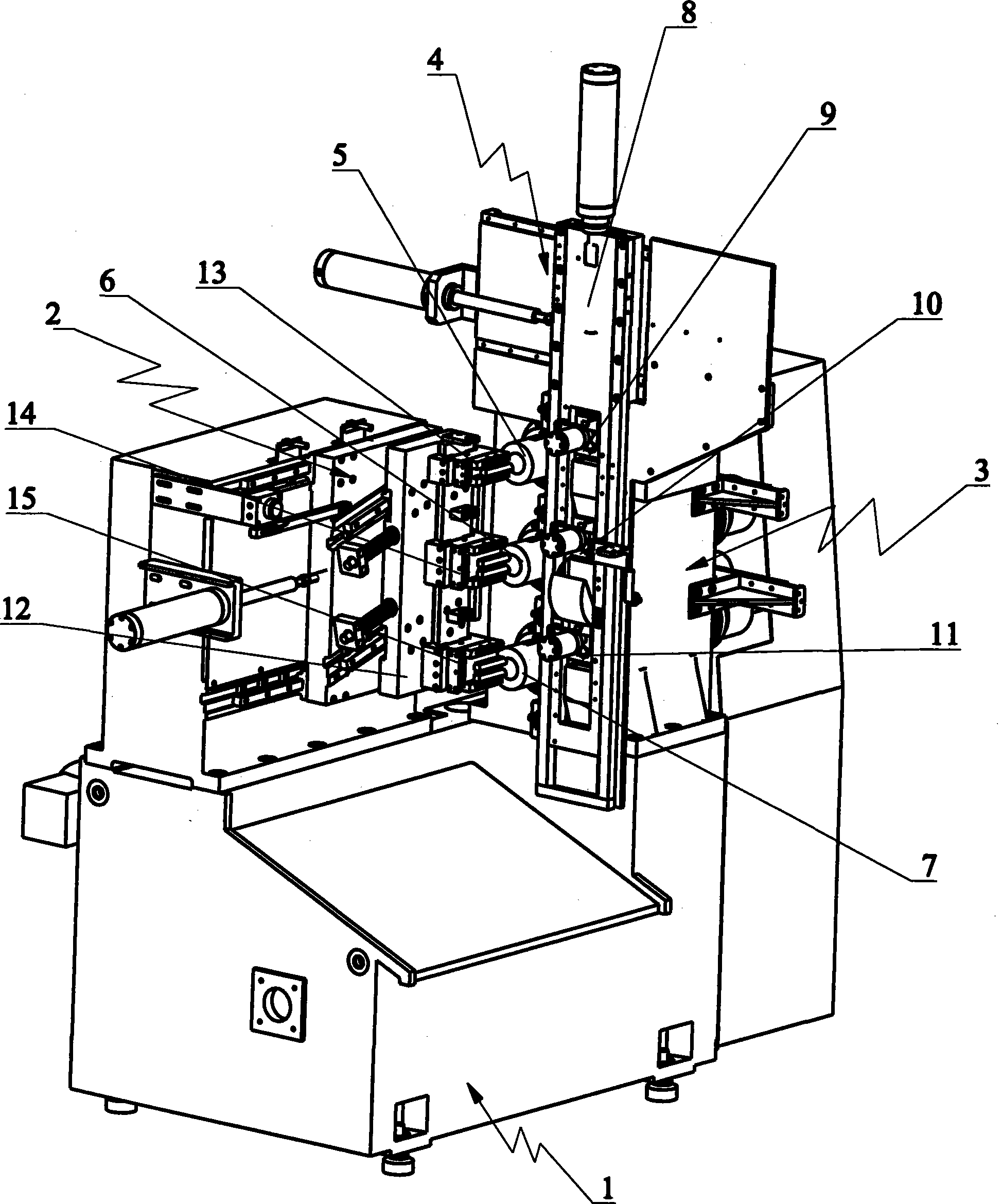

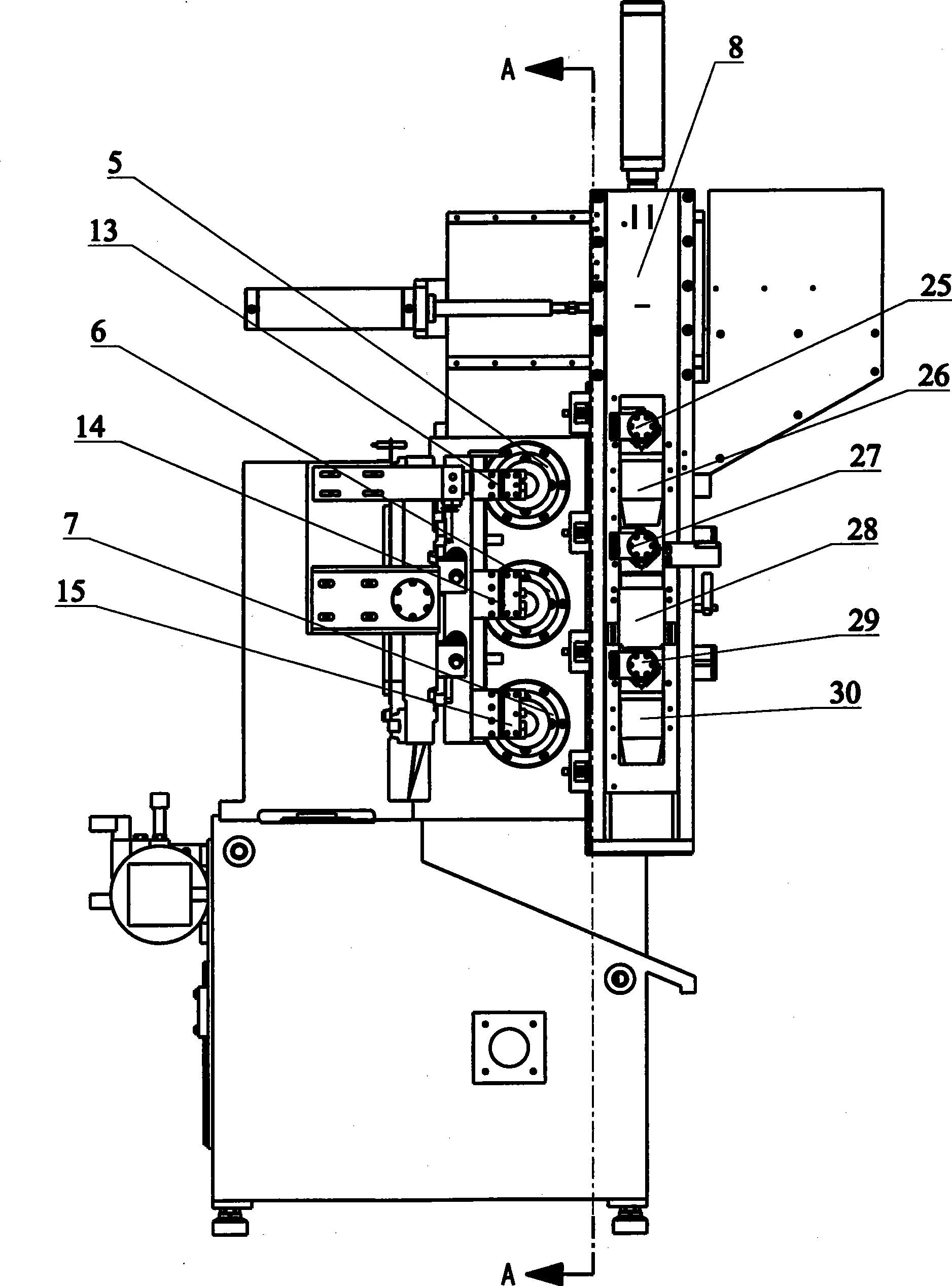

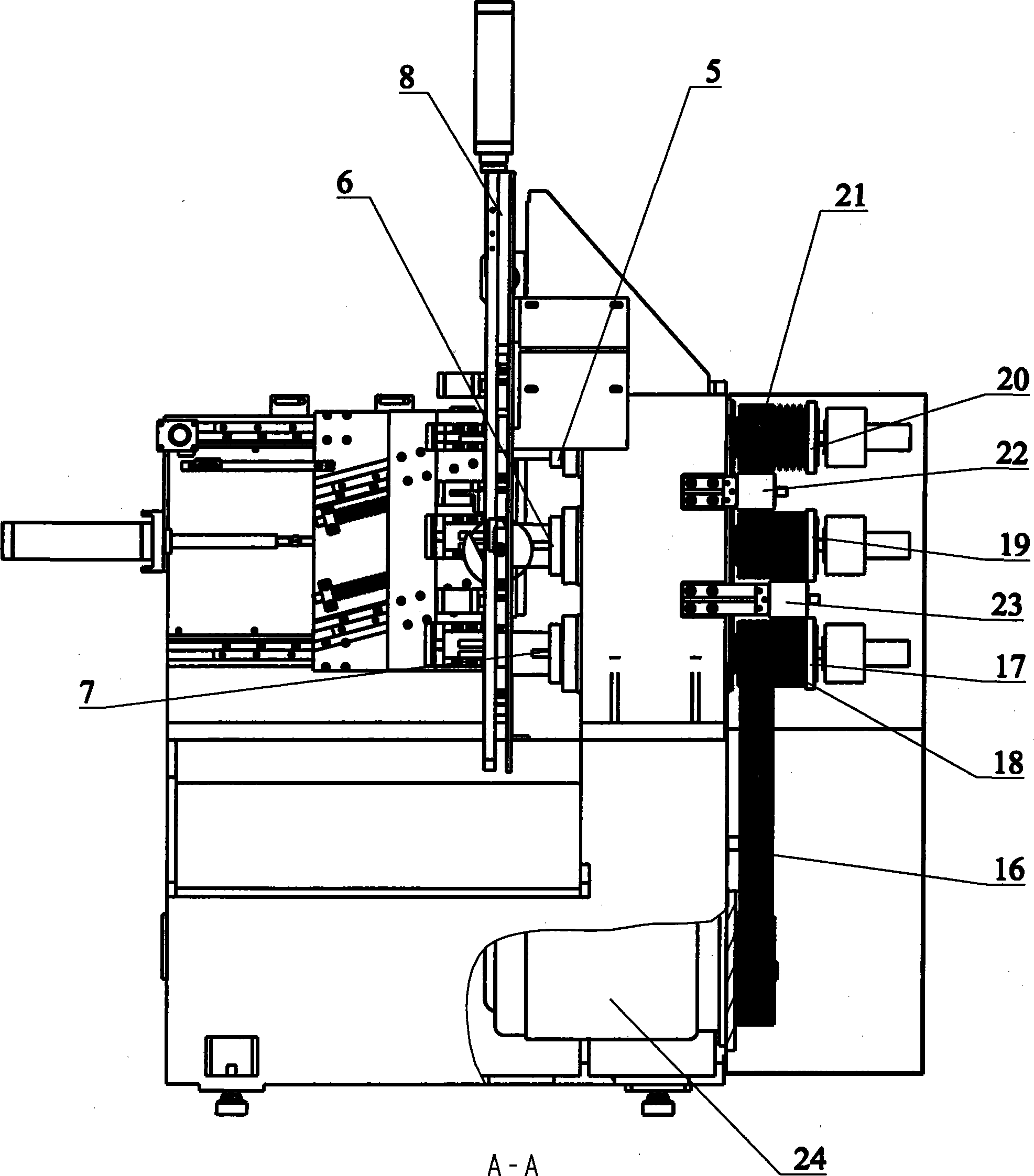

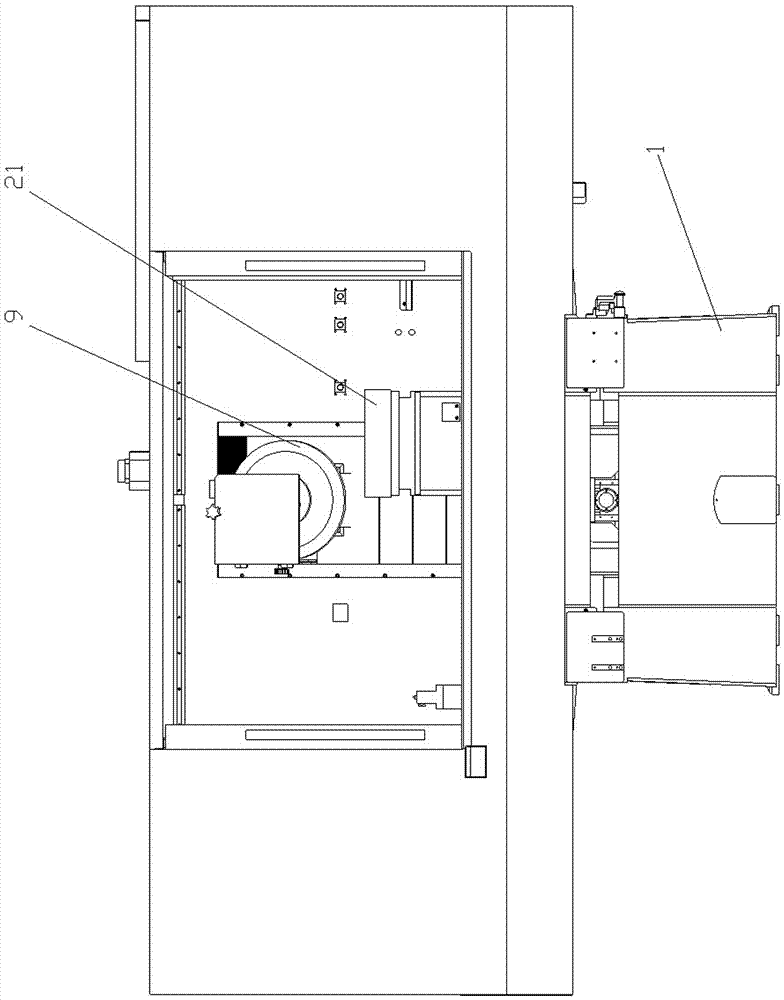

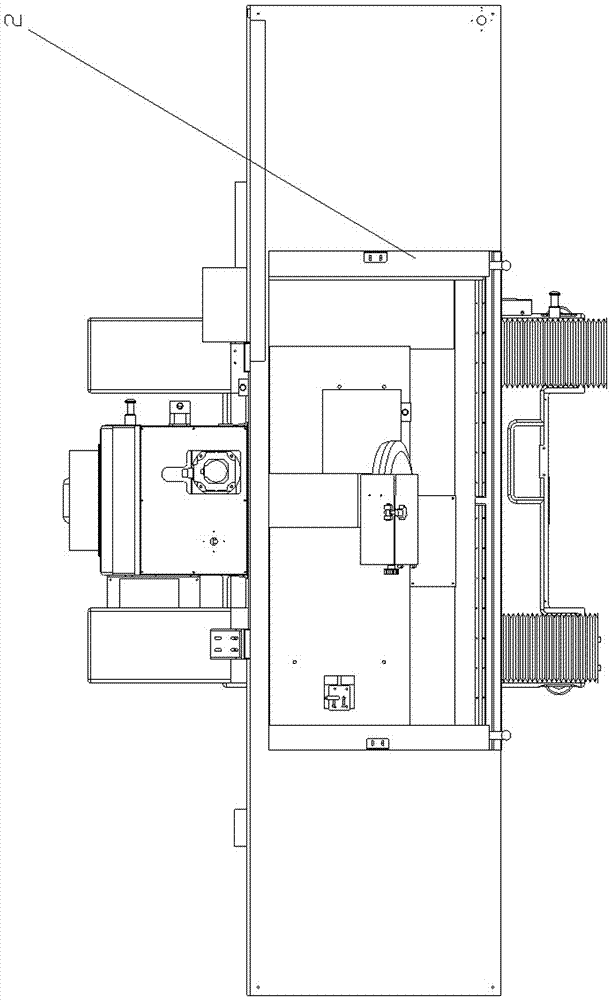

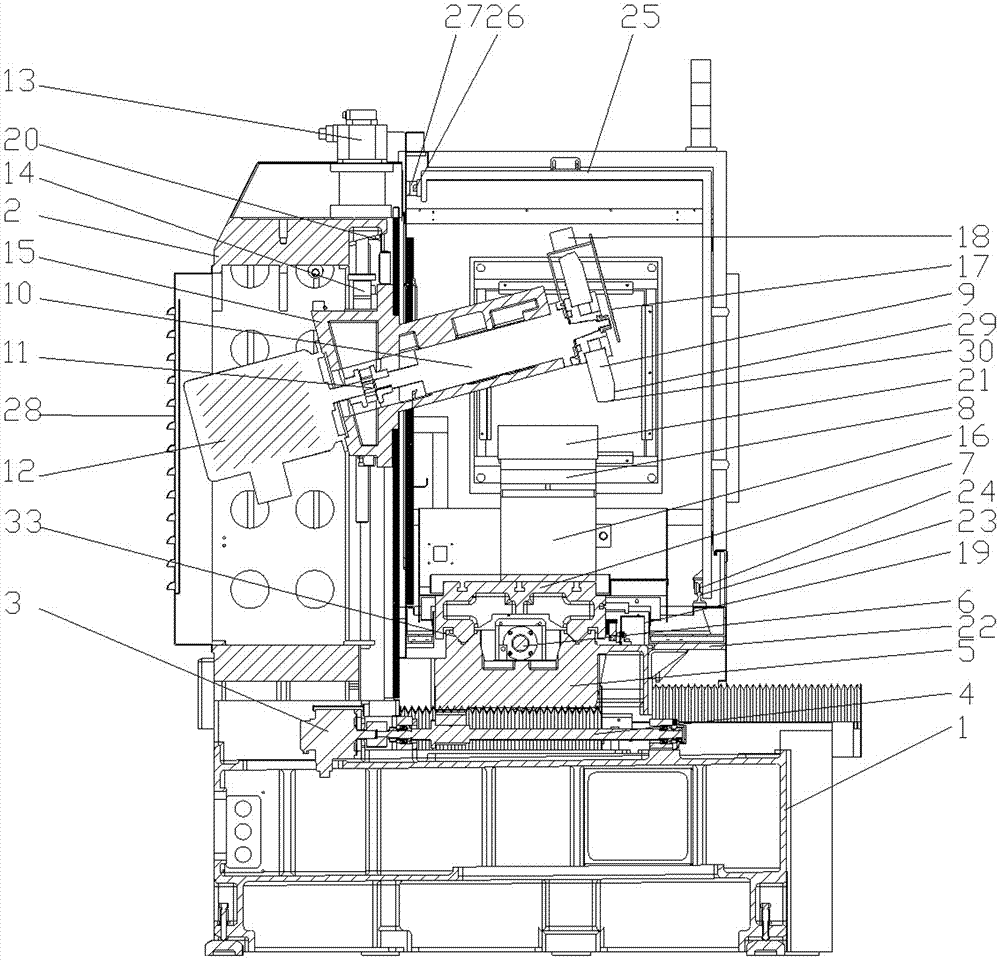

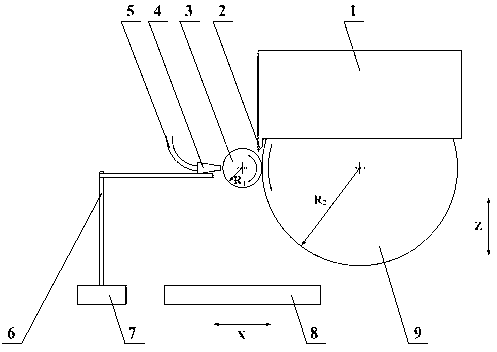

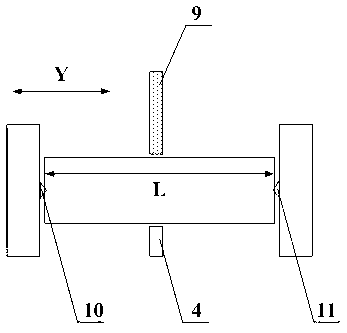

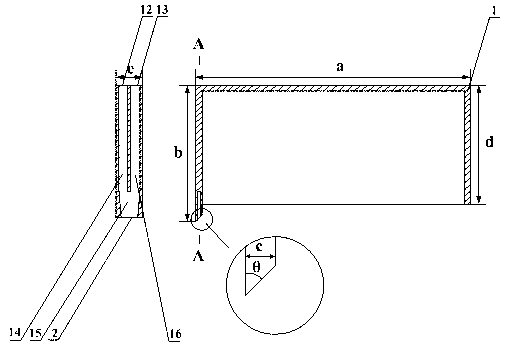

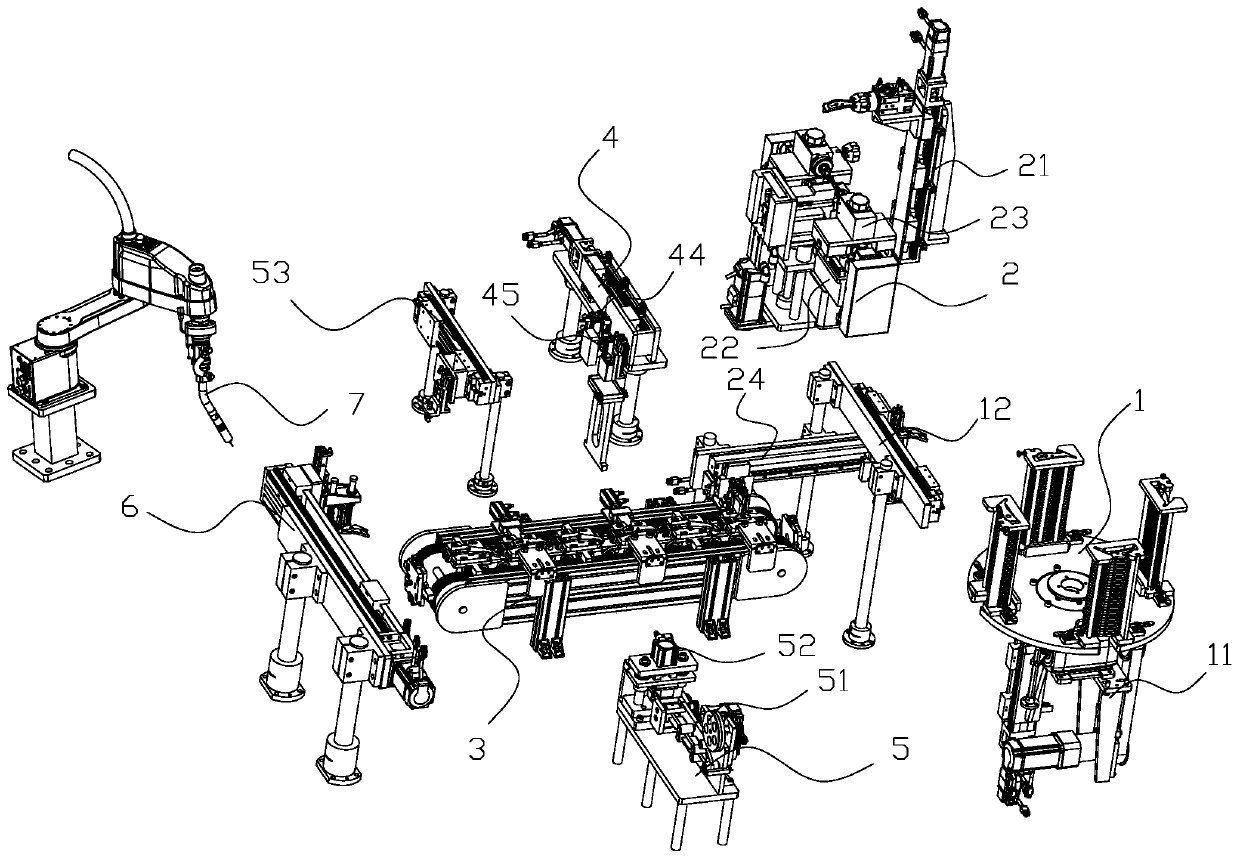

Blade processing machine tool integrating processing and detecting functions

ActiveCN109664111AImprove machine performanceImprove rigidityMeasurement/indication equipmentsOther manufacturing equipments/toolsSlide plateMachine tool

The invention discloses a blade processing machine tool integrating processing and detecting functions. The blade processing machine tool comprises a machine tool processing unit, an automatic feeding-discharging unit and an automatic detecting unit, wherein the machine tool processing unit structurally comprises a base; a longitudinal sliding rail and a transverse sliding rail are arranged on thebase; a workbench is arranged on the transverse sliding rail of the base; a horizontal rotating table is arranged on the workbench in the longitudinal direction; a sliding seat is arranged on the longitudinal sliding rail of the base; a vertical column is fixedly connected onto the sliding seat; a sliding plate is slidably arranged on the vertical column in the vertical direction; a support is fixedly mounted on the sliding plate; an electric spindle is mounted in the support through a double-joint mechanism; and a cutter is mounted at the front end of the electric spindle. The blade processing machine tool disclosed by the invention has the beneficial effects that through the double-station processing operation, the multi-procedure processing of workpieces under the condition of one-timeclamping can be achieved; not only can the processing efficiency be improved, but also the processing precision can be guaranteed; and the automatic feeding-discharging and the on-machine detecting of the workpieces can be achieved.

Owner:XIAN UNIV OF TECH

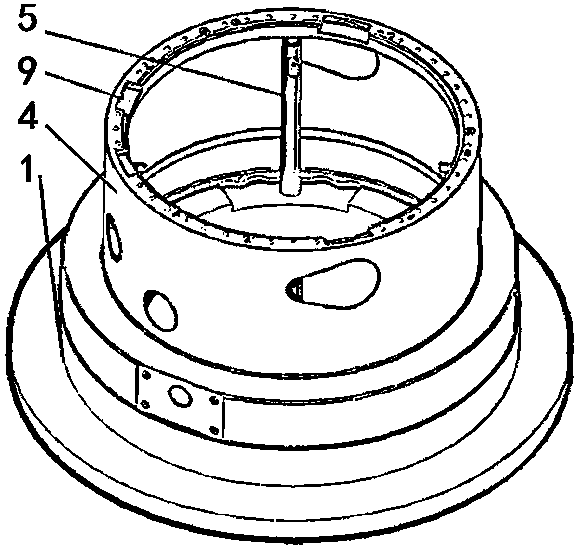

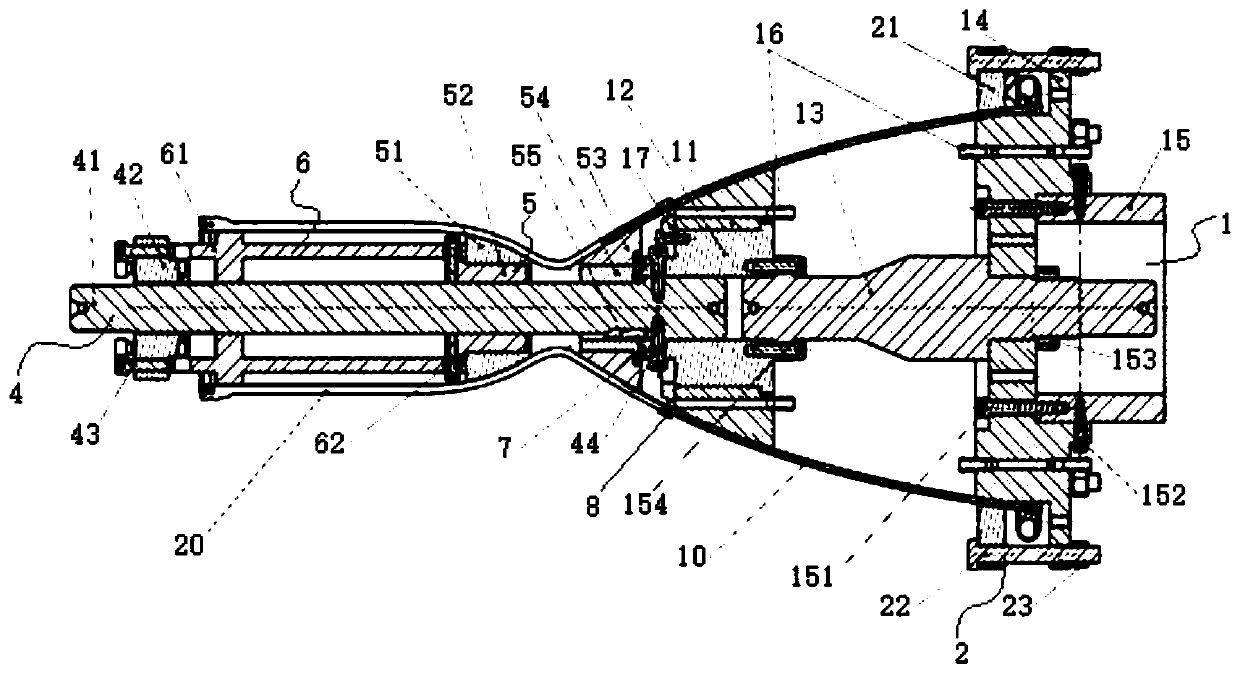

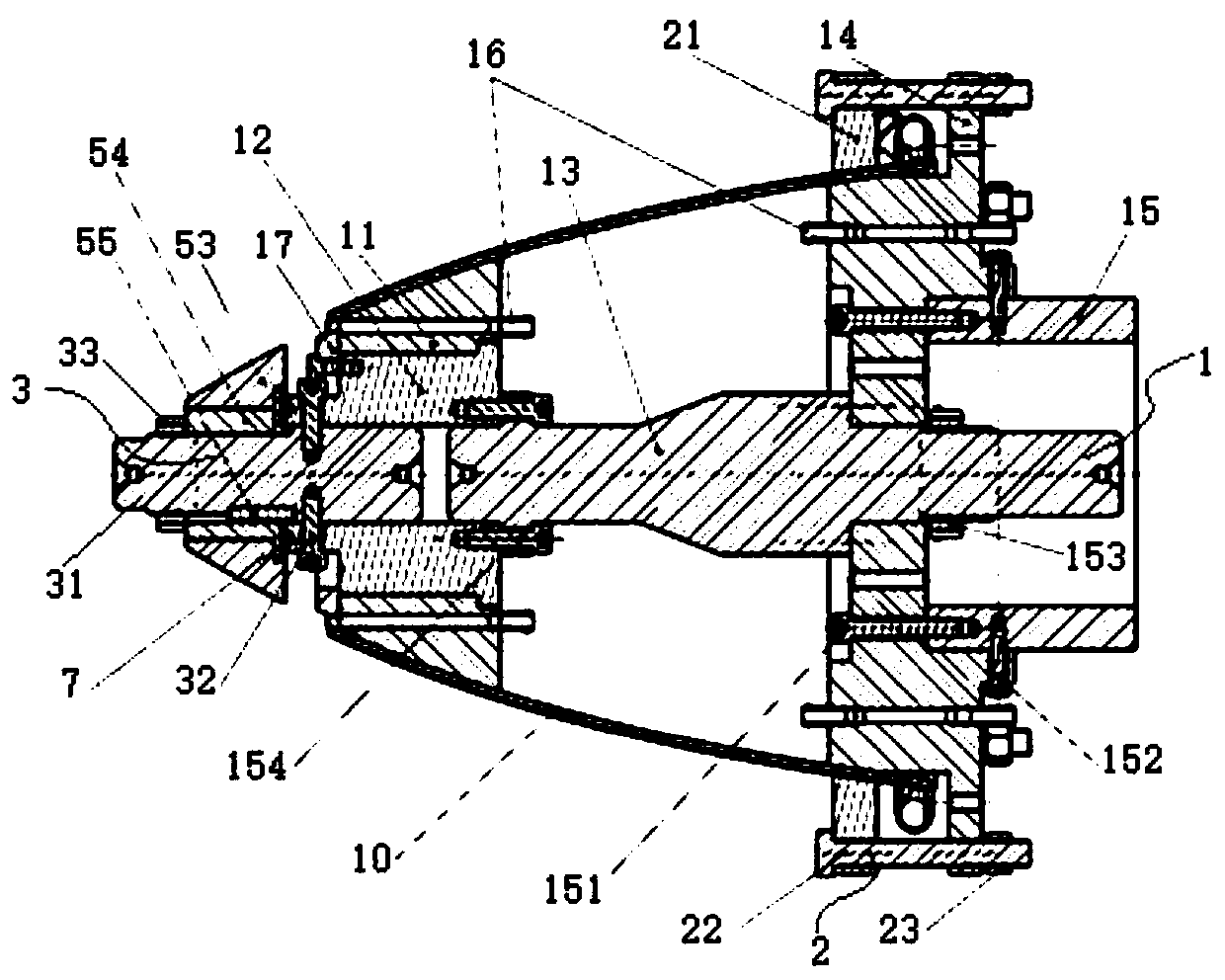

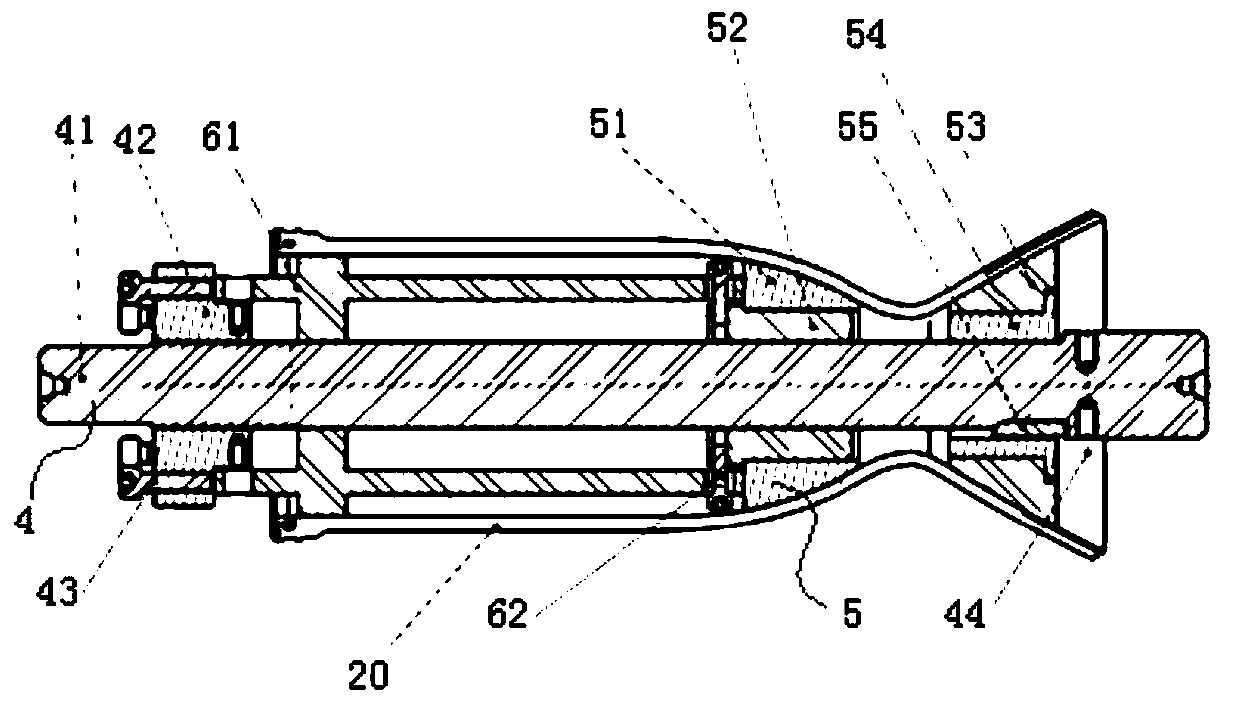

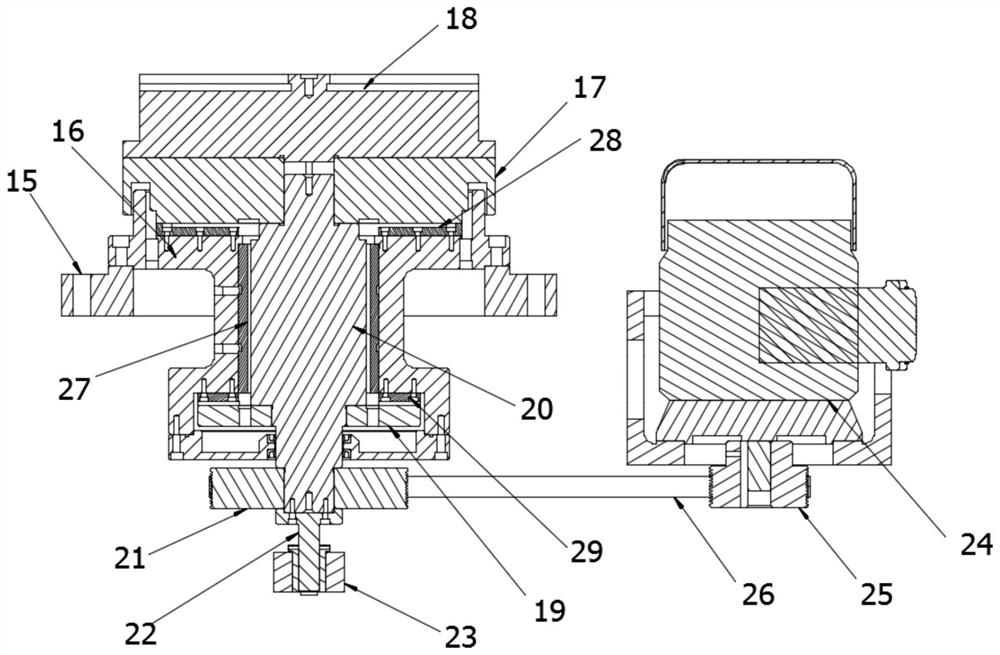

Combined tool for thrust chamber preparation process and thrust chamber preparation process

PendingCN110202320AEasy to weldFacilitate welding groove processingRocket engine plantsThrust chamberAerospace engineering

The invention provides a combined tool for a thrust chamber preparation process and the thrust chamber preparation process. The combined tool comprises a spray pipe section tool body and a body section tool body; the spray pipe section tool body comprises a spray pipe positioning assembly, a pressing ring assembly and a short shaft assembly; the body section tool body comprises a body shaft assembly, a pressing block assembly and a force transmission assembly; in a spray pipe short shaft state, the spray pipe positioning assembly, the pressing ring assembly and the short shaft assembly cooperate for use, and thus a thrust chamber spray pipe is positioned and clamped; in a body shaft state, the body shaft assembly, the pressing block assembly and the force transmission assembly cooperate for use, and a thrust chamber body is positioned and clamped; and in a spray pipe short shaft state, the spray pipe positioning assembly, the pressing ring assembly, the body shaft assembly, the pressing block assembly and the force transmission assembly cooperate for use, and thus the thrust chamber body and the thrust chamber spray pipe are positioned and clamped in a whole. By means of the combined tool for the thrust chamber preparation process and the thrust chamber preparation process, the number of single tools can be greatly reduced, floor occupation and management of multiple single tools are reduced, and the production cost of thrust chambers is reduced.

Owner:LANDSPACE TECH HUZHOU CO LTD

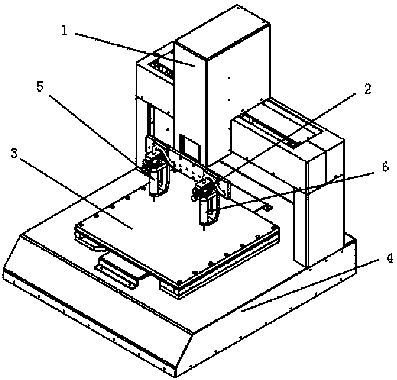

Multifunctional COB (chip on board) automatic dispenser

PendingCN107790336AReduce the number of clampingReduce clamping errorsLiquid surface applicatorsCoatingsOn boardElectric machinery

The invention discloses a multifunctional COB (chip on board ) automatic dispenser comprising a dispensing controller and two multifunctional dispensing heads. The multifunctional COB automatic dispenser is characterized in that a fixture table is mounted on the dispensing controller which is provided with a bracket; an X-axis movement mechanism installed with a Z-axis movement mechanism is arranged on the bracket; the Z-axis movement mechanism is provided with a lifting skateboard; the two multifunctional dispensing heads are all mounted on the lifting skateboard; the X-axis movement mechanism comprises an X-axis motor, an X-axis screw rod and an X-axis guide rail; the X-axis motor is arranged on one side of the bracket; the X-axis screw rod is in parallel arrangement with the X-axis guide rail which is provided with a moving flange; the moving flange is fixedly connected with the X-axis screw rod; the X-axis screw rod is connected with the X-axis motor. The multifunctional COB automatic dispenser has the advantages of realizing the multifunctional work of the dispenser, guaranteeing the spraying of glue and phosphor to be completed in the same device, reducing installation time and improving dispensing efficiency.

Owner:深圳市佳思特光电设备有限公司

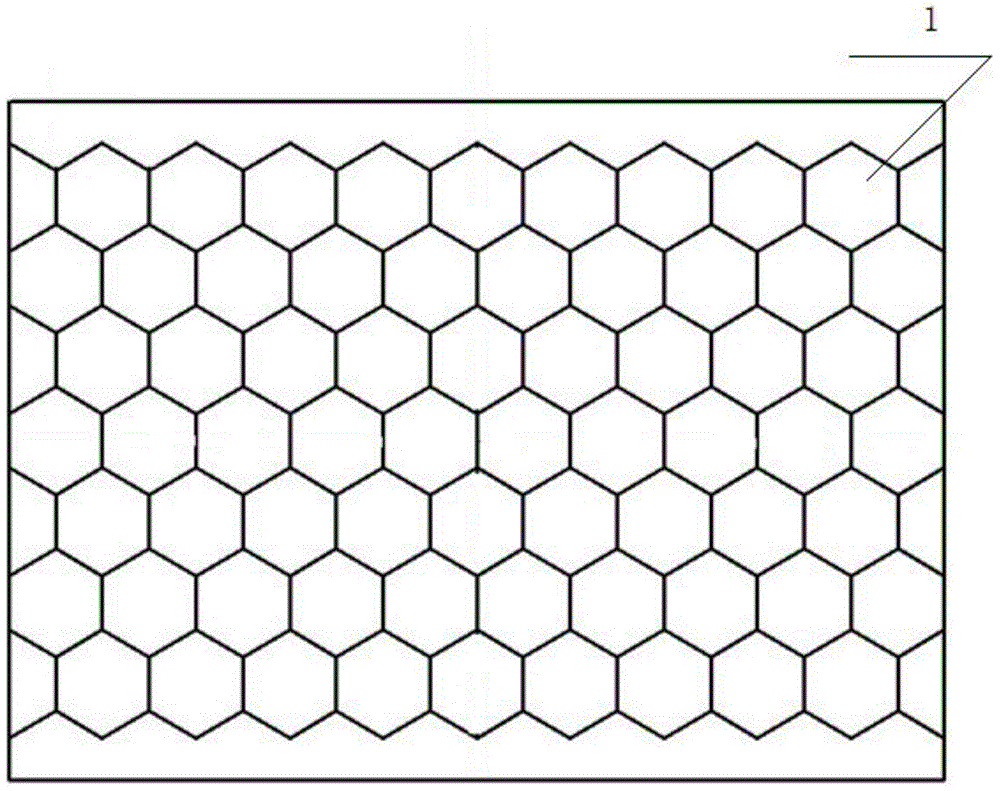

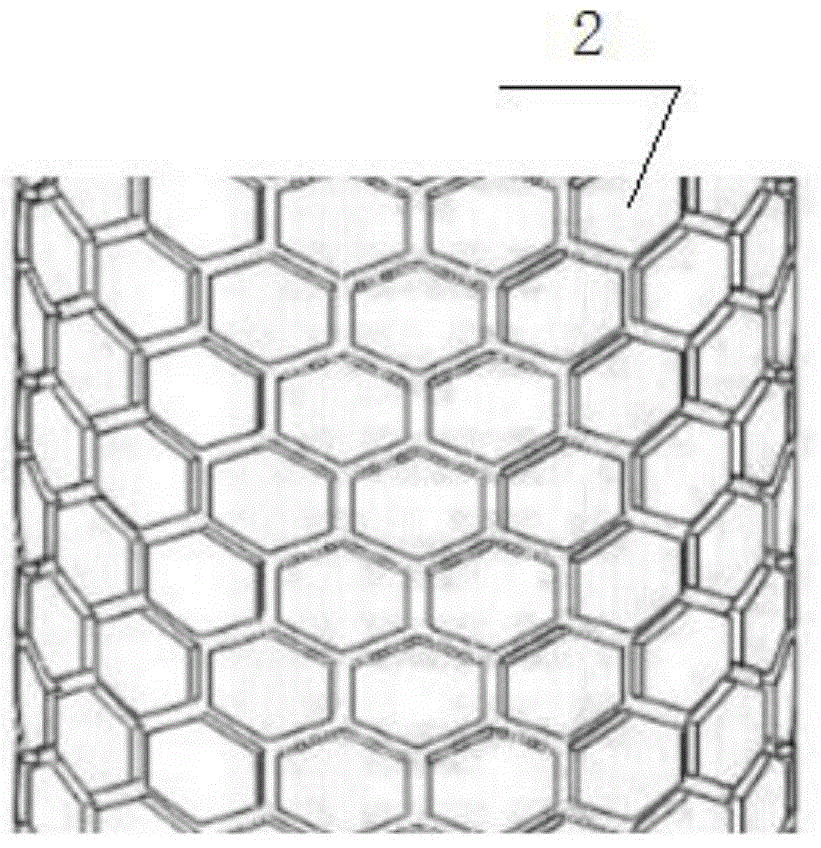

Lubricating and sealing method of hexagonal bionic texture of reciprocating column casing structure

The invention discloses a lubricating and sealing method of a hexagonal bionic texture of reciprocating column casing structure, which belongs to the technical field of bionic metal surface project. The method comprises the following steps of: processing the shape of the bar blank of a No.45 steel on a lathe, clamping one end of the bar blank on a three-jaw chuck of the lathe, starting the lathe, and then lathing the bar blank; according to the program of tool walking routes of a numerical control milling machine for mechanically processing, mechanically processing the No.45 steel of which shape is processed, and then obtaining the texture of the No.45 steel of which surface is in a regular hexagonal shape; adopting an ordinary quenching and insulating process to quench at 840 DEG C, and insulating for half an hour; after water quenching, tempering to 280 DEG C, and insulating for one hour, so as to meet the hardness requirement. The invention adopts the bionic technology to process the hexagonal texture on the surfaces of parts of the column cylinder structures, such as pistons, plungers and pump cylinders, so that the sealing performance is ensured while the lubrication effect is increased, and finally friction is reduced and efficiency of pump is improved.

Owner:JILIN UNIV

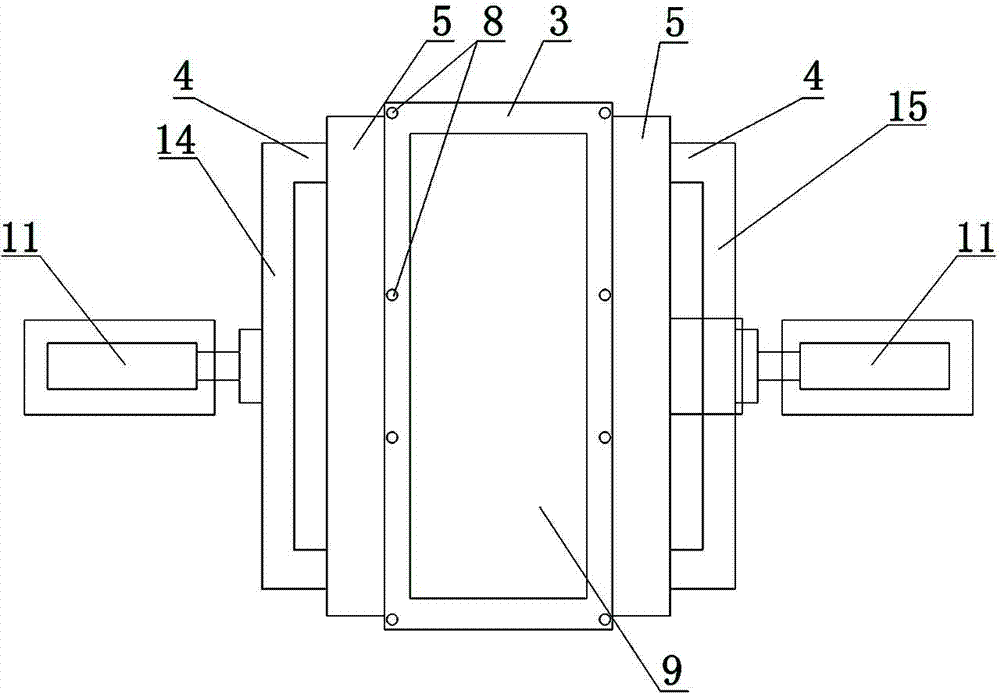

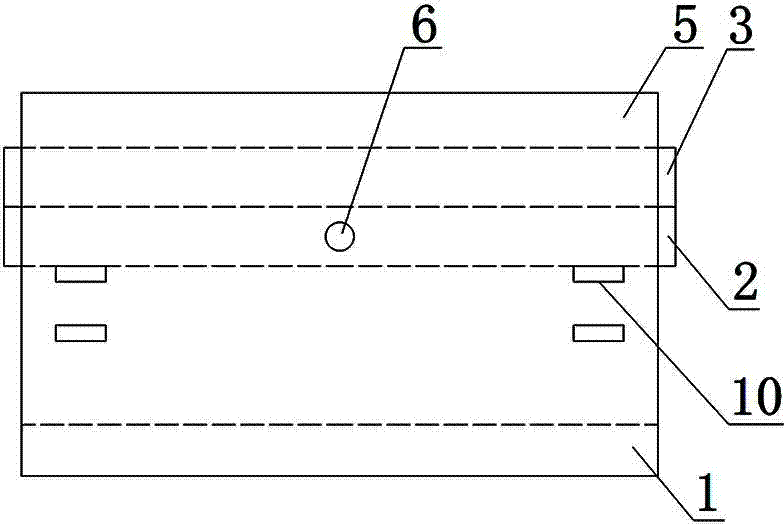

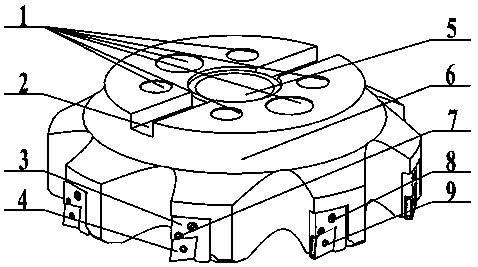

Automatic turning clamp saving space

ActiveCN103894850ARealize automatic rotation positioningAvoid pinchingWork clamping meansPositioning apparatusTurning framesAutonomation

The invention discloses an automatic turning clamp saving space. The automatic turning clamp comprises a supporting base (1), a turning frame (2), a pressing frame (3), supporting boards (4), an upper driving air cylinder (11), a lower driving air cylinder (12) and a rotary motor (13), wherein the turning frame (2) is rotationally arranged in shaft holes of supporting boards (5) of the supporting boards (4), the pressing frame (3) is arranged on the upper surface of the turning frame (2), each supporting board (4) is arranged in one through hole (10), the tail ends of the supporting boards (4) located on the same supporting board at the same height are connected into a whole through connection boards which are connected with the driving air cylinders respectively, and an output shaft of the rotary motor (13) is in transmission connection with a rotary shaft (6). The automatic turning clamp has the advantages of being simple in structure and convenient to operate, can be used for machining two surfaces of a workpiece, improve machining efficiency, and achieve automatic rotary locating of the clamped workpiece, and is high in automatic degree.

Owner:TAICANG DENASEN MECHANICAL & ELECTRICAL ENG CO LTD

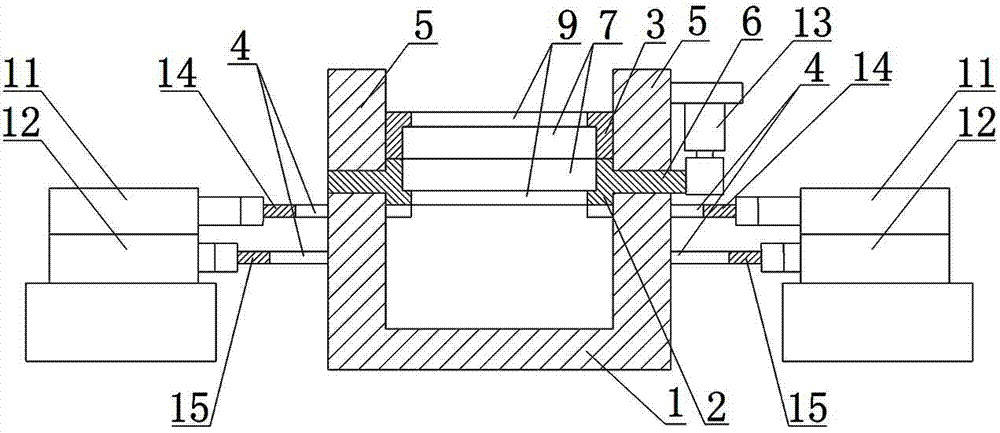

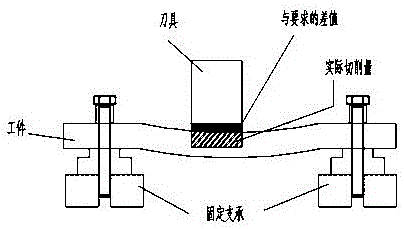

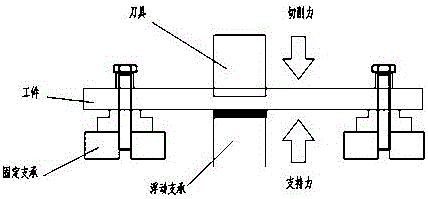

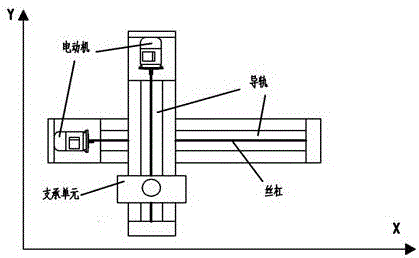

Design method for numerical control milling intelligent clamp for thin-wall structural piece

InactiveCN105904271AAccuracy is not affectedEven by forceAutomatic control devicesFeeding apparatusNumerical controlEngineering

The invention discloses a design method for a numerical control milling intelligent clamp for a thin-wall structural piece. The design method is characterized in that firstly, an X-Y direction translation motion structure comprises an X-direction feed structure and a Y-direction feed structure; secondly, a support unit structure comprises a Z-direction supporting structure and a contact unit structure of the Z-direction supporting structure; thirdly, a clamp overall structure comprises a clamp base; and fourthly, an intelligent clamp system comprises a computer for obtaining the feed path and conducting storage and analysis and a displacement sensor arranged below a workpiece and used for obtaining and recording the initial position of the workpiece before machining. The design method has the advantages that a support manner with fixed supports as an auxiliary part and movable floating supports as a main part is adopted, the fixed supports are located on the periphery of the workpiece, and after machining is finished, parts deforming due to fixed clamping can be removed, and the precision of a component is not affected. During initial clamping, due to the joint action of the fixed supports and the floating supports, the workpiece is stressed evenly, unnecessary residual stress is prevented from being generated, accordingly, the clamping error is reduced, and the machining precision is improved.

Owner:SHENYANG AEROSPACE UNIVERSITY

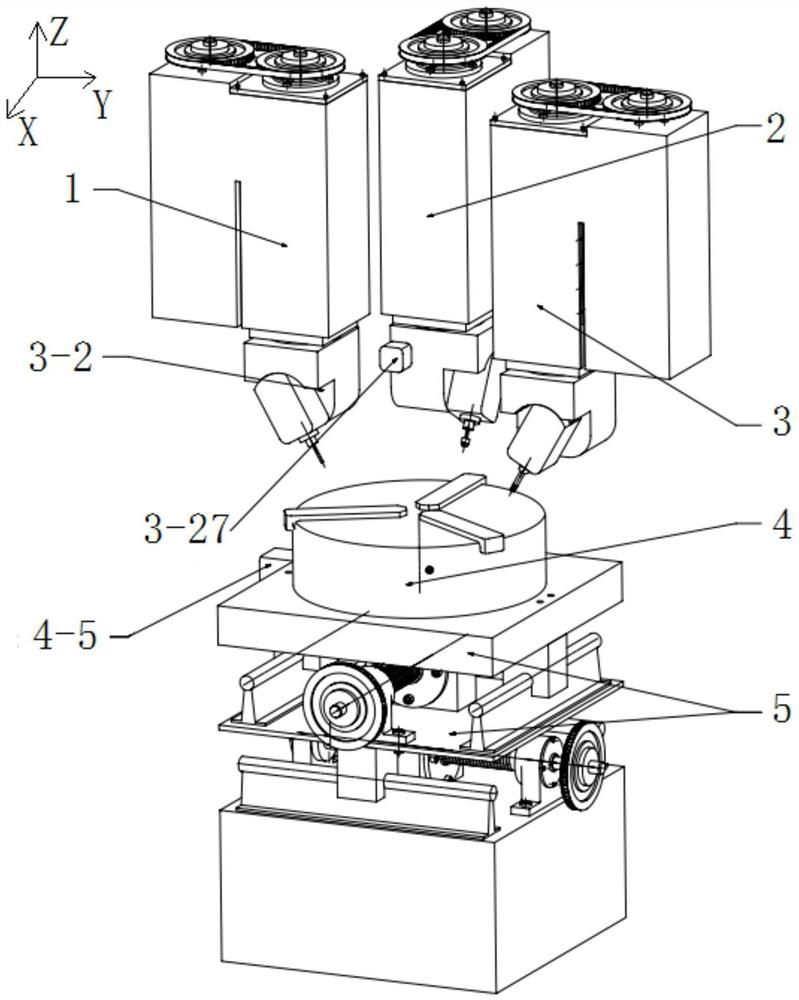

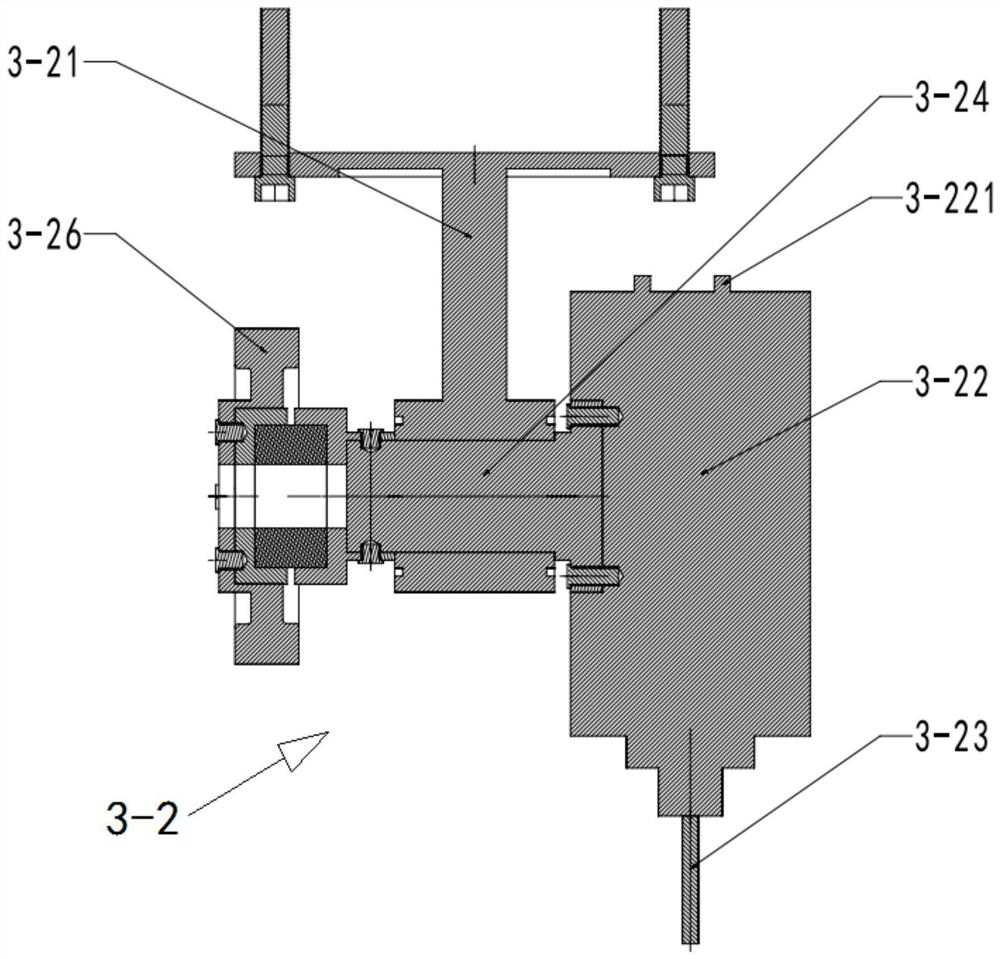

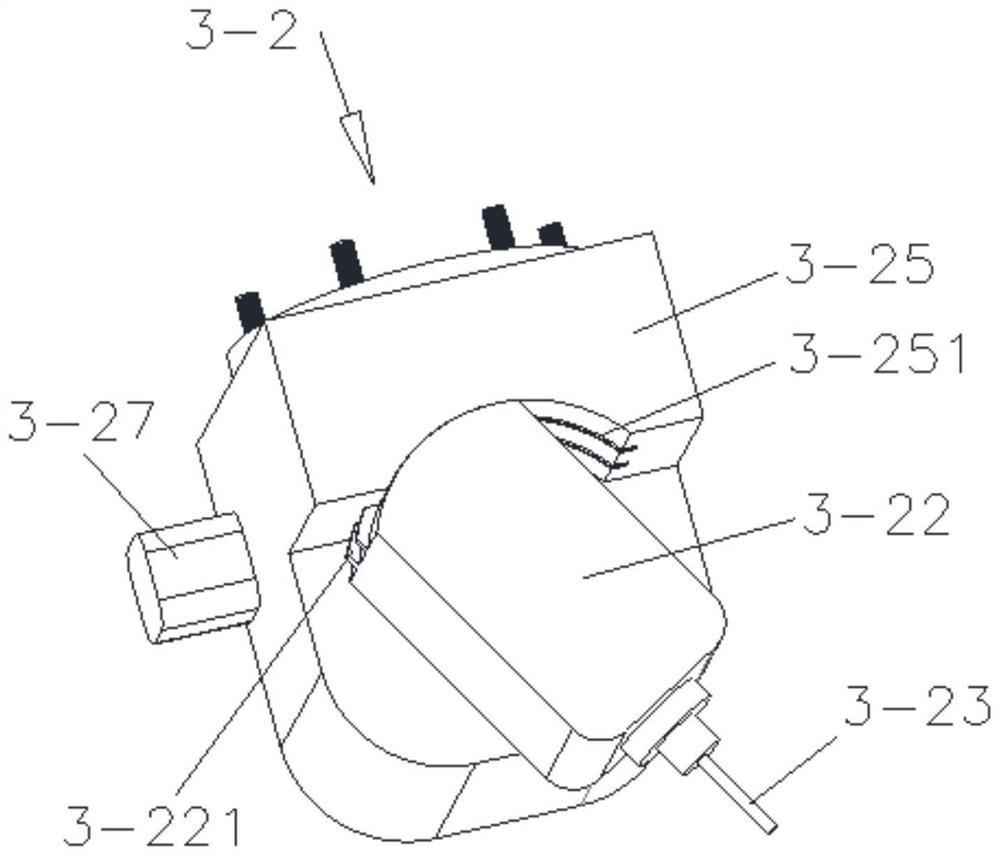

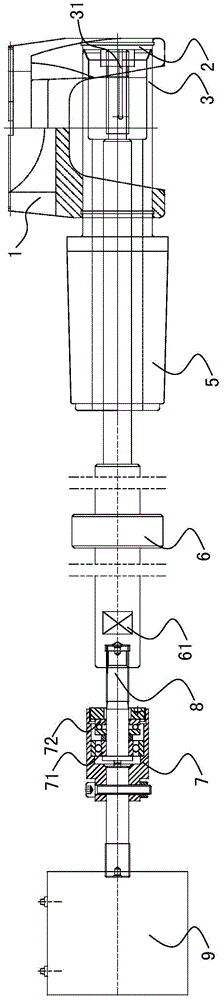

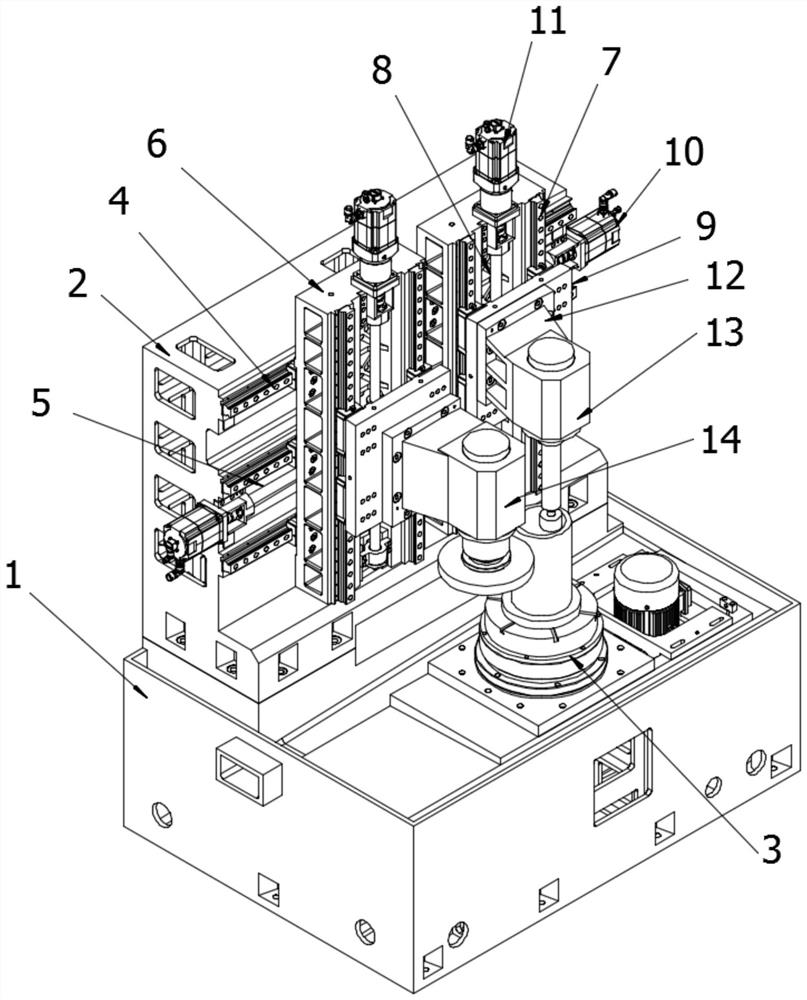

Multi-station multi-angle electrosparking device and method

PendingCN111889828ARealize multi-angle complex processingReduce processing timeElectrical-based auxillary apparatusEngineeringWorkbench

The invention belongs to the technical field of electrospark forming machining, and particularly relates to a multi-station multi-angle electrosparking device. The multi-station multi-angle electrosparking device comprises a first spindle mechanism, a second spindle mechanism, a third spindle mechanism, a rotary workbench and a sliding table mechanism. The first spindle mechanism, the second spindle mechanism and the third spindle mechanism have the same structure and comprise spindle assemblies and spindle biasing assemblies. The spindle biasing assemblies comprise rotary supporting seats, electrode chucks and tool electrodes. The tool electrodes are fixedly arranged on the electrode chucks, the electrode chucks are rotationally arranged on the rotary supporting seats through rotary shafts, and the rotary axes of the electrode chucks are located in an X-Y plane. The first spindle mechanism, the second spindle mechanism and the third spindle mechanism are sequentially distributed around the circumference of the Z axis, the sliding table mechanism is used for driving the rotary workbench to move in the X-axis direction and the Y-axis direction, the rotary axis of the rotary workbench faces the Z axis, the tool electrodes face the rotary workbench, and the rotary supporting seats and the spindle assemblies are slidingly connected in the Z-axis direction.

Owner:HEFEI UNIV OF TECH +1

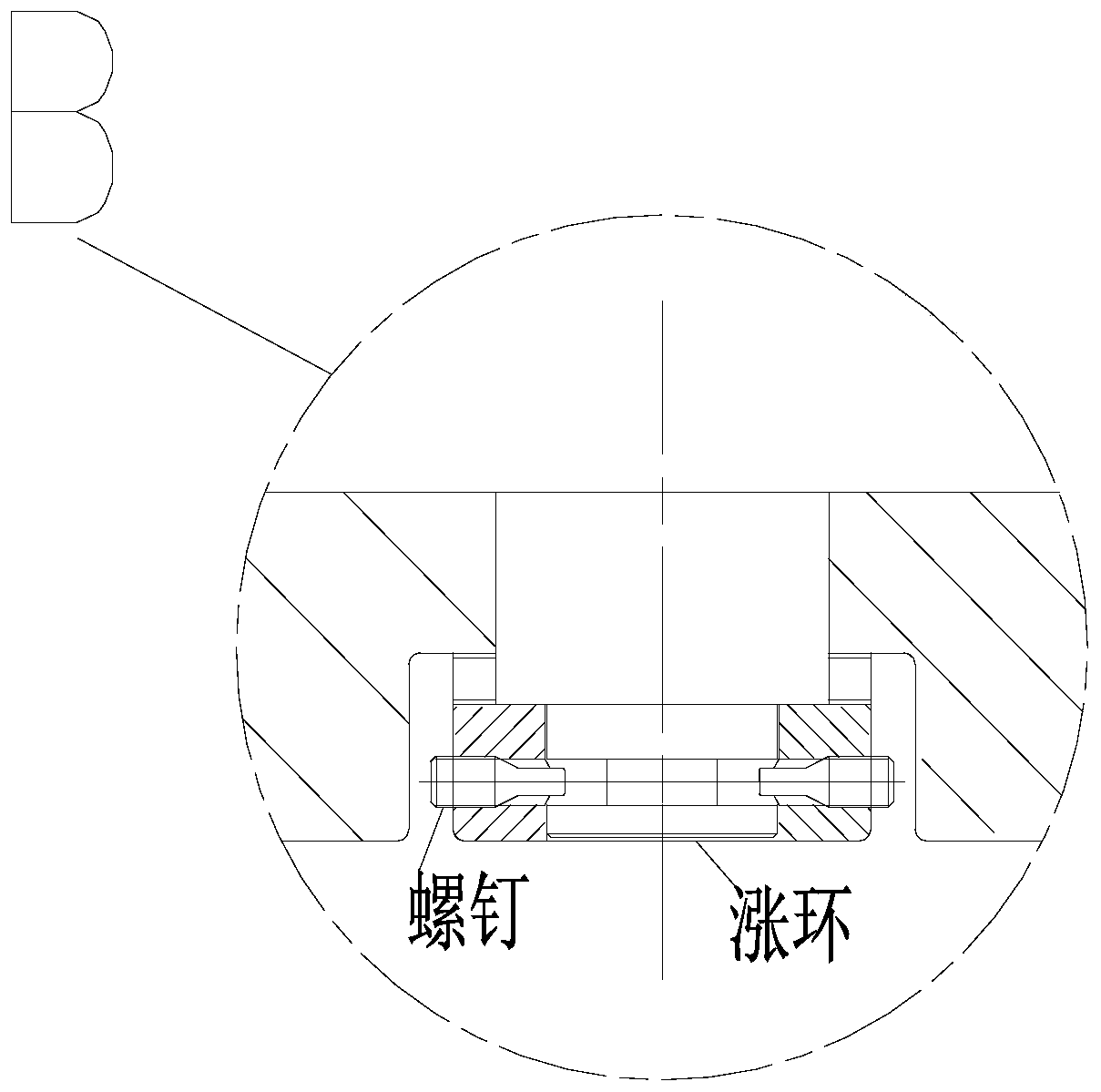

Positioning device for grooving of end tooth flange fork

The invention discloses a positioning device for grooving of an end tooth flange fork. The positioning device comprises an expansion mandril corresponding to a lug hole of the end tooth flange fork to be machined; the expansion mandril is connected onto a conical handle matched with a conical hole of a lathe; a through hole is formed in a central shaft of the conical handle and the expansion mandril; the free end part of the expansion mandril is provided with a plurality of axially arranged seam ports; a pull rod penetrates through the through hole; one end of the pull rod is connected with a conical puller matched with a conical inner hole in the end part of the expansion mandril; the other end of the pull rod is provided with a cylinder rod and a cylinder capable of rotating relative to the pull rod. The conical shape on the puller is matched with the conical inner hole in the expansion mandril, so the free end part of the expansion mandril is tensioned on the lug hole in the end tooth flange fork to be machined to achieve the aim of axially positioning the end tooth flange fork to be machined, so the symmetry and concentricity during secondary clamping of the product are improved, the clamping error brought by the secondary clamping is reduced, and the product grooving precision is improved.

Owner:CHONGQINGS FAR EAST TRANSMISSION SHAFT

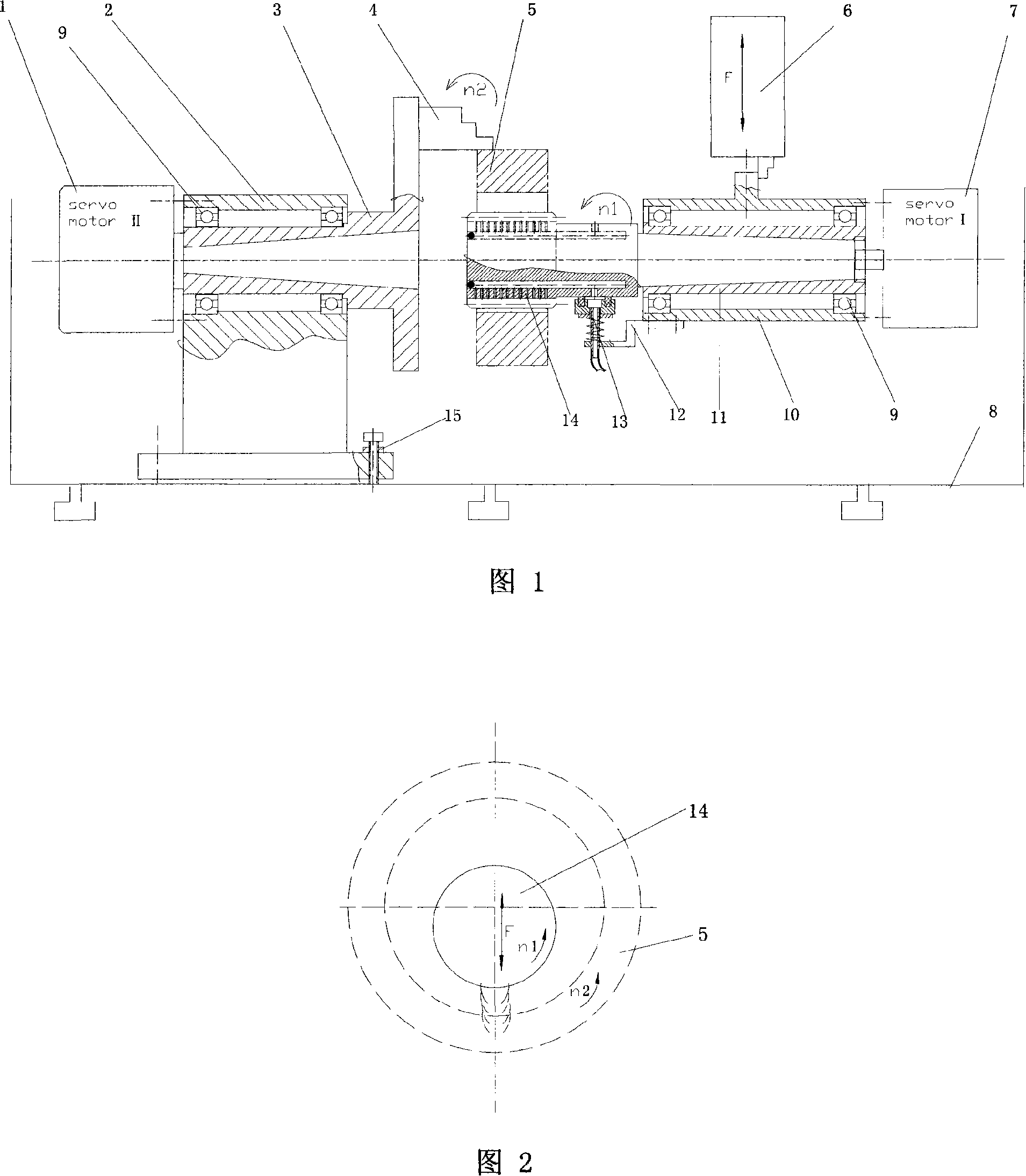

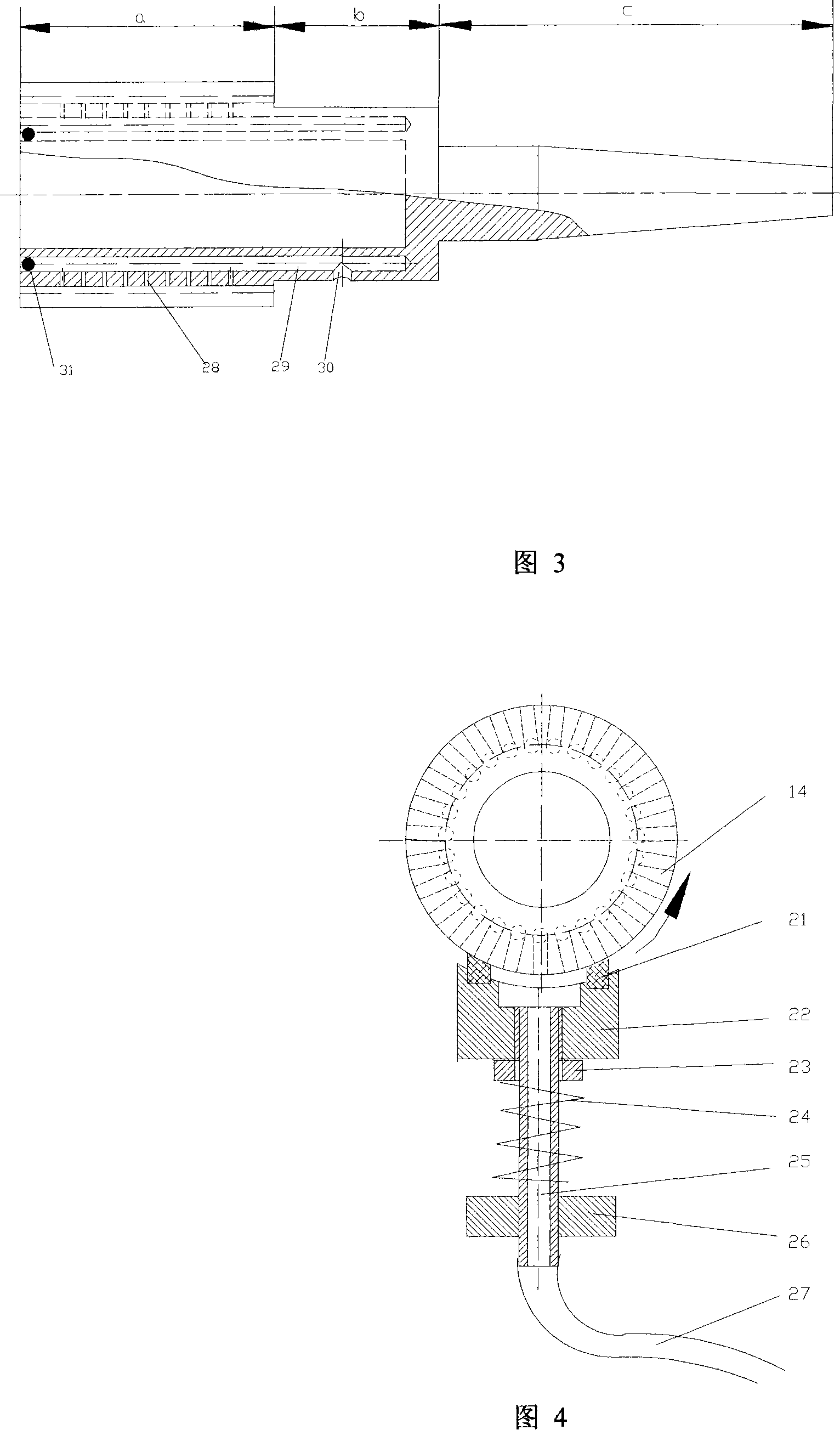

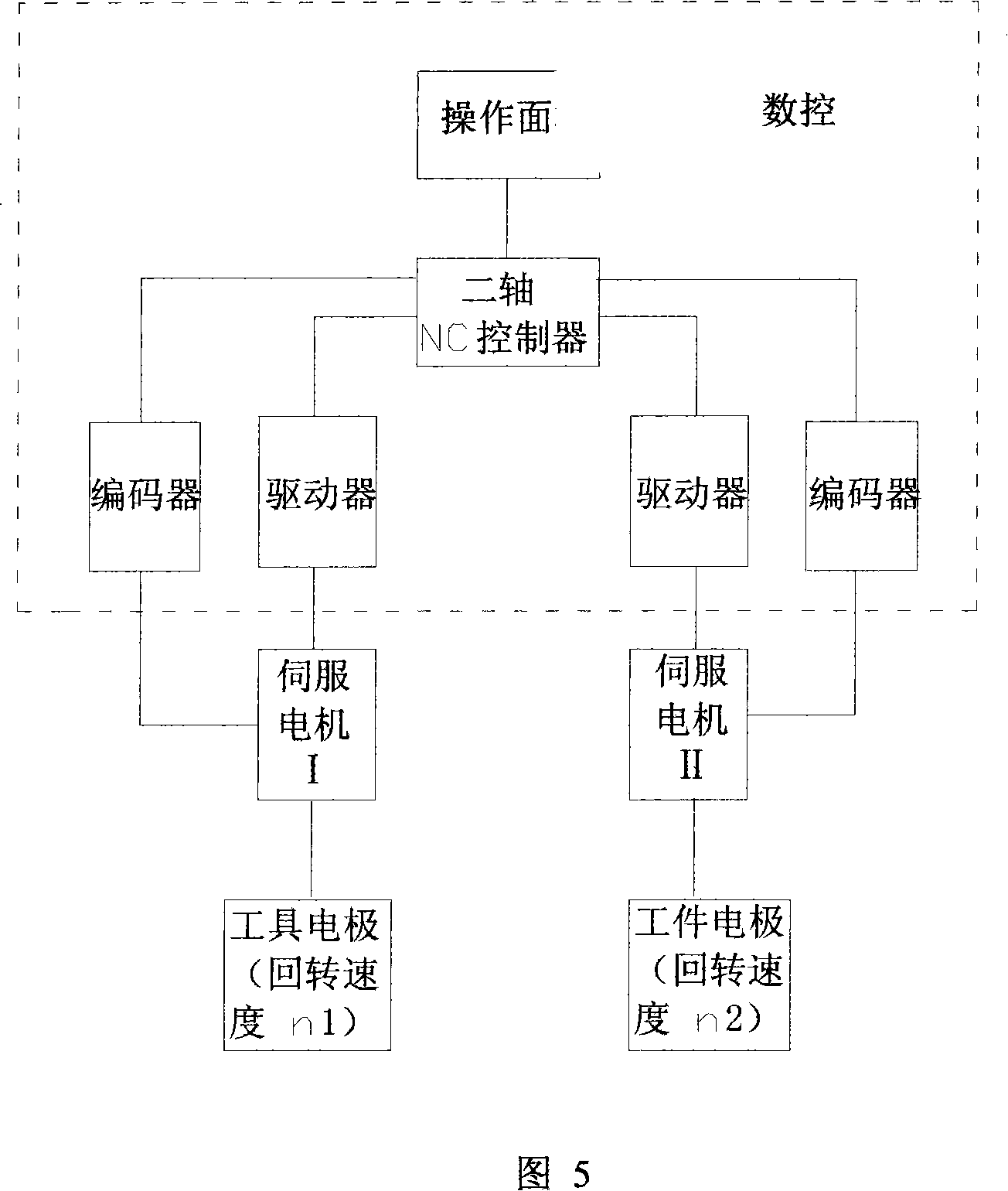

Large deep/dameter ratio dentiform female die numerically-controlled electric spark expanding and processing device and processing method thereof

InactiveCN101147992AImprove efficiencyHigh precisionElectrical-based machining electrodesDiameter ratioSurface roughness

The present invention discloses numerically controlled electric spark machining apparatus and process for great depth / diameter ratio toothed female die. The horizontal machining apparatus includes one biaxial numerically controlling device, two servo motors, one tool electrode, one fixture with three claws, one rotary inner sleeve for workpiece, one local directional liquid leading unit and one tool electrode holding casing. The present invention has combination of electric spark generating technology and numerically controlling technology to expand the machining range, and is especially suitable for machining hard-to-machine materials.

Owner:GUANGDONG IND TECHN COLLEGE +1

Vertical internal and external grinding machine capable of simultaneously grinding internal and external circles

PendingCN112548703AHigh precisionImprove processing efficiencyRevolution surface grinding machinesPhysicsGrinding

The invention discloses a vertical internal and external grinding machine capable of simultaneously grinding internal and external circles. The vertical internal and external grinding machine comprises a machine body base, wherein a stand column is fixedly installed on one side of the machine body base, a rotary workbench is fixedly installed on the other side of the machine body base, a pluralityof horizontal linear guide rails are fixedly installed on the vertical side wall of the side, facing the rotary workbench, of the stand column at equal intervals, the vertical side wall of the standcolumn is further fixedly provided with horizontal ball screws on the upper side and the lower side of the horizontal linear guide rail located in the middle respectively, and two horizontal moving dragging plates are further arranged on the linear guide rails in a sliding mode. In order to overcome the defects in the prior art, the vertical internal and external grinding machine capable of simultaneously grinding the internal and external circles is designed, four pairs of feeding shafts in the vertical direction and the horizontal direction are designed, and an inner hole grinding head bodyand an external grinding head body can be driven to simultaneously machine the internal diameter and the external circle of a tubular workpiece; and meanwhile, the upper end face can be machined.

Owner:ANJI YUANMO MECHANICS TECH CO LTD

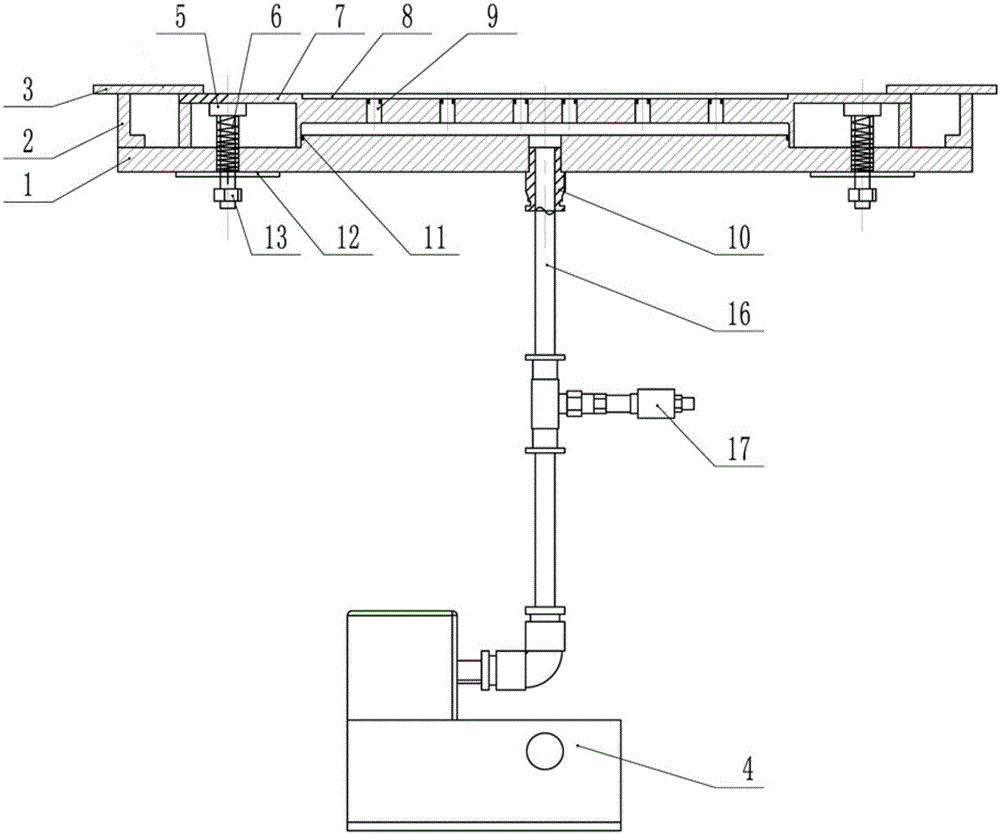

Automatic adjustment device for vacuum clamp for polishing workpieces

ActiveCN105834900AEasy clampingCompact structureGrinding feed controlGrinding work supportsConvex structureHydraulic pump

The invention discloses an automatic adjustment device for a vacuum clamp for polishing workpieces. The automatic adjustment device comprises a hydraulic clamp fixing module, a vacuum clamp module and a vacuumizing module, wherein the vacuum clamp module comprises an upper clamp and a lower clamp, an upward concave structure is arranged at the bottom of the upper clamp, a downward convex structure is arranged at the upper end of the lower clamp, the upward concave structure of the upper clamp and an upward convex structure of the lower clamp form a sealed cavity, a plurality of through holes communicating with the cavity are arranged in the bottom of a circular workpiece installation groove, and a vacuum connector used for connecting the vacuumizing module is arranged at the bottom of a downward concave structure of the lower clamp; the vacuumizing module comprises an air pump, a vacuum pipeline and an air pressure sensor; the hydraulic clamp fixing module comprises a fixed support gasket, hydraulic clamps and a plurality of floating supports used for providing an auxiliary support force; and each floating support comprises a floating support rod, a support head, a gasket, a compression spring and an adjustment nut. The automatic adjustment device disclosed by the invention is simple and compact in structure, low in production cost, reasonable in design, convenient for workpiece clamping, capable of automatically adjusting, and wide in use range.

Owner:ZHEJIANG UNIV OF TECH

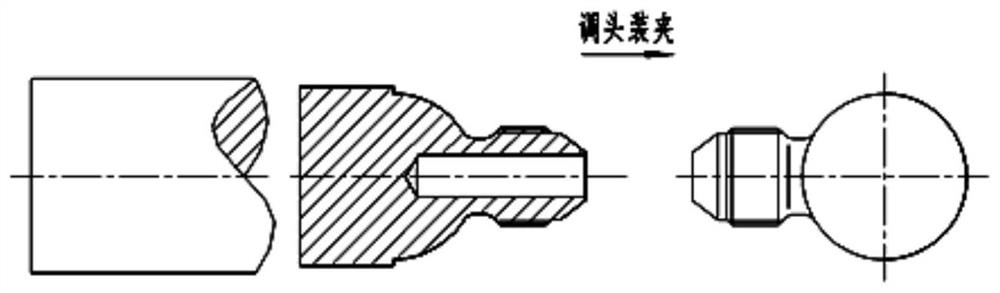

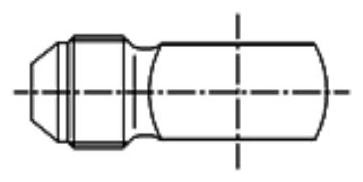

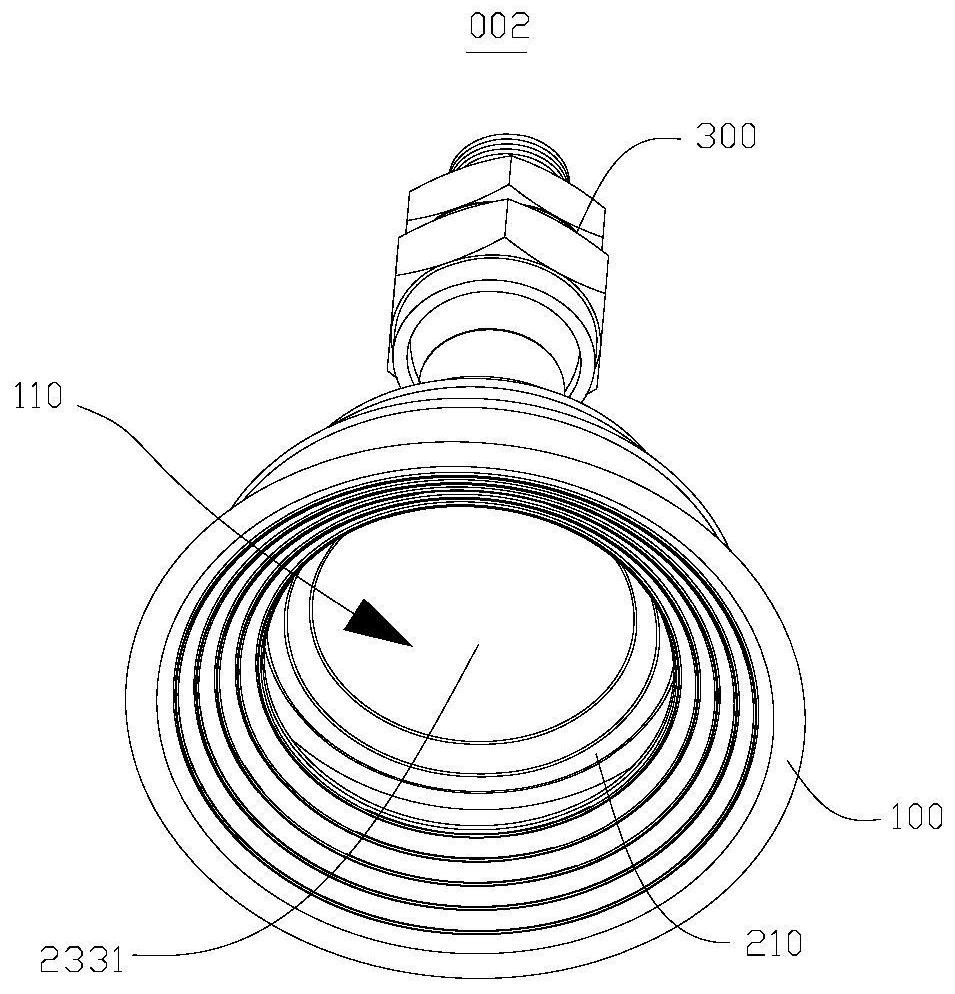

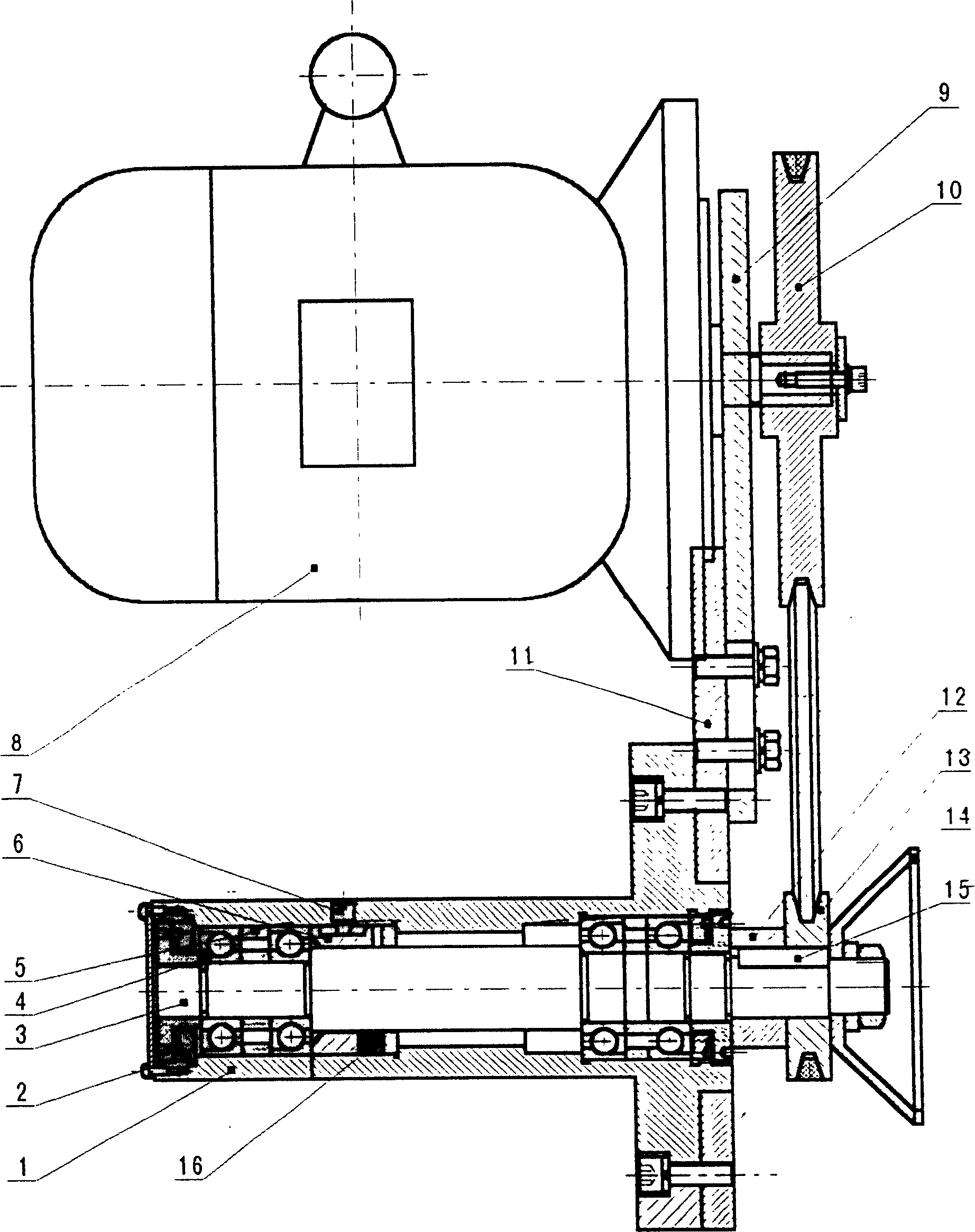

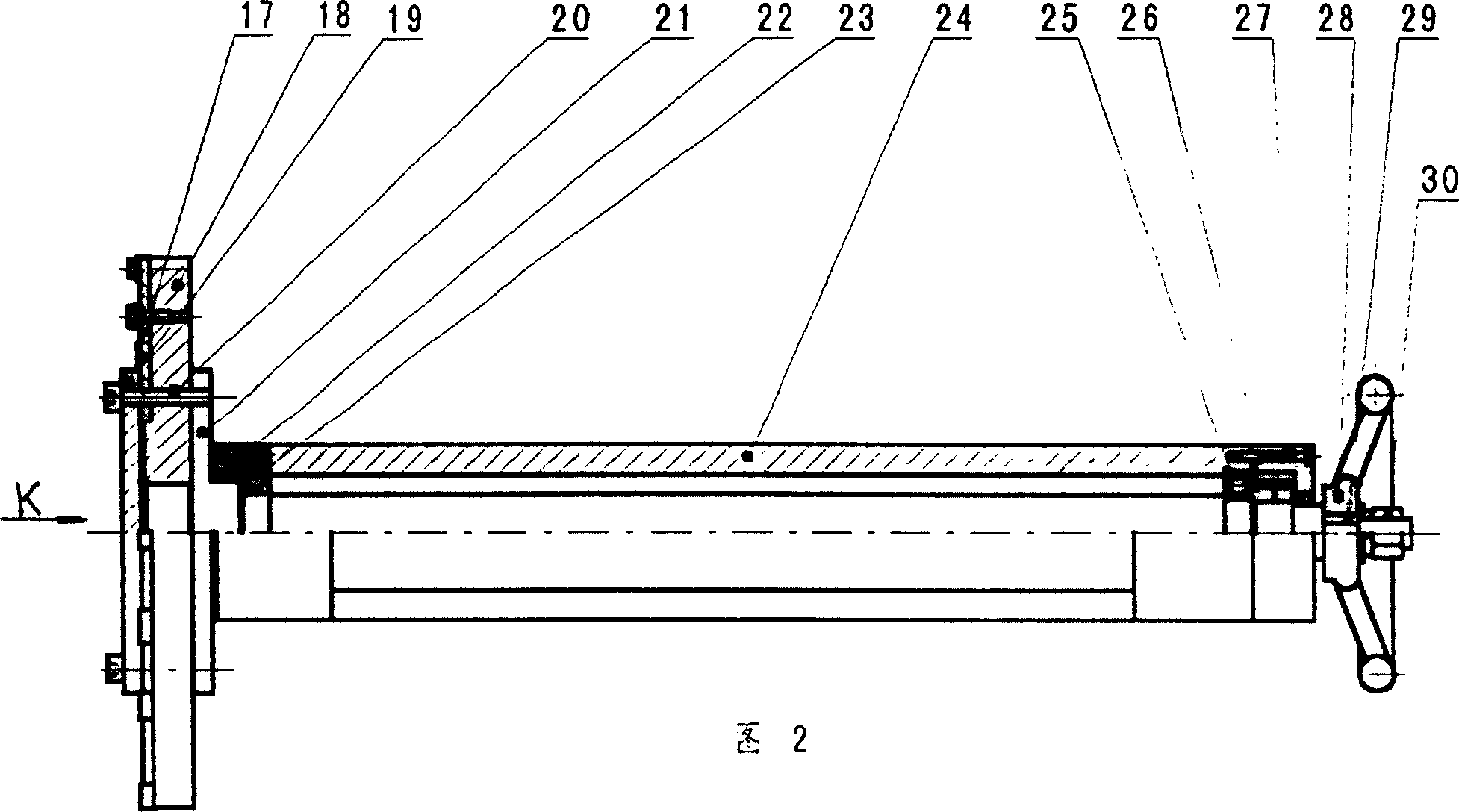

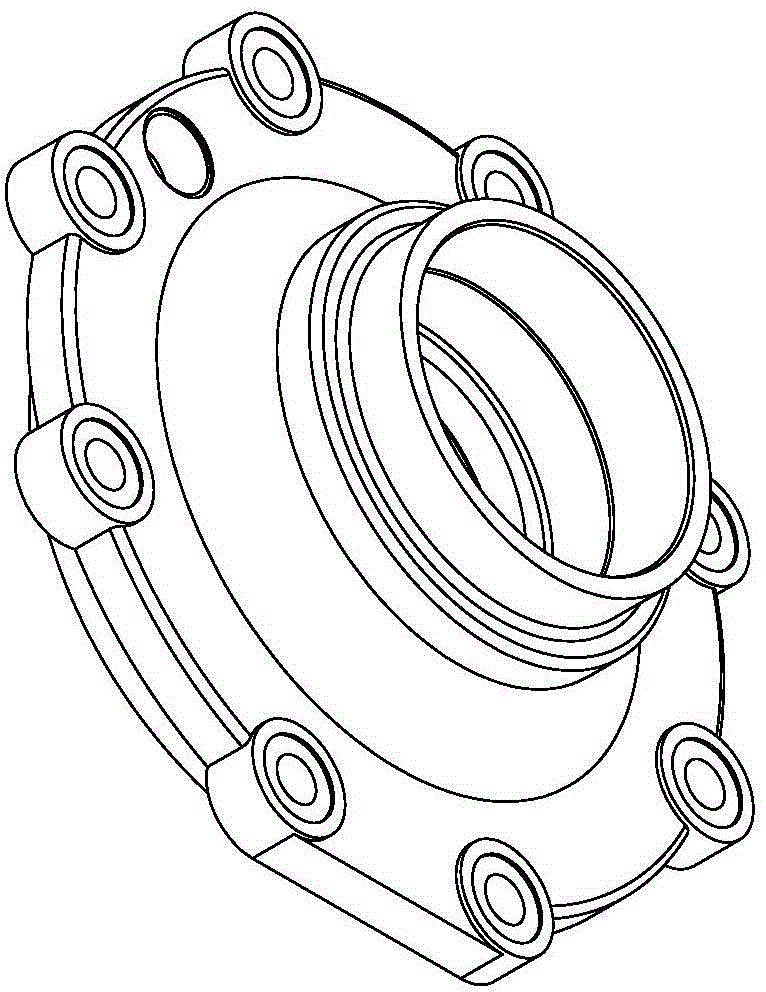

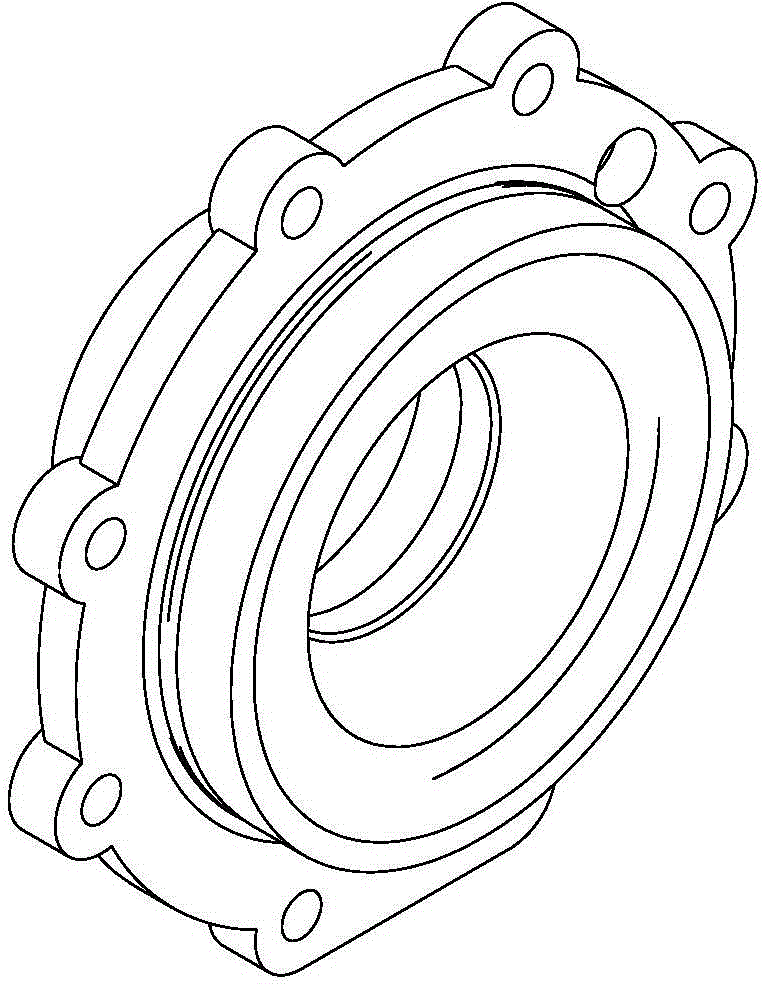

Numerically controlled lathe clamp assembly for machining rotary pipe joints with balls and machining method thereof

ActiveCN112388362AReduce clamping errorsReduce processing timePositioning apparatusMetal-working holdersMachineMachining time

The invention discloses a numerically controlled lathe clamp assembly for machining rotary pipe joints with balls and a method for machining rotating pipe joints with the balls on a numerically controlled lathe by using the clamp assembly. The clamp comprises a first working step clamp and a second working step clamp, wherein the first working step clamp is used for clamping a workpiece so as to machine a structure of one side of the workpiece, and the first working step clamp comprises a clamp base, a clamp pressing plate and a fastener; the second working step clamp is used for positioning acharacteristic surface processed by a first procedure to clamp a rotary pipe joint so as to machine a structure of of the other side of the rotary pipe joint; the clamp base is provided with a clamping handle, a workpiece positioning structure and a pressing plate assembling structure; and the clamp pressing plate is provided with a workpiece positioning structure, a machining avoiding area and afastener assembling structure. Through the clamp assembly, the procedures of milling planes, turning step inner holes and boring inner cavities are combined; the numerically controlled lathe is usedfor machining, so that the clamping errors caused by clamping reference conversion are reduced; meanwhile, the numerically controlled lathe is used for replacing a milling machine to mill the planes;and the machining time is shortened.

Owner:贵州特冶科技有限公司

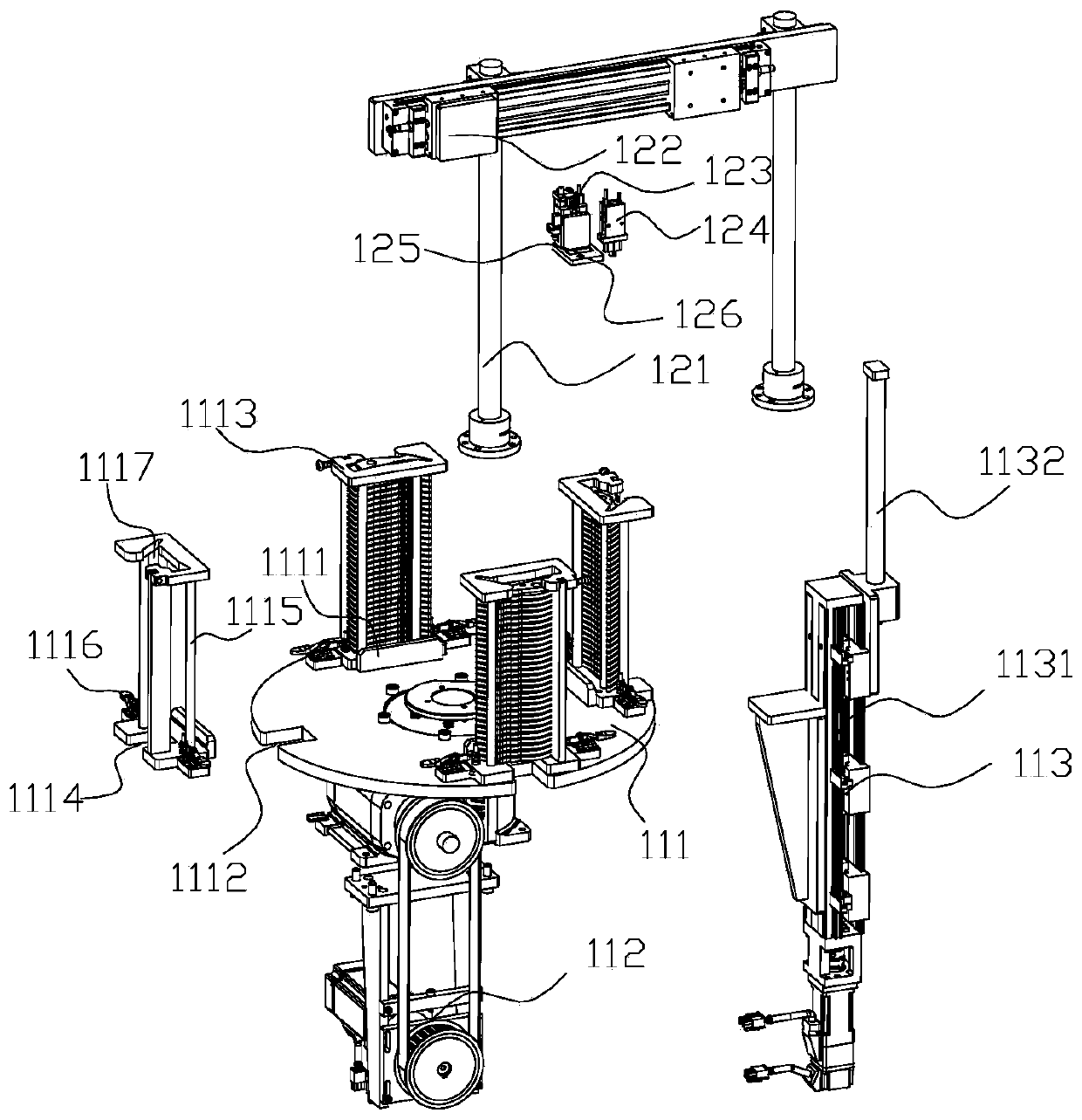

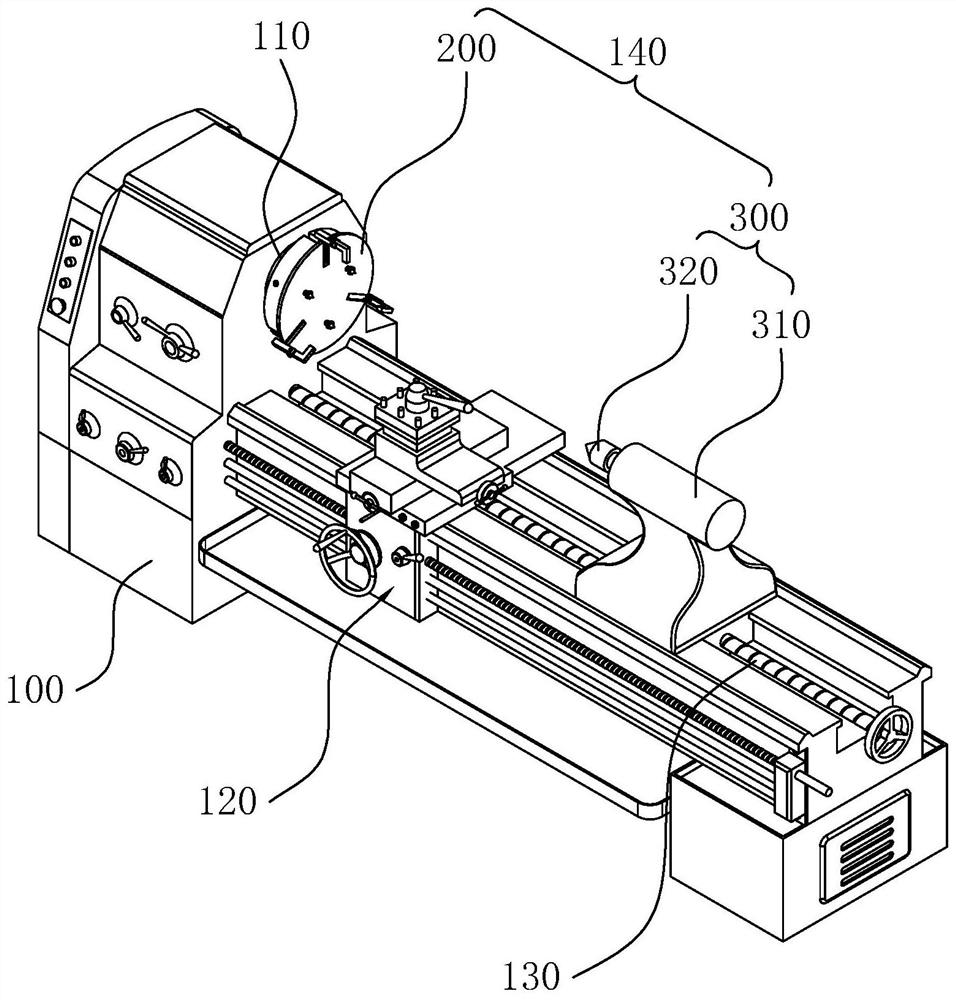

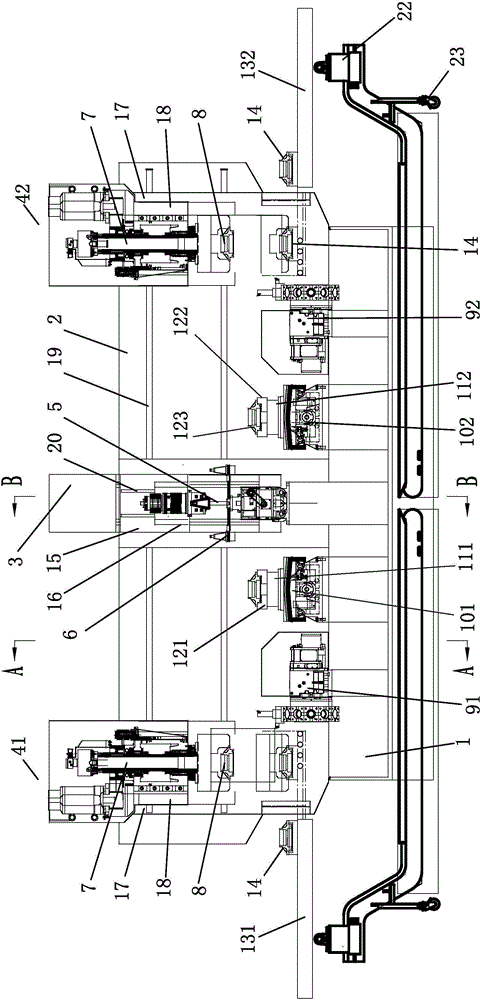

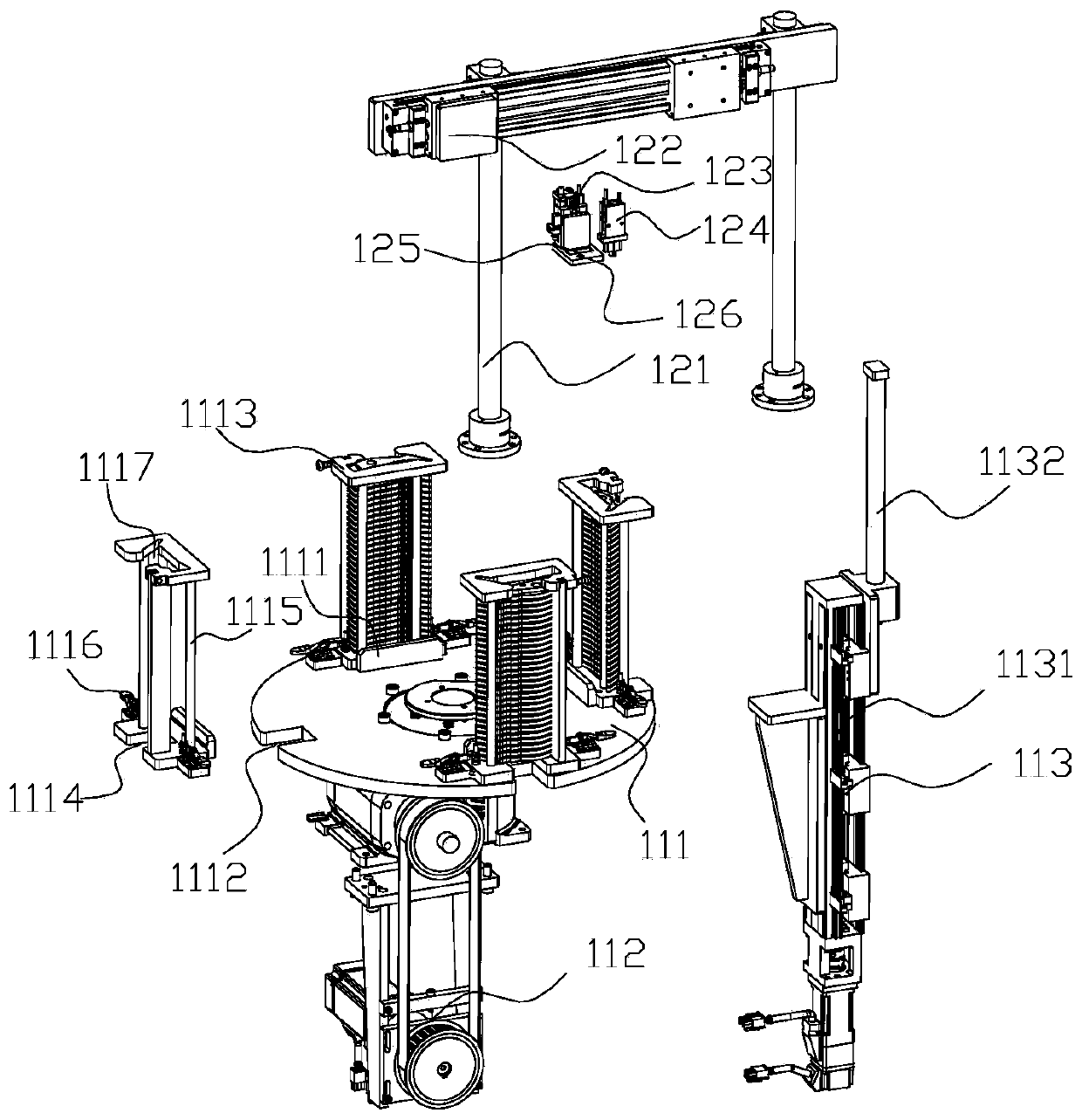

Full-automatic three-primary shaft combined lathe

ActiveCN101367131ALow costReduce labor costsAutomatic/semiautomatic turning machinesAutomatic conveying/guiding stockCharge and dischargeEnergy consumption

Owner:浙江陀曼智能科技股份有限公司

One-clamping type grinding machine for three-sided right-angular workpieces

PendingCN107297652AGuaranteed right angleReduce clamping errorsGrinding carriagesGrinding drivesBall screwCoupling

The invention relates to a grinding machine, in particular to a one-clamping type grinding machine for three-sided right-angular workpieces, aiming to solve the technical problems that convention processing procedures are complicated as multiple clamping is needed for workpieces when the conventional grinding machines are used for processing multiple-sided workpieces, the processing progress is poor due to the facts that positioning precision of the workpieces in moving is low and the process is easy to be affected by chips generated during grinding, and the like. The one-clamping type grinding machine comprises a main engine base; an upper rack is fixed to the upper portion of the main engine base; a front-and-back servo motor is arranged on the lower portion of the main engine base and is connected with a front-and-back ball screw; the front-and-back ball screw is connected with a front-and-back support which is provided with a left-and-right servo motor; the left-and-right servo motor is connected with a left-and-right ball screw which is further movably connected with a workbench; the workbench is provided with permanent magnetic clamps for clamping the workpieces; a grinding wheel arranged obliquely is arranged above the permanent magnetic clamps and is connected with a spindle; the spindle is connected to a spindle motor through a coupling.

Owner:浙江固本精密机械有限公司

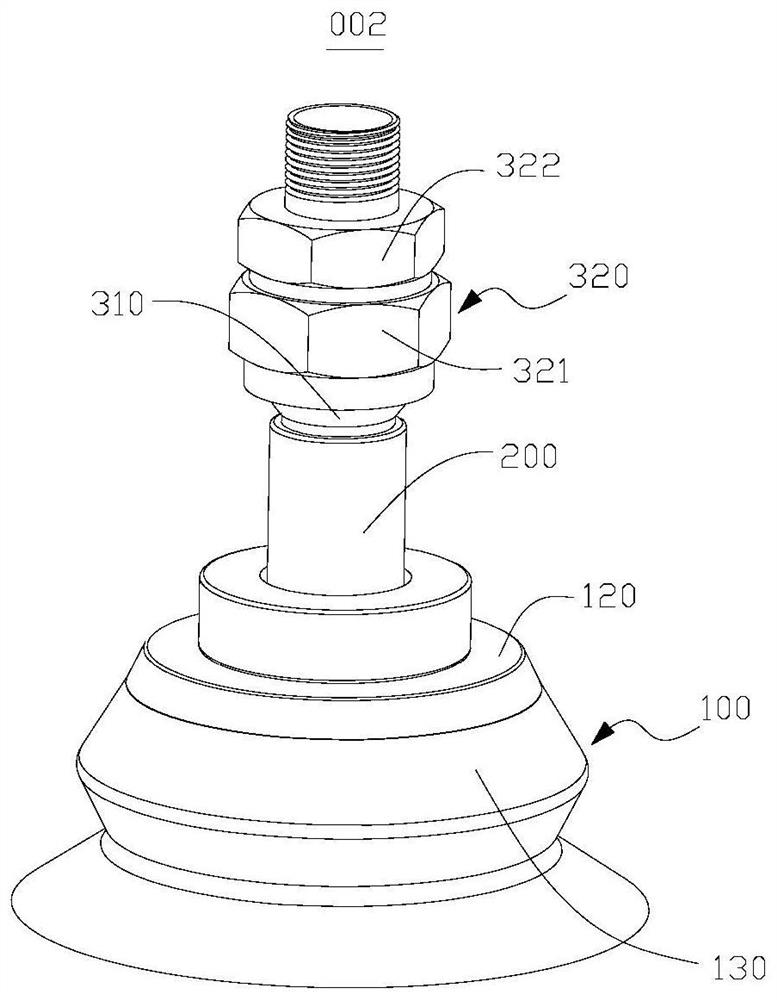

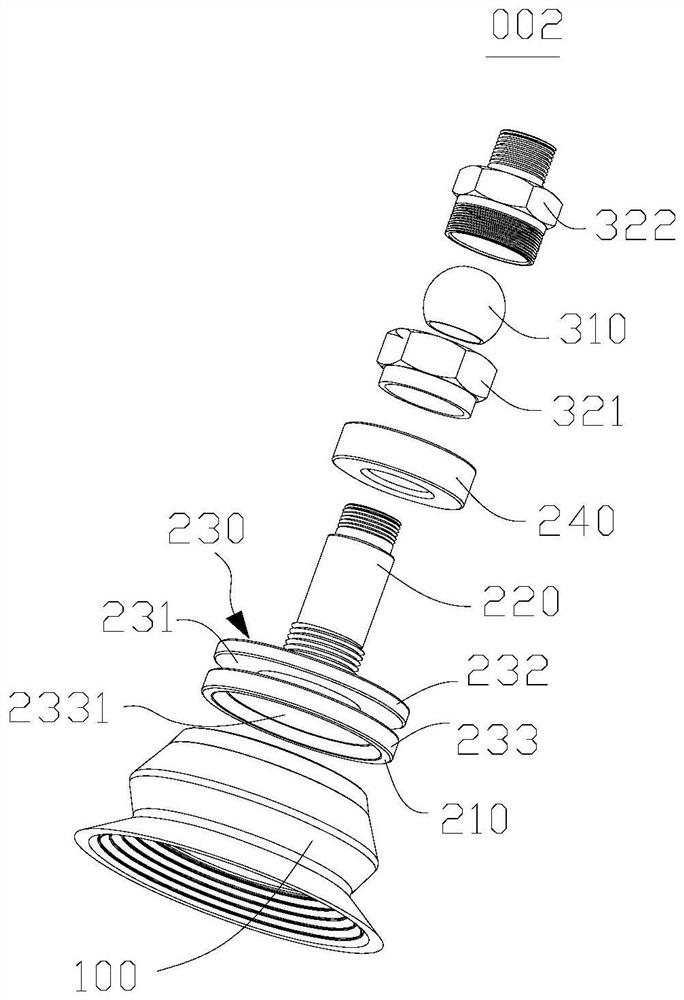

Self-suction positioning mechanism and clamp

The invention provides a self-suction positioning mechanism and a clamp. The self-suction positioning mechanism comprises a self-suction disc and a rigid positioning piece. The self-suction disc is provided with an inner cavity. The rigid positioning piece is provided with a positioning part used for abutting against a workpiece, the rigid positioning piece is connected with the self-suction disc,and a positioning part is located in the inner cavity. When the self-suction positioning mechanism is matched with the workpiece, clamping errors are not prone to occurring, positioning is accurate and reliable, and machining of the workpiece is facilitated. The clamp comprises the self-suction positioning mechanism and an air suction clamping mechanism, the workpiece is clamped firmly and reliably, and clamping errors are not likely to exist.

Owner:NINGXIA UNIVERSITY

Arrangement for grinding repeated usable machine tooled knife

InactiveCN1765573AImprove use valueReduce clamping errorsOther manufacturing equipments/toolsDrive shaftEconomic benefits

The invention relates to a repeatedly-usable reconditioning device of machining blade. The invention comprises a reconditioning integration and a blade clamp integration, wherein, the reconditioning integration comprises: a support plate, a motor mounted on the support plate, a belt wheel, a linkage plate, a muffle, a chief axis in the muffle and a bearing, while the chief axis via the keys has a separation sheath and a carborundum grinding wheel; and the blade clamp integration comprises: a drive shaft mounted in the support sheath, whose one end is connected to the blade fixing plate, a blade positioning plate with a positioning slot and a compressing mounted on the blade fixing plate; end caps mounted on the two ends of support sheath, and a hand-wheel mounted on another end of drive shaft. The invention can solve the problem of present machining blade which can not be reconditioned, while the invention has simple producing process and higher reconditioning efficiency. The invention has better social and economic benefits.

Owner:TIANJIN TIANDUAN PRESS CO LTD

Processing method for ultra-high strength steel axis parts

InactiveCN103072053AImprove brittlenessEasy to processRevolution surface grinding machinesGrinding work supportsMachined surfaceCylindrical grinder

The invention relates to a processing method for ultra-high strength steel axis parts. According to the method, the ultra-high strength steel axis parts are clamped on a high speed cylindrical grinder; in the four process flows of device setting and parts clamping, coarse grinding, semi-grinding and accurate grinding, the parts are cooled intensely after and before the process flows of coarse grinding, semi-grinding and accurate grinding; high-pressure gas and liquid mixed fluid is sprayed into a grinding area from top to bottom in the three process flows of coarse grinding, semi-grinding and accurate grinding. The processing method for the ultra-high strength steel axis parts has the advantages of small grinding force, high grinding efficiency, improving the fragility of a material, improving the processability of the material, reducing the generation of grinding heat and temperature rising, reducing burning and hardening of a processed surface, reducing clamping errors, improving processing precision and processing efficiency and no need of secondary clamping.

Owner:唐昆

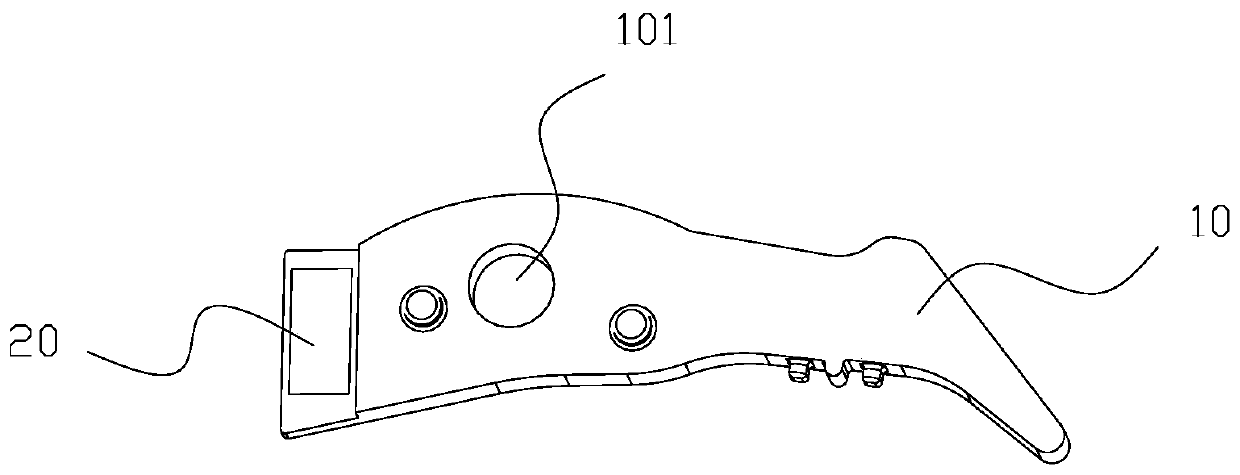

Turning clamp for blind flange

ActiveCN112872394ATurn easilyReduce clamping errorsChucksTurning machinesClassical mechanicsMetal machining

The invention relates to a turning clamp for a blind flange, and relates to the technical field of metal machining equipment. The turning clamp for the blind flange comprises a base plate, a first pressing mechanism and a second pressing mechanism, wherein the first pressing mechanism comprises a tailstock and a tail cone; the tail cone is rotatably connected onto the tailstock; the tail cone and the base plate are coaxially arranged; the base plate is coaxially and fixedly connected onto a main shaft of a lathe; the second pressing mechanism comprises a clamping jaw; and the clamping jaw is connected onto the base plate in a sliding mode. According to the turning clamp for the blind flange provided by the invention, when the peripheral face of a workblank is machined, the base plate and the tail cone are used for clamping the workblank, so that the peripheral face of the workblank can be completely exposed outside; and when a boss of theworkblank is machined, the workblank is clamped by the base plate and the clamping jaw, so that the axis part of the workblank can be completely exposed outside, and feeding of a turning tool is facilitated.

Owner:济南江华锻铸机械有限公司

High-efficiency vertically-arranged milling cutterhead and special blades

InactiveCN110315120AEasy to connect and fixAvoid loose connectionsMilling cuttersMachining vibrationsDrive shaft

The invention relates to a high-efficiency vertically-arranged milling cutterhead and special blades, and belongs to the technical field of cutters for metal cutting machining. A main fastening bolt hole is formed in the top of the cutterhead, the cutterhead is connected with a power transmission shaft through a bolt, the cutterhead is positioned through a key slot, so that the cutterhead can be well mounted and fixed on the main shaft, and machining vibration is reduced; a plurality of cutter grooves of vertically-arranged cutter clamps are uniformly formed in the periphery of the cutterhead,and the cutter clamps are locked in the cutter grooves through locking screws; and each cutter clamp is provided with a cutter holder for installing the special blades, the special blades are fixed in cutter holders through pressing screws, and the axial cutting depth of the special blade can be adjusted through eccentric adjusting pins. The special blades and the cutter clamps adopt a vertical installation mode, the operation is simple and convenient, the service life of a cutter can be prolonged, and the production efficiency is improved.

Owner:HARBIN UNIV OF SCI & TECH

Double-handstand turning center lathe

ActiveCN104815993AShort processing timeIncrease productivityAutomatic/semiautomatic turning machinesSlide plateOptimal matching

The invention discloses a double-handstand turning center lathe. The double-handstand turning center lathe comprises a bed base; the bed base is provided with a standing column; the standing column is provided with a standing column guide rail; the standing column guide rail is connected with the lathe and a left-right handstand turning center; the lathe comprises a lathe carriage, a lathe sliding plate, a left work bench, and a right work bench; the lathe carriage is matched with the lathe sliding plate; the lathe sliding plate is provided with a lathe main shaft; a lathe tool changer at the front side of the lower part of the lathe main shaft is connected with the base; the left-right handstand turning center comprises a handstand turning center carriage, a handstand turning center sliding plate, and a handstand turning center main shaft; the lower part of the handstand turning center main shaft is connected with a handstand chuck; the base between the lathe main shaft and the handstand turning center main shaft is provided with a work bench base; the work bench is provided with a left clamping fixture; and the bed base is provided with a turning head. The double-handstand turning center lathe is capable of achieving the optimal matching of the turning and lathe time during the processing of the disc parts, saving the labor, reducing the manufacturing cost, and ensuring the precision and quality of the part production, the whole processing time is the shortest, and the production efficiency is high.

Owner:JINAN FIRST MACHINE TOOL GROUP

Assembly device and method of copper sheets for circuit breaker

InactiveCN111376059AEasy to transportStable and accurate transferMaterial gluingCleaning using toolsEngineeringMaterials science

The invention relates to the technical field of production of circuit breakers. An assembly device of copper sheets for a circuit breaker comprises a copper sheet feeding bracket, a copper sheet feeding assembly, a copper sheet cutting assembly and a copper sheet assembling assembly, wherein the copper sheet feeding assembly and the copper sheet cutting assembly are arranged on the copper sheet feeding bracket separately, the copper sheet feeding assembly is located at the feeding end of the copper sheet cutting assembly, and is used for conveying a copper sheet band for feeding, the copper sheet cutting assembly is used for cutting the copper sheet band sheet by sheet, and the copper sheet assembling assembly is located at the discharging end of the copper sheet cutting assembly, and is used for transferring and assembling the cut copper sheets. The assembly device has the advantages of being capable of improving the copper sheet cutting quality and stability as well as the copper sheet assembling efficiency and quality.

Owner:丁水珍

Drilling and milling device for adjustment sheet type part

InactiveCN106624893ACheap manufacturingReduce management costsPositioning apparatusMetal-working holdersStressed stateSupport point

The invention discloses a drilling and milling device for an adjustment sheet type part. The drilling and milling device comprises a clamp body, centering screws and centering press plates. The clamp body is provided with screw mounting grooves, and press block mounting grooves are formed in the clamp body and located at the two ends of each screw mounting groove. The centering screws are mounted in the screw mounting grooves, the two ends of each centering screw are sleeved with the corresponding centering press plates which are arranged in the press block mounting grooves, and supporting blocks are further arranged on the clamp body and located outside the screw mounting grooves. By the adoption of the clamp body, when the adjustment sheet type part is clamped, except four supporting points and four pressing points opposite to the supporting points of the part, other thin walls are all in a non-stressed state, and part deformation caused by clamping can be greatly reduced; drilling and lug milling are completed through one-time clamping, and clamping errors are greatly reduced; and the center distance size can be guaranteed during drilling and reaming, and the device can be used for the lug milling procedure, so that clamp manufacturing and managing cost is saved, workers can conveniently use the device for machining on site, and the part machining cycle is shortened.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

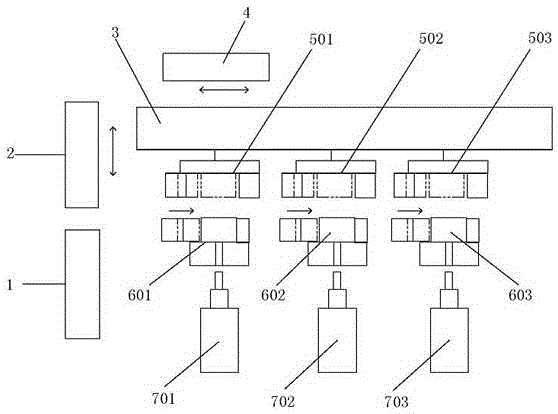

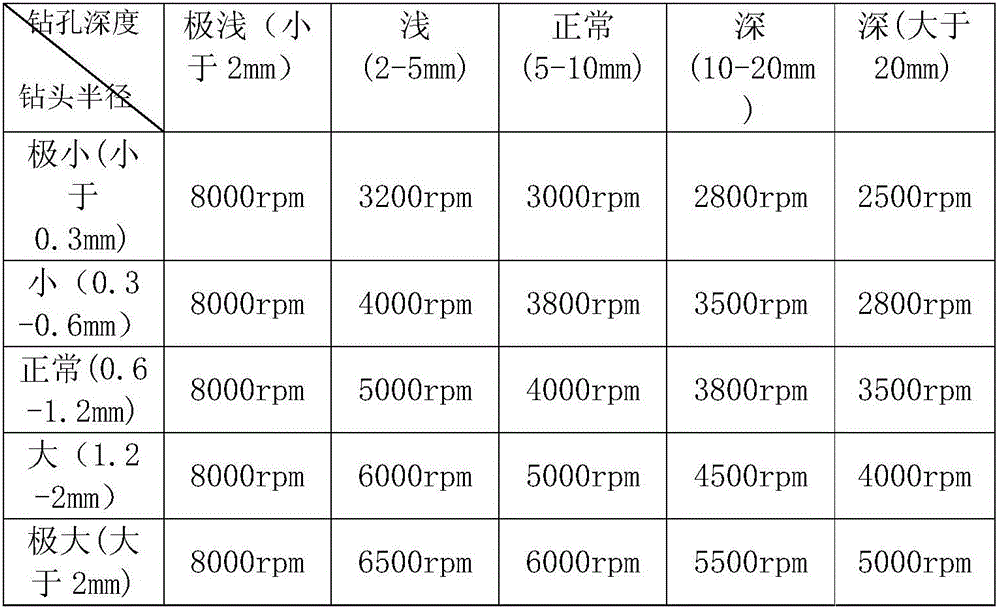

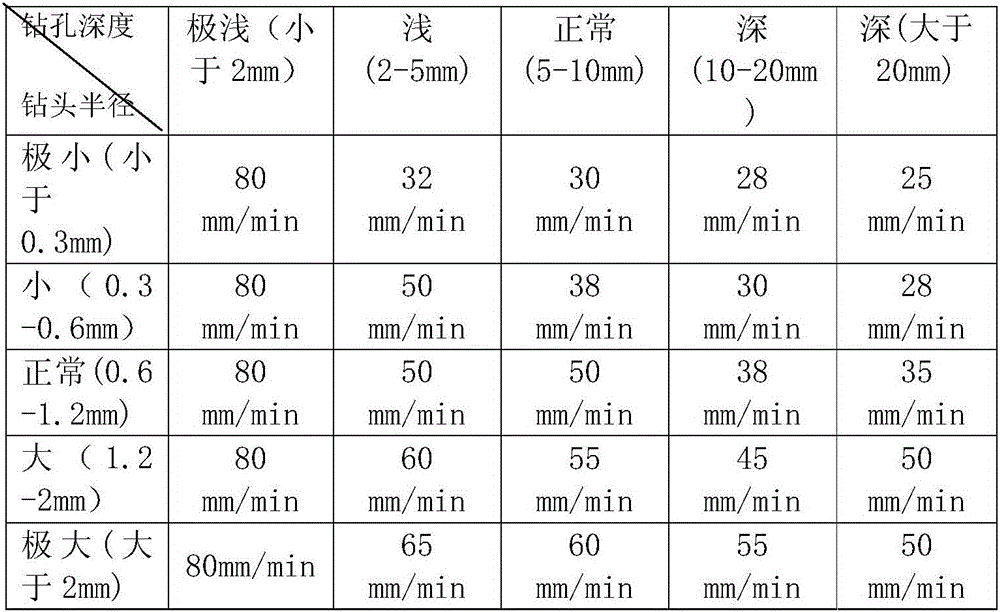

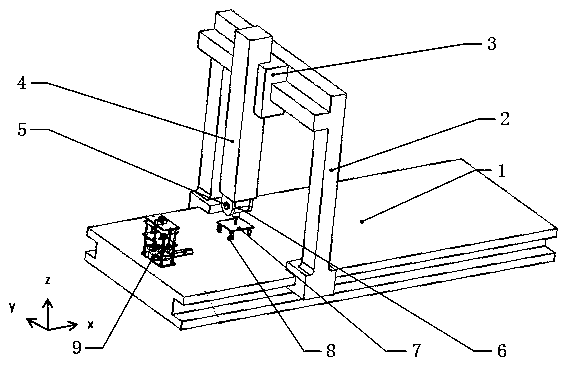

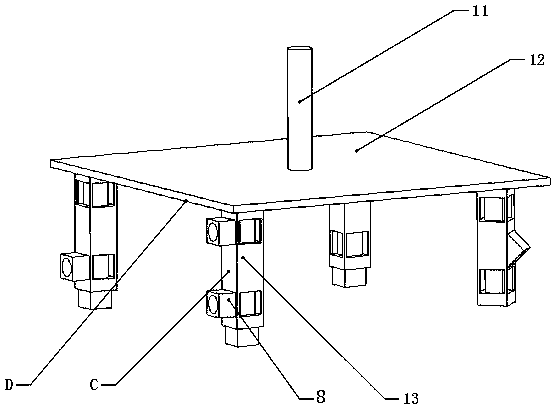

Three-axis drilling device and control method thereof

InactiveCN106270623AImprove processing efficiencyReduce clamping errorsSpecial data processing applicationsBoring/drilling machinesDrive shaftDrive motor

The invention discloses a three-axis drilling device and a control method thereof. The three-axis drilling device comprises a working platform and a trough, and the working platform is provided with a first associated fixture, a second associated fixture and a third associated fixture, and the working platform is connected with an X-axis transverse motor and a Y-axis mobile motor; the three-axis drilling device further comprises three drilling machines, each drilling machine comprises a driving motor and a drill bit installed on a driving shaft of the driving motor, and the drilling machines are the first drilling machine, the second drilling machine and the third drilling machine; a first machining fixture is arranged in front of the first drilling machine, a second machining fixture is arranged in front of the second drilling machine, and a third machining fixture is arranged in front of the third drilling machine. According to the three-axis drilling device and the control method thereof, rough drilling, semi-finishing drilling and finishing drilling of clock or watch parts are achieved, the speed is high, the efficiency is high, and improvement of the machining quality is promoted.

Owner:东莞汉为智能技术有限公司 +1

Reflector set clamp for precision detection of numerical control machine tool

ActiveCN111251072AReduce frequent replacementReduce frequent mirror group replacement operationsMeasurement/indication equipmentsUsing optical meansNumerical controlControl engineering

The invention discloses a reflector set clamp for precision detection of a numerical control machine tool. The reflector set clamp comprises a machine tool bed, a moving unit mounted on the machine tool bed, a swing unit mounted on the side, close to the machine tool bed, of the moving unit and a reflector set unit mounted on the side, close to the machine tool bed, of the swing unit. The reflector set unit comprises a reflector set clamp body connected with the swing unit and reflectors mounted on the reflector set clamp body. By means of the reflector set clamp, the operation that the reflector set is frequently replaced due to axis changes of a detected target in the geometric accuracy detection process of the translation axis of the machine tool can be effectively reduced, meanwhile, clamping errors generated by adjusting of the space posture of the reflector set are reduced, and convenience is provided for detection and recognition of the geometric accuracy of the translation axisof the multi-axis numerical control machine tool.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

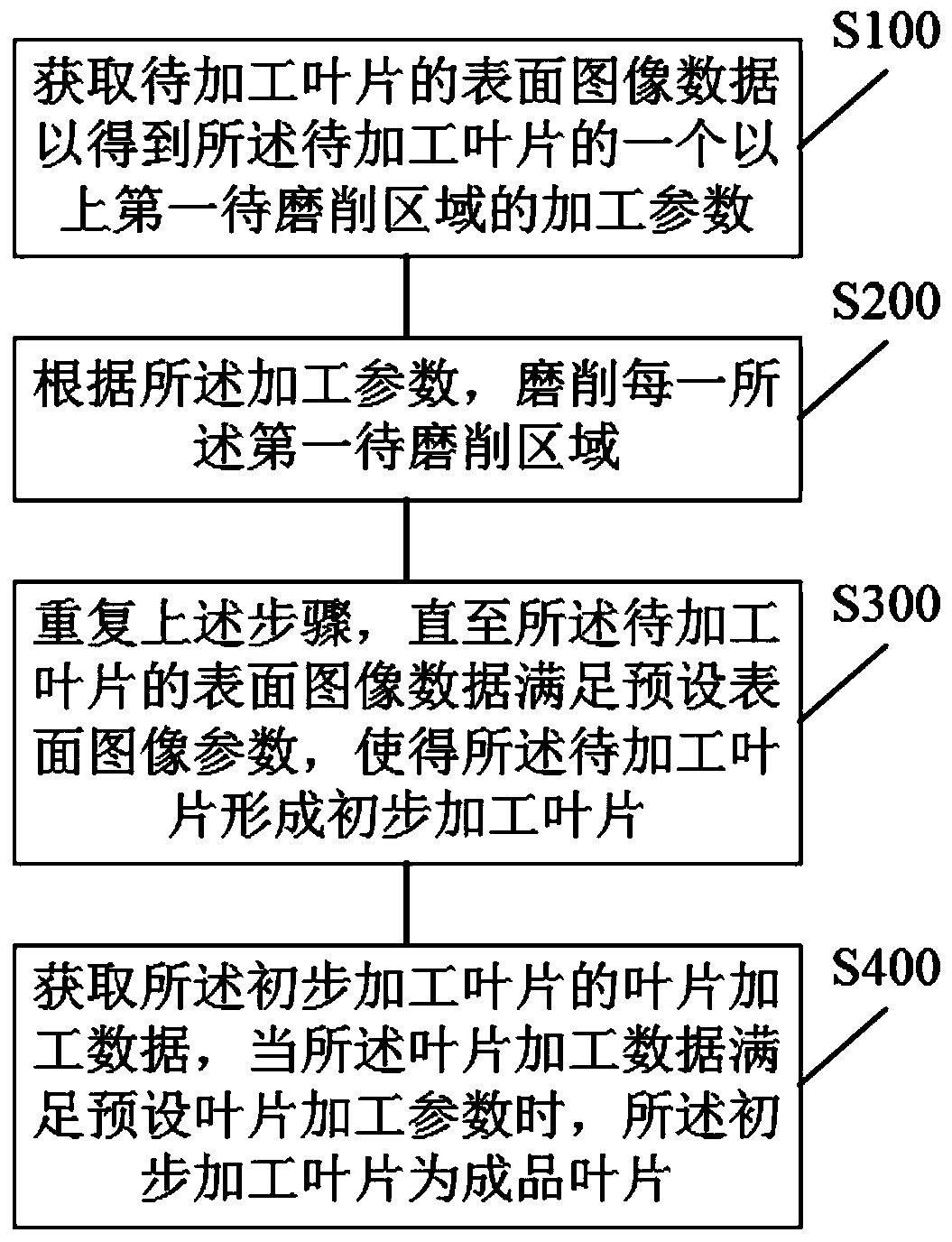

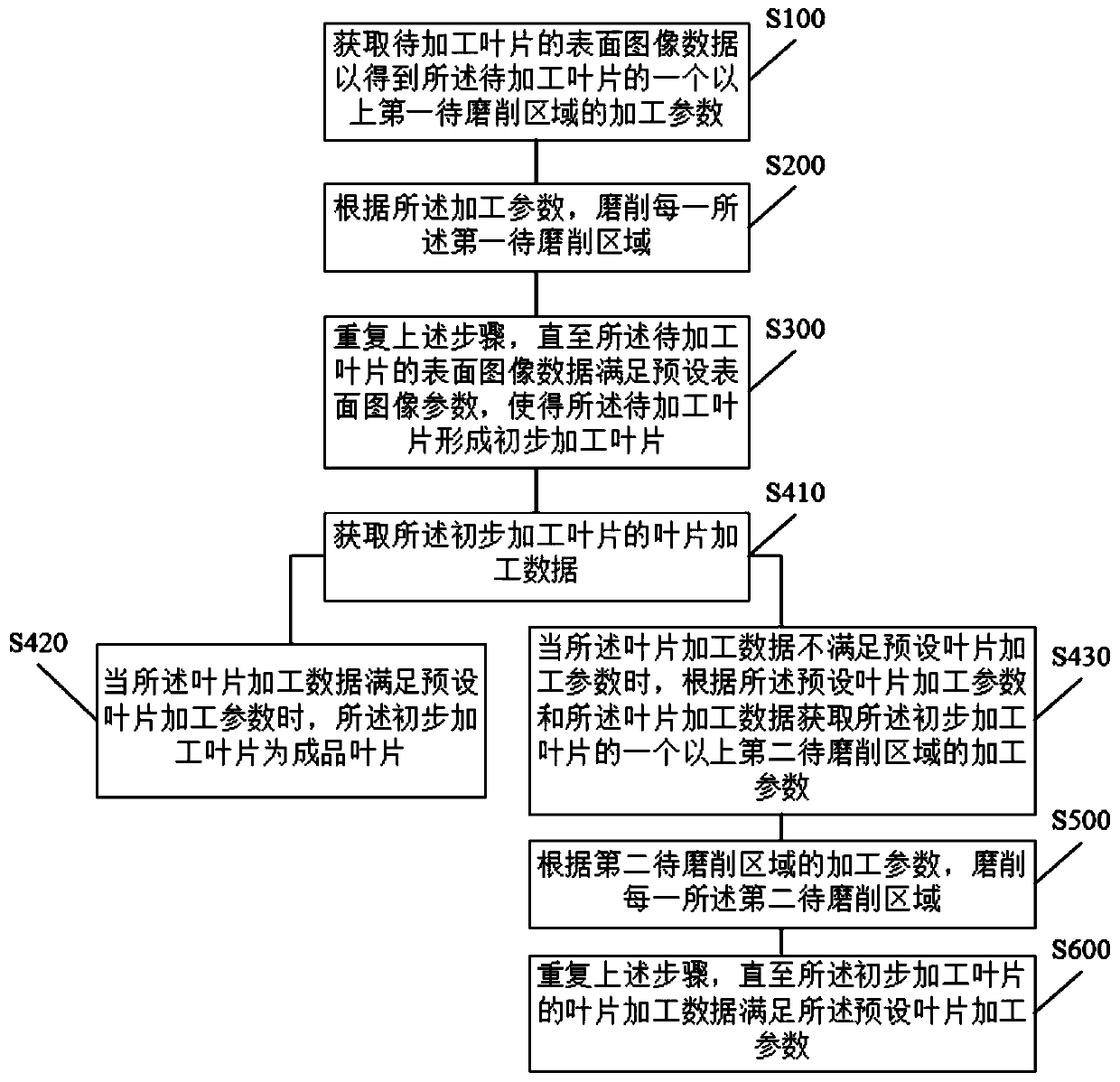

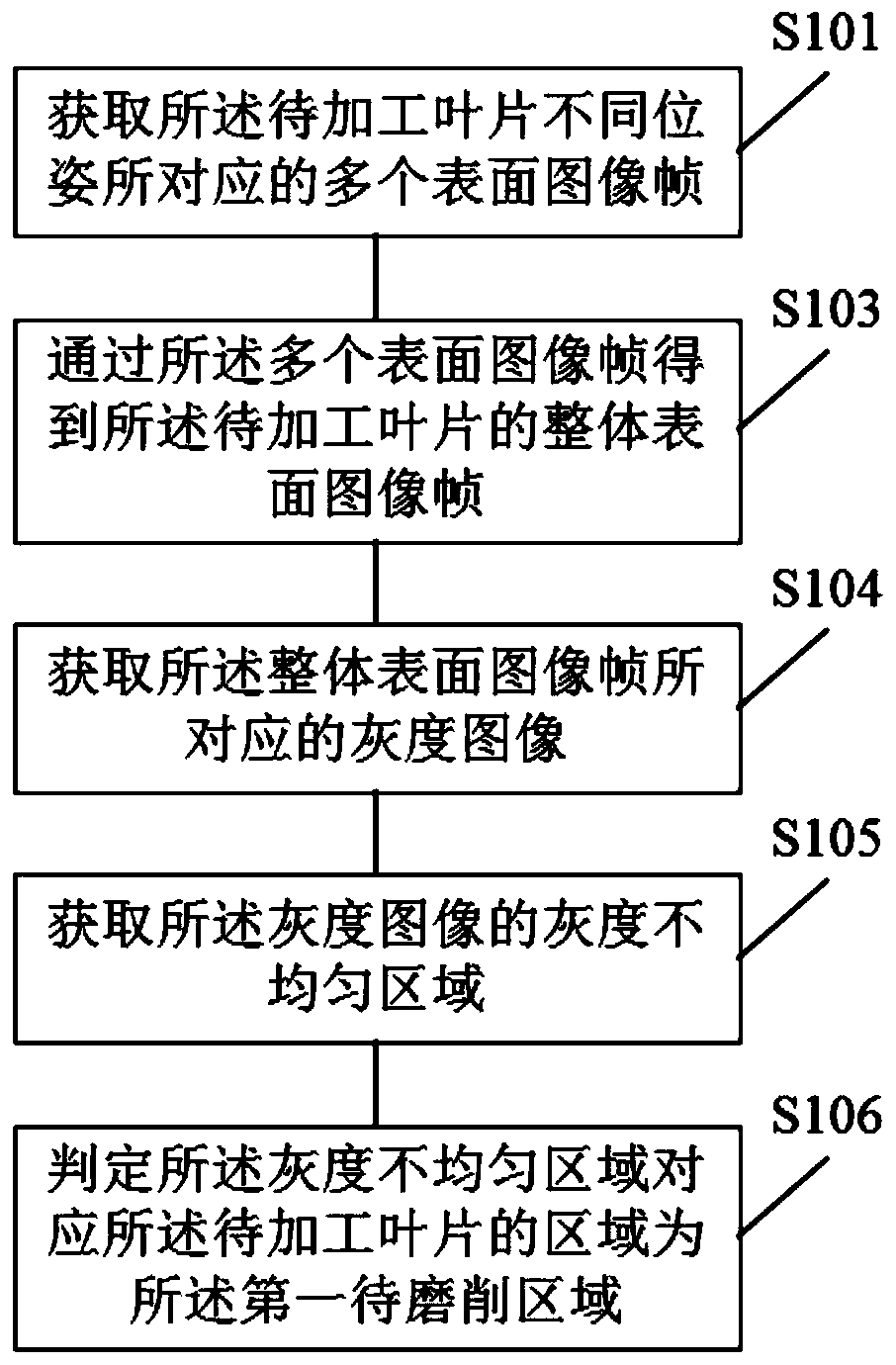

Robot intelligent grinding and detecting method, terminal equipment and storage medium

ActiveCN111583206AProtect your healthAvoid pollutionGeometric CADImage enhancementTerminal equipmentSelf adaptive

The invention discloses a robot intelligent grinding and detecting method, terminal equipment and a storage medium. The method comprises the steps that S100, surface image data of a to-be-machined blade are acquired to obtain machining parameters of one or more first to-be-ground areas of the to-be-machined blade; S200, each first to-be-ground area is ground according to the machining parameters;S300, the steps are repeated until the surface image data of the to-be-machined blade meet preset surface image parameters, so that the to-be-machined blade forms a preliminary machined blade; and S400, blade machining data of the primarily-machined blade are obtained, and when the blade machining data meet preset blade machining parameters, the primarily-machined blade is a finished blade. The self-adaptive closed-loop and unmanned machining of the to-be-machined blade is achieved, the body health of workers is protected, the labor cost is reduced, repeated disassembly and assembly are not needed, the clamping error is small, and the machining precision and the yield are high.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com