Positioning device for grooving of end tooth flange fork

A technology of positioning device and flange fork, which is applied in the direction of expanding the mandrel, etc., can solve the problems of not being able to guarantee the symmetry and concentricity of the two clamping, clamping error, and affecting the quality of the grooving, so as to reduce the clamping error , Improve symmetry and concentricity, improve the effect of cutting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

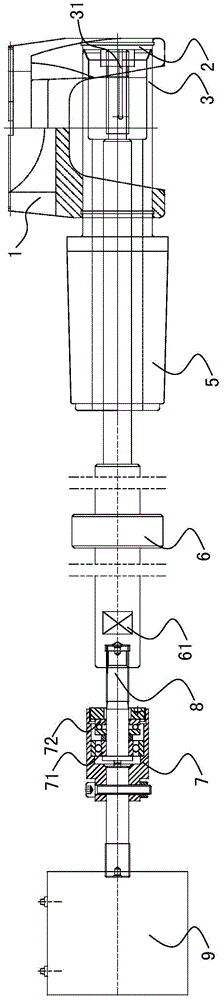

[0014] a kind of like figure 1 The shown end-tooth flange fork slotting positioning device includes an expanding mandrel 3 corresponding to the ear hole of the end-tooth flange fork 1 to be processed, and the expanding mandrel 3 is connected to a taper handle that matches the taper hole of the machine tool 5, a through hole is provided on the central axis of the taper shank 5 and the expansion mandrel 3, and there are several axially arranged slits 31 at the free end of the expansion mandrel 3. A pull rod 6 runs through the hole, and one end of the pull rod 6 is connected with a tapered pull head 2 matching the tapered inner hole at the end of the expansion mandrel 3, and a cylinder rod is arranged at the other end of the pull rod 6. A cylinder 9 that is relatively rotatable with the pull rod 6 .

[0015] The present invention drives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com