Arrangement for grinding repeated usable machine tooled knife

A technology of using machines and blades, applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems of not meeting the requirements of sharpening accuracy, increasing the number of forming knife blades, and reducing the quality of blade sharpening, etc., to achieve grinding High efficiency, improved sharpening quality, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

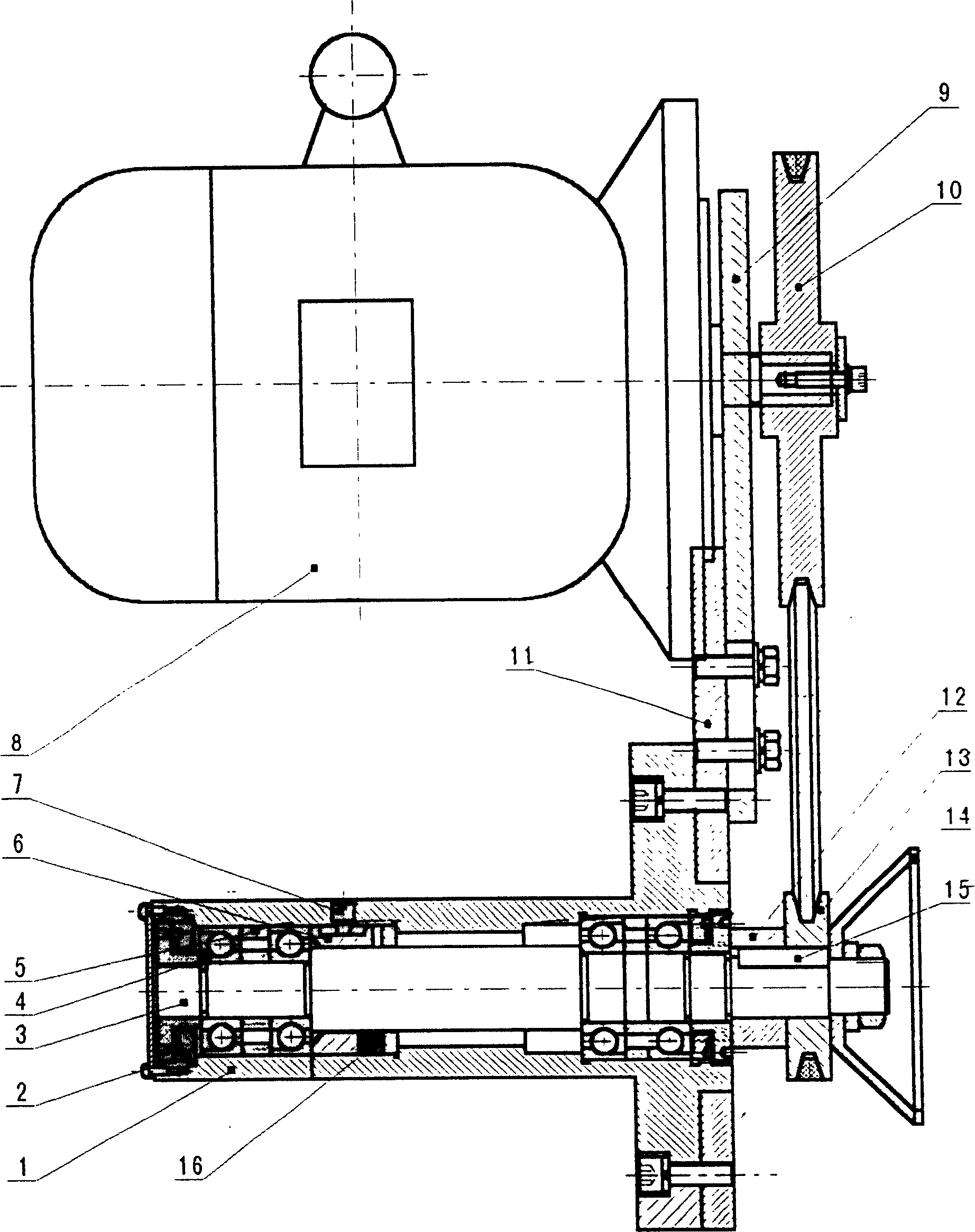

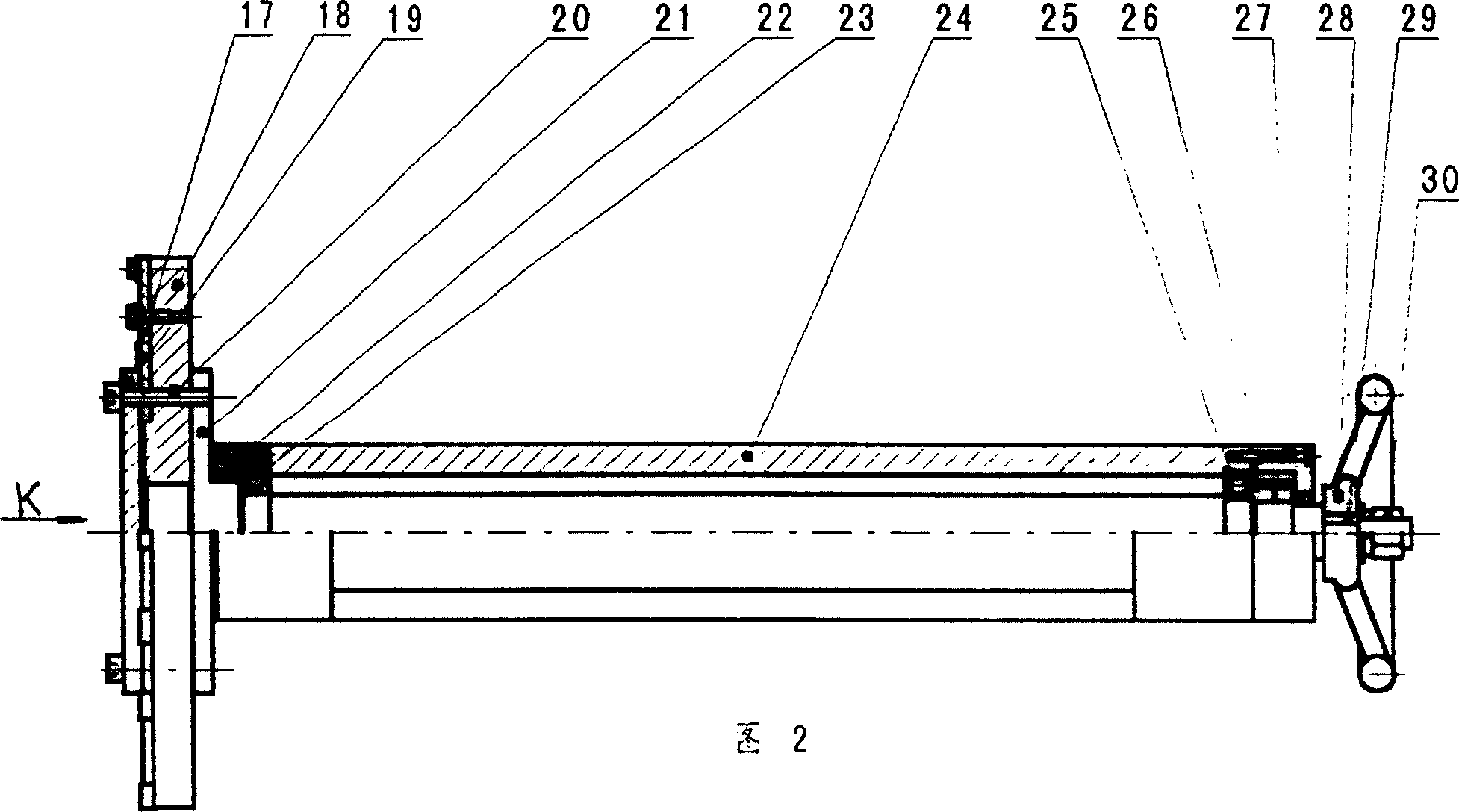

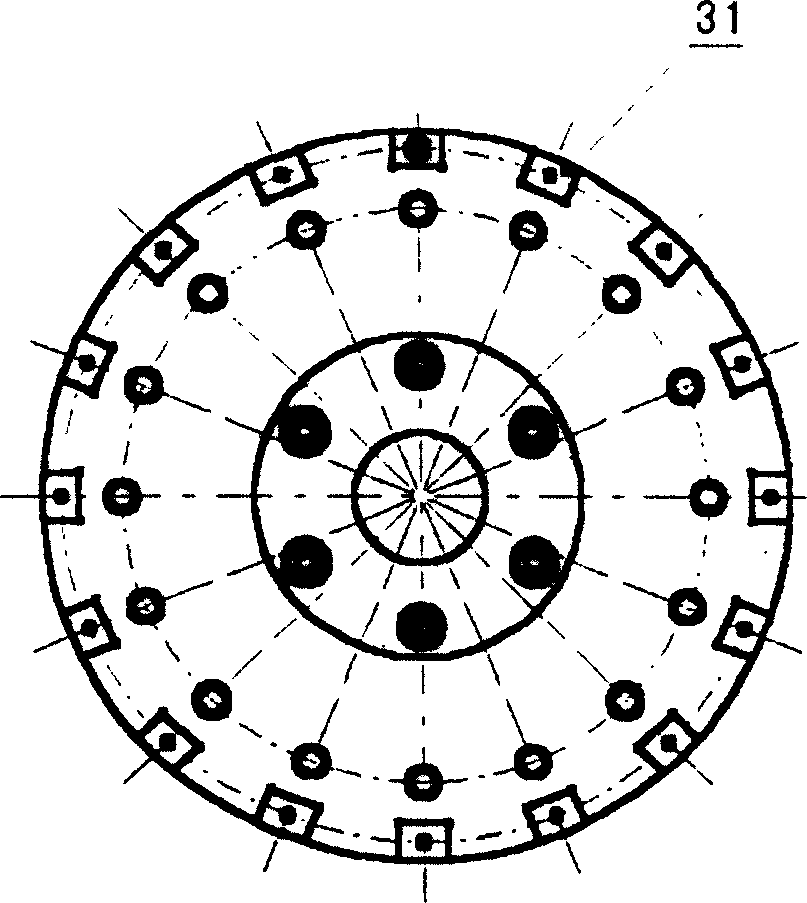

[0016] see figure 1 — image 3 , a regrinding device for reusable machined blades, which is composed of a regrinding assembly and a blade clamping assembly, the regrinding assembly includes: a support plate 9, a motor 8 fixed on the support plate, connected to The pulley 10 of the motor shaft and the connection plate 11 connected to the lower part of the support plate, the other end of the connection plate is connected to the sleeve 1, and the main shaft 3 and two sets of bearings 4 are installed in the sleeve 1, and a spacer is arranged between each set of bearings. Sleeve 5, place grease between the spacers so that the bearings are lubricated. Since the main shaft is prone to overheating and elongation deformation when it is running at hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com