Reflector set clamp for precision detection of numerical control machine tool

A mirror group and precision detection technology, which is applied in the field of mechanical manufacturing design and detection instruments, can solve the problems of low adjustment efficiency and precision, unfavorable industrial automation, etc., and achieve the effect of reducing clamping errors and facilitating detection and identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

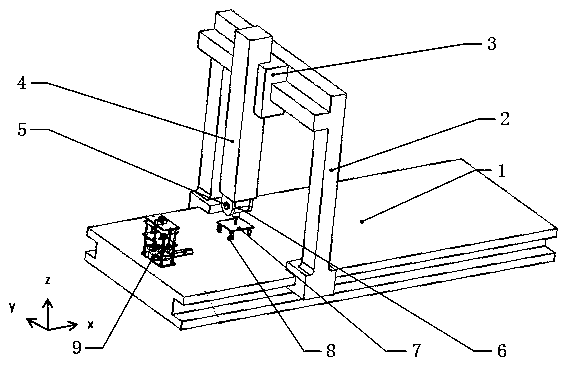

[0027] The present invention is realized through the following technical solutions, as Figure 1-Figure 6 As shown, a mirror group fixture 7 for precision testing of a CNC machine tool includes a machine bed 1, a moving unit 2 installed on the machine bed 1, a swing unit installed on the side of the moving unit 2 close to the machine bed 1, And the reflector 8 group unit installed on the side of the swing unit close to the machine bed 1; the reflector 8 group unit includes the reflector group fixture 7 connected with the swing unit, the reflector 8 installed on the reflector group fixture 7 .

[0028] It should be noted that, through the above improvements, the mobile unit 2 can move relative to the machine bed 1 in the X-axis direction, the Y-axis direction and the Z-axis direction; since the mobile unit 2 is connected to the 8 groups of mirrors through the swing unit, Therefore, by controlling the movement of the mobile unit 2, the movement of the 8 groups of mirrors is rea...

Embodiment 2

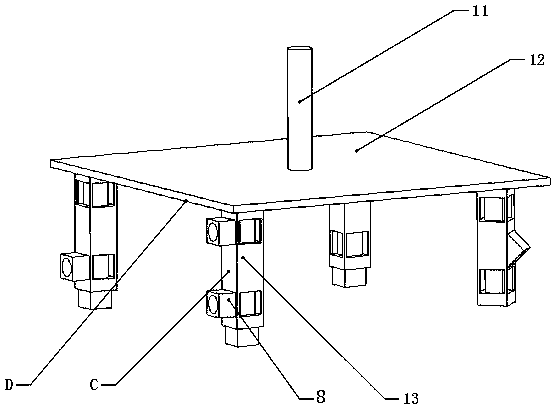

[0030] This embodiment is further optimized on the basis of the above embodiments, such as figure 2 As shown, further, in order to better realize the present invention, the mirror group fixture 7 includes a clamping rod 11 connected to the swing unit, a mounting plate 12 installed on the side of the clamping rod 11 away from the swing unit, and mounted on The mounting plate 12 is away from the side of the clamping rod 11 and is used for mounting the reflector 8 group mounting posts 13 of the reflector 8 .

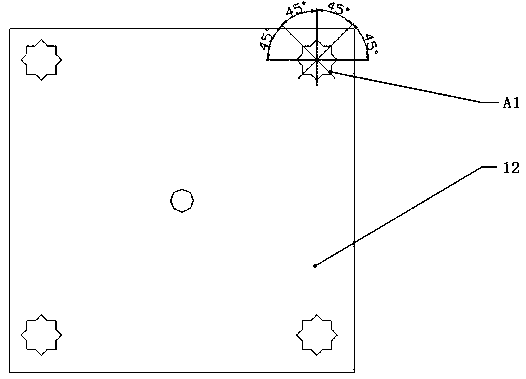

[0031] Further, in order to better realize the present invention, Figure 4 As shown, the side of the 8 sets of mounting columns 13 of the reflecting mirrors is provided with a first mounting groove B1 on the side away from the mounting plate 12, and the surrounding sides of the 8 sets of mounting columns 13 of the reflecting mirrors are provided with a second mounting groove B2 and a third mounting groove B2. Groove B3; the bottom of the second mounting groove B2 is arra...

Embodiment 3

[0042] This embodiment is further optimized on the basis of the above embodiments, such as figure 1 As shown, further, in order to better realize the present invention, the number of mounting posts 13 of the reflector 8 group is four and are uniformly installed on the side of the mounting plate 12 away from the clamping rod 11 .

[0043] Further, in order to better realize the present invention, the moving unit 2 includes two X-axis moving support frames that are perpendicular to the side of the machine bed 1 close to the mirror 8 group unit and are slidably connected with the machine bed 1. The connecting rod 4 between the two X-axis movable support frames, and the Z-axis support frame slidingly installed on the connecting rod 4 and moving along the Y-axis direction; the two X-axis movable support frames are arranged in parallel.

[0044] Further, in order to better realize the present invention, the Z-axis support frame includes a slider 3 that is slidably installed on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com