Fixing device of main transmission shaft of spinning machine

A main drive shaft and fixing device technology, applied in couplings, mechanical equipment, rigid shaft couplings, etc., can solve the problems of increased vibration value of the laying machine, de-soldering, hidden troubles, etc., and achieve the overall structural design. Ingenious, reduce frequent replacement, easy to prevent loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

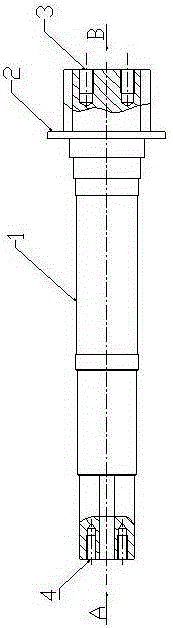

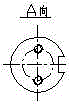

[0026] see figure 1 , diagram 2-1 , Figure 2-2 , Figure 5 , a main transmission shaft fixing device for a laying machine, the fixing device includes a main transmission shaft 1, a flange 5, a screw umbrella 6, and the flange 5 is arranged on the main transmission shaft 1, and the screw umbrella 6 is set On the flange 5 , a cylindrical pin 12 is arranged on the screw umbrella 6 and the flange 5 . The fixing device can adapt to the stable rolling requirements of the main drive shaft of the high-speed wire laying machine, overcomes the phenomenon of desoldering and cracking caused by the connection between the main drive shaft of the laying machine and the flange plate, and reduces the cost of the laying machine. The vibration value during operation avoids frequent replacement of the main drive shaft, thereby ensuring the safe operation of the equipment and reducing production costs.

Embodiment 2

[0028] see figure 1 , Figure 5 , as an improvement of the present invention, the fixing device further includes an annular rib 2, and the annular rib 2 is arranged on the main transmission shaft 1, which facilitates the positioning of the flange. The length of the entire main transmission shaft remains unchanged, and the annular rib is close to the flange, which ensures that one side of the main transmission shaft is fixed. The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

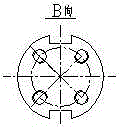

[0030] see figure 1 , image 3 , Figure 5 , as an improvement of the present invention, the fixing device further includes a main transmission shaft pressure plate 7, the main transmission shaft pressure plate 7 is arranged on the main transmission shaft 1 and the flange 5, and is fixed by pressure plate bolts 9. The rest of the structures and advantages are exactly the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com