Synthetic compressor lubricant for compressing multi-component hydrocarbon mixture gas

A mixed hydrocarbon, multi-component technology, used in lubricating compositions, petroleum industry, etc., to achieve good anti-carrying ability, good anti-rust performance, good friction pair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

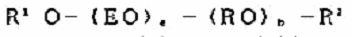

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: this product is to be base oil with polyether synthetic oil, is equipped with additive composition again, wherein the weight ratio of each component is as follows:

[0041] Polyether A225: 94.645%

[0042] 2,6 di-tert-butyl-p-cresol (T501): 0.05%

[0043]Sodium petroleum sulfonate rust inhibitor: 2%

[0044] Benzotriazole fatty acid salt: 1%

[0045] Thiadiazole metal deactivator: 0.3%

[0046] Zinc dialkyldithiophosphate (ZDDP): 2%

[0047] No. 10000 methyl silicone oil antifoaming agent: 0.005%.

Embodiment 2

[0048] Embodiment 2: This product is to be base oil with polyether synthetic oil, is equipped with additive composition again, wherein the weight ratio of each component is as follows:

[0049] Polyether F-6: 94.997%

[0050] 2,6-di-tert-butyl-α-dimethylamino-p-cresol: 0.5%

[0051] Palmitoleic Acid: 0.2%

[0052] Benzotriazole dodecylamine: 1%

[0053] Thiadiazole derivative T561: 0.3%

[0054] Molybdenum dithiocarbamate: 3%

[0055] 10000#Simethicone antifoaming agent: 0.003%.

Embodiment 3

[0056] Embodiment 3: this product is to be base oil with polyether synthetic oil, is equipped with additive composition again, wherein the weight ratio of each component is as follows:

[0057] NPE-108: 93.995%

[0058] Dialkyldiphenylamine: 1%

[0059] Barium petroleum sulfonate: 1%

[0060] Benzotriazole octadecylamine: 1%

[0061] Triazindene (T706): 0.5%

[0062] Tributyl phosphate extreme pressure antiwear agent: 2.5%

[0063] Polymethacrylate antifoam agent: 0.005%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com