Multifunctional liquid feeding and discharging device for electroplating and working method of multifunctional liquid feeding and discharging device

A multi-functional, electroplating solution technology, applied in electrolytic components, electrolysis process, cells, etc., can solve the problems of decreased electroplating solution concentration, unstable product quality, waste of electroplating chemical accessories, etc., to achieve the effect of ensuring ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

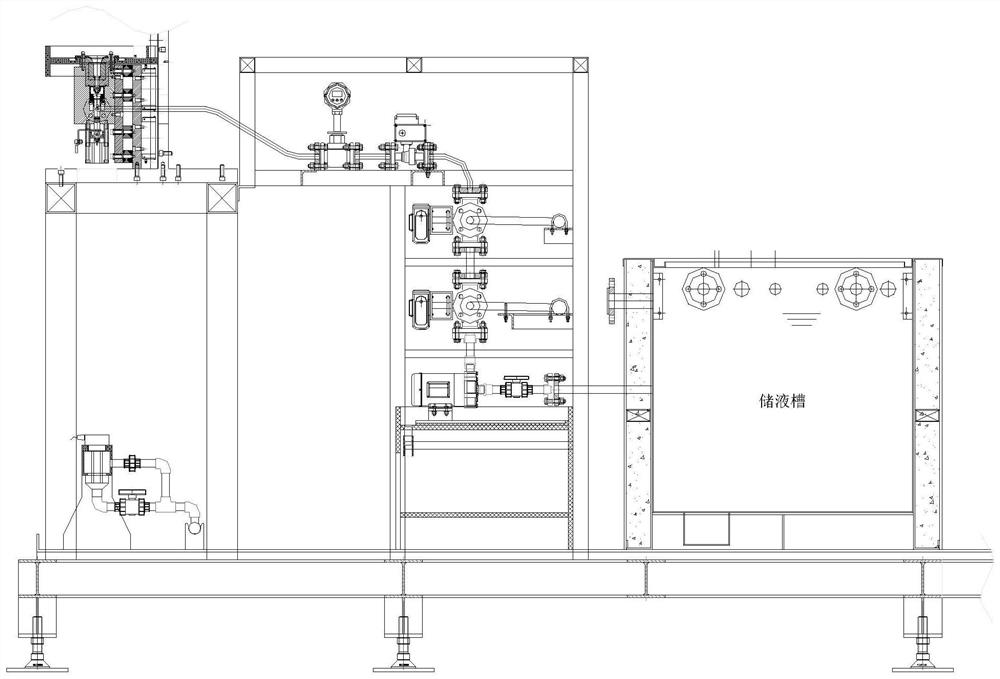

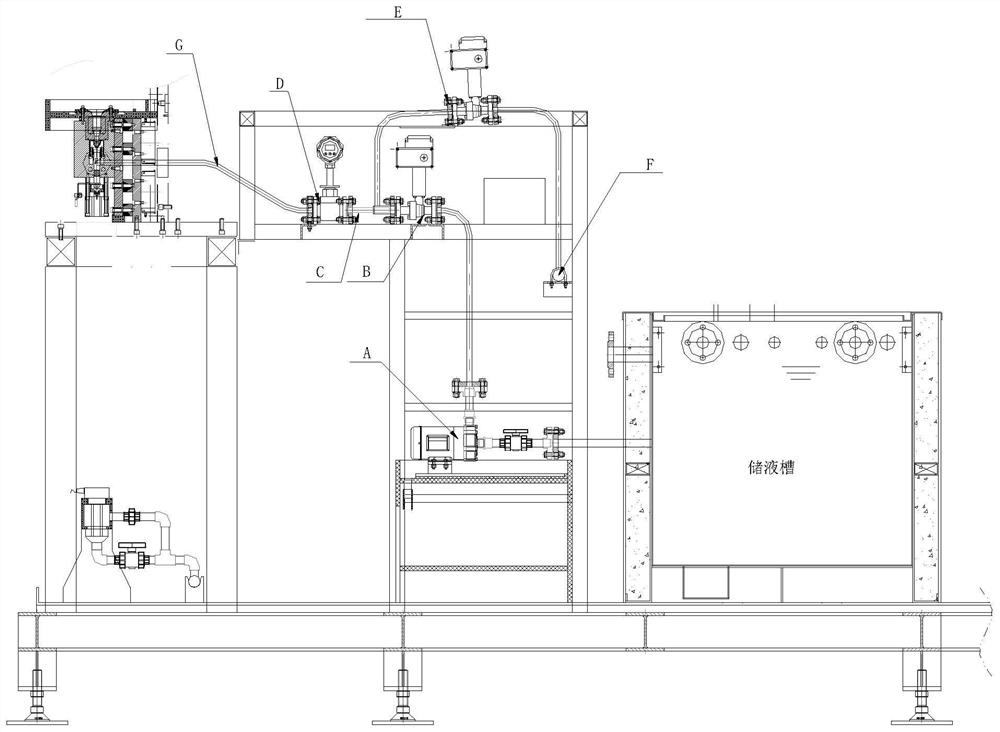

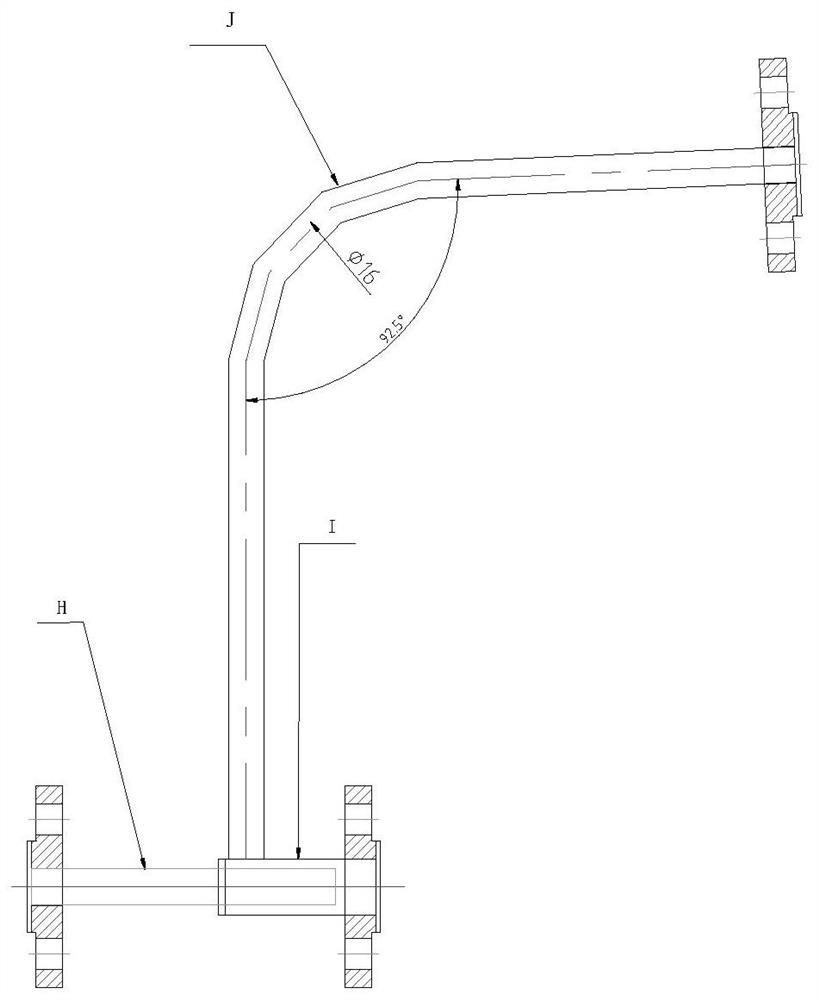

[0027] see figure 2 , image 3 , a multifunctional liquid inlet and discharge device for electroplating, including a water pump connected in sequence and showing an upward trend, a liquid inlet valve, a multifunctional liquid discharge combination pipe, and a workpiece liquid inlet pipe, and the water pump is used to draw water from the liquid storage tank Electroplating solution, the workpiece liquid inlet pipe is used to provide electroplating solution to the workpiece.

[0028] The multifunctional liquid discharge combined pipe includes a first pipe adjacent to the workpiece liquid inlet pipe, a second pipe adjacent to the liquid inlet valve, the first pipe is inserted into the pipe hole of the second pipe, and the second pipe The end is sealed, and there is an overflow gap between the first pipe and the second pipe. The upper end of the second pipe is connected to the water inlet and discharge common pipe. The over-current gap between them is connected, and the water in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com