Liquid analysis device and method based on online dilution

A liquid analysis device and liquid analysis technology, which are applied in the preparation of test samples, etc., can solve the problems of inability to provide and high reagents, and achieve the effect of solving the dilution problem, realizing automation and rapid transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The liquid analysis device based on online dilution according to the embodiment of the present invention, the liquid analysis device based on online dilution includes:

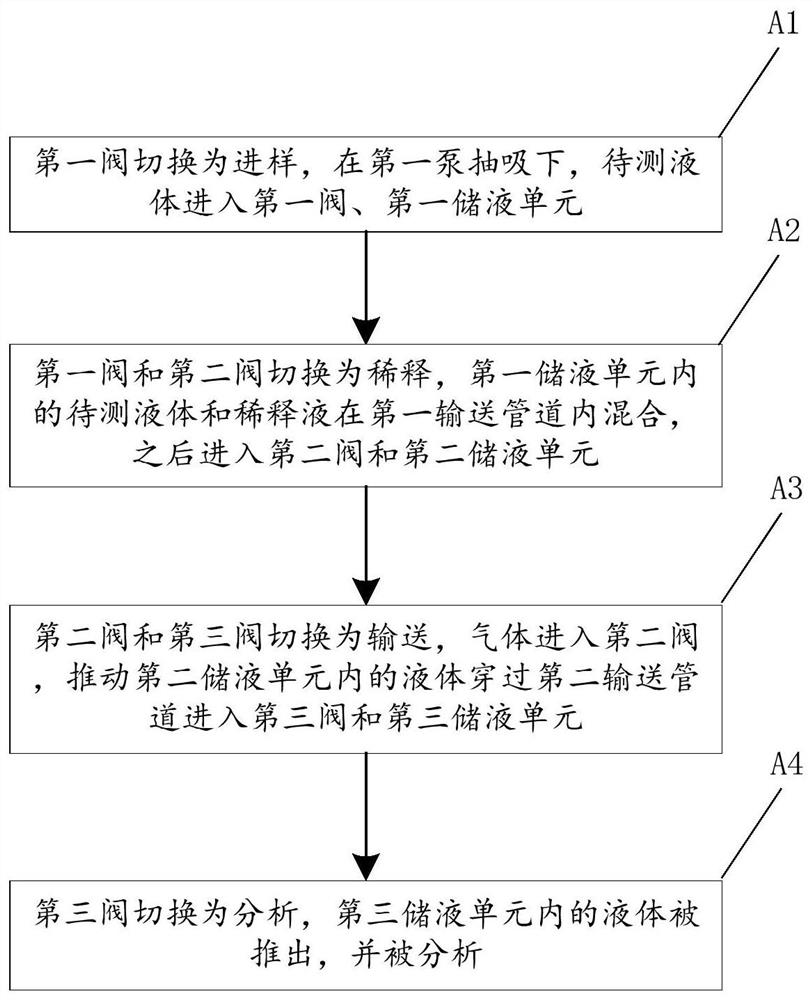

[0032] The first valve and the first liquid storage unit, the first valve, such as a multi-way valve, has multiple ports; when the first valve is switched to sample injection, the liquid to be tested passes through the first pump under the suction of the first pump, such as a syringe pump. One valve, the first liquid storage unit; when the first valve is switched to dilution, the second pump pushes the carrier liquid and the liquid to be tested in the first liquid storage unit, and the third pump pushes the diluent through the first valve and enters the second liquid in turn. a delivery pipeline, a second valve and a second liquid storage unit;

[0033] a second pump and a third pump, the second pump and the third pump are used to draw liquid and push the liquid to move;

[0034] The second valve and t...

Embodiment 2

[0051] An application example of the online dilution-based liquid analysis device and method according to Embodiment 1 of the present invention.

[0052]In this application example, the first pump, the second pump and the third pump all use syringe pumps. By switching, the first pump selectively communicates with the first valve and the waste liquid pool, and the second pump selectively communicates with the first valve and the load tank. liquid, the third pump selectively connects the first valve and diluent;

[0053] The first valve adopts a two-position seven-way valve, and the multiple ports are: the first port selectively communicates with the second port and the sixth port, the third port selectively communicates with the second port and the fourth port, and the fifth port selectively communicates with the second port and the sixth port. The common port is selectively connected to the second port and the third port; the first port is connected to the liquid to be tested,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com