Rapid mechanical deoxidation and nitrogen-enriching gas-conditioning insect prevention method for closed carriage

A technology of deoxygenation and nitrogen enrichment, deoxygenation and nitrogen enrichment, applied in chemical instruments and methods, inorganic chemistry, nitrogen compounds, etc., can solve problems such as time consumption, and achieve the effect of gas flow balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

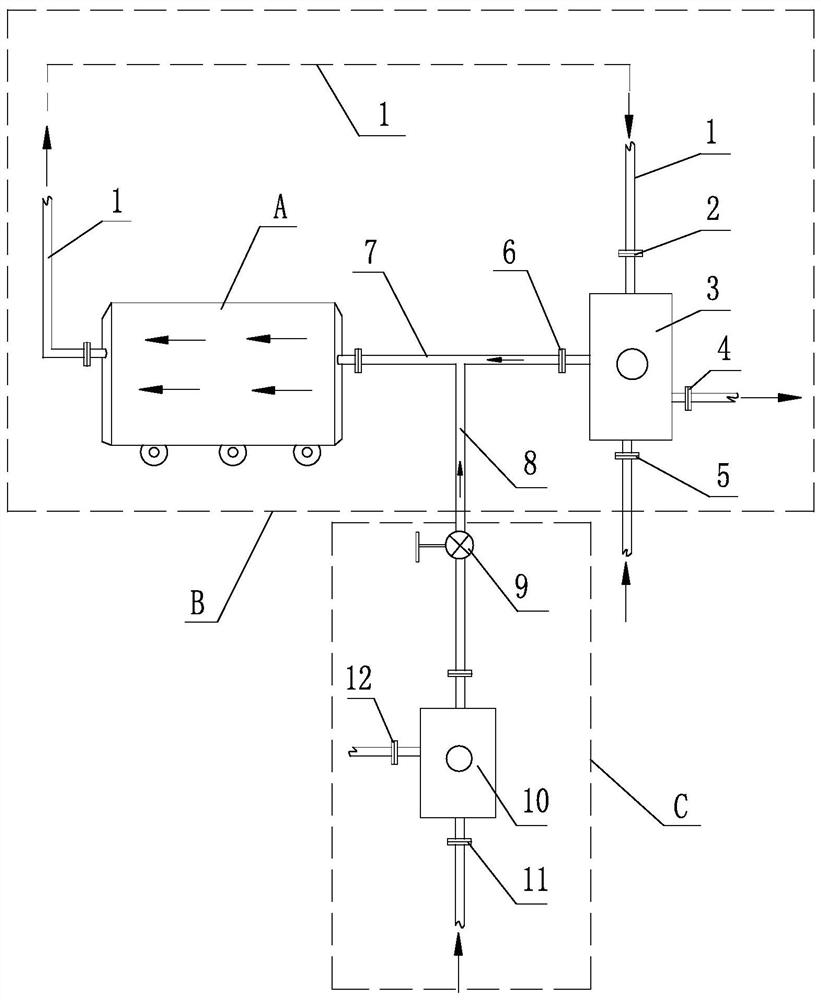

[0075] A method for fast mechanical deoxygenation and nitrogen-enriched atmosphere adjustment and pest control in a closed compartment, in any symmetrical compartment (which can be a high-speed rail compartment, an aircraft cabin, a ship cabin, a container, or a bus compartment, referred to as "closed compartment", the same below) A 1-10 gas output pipes 1 and 1-10 gas input pipes 7 are respectively drawn from the two sides or the top and bottom of the airtight compartment. Choose the size of plastic, rubber or metal pipes with an inner diameter of 10-100mm, the gas output pipe (or gas discharge pipe) 1, the gas input pipe 7 is connected to the closed compartment through the pipe joint, and the pipe joint is used by Wuhan Dongchang Storage Technology Co., Ltd. The plastic joints of various specifications produced by the company are used to check for leaks and mend holes in the closed compartment, and use the negative pressure detection method to test the airtightness of the clo...

Embodiment 2

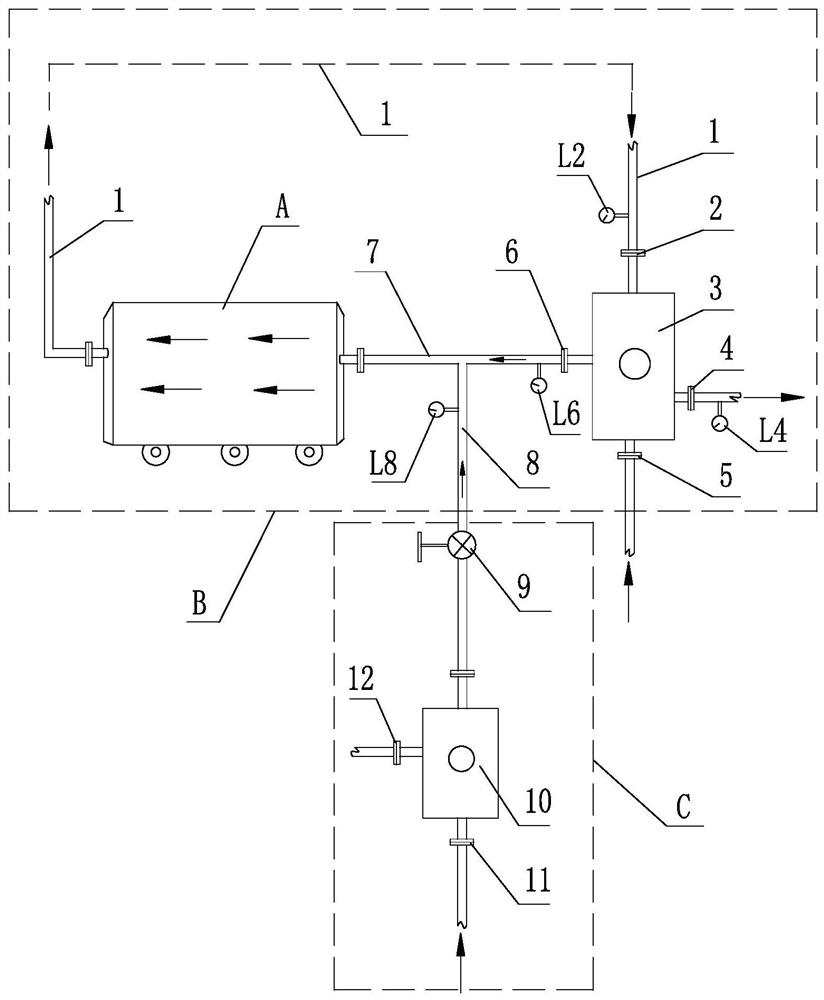

[0092] It is basically the same as Embodiment 1, except that the gas flow between the exhaust pipe of the closed compartment and the input gas pipe and the pressure inside and outside the system are kept in a balanced state by the following method. The gas flow detector L6 is set on the gas outlet 6 of the main component, the gas flow detector L2 is set at the raw material gas inlet 2 of the mechanical deoxygenation and nitrogen-enriching equipment, and the gas flow detector L8 is set on the nitrogen-enriched gas output pipeline 8. The detection quantity of the flow detector calculates the need for the mechanical nitrogen filling pressure tolerance linkage device C to compensate the nitrogen-rich gas compensation amount in the closed cycle mechanical deoxygenation and nitrogen filling system, and adjusts the control valve 9 so that the detection value of the "gas flow detector L8 ≈The detection value of the flow detector L2 - the detection value of the flow detector L6", the ab...

Embodiment 3

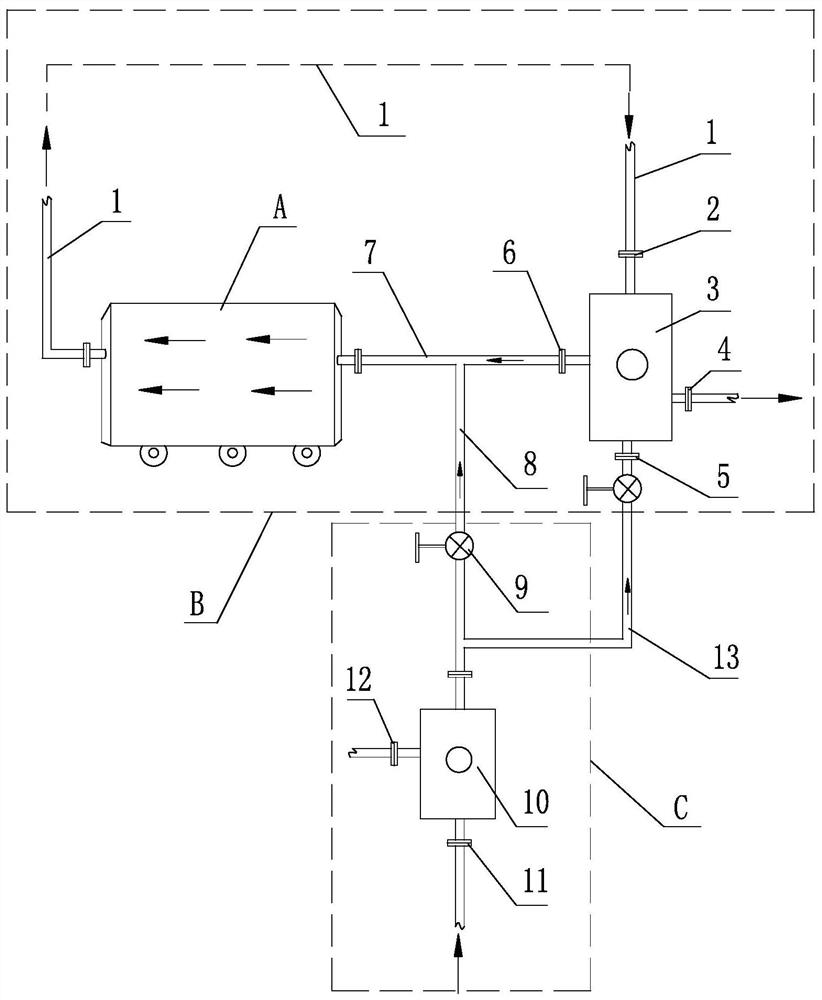

[0094] It is basically the same as Embodiment 1 and 2, except that a pressure sensor is set in the airtight compartment, and when the pressure sensor detects that there is a pressure difference inside and outside the airtight compartment, by adjusting the control valve of the nitrogen-enriched source of uniform pressure 9 to control the flow of nitrogen-rich gas in the nitrogen-rich gas output pipeline 8 to ensure that the pressure difference inside and outside the closed compartment A tends to balance. The pressure sensor in this embodiment can use the pressure sensor product of Honeywell (China) Co., Ltd.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com