Patents

Literature

54results about How to "Reduce downtime losses" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

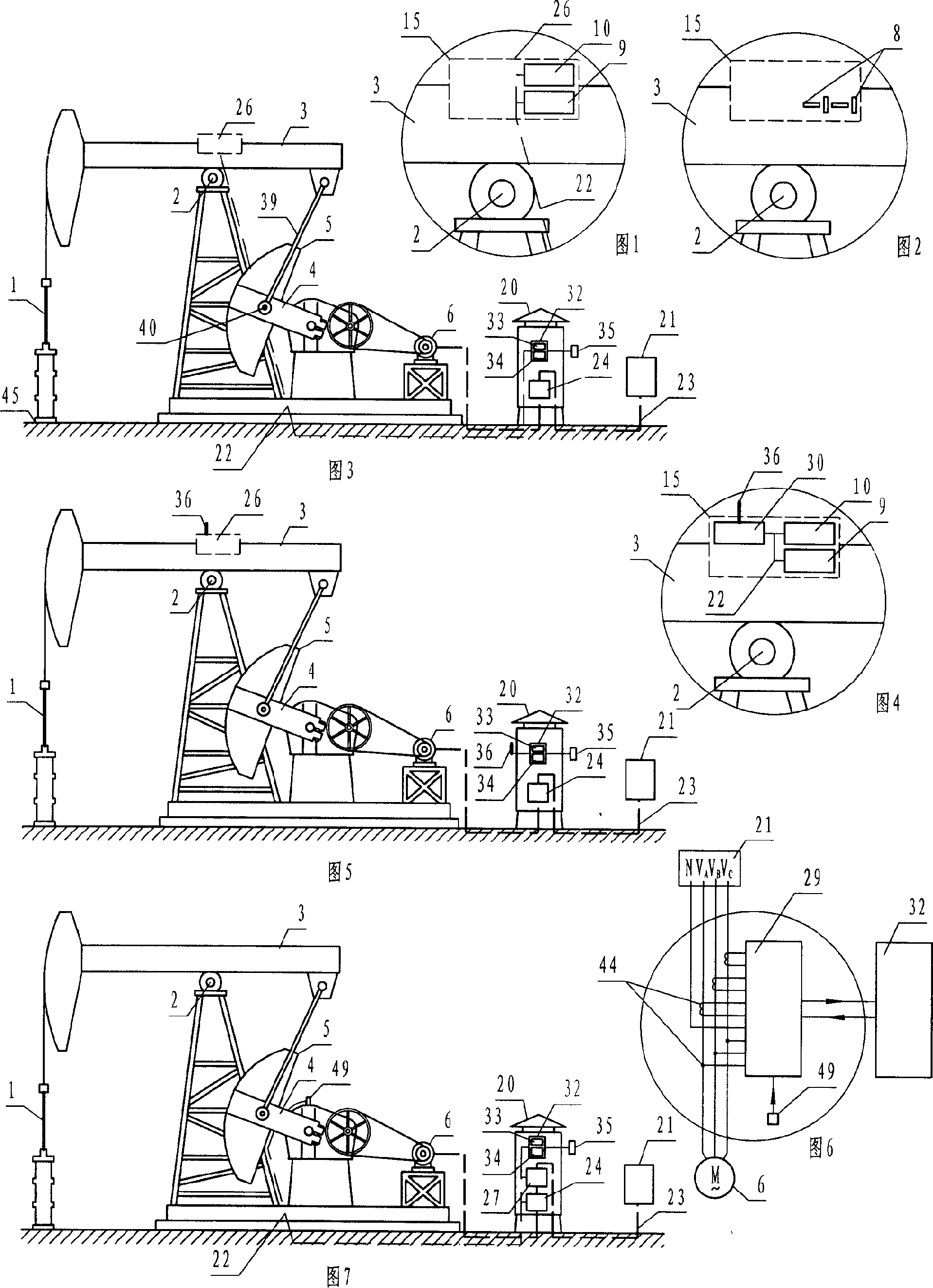

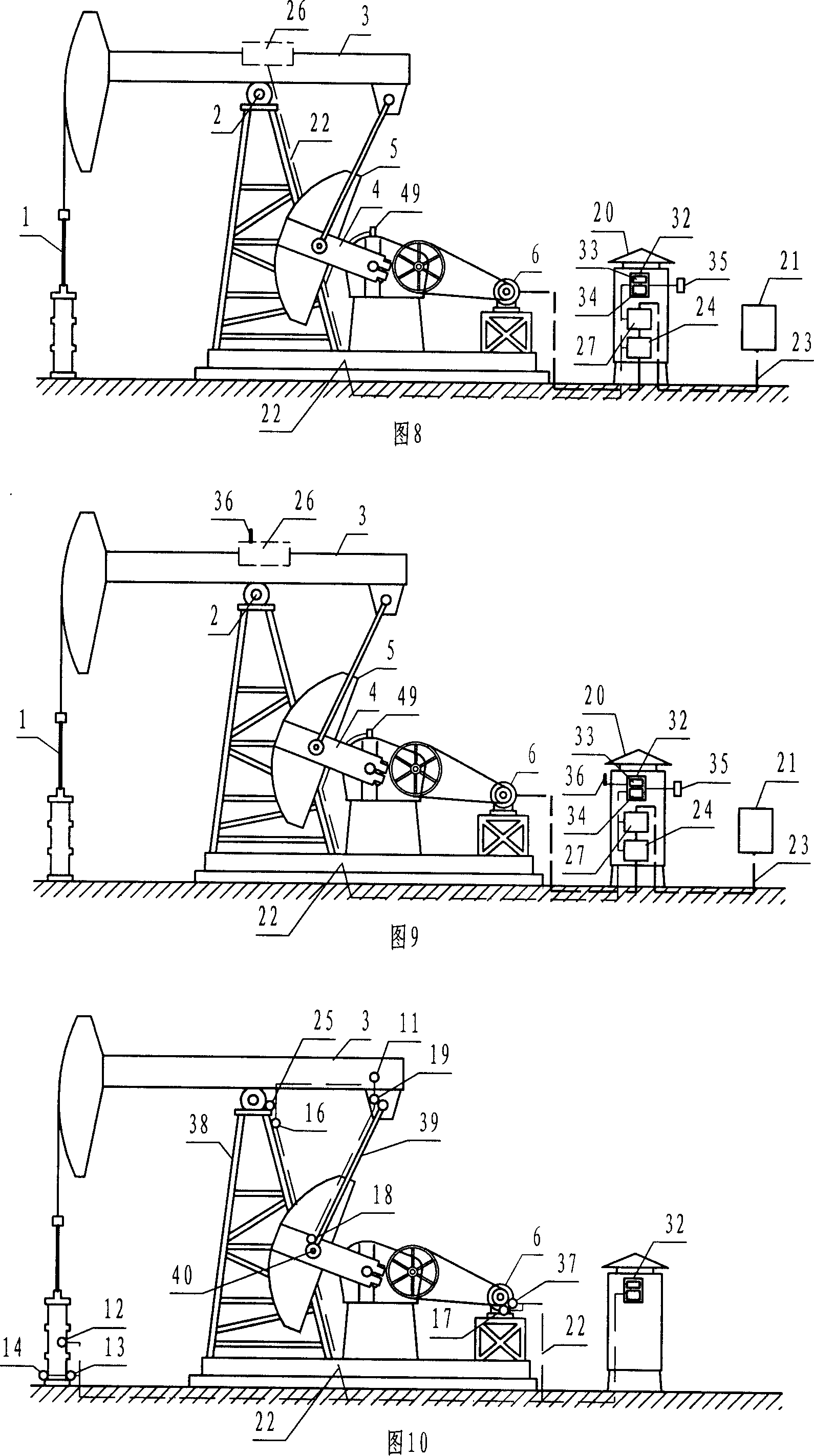

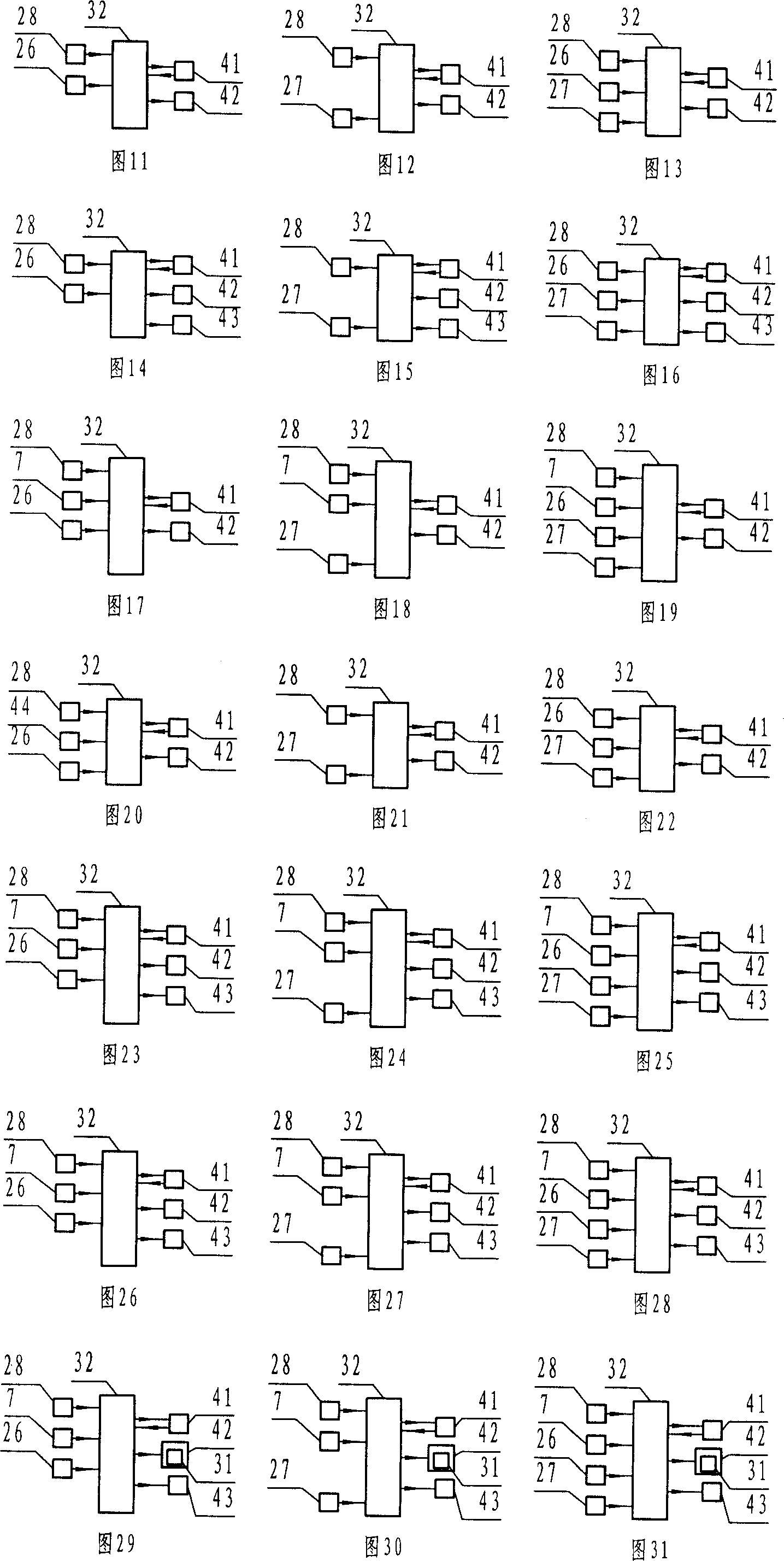

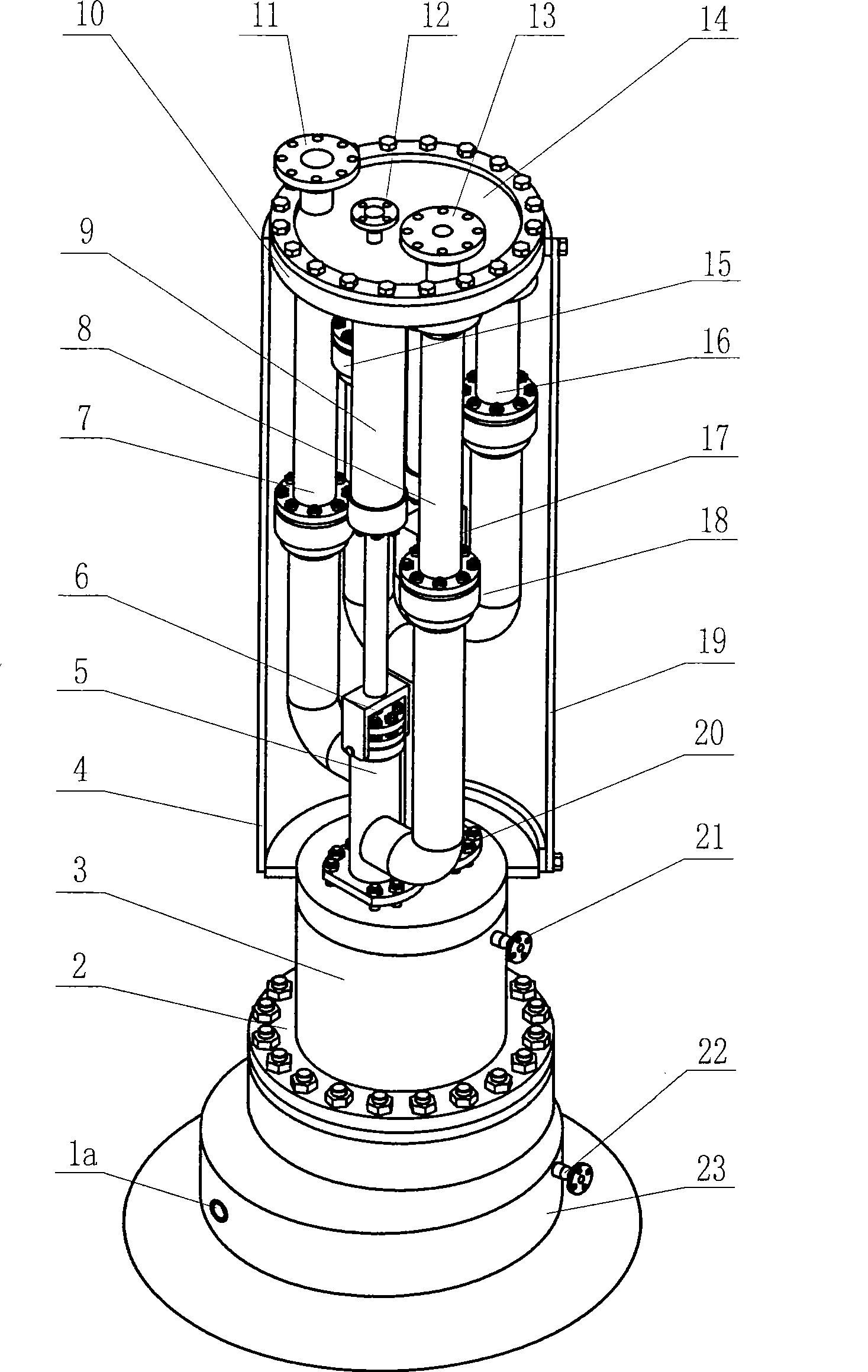

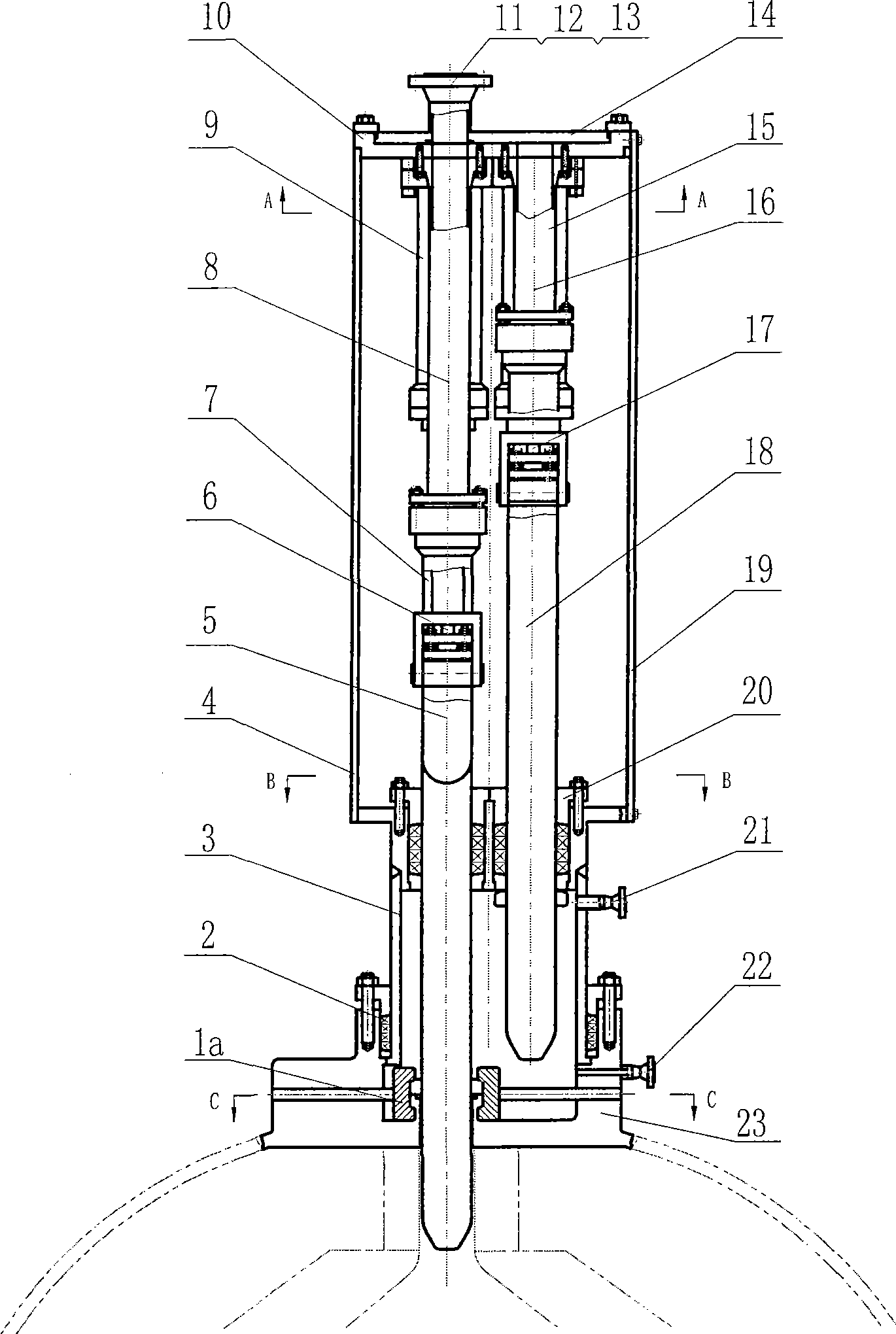

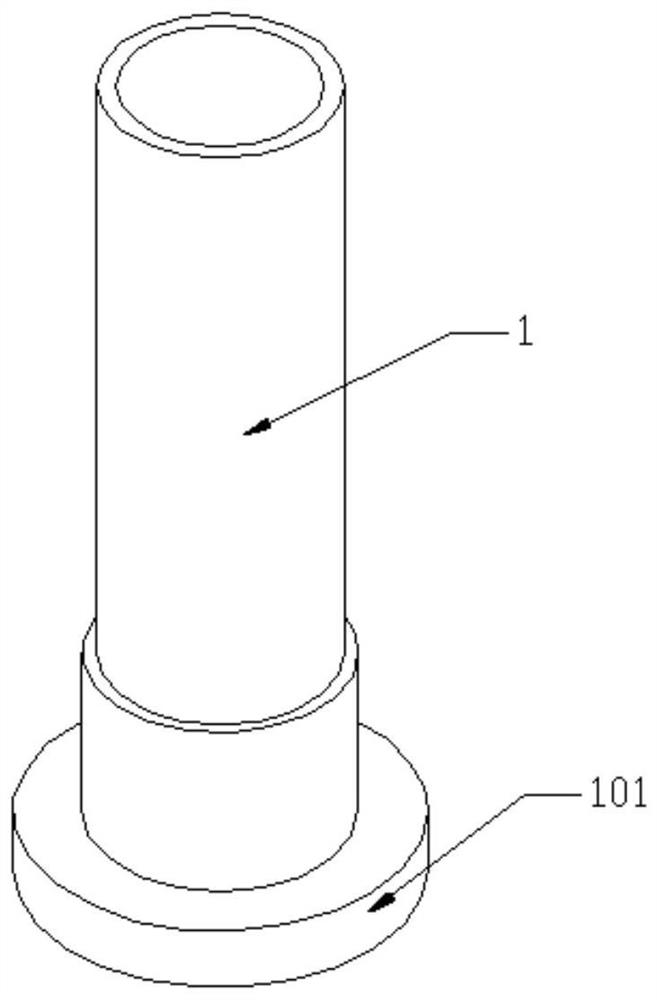

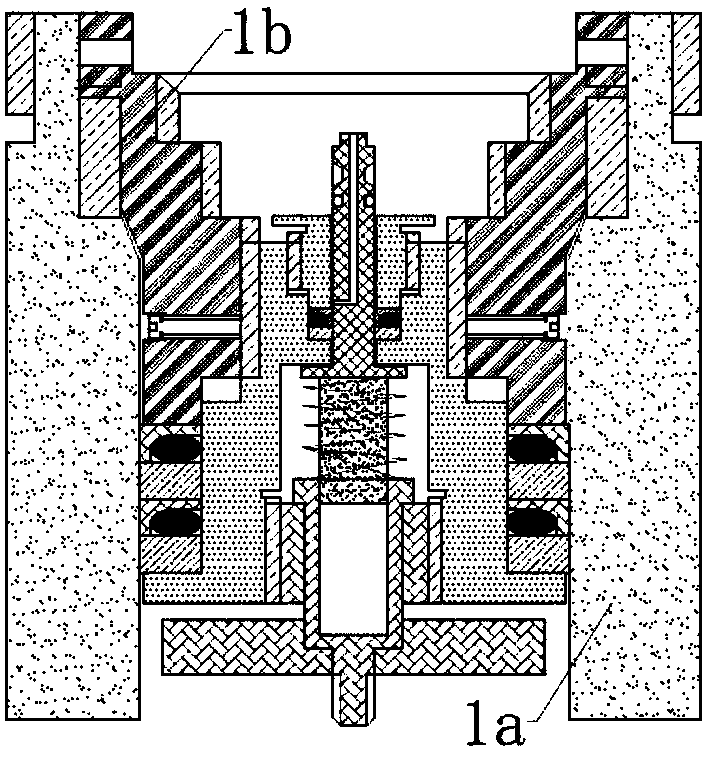

Pumping unit balance adjusting apparatus and pumping unit balance structure adjusting method

InactiveCN101105119AGuaranteed uptimeEliminate hidden dangersSurveyConstructionsControl systemData acquisition

The invention discloses a balance adjustment device for oil pumping machine and balanced structure adjustment method of oil pumping machine, by which the balanced structure adjustment is changed from using indirect parameter-electric current to using direct parameter-displacement, so that the adjustment is accurate and rapid, and the energy is remarkably saved. The invention also discloses an oil extraction control device, a color power indicator, an oil extraction measurement meter, an oil extraction integrated protection device, an oil extraction integrated testing and diagnosis control device, and a data acquisition and transmission unit for an oil extraction measurement and control system. The color power indicator provides a novel mean and method for diagnosis of oil pumping machine, which remarkably improves the effectiveness of diagnosis. The oil extraction integrated diagnosis control device and the data acquisition and transmission unit for the oil extraction measurement and control system have the advantages of high degree of automation, more monitored and controlled parameters, and large protection range; can perform onsite automatic acquisition and control and can perform long-distance automatic acquisition and control in management center; and provides a fundamental mean with high feasibility for realizing automated management of the full oil field.

Owner:刘克文

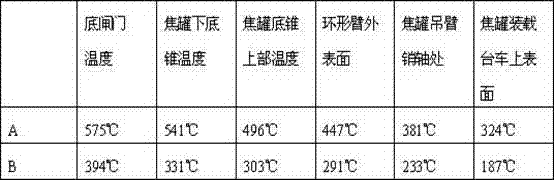

High-temperature-wear-resistant lining plate for coke pot for coke dry quenching and preparation method thereof

InactiveCN102212820ASuitable for harsh working conditionsImprove corrosion resistanceCoke quenchingMetallic material coating processesQuenchingHigh power lasers

The invention discloses a preparation method of a high-temperature-wear-resistant lining plate for a coke pot for coke dry quenching. The high-temperature-wear-resistant lining plate is prepared by cladding a metal ceramic layer on a metal lining plate. The preparation method comprises the following steps: (1) preparing uniformly mixed metal ceramic powder; (2) brushing light absorbing coatings on the surface of the metal lining plate uniformly; (3) after the coating of the light absorbing coatings is dry, feeding the powder pneumatically or feeding the powder by way of powder spreading or gravity, wherein the thickness of the powder layer is 0.5-4.0mm; and (4) scanning the metal ceramic powder which has been spread or delivered in place by virtue of a high power laser and forming the cladded high-temperature-wear-resistant metal ceramic layer on the metal lining plate. By utilizing the method to prepare the high-temperature-wear-resistant metal lining plate for the coke pot for coke dry quenching, low cost and stable production quality are ensured, and implementation is convenient; and the method is convenient for mass production and has prominent economic and social benefits.

Owner:SHIJIAZHUANG HUADING HI TECH STRENGTHEN ALLOY EQUIP MFG

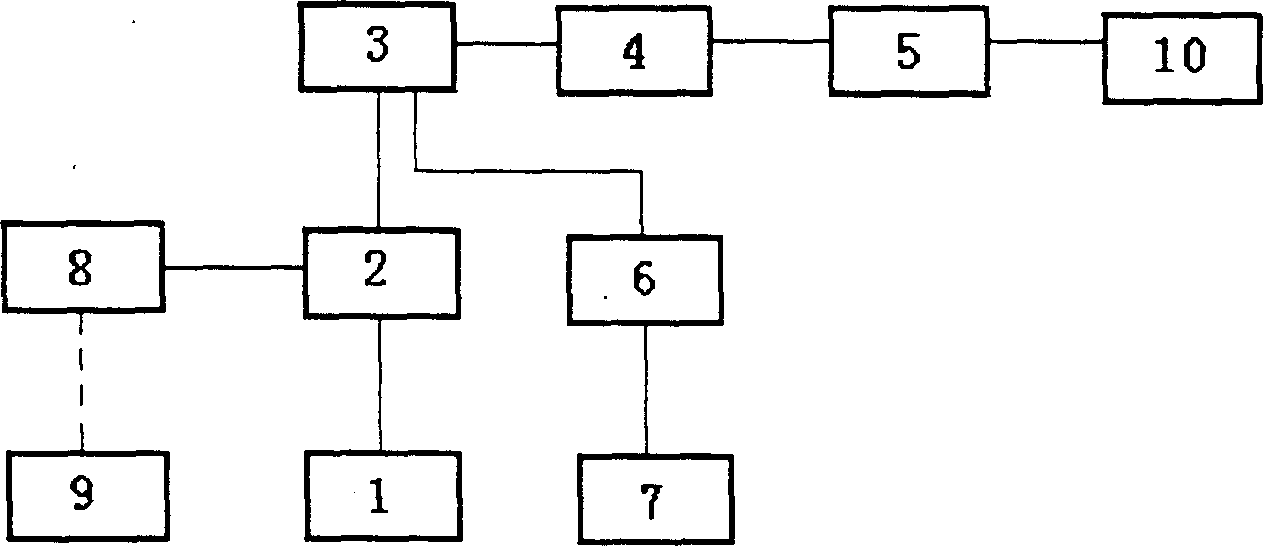

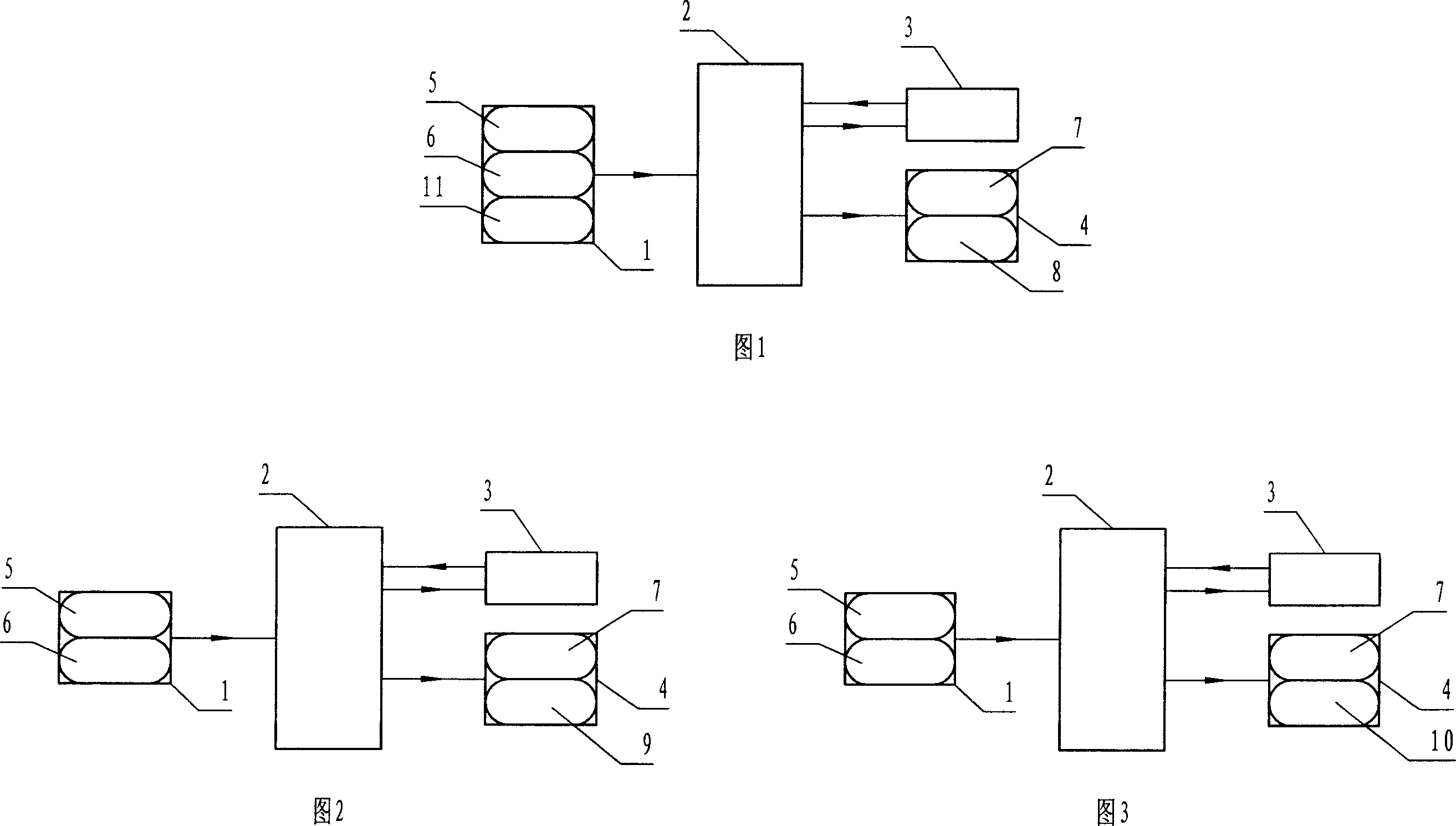

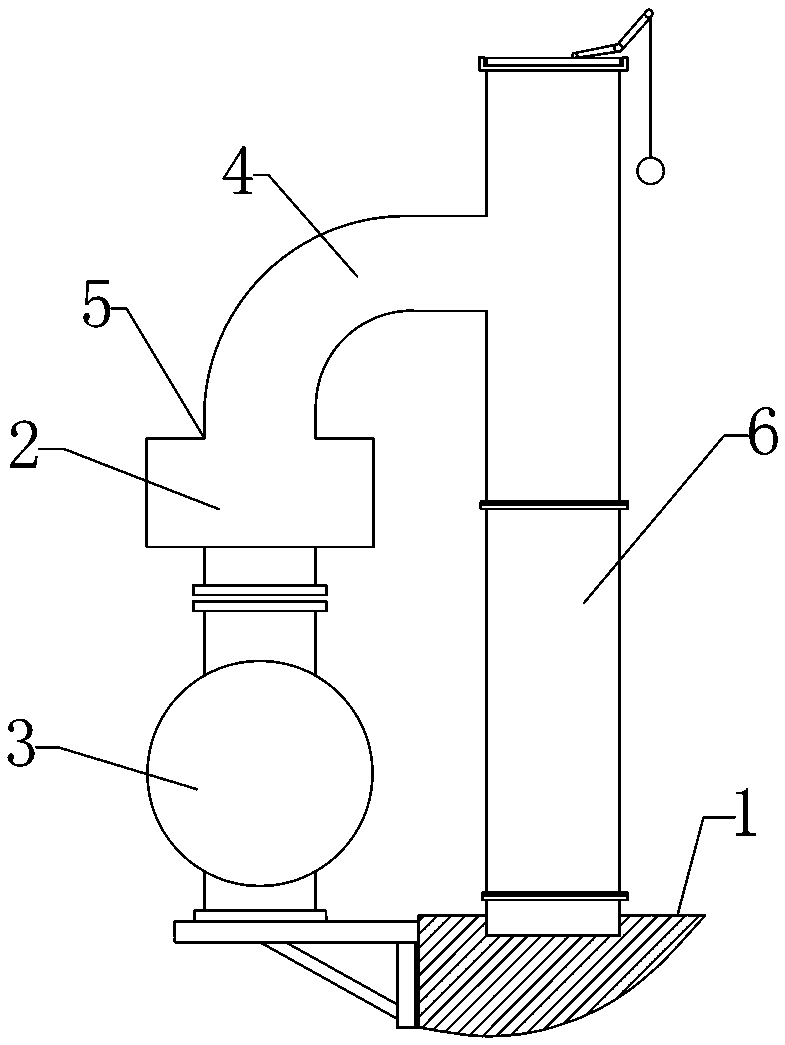

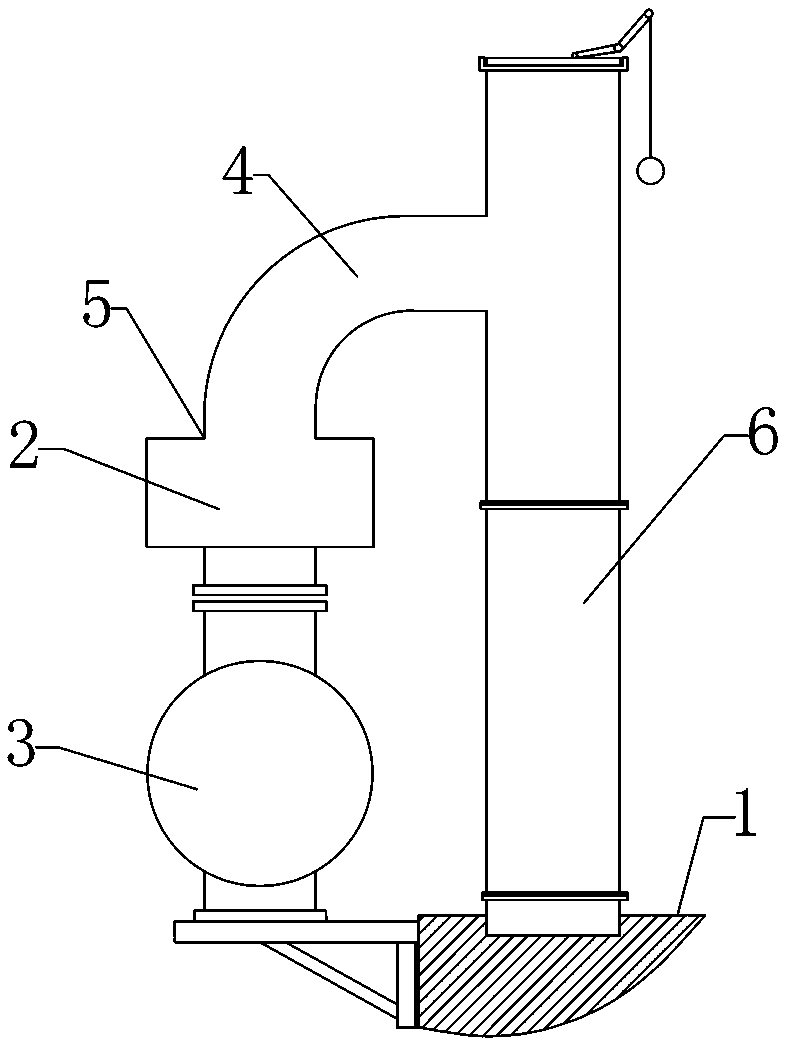

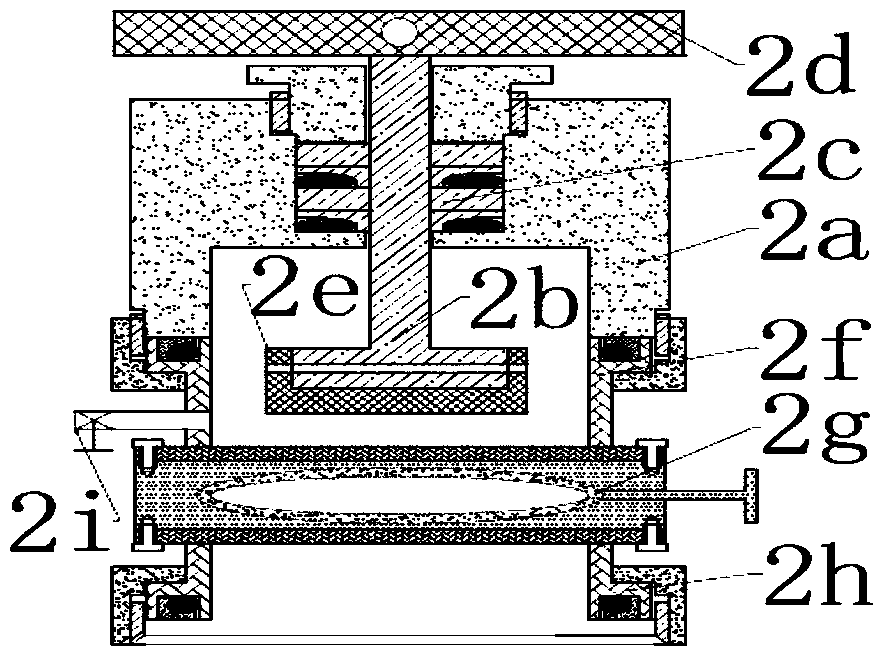

High precision all-purpose autogiro and composing method thereof

InactiveCN1721820AImprove efficiencyFast positioning and orientation measurementTurn-sensitive devicesTheodolitesPower controllerTrilinear coordinates

The invention relates to a fast orientation system, which is formed by gyroscope used to ascertain north direction, and automatic following electric instrument used to measure trilinear coordinates. It id formed by automatic gyroscope 3, automatic following electric instrument 1, screw coupling device 2, timing signal channel 4, palmtop 5, power controller 6, GPS RTK receiver 8, GPS base station 9 and fast orientation measuring control software 10. It is suit for subway shield driving, channel piercing, remote weapon fast orientating, city cadastral measuring, craft cabin measuring and mine emergency orientating and so on.

Owner:张驰

Synthetic compressor lubricant for compressing multi-component hydrocarbon mixture gas

ActiveCN101955841ASolving Dilution ProblemsReduce downtime lossesLubricant compositionHydrocarbon mixturesAntioxidant

The invention provides synthetic compressor lubricant for compressing a multi-component hydrocarbon mixture gas. The synthetic compressor lubricant consists of polyalkalene glycol synthetic oil serving as base oil and an additive. The synthetic compressor lubricant comprises the following components in percentage by weight: 90 to 97 percent of polyalkalene glycol synthetic oil, 0.05 to 2 percent of antioxidant, 0.01 to 2 percent of anti-rusting agent, 0.5 to 3 percent of oiliness agent, 0.01 to 0.5 percent of metal passivator, 0.5 to 5 percent of extreme-pressure antiwear agent and 0.001 to 0.01 percent of antifoaming agent. The synthetic compressor lubricant can resist dilution of a hydrocarbon gas to a lubricant, can adapt to the compression to the hydrocarbon gas, has good compatibility with a water vapor-containing gas mixture, and meets special requirement on the oil for a multi-component hydrocarbon mixture (such as flare gas) compressor system. The problem of dilution of the multi-component hydrocarbon mixture gas (such as the flare gas or gas) to the lubricant is successfully solved; accidents, such as stop, shaft locking and the like, of a compressor, caused by reducing of viscosity, are radically avoided; and the work stoppage loss and the worker labor intensity of enterprises are reduced.

Owner:CHINA PETROLEUM & CHEM CORP

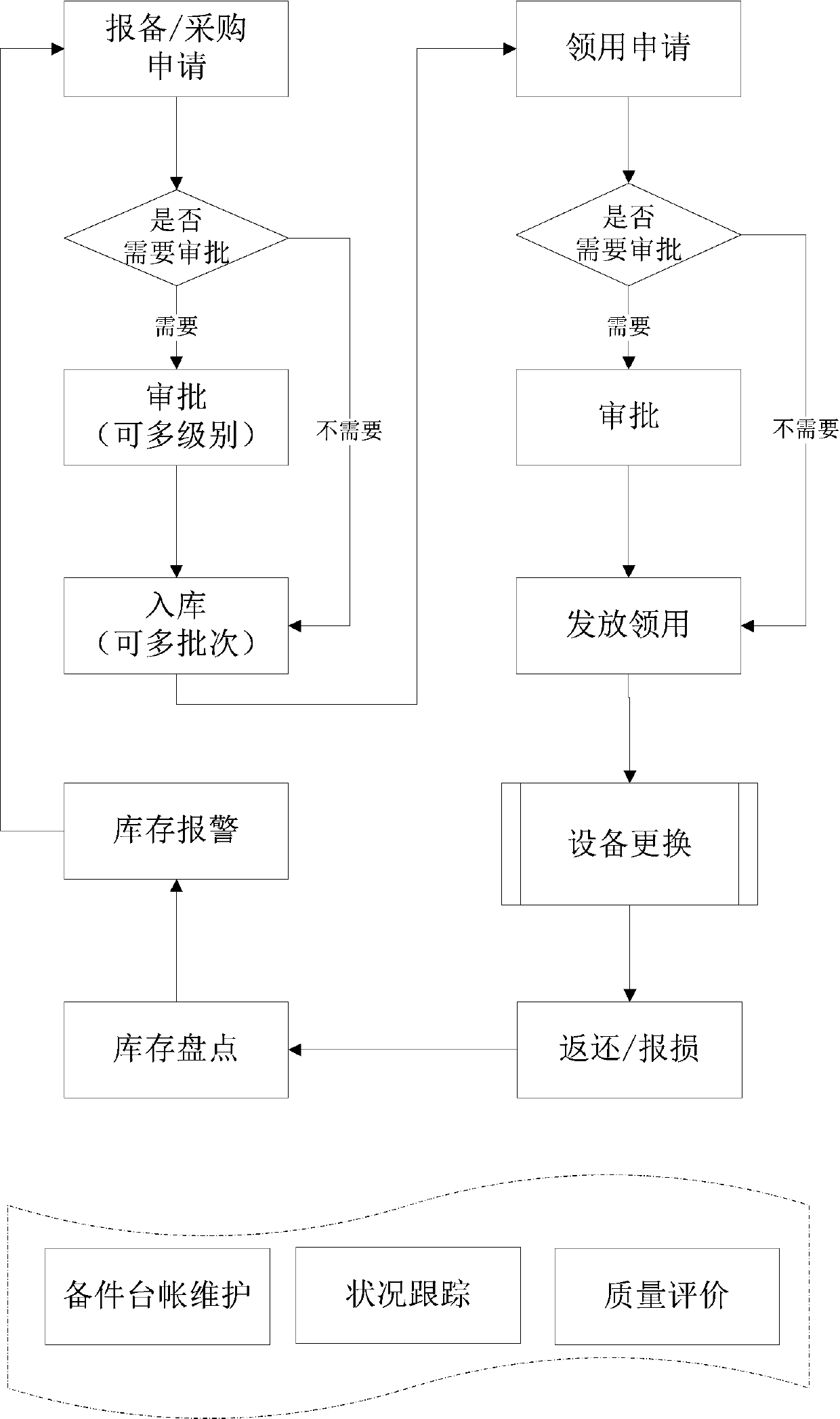

Code scanning technology based spare part full life circle tracking method

InactiveCN107688913ASmooth maintenanceSmooth Overhaul ProgramLogisticsSpare parts managementControllability

The invention discloses a code scanning technology based spare part full life circle tracking method, and relates to a life circle tracking method. At present, a spare part management mode exposes thedefects that the efficiency is low, and the controllability is poor, and very big hidden danger is brought to safety production of a company. The method comprises the following steps of spare part filing application, spare part storage, spare part receiving, equipment replacement, spare part returning / breakage, spare part stock-taking, spare part early warning report, spare part quality evaluation, status tracking, spare part account maintenance and file information maintenance conducted on frequently-used spare parts according to production requirements. According to the technical scheme, normal maintenance of production equipment and smooth maintenance plan implementation are guaranteed, safe and stable production of an automatic production operation system is guaranteed, centralized and unified management of the spared parts is strengthened, spare parts are stocked, people pay adequate attention to four links of use, management, repairing and supplying, and spare part post-use tracking is well conducted.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO MARKETING SERVICE CENT +1

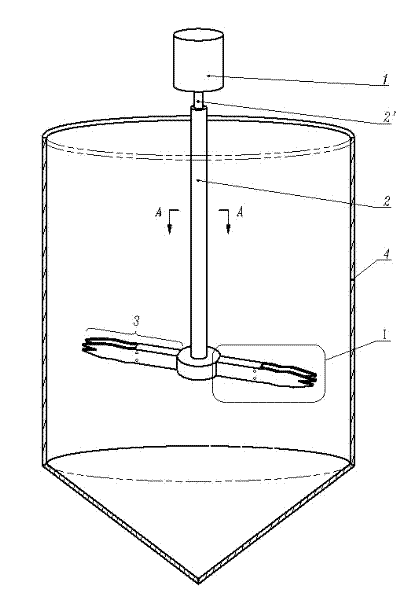

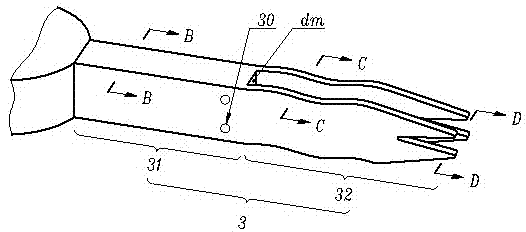

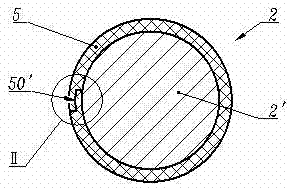

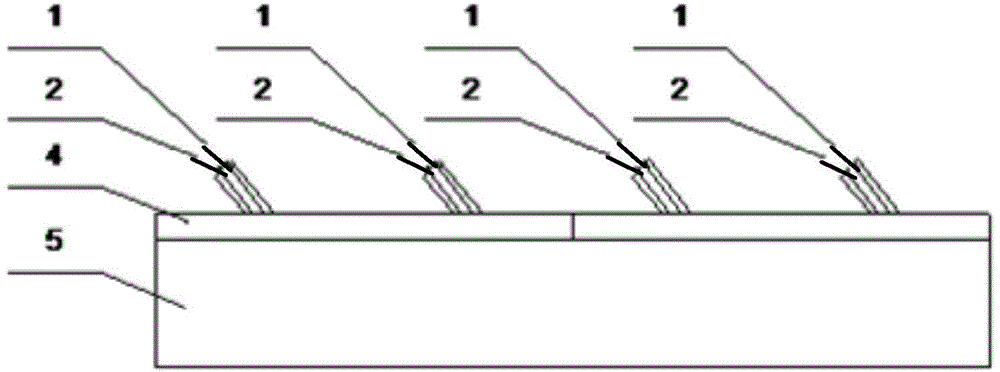

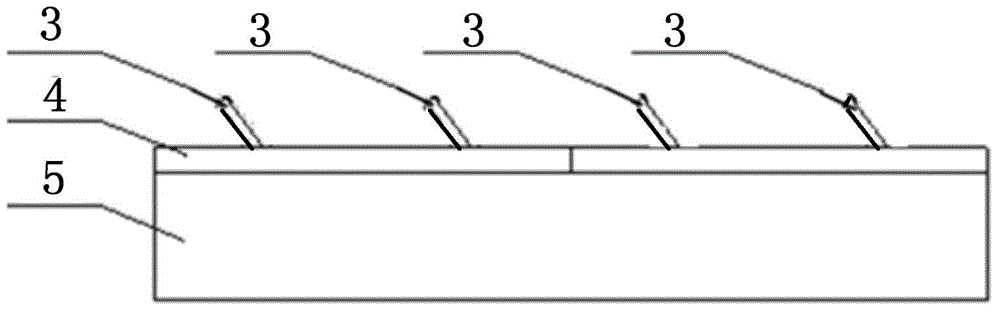

Manganese ore pulp stirring paddle with long service life

InactiveCN102210991AWeight increaseExtended service lifePhotography auxillary processesTransportation and packagingIsolation layerManganese

The invention provides a manganese ore pulp stirring paddle with long service life. The manganese ore pulp stirring paddle provided by the invention comprises a stirring shaft and a stirring paddle connected to the stirring shaft and immersed in manganese ore pulp. In the invention, the outer surfaces of the stirring shaft and the stirring paddle are respectively provided with an isolation layer covered by chloroprene rubber or natural rubber. In the invention, the stirring shaft and the stirring paddle are isolated from manganese ore powders by means of covering the chloroprene rubber or natural rubber, so that the stirring shaft and the stirring paddle are not directly rubbed with the manganese ore powders, equivalently, the diameter of the stirring shaft is increased, and the width and thickness of the stirring paddle are widened and thickened. The densities of the chloroprene rubber and the natural rubber are far less than that of the material of the stirring paddle, so that the weight of the whole stirring paddle is slightly increased, and motors with larger power are not necessary to be replaced. Briefly, in the invention, the service life of the stirring paddle is prolonged by virtue of additionally arranging the isolation layer, so that the production halt loss (caused by replacing the crapped stirring paddle) is reduced. Compared with the prior art, the manganese ore pulp stirring paddle provided by the invention has the advantage that the total production cost is greatly reduced.

Owner:XIUSHAN TUJIA MIAO AUTONOMOUS COUNTY SCI TECH COMMITTE

Oil extraction indicator and using method thereof

The invention discloses a color dynamometer for oil extraction and application method thereof. The color power indicator for oil extraction relates to a device for measuring and monitoring curves, figures and related data reflecting operating state of pumping well, in particular to a device for measuring and monitoring various dynamometer diagrams and related data reflecting operating state of oil well pump, and its display device is directly or indirectly provided with a color display screen. During application, the device continuously measures dynamometer diagrams and then stores corresponding data. When analyzing, the device transmits a plurality of curves and figures that is needed to be compared and has been stored in the device, in the form of single curve and figure, multiplex static curves and figures and dynamic curves and figures, to the color display screen for displaying. The invention provides a powerful novel mean for diagnosis of oil well pump, thereby remarkably improving the accuracy and effectiveness of the diagnosis, and is important for failure prediction of oil well pump.

Owner:刘克文

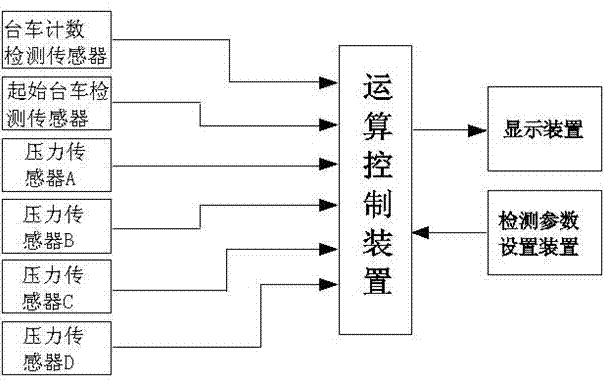

Wheel state detecting method of sintering machines

ActiveCN103196677AImprove operational efficiencyReduce downtime lossesVehicle wheel testingEngineeringPressure sensor

The invention relates to the field of raw material sintering in metallurgy iron manufacture, in particular to a loop wheel machine operational state detecting method of sintering machines in iron manufacture sintering. A wheel state detecting method of sintering machines includes: firstly, confirming the number of loop wheel machines, sequence number arrangement is carried out on all loop wheel machines along the operating direction of the loop wheel machines; then, corresponding sequence numbers with detecting values of four pressure sensors, using an ultra difference method to carry out judgment through the detecting values of the four pressure sensors, confirming breakdown wheels. According to working states of the loop wheel machines of the sintering machines, the wheel state detecting method of sintering machines is capable of achieving automatically detecting states of wheels during operation on line through detection that whether bearing force is in accordance or not when four wheels of a loop wheel machine operates, and the conditions that degradation of wheel states is forecasted in advance, or wheels fall off possibly are achieved, and examining and repairing the wheels designedly is achieved, so that operating efficiency of the sintering machines is improved, and damage of stopping production is reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

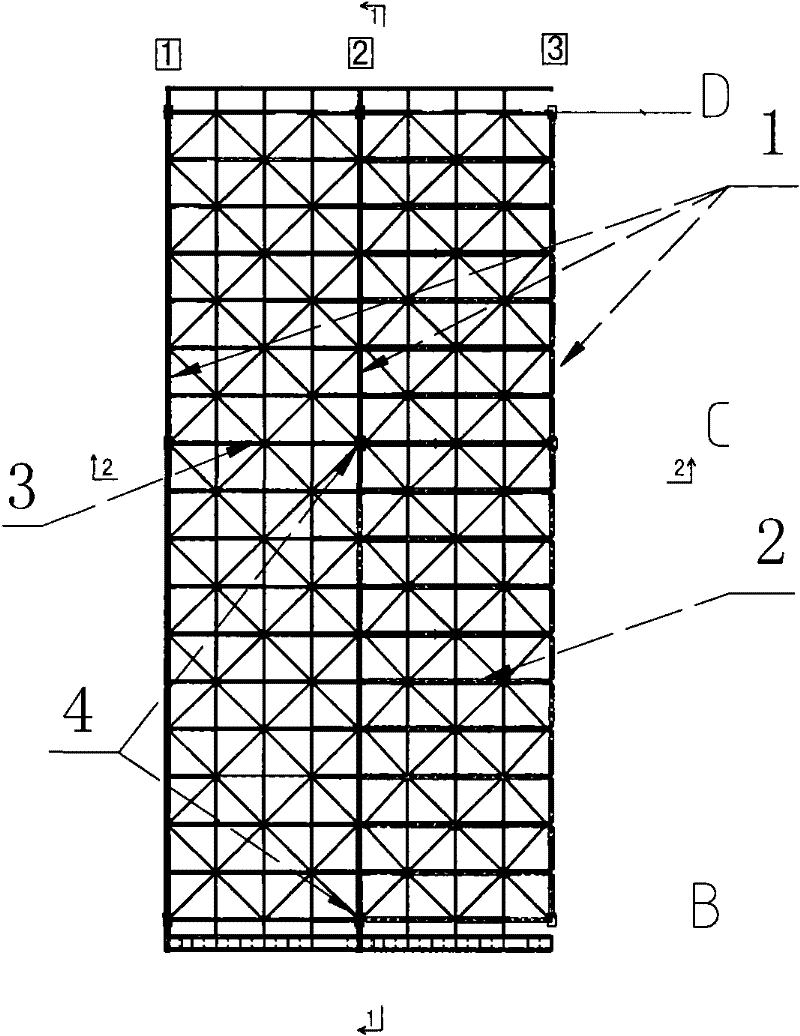

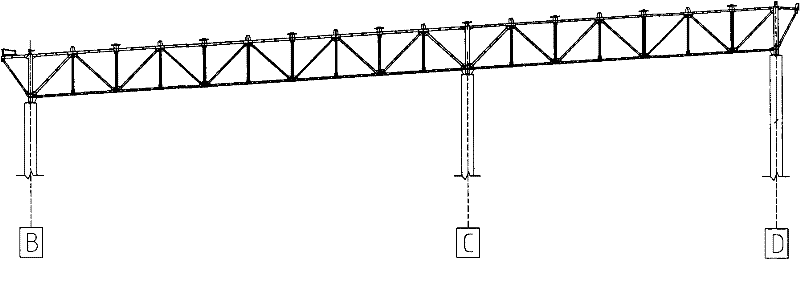

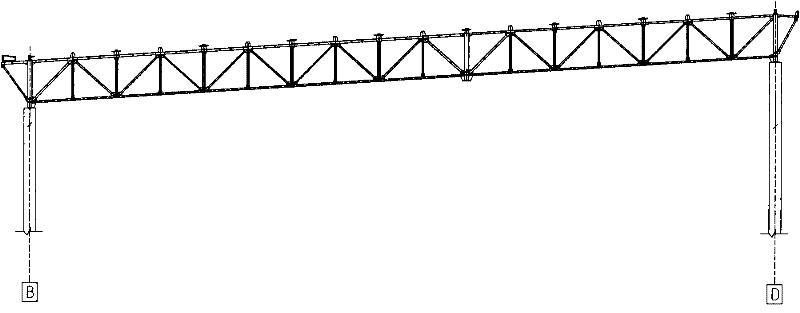

Method for drawing columns and enlarging distances after replacing beams at high altitude in industrial factory building

ActiveCN102242569AReduce installationReduce demolitionBuilding repairsReinforced concrete columnJoist

The invention relates to a method for drawing columns and enlarging distances after replacing beams at high altitude in an industrial factory building. The method comprises the following steps: 1) under the condition of maintaining small capital steel columns of to-be-removed reinforced concrete columns of the industrial factory building, locally removing the upper roof from a roof truss joist of the industrial factory building and then removing an original roof truss upright joist in sections; 2) preparing a new reinforcing joist in two sections according to the length of the original roof truss upright joist; 3) hoisting the new reinforcing joist in sections, welding the new reinforcing joist with the small capital steel columns of the columns on two sides of the industrial factory building after placing the new reinforcing joist in position, and then separating the to-be-removed small capital steel columns of the industrial factory building from the original columns, arranging end plates at bottoms of the small capital steel columns of the columns on the two sides of the industrial factory building, and arranging reinforcing rib plates at the joint parts of the small capital steel columns and the upright joist; and 4) after removing a crane beam from the original reinforced concrete columns, removing the original reinforced concrete columns, recovering the roof and mounting a new crane beam.

Owner:MCC5 GROUP CORP SHANGHAI

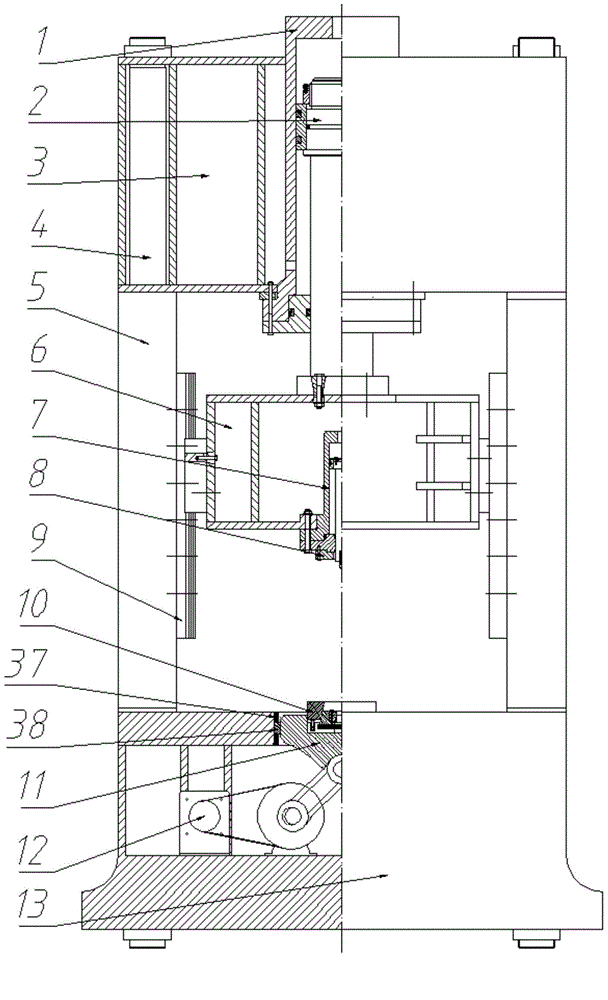

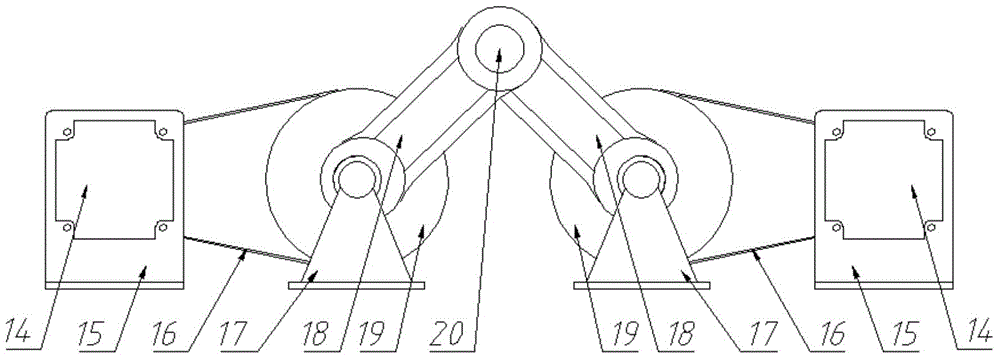

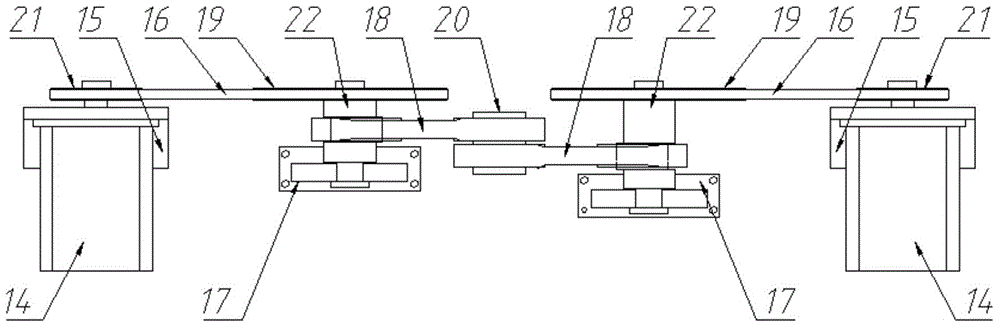

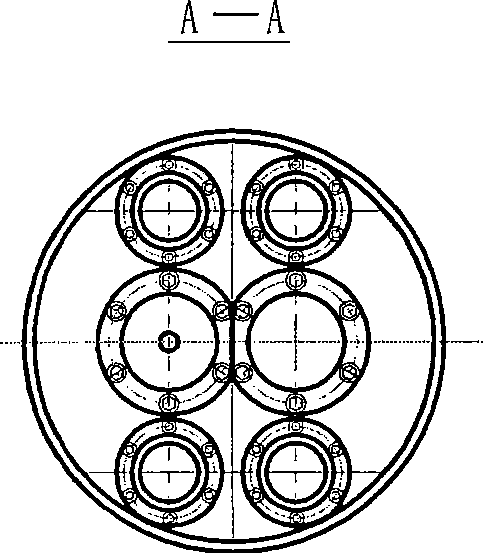

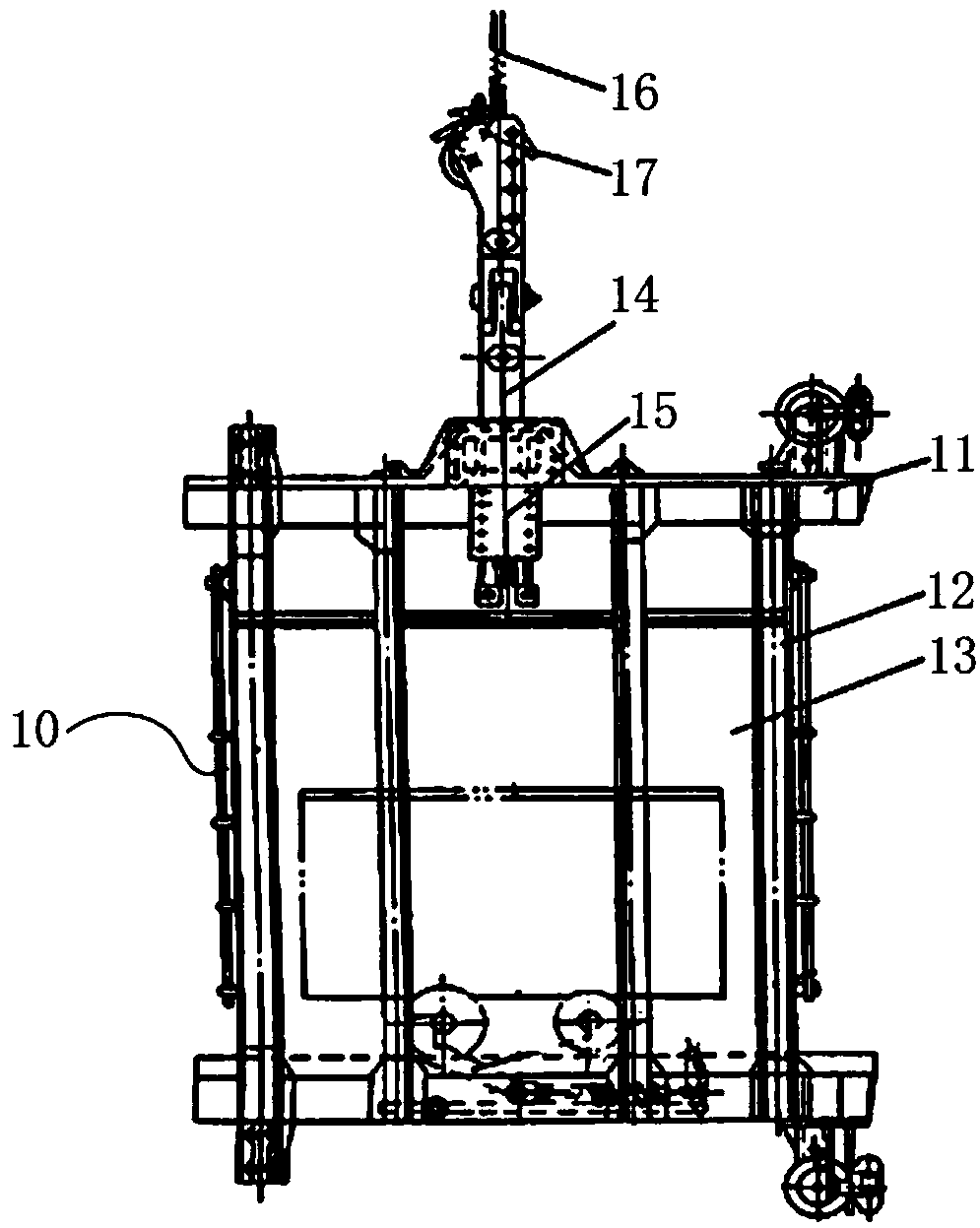

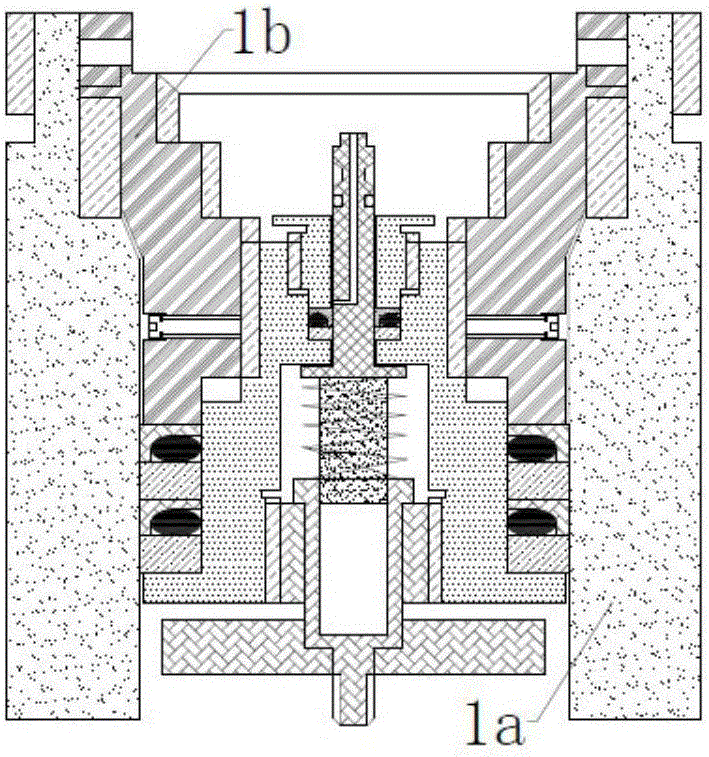

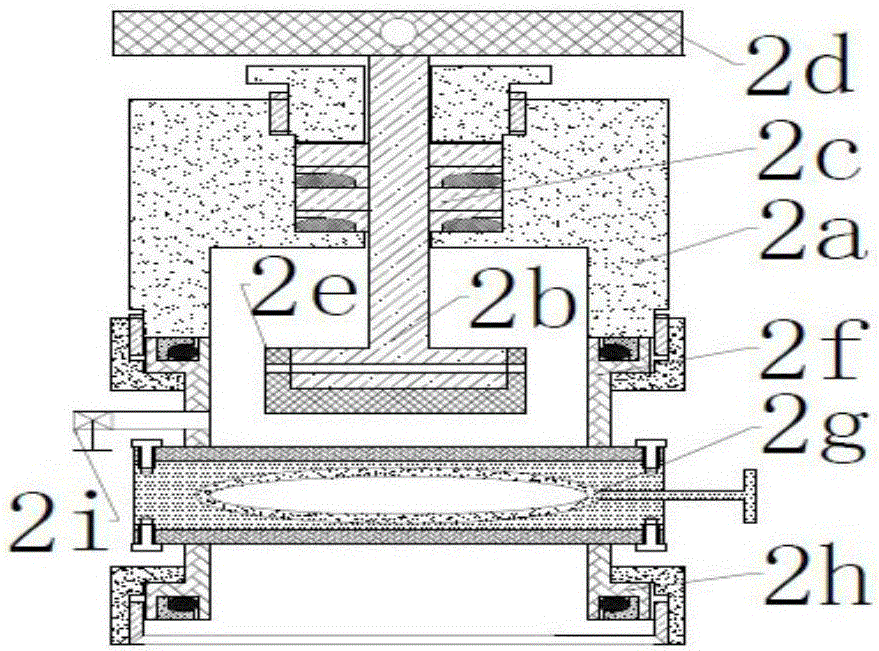

Vertical mechanical vibrating hydraulic extruder

The invention discloses a vertical mechanical vibrating hydraulic extruder, which comprises four pillars, wherein the two ends of the four pillars are respectively connected with an upper cross beam and a base, a first hydraulic cylinder is fixed on the upper cross beam, the end part of a piston rod of the first hydraulic cylinder is matched with a first sliding rail by a first slide block, a second hydraulic cylinder is fixed at the lower part of the first slide block, a mold is connected to the lower part of the second hydraulic cylinder, a vibrating mechanism is fixed in a base and connected with the bottom of a workbench, a clamping mechanism is arranged at the upper part of the workbench, a second slide block connected with the workbench is matched with a second sliding rail, the second sliding rail is connected to the base, the clamping mechanism clamps workpieces, and the vibrating mechanism drives the workbench to vibrate. According to the invention, axial feeding is separated from a vibrating process, therefore, the extruder is easy to control; the structure of the hydraulic cylinder is simplified, and the seal requirements of the hydraulic cylinder are reduced; and the extruder is compact in overall structure, and more stable and reliable in the extrusion process.

Owner:XI AN JIAOTONG UNIV

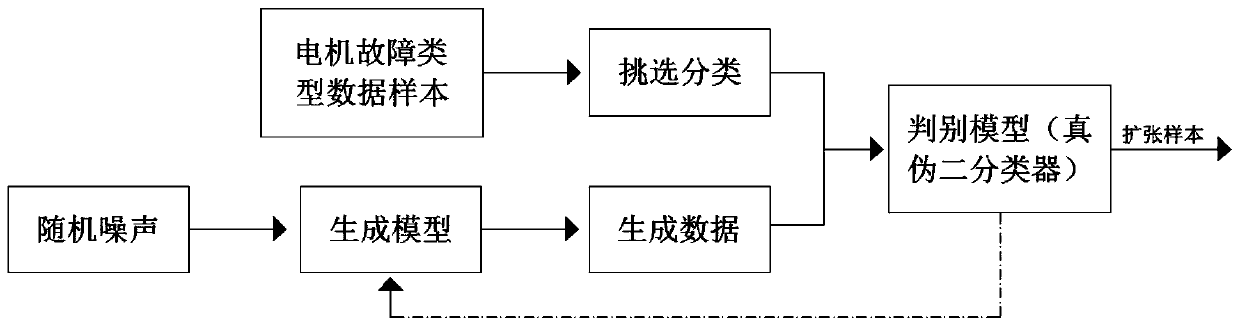

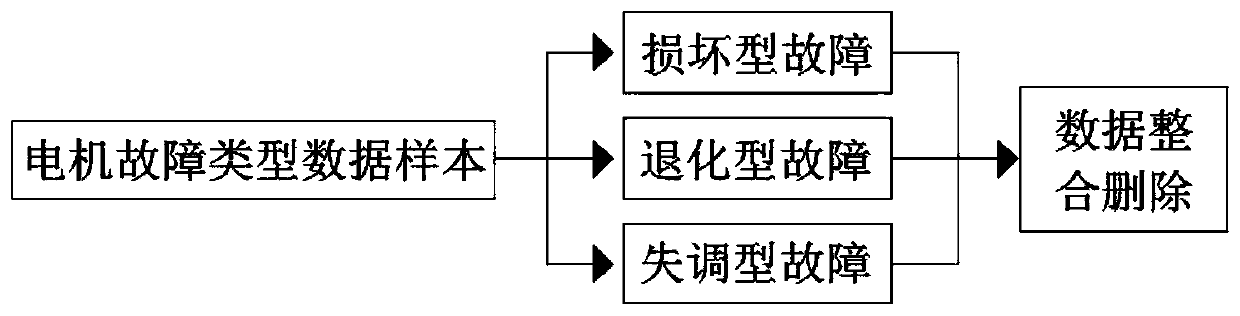

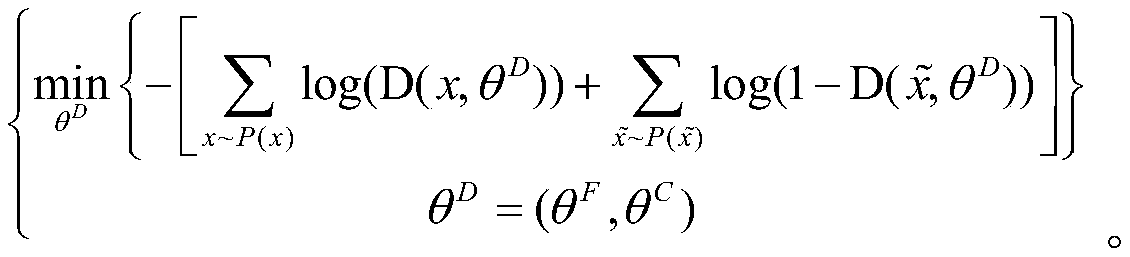

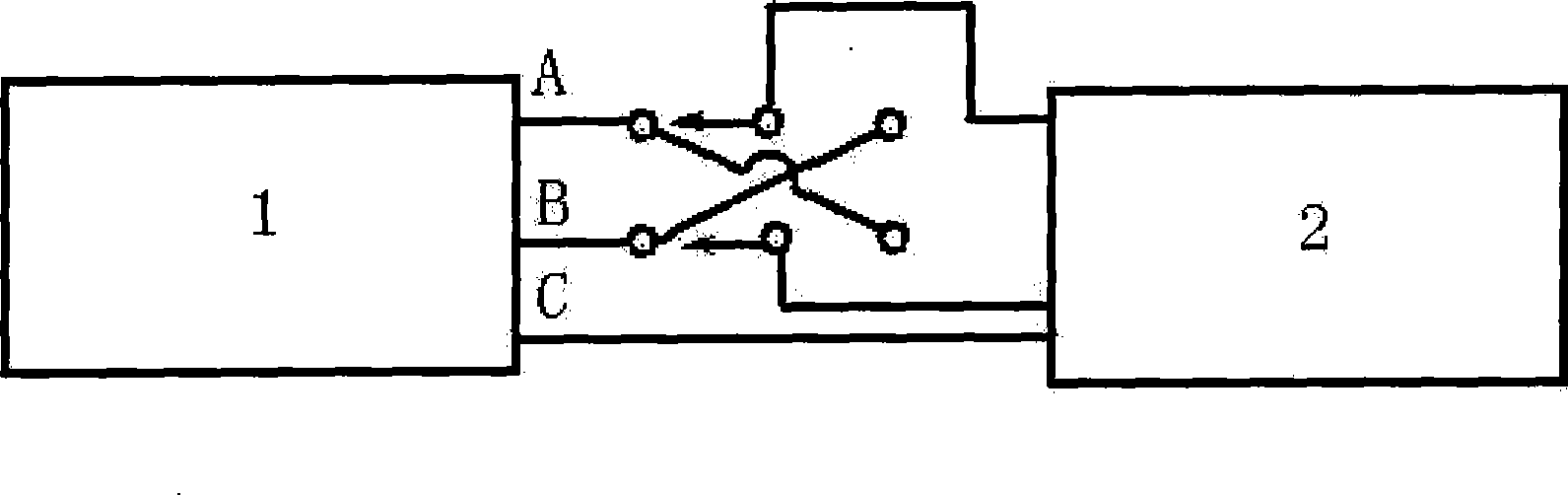

Motor fault data enhancement method based on deep convolution generative adversarial network

PendingCN110955651AHigh precisionQuality improvementDigital data information retrievalCharacter and pattern recognitionElectric machineGenerative adversarial network

The invention discloses a motor fault data enhancement method based on a deep convolution generative adversarial network. A motor fault type data sample and random noise are provided, the random noisecan be integrated into a generation model, and the generation data and the motor fault type data are classified and integrated according to a discrimination model, so that the effect of expanding themotor fault type data is achieved. According to the motor fault data enhancement method based on the deep convolution generative adversarial network, various information is generated in a motor operation process, a learning model is generated, through continuous learning and training, whether the motor operates normally or abnormally is predicted, the fault type of the motor is identified, whether a fault exists or not and the reason of the fault position are judged through detection and analysis of state parameters of the motor when the motor operates with a load or under the condition thatthe motor is not disassembled, and the future state of the motor is predicted.

Owner:WUHAN UNIV OF SCI & TECH

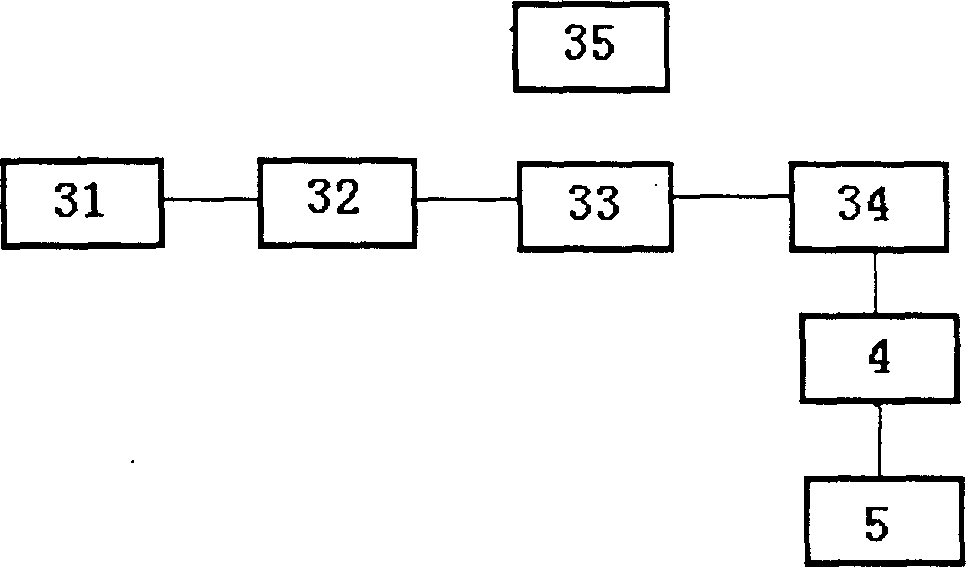

Gyrotheodolite integrated with north and south seeking function and implementing method thereof

InactiveCN101451840AAchieve the purpose of orientationReduce designSpeed measurement using gyroscopic effectsTheodolitesElectrical polarityEngineering

The invention discloses a gyrotheodolite integrating north-finding and south-finding function and a method of realizing the same. The gyrotheodolite comprises a gyro power and a gyro motor; the gyro power supplies three phase alternating voltage or a one path direct voltage to the gyro motor; the gyrotheodolite is characterized that: the gyrotheodolite further comprises a controlling unit for controlling the phase sequence change of the three phase alternating voltage or controlling the polarity change of the one path direct voltage. The method comprises changing the phase sequence or polarity of the supplying power of the gyro motor in the gyrotheodolite to realize the positive rotation and reversing switch of the gyro motor, thereby realizing the switch of the north-finding and south-finding function of the gyrotheodolite. When the gyrotheodolite produced or remodeled by the invention is located, the gyrotheodolite is not affected by measuring controlling point set and the surrounding environment, that is to say it is measured at each environment, which solves the long-standing problem of affecting the measuring work in orientation of the gyrotheodolite.

Owner:CENT SOUTH UNIV

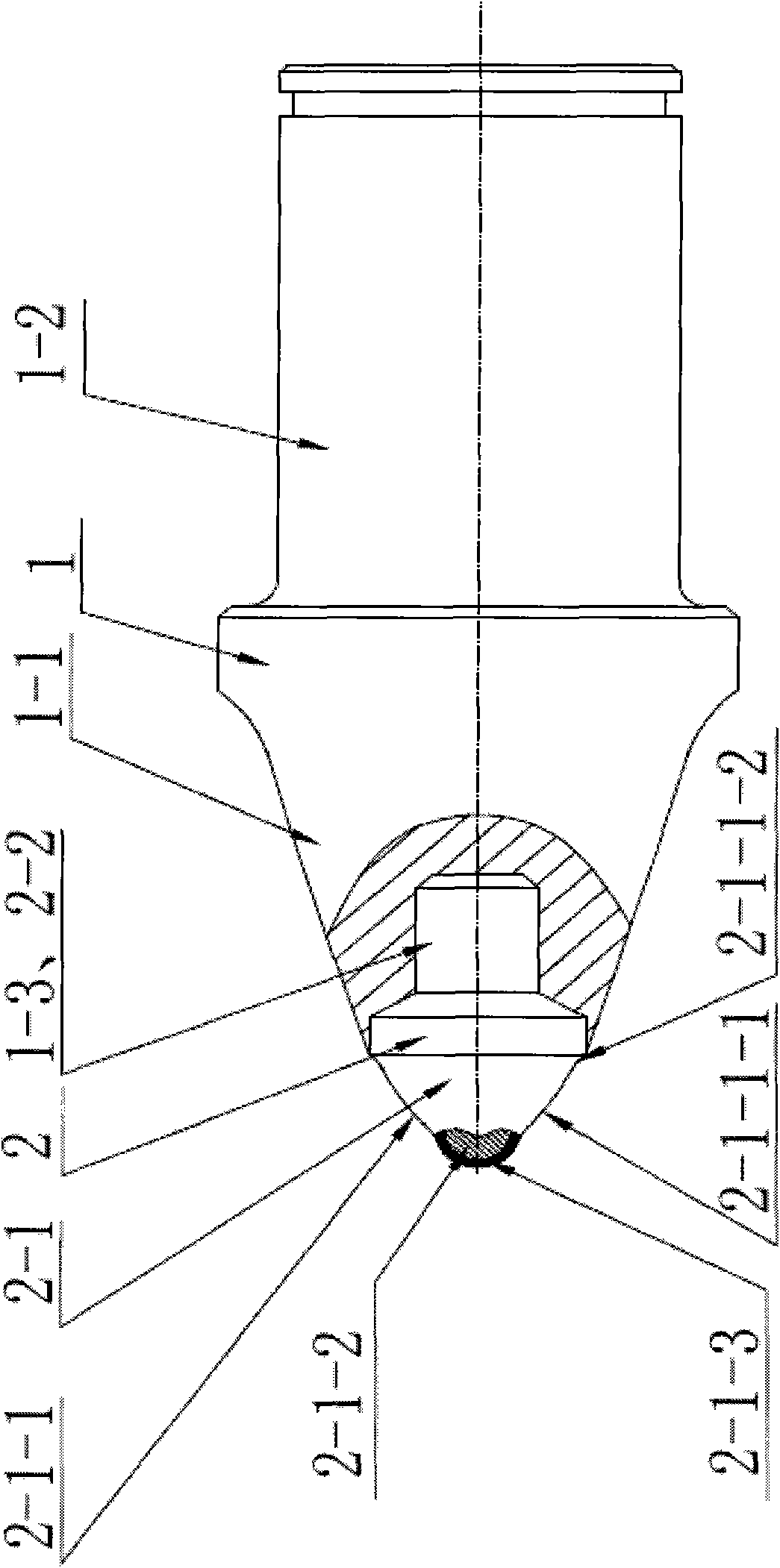

Cutting pick, cutting pick head and manufacturing method thereof

The invention discloses a cutting pick, a cutting pick head and a manufacturing method thereof. The cutting pick head is welded on the end of the cutting pick, and one end of a conical section is provided with an axial blind hole to be connected with the cutting pick head; the cutting pick head is provided with a working section and a connecting section, and the connecting section is spliced in the axial blind hole; and the working section of the cutting pick head is provided with a conical camber section and a spherical top end, the spherical top end is provided with a diamond layer, and thediamond layer and the conical camber section are connected through smooth transition. The manufacturing method of the cutting pick and the cutting pick head comprises the following steps: die-castingsintered carbide into a shape of a cutting pick head with a die; compounding diamond powder on the surface of the spherical top end of the cutting pick head through die pressing under high temperature and high pressure; carrying out thermal treatment of the processed cutting pick head; and welding the cutting pick head and the cutting pick body with a welding machine. The cutting pick and the cutting pick head have the advantages of simple structure, high hardness and high wear resistance, and the service lives thereof can be prolonged significantly.

Owner:JIANGYIN CITY YUANFENG HEAT TREATMENT TECH

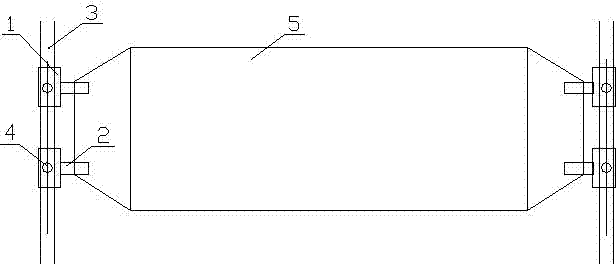

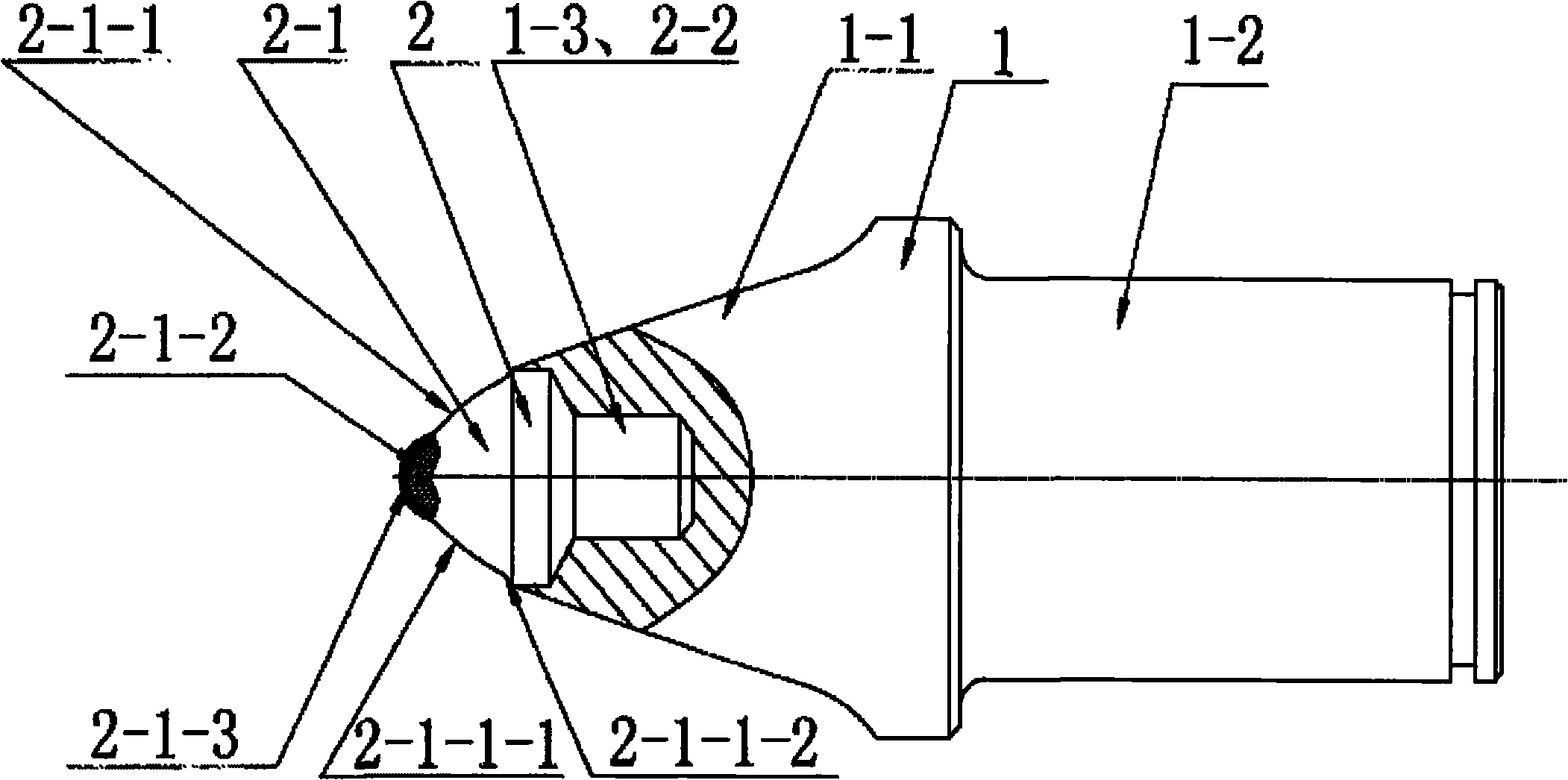

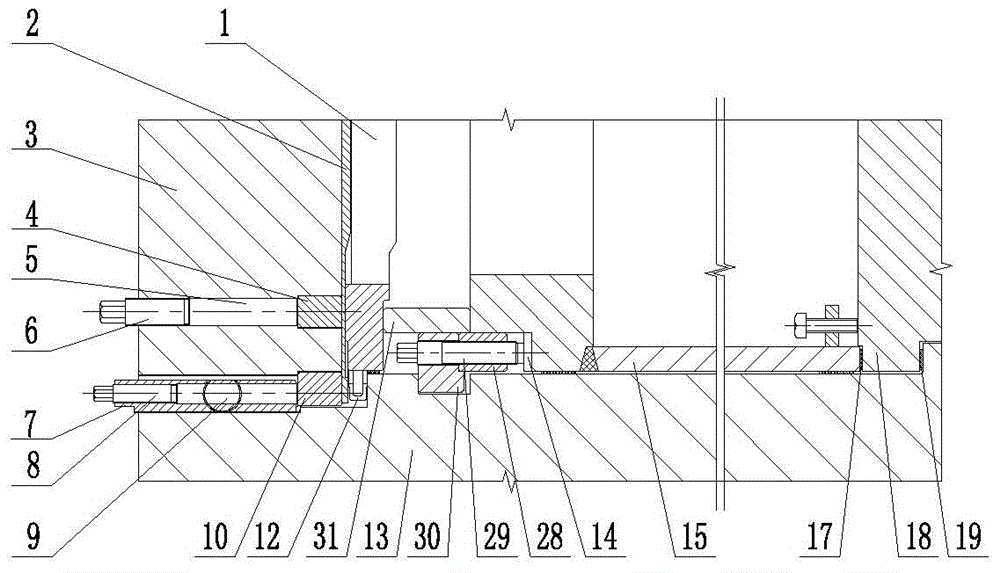

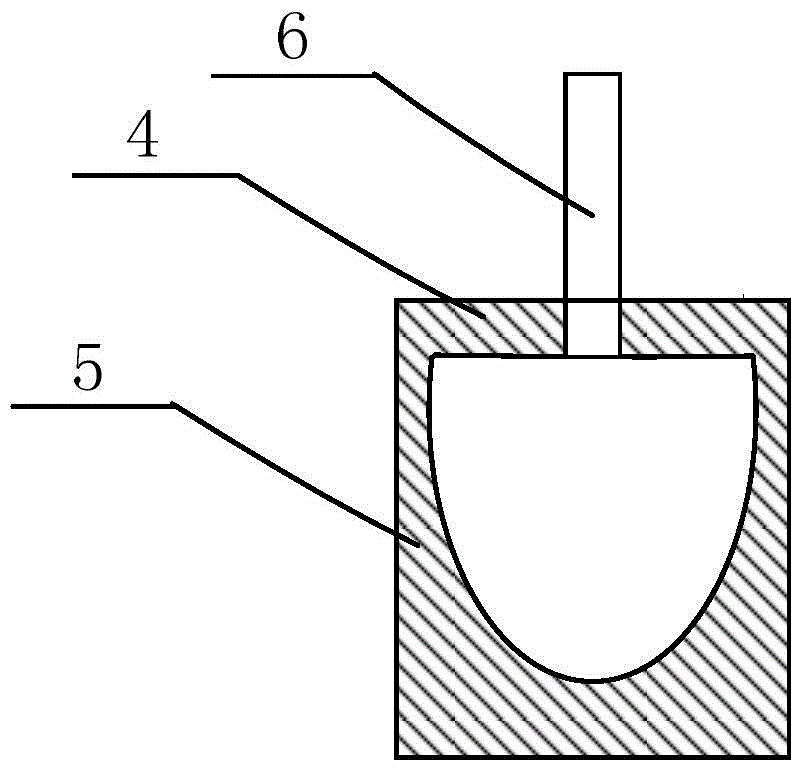

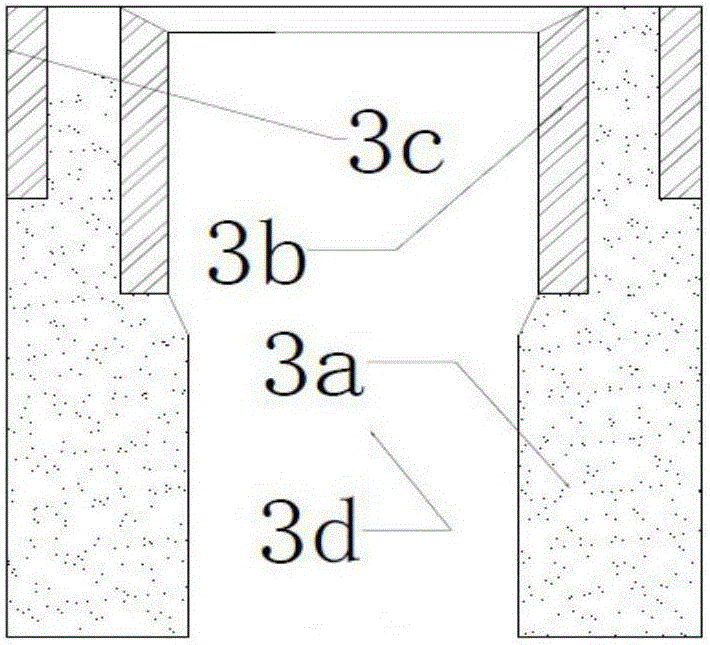

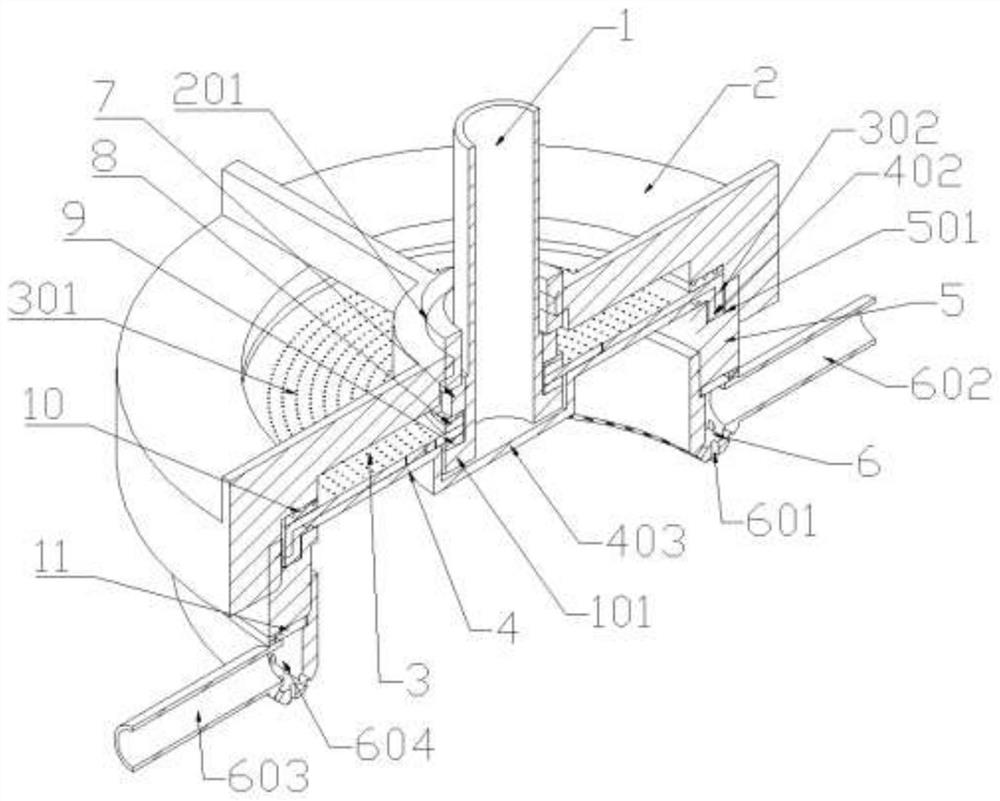

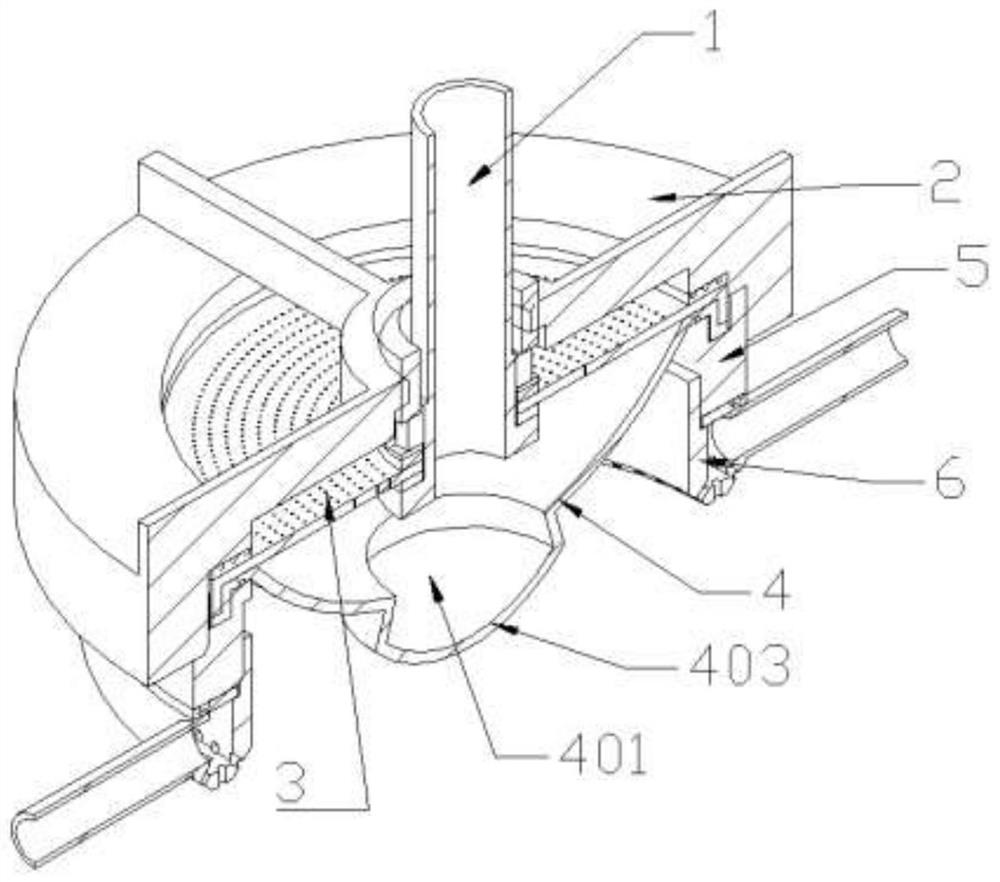

Method and apparatus for exchanging nozzle on line

InactiveCN101373066ASimple fully automatic program control processConvenient automatic program control processBurnersPerformance indexEngineering

The invention discloses a nozzle on-line replacement method and a replacement device thereof. The invention is characterized that an excessive pressure tank (3) is arranged on the flange of a furnace mouth (23); the excessive pressure tank is provided with an in-service nozzle (5) and a waiting-for-service nozzle (18); and the in-service nozzle (5) and the waiting-for-service nozzle (18) are arranged in the excessive pressure tank (3) and no pressure difference exists between the furnace and the tank. Through the effect of the driving mechanism in the replacement device and the off-on switch of a quickly assembling and disassembling sealed connection module (1), the on-line replacement of the in-service nozzle (5) and the waiting-for-service nozzle (18) can be completed. The invention has the advantages that the invention can carry on the nozzle on-line replacement without stopping the use of the furnace, and without replacement, drawing and warm-up heating; can prevent furnace blocks from suffering the damages caused by rapid cooling and heating, thereby extending the service life of the furnace blocks; can conduct the replacement before the worsening of the nozzle gasification index, thereby ensuring that the nozzle performance index always run under good conditions; and can ensure the gasification furnace achieves long-term smooth running, thereby reducing the cost caused by replacement of nozzles and furnace blocks and avoiding the loss of off production.

Owner:刘清林

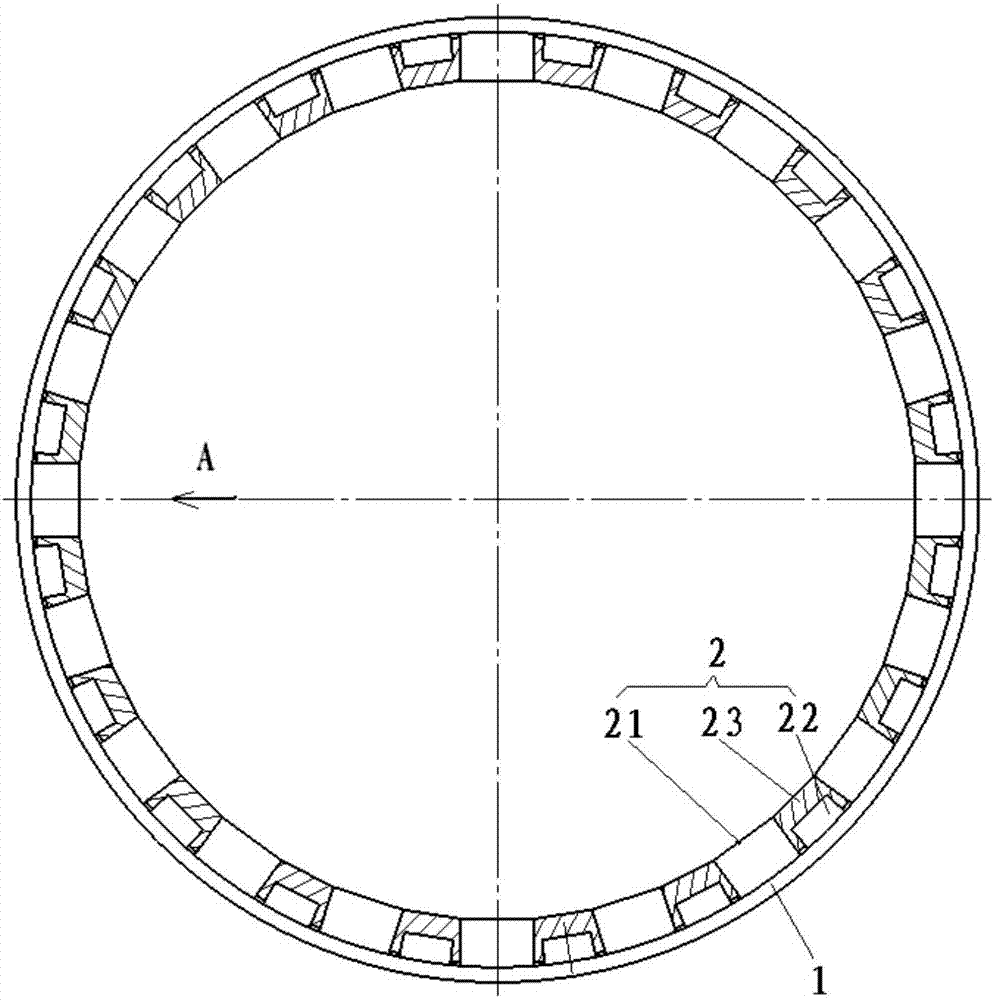

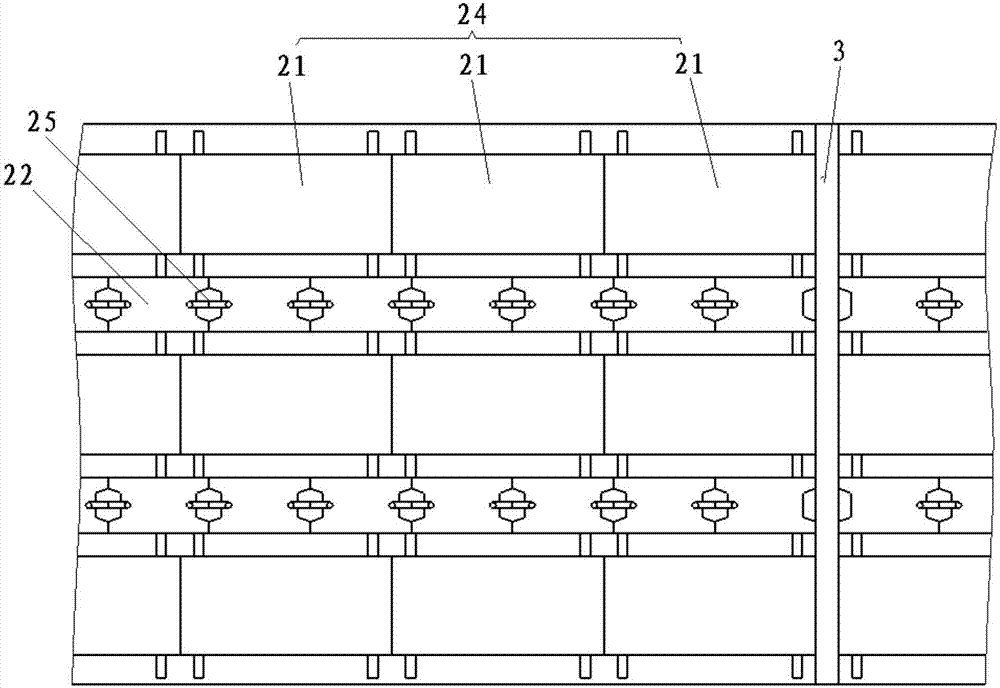

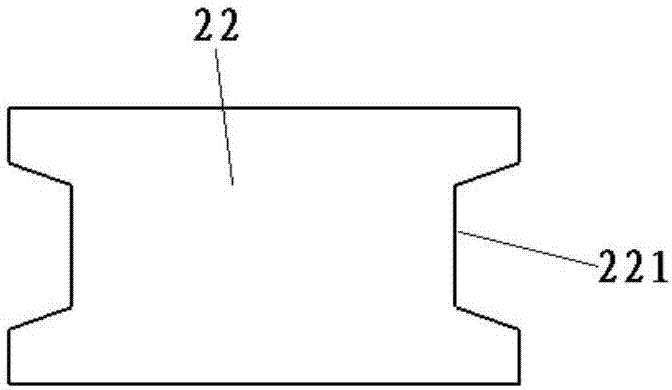

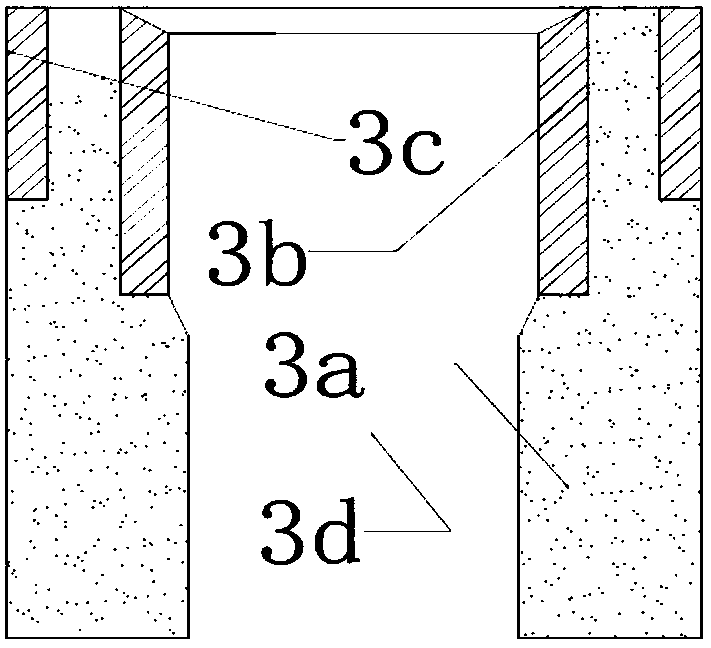

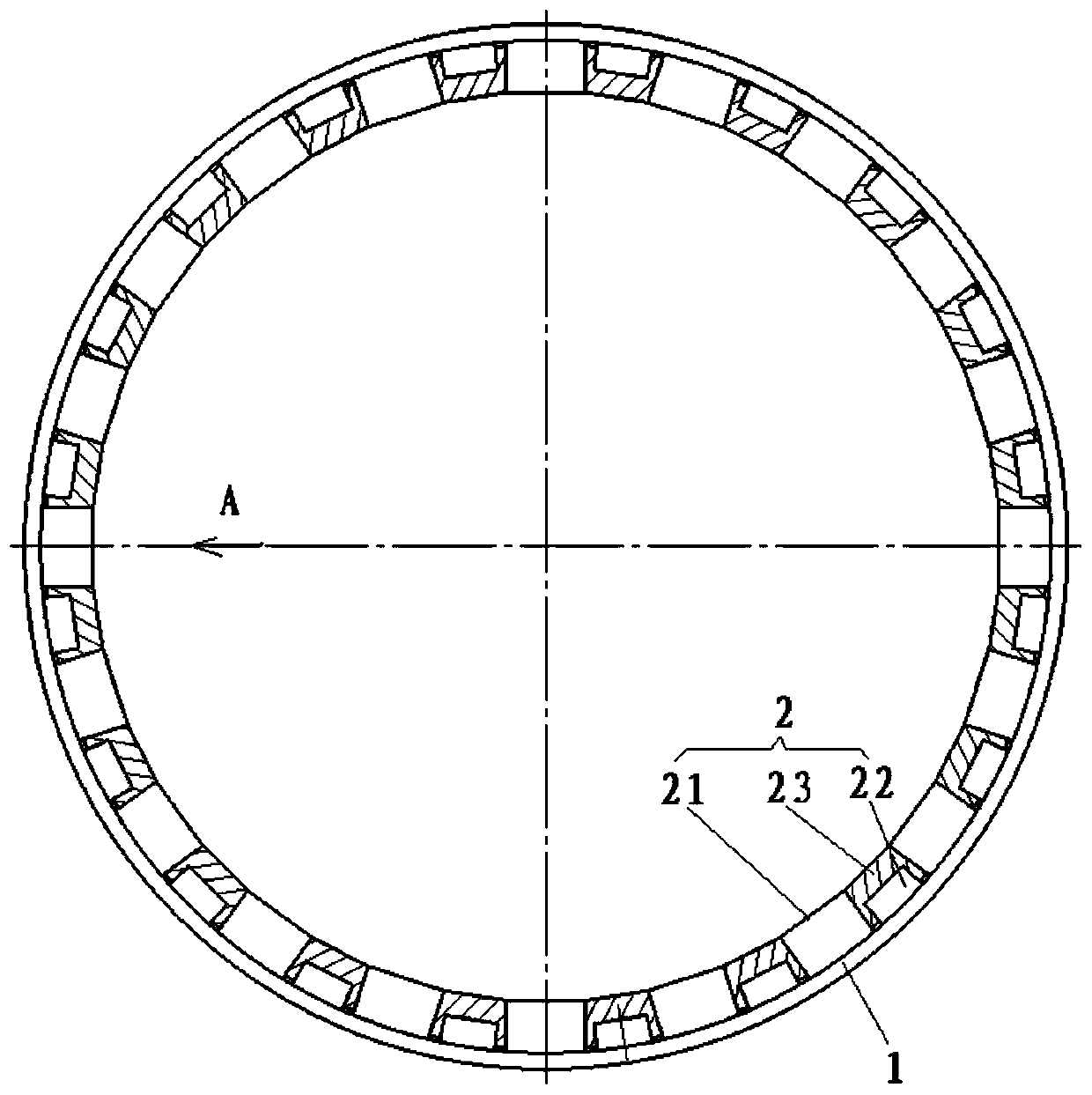

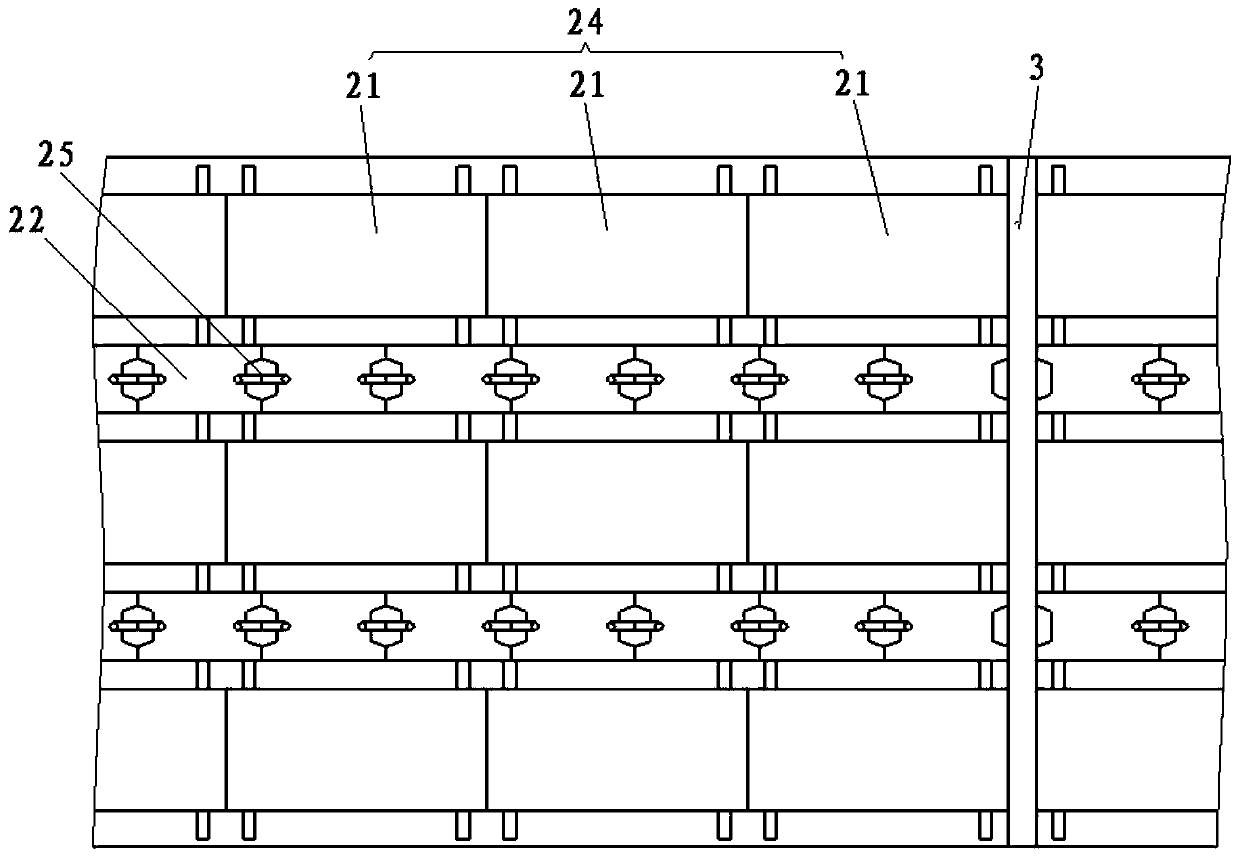

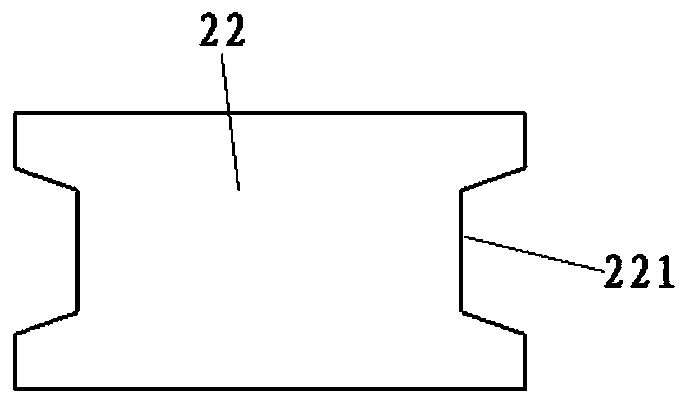

Rotary kiln building structure

ActiveCN107356110AFirmly connectedNot easy to fall offRotary drum furnacesMonolithic liningsBrickSteel bar

The invention discloses a rotary kiln building structure, relates to the technical field of rotary kiln manufacturing and maintaining, and provides a rotary kiln building structure not prone to being damaged. The rotary kiln building structure comprises a rotary kiln barrel body, a building structure and blocking brick rings. The building structure comprises fire-resisting insulating bricks, bottoming bricks and fixed steel bars. The fire-resisting insulating brick are built in the length direction of the rotary kiln barrel body to form multiple fire-resisting insulating brick lines in a circumferential array, and connecting steel bars welded to the rotary kiln barrel body are arranged at the bottoms of the fire-resisting insulating bricks. The bottoming bricks are arranged between the adjacent fire-resisting insulating brick lines. Each fixed steel bar is in a V shape. The fixed steel bars are located in space between the adjacent bottoming bricks, and the pointed ends of the fixed steel bars and the rotary kiln barrel body are welded, and the bottoming bricks are pressed down. The remaining space between the adjacent fire-resisting insulating brick lines is filled with refractory castables. The blocking brick rings are arranged in the length direction of the rotary kiln barrel body at intervals and are connected with the rotary kiln barrel body, and the building structure is divided by the blocking brick rings into multiple sections. The rotary kiln building structure can be applied to manufacturing or maintaining of a rotary kiln.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

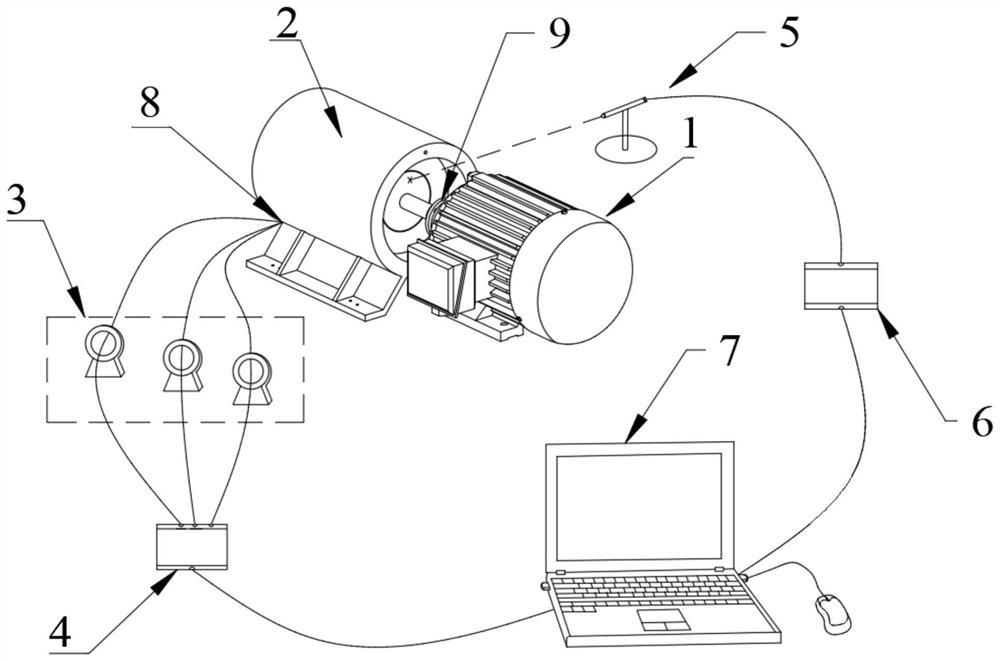

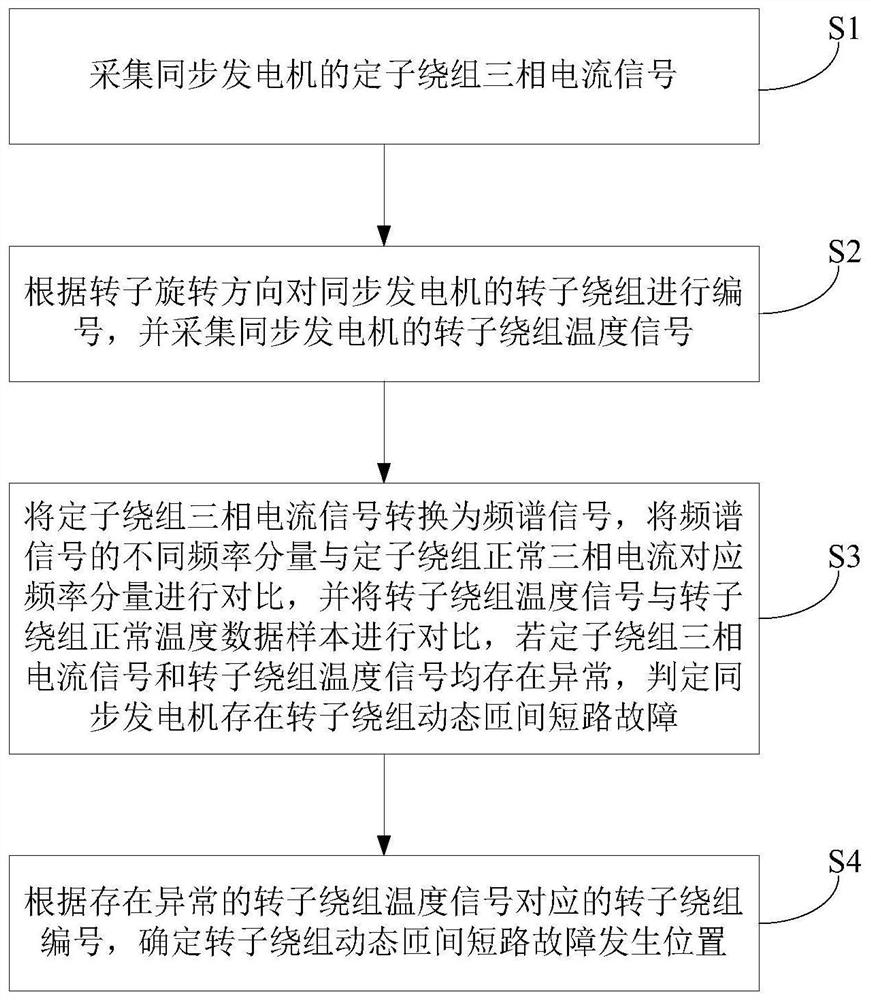

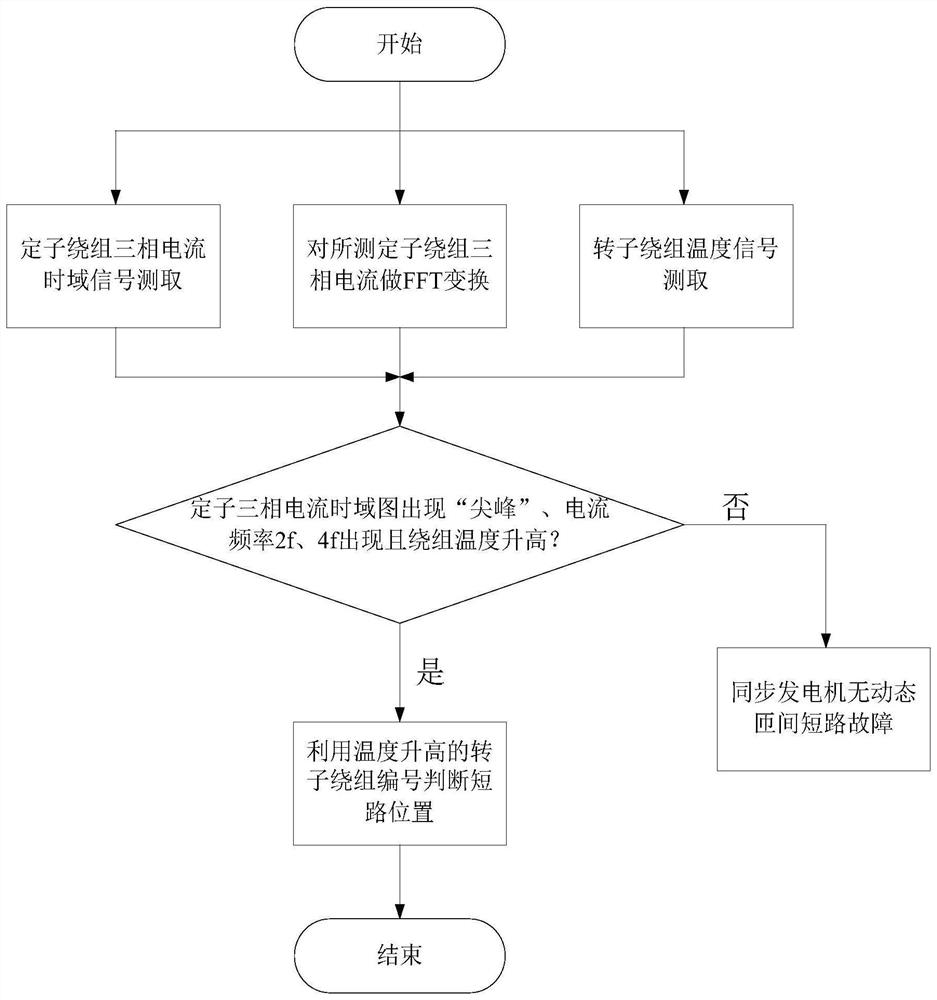

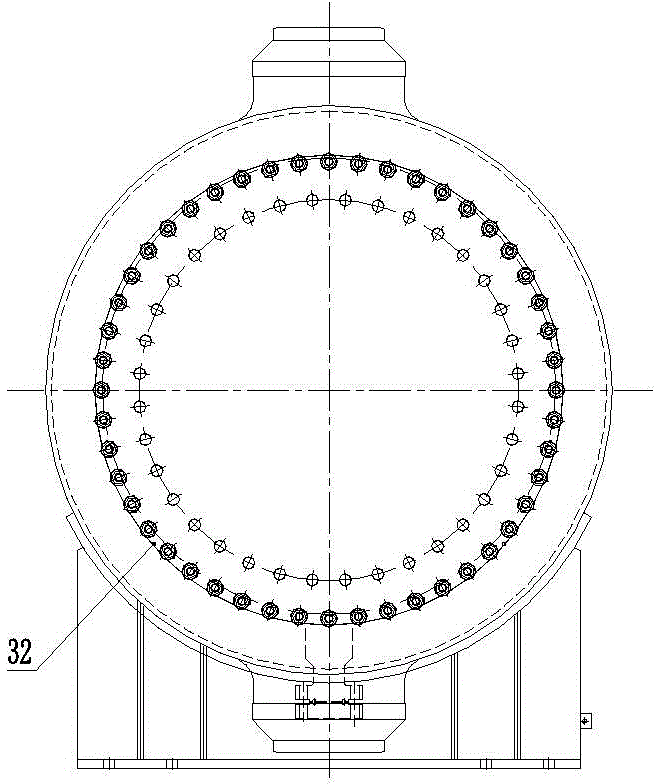

Synchronous generator rotor dynamic turn-to-turn short circuit fault detection system and method

ActiveCN113391235AReduce downtime lossesEasy to operateElectric motor controlGeneration protection through controlPhase currentsControl engineering

The invention discloses a synchronous generator rotor dynamic turn-to-turn short circuit fault detection system and method. The system comprises a motor, a synchronous generator, a current transformer, an acquisition card, an infrared temperature sensor, a temperature acquisition instrument and a control terminal. Based on the fact that the infrared temperature sensor can sensitively acquire the temperature of a rotor winding and perform non-contact measurement and the rotor winding has an obvious temperature rise phenomenon during a dynamic turn-to-turn short circuit, a dynamic turn-to-turn short circuit fault of the rotor winding of the synchronous generator is detected through double judgment standards of the actually measured temperature signal of the rotor winding and the three-phase current signal of a stator winding, and fault positioning is carried out. The method is easy to operate and high in sensitivity, the fault detection and positioning process is efficient and reliable, and a dynamic turn-to-turn short circuit fault can be detected in the early stage of rotor static turn-to-turn short circuit formation, so that the fault shutdown loss of a power plant is reduced, and the actual application requirement can be better met.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

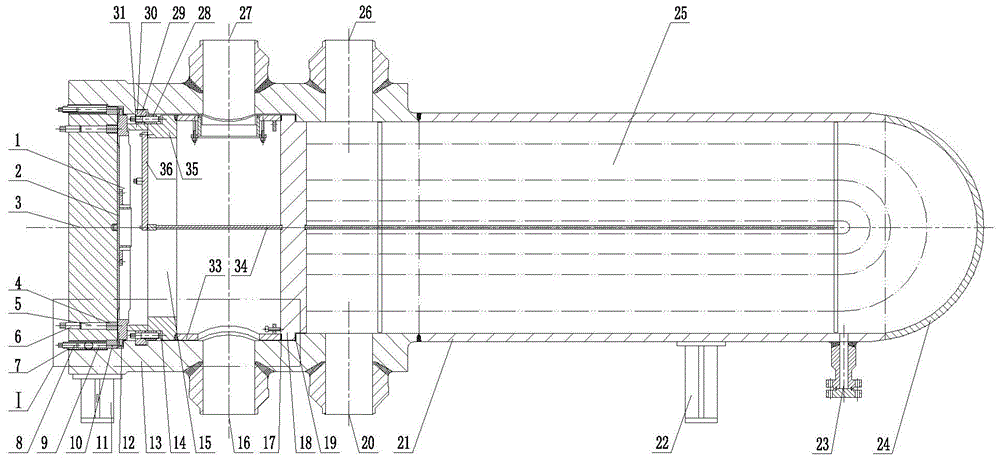

D-shaped bolt U-shaped pipe high-pressure heat exchanger

InactiveCN104913667AAvoid crackingAvoid corrosionHeat exhanger sealing arrangementHeat exchanger casingsEngineeringAxial force

The invention discloses a D-shaped bolt U-shaped pipe high-pressure heat exchanger. The D-shaped bolt U-shaped pipe high-pressure heat exchanger is mainly used for solving the problem existing in an existing bolt flange type heat exchanger, an existing omega sealing ring heat exchanger, an existing screw locking ring heat exchanger and an existing diaphragm seal heat exchanger. A flat deck roof (3) is arranged at the end portion of a pipe chamber cylinder (13), and the pipe chamber cylinder (13) is connected with the flat deck roof (3) through a round of eccentrically and uniformly distributed D-shaped bolts (7) to bear axial force. The D-shaped bolts (7) can be fixed into about 3 / 4 threaded holes of the flat deck roof or the end portion of the pipe chamber cylinder, and an outer sealing gasket (12) can select a winding gasket or a wave tooth composite gasket or a stainless steel C-shaped sealing ring. Inner ring compression bolts (6) and outer ring compression bolts (8) are arranged on the flat deck roof, internal bolts (29) are arranged in grooves of the pipe chamber cylinder, both the inner ring compression bolts and the internal bolts can provide sealing force for an inner sealing gasket (19), and the outer ring compression bolts provide sealing force for the outer sealing gasket. The D-shaped bolt U-shaped pipe high-pressure heat exchanger is mainly used for the heat exchange process of petroleum refining hydro-treatment technology.

Owner:BEIJING UNIV OF CHEM TECH

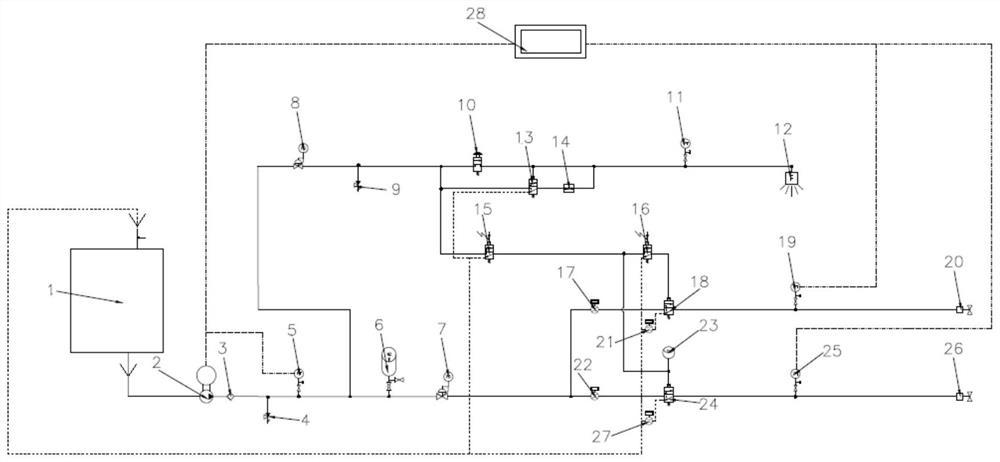

Intelligent well head safety control system with flow monitoring

InactiveCN111720093AImprove safety in production operationsIncrease productionWell/borehole valve arrangementsSealing/packingComputer control systemFusible plug

The invention discloses an intelligent well head safety control system with flow monitoring. The intelligent well head safety control system with flow monitoring comprises a high-pressure hydraulic system, a safety valve hydraulic control main path, a low-pressure control system and an upper computer control system, wherein the safety valve hydraulic control main path comprises an overground safety valve hydraulic control branch and an underground safety valve hydraulic control branch, and the input ends of the two are connected to the output end of the high-pressure hydraulic system; the output end of the overground safety valve hydraulic control branch is connected to an overground safety valve, and the output end of the underground safety valve hydraulic control branch is connected to an underground safety valve; the low-pressure control system comprises a fusible plug control branch and a safety valve pilot control branch; the input end of the fusible plug control branch is connected to the output end of the high-pressure hydraulic system; and the fusible plug control branch is connected to the overground safety valve hydraulic control branch and the underground safety valve hydraulic control branch through the safety valve pilot control branch. The intelligent well head safety control system with flow monitoring solves the technical problem of safety valve leakage and valve opening degree judgment, and realizes intelligent control on a well head control disc.

Owner:维特力(深圳)流体工程有限公司

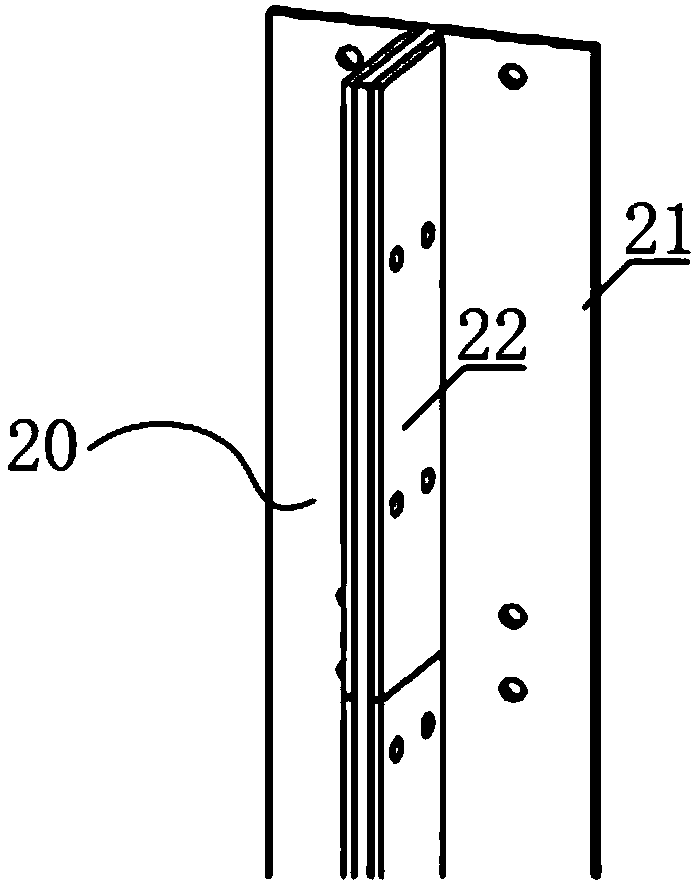

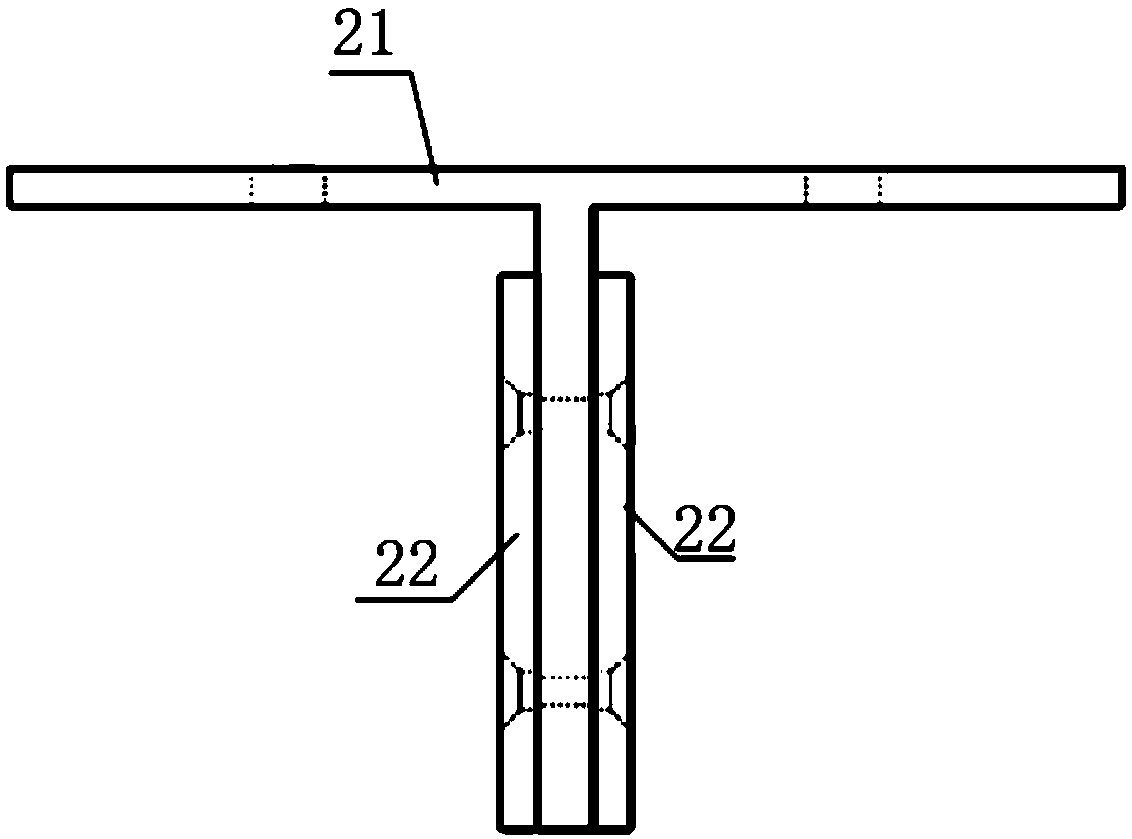

Mine transportation equipment provided with safety slow speed device and safe operation method thereof

PendingCN110577127AThe principle is simpleImprove reliabilityElevatorsHoisting equipmentsEngineeringSafe operation

The invention discloses mine transportation equipment provided with a safety slow speed device and a safe operation method thereof. The mine transportation equipment comprises a cage, a slow speed guide rail, a permanent magnet retarder and a trigger device, wherein the slow speed guide rail comprises a guide rail body and a metal cover plate, and the metal cover plate is fixedly connected with the side surface of the guide rail body; the permanent magnet retarder is fixedly connected with the cage; a permanent magnetic braking unit of the permanent magnet retarder is arranged on the side surface of the slow speed guide rail, and in a non-triggering state, the interval distance between the permanent magnetic braking unit and the slow speed guide rail is a non-braking distance; and the trigger device is connected with a lifting steel wire rope, and when the lifting steel wire rope breaks, the trigger device drives the permanent magnetic braking unit of the permanent magnet retarder to be close to the slow speed guide rail so that the interval distance between the permanent magnet braking unit and the slow speed guide rail can meet a braking gap. The transport equipment has the advantages of being simple in principle, reliable in action, and high in reliability and capable of ensuring the safety of personnel in the cage under the condition of cage failing; and moreover, based onthe working characteristics of the equipment, a cage body is prevented from being damaged after falling of the cage, so that the production loss of an enterprise is reduced.

Owner:MAGNA MAGNETOMOTIVE CO LTD

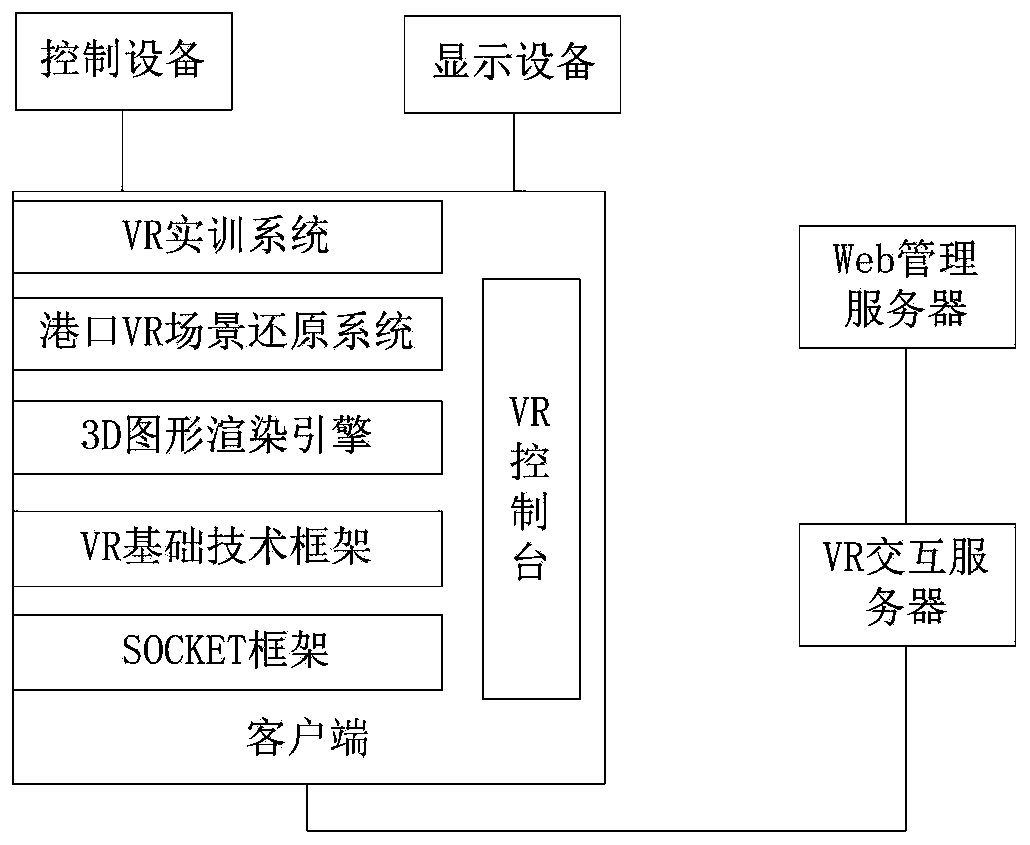

VR-based tire crane practical training system and method

ActiveCN110879660AImprove the quality of trainingReduce human error rateInput/output for user-computer interactionData processing applicationsData synchronizationGraphics

The invention provides a VR-based tire crane practical training system. The VR-based tire crane practical training system comprises control equipment and display equipment; a client, the VR basic technology framework and the port VR scene restoration system perform 3D real-time rendering on the RTG operation scene to restore a port tire crane operation real scene; a 3D graphic rendering engine which is used for reading dynamic data in the TOS production system from a preset JSON interface by taking a port real scene as a blueprint, and is used for constructing scene elements in a training system to form a port tire crane VR training system; an integration system of a space sound effect and a physical system; and a VR interaction server which is connected with the at least one client and isused for realizing scene position and physical data synchronization and broadcasting with the at least one client. By applying the system of the invention, the overall training quality is improved, and the human error rate in the practical operation process is reduced, so that the maintenance budget is indirectly saved, and the shutdown loss caused by errors is reduced.

Owner:上海咪啰信息科技有限公司

Heating method for chute

The invention relates to the field of the metallurgical industry, and discloses a heating method for a chute. According to the heating method, fuel and mixed gas containing high-concentration oxygen or oxygen-rich air serving as accelerants are fed into the chute through a combustion spraying-in assembly to be combusted in a mixed mode, and the heat generated during mixed combustion is used for achieving heating and heat preservation of the chute. According to the method, the combustion spraying-in assembly used for feeding the fuel and the accelerants into the chute comprises a group of coaxial metal sleeve pipe spraying guns and / or metal single-pipe spraying guns arranged on a chute covering plate at intervals. The heating method for the chute can greatly reduce fuel consumption, improve the heating speed and uniformity of the chute, and greatly reduce combustion smoke amount and emission of pollutants.

Owner:爵翔(上海)能源科技有限公司

Anti-corrosion ultrahigh-pressure online piece hanging and taking device and using method thereof

ActiveCN105675478AImprove pressure resistanceAvoid failureWeather/light/corrosion resistanceUltra high pressureEngineering

The invention discloses an anti-corrosion ultrahigh-pressure online piece hanging and taking device and a using method thereof.The anti-corrosion ultrahigh-pressure online piece hanging and taking device comprises a piece hanging device and a piece taking device.The piece hanging device comprises a welding nipple and a piece hanging sealing rod.A movable sealing rod is designed and installed in an upper hole in a sealing cavity of the piece taking device, an ultrahigh-pressure combined seal for rods is designed and installed around the upper hole in the sealing cavity and the movable sealing rod, a force application rod is installed at one outer end of the sealing cavity, the end, in the sealing cavity, of the movable sealing rod is connected with a piece taking head, the lower portion of the sealing cavity is connected with an upper connector, the upper connector is connected with a high-pressure ball valve, the high-pressure ball valve is connected with a lower connector, and a vent valve is installed on a connecting pipe of the upper connector.Due to the design of an anti-corrosion nipple in the piece hanging device, corrosion of the piece hanging device and a welding line can be effectively controlled, and thus the piece hanging device can be used for a long time.Due to the matching design of the movable sealing rod, the piece taking head, an upper sealing nipple and a pressure release sealing rod, the high-pressure ball valve can be replaced once leakage occurs, the piece hanging and taking device can be used for a long time, and the operating force in the piece hanging and taking process is small.

Owner:西安华诺环境科技有限公司

A method for online replacement of coke oven valve body

ActiveCN107671790BAvoid enteringQuick dismantlingCoke oven detailsMetal-working hand toolsPositive pressureCoke oven

Owner:CHINA MCC20 GRP CORP +1

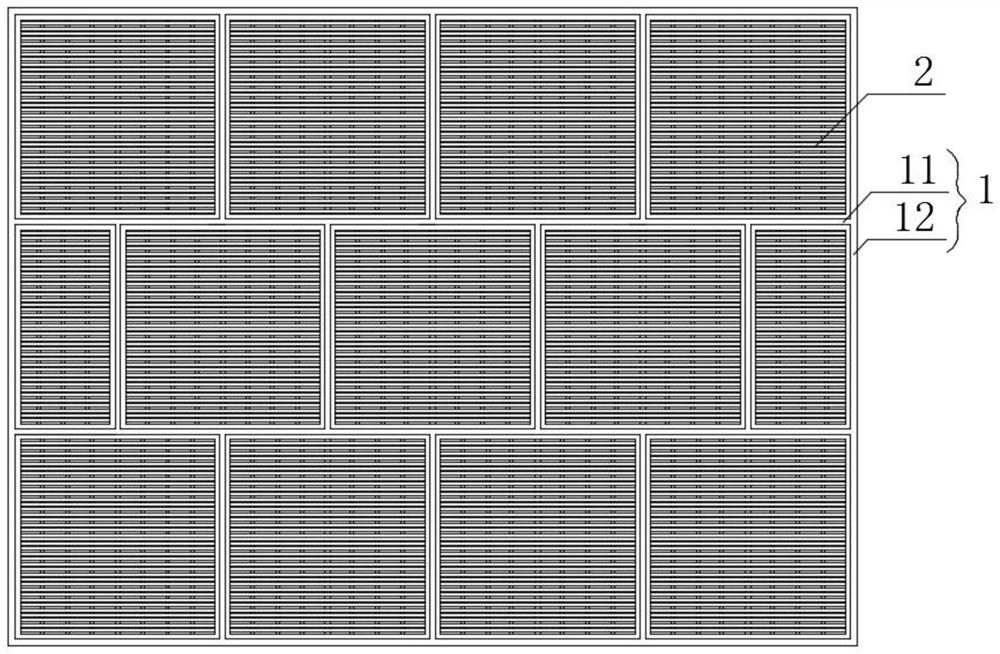

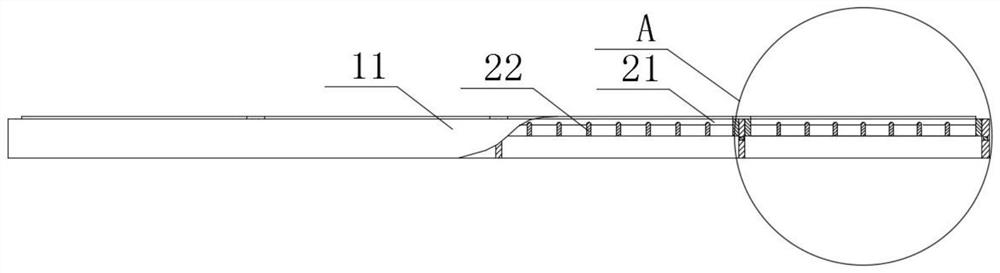

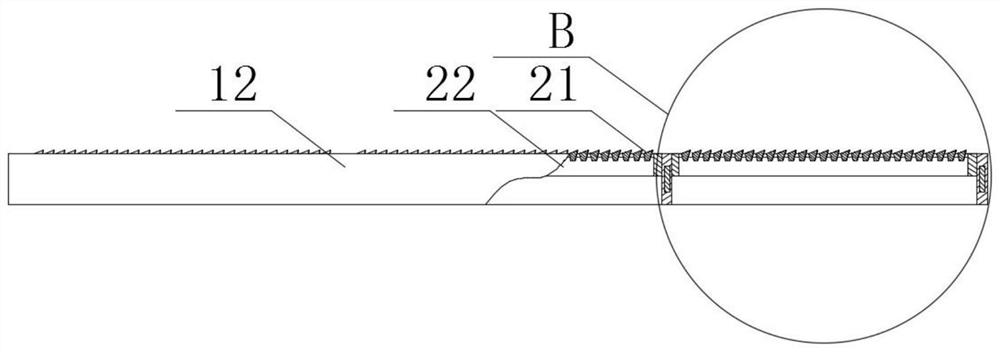

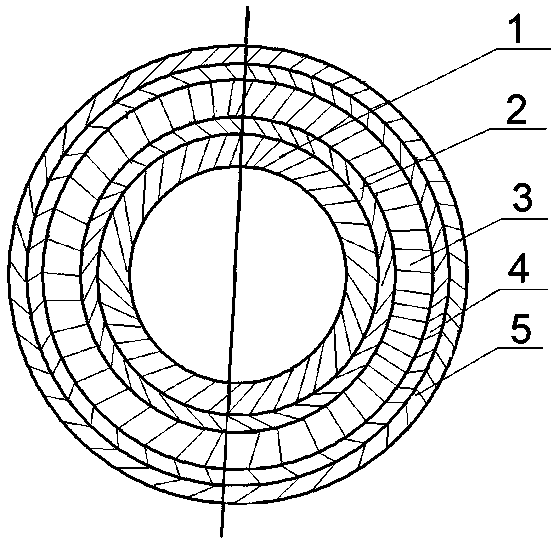

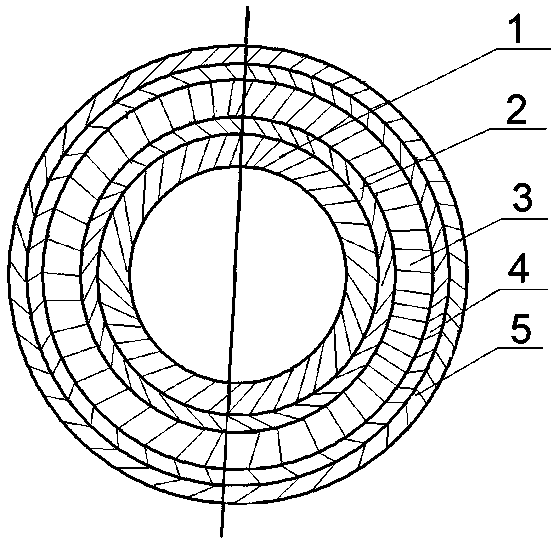

Polyurethane arc-shaped screen

InactiveCN112023493AHigh strengthIncrease elasticityDomestic articlesMoving filtering element filtersThermoplastic polyurethaneEngineering

The invention relates to the technical field of ore dressing devices, and particularly discloses a polyurethane arc-shaped screen which is characterized in that a supporting frame is of a latticed structure composed of transverse supporting strips and longitudinal supporting strips, and transverse frameworks and longitudinal frameworks are embedded in the transverse supporting strips and the longitudinal supporting strips respectively; a screen piece comprises a frame, a plurality of transverse screen bars and a plurality of longitudinal screen bars, the transverse screen bars and the longitudinal screen bars are connected to the inner edge of the frame, the bottom ends of the transverse screen bars are fixedly clamped in the connecting grooves, and the two ends of each transverse screen bar are perpendicularly and fixedly connected to the two side walls of an inner cavity of the frame respectively. The cross section of the upper portion of each screen strip is in an obtuse triangle shape, the lower surface of the upper portion of each screen strip is flush with the upper surface of the frame, the screen pieces are integrally formed through thermoplastic polyurethane elastic materials, the supporting frame body and the screen pieces form an integral structure through secondary pouring, and the supporting frame body is made of polyurethane materials. The problems that a screen for an arc-shaped screen is short in service life and low in screening efficiency are solved.

Owner:ANHUI FANGYUAN PLASTIC & RUBBER

High-strength non-cracking antiwear precise hollow axle and its making technology

A high-strength antiwear precise hollow shaft without breaking is made up of low-alloy cast steel containing C, Si, Mn, Cr, Ni, Mo, V and Fe through smelting, casting, annealing, coarse turning, modifying, fine turning, grinding, drilling and reaming. Its advantages include high strength, toughness and hardness, no defects and stress, high accuracy, long service life and low cost.

Owner:松滋市菱角铸钢有限责任公司

Method for repairing and reinforcing fluid transportation pipeline without stopping production

The invention discloses a method for repairing and reinforcing a fluid transportation pipeline without stopping production. The method comprises the following steps of (1) detecting the detect location and size of the pipeline; (2) carrying out metal tape pressure plugging repair for the perforated part of the pipeline; (3) brushing a soakage agent on the part to be repaired of the pipeline, adopting a high-temperature repair agent, and integrating with the steel pipe to form a repair layer after curing; (4) adopting fiber impregnated with high temperature resistant resin or fiber fabric at the part to be repaired of the pipeline for twining and pasting, and thus forming a reinforcement layer after curing; (5) adopting high strength fiber or fiber fabric to combine with a body material atthe outer part of the reinforcement layer for twining and reinforcing, and thus forming a reinforcing layer after curing; and (6) brushing high temperature resistant protective coating at the outer part of the reinforcing layer, and thus forming a protective layer after curing. The method is safe and reliable and has low repair cost and short repair period, the composite repair layer has excellentcorrosion resistance, the high temperature pipeline can be repaired and reinforced with stopping production, a lot of engineering monitoring time is saved, and the working efficiency is improved.

Owner:马付林

Cutting pick, cutting pick head and manufacturing method thereof

The invention discloses a cutting pick, a cutting pick head and a manufacturing method thereof. The cutting pick head is welded on the end of the cutting pick, and one end of a conical section is provided with an axial blind hole to be connected with the cutting pick head; the cutting pick head is provided with a working section and a connecting section, and the connecting section is spliced in the axial blind hole; and the working section of the cutting pick head is provided with a conical camber section and a spherical top end, the spherical top end is provided with a diamond layer, and thediamond layer and the conical camber section are connected through smooth transition. The manufacturing method of the cutting pick and the cutting pick head comprises the following steps: die-castingsintered carbide into a shape of a cutting pick head with a die; compounding diamond powder on the surface of the spherical top end of the cutting pick head through die pressing under high temperature and high pressure; carrying out thermal treatment of the processed cutting pick head; and welding the cutting pick head and the cutting pick body with a welding machine. The cutting pick and the cutting pick head have the advantages of simple structure, high hardness and high wear resistance, and the service lives thereof can be prolonged significantly.

Owner:JIANGYIN CITY YUANFENG HEAT TREATMENT TECH

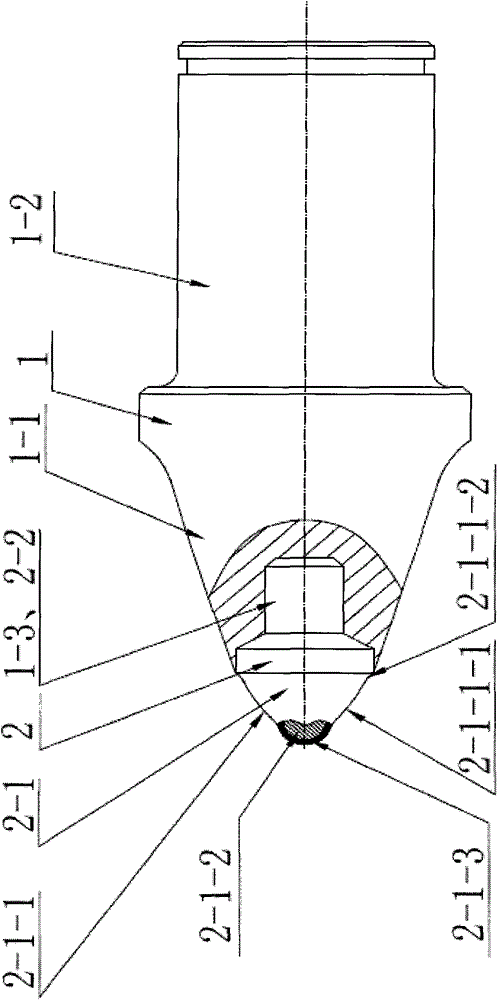

Anti-backflow perforated aerator

ActiveCN113072174AImprove oxygen transfer rateEasy to carry outWater aerationBiological treatment apparatusOxygen supplyMechanical engineering

The invention relates to the technical field of environmental protection equipment, and discloses an anti-backflow perforated aerator, which comprises an air inlet pipe, a clamping device, an oxygen supply aeration diaphragm, an anti-backflow rubber diaphragm, a locking ring and a pressing cover, wherein the oxygen supply aeration diaphragm is in a circular ring shape, oxygen supply aeration holes are formed in the ring surface of the oxygen supply aeration diaphragm at equal intervals, a boss is arranged at the bottom of the air inlet pipe, the inner ring of the oxygen supply aeration diaphragm is clamped between the clamping device and the boss, the anti-backflow rubber diaphragm is arranged below the oxygen supply aeration diaphragm and is provided with a groove matched with the boss, and the outer ring of the oxygen supply aeration diaphragm and the outer ring of the anti-backflow rubber diaphragm abut against each other and are fixedly clamped between the locking ring and the pressing cover. According to the invention, the oxygen supply function and the stirring function can work independently and can also work cooperatively, and the oxygen supply power efficiency and stability are greatly improved.

Owner:镇江伊博特环保科技有限公司

An anti-corrosion ultra-high-voltage online hanging device and its application method

ActiveCN105675478BImprove pressure resistanceAvoid failureWeather/light/corrosion resistanceUltra high voltageEngineering

The invention discloses an anti-corrosion ultrahigh-pressure online piece hanging and taking device and a using method thereof.The anti-corrosion ultrahigh-pressure online piece hanging and taking device comprises a piece hanging device and a piece taking device.The piece hanging device comprises a welding nipple and a piece hanging sealing rod.A movable sealing rod is designed and installed in an upper hole in a sealing cavity of the piece taking device, an ultrahigh-pressure combined seal for rods is designed and installed around the upper hole in the sealing cavity and the movable sealing rod, a force application rod is installed at one outer end of the sealing cavity, the end, in the sealing cavity, of the movable sealing rod is connected with a piece taking head, the lower portion of the sealing cavity is connected with an upper connector, the upper connector is connected with a high-pressure ball valve, the high-pressure ball valve is connected with a lower connector, and a vent valve is installed on a connecting pipe of the upper connector.Due to the design of an anti-corrosion nipple in the piece hanging device, corrosion of the piece hanging device and a welding line can be effectively controlled, and thus the piece hanging device can be used for a long time.Due to the matching design of the movable sealing rod, the piece taking head, an upper sealing nipple and a pressure release sealing rod, the high-pressure ball valve can be replaced once leakage occurs, the piece hanging and taking device can be used for a long time, and the operating force in the piece hanging and taking process is small.

Owner:西安华诺环境科技有限公司

Rotary kiln masonry structure

ActiveCN107356110BFirmly connectedNot easy to fall offRotary drum furnacesMonolithic liningsBrickRebar

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com