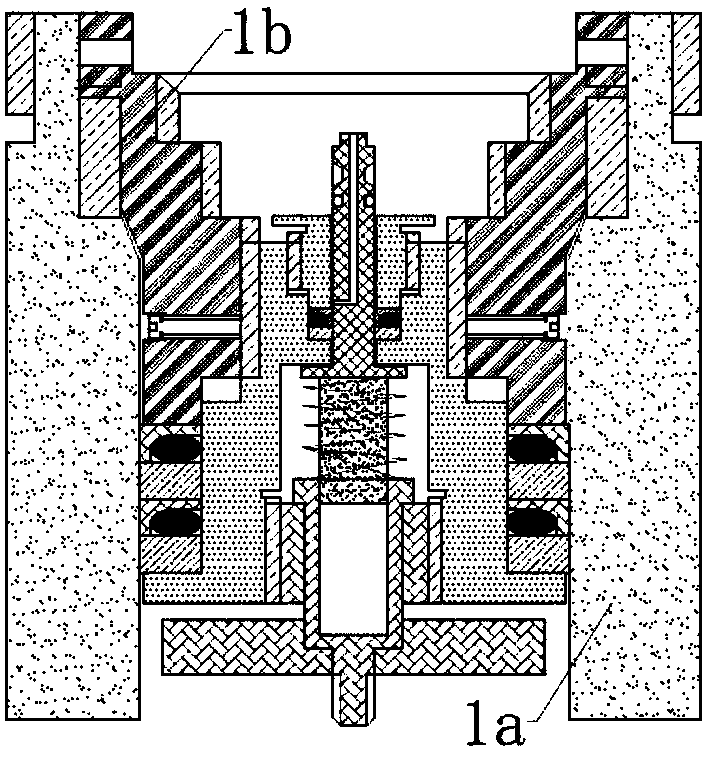

An anti-corrosion ultra-high-voltage online hanging device and its application method

An ultra-high pressure, hanging piece technology, used in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., which can solve problems such as easy leakage, inability to open, and excessive torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

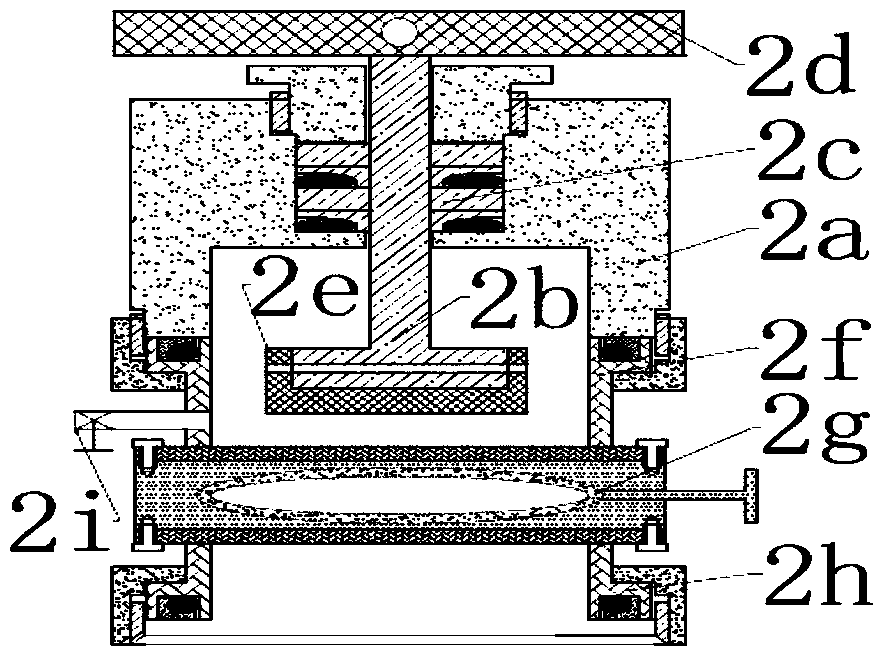

[0165] 1. Production of the moving sealing rod 2b

[0166] 1.1. Design of 6R1 in moving sealing rod 2b

[0167] In the oilfield production system, the general pressure P 1 No more than 60MPa, according to manual operation requirements, working force F 1 Not exceeding 50kg, according to formula F 1 =3.14×(6R1) 2 ×P 1 ÷4 calculates the diameter of 6R1: 50=3.14×(6R1) 2 ×60÷4, 6R1=10.3m. Select 6R1=10.0mm.

[0168] 1.2 Design of other parameters of the moving sealing rod 2b

[0169] 6R2=φ28mm; 6R3=M8; 6R4=φ7.5; 6H1=7mm; 6H2=20mm; 6H3=489mm; 6H4=4mm; 6H5=15mm; 6H6=4mm.

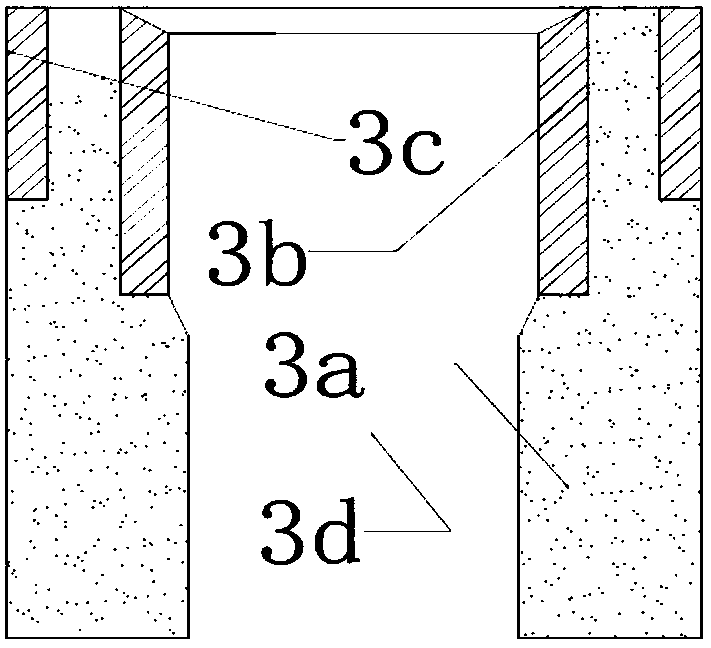

[0170] 2. Manufacture of pressure relief sealing rod 4c

[0171] The design of each parameter in the pressure relief sealing rod 4c: 12R1=φ8mm; 12R2=φ1.5mm; 12R3=φ1.5mm; 12R4=φ14mm; 12H1=7.5mm; 12H2=28mm; 53mm; 12H6=1.5mm; 12H7=3mm; 12H8=7mm; 12H9=3mm; 12H10=10mm; 12H11=5mm; 12H13=24.5mm.

[0172] 3. Fabrication of the lower sealing nipple 4b

[0173] The design of various parameters in the lower sealin...

Embodiment 2

[0192] 1. Production of the moving sealing rod 2b

[0193] 1.1. Design of 6R1 in moving sealing rod 2b

[0194] When the pressure P 1 Up to 80MPa, according to manual operation requirements, working force F 1 Not exceeding 50kg, according to formula F 1 =3.14×(6R1) 2 ×P 1 ÷4 calculates the diameter of 6R1: 50=3.14×(6R1) 2 ×80÷4, 6R1=7.98mm. Select 6R1=8.0mm.

[0195] 1.2 Design of other parameters of the moving sealing rod 2b

[0196] 6R2=φ26mm; 6H1=6mm; other parameters are the same as example 1.

[0197] 2. Manufacture of pressure relief sealing rod 4c

[0198] The design of each parameter in the pressure relief sealing rod 4c: 12R1=φ6mm; 12R2=φ1mm; 12R4=φ12mm; 12H1=5.5mm; 12H11=4mm; other parameters are the same as example one.

[0199] 3. Fabrication of the lower sealing nipple 4b

[0200] The design of various parameters in the lower sealing nipple 4b: 11R1 = φ32-0.04mm; 11R2 = φ24.9mm; 11R3 = M16; 11R4 = φ6mm; 11R5 = φ11.4mm; 11R6 = M15.4; 11R7 = M23.4; 11R8=...

Embodiment 3

[0219] 1. Production of the moving sealing rod 2b

[0220] 1.1. Design of 6R1 in moving sealing rod 2b

[0221] When the pressure P 1 Up to 40MPa, according to manual operation requirements, working force F 1 Not exceeding 50kg, according to formula F 1 =3.14×(6R1) 2 ×P 1 ÷4 calculates the diameter of 6R1: 50=3.14×(6R1) 2 ×40÷4, 6R1=12.618mm. Select 6R1=12.0mm.

[0222] 1.2 Design of other parameters of the moving sealing rod 2b

[0223] 6R2=φ30mm; 6H1=9mm; other parameters are the same as example 1.

[0224] 2. Manufacture of pressure relief sealing rod 4c

[0225] The design of each parameter in the pressure relief sealing rod 4c: 12R1=φ10mm; Other parameters are the same as example one.

[0226] 3. Fabrication of the lower sealing nipple 4b

[0227] The design of various parameters in the lower sealing pup joint 4b: 11R1 = φ35-0.04mm; 11R2 = φ28.9mm; 11R4 = φ10mm; 11R5 = φ15.4mm; 11R6 = M19.4; 11R7 = M27.4; 11R8 = φ27; Other parameters are the same as example on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com