Patents

Literature

119 results about "Spare parts management" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Service parts management is the main component of a complete strategic service management process that companies use to ensure that right spare part and resources are at the right place (where the broken part is) at the right time.

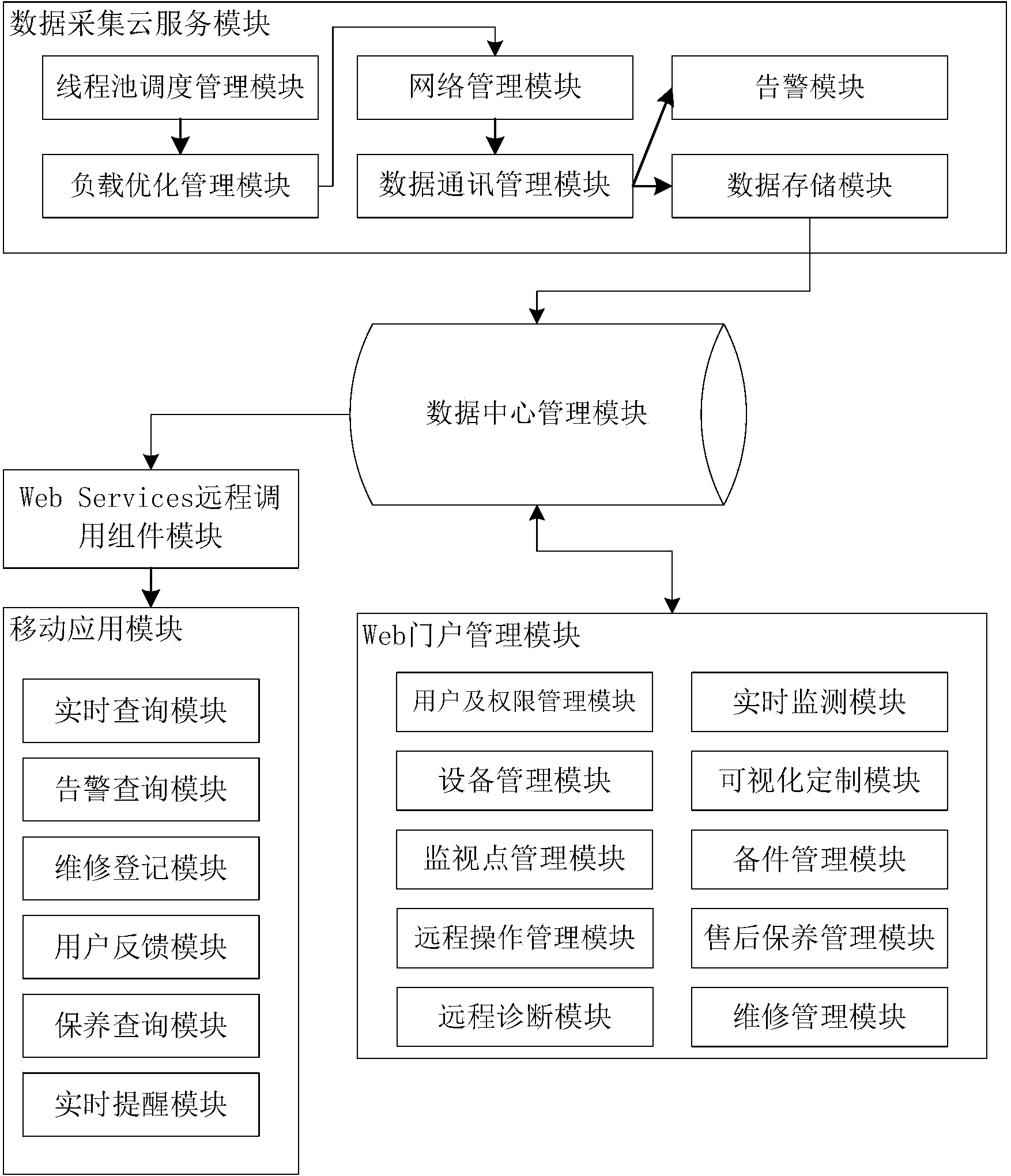

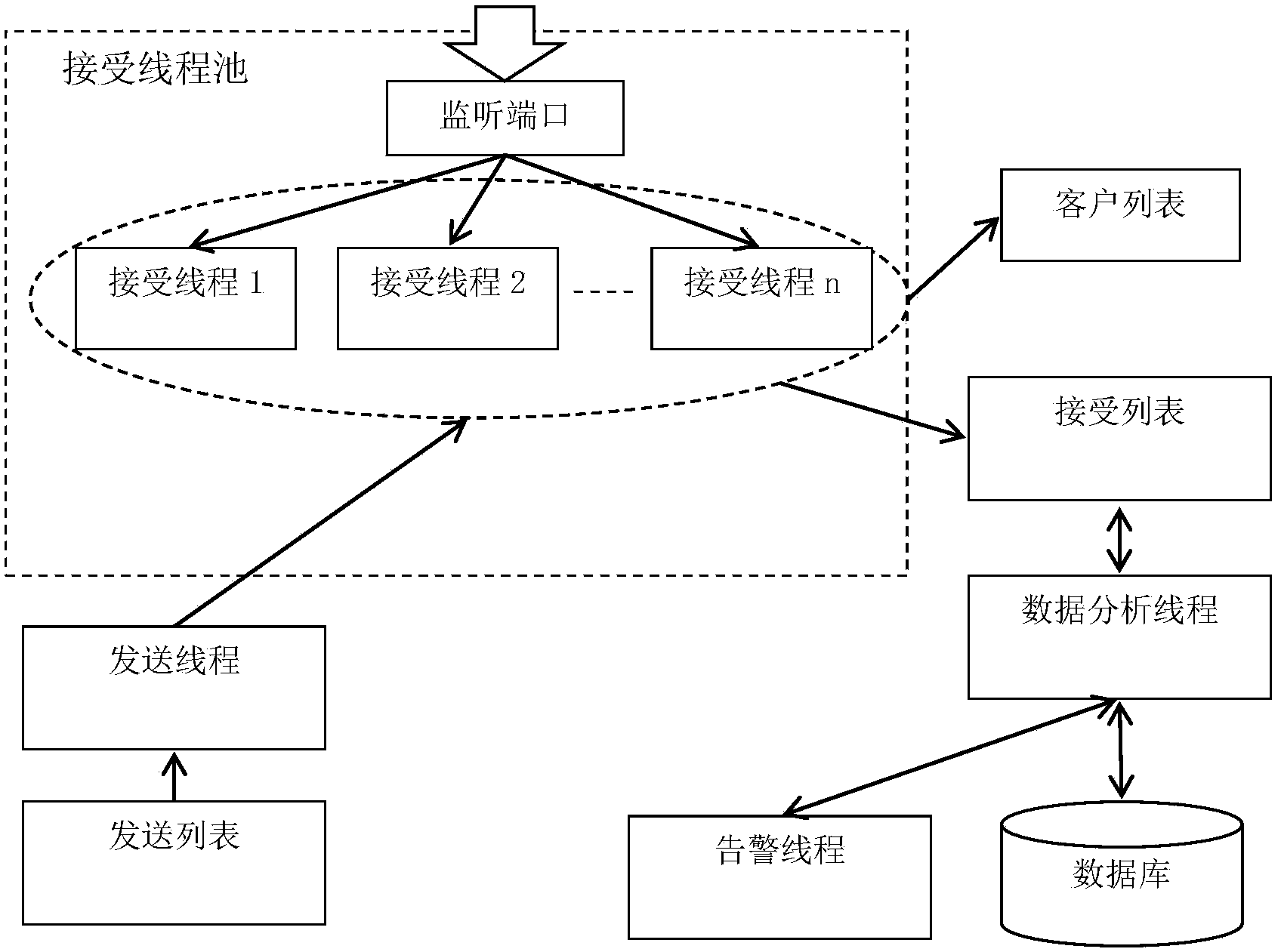

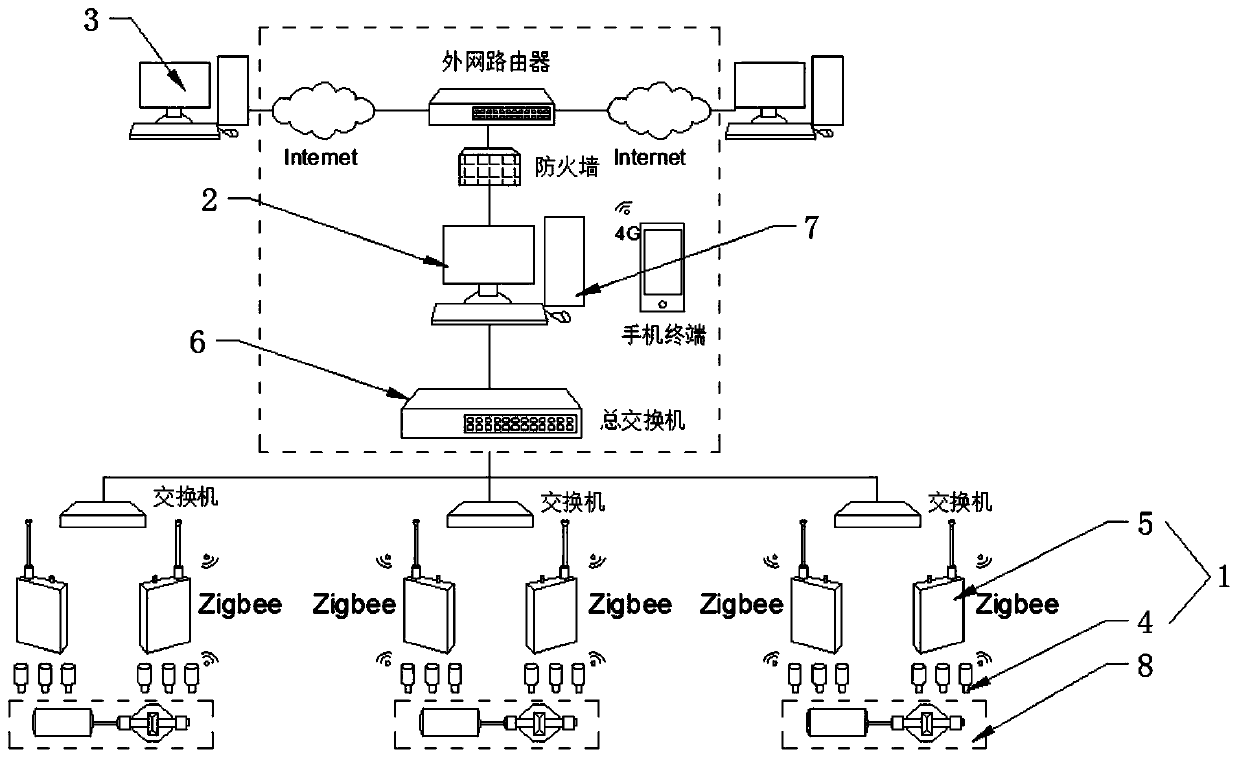

Third-party data service system based on Internet-of-Things data collecting

ActiveCN104283967ARealize remote mobile monitoringFlexible configurationTransmissionData centerLoad optimization

The invention discloses a third-party data service system based on Internet-of-Things data collecting. The third-party data service system comprises a data collecting cloud service module, a Web portal management module, a Web Service remote calling assembly module, a mobile application module and a data center management module. The data collecting cloud service module comprises a thread pool dispatching management module, a load optimization management module, a network management module, a data communication management module, a data storage module and an alarm module. The Web portal management module comprises a user and authority management module, an equipment management module, a monitoring point management module, a real-time monitoring module, a visual customization module, a spare part management module, an after-sale maintenance management module, a repair management module, a remote operation management module and a remote diagnosis module. The mobile application module comprises a real-time inquiry module, an alarm inquiry module, a repair registration module, a user feedback module, a maintenance inquiry module and a real-time warning module.

Owner:武汉华喻燃能工程技术有限公司 +1

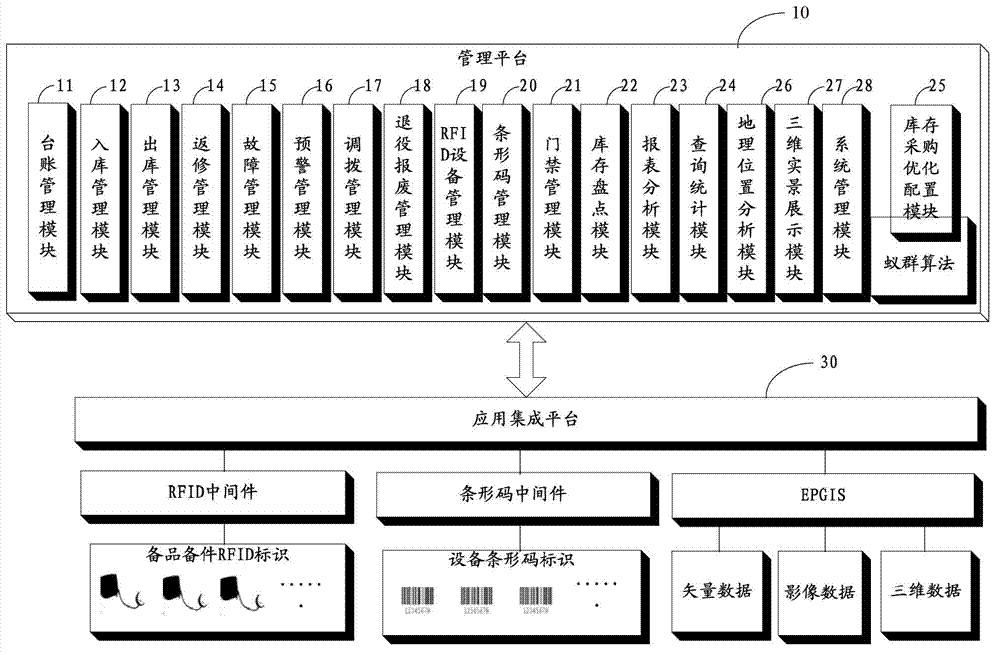

Electric power communication spare part management system and method based on ant colony algorithm

ActiveCN103198391AGet out of job modeImprove work efficiencySensing record carriersLogisticsStock managementSpare parts management

The invention discloses an electric power communication spare part management system and method based on an ant colony algorithm. Through the adoption of radio frequency identification device (RFID) technology, the system and method can achieve automatic identification management, automatic data collection and human error removing for various spare part devices under different states, achieves seamless connection with a spare part information management system, and achieves functions such as basic data management, stock management, stock removal management, repair management, failure management, early-warning management, allocating management, RFID label management, bar code management, inventory verification, inquiry statistics, report analysis statistics, access control, inventory verification, geographic position analysis, three-dimensional live-action showing and system management. The invention discloses the electric power communication spare part management system and method based on the ant colony algorithm.

Owner:STATE GRID CORP OF CHINA +2

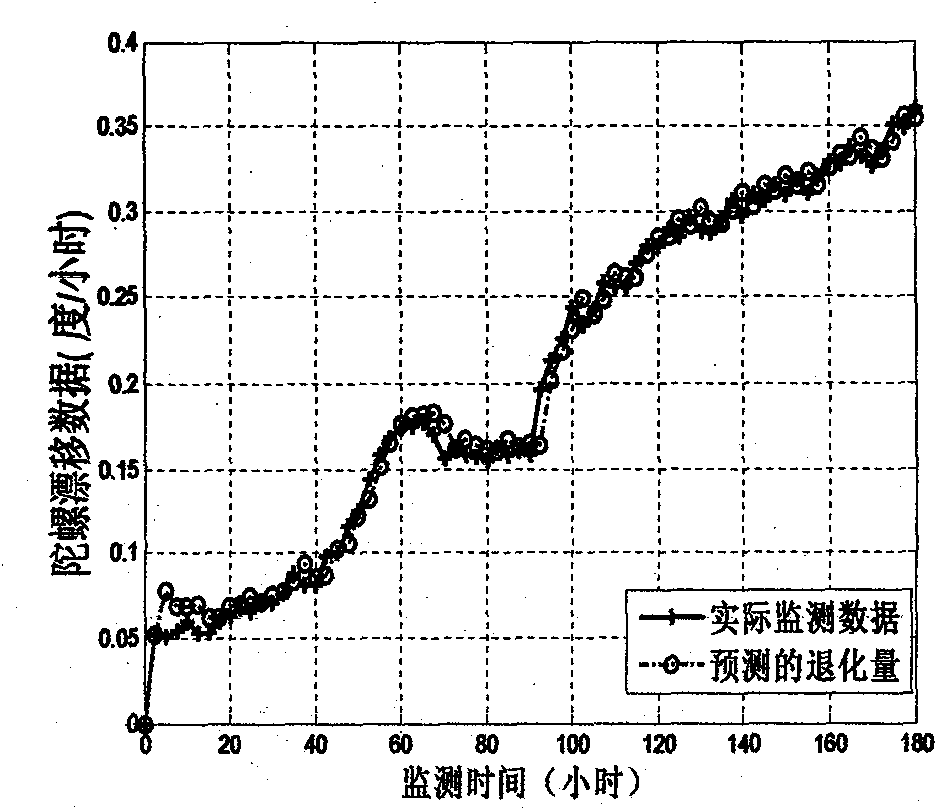

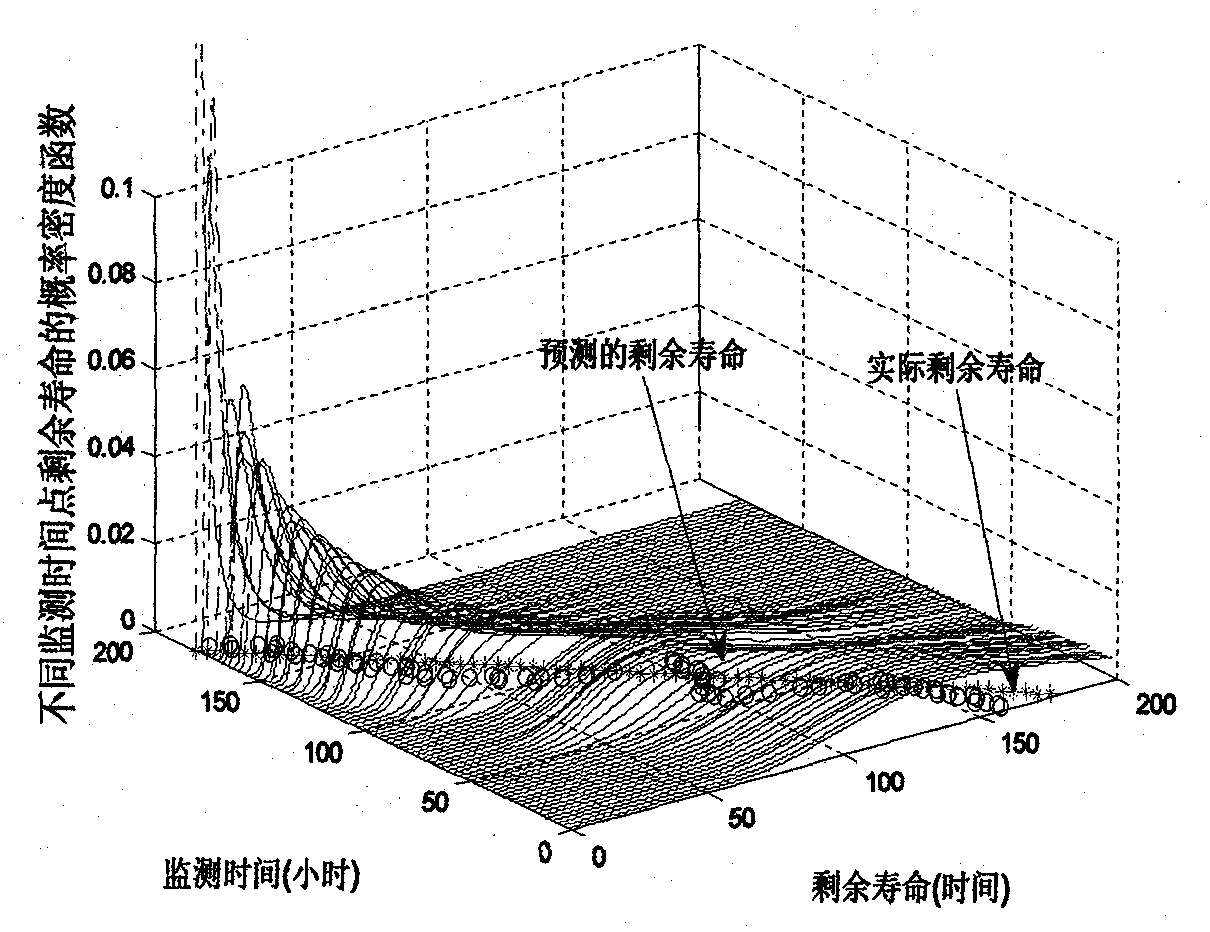

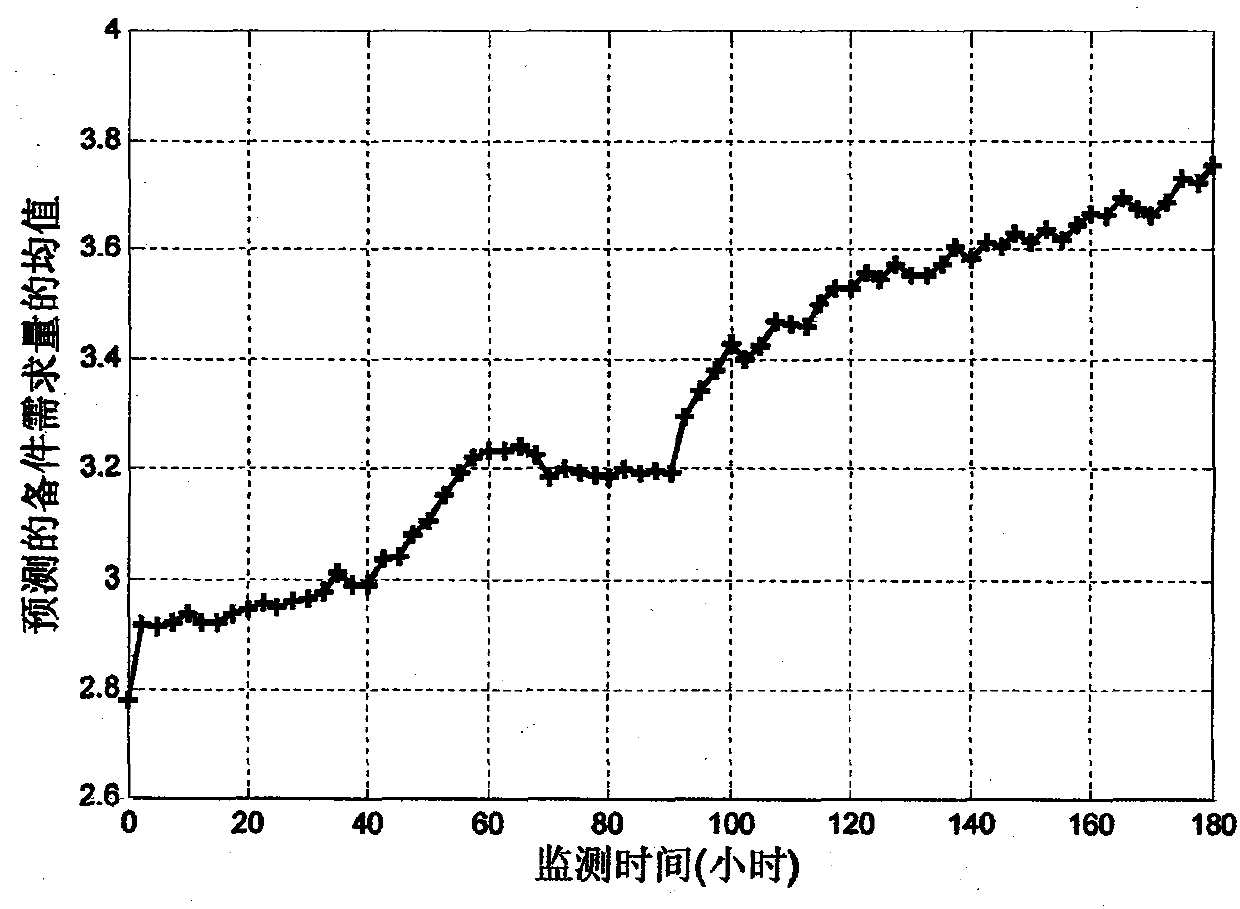

Degradation modeling-based equipment failure number prediction method

The invention relates to a degradation modeling-based equipment failure number prediction method. Performance degradation data obtained by a product during a performance changing process is fully utilized to predict the residual life of the single high-reliability product; a failure number of the equipment is determined; and spare part management is optimized based on the prediction of the failure number of the equipment. The method comprises the following four steps: establishing a performance degradation model of the equipment; carrying out parameter estimation in the performance degradation model; carrying out residual life prediction; and carrying out equipment failure number prediction. Compared with the prior art, the provided method enables prediction parsing to be carried out on the individual residual lift and the general reliability service life of the product; and the provided method can be used as an effective analytic tool for predicting the product residual life and the failure number. And a powerful theoretical basis and technical support can be provided for product maintenance and spare parts ordering strategy determination. Therefore, the expenditure can be saved and unnecessary economic loss can be avoided. And thus the method has the great engineering application value.

Owner:PLA SECOND ARTILLERY ENGINEERING UNIVERSITY

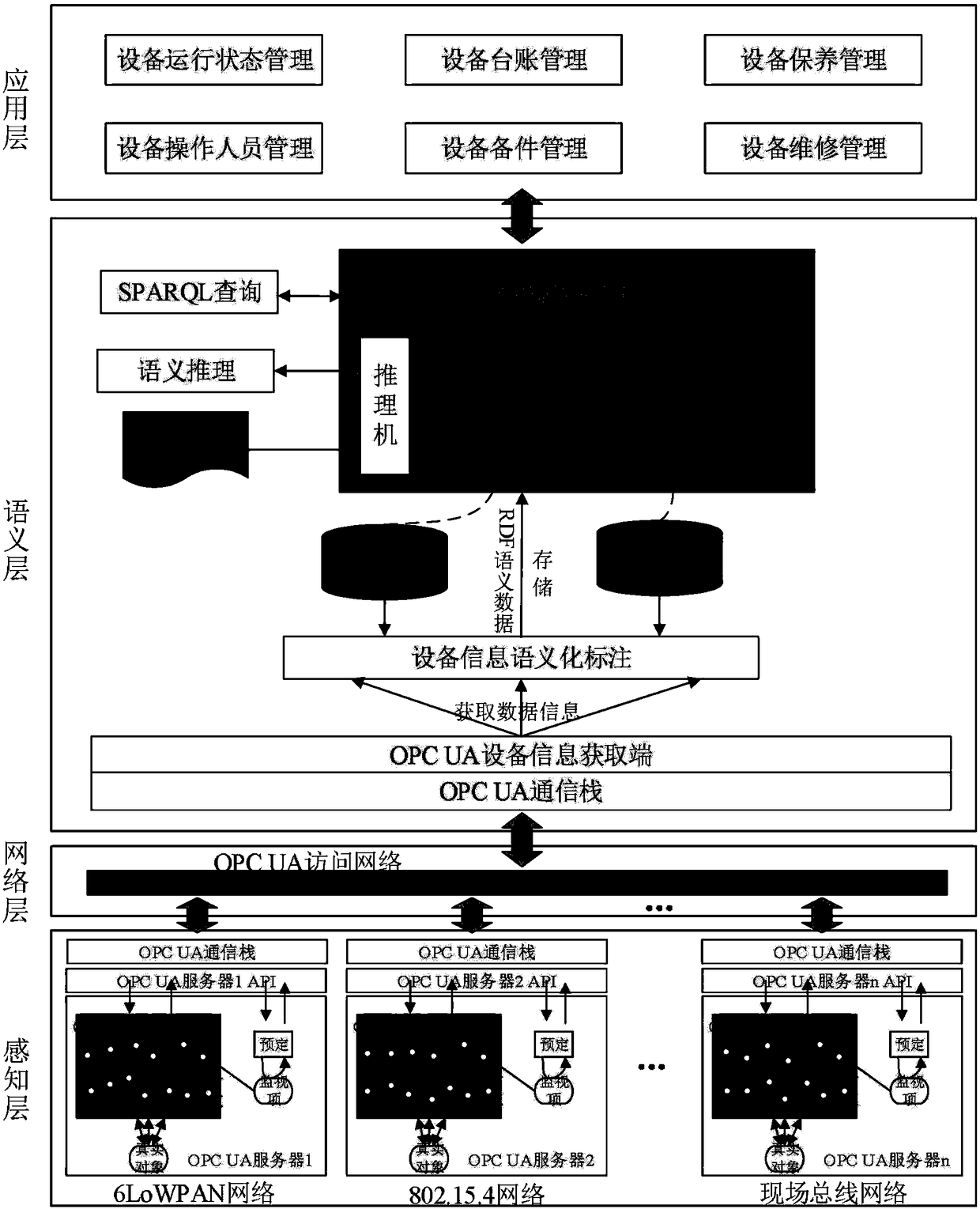

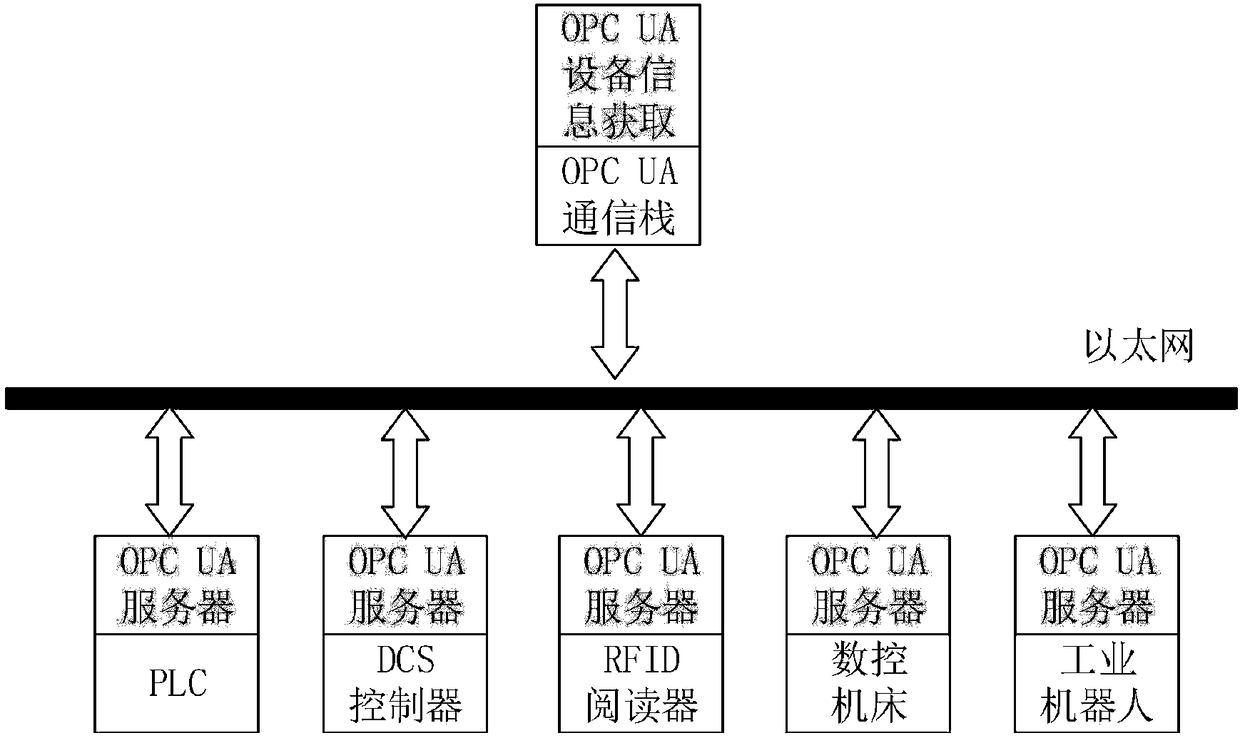

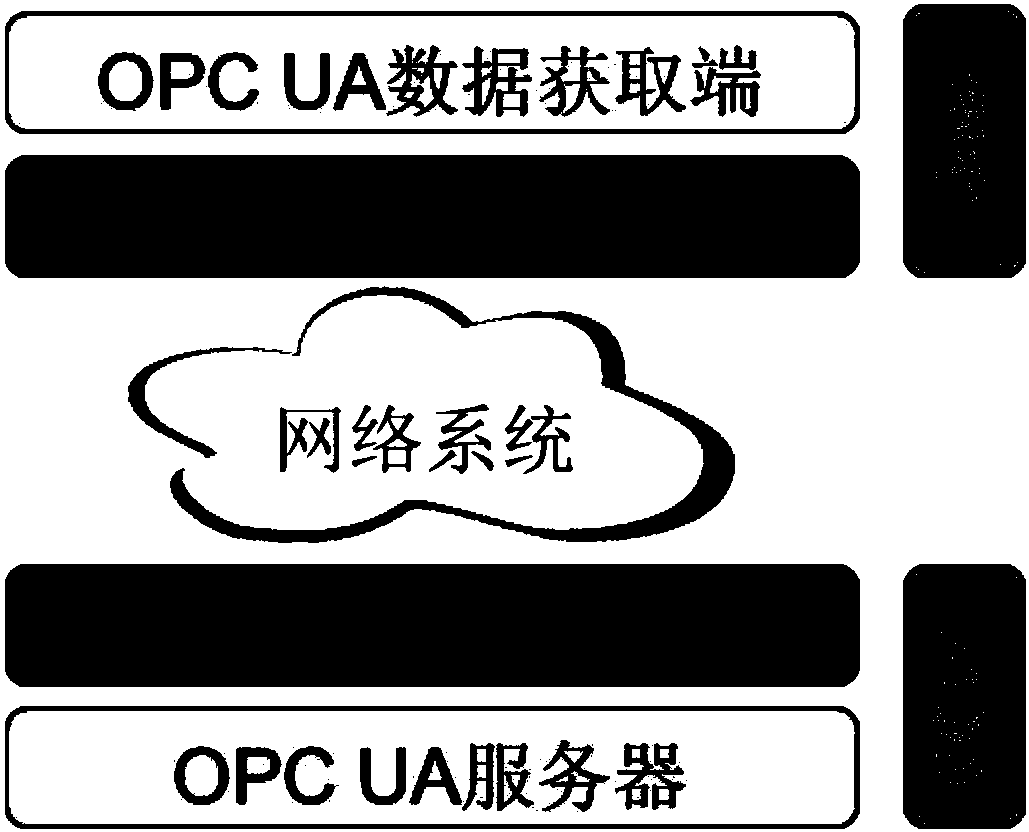

Field device information management system based on semantics and OPC UA

InactiveCN108459574AGuaranteed interoperabilityRealize intelligent management servicesTotal factory controlProgramme total factory controlIndustrial InternetSemantic Web

The invention relates to a field device information management system based on semantics and OPC UA and belongs to the combined field of the semantic network and the industrial Internet of things. Theintegral configuration of the system comprises a sensing layer, a network layer, a semantic layer and an application layer, wherein the sensing layer comprises a bottom field device and an OPC UA server, the network layer comprises each network system accessed by the OPC UA, the semantic layer comprises an OPC UA device information acquisition end, a device information management domain knowledgeontology model, a device information semantic annotation module, a semantic reasoning and query module, an ontology database and a semantic rule file, and the application layer comprises a device running state management module, a device operator management module, a device machine account management module, a device spare part management module, a device maintenance management module and a device repair management module. The management system is advantaged in that semantic integration of the heterogeneous device information is realized, through semantic reasoning and query, the relatively rich semantic knowledge in the field can be acquired, and needs of each functional module of the system are satisfied.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

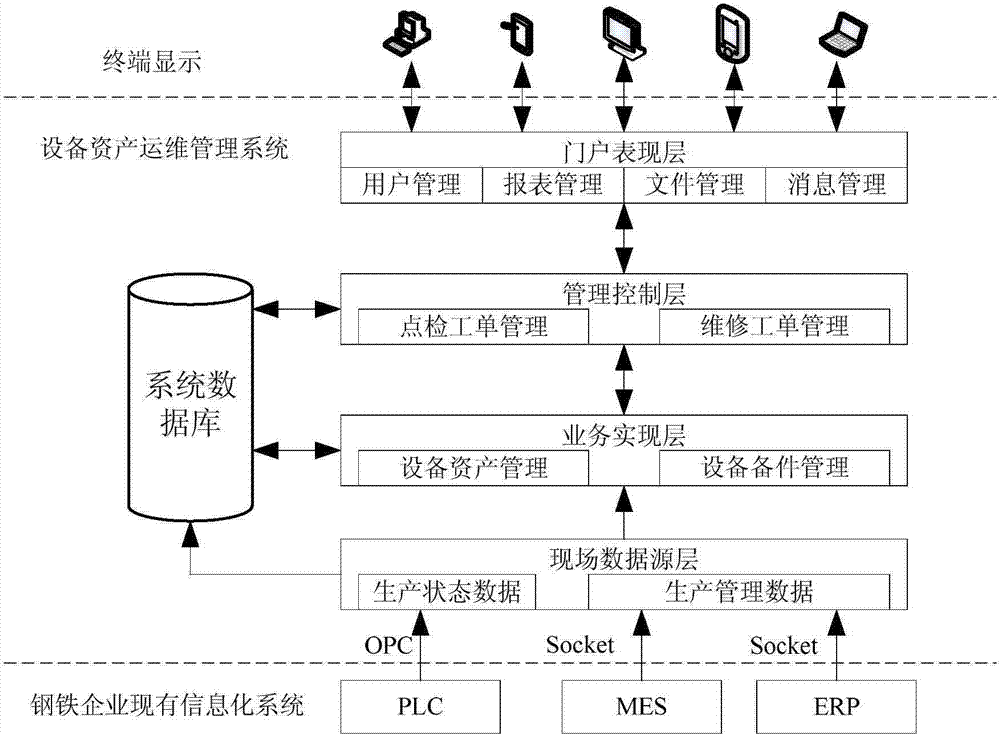

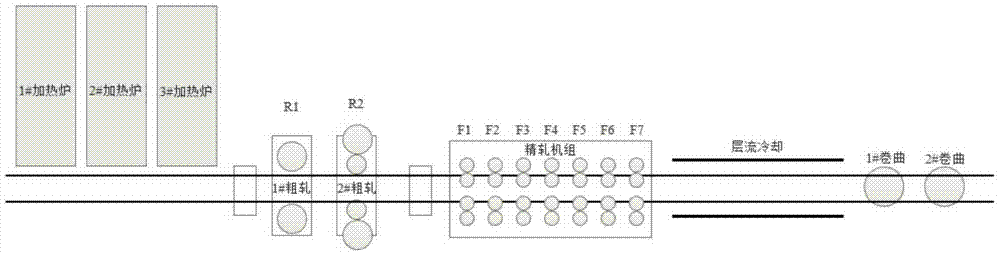

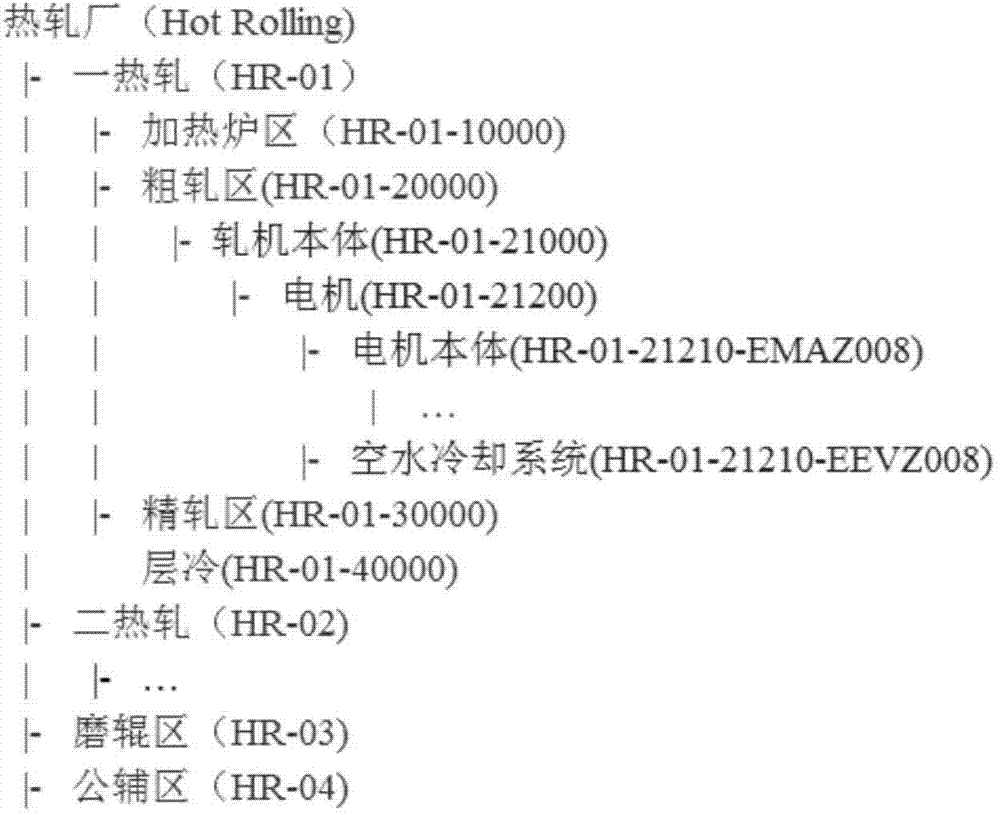

Equipment asset operation and maintenance management system for iron and steel enterprises

InactiveCN104850968ARealize transparent managementAchieving the goal of reducing costs and increasing efficiencyResourcesManufacturing computing systemsControl layerStructure of Management Information

The invention relates to an equipment asset operation and maintenance management system for iron and steel enterprises, and the system comprises an on-site data source layer, a business implementation layer, a management control layer, and a gateway presentation layer. The on-site data source layer receives status data of equipment in a production process in real time through an OPC protocol, is connected with an existing MES and an existing ERP system through a Socket protocol, and obtains production management data related to the equipment. The business implementation layer displays the position and equipment information corresponding to a production layout in a manner of a layered structure tree, enables the information to be related to the production data, and achieves the relation of on-line equipment with a spare part through a spare part management system. The management control layer achieves the automatic and manual generation of a point inspection work order and a maintenance work order according to the condition of the equipment, and the work orders are sent and executed. The gateway presentation layer provides a desktop, a mobile terminal and other terminal display modes, and achieves the multi-point deployment of the system. The system helps the iron and steel enterprises achieve refined and transparent management of equipment assets, can reduce the fault rate of equipment, and improves the guarantee capability of the equipment.

Owner:中冶赛迪电气技术有限公司

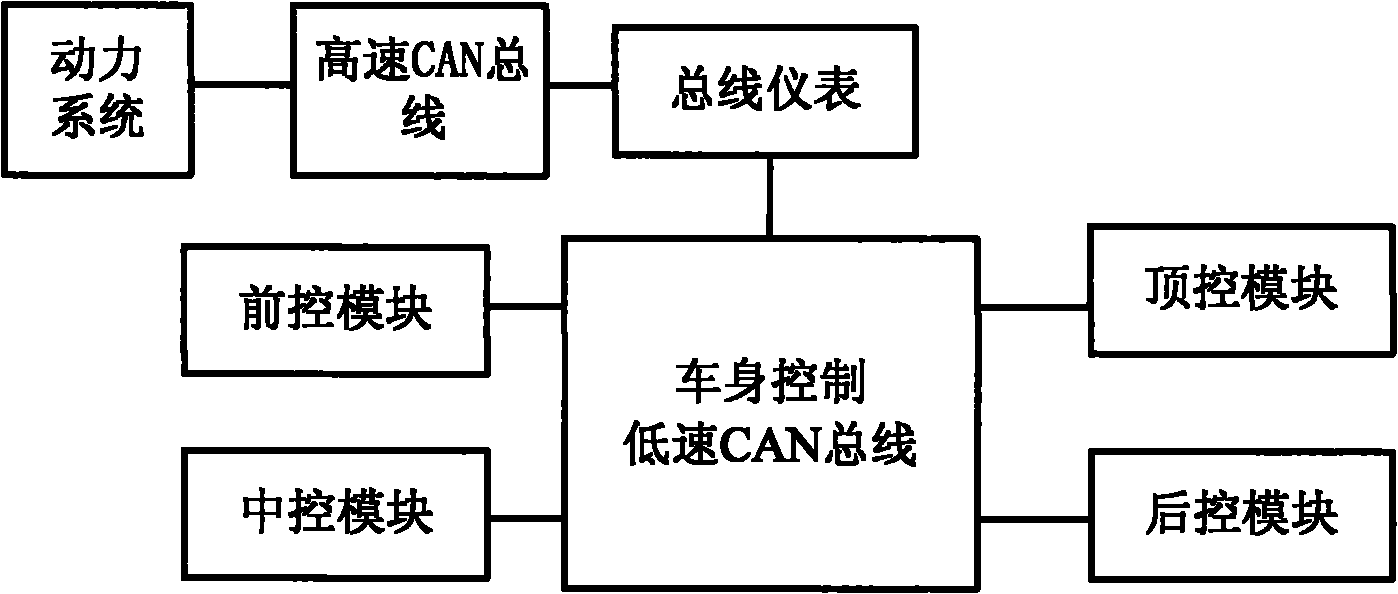

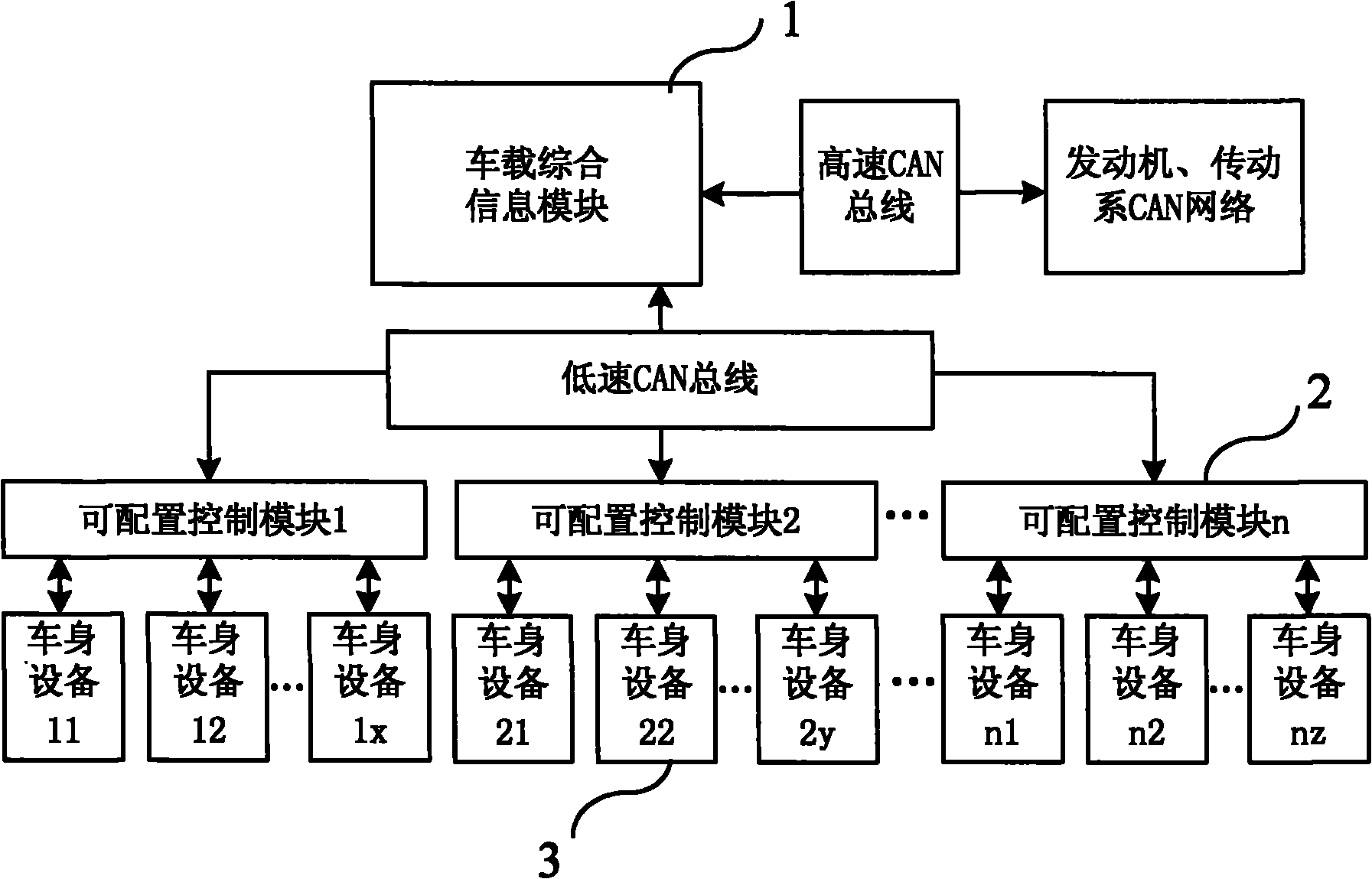

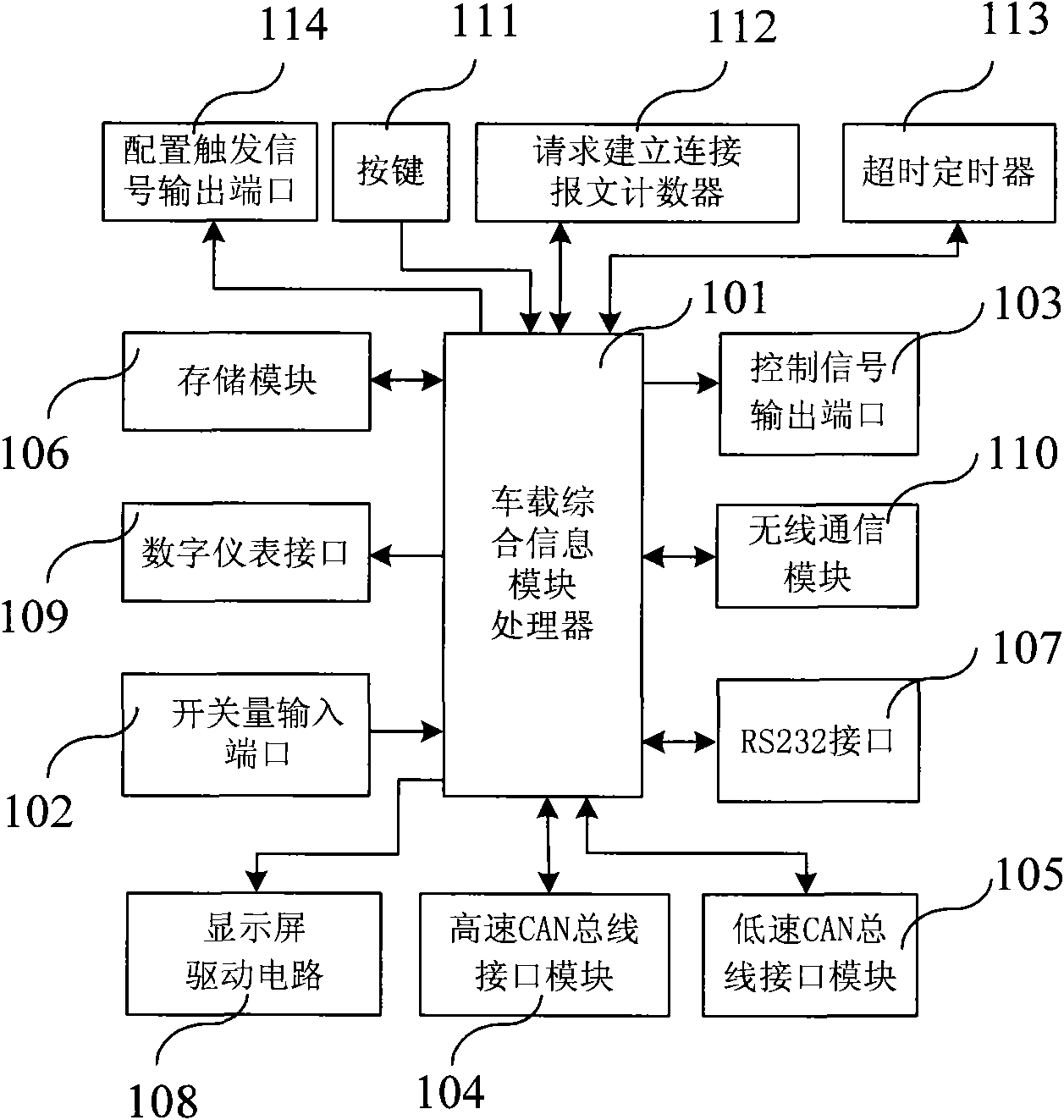

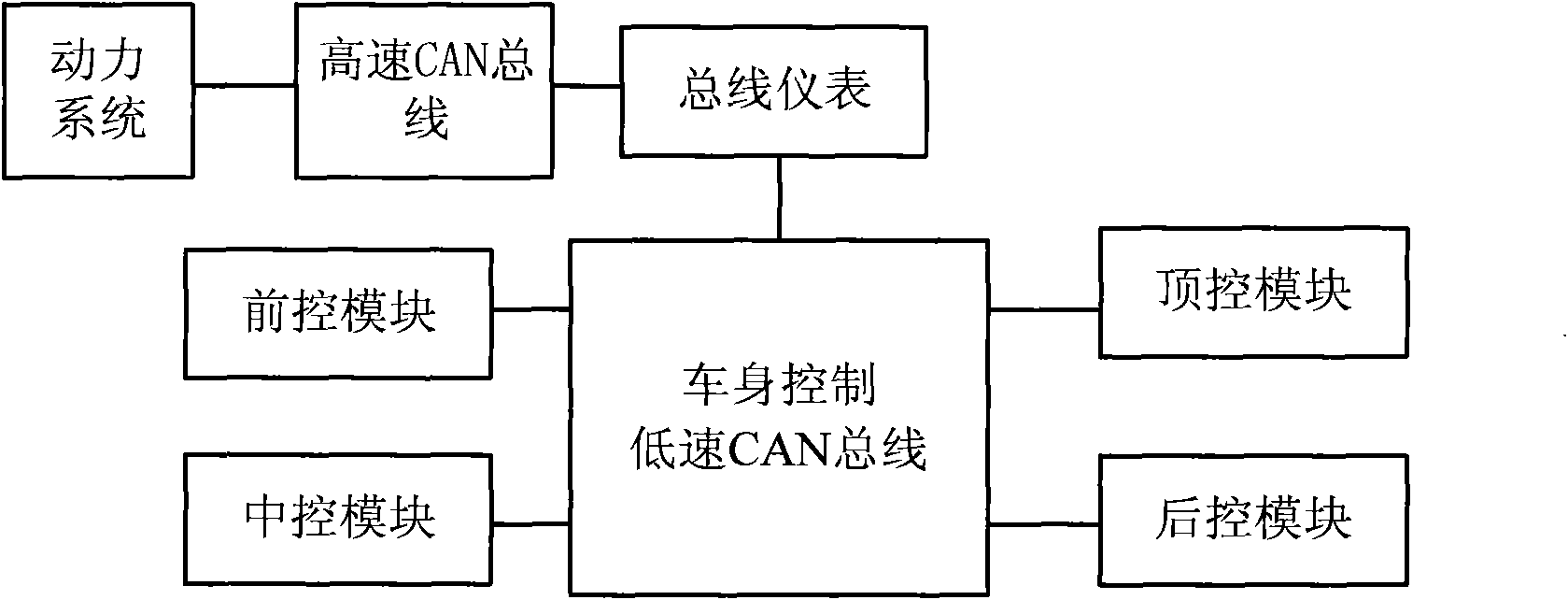

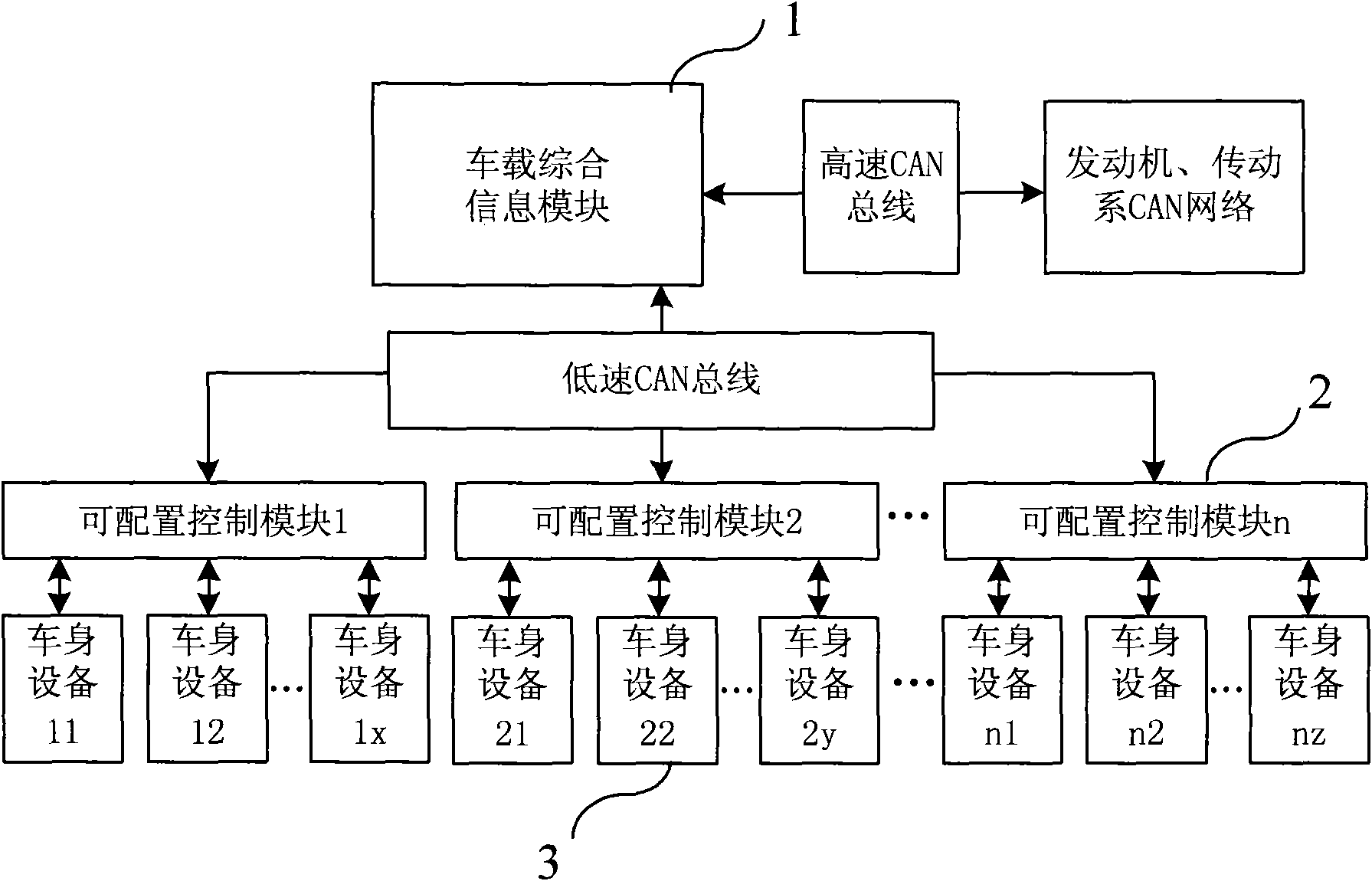

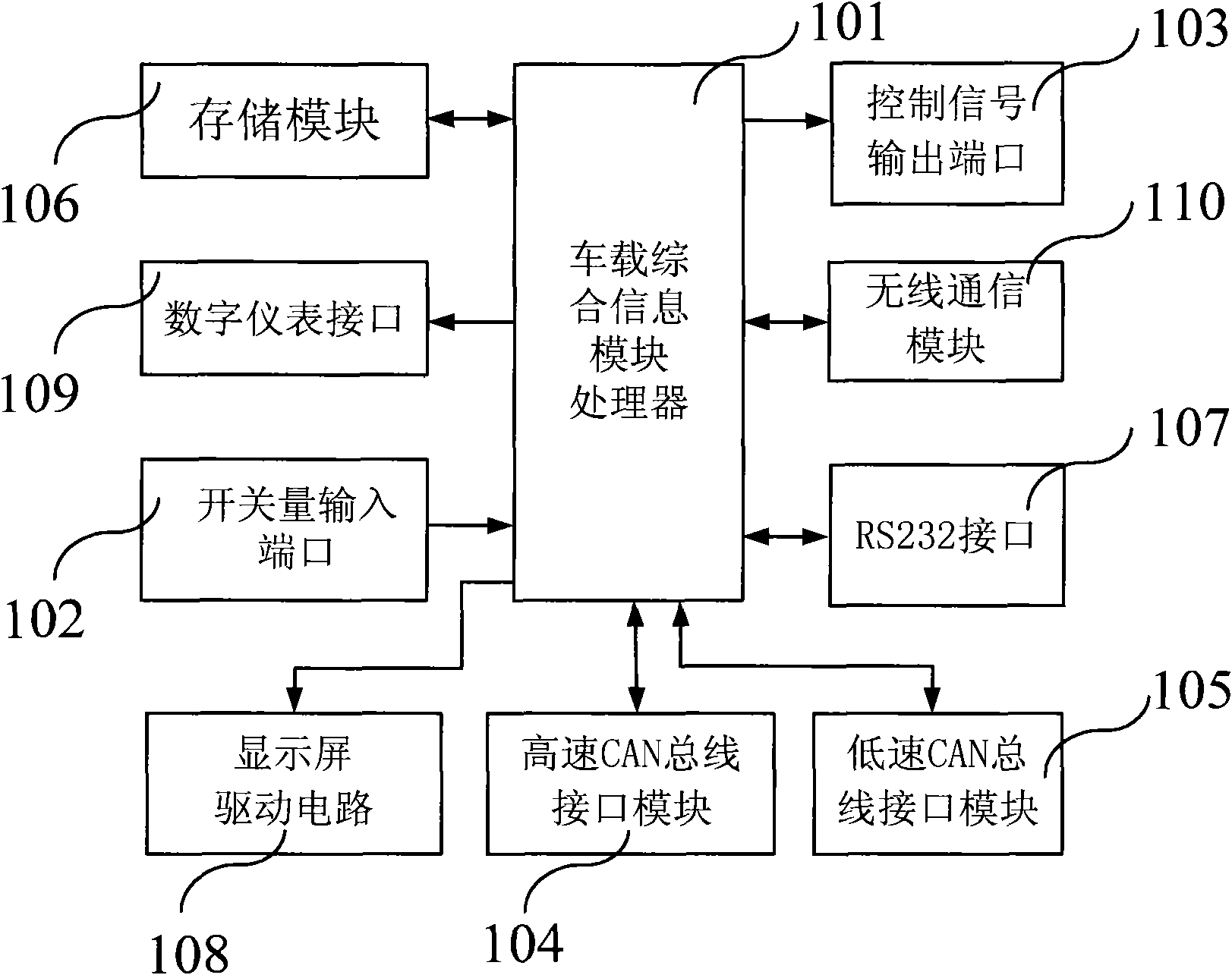

Configurable passenger car body control system and parameter configuration method thereof

ActiveCN101916089AFlexibleVersatilityElectric/fluid circuitTotal factory controlCustomer requirementsLow speed

The invention discloses a configurable passenger car body control system which comprises a vehicle-mounted integrated information module and a plurality of configurable control modules, wherein the vehicle-mounted integrated information module comprises a processor, an on-off input port, a control signal output port, high-speed and low-speed CAN bus interface modules, a digital instrument interface, a storage module and an RS232 interface; and each configurable control module comprises a processor module, an on-off and analog input circuit, a control signal output circuit, a low-speed CAN bus communication module and a storage unit. The invention also discloses a parameter configuration method of the system, which comprises the following steps: generating, downloading and interpreting parameter configuration files, wherein input and output signals of the passenger car body control system are set by the parameter configuration files. The invention enables the passenger car body control system to be flexible and universal and to be used on different models so as to meet different customer requirements, has the advantages of short development cycle and low development cost, and facilitates the after-sale service of the cars and the management of standby and spare parts.

Owner:HIGER

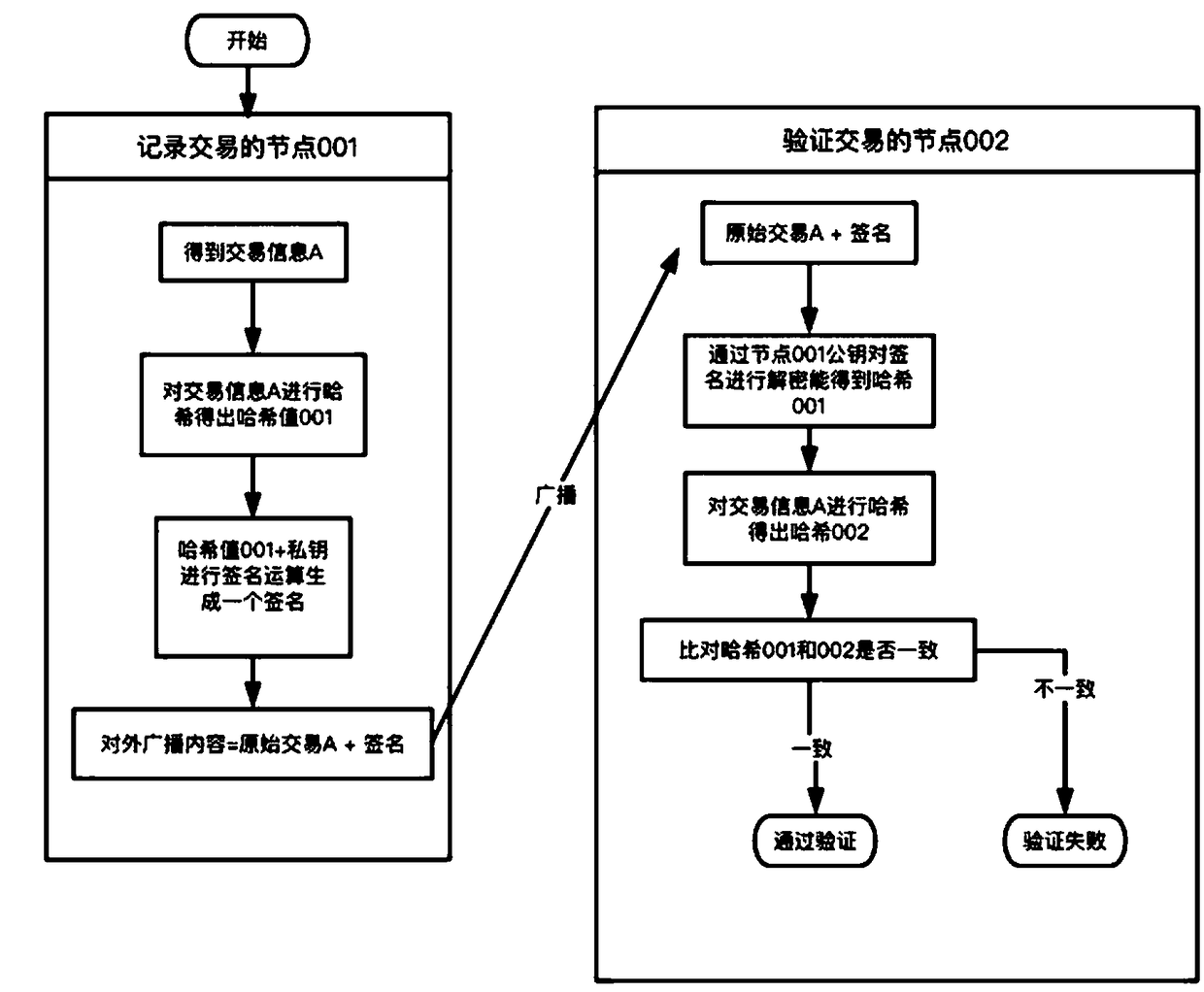

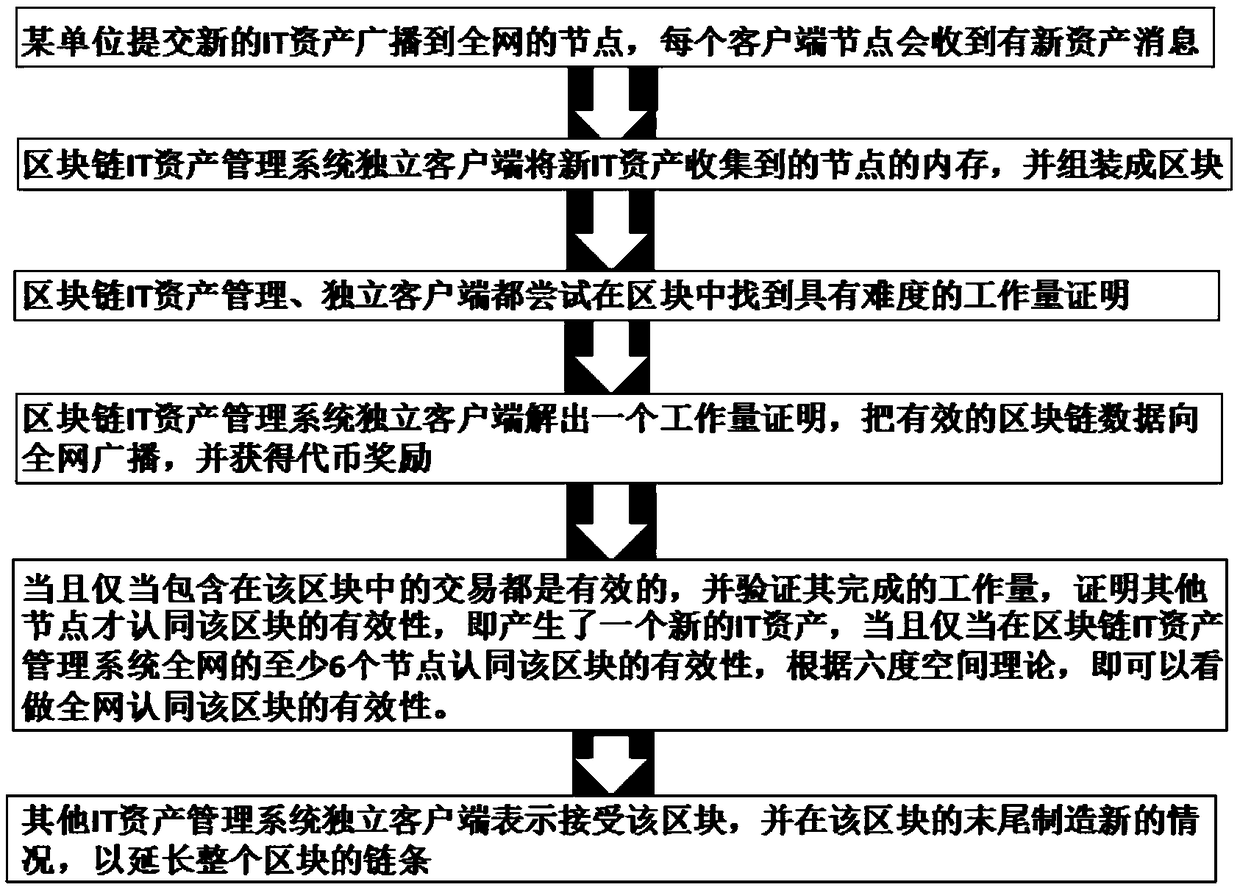

An IT asset management method based on a block chain

InactiveCN109409749ASolve storage problemsValue maximizationResourcesProblem managementAccident management

The invention discloses an IT asset management method based on a block chain. The invention solves the problem of decentralized accounting and unified server storage by building an economic system centered on competition-bookkeeping-reward. The IT asset management system builds a forward circulation economic system by means of a block chain, so that the IT asset management system naturally grows and develops and expands under the condition that no powerful centralization mechanism or organization promotion exists. The method is applicable to owned management organizations; Hardware, software and information assets which can play a value for organizing services are also suitable for management of the whole process including but not limited to IT asset demand proposing, type selection, fundbudget and preparation, purchasing, contract, registration and entry, installation, use, asset accident management, problem management, maintenance, upgrade, change, migration, transfer, spare part management, scrapping and the like.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

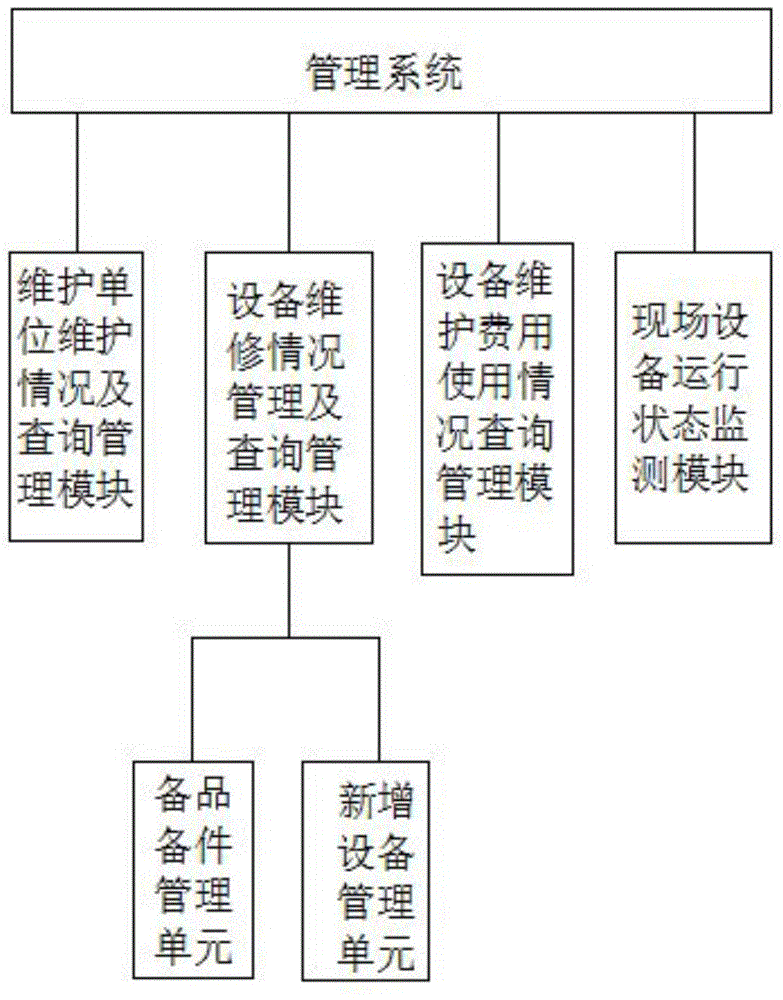

Expressway data management system

The invention relates to the technical field of expressway data management and maintenance, and specifically discloses an expressway data management system. Specifically, the system comprises server platform software, a data management system, and a monitoring system of an internet of things communication system. The system uses a BS architecture, and comprises a maintenance unit maintenance condition and inquiry management module, a personnel management module, a device maintenance condition management and inquiry module, a device maintenance cost use condition inquiry management module, a spare part management inquiry module, an intelligent terminal APP module, and a filed device operating state monitoring module. The system is advantaged in that the management system can monitor and manage personnel, device maintenance cost, toll equipment, communication equipment, monitoring equipment, tunnel electromechanical equipment, ventilation and illumination equipment, and road out-field equipment, thereby improving efficiency of device operation, maintenance, and equipment inventory management. The system has functions of inquiring, retrieving, managing, and leading out all generated data in real time through a WEB method. Persons in different identities can operate and manage according to authority.

Owner:黄日芳

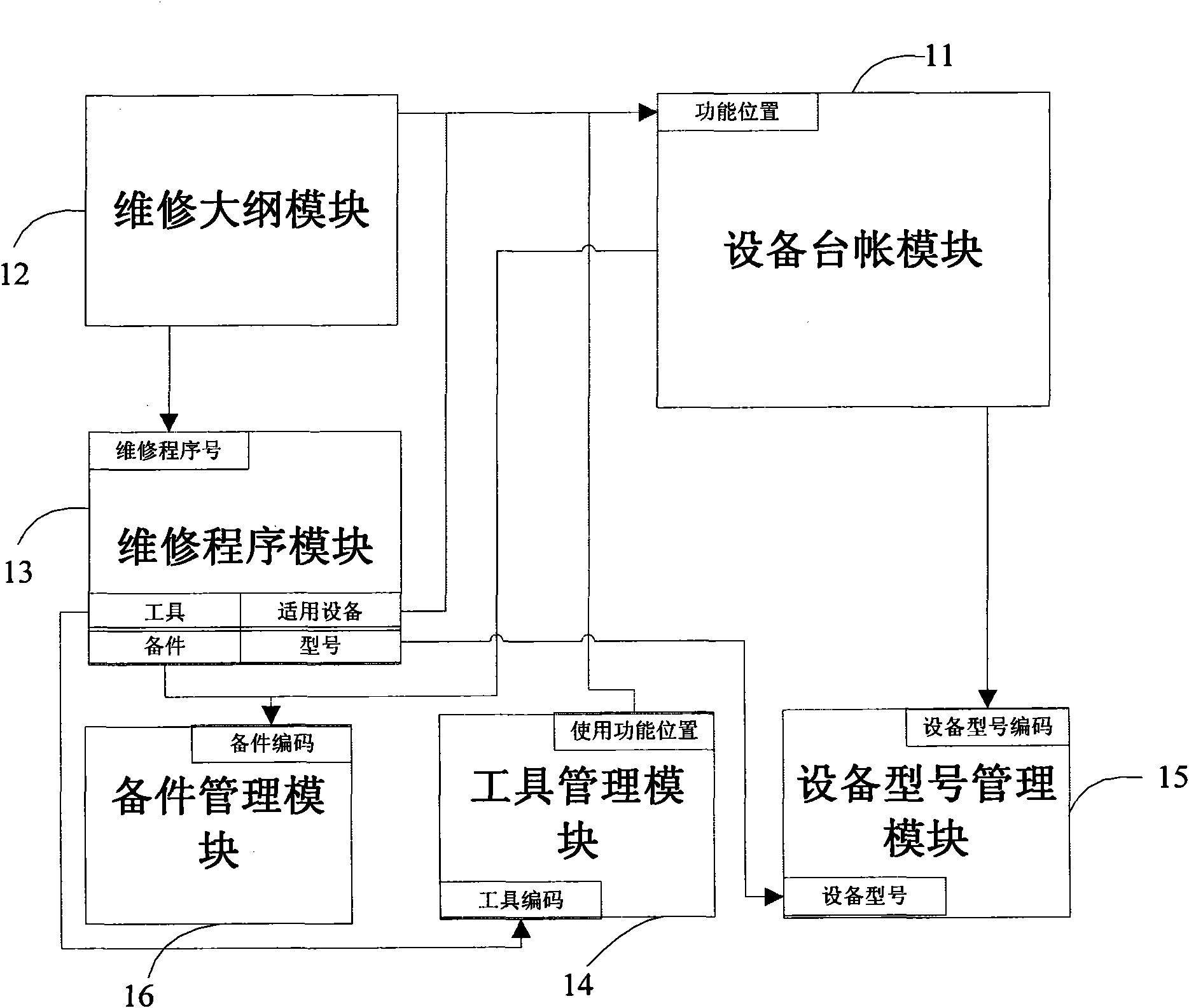

Production material management system and method of nuclear power plant

InactiveCN101819653AEnsure consistencySolve the island problemTechnology managementResourcesData coherenceDevice type

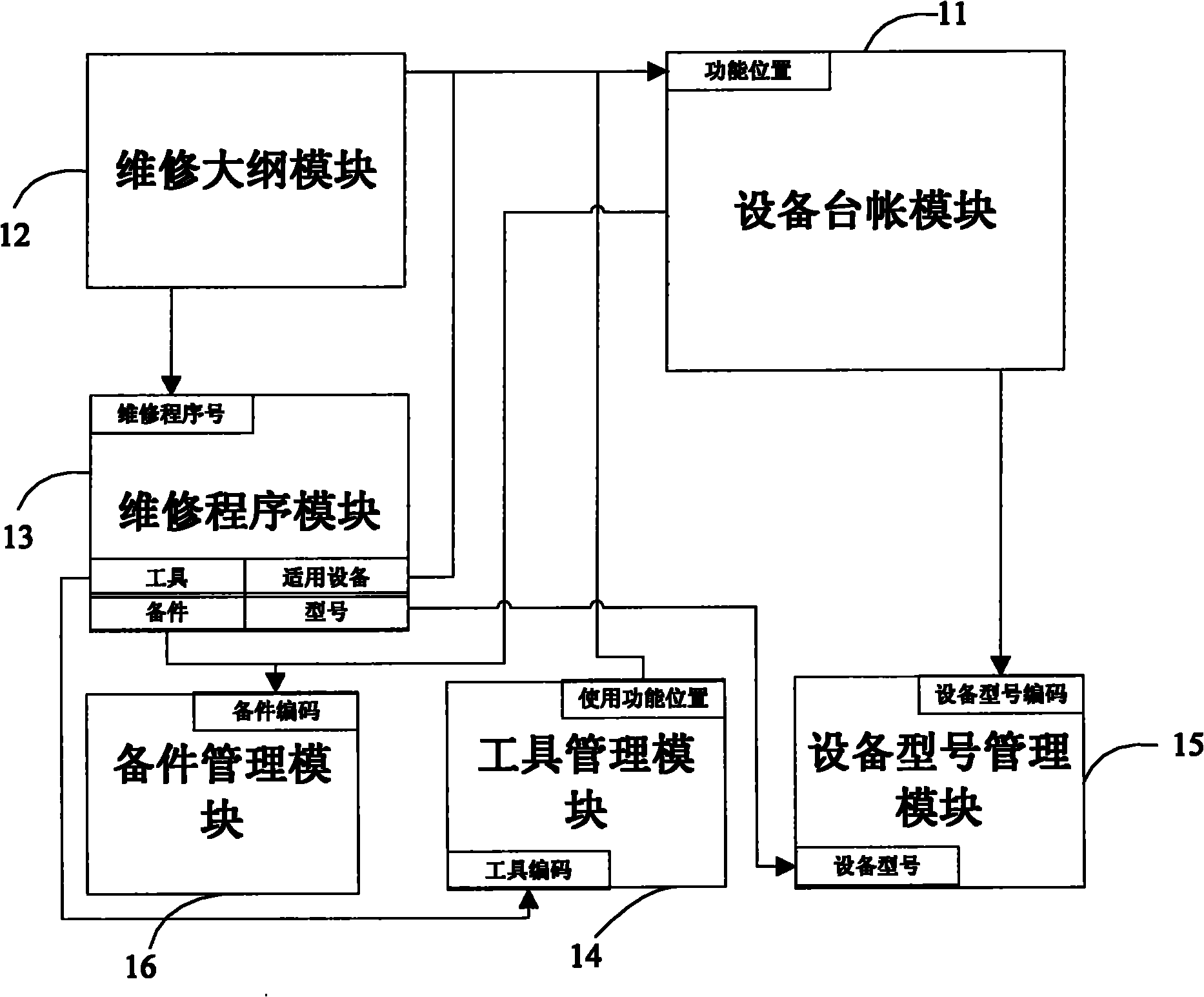

The invention relates to production material management system and method of a nuclear power plant. The system comprises a device ledger module, a maintenance outline module, a maintenance program module, a tool management module, a device type management module, a spare part management module, and the like. In the invention, a unified work platform system is formed, the works of query, treatment, and the like are greatly convenient, relationships are established among the modules, data is combined together in an organic mode, the problem of information isolated island is deracinated, data coherence is ensured, the system friendliness is strengthened, the problems of complex query operation are also solved, and the work efficiency is greatly improved.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +3

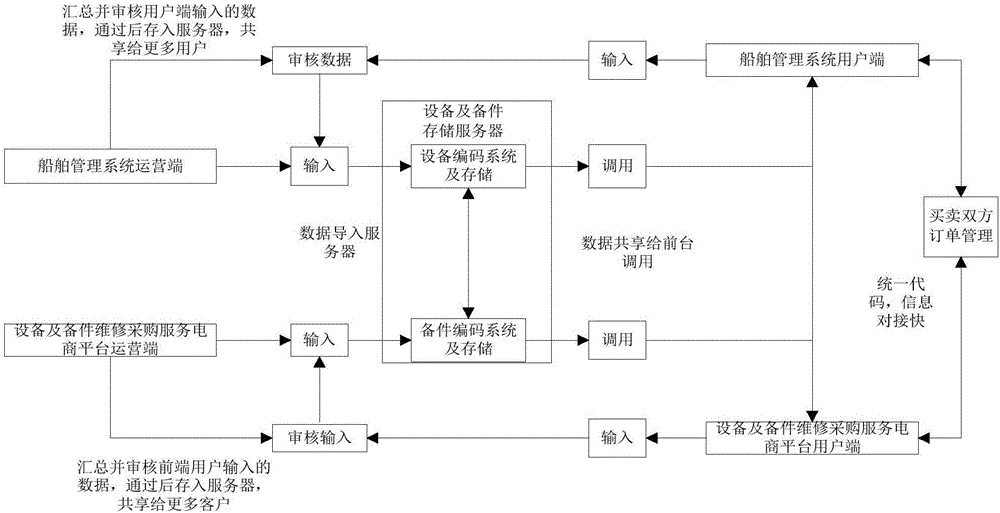

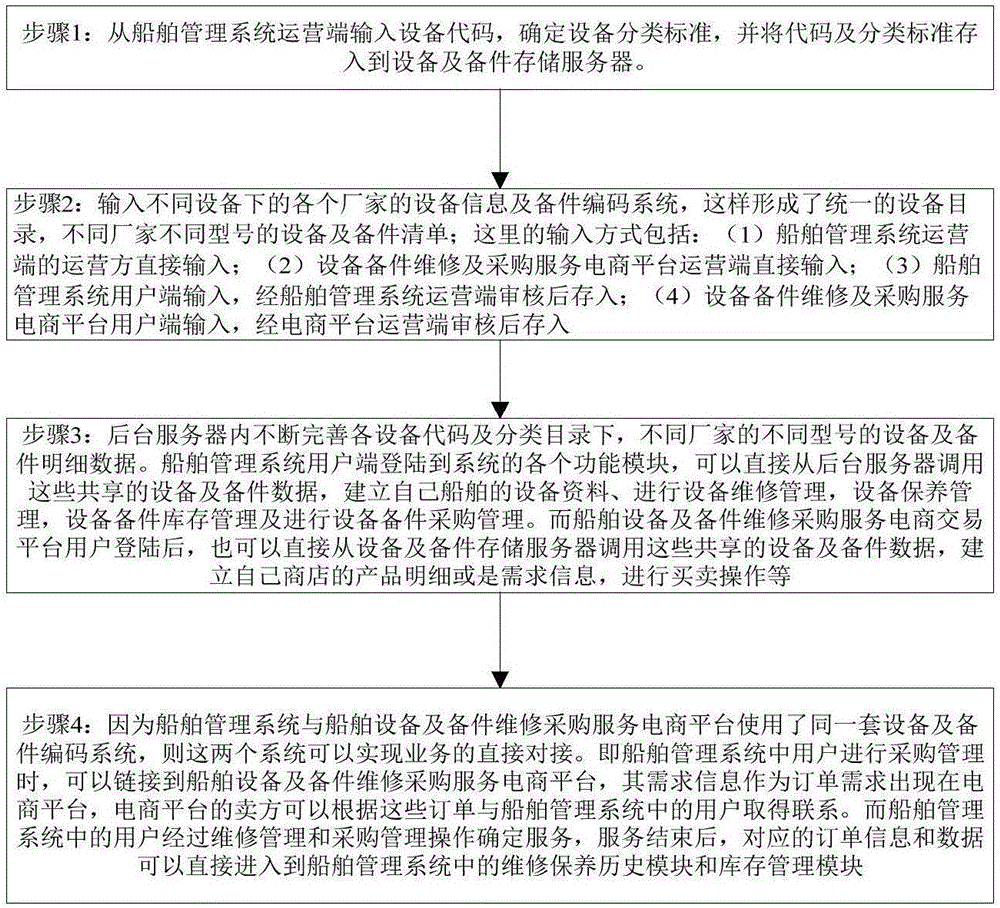

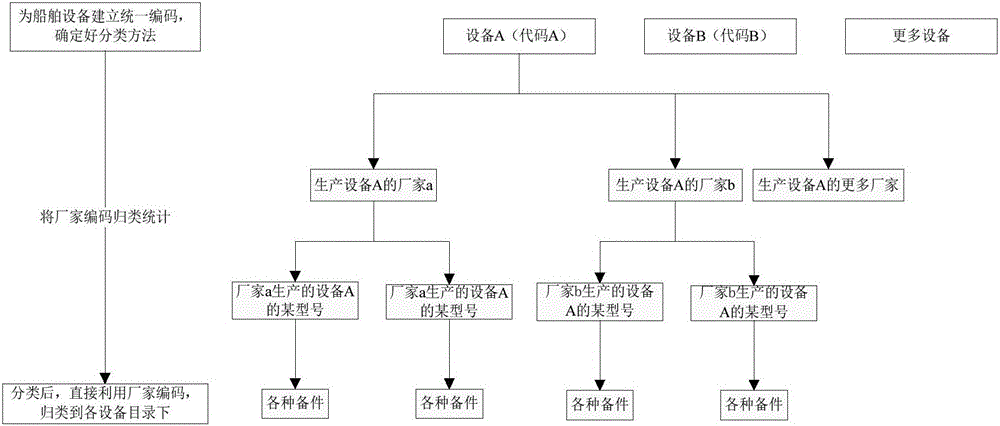

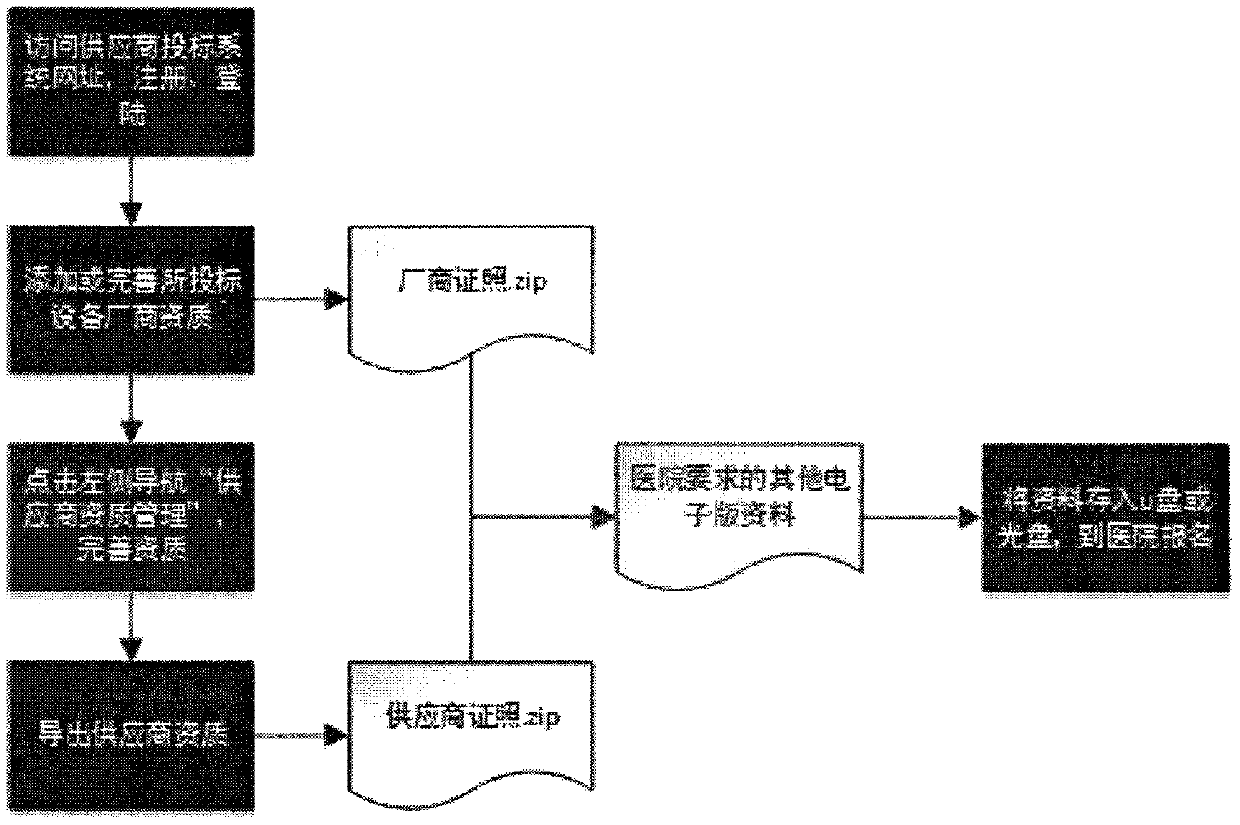

System and method of ship equipment spare part management

ActiveCN106408095AQuick useQuick buildBuying/selling/leasing transactionsInventory managementPurchasing management

The invention discloses a system and a method of ship equipment spare part management. A ship management system, an equipment spare part maintenance and procurement service e-commerce platform, and an equipment and spare part storage server are included, wherein the ship management system is provided with a ship management system operation end and a ship management system user end; the equipment spare part maintenance and procurement service e-commerce platform is provided with an e-commerce platform operation end and an e-commerce platform user end; and the equipment and spare part storage server is used for receiving inputted equipment information of different factories for each piece of equipment and coding standards, and associating the equipment with the corresponding equipment information and the coding standards inputted by different factories according to equipment classification standards and carrying out storage. The system and the method of the invention have the effects that equipment and equipment spare parts on the ship can be well classified, the user can quickly use the spare part data, the user does not need to manually add the spare part data but can directly call the equipment data from the server, and self spare part management, inventory management and procurement management are built.

Owner:上海互海信息科技有限公司

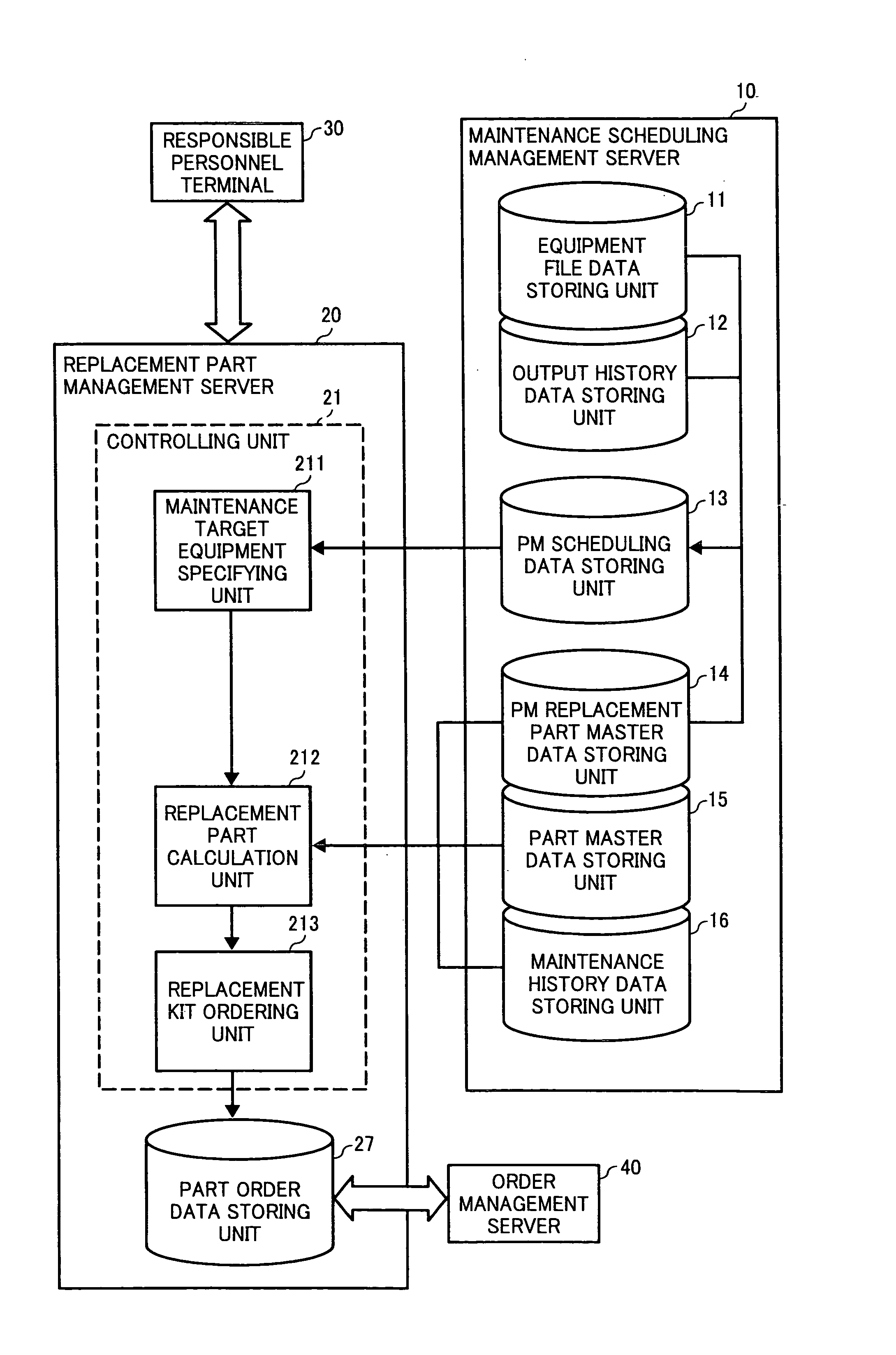

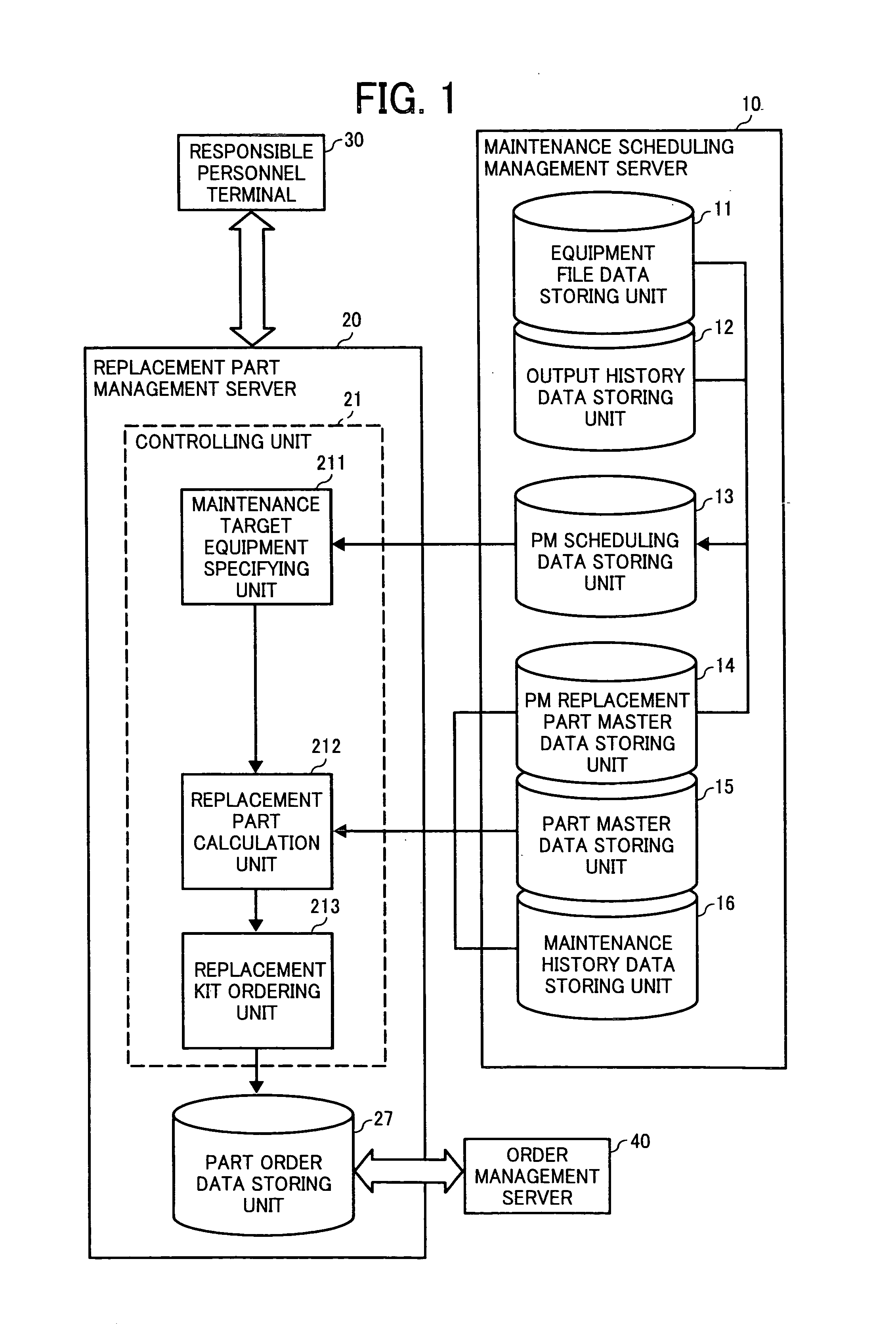

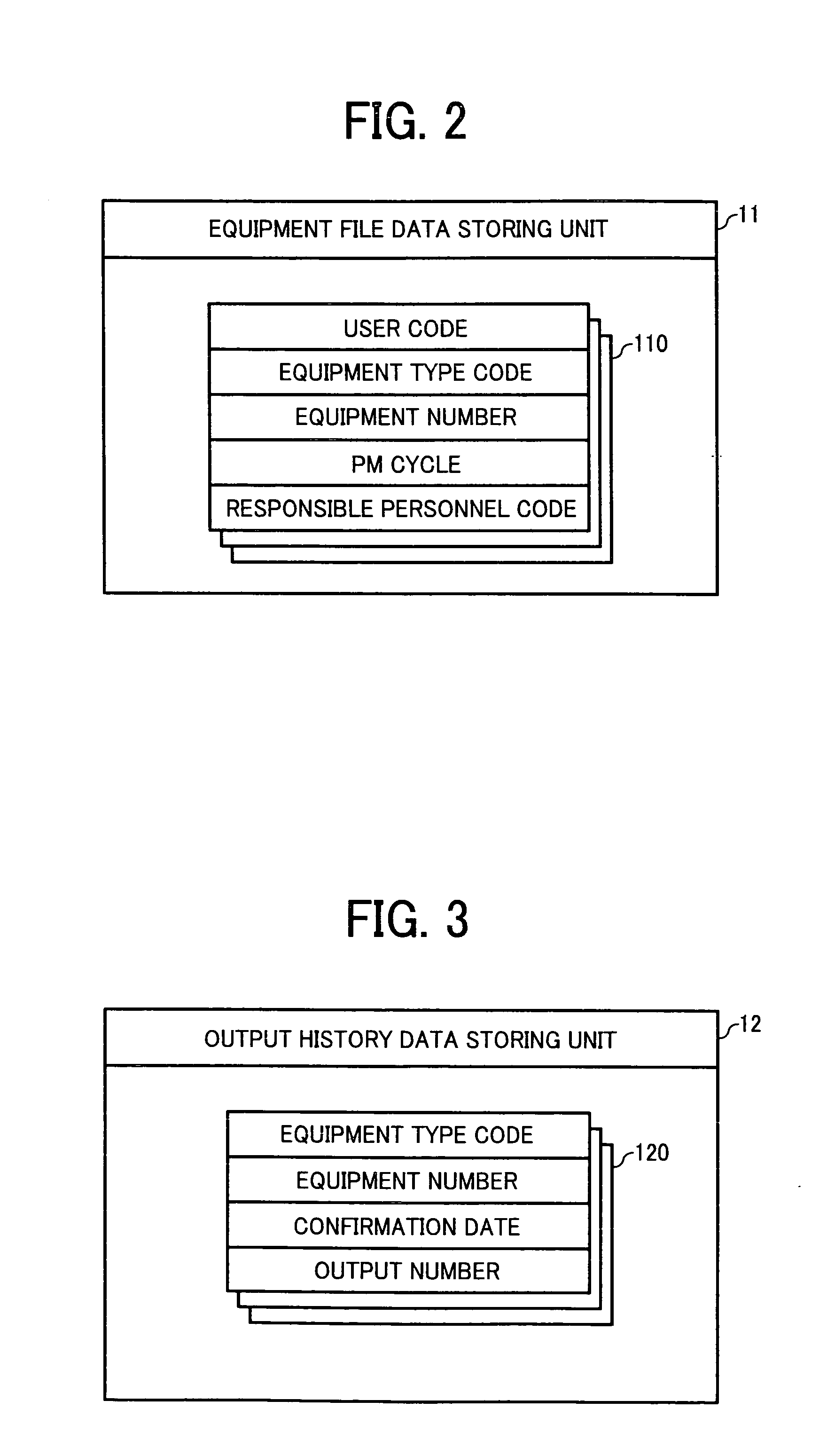

Replacement part order processing apparatus, method for ordering replacement parts and computer-readable recording medium

InactiveUS20080215628A1Effective maintenanceVehicle testingRegistering/indicating working of vehiclesControl cellData store

A controlling unit of a replacement part management server specifies a maintenance target equipment and acquires order conditions from a responsible personnel terminal. The controlling unit acquires maintenance information and part information both relating to the maintenance target equipment. The controlling unit calculates prediction residual regarding target parts of an initial value setting process, and compares the prediction residual with the shortest cycle. When the prediction residual is smaller than the shortest cycle, the controlling unit sets the number of replacements in the part order data storing unit. When an initial value setting process regarding all the parts is completed, an order input screen is output. When an order request is received from the responsible personnel terminal, an order management server acquires part order data and transmits a preparation instruction of a PM kit to the purchaser.

Owner:RICOH KK

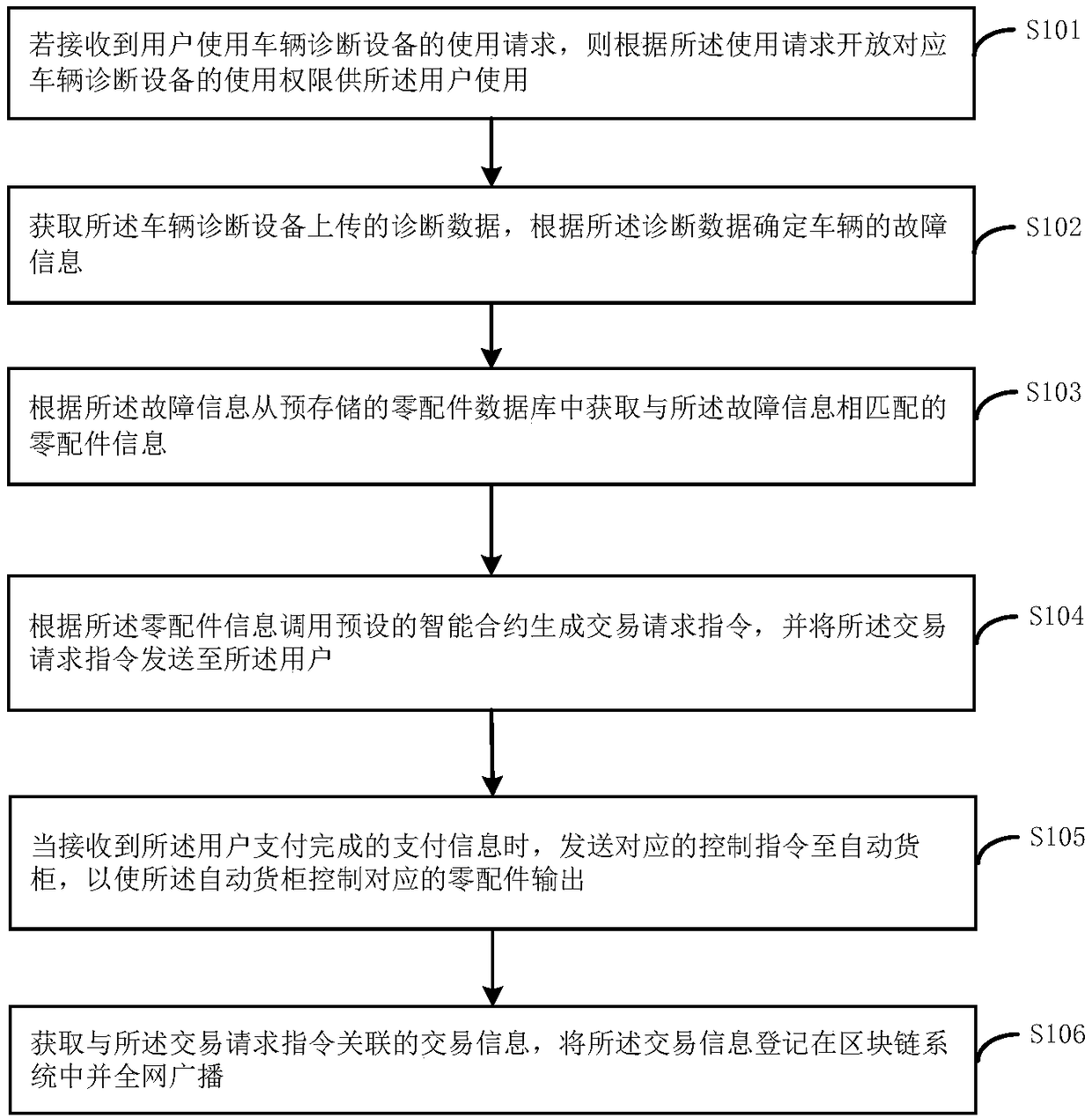

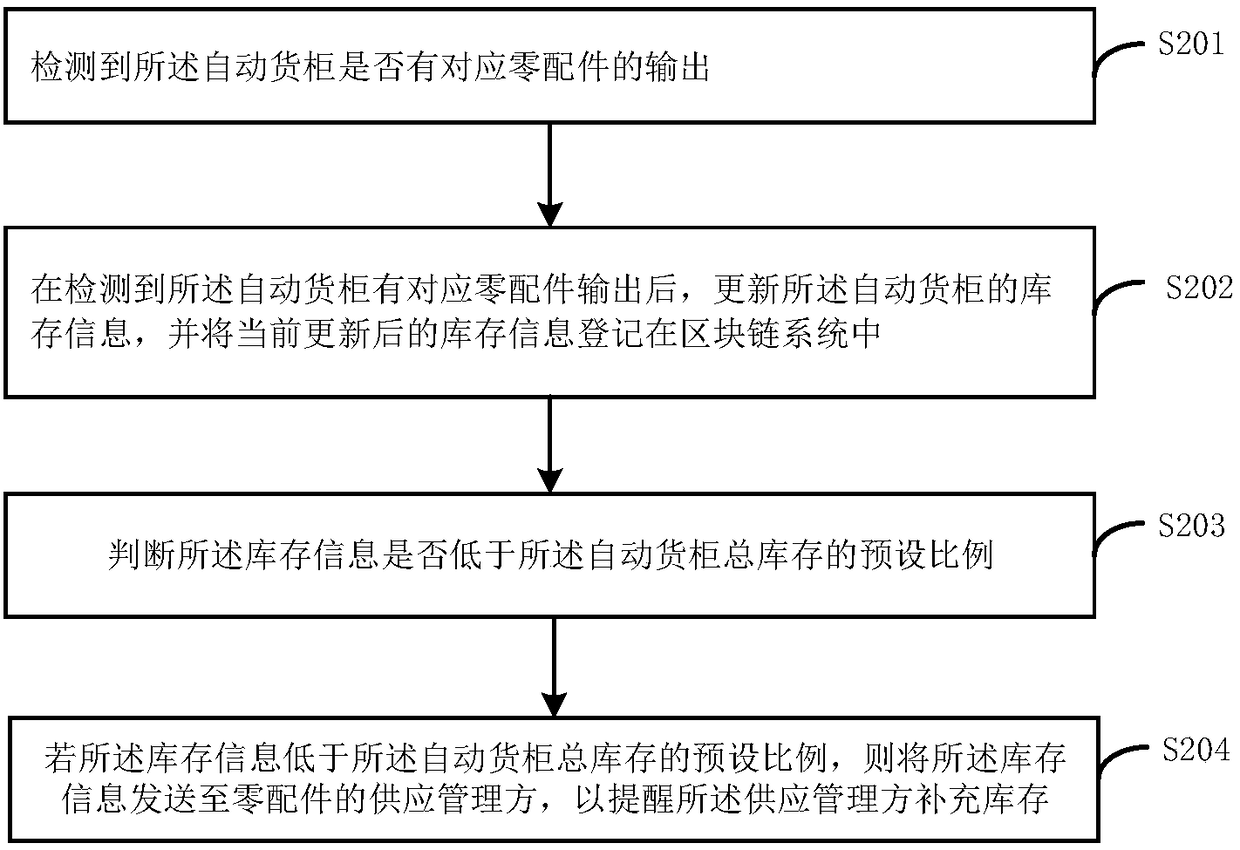

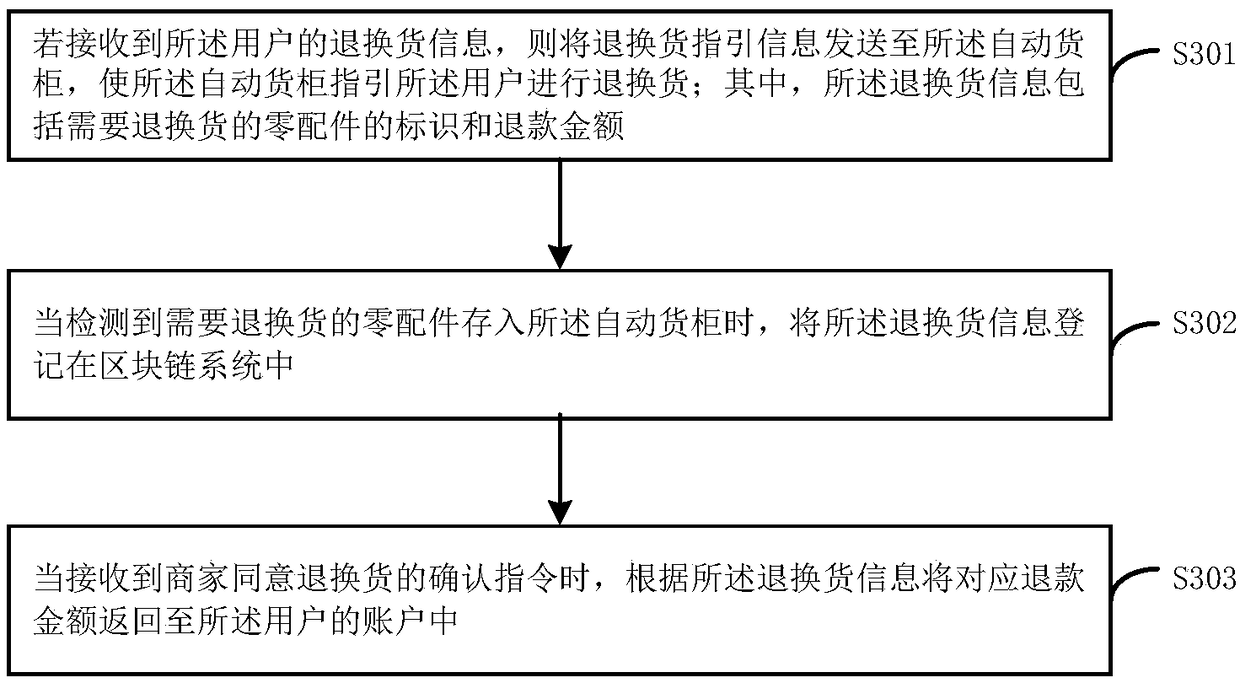

Vehicle spare parts management method, device and block chain node device

ActiveCN109409538AReduce maintenance costsImprove maintenance efficiencyBuying/selling/leasing transactionsLogisticsDiagnostic dataPayment

The invention belongs to the technical field of vehicles, and provides a management method, a device and a block chain node device of vehicle spare parts. The method comprises the following steps: obtaining diagnostic data uploaded by a vehicle diagnostic device, and determining fault information of the vehicle according to the diagnostic data; obtaining the spare parts information matching with the fault information from the pre-stored spare parts database according to the fault information; calling a preset intelligent contract according to the spare parts information to generate a transaction request instruction, and sending the transaction request instruction to the user; when receiving the payment information of the user's payment completion, the corresponding control instruction is sent to the automatic container so that the automatic container controls the output of the corresponding spare parts. As the fault information of the vehicle can be determined and the spare part information matched with the fault information can be obtained, when the user pays the fee, the automatic container controls the output of the corresponding spare parts, and the user can use the output spare parts to replace and repair the vehicle, so that the repair cost of the vehicle can be reduced, and the repair and maintenance efficiency can be improved.

Owner:GOLO IOV DATA TECH CO LTD

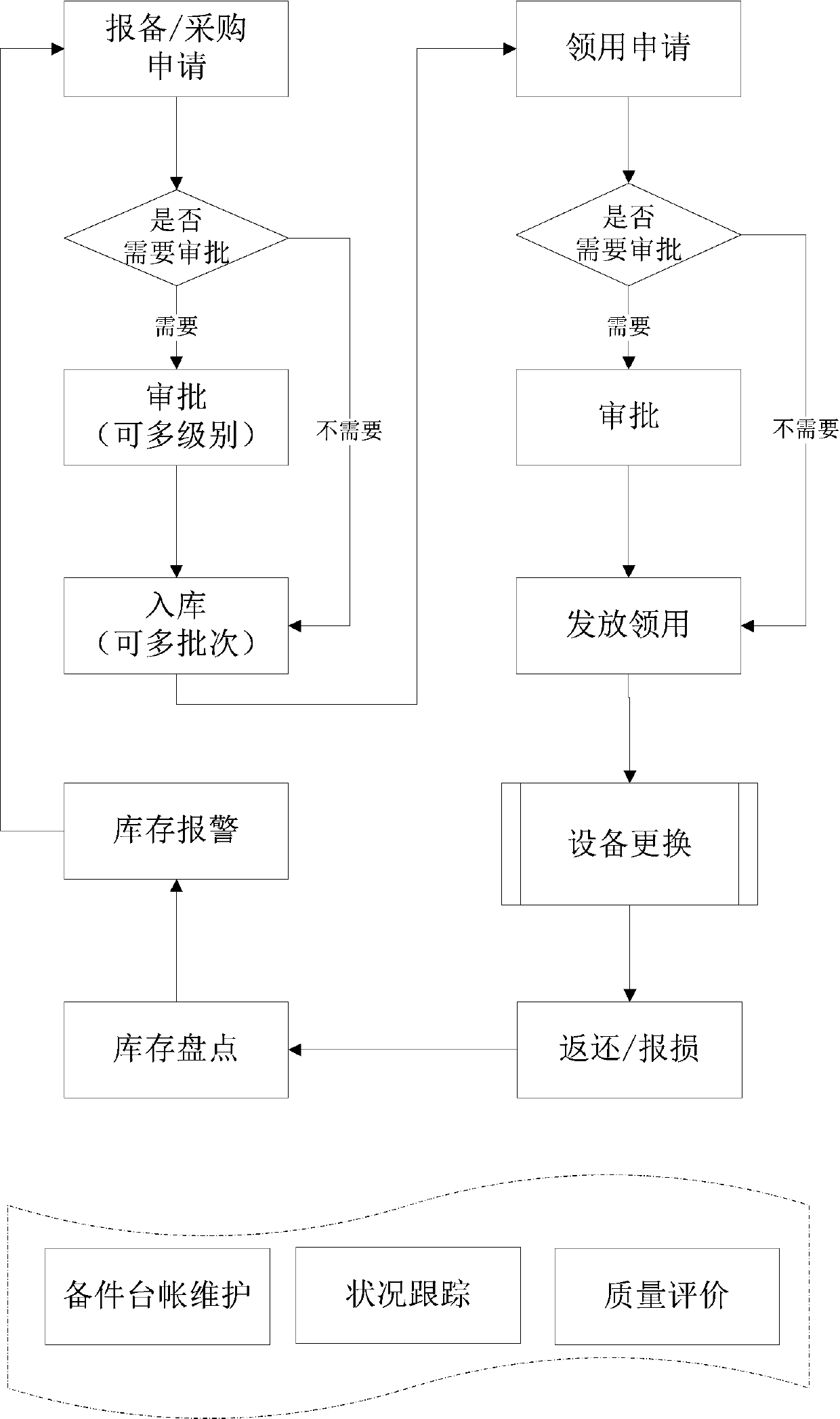

Code scanning technology based spare part full life circle tracking method

InactiveCN107688913ASmooth maintenanceSmooth Overhaul ProgramLogisticsSpare parts managementControllability

The invention discloses a code scanning technology based spare part full life circle tracking method, and relates to a life circle tracking method. At present, a spare part management mode exposes thedefects that the efficiency is low, and the controllability is poor, and very big hidden danger is brought to safety production of a company. The method comprises the following steps of spare part filing application, spare part storage, spare part receiving, equipment replacement, spare part returning / breakage, spare part stock-taking, spare part early warning report, spare part quality evaluation, status tracking, spare part account maintenance and file information maintenance conducted on frequently-used spare parts according to production requirements. According to the technical scheme, normal maintenance of production equipment and smooth maintenance plan implementation are guaranteed, safe and stable production of an automatic production operation system is guaranteed, centralized and unified management of the spared parts is strengthened, spare parts are stocked, people pay adequate attention to four links of use, management, repairing and supplying, and spare part post-use tracking is well conducted.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO MARKETING SERVICE CENT +1

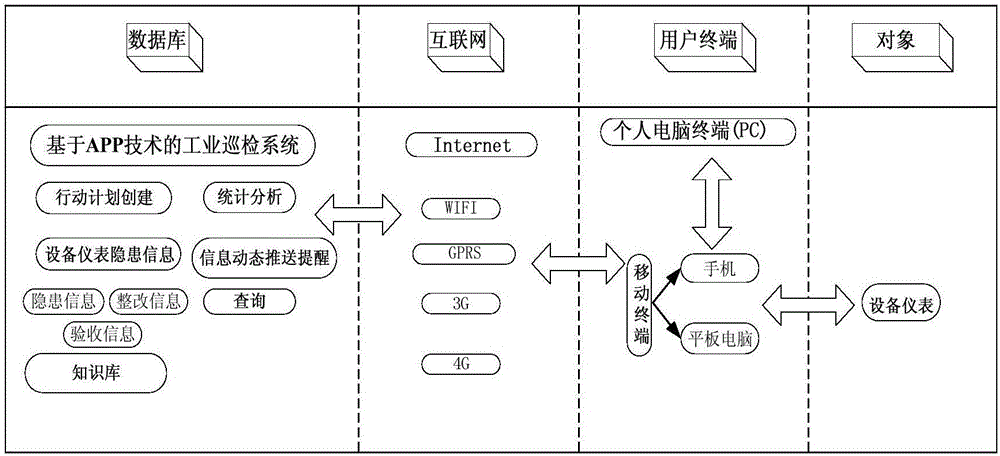

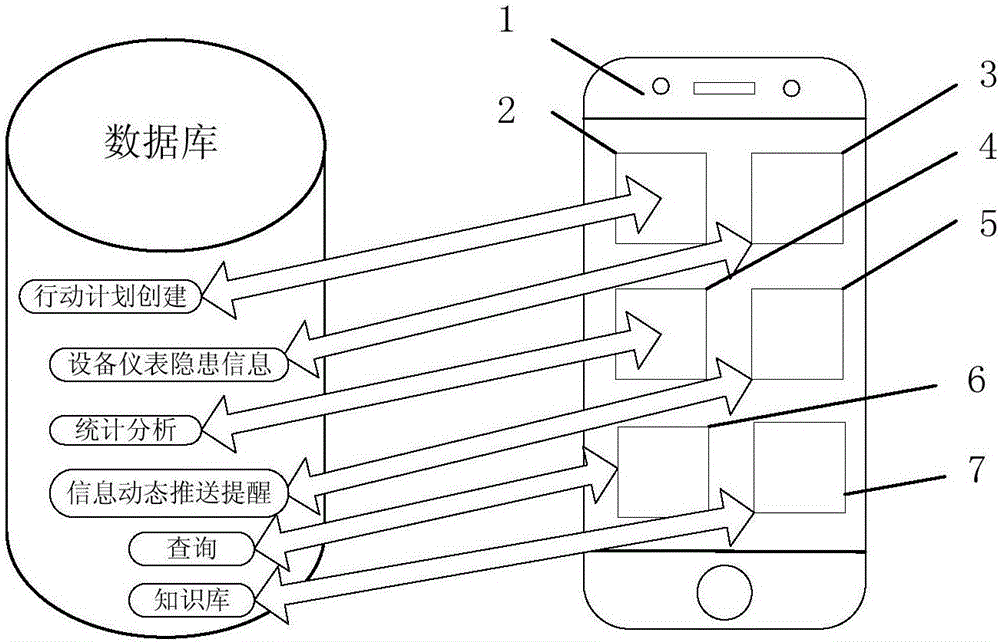

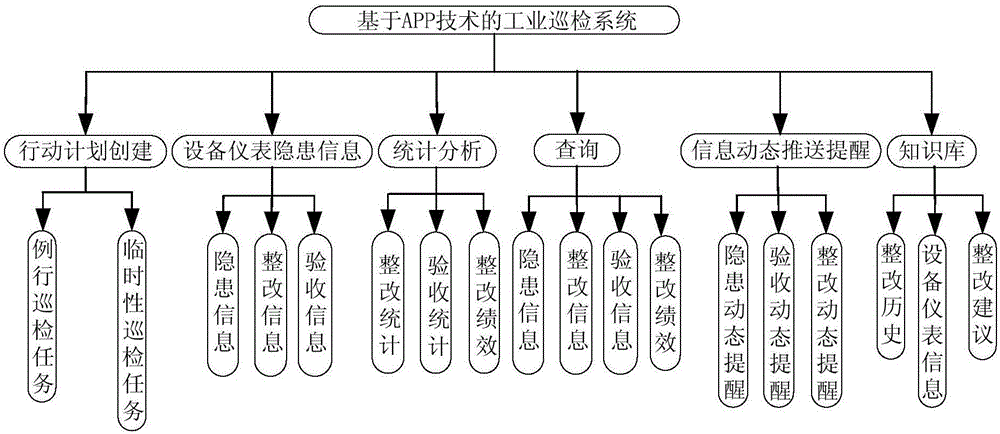

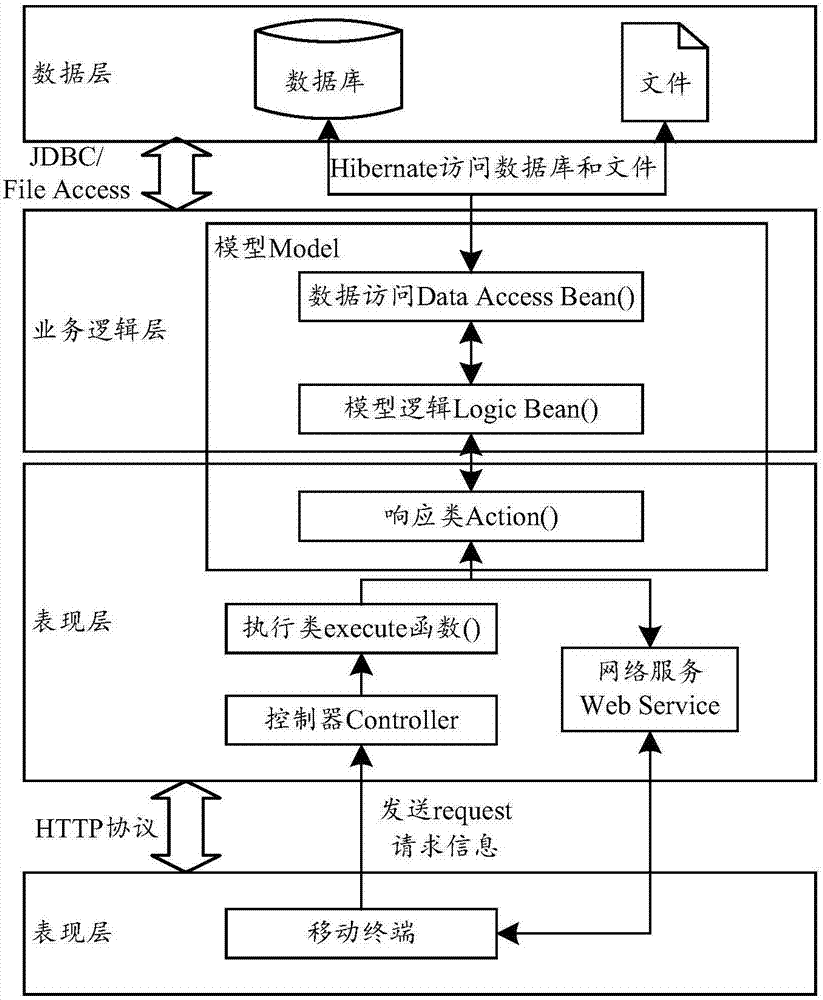

APP technology based industrial inspection system

InactiveCN106408197APerformance appraisal saves time and effortImprove management efficiencyResourcesSpecial data processing applicationsProgram planningAction plan

The invention relates to an APP technology based industrial inspection system which is based on the mobile internet and APP technology to realize the mobile management and control over on-the-spot equipment and instruments. The system comprises the following steps: action plan creating, instrument and equipment hidden hazard recording, hidden hazard modifying process recording, hidden hazard and modification state pushing, modification inquiring, modification statistics, modification evaluation performance statistics, equipment and instrument inquiring, spare component management and knowledge database function realizing. According to the invention, it is possible to rapidly and effectively solve the problems that on-the-spot hidden hazard cannot be instantly reported; that the modification process is hard to trace back; that the equipment and instrument information is incomplete and that the spare components are hard to manage. Therefore, in the end, the hidden hazard in equipment and instrument can be recorded on the spot and reported. The entire modification process can be tracked. The hidden hazard of the equipment and instrument can be predicted so that people can know in advance. The evaluation performance of a person can be done in a more effort saving manner. Therefore, the management efficiency of the factory is obviously increased, the operation cost is reduced and long term safe and stable production can be achieved.

Owner:上海异工同智信息科技有限公司

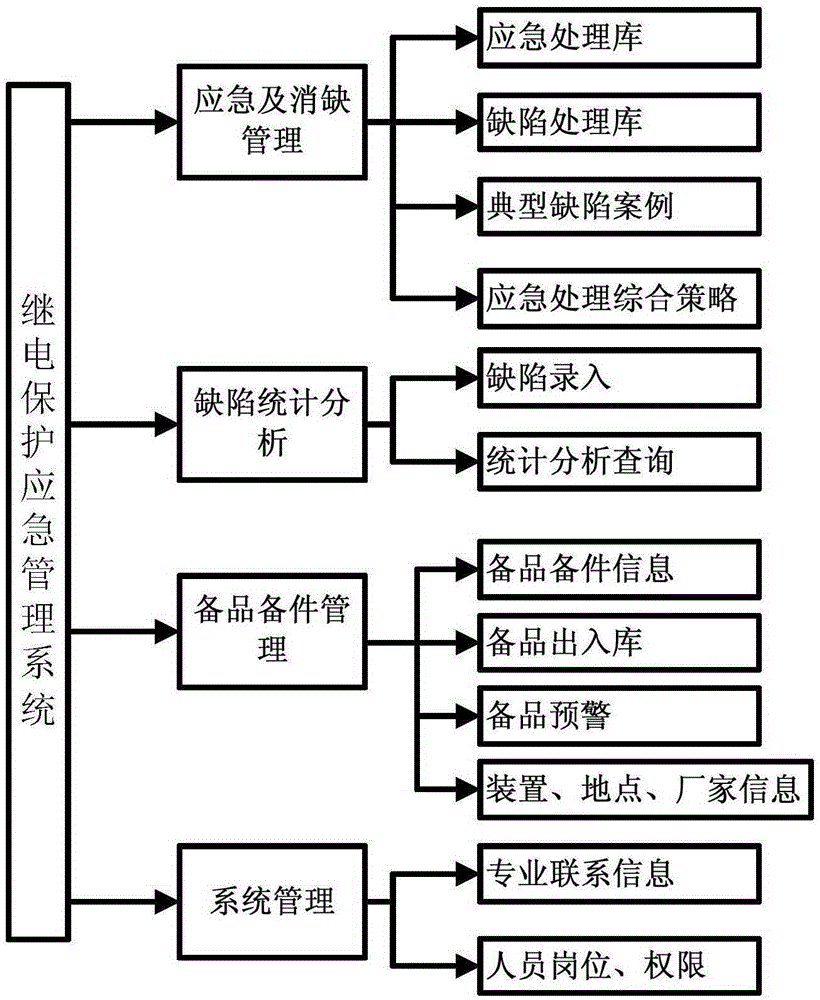

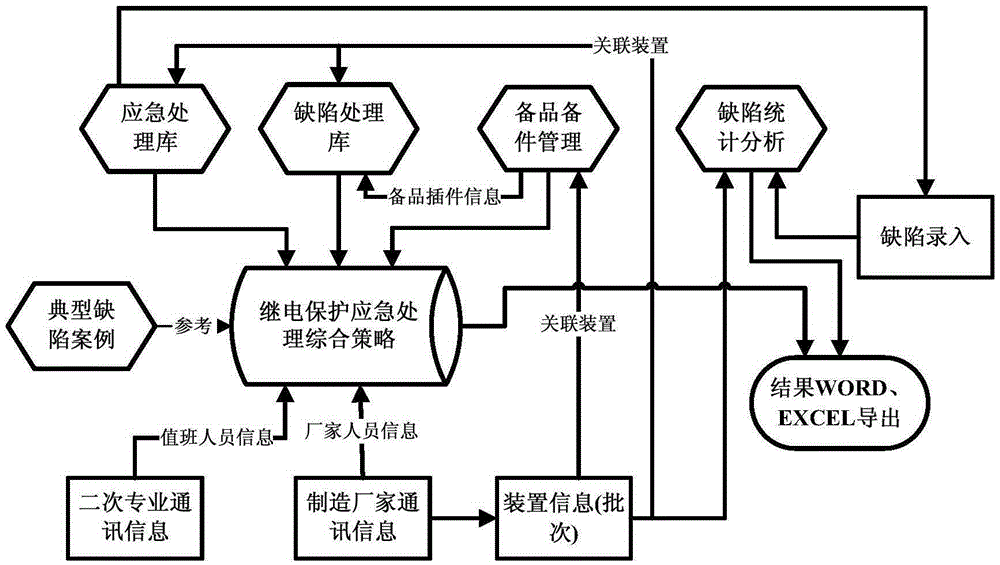

Power grid relay protection emergency management system

InactiveCN105305365AReduce triple errorAvoid accidentsEmergency protective arrangement detailsEmergency treatmentStatistical analysis

The invention discloses a power grid relay protection emergency management system. The system comprises an emergency and defect-eliminating management module, a defect statistical analysis module, a spare unit and spare part management module and a system management module. The system provided by the invention provides expert diagnosis and decision information of typical protection equipment abnormities, can effectively guide onsite emergency treatment, realizes rapid response, represents an effective measure for reducing three error accidents, improving professional management level and cultivating technical backbones, and at the same time, provides technical support for service integration of integrated operation and integrated regulation and control, thereby having good popularization and application prospect.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +2

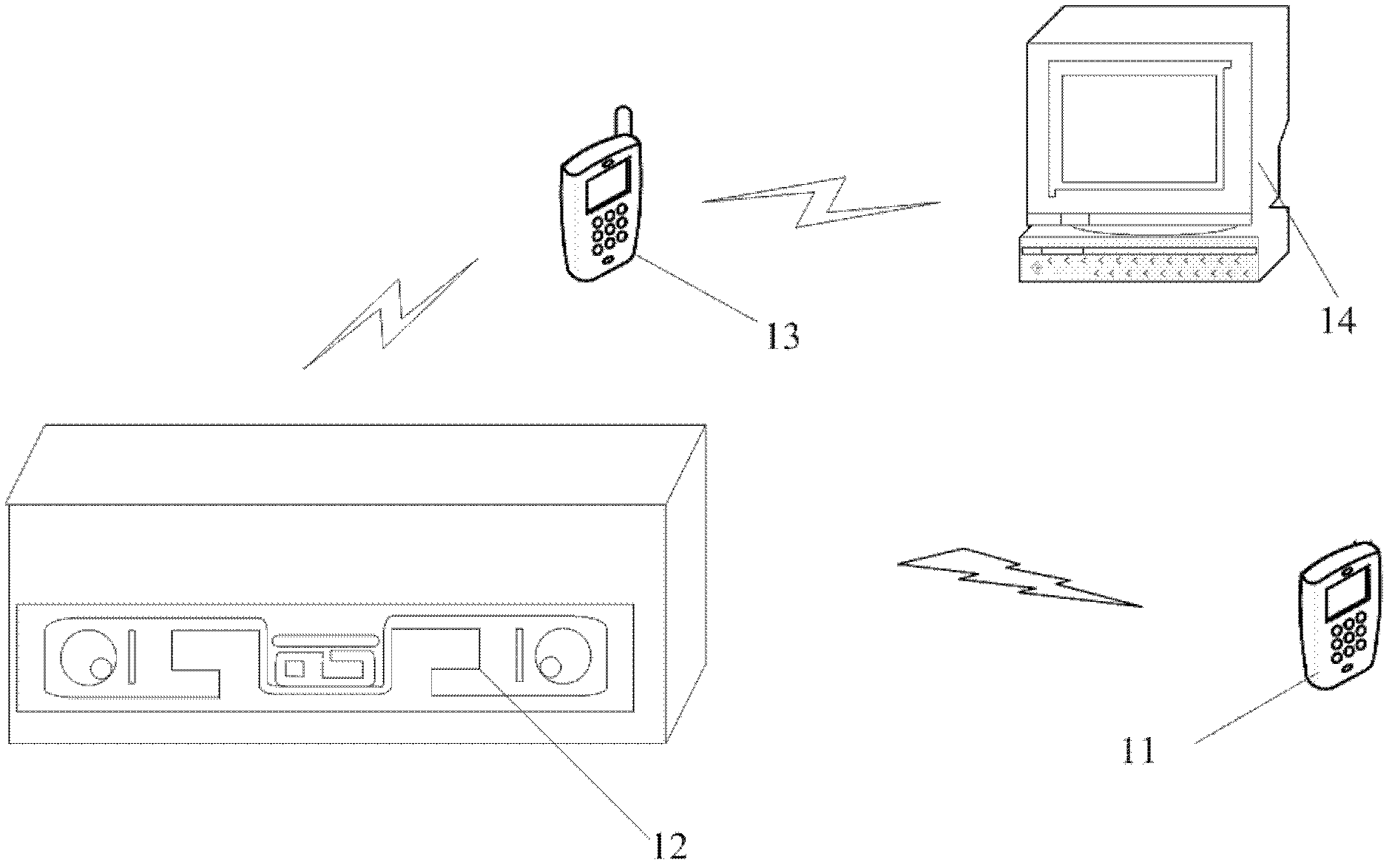

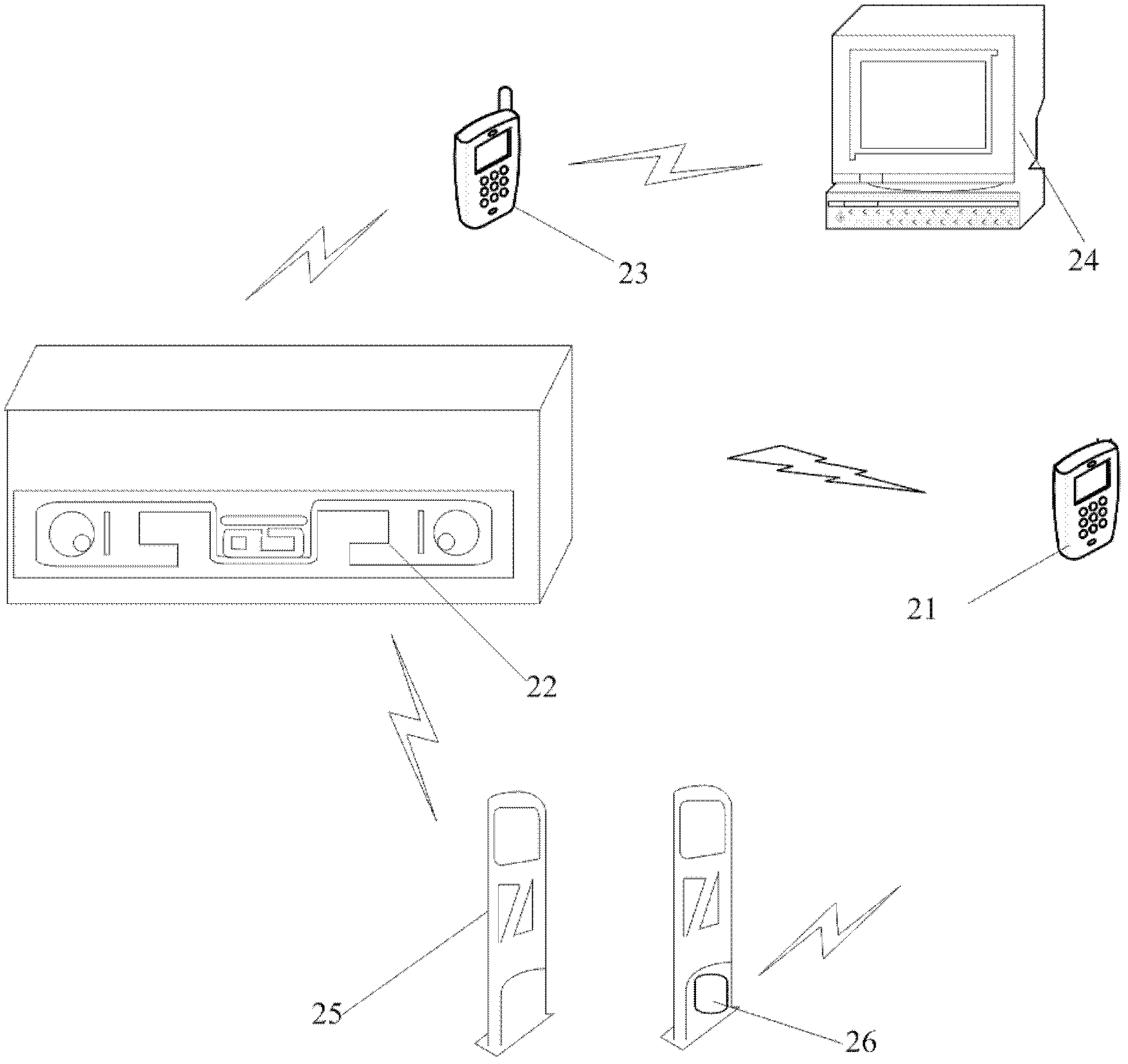

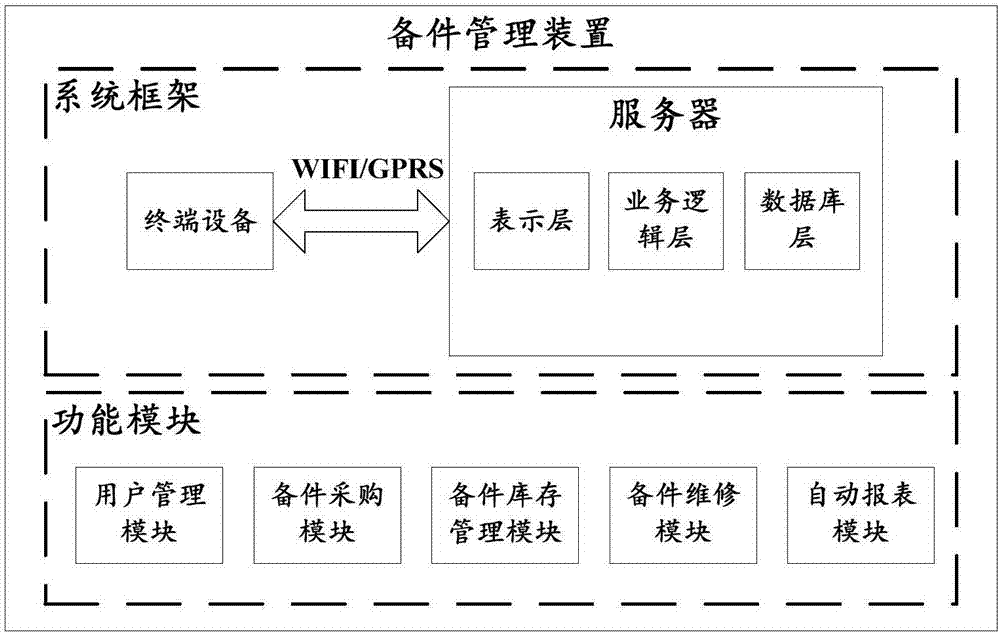

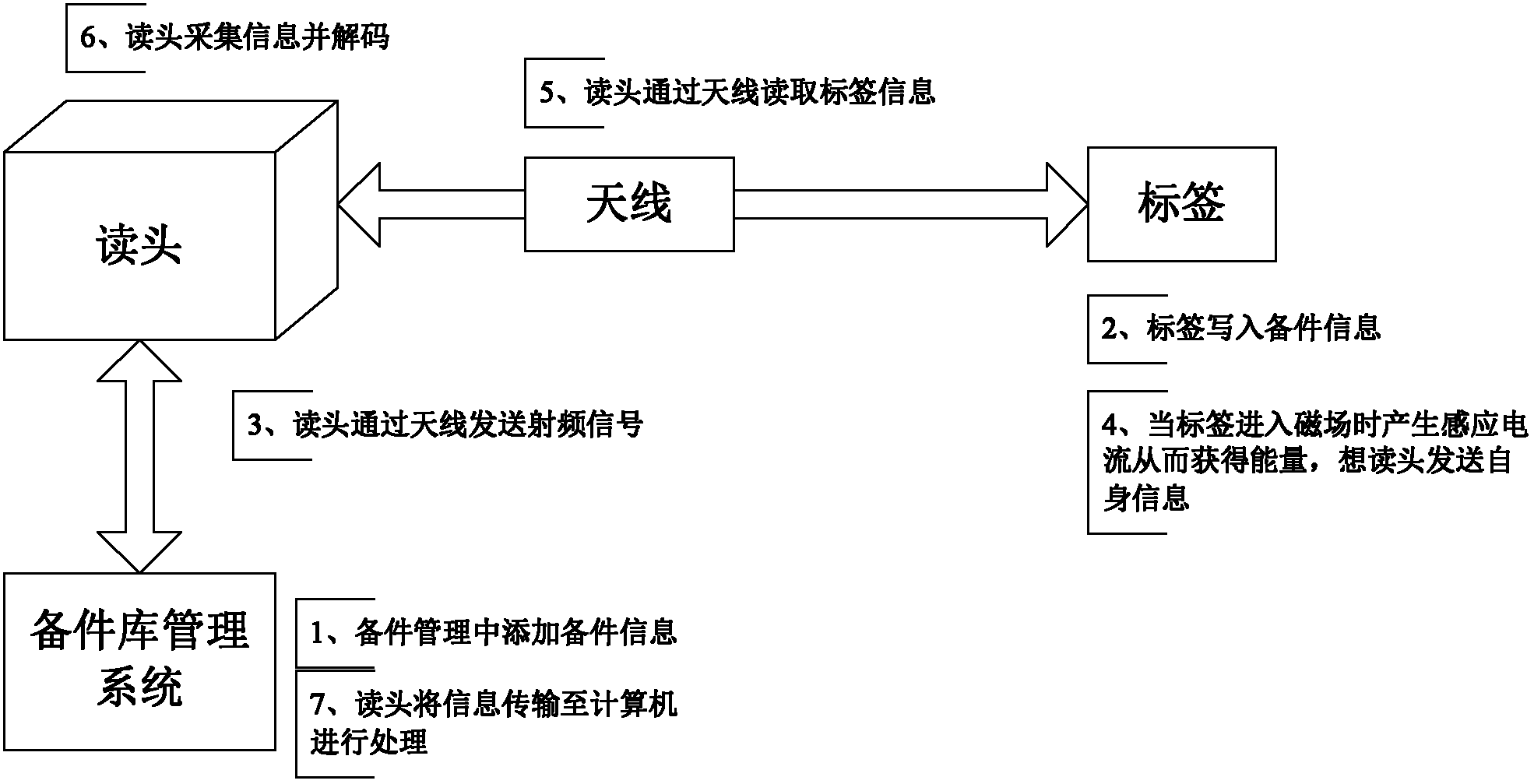

System for managing spare part

InactiveCN102254258ARealize managementSimplify the reading processCo-operative working arrangementsRadio frequencyEmbedded system

The invention discloses a system for managing a spare part. The system comprises a radio frequency identification (RFID) card sender, an RFID tag, an RFID reader and a client, wherein the RFID card sender writes tag information which corresponds to the spare part into the RFID tag; the RFID tag is arranged on the spare part; when the spare part is in a predetermined distance, the RFID reader reads the tag information of the spare part; and when a storage state of the spare part varies, the client rewrites the storage state in the tag information on the spare part. The system for managing the spare part provided by the embodiment of the invention has the advantages that: based on an RFID technology, by equipment such as the RFID tag, the RFID reader and the client, the management of the spare part is realized; and because the RFID tag can intuitively embody the tag information of the spare part by the RFID reader, and the tag information in the RFID tag can be directly rewritten by the client, the reading or writing process of the tag information of the spare part is simplified, and efficiency is improved.

Owner:STATE GRID JIBEI ELECTRIC POWER COMPANY +1

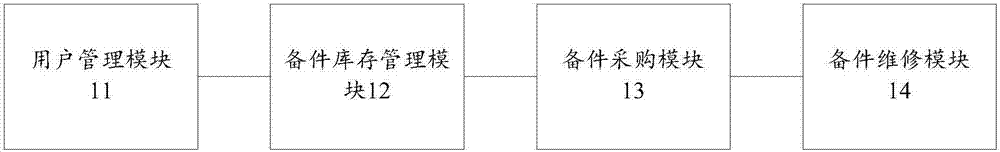

Spare part management system and apparatus

The invention provides a spare part management system and apparatus. The system includes: a user management module, a spare part inventory management module, a spare part purchase module and a spare part maintenance module. The user management module is intended for managing at least one of the following user information which includes user login information, user type information, user authorization information, and user operation log. The spare part inventory management module is intended for providing inventory state of the spare parts in a warehouse. The spare part purchase module is intended for determining whether to purchase the spare parts on the basis of the inventory state of the spare parts in the warehouse provided by the spare part inventory management module. The spare part maintenance module is intended for providing maintenance information of the spare parts that maintained and / or to be maintained. The system addresses the technical problem of single management mode of the spare parts in the prior art.

Owner:BEIJING BENZ

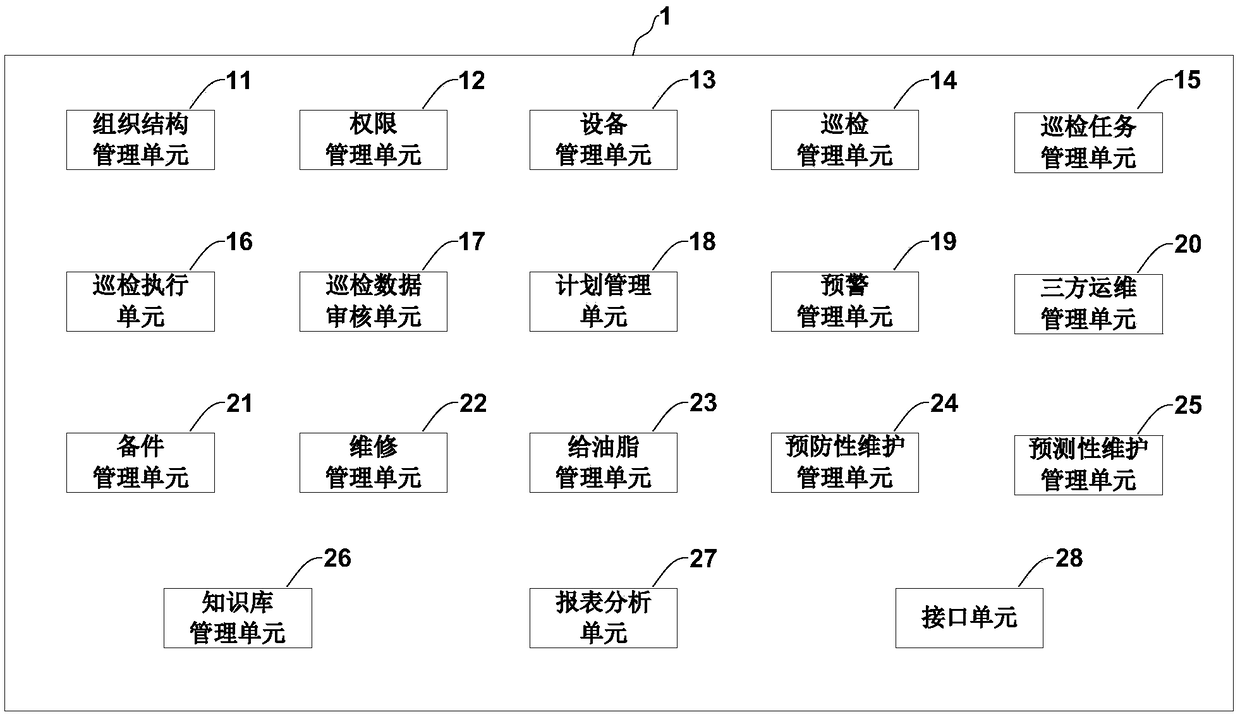

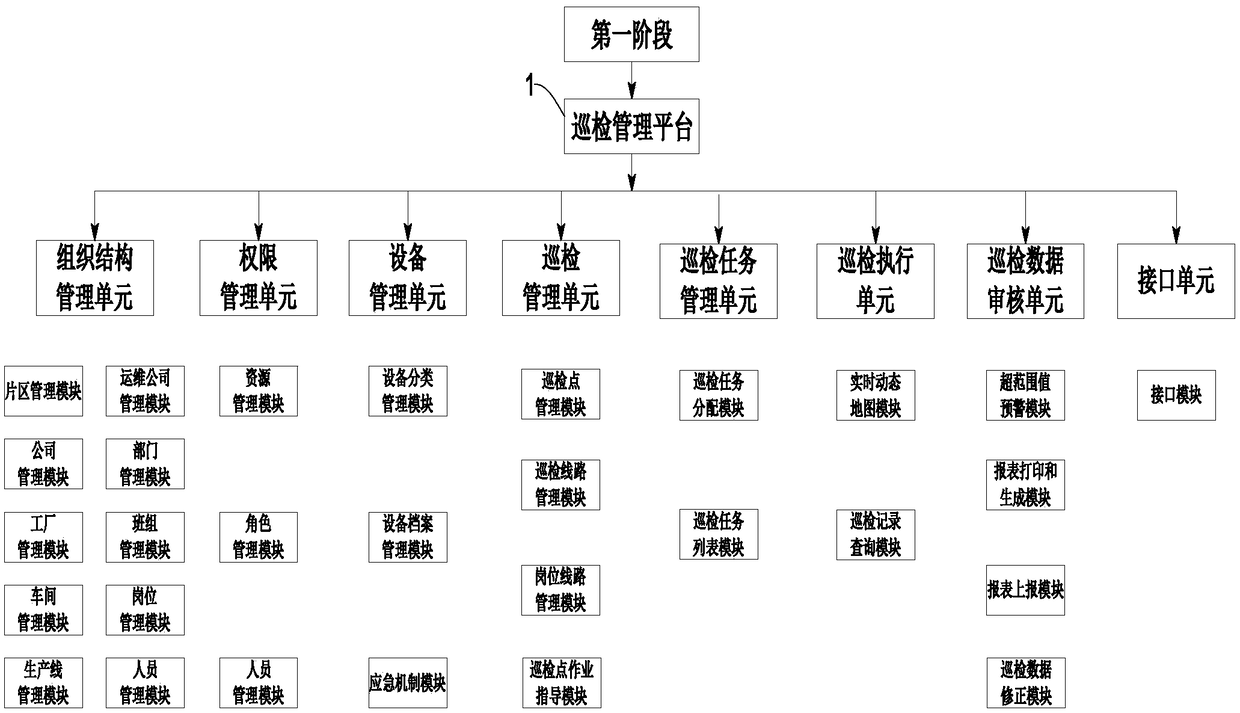

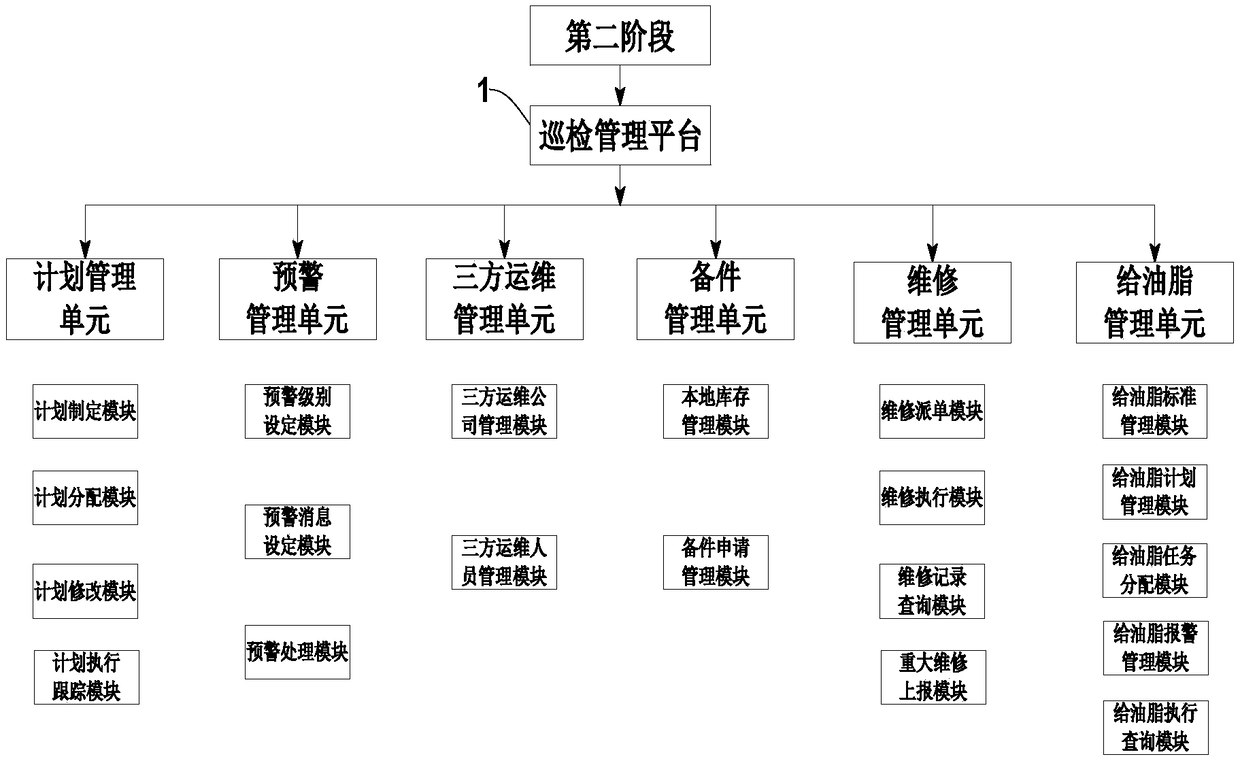

Patrol inspection management platform

InactiveCN109359900AAnalyze statistics in timeScientific Analysis StatisticsChecking time patrolsResourcesSpare parts managementPreventive maintenance

The invention discloses a patrol inspection management platform, and belongs to that technical field of patrol inspection. The patrol inspection management platform comprises an organization structuremanagement unit, a right management unit, an equipment management unit, a patrol management unit, a patrol inspection task management unit, a patrol inspection execution unit, a patrol inspection data approval unit, a plan management unit, an alert management unit, a tripartite operation and maintenance management unit, a spare parts management unit, a repair management unit, a grease supply management unit, a preventive maintenance management unit, a predictive maintenance management unit, a knowledge base management unit, a report statistical analysis unit and an interface unit. The patrolinspection management platform of the invention realizes the standardization, standardization and refinement of the maintenance inspection work through the perfection of the function.

Owner:重庆赛科机电技术服务有限公司

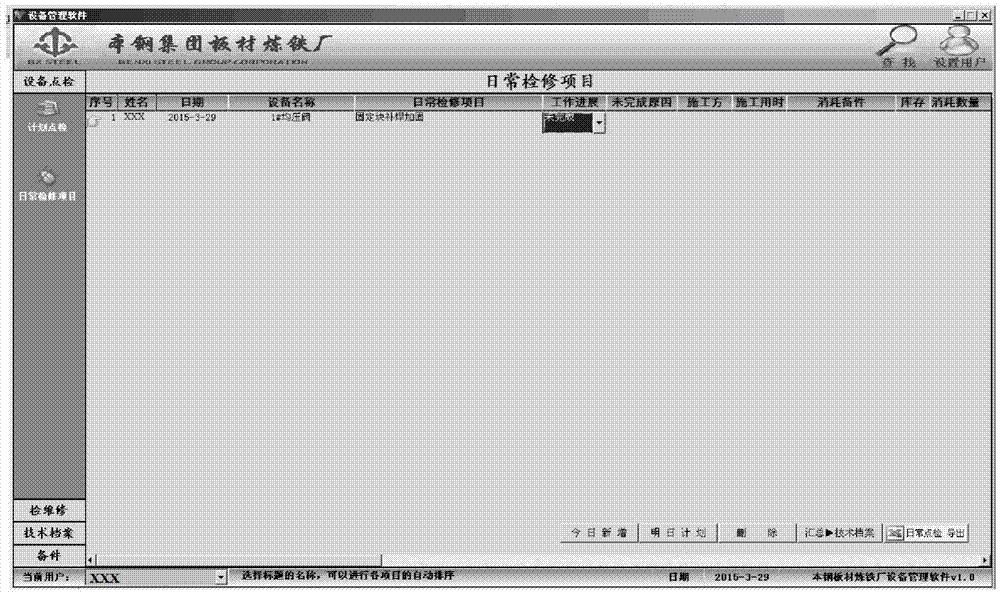

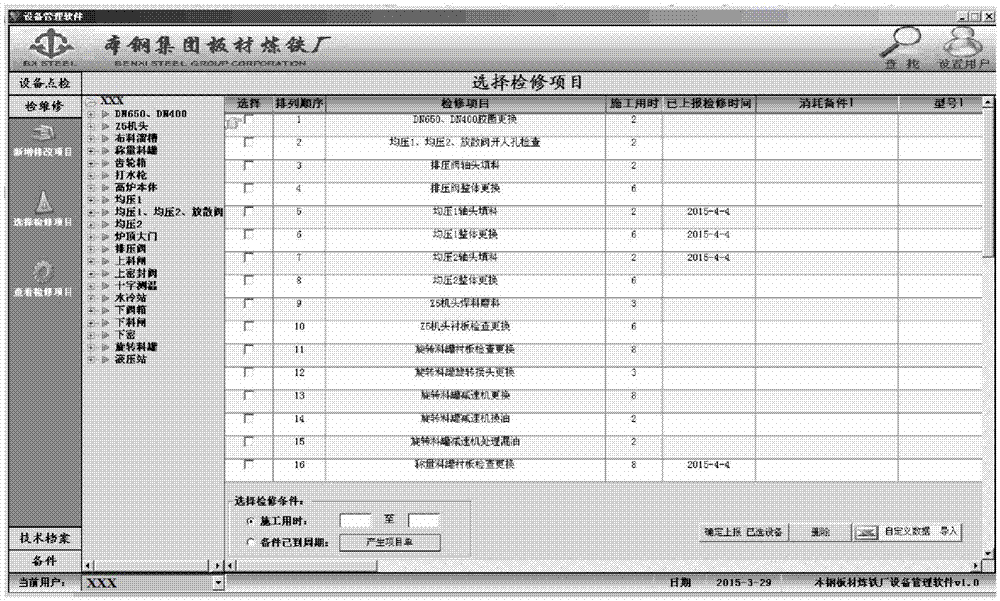

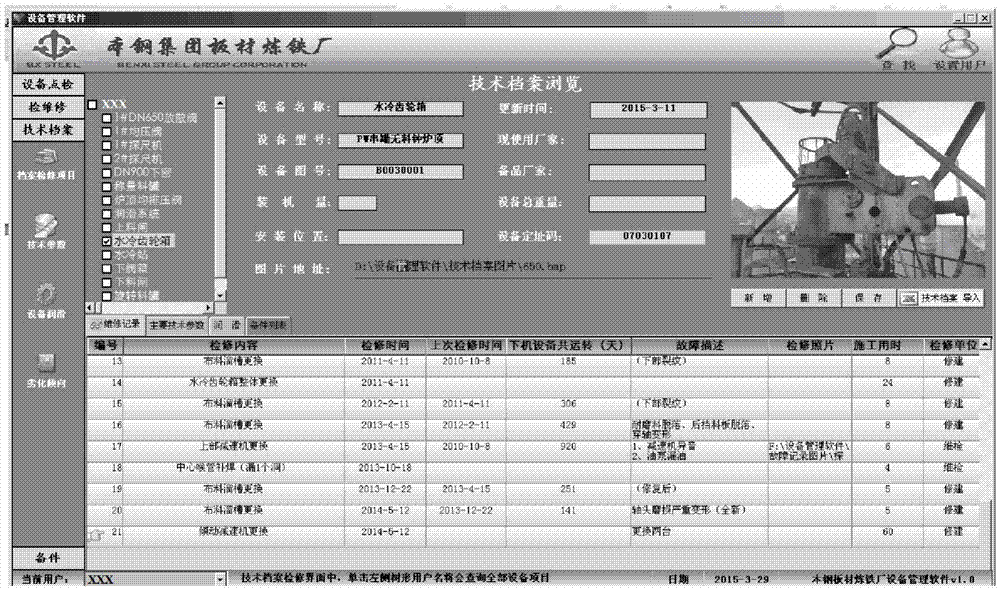

Equipment management system

InactiveCN105447576AReduce labor intensityReduce accidentsHardware monitoringLubricationManagement system

The invention relates to an equipment management system. The equipment management system comprises an equipment point inspection module, an inspection and maintenance module, a technical archive module and a spare part management module, wherein the equipment point inspection module comprises a planned point inspection sub-module and a daily overhaul item sub-module; the planned point inspection sub-module automatically filters and displays working items of the day, reminding a user of key work of the day and displays faulted item names in the daily overhaul item sub-module; the inspection and maintenance module is used for displaying all the overhauling items; the technical archive module displays all the equipment information, including, equipment maintenance records, technical parameters, equipment lubrication, equipment degradation tendency and spare part information; the spare part management module comprises a spare part setting sub-module and an reported part planning sub-module, and is used for management and control of the number of the spare parts. According to the method of the equipment management system, a hint can be given when abnormality is found, labor intensity of workers is lightened, equipment accidents are reduced, a maintenance cost is reduced, equipment operating reliability is improved, and labor intensity of workers is reduced.

Owner:BENGANG STEEL PLATES

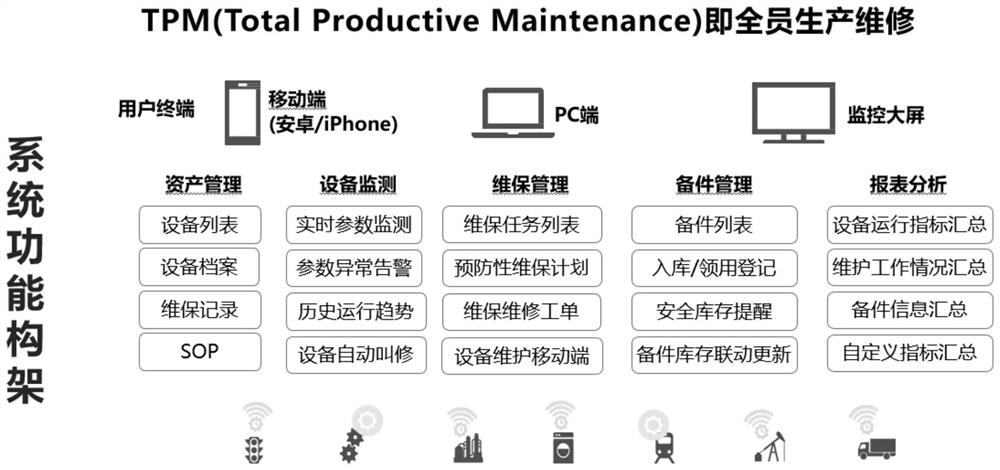

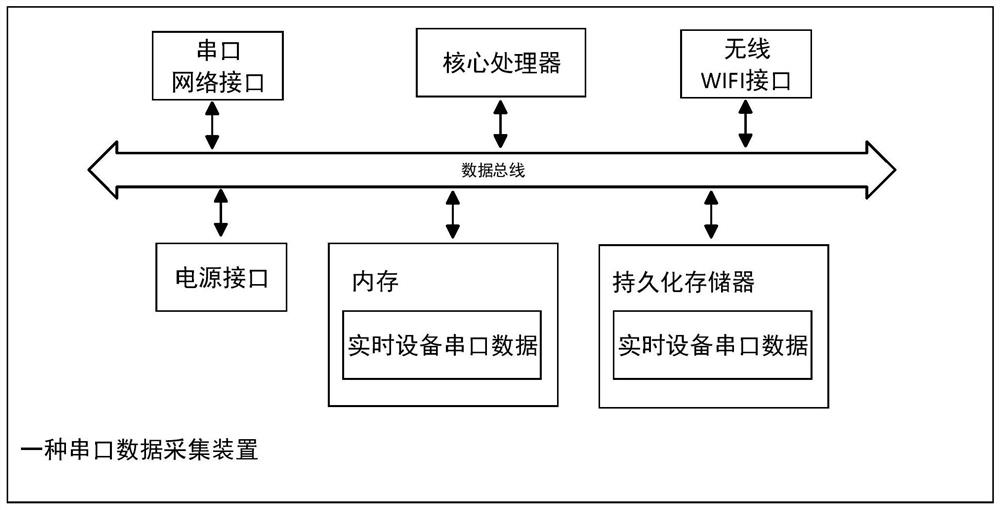

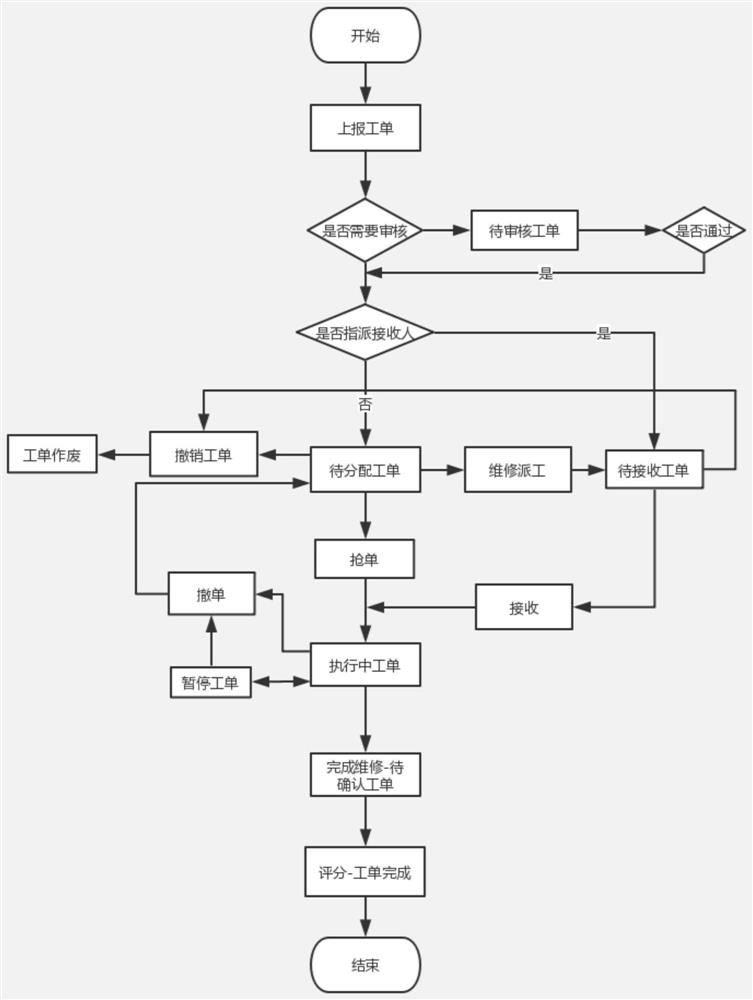

TPM platform and method based on Internet of Things

PendingCN111932077AFacilitate real-time early warningGood coordinationResourcesInformatizationThe Internet

The invention relates to a TPM platform and method based on the Internet of Things, and the platform comprises a production and maintenance system and a serial port data collection device, the serialport data collection device is used for being connected with production equipment to collect the data of the production equipment, and the production and maintenance system comprises an asset management module which is used for processing the basic information of the equipment; an equipment monitoring module which is used for processing parameter information of production equipment; a maintenancemanagement module which is used for processing maintenance information of the production equipment; a spare part management module which is used for processing spare part information of the productionequipment; and a report analysis module which is respectively communicated with the asset management module, the equipment detection module, the maintenance management module and the spare part management module to generate report information. According to the invention, a set of stable, simple-to-operate, real-time and reliable TPM informatization system can be established, maintenance personnelare reminded to do equipment maintenance work, productivity reduction caused by equipment faults is reduced, the communication cost is reduced, the business process is standardized, and maximizationof enterprise productivity and benefits is realized.

Owner:江苏玻二代网络科技有限公司

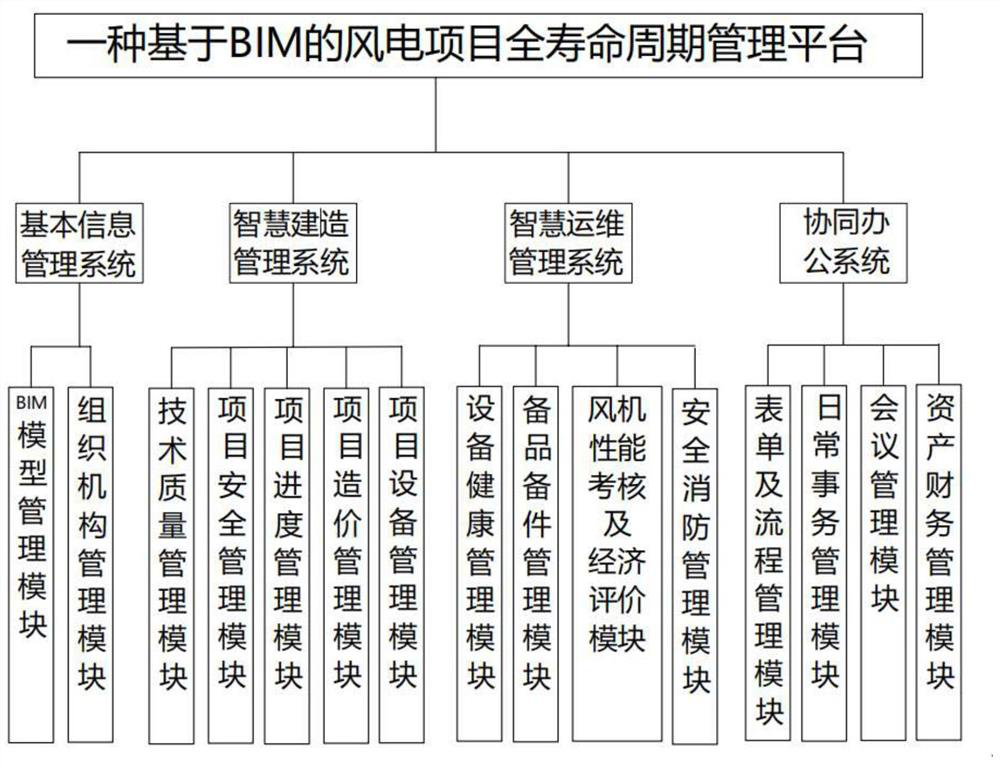

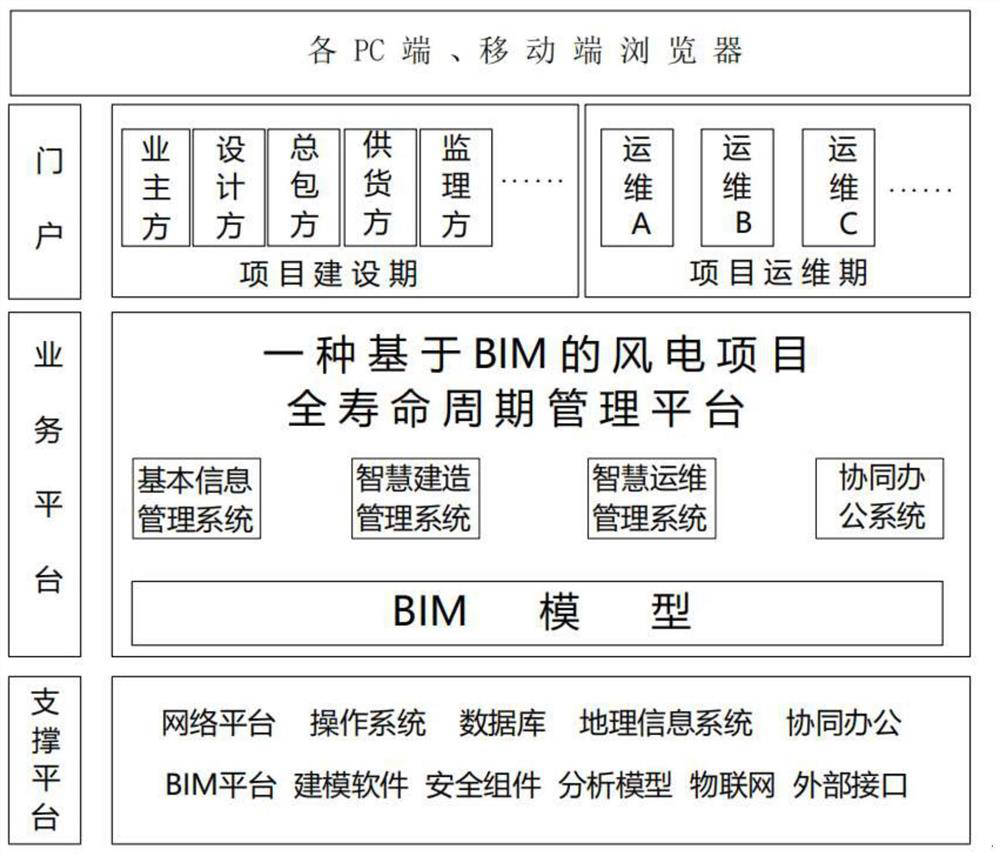

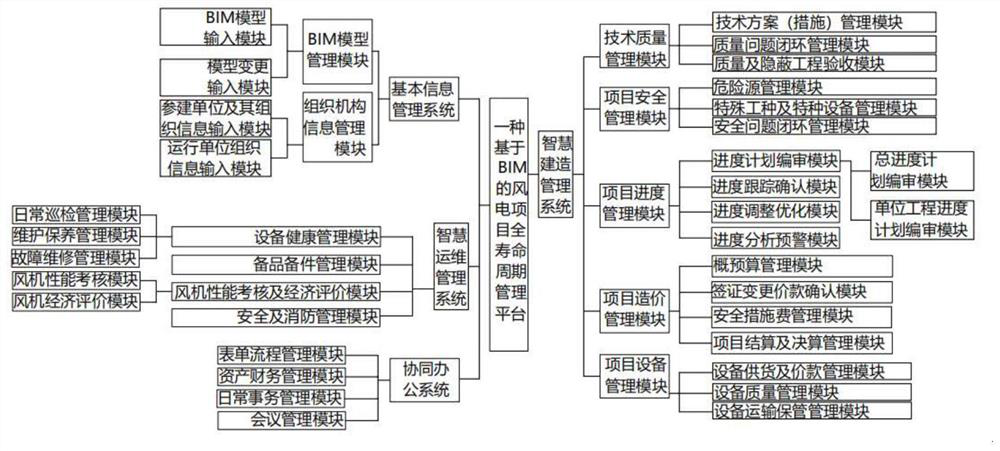

BIM-based wind power project full-life-cycle intelligent management method and platform

PendingCN113112233ARealize dynamic managementAdjust and optimize operation strategyFinanceForecastingMaintenance managementProject management

The invention belongs to the technical field of project management, and particularly relates to a BIM-based wind power project full-life-cycle intelligent management method and platform. The platform comprises a basic information management system, an intelligent construction management system, an intelligent operation and maintenance management system and a collaborative office system. The basic information management system comprises a BIM model management module and an organization management module, and the intelligent construction management system comprises a technical quality management module, a project safety management module, a project progress management module, a project cost management module and a project equipment management module. The intelligent operation and maintenance management system comprises an equipment health management module, a spare part management module, a fan performance assessment and economic evaluation module and a safety fire-fighting management module, and the collaborative office system comprises a form and process management module, a daily affair management module, a conference management module and an asset financial management module.

Owner:XIAN THERMAL POWER RES INST CO LTD

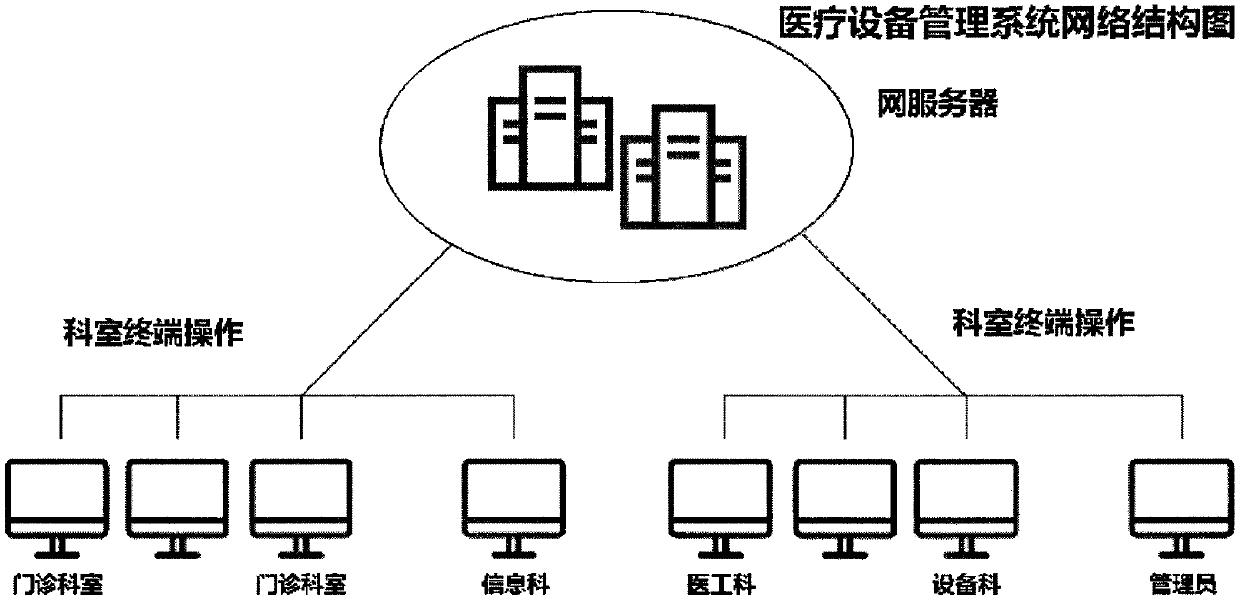

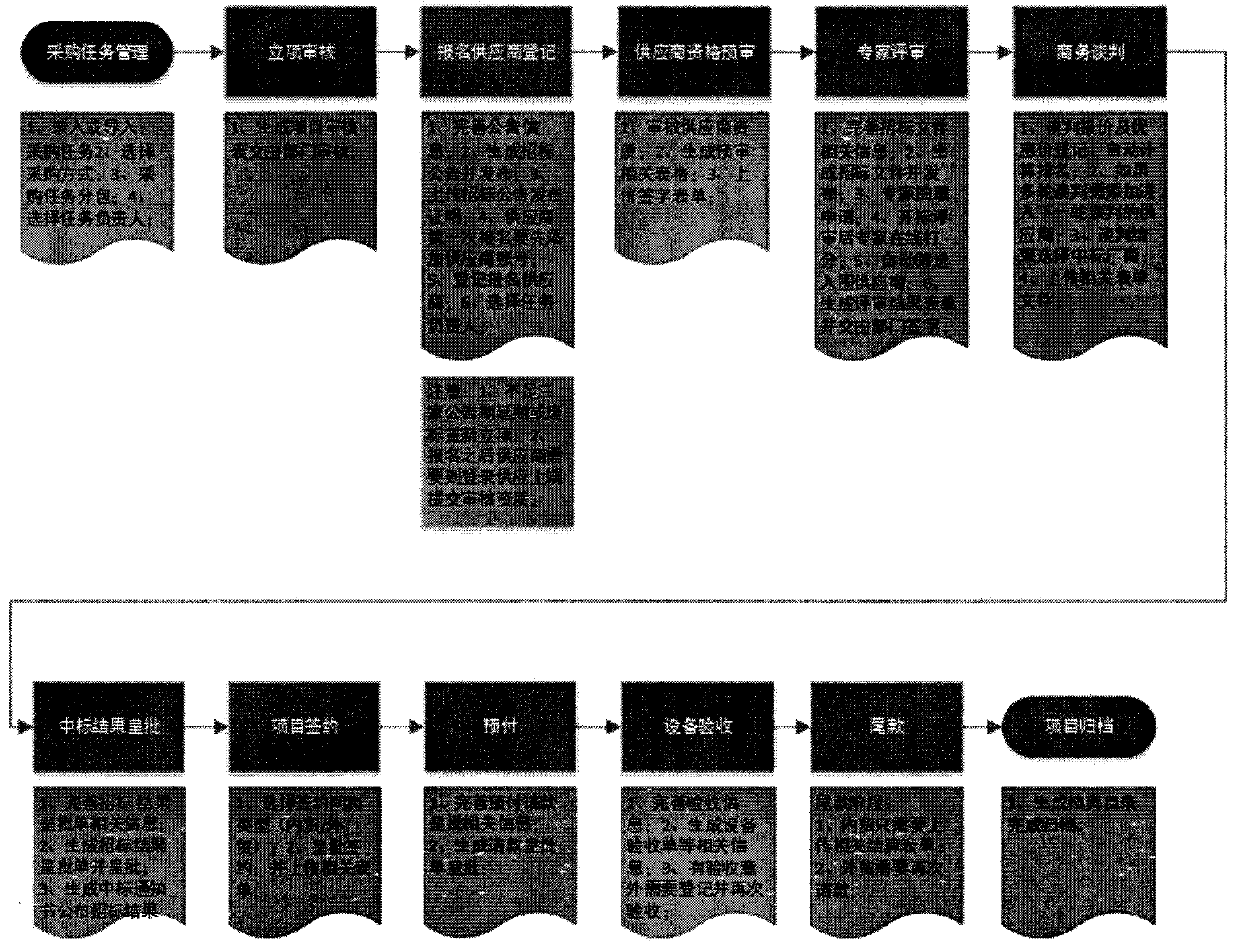

Medical equipment full-life-cycle network management system

InactiveCN109949910AReduce workloadImprove work efficiencyOffice automationHealthcare resources and facilitiesMedical equipmentFull life cycle

The invention relates to a medical equipment full-life-cycle network management system for settling a problem of supporting medical service by medicine expense. The medical equipment full-life-cycle network management system comprises a network server, hospital department terminals and a manager terminal, wherein the hospital department terminals and the manager terminal are in communication connection with the network server. The system is equipped with a system management main module which comprises user management, equipment directory, mechanism organization, role management, system log submodules; a plan management main module which comprises a task management submodule, a basic setting submodule and a plurality of parallel plan management submodules; a purchasing management main module which comprises a project management submodule, a record management submodule and a basic setting submodule; a warehouse management main module which comprises a warehouse management submodule, an equipment inventory submodule, an equipment renting submodule, a record management submodule, a financial affair management submodule, a spare part management submodule and a basic setting submodule; an equipment operation management main module which comprises an equipment monitoring submodule, an equipment management submodule and a basic setting submodule; and a statistics benefit analysis mainmodule which comprises a data statistics submodule and a benefit analysis submodule. The medical equipment full-life-cycle network management system has advantages of remarkably improving medical equipment operation efficiency and economic benefit, and changing a defect of supporting the medical service by the medicine expense, wherein the defect exists for a long time period and is difficult to settle.

Owner:BEIJING JXCR TECH DEV CO LTD

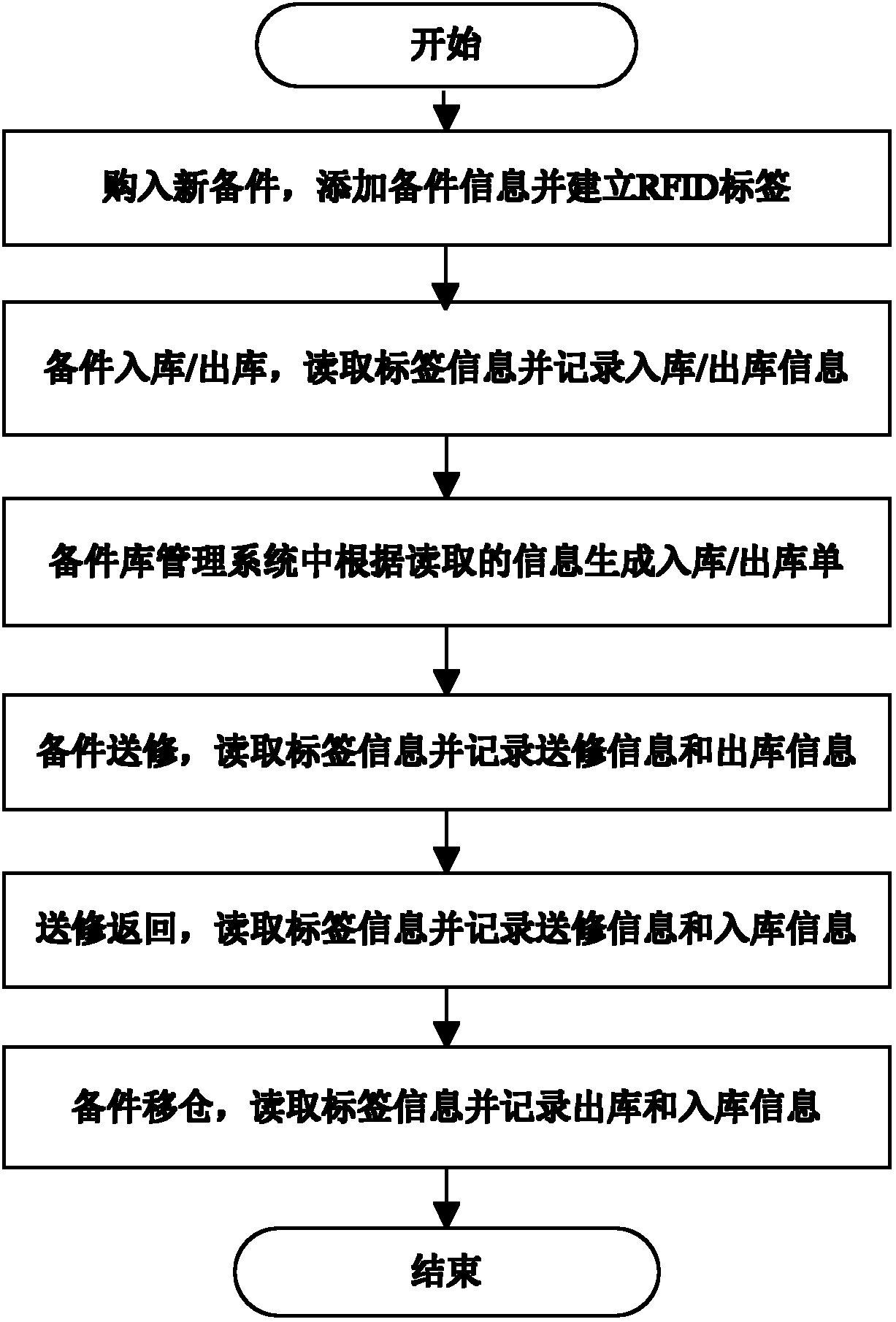

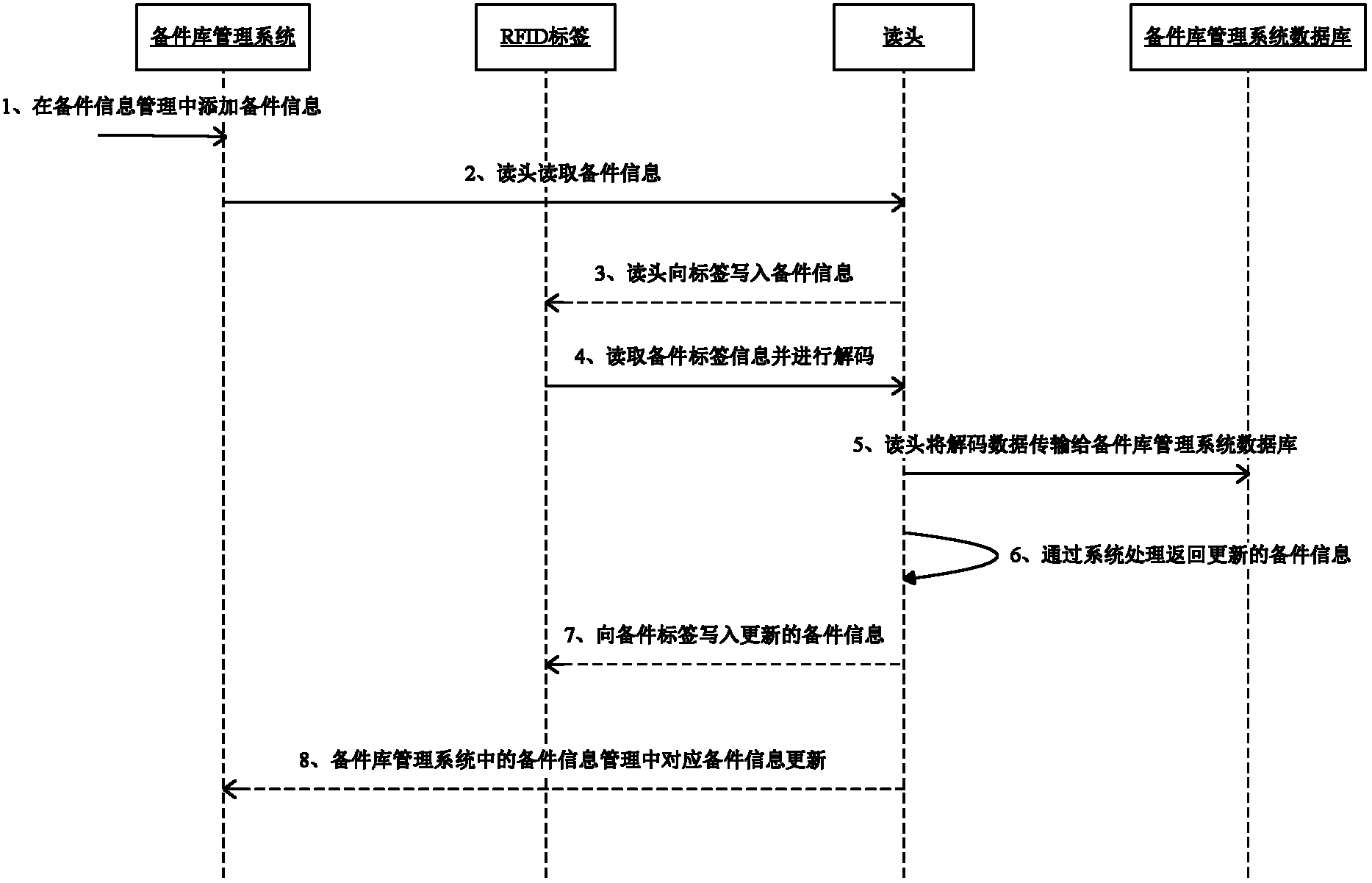

Operation spare parts library management method based on RFID

InactiveCN103325026AImprove management levelAccurately knowCo-operative working arrangementsLogisticsLabeled dataManagement system

An operation spare parts library management method based on RFID comprises the following steps of: S1, purchasing new spare parts, adding attribution information of the spare parts to a spare parts library management system, establishing RFID labels for the spare parts, S2, reading label data with a reading head when the spare parts are put in / taken out from a spare parts library, recording warehousing / exit information in the spare parts library management system, S3, generating a warehousing / exit list in the spare parts library management system, S4, taking the spare parts which need to be repaired out from the library according to a repair list in the spare parts library management system, reading the label data of the spare parts which need to be repaired with the reading head, recording repair information and warehousing information in the spare pars library management system, S5, reading the information spare parts which are repaired with the reading head and associating the information with the repair list before the spare parts are warehoused when the spare parts are returned after repair, recording repair information and warehousing information, S6, reading the label data of the spare parts with the reading head when the spare parts are transferred to another library, and recording the original exit information and new warehousing information in the spare parts library management system. Therefore, the spare parts are managed automatically.

Owner:勤智数码科技股份有限公司

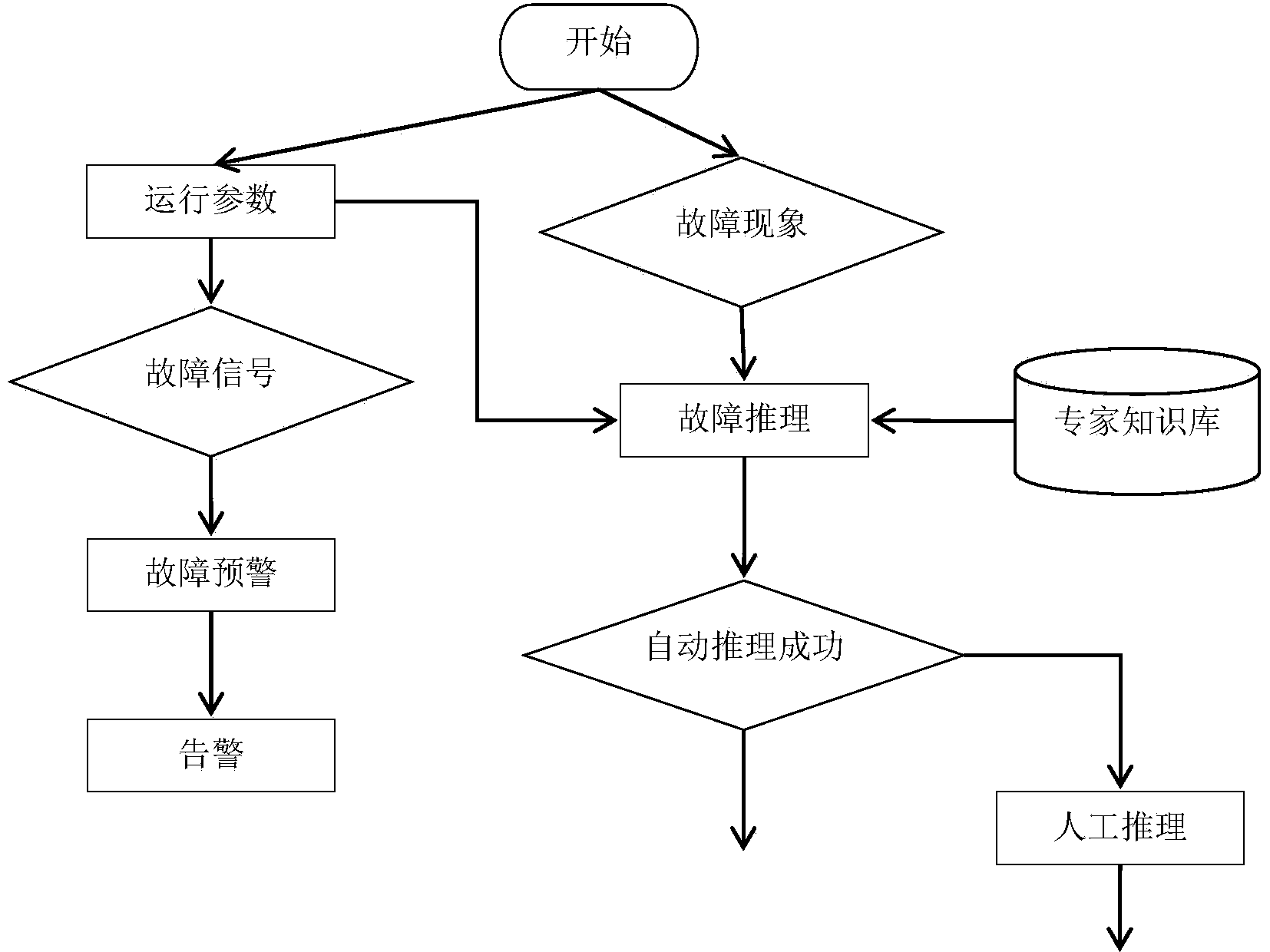

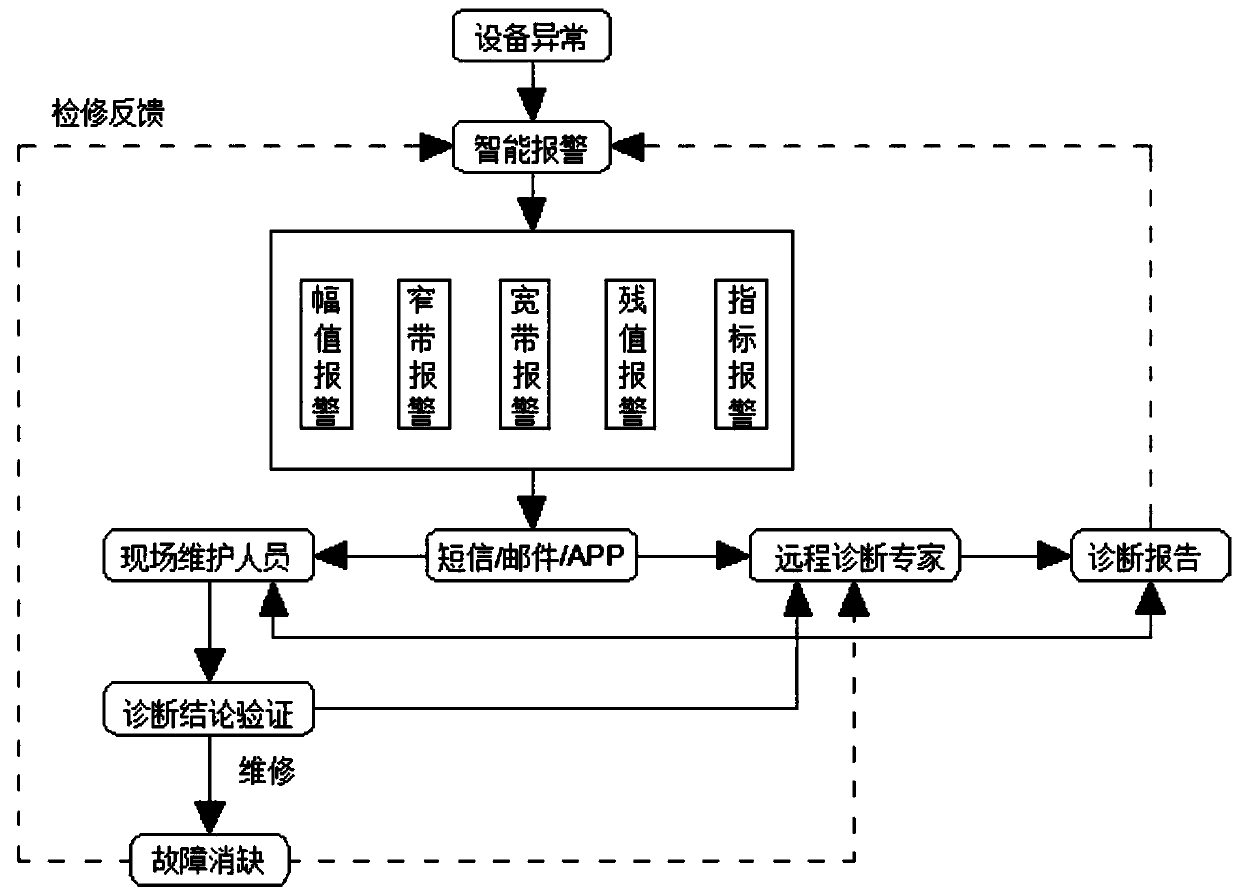

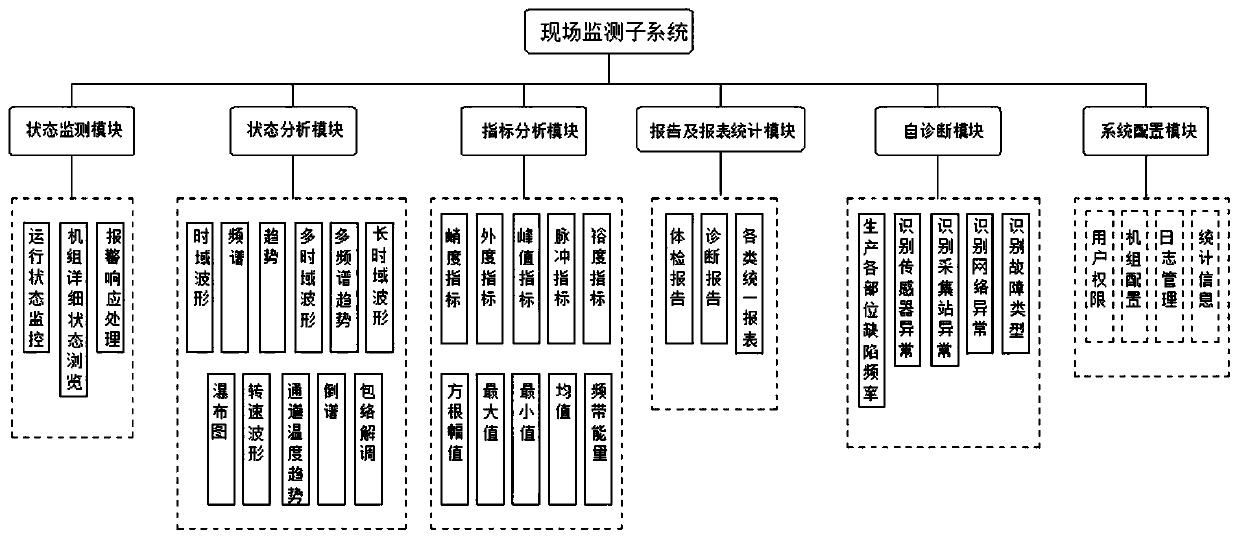

Remote intelligent monitoring system for petrochemical key unit equipment

PendingCN110445830AImprove availabilityEfficient managementMeasurement devicesTransmission systemsOriginal dataData acquisition

The invention discloses a remote intelligent monitoring system for petrochemical key unit equipment in the technical field of petrochemical engineering. The system comprises a data collection subsystem which is used for collecting original data and transmitting the original data to an on-site monitoring subsystem; the field monitoring subsystem is used for integrating the existing monitoring data,configuring a targeted data acquisition method according to the operation characteristics of the equipment unit, capturing, analyzing and positioning effective vibration and temperature data of the equipment unit fault through the data acquisition subsystem, and giving an intelligent alarm according to an output instruction of the remote diagnosis subsystem; remote diagnostic subsystem, the system is used for carrying out remote data analysis and fault diagnosis on an equipment unit monitored by an on-site monitoring subsystem. The problem of data acquisition is solved by setting up the Internet of Things through arrangement of sensors, and data sharing and analysis are performed by applying a large number of intelligent algorithms, so that the risks of equipment loss and repair loss areeffectively reduced. The unplanned shutdown is reduced. The availability of parts is improved. The spare part management is efficient, and the operation efficiency is improved.

Owner:SINOCHEM XINGZHONG OIL STAGING ZHOUSHAN

Configurable control module of control system of passenger car body and parameter configuring method thereof

InactiveCN101913343AReusableShort development cycleElectric/fluid circuitTotal factory controlCar modelControl system

The invention discloses a configurable control module of a control system of a passenger car body, which comprises a processor module, an on-off input circuit, an analog input circuit, a control signal output circuit, a CAN bus communicating module and a memory, wherein the on-off input circuit, the analog input circuit, the control signal output circuit, the CAN bus communicating module and the memory are respectively connected with the processor module; and the memory is used for storing parameter configuration files. The invention also discloses a parameter configuring method of the configurable control module, and the signal types of an input port and an output port and the control logic of the output port of the configurable control module are all set by the parameter configuration files. The configurable control module of the invention has the characteristics of flexibility and versatility, a plurality of configurable control modules with the same hardware can be installed on different car models, and the different parameter configuration files enable each configurable control module to have functions for controlling different passenger car body equipment, thus the control system of the passenger car body with programmable configuration has the characteristics of reusability, short development cycle and low cost, and is convenient for after-sale service and spare parts management of the car.

Owner:SUZHOU UNIV

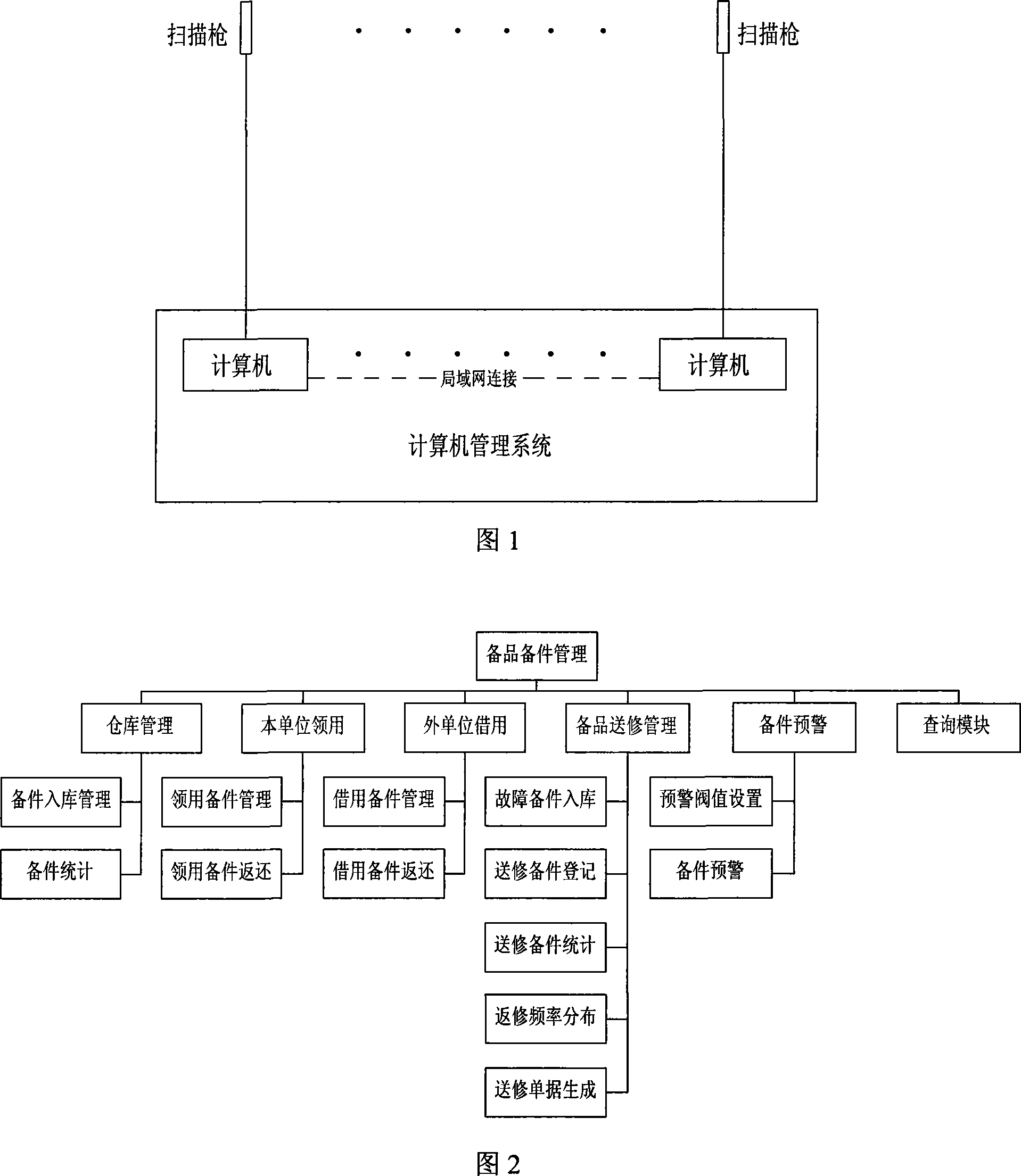

Peripheral apparatus central reserve part management system device

The invention relates to a central spare product and spare part managing system device for peripheral equipments, and is characterized in that: the device comprises a computer managing system and a managing module. The computer managing system comprises computers arranged at each workstation, each computer is connected via a LAN, the COM port of each computer is connected with a scanning gun, and the computer is provided with an independent managing module. The managing module can realize input of bar codes, the warehousing of spare parts, the counting of various spare parts in the warehouse, the taking, lending and returning record managing for spare parts, warehousing of fault spare parts, repairing of fault spare parts, counting of fault spare parts, analyzing of repair frequency, generating of repair sheet and comprehensive inquiring of spare part database. The invention can accomplish automation of peripheral central warehouse managing and exert working efficiency of housekeepers to the maximum extent.

Owner:CHINA MOBILE GRP FUJIAN CO LTD

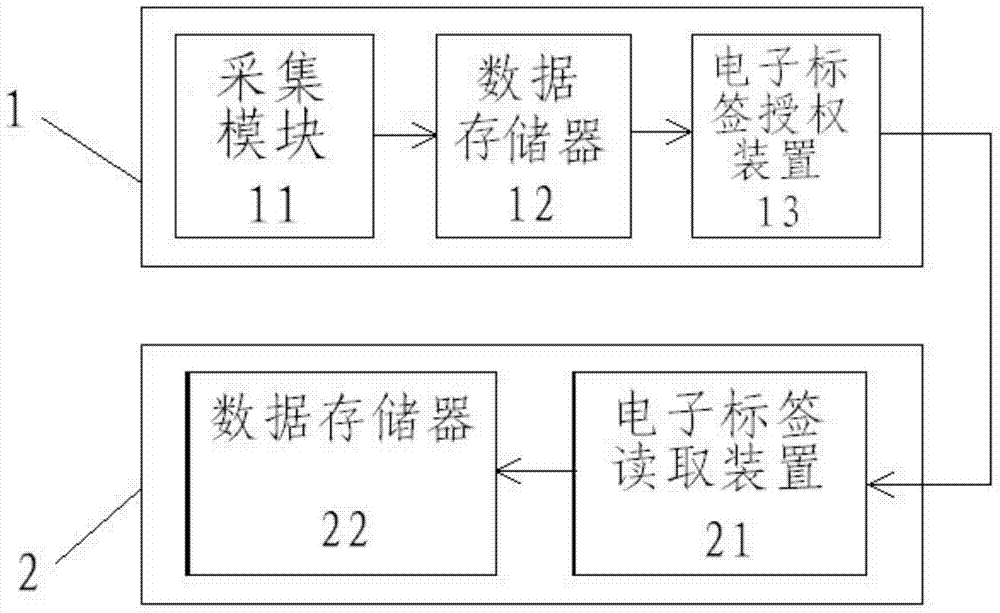

Electronic tag-based automobile spare part tracing management method

InactiveCN104517165AEasy to findResourcesManufacturing computing systemsElectronic taggingComputer module

The invention relates to the technical field of automobile spare part management, and particularly relates to an electronic tag-based automobile spare part tracing management method. The management method involves a spare part information generating module and a spare part maintenance information tracing module. The spare part information generating module comprises an acquisition module, a data memory, and an electronic label authorization device. The spare part maintenance information tracing module comprises an electronic tag reading device and a data memory. An electronic tag is pasted on a spare part. The invention aims to provide an electronic tag-based automobile spare part tracing management method which can realize fast searching and is simple and convenient.

Owner:NINGXIA XIANFENG SOFTWARE

A relay protection spare part management system and method

InactiveCN109272273AImprove management levelImprove the level of standardizationDatabase management systemsOffice automationStandardizationSpare parts management

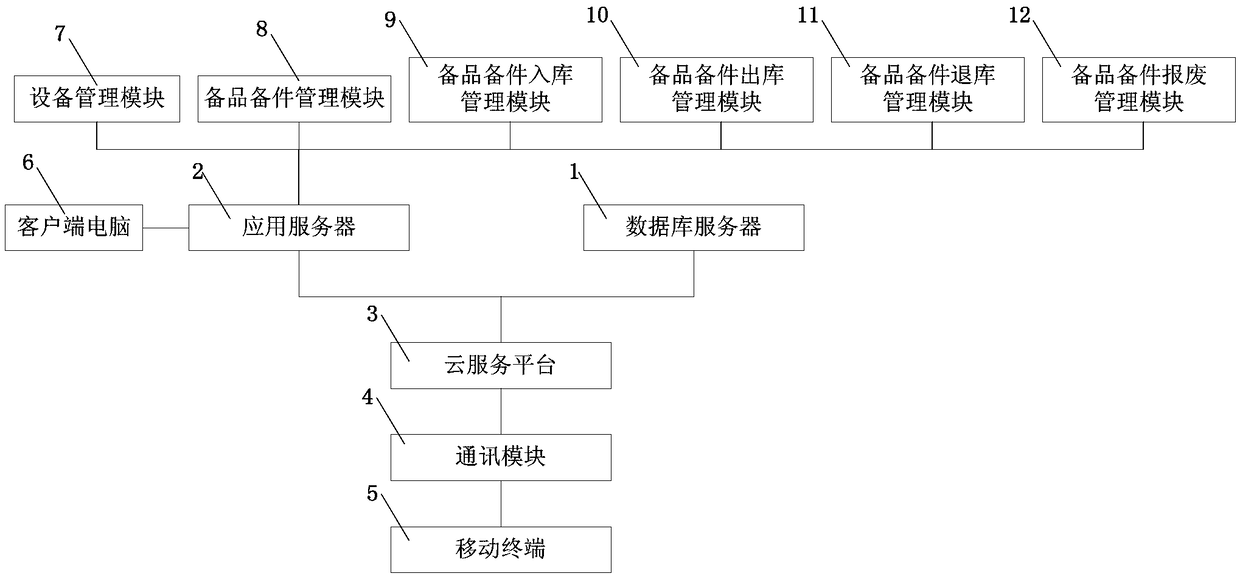

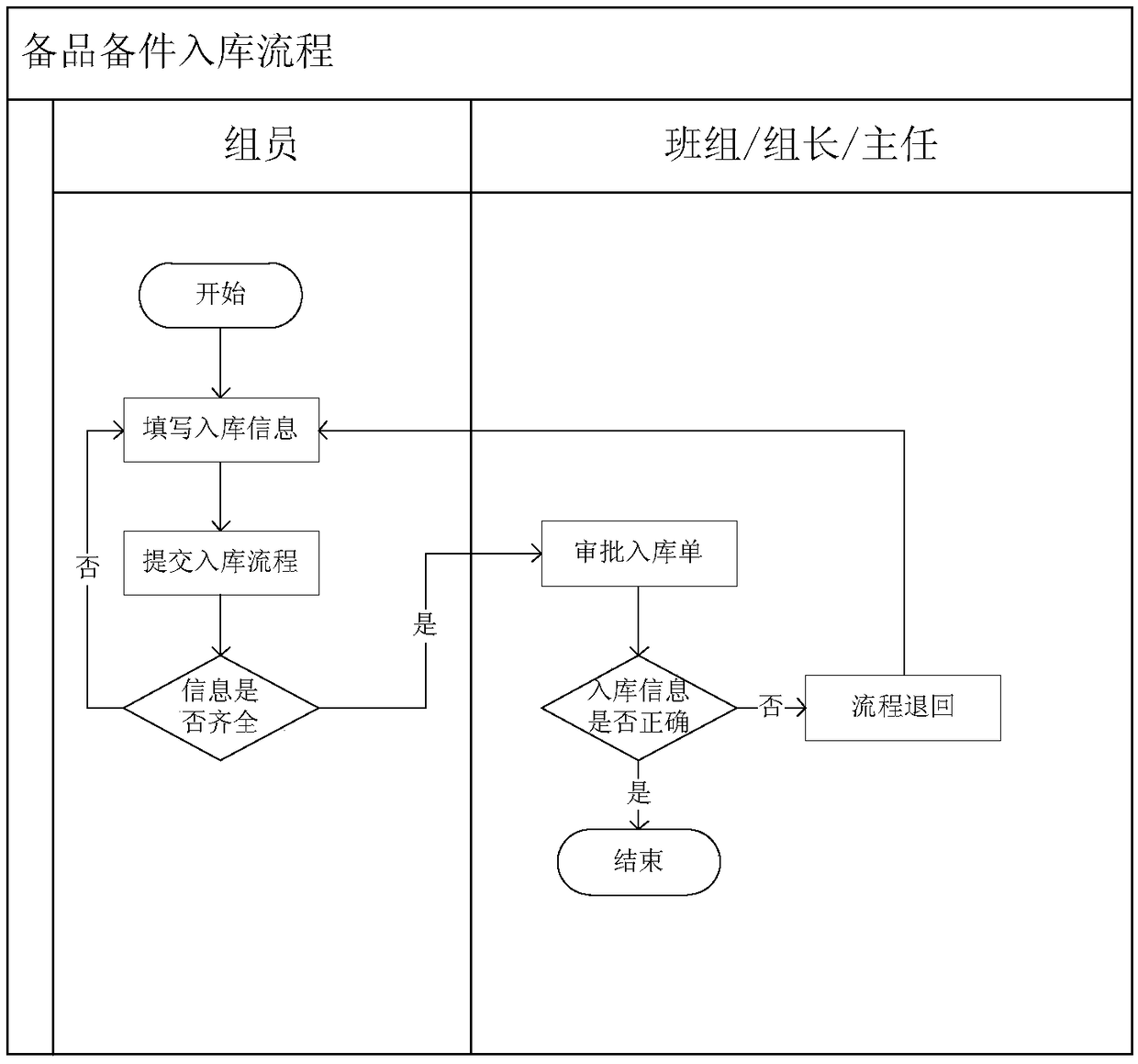

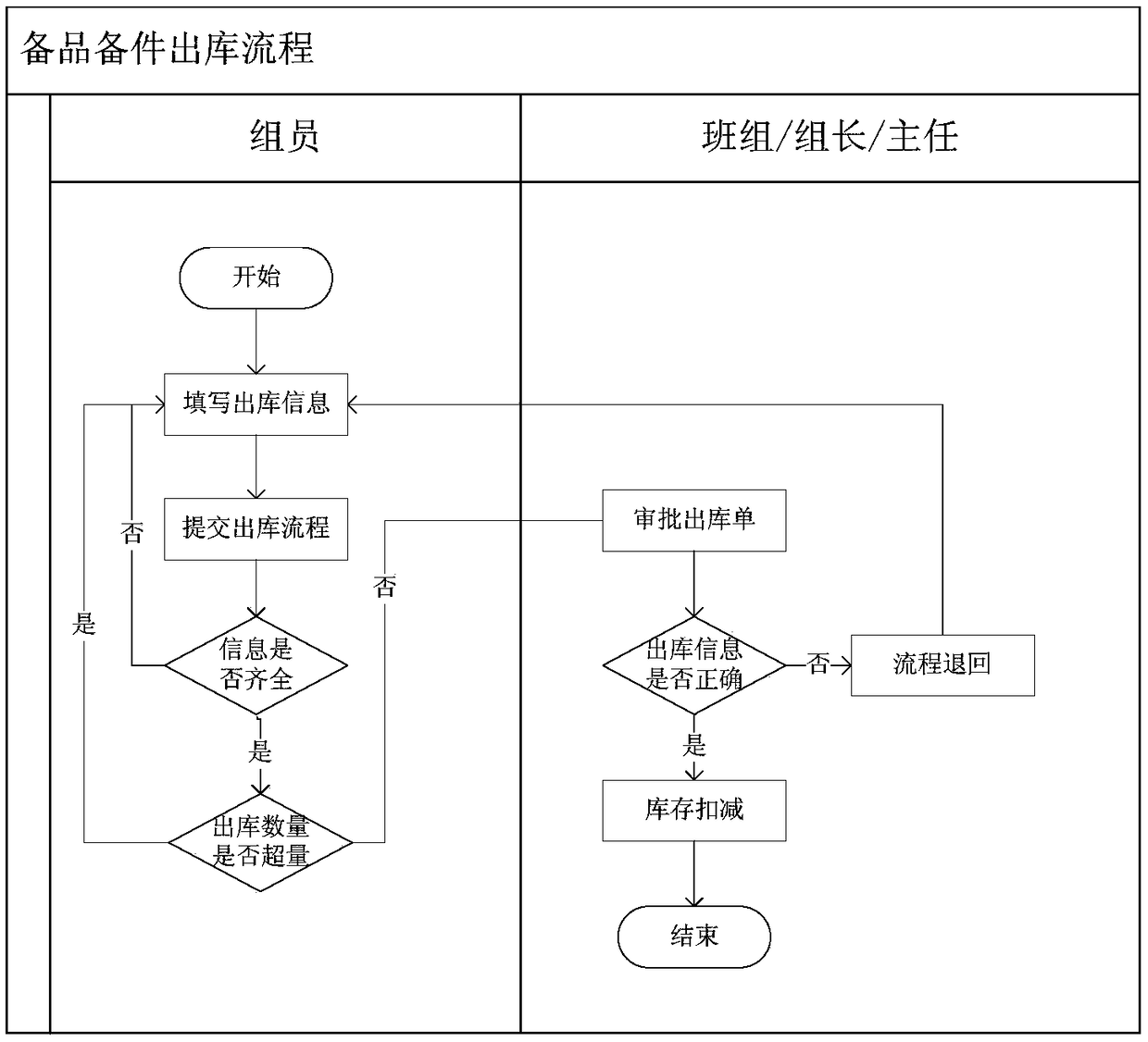

The invention discloses a relay protection spare part management system, which comprises a database server and an application server. The database server and the application server are connected to the cloud service platform; the cloud service platform is connected with the mobile terminal through a communication module. The application server is connected with a plurality of client computers; Theapplication server is provided with an equipment management module, a spare parts management module, a spare parts stock-in management module, a spare parts stock-out management module, a spare partsstock-out management module, a spare parts stock-out management module and a spare parts scrap management module. In accordance with that prior art, the relay protection spare part management management system and method adopt Internet of things and mobile Internet technology, 'full information identification code' of spare part is realized, the intelligent supervision of spare parts in and out of warehouse, automatic reminder of inventory, intelligent analysis of big data, and establishment of intelligent, dynamic and accurate management system of spare parts for relay protection are realized, which greatly improves the standardization level of the site, enhances the management level of spare parts, reduces the difficulty of management, and has high production efficiency.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

Operation and maintenance management system

InactiveCN108388211ARealize data collectionRealize scientificTotal factory controlProgramme total factory controlInformatizationDecision management

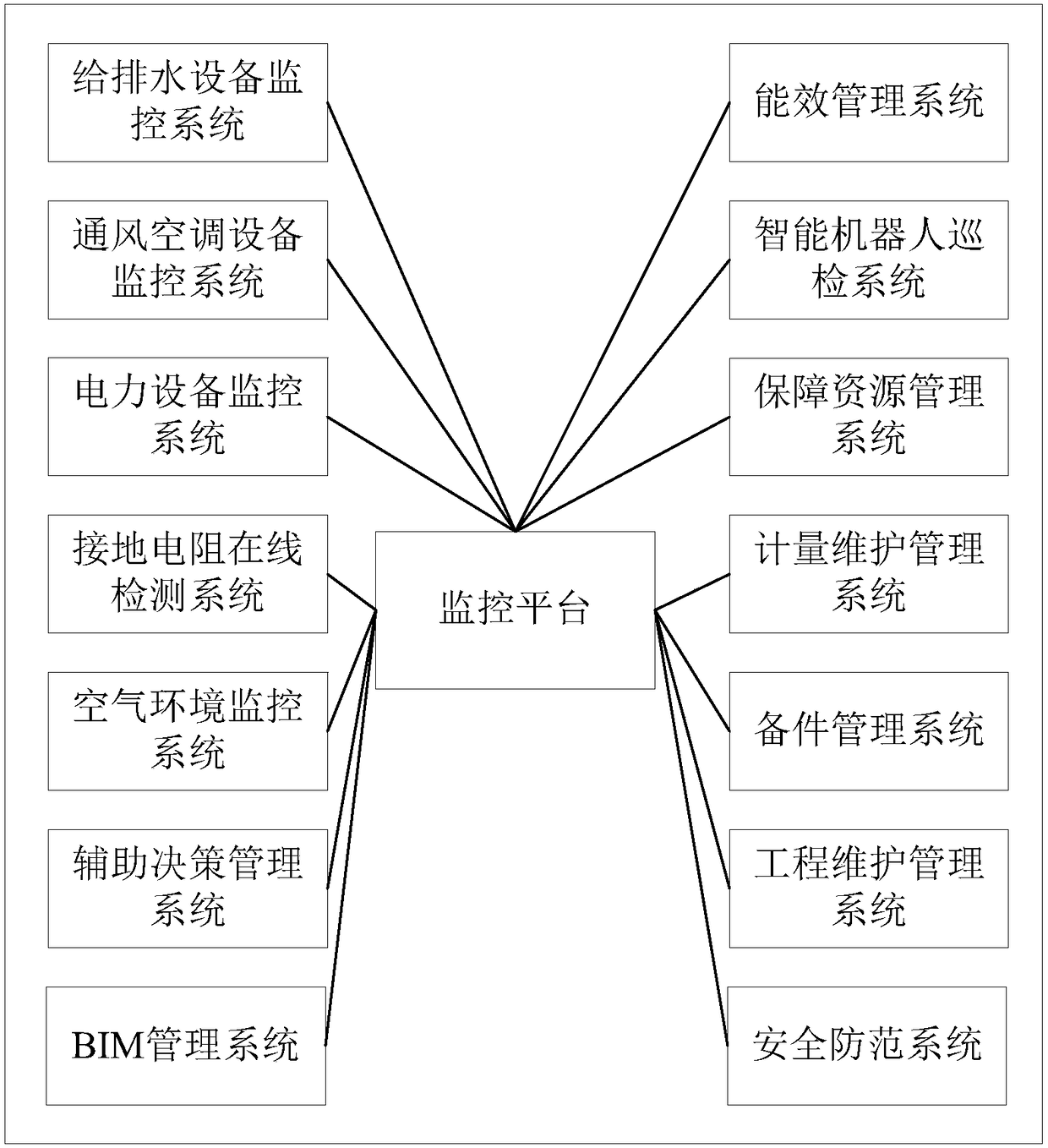

The invention discloses an operation and maintenance management system. The operation and maintenance management system comprises a monitoring platform, and a water supply and drainage equipment monitoring system, a ventilation air conditioning equipment monitoring system, a power equipment monitoring system, a grounding resistance online detection system, an air environment monitoring system, anenergy efficiency management system, an inspection system, a support resource management system, a measurement maintenance management system, a spare part management system, an auxiliary decision management system, an engineering maintenance management system, a BIM management system and a safety protection system which are connected with the monitoring platform. With application of the operationand maintenance management system, the operation and maintenance personnel can monitor and control all the equipment of the engineering in real time through the corresponding authority to realize informatized and scientific data acquisition of the engineering, operation and maintenance and decision commanding so as to provide effective means for safe operation of the engineering and effectively preventing and timely handling various sudden accidents and lay the foundation of engineering informatized application and development.

Owner:深圳中物兴华科技发展有限公司

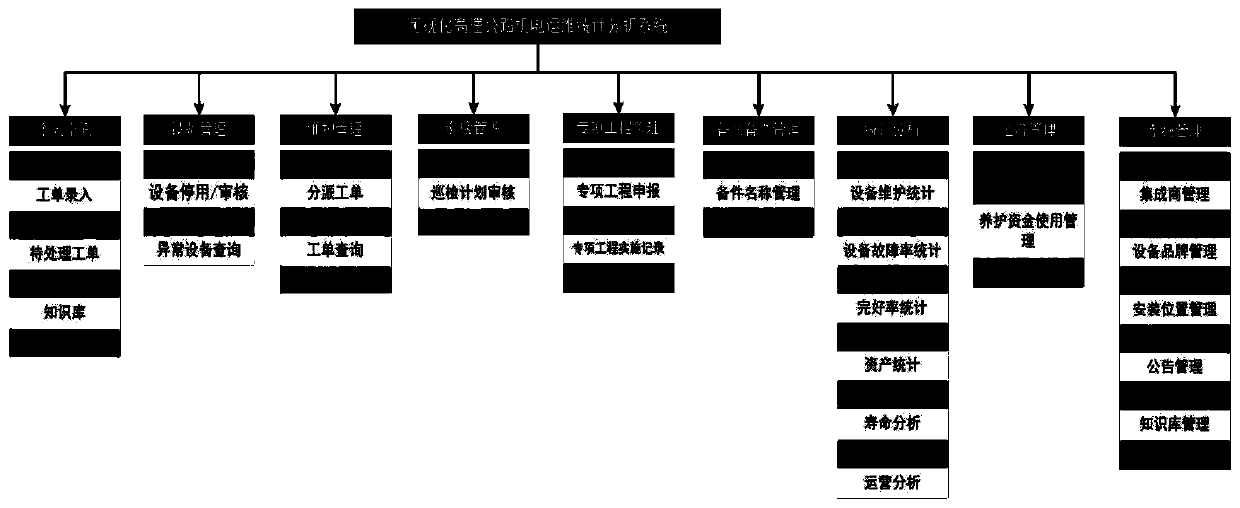

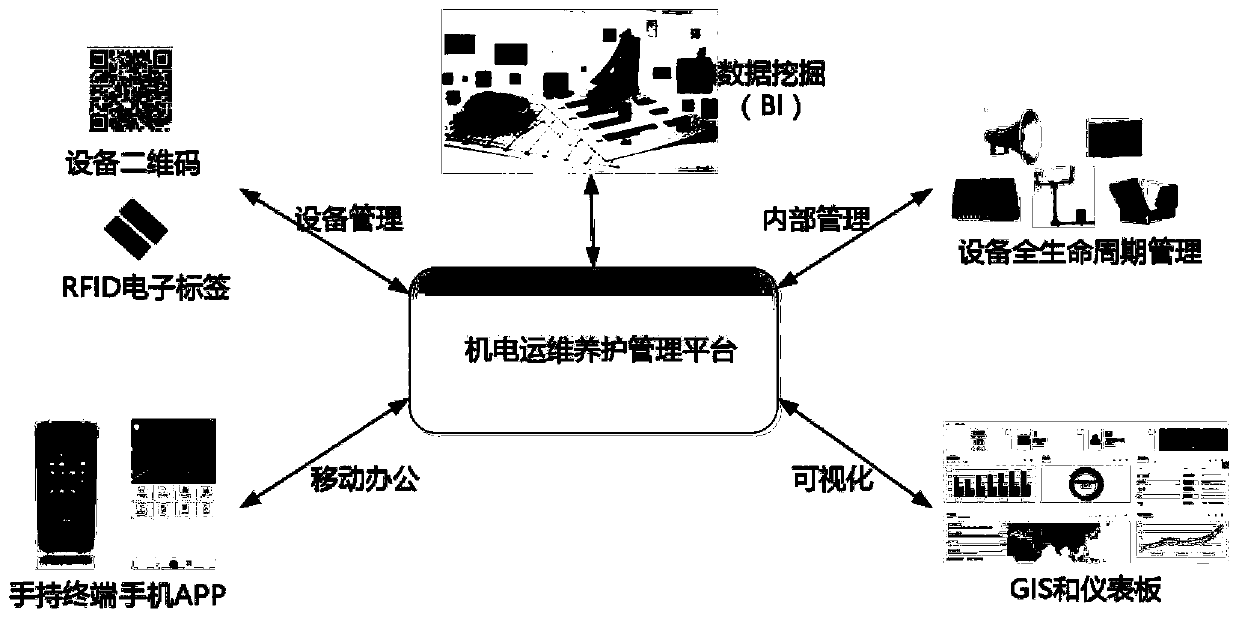

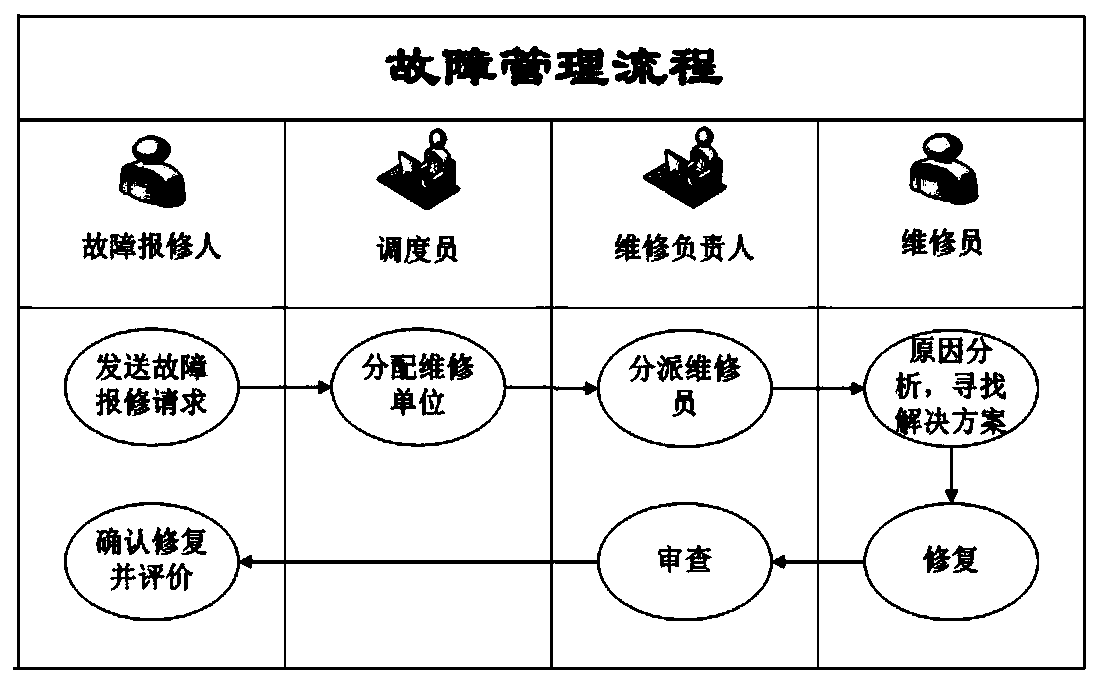

Intelligent operation and maintenance cloud platform for highway electromechanical equipment

PendingCN110472838APowerful whole-process dynamic management performanceImprove management levelResourcesPurchasing managementSpare parts management

The invention provides an intelligent operation and maintenance cloud platform for highway electromechanical equipment. The platform comprises a personal space module, an equipment management module,a GIS service module, a maintenance management module, an inspection management module, a spare part management module, a purchase management module, a statistical analysis module, a special project management module, a system management module and a handheld terminal APP. The method has the advantages that the whole-process dynamic management performance is high. The equipment management level isimproved. The full integration of electromechanical operation and maintenance management, intelligent transportation and other fields is achieved.

Owner:HEBEI SHANGYUAN IND CONTROL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com