Equipment asset operation and maintenance management system for iron and steel enterprises

A technology for equipment asset and operation and maintenance management, applied in the direction of manufacturing computing systems, resources, data processing applications, etc., can solve problems such as not being suitable for management, focusing on technical aspects, and restricting the development of iron and steel enterprises, so as to improve equipment support capabilities and transparency The effect of management and reduction of equipment failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0031] The present invention is independent of the existing automation and information systems of iron and steel enterprises, and mainly provides a simple and effective equipment asset operation and maintenance management method for point inspection maintenance personnel and enterprise management personnel.

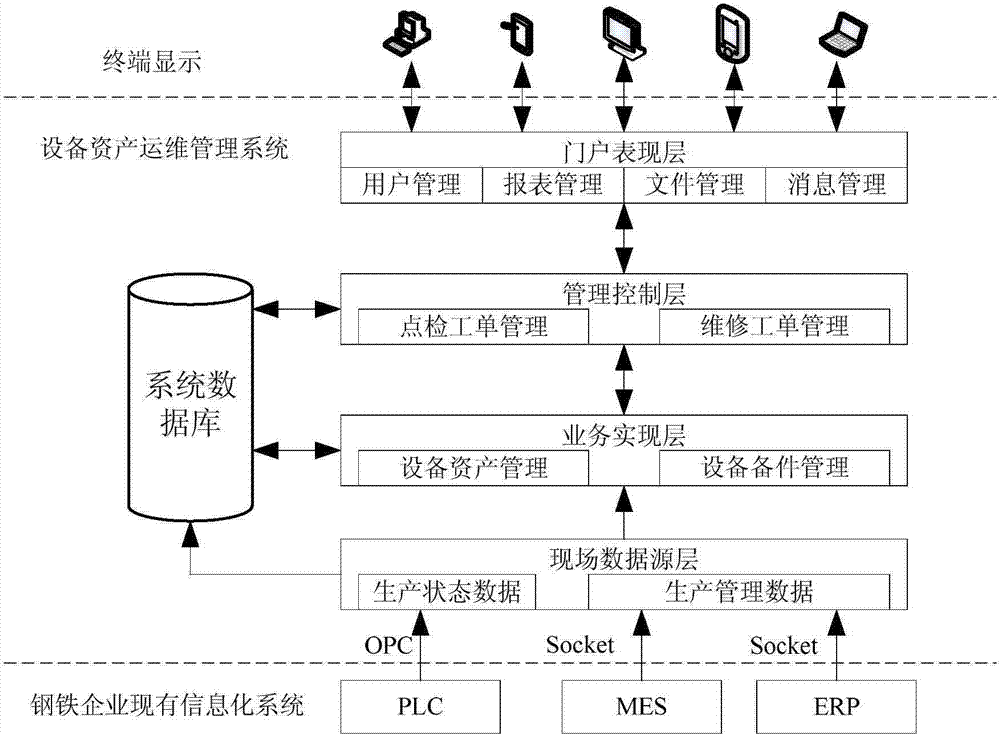

[0032] figure 1 It is a system architecture diagram of the present invention, composed of figure 1 It can be seen that the system of the present invention will utilize the existing automated information systems including L1 to L3 as much as possible, and build an equipment asset operation and maintenance management system for iron and steel enterprises on this basis. Adopt the Java Web Browser / Server architecture, deploy the equipment asset operation and maintenance management system on the server side, realize the functions of on-sit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com