Intelligent factory informatization system

A kind of factory and intelligent technology, applied in the field of intelligent factory information system, can solve the problems of inability to realize intelligent early warning, reduce factory operation efficiency, waste manpower and material resources, etc., achieve the effect of saving manpower and material resources, improving operation process and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

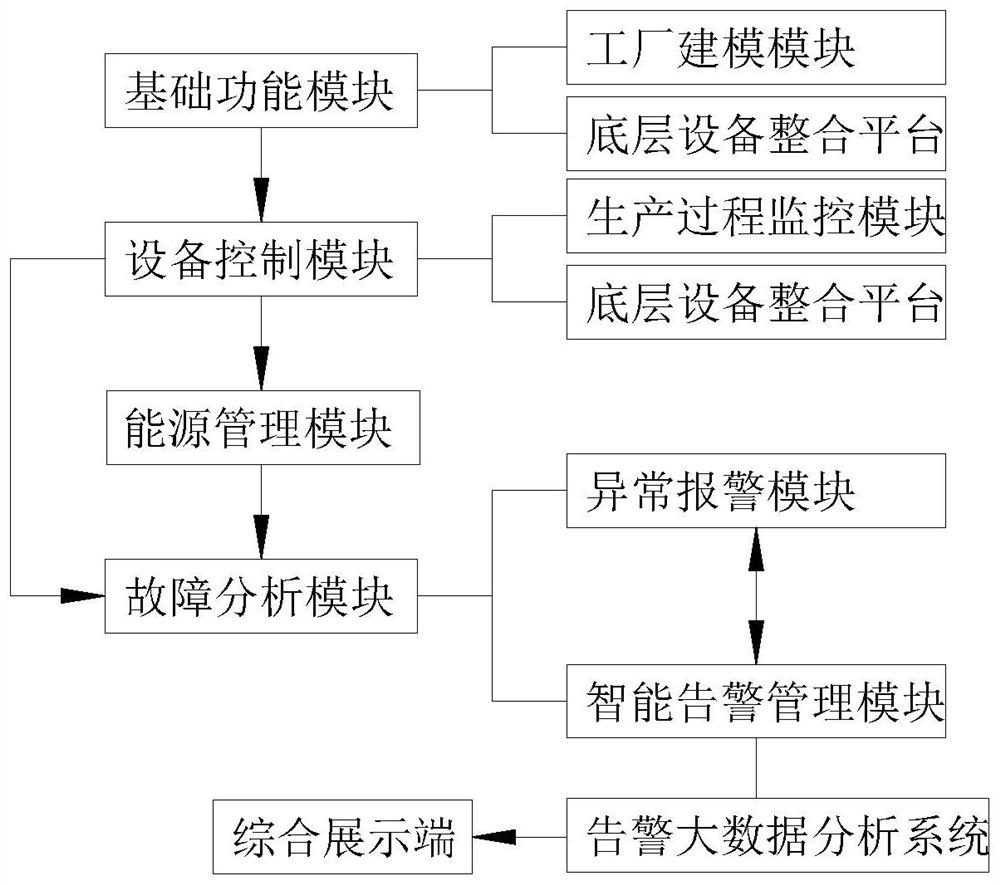

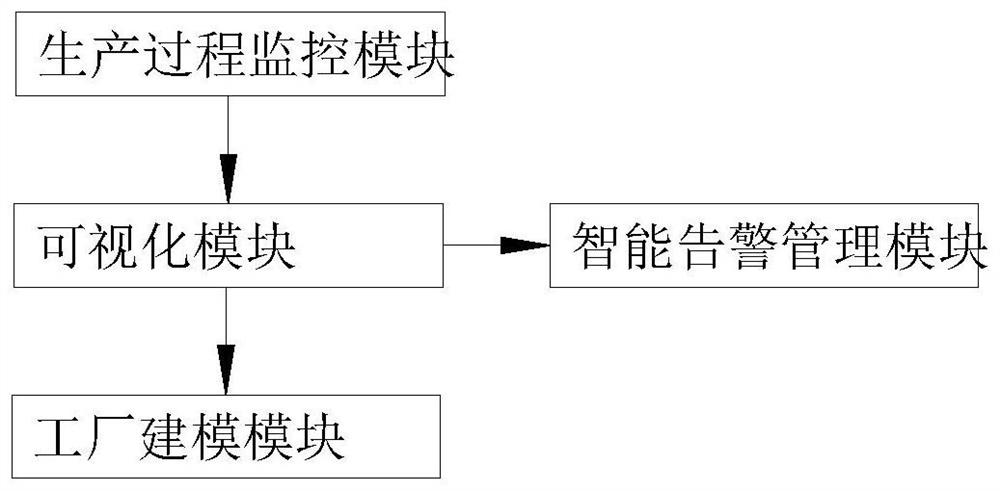

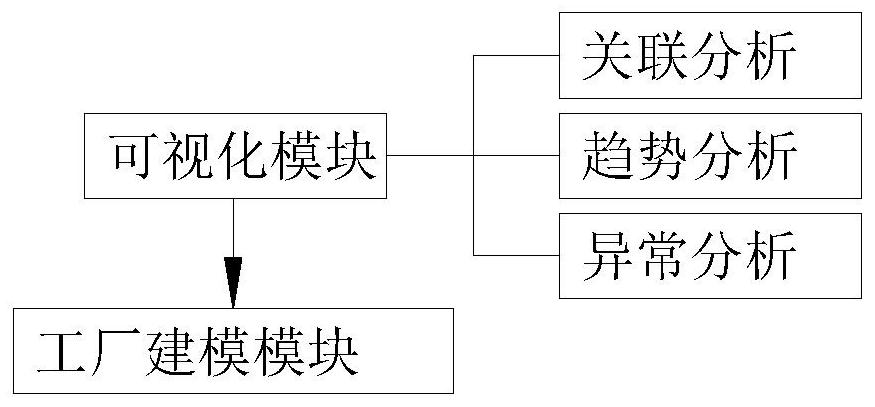

[0030] see Figure 1 to Figure 4 , Figure 1 to Figure 4 Shown is a schematic diagram of the principle of the smart factory information system provided by the embodiment of the present application. A smart factory information system, which includes a basic function module, an equipment control module, an energy management module and a fault analysis module; the basic function module includes a factory modeling module and an underlying equipment integration platform; the equipment control module includes a production process monitoring module and a production process control module; the fault analysis module includes an abnormal alarm module and an intelligent alarm management module; the underlying device integration platform is used to manage the communication interfaces connecting each device; the production process monitoring module is used to collect the data of multiple devices. a plurality of pieces of equipment data; the production process control module is connected t...

Embodiment 2

[0056] see Figure 5 , Figure 5 This is a schematic structural block diagram of an electronic device provided in an embodiment of the present application. The electronic device includes a memory 101, a processor 102, and a communication interface 103. The memory 101, the processor 102, and the communication interface 103 are directly or indirectly electrically connected to each other to realize data transmission or interaction. For example, these elements may be electrically connected to each other through one or more communication buses or signal lines. The memory 101 can be used to store software programs and modules, such as program instructions / modules corresponding to the smart factory information system provided in Embodiment 1 of this application. The processor 102 executes the software programs and modules stored in the memory 101 to execute each functional applications and data processing. The communication interface 103 can be used for signaling or data communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com