TPM platform and method based on Internet of Things

A maintenance platform and technology of the Internet of Things, applied in the direction of instruments, data processing applications, resources, etc., can solve the problems of production equipment management, unreasonable maintenance, affecting the output and production capacity of enterprises, and untimely communication within enterprises, so as to reduce communication costs. , promote intelligence, reduce the effect of reducing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

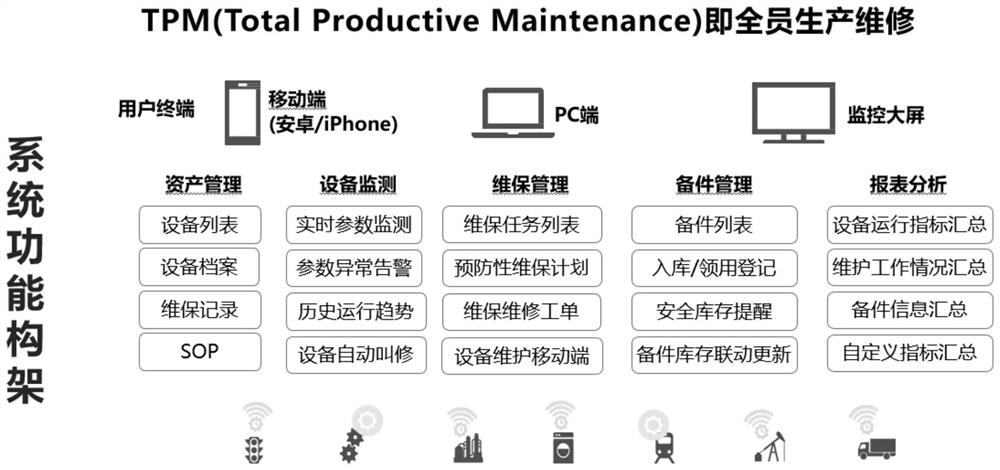

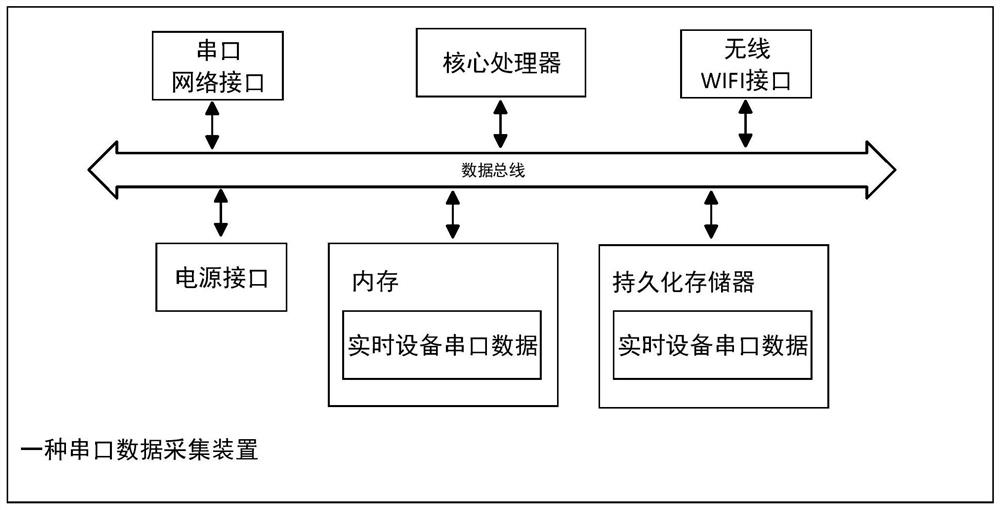

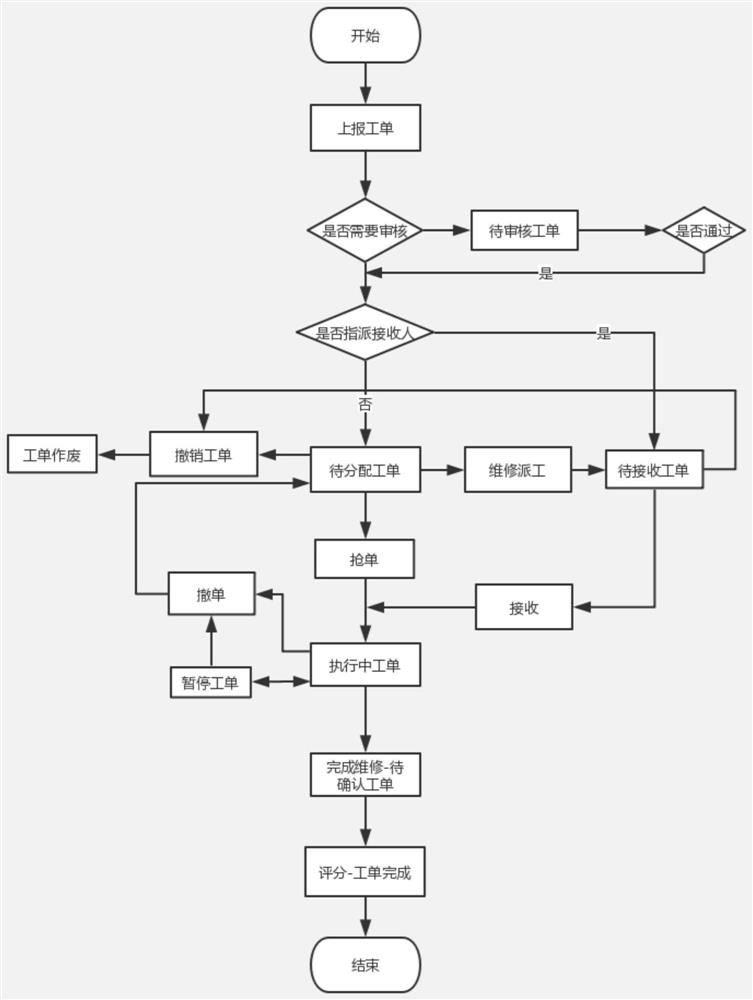

[0028] Such as figure 1 and figure 2 As shown, the TPM production and maintenance platform based on the Internet of Things in this embodiment includes a production maintenance system and a serial data acquisition device, the serial data acquisition device is used to connect production equipment to collect data of production equipment, and the production maintenance system includes : The asset management module is used to process the basic information of the equipment; the equipment monitoring module is used to process the parameter information of the production equipment; the maintenance management module is used to process the maintenance information of the production equipment; the spare parts management module is used to process the spare parts of the production equipment I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com