Water-permeable brick plate with composite surface layer and for road surface as well as preparation method thereof

A technology of composite surfaces and brick panels, applied to roads, roads, pavement details, etc., can solve the problems of loss of rainwater infiltration and evaporation, pavement noise reflection, pavement color difference, etc., to achieve good water storage effect, The effect of preventing urban waterlogging and large pore space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

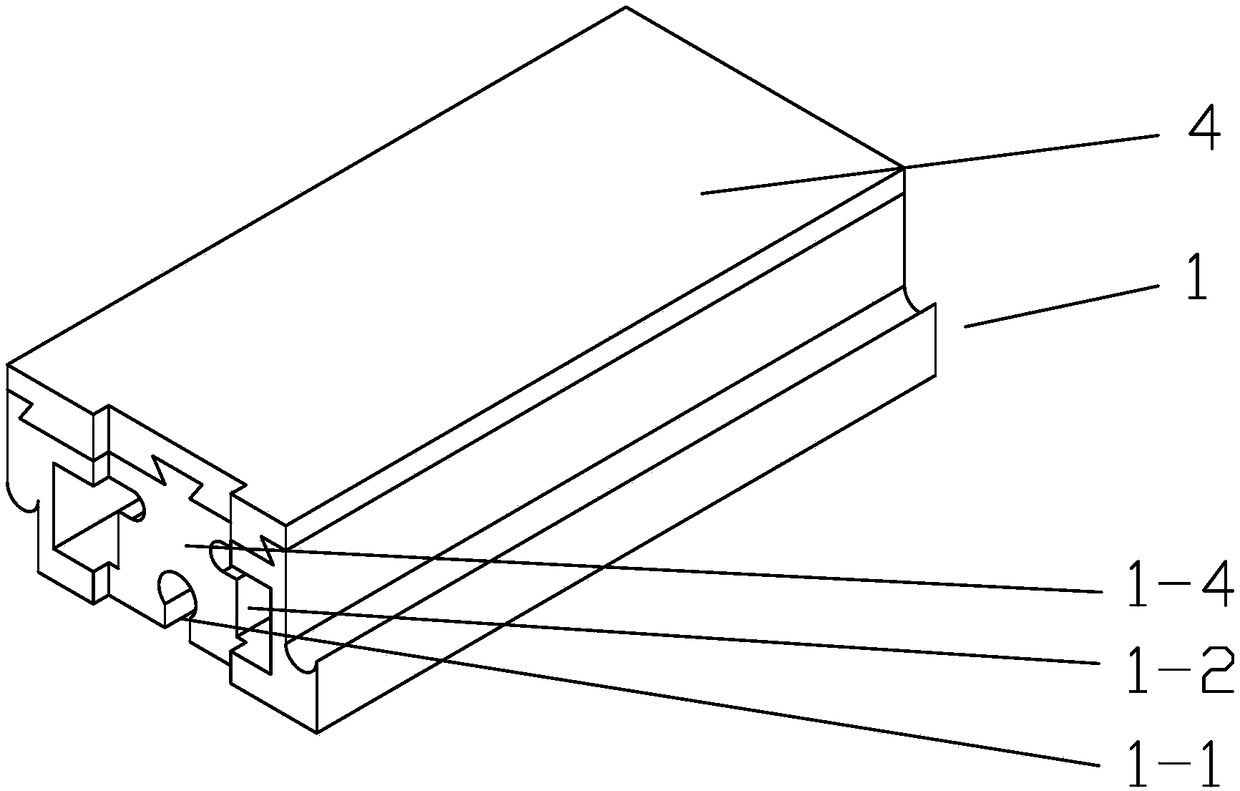

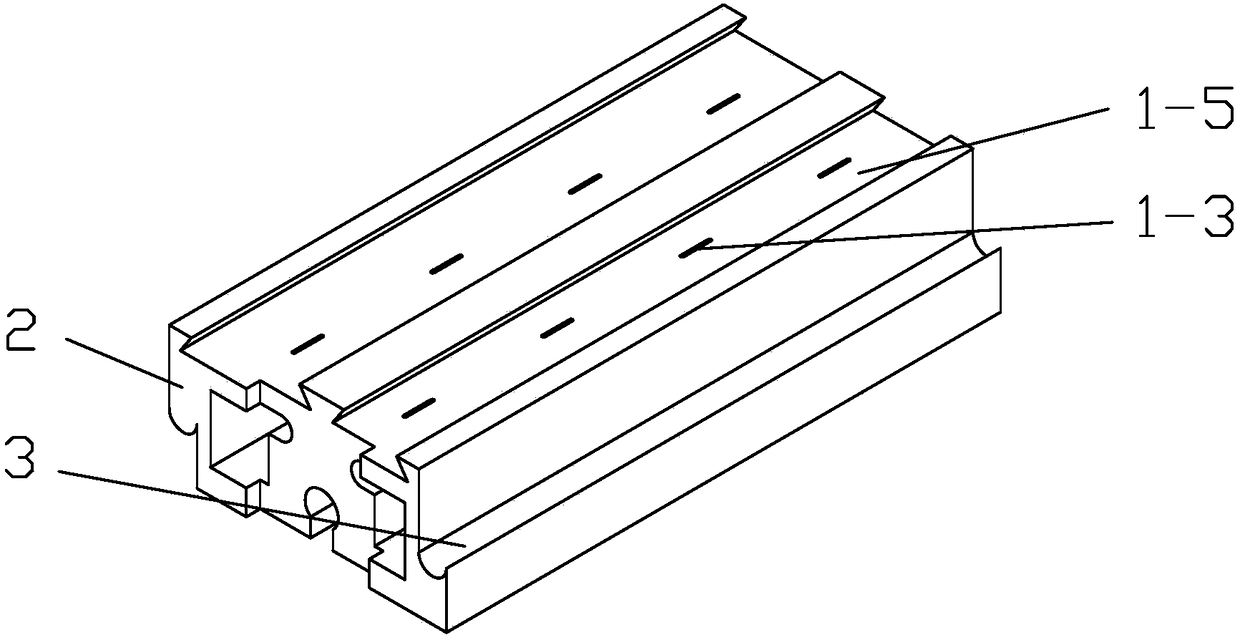

[0064] A permeable brick board for pavement with a composite surface layer, comprising a brick body 1, the upper side of the brick body 1 is provided with more than one upper groove 1-5 extending longitudinally and with the notch upward, the upper The transverse dimension of the groove bottom of the cross-section of the groove 1-5 is greater than the transverse dimension of the notch, and when the number of the upper grooves 1-5 is more than two, each upper groove 1-5 is distributed sequentially along the transverse direction; The above-mentioned permeable brick board for pavement with a composite surface layer also includes a water-permeable material layer 4 laid on the upper side of the brick body 1 and filled into the upper groove 1-5; permeable channels.

[0065] The water-permeable channel of the present invention can be a self-permeable channel in the brick body, or a channel through the upper and lower surfaces. Preferably, the brick body 1 is made of impermeable or low...

Embodiment 1

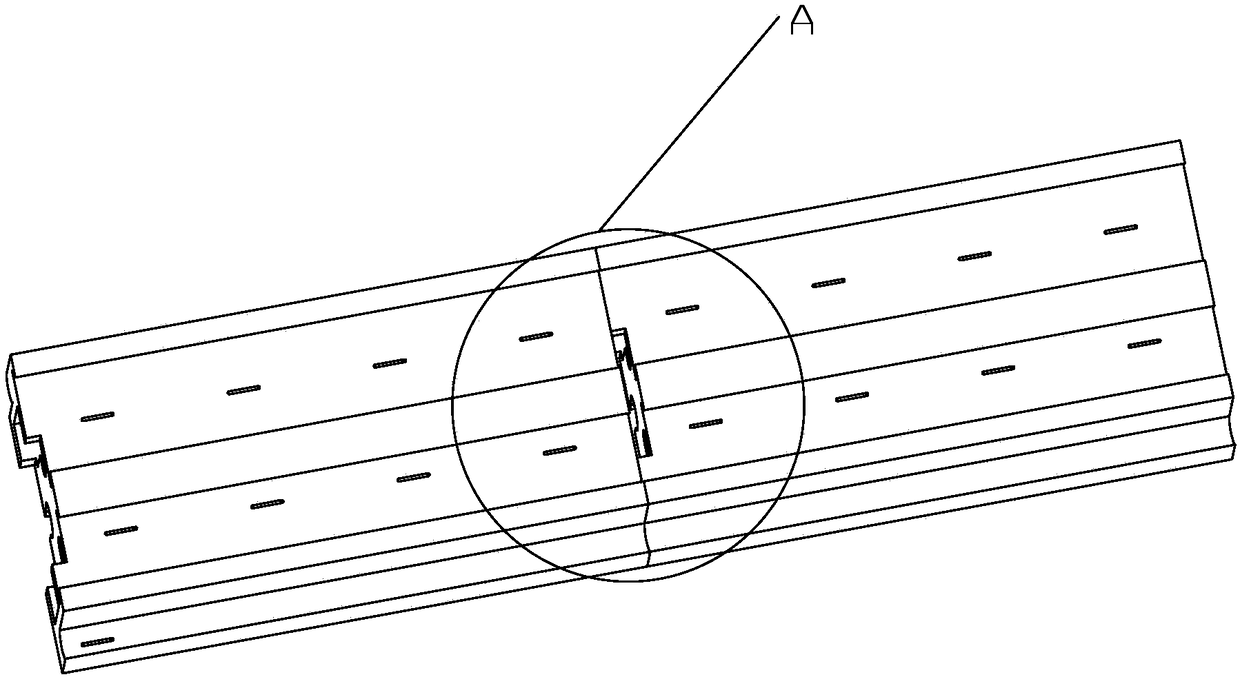

[0098] Such as Figure 1-4 As shown, a permeable brick slab for pavement with a composite surface layer includes a brick body 1, and the upper side of the brick body 1 is provided with more than one upper groove 1-5 extending longitudinally and with the notch upward. The transverse dimension of the groove bottom of the cross-section of the upper groove 1-5 is greater than the transverse dimension of the notch, and when the number of the upper groove 1-5 is more than two, each upper groove 1-5 is spaced sequentially along the transverse direction Distribution; the permeable brick slab for pavement with a composite surface layer also includes a permeable material layer 4 laid on the upper side of the brick body 1 and filled into the upper groove 1-5; And the permeable channel connected to the lower part.

[0099] The water-permeable passage in this embodiment can be a self-permeable passage in the brick body, or a passage through the upper and lower surfaces. The brick body 1 i...

Embodiment 2

[0111] Such as Figure 5 As shown, the difference from the above-mentioned embodiment is that the water storage hole 1-2 is located above the lower groove 1-1, and the lower water permeable channel is connected by more than one bottom wall of the water storage hole 1-2. The second lower permeable hole 1-7 in the lower groove 1-1 is formed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com