APP technology based industrial inspection system

An inspection system and industrial technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems that managers cannot fully grasp the on-site work, the process of querying data is complicated and cumbersome, and the efficiency of multi-departmental collaboration is low. Achieve the effect of saving time and effort in personnel performance appraisal, improving management efficiency and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

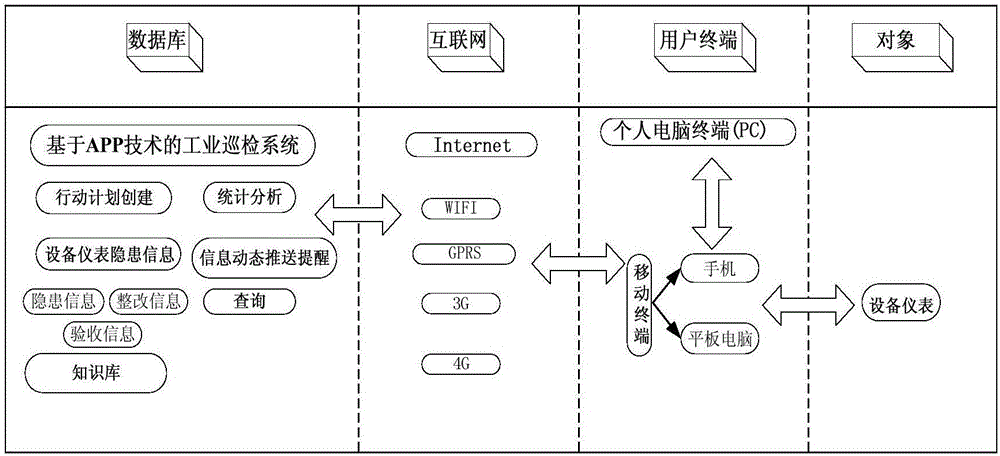

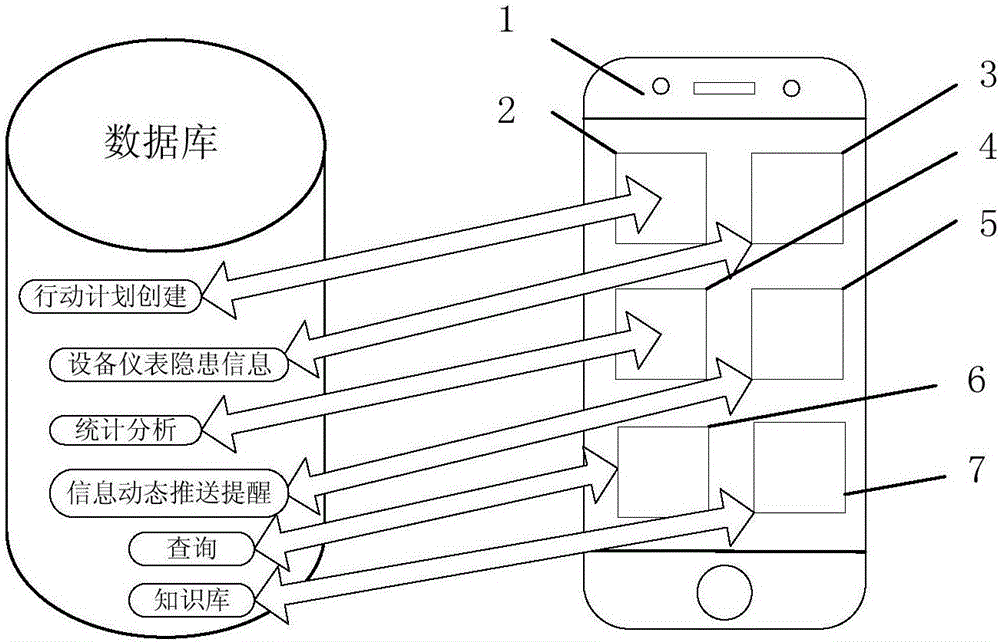

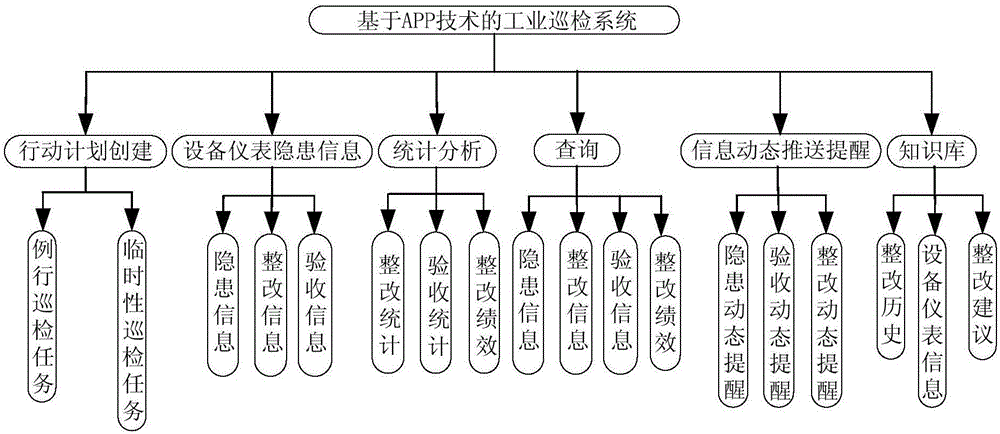

[0029] This embodiment relates to an industrial inspection system based on APP technology. The general architecture diagram of the application environment of the system is as follows: figure 1 As shown, the schematic diagram of the hardware architecture is shown in figure 2 As shown, the software function schematic diagram is as follows image 3 shown.

[0030] Such as figure 1 As shown, the overall structure of the environment used by the intelligent management system includes four parts: database, Internet, user terminal and evaluation object. The database stores the action plan creation module, equipment and meter hidden danger information module, statistical analysis module, information dynamic push reminder module and related information of the query module. The tasks created by the action plan creation module include routine factory inspection tasks or temporary inspection tasks; the hidden danger information module of equipment and meters registers the hidden danger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com