Patents

Literature

90results about How to "Long production cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of silicon dioxide super-hydrophobic thin film and super-hydrophobic material

InactiveCN103359954AImprove surface hydrophobicityImprove stabilityOther chemical processesCoatingsAdhesion forcePtru catalyst

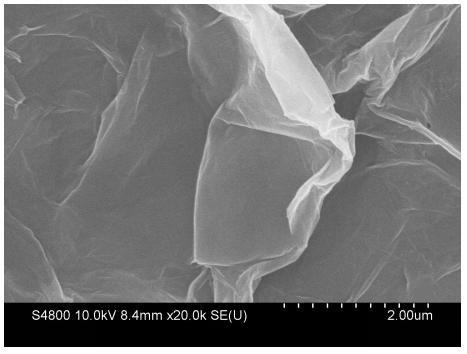

The invention provides a preparation method of a silicon dioxide super-hydrophobic thin film. The preparation method comprises the following steps of: step one. preparing alkaline colloidal sol, namely mixing orthosilicate ester, a basic catalyst, a solvent and water to prepare the SiO2 alkaline colloidal sol; step two. adding hexamethyl disilazane to the SiO2 alkaline colloidal sol for reaction to obtain modified SiO colloidal sol; and step three. coating the modified SiO colloidal sol on the surface of a substrate, and drying to obtain the silicon dioxide super-hydrophobic thin film. The invention also provides a super-hydrophobic material. The silicon dioxide super-hydrophobic thin film prepared by the method has strong adhesion force with a substrate and a good dewatering effect; complicated equipment is not needed; the process is simple; the preparation cycle is shortened; the cost is saved; and the application range is wide.

Owner:BYD CO LTD

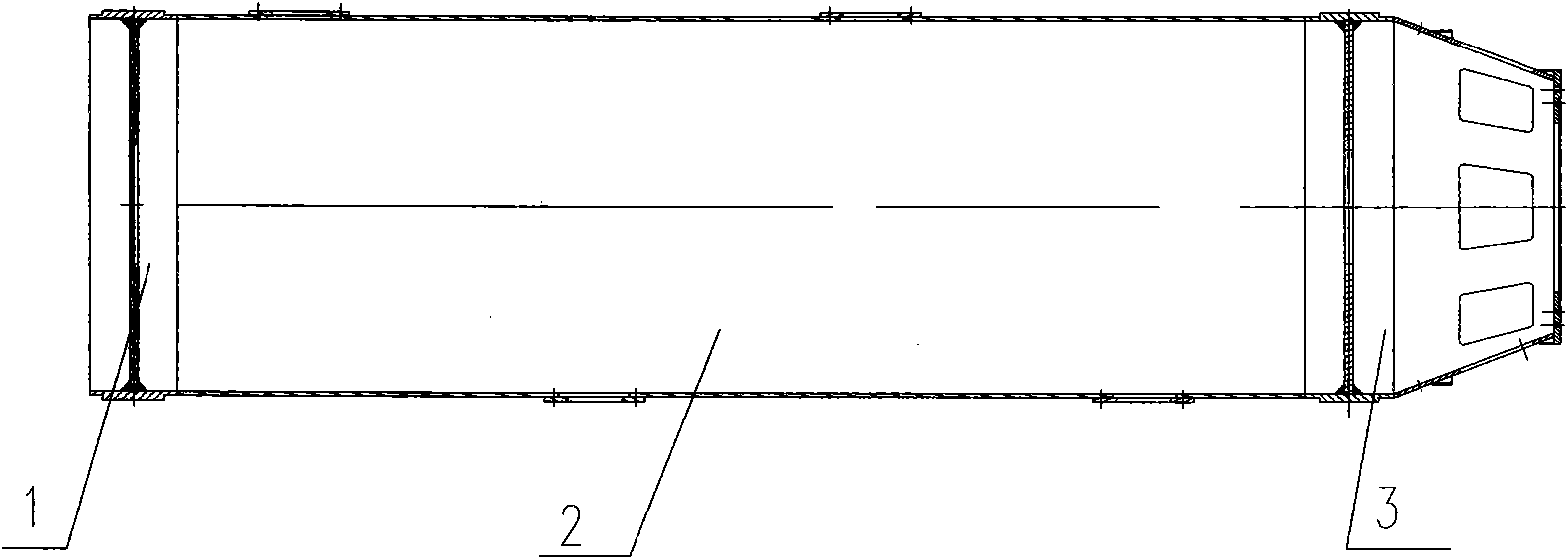

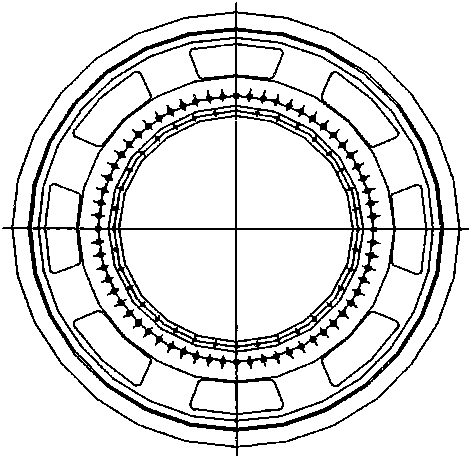

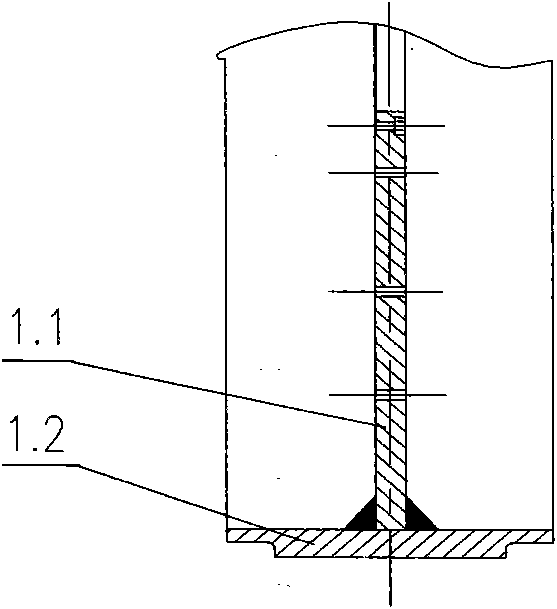

Field repairing method of welding cracks of feeding slip-ring body of large-sized slide mill

The invention provides a field repairing method of welding cracks of a feeding slip-ring body of a large-sized slide mill, wherein a field detection step comprises the following steps of coloring, detecting defects, drilling crack arrest holes and cleaning and polishing a surface; a repairing welding step comprises reinforcing plate repairing welding, repairing welding method and defect re-detection; in a machine processing step, a supporting frame arranged near a feeding slip-ring body is used for installing a turning machine for grinding and processing the surface of the maximum outside diameter of a slip ring; and finally, the field repairing is achieved by replacing a new bearing bush and commissioning and inspecting a cylinder body. The invention utilizes an installation base of the traditional device without disassembling the cylinder body of the traditional large-sized slide mill and has short repairing period, simple operation and safe and reliable running. The field repairing method of the welding cracks of the feeding slip-ring body is also suitable for the field reparation of welding cracks of a discharging slip-ring cone.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

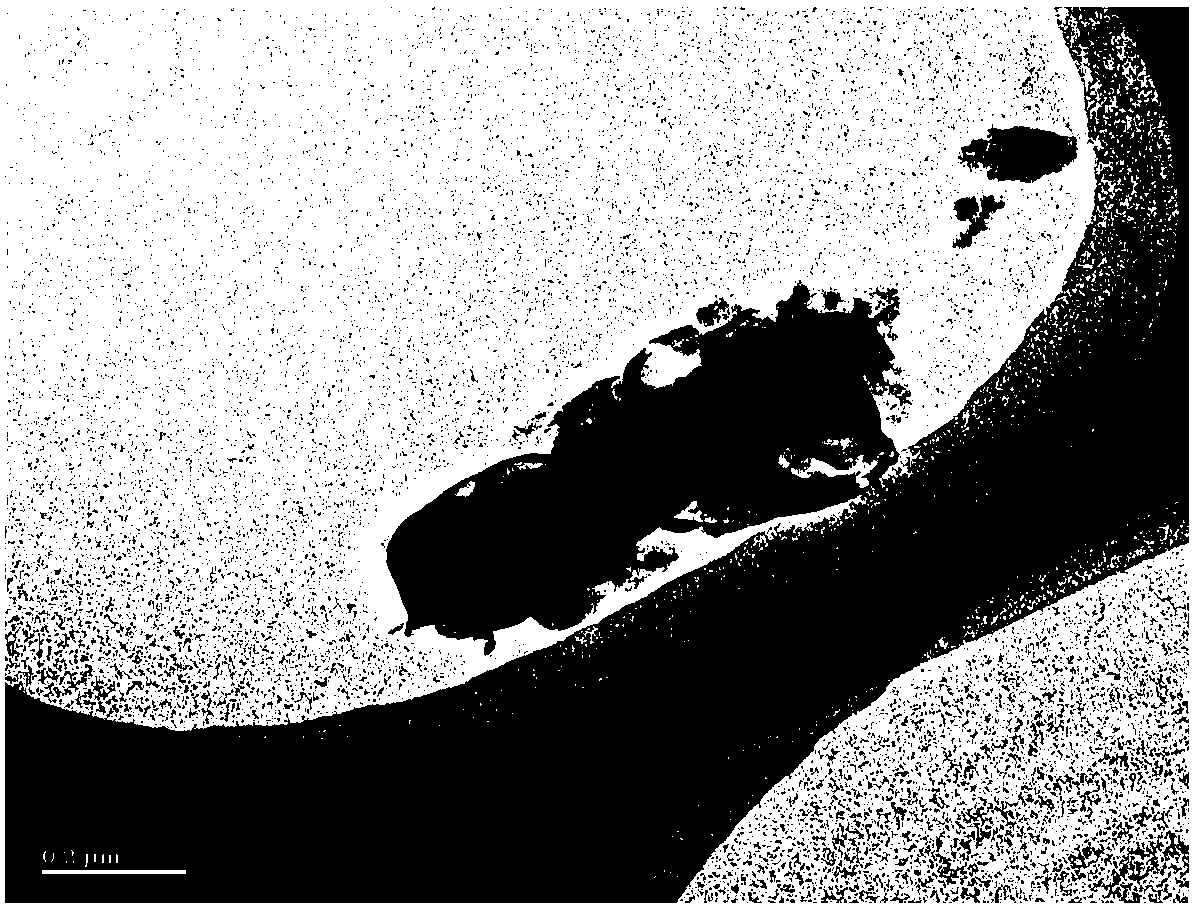

Carbon base porous electrode film used in super capacitor and its preparation method

InactiveCN1753116AReduce dosageNo pollution in the processElectrode manufacturing processesElectrolytic capacitorsPorous electrodeControllability

The invention is a carbon base porous electrode film for super capacitor and the preparing method thereof. And the composition contents of the film: activated carbon 72 mass%-99mass%, conducting carbon black or graphite 0.1mass%-20mass%, zirconium oxide nano powder 0.1mass% -5mass%, and nano metallic Ni powder 0.1mass%-3mass% and the gas ratio of the film is 45%-75% and the preferential one is 55%-65%. The method firstly uniformly mixes deionized water and organic monomer with cross-linking agent; then adds dispersant in the solution and blends uniformly to obtain a preset solution; then adds in raw materials and makes ball-milling mixing to make the pulp; adds defoaming agent in the pulp for vacuum defoaming; then adds in initiator and catalyst and blends uniformly, then obtains raw blanks on a casting machine by molding, curing and defilming, and then makes weak oxidizing atmosphere thermal treatment to obtain the target porous electrode film. The invention has simple molding process, short molding time, easy operation, good film thickness controllability, and developed medium holes.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

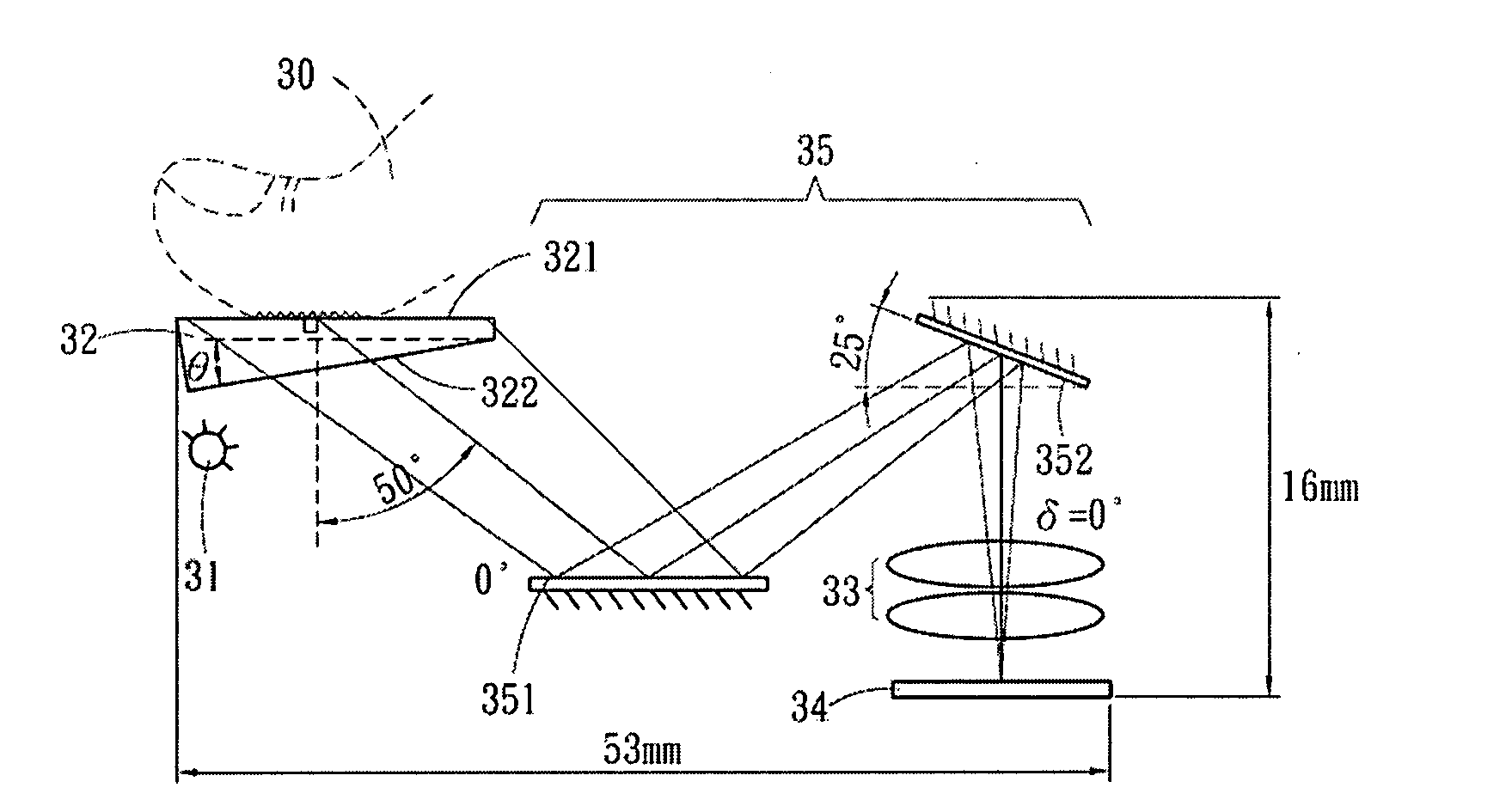

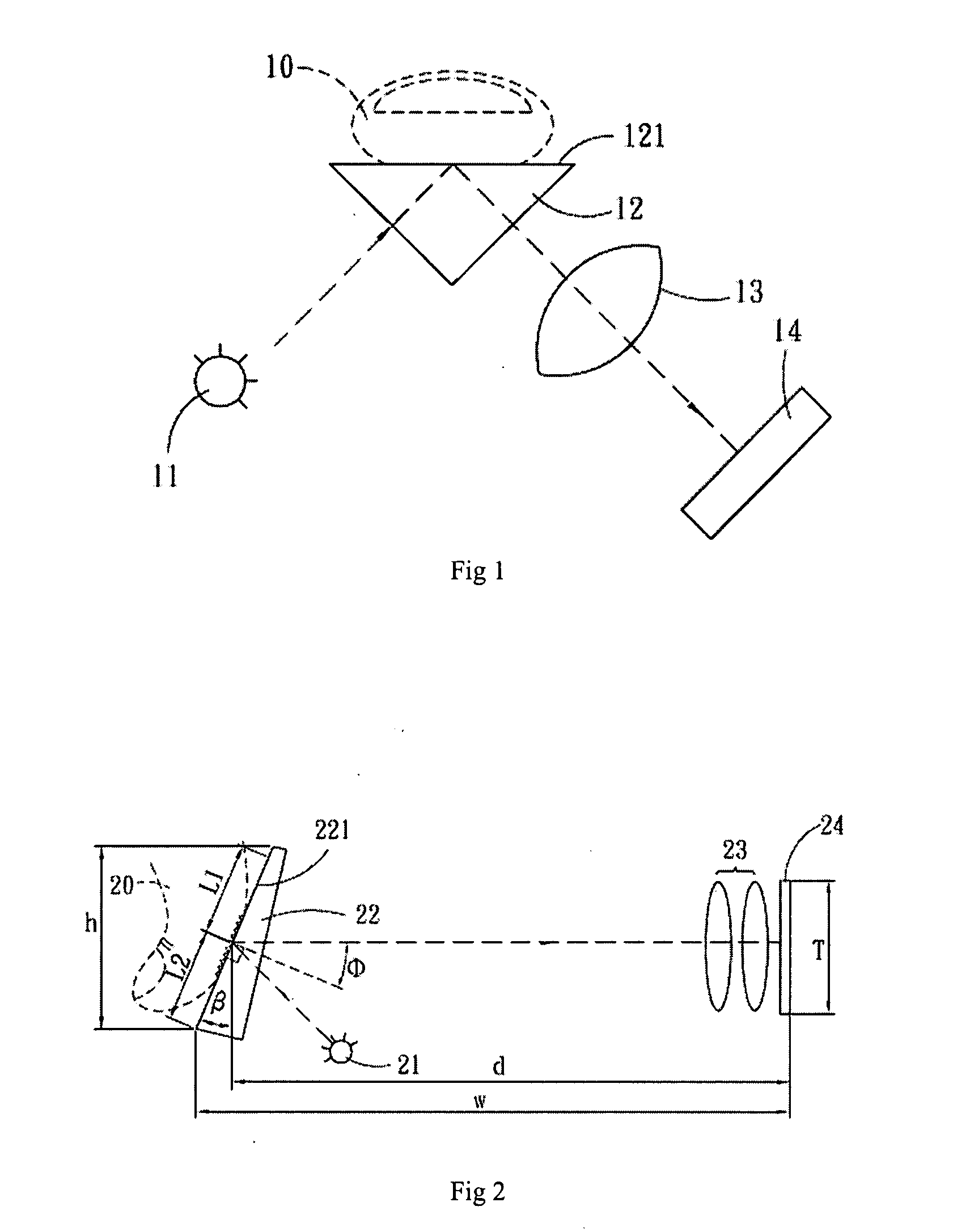

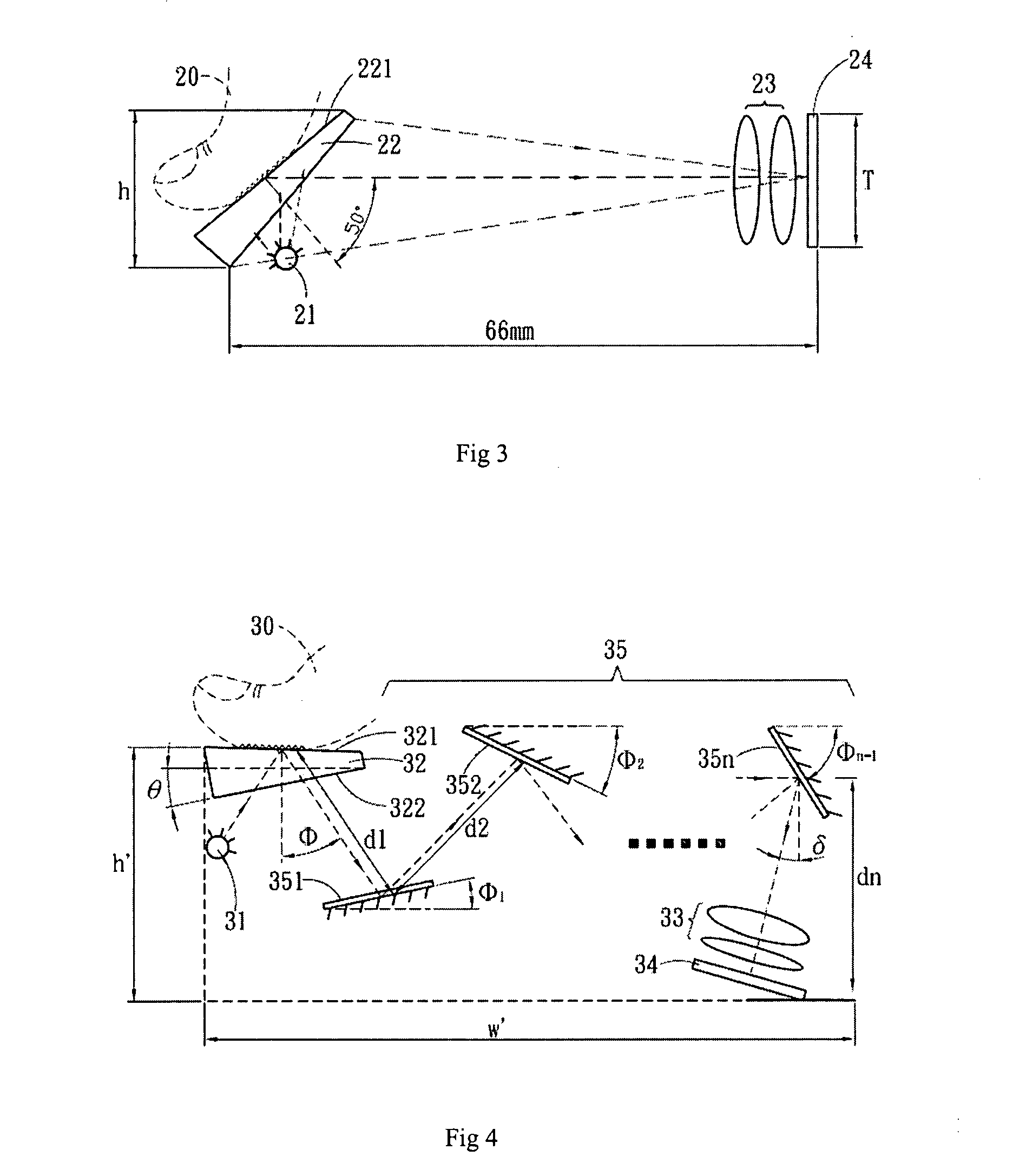

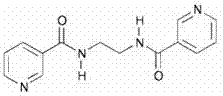

Fingerprint identification system

InactiveUS20080239285A1Long production cycleReduce outputCharacter and pattern recognitionImage planeFingerprint

A fingerprint ID system providing function of compressed volume of the fingerprint ID system is comprised of adding a reflection device group between fingerprint plane of the device pervious to light and imaging plane of an image sensor; and the device pervious to light and a flat reflection plane group is integrated into one device for reducing the size of the fingerprint ID system and significantly upgrading automated precision assembly and easier alignment of devices to effectively reduce production cost and shorten production cycle.

Owner:CHUAN LIANG IND

Preparation method of graphite phase carbon nitride@MOF nano-crystals and application thereof

InactiveCN107576714ASimple processEasy to operateMaterial nanotechnologyNanosensorsChemistryMetal-organic framework

The invention discloses a preparation method of graphite phase carbon nitride@MOF nano-crystals and application for detecting chiral drug enantiomers based on a composite material, belonging to the technical fields of nanometer materials, metal organic frameworks, analytical chemistry and chiral sensing detection. The preparation method comprises the following main steps: blending an aqueous solution of g-C3N4@Co(II) and an alkaline aqueous solution of H2BDC at a room temperature, adding a DMA solution of a ligand L so as to prepare gel, aging, separating, washing and drying the gel, thereby obtaining the product. A graphite phase carbon nitride@MOF nano-crystal sensor constructed by adopting a hybrid material is used for sensitive detection of the content of the chiral drug enantiomers.

Owner:UNIV OF JINAN

Middle frame of liquid crystal display device and liquid crystal display device

InactiveCN102608783AReliable positioningLong production cycleMechanical apparatusLight guides for lighting systemsLiquid-crystal displayEngineering

The invention discloses a middle frame of a liquid crystal display device and the liquid crystal display device. The middle frame of the liquid crystal display device comprises a connecting portion and a buffer portion, wherein the connecting portion corresponds to an incidence side of the liquid crystal display device, and the buffer portion is fixedly connected with the connecting portion and corresponds to a non-incidence side of the liquid crystal display device. The connecting portion is made of a hard material, and the buffer portion is made of a soft material. The middle frame of the liquid crystal display device can be directly used for clamping a light guide plate and achieving positioning of the light guide plate. Besides, the connecting portion is made of a plastic material which has a certain hardness, the flatness of the whole middle frame can be maintained, the connecting portion corresponds to the position of a light source, and the plastic material has a certain high temperature resistance capability. An existing middle frame is ordinarily formed by plastic injection, the manufacturing cycle of a plastic injection die is long, and the cost of the plastic injection die is high. The connecting portion and the buffer portion can respectively undergo die sinking, a die structure is simplified, and the middle frame is favorable for cost reduction.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

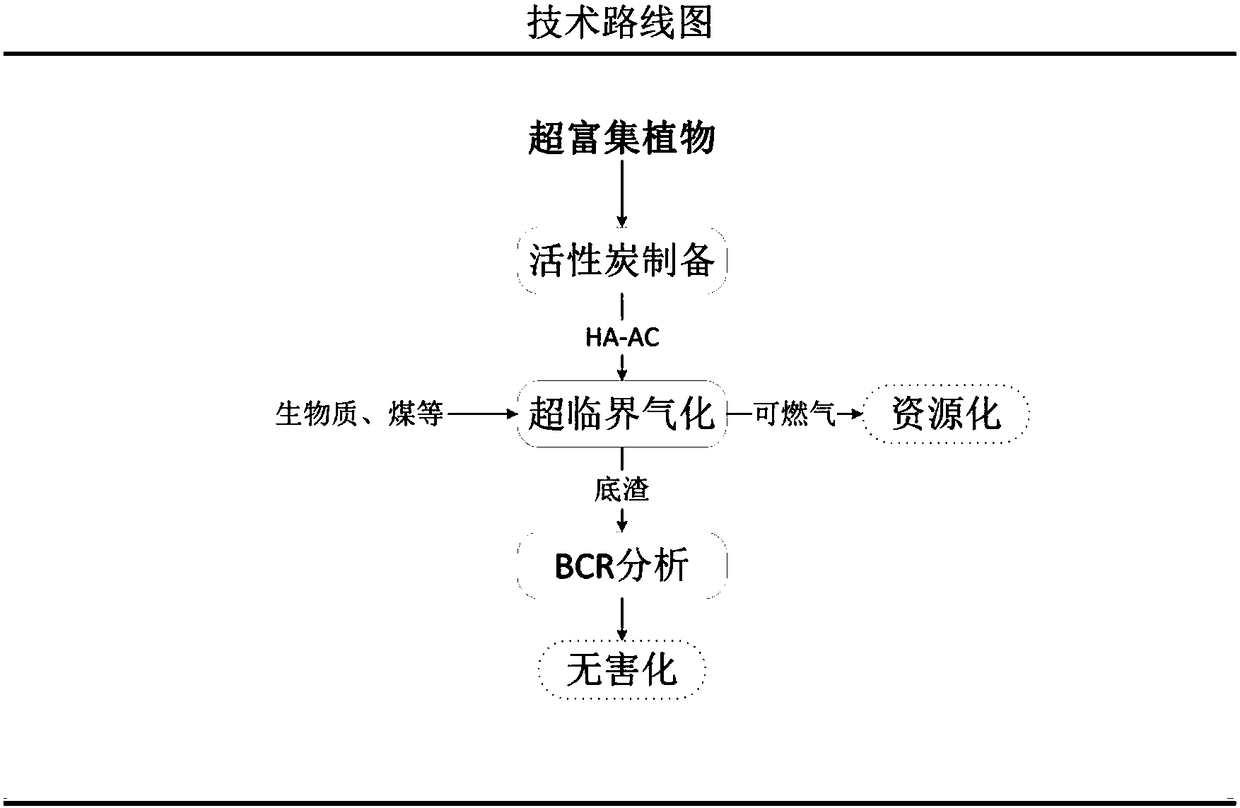

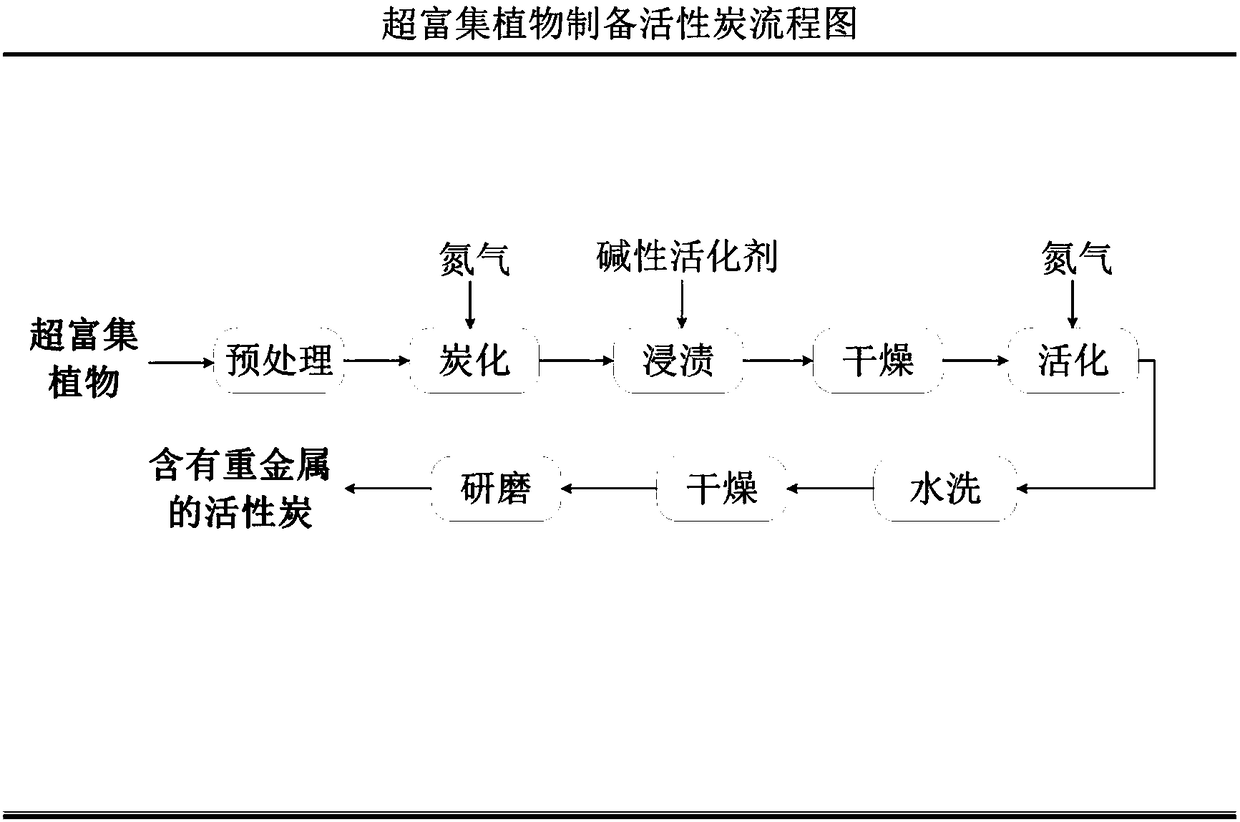

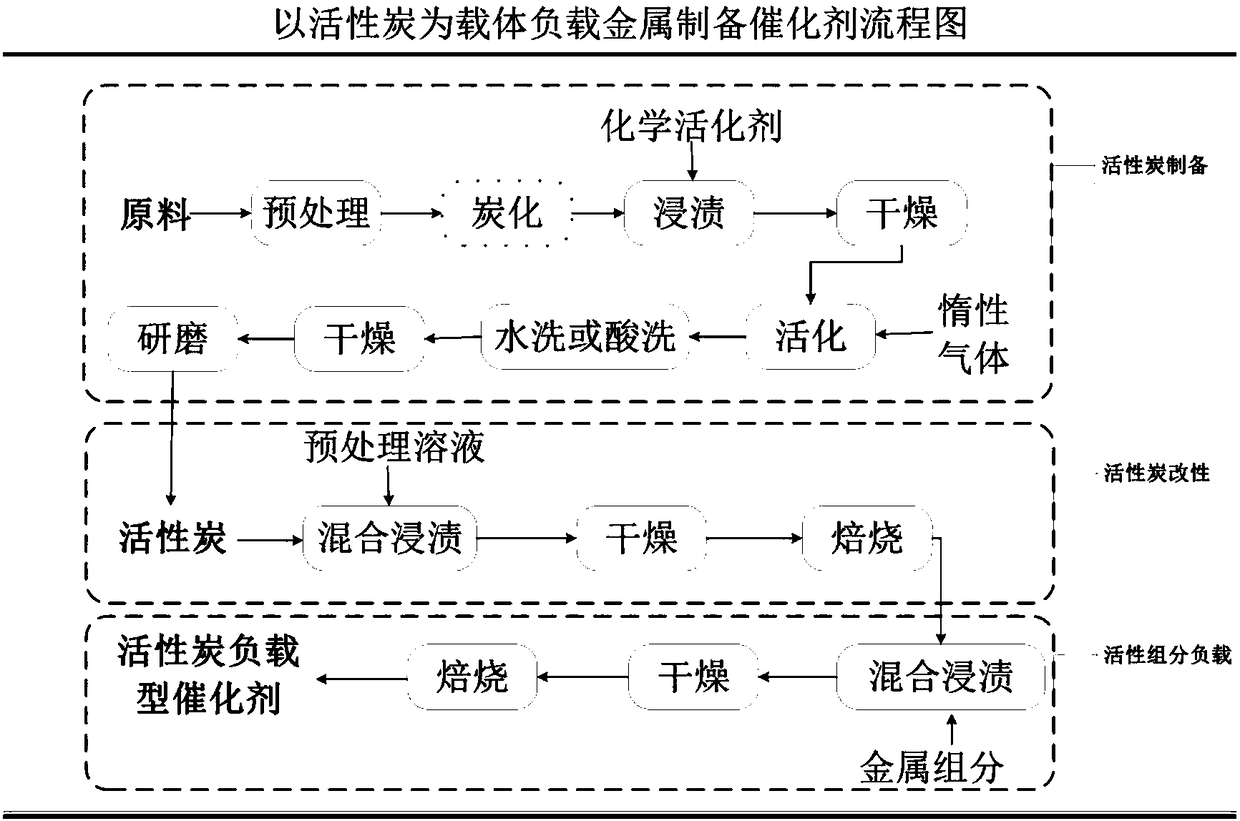

High-quality harmless utilizing method of hyperaccumulator

ActiveCN108485692ARealize resource processingSimple processProcess control/regulationProductsActivated carbonChemistry

The invention discloses a high-quality harmless utilizing method of a hyperaccumulator. The high-quality harmless utilizing method comprises the following steps: smashing and drying the hyperaccumulator, and sieving through a sieve of which the density is 100 meshes; carbonizing at a carbonization temperature being 450 to 550 DEG C and in carbonization time being 25 to 35 minutes, thus obtaining acarbonized material; immersing the carbonized material by using an alkaline solution of which the mass percentage is 45 to 55 percent; drying at 90 to 120 DEG C for 10 to 15 hours after immersing for20 to 28 hours, thus obtaining an amorphous particulate carbon block; activating the amorphous particulate carbon block into an activated carbon coarse product under a nitrogen atmosphere, wherein the activating temperature is 750 to 850 DEG C, and the activation time is 25 to 35 minutes; drying for 10 to 15 hours, thus obtaining metal-containing activated carbon with a catalytic effect; grindingthe activated carbon, thus obtaining an activated product HA-AC; adding 5 to 15 percent of the activated carbon product HA-AC to biomass or other reaction raw materials; putting a swelled material ina supercritical reaction kettle, and carrying out sealing reaction at the reaction temperature being 380 to 600 DEG C and the reaction pressure being 22.1 to 30 MPa, thus obtaining a hydrogen-rich gas. The high-quality harmless utilizing method disclosed by the invention has the advantages that additional metal loading is not required, a complicated preparation technology and a longer preparationperiod are not required, heavy metal can be fully stabilized, and secondary pollution can be avoided.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Preparation method and application of ternary nano composite material based on MOF

InactiveCN107589160AReduce dosageIncrease costMaterial electrochemical variablesEnantiomerMetal-organic framework

The invention discloses a preparation method of a ternary nano composite material based on MOF and an application of the composite material for detecting chiral drug enantiomers, and belongs to the technical fields of nanomaterials, metal organic frameworks, analytical chemistry and chiral sensing detection. The preparation method comprises the main steps of firstly preparing graphite-phase C3N4 supported metal organic framework [(AgL)ClO4]n nano crystals, continuing to add potassium bromide, and carrying out in situ reduction to prepare the ternary nano composite material g-C3N4@MOF@Ag basedon MOF. The chiral drug enantiomers are sensitively detected by a sensor constructed by the composite material.

Owner:UNIV OF JINAN

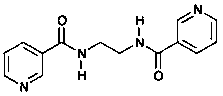

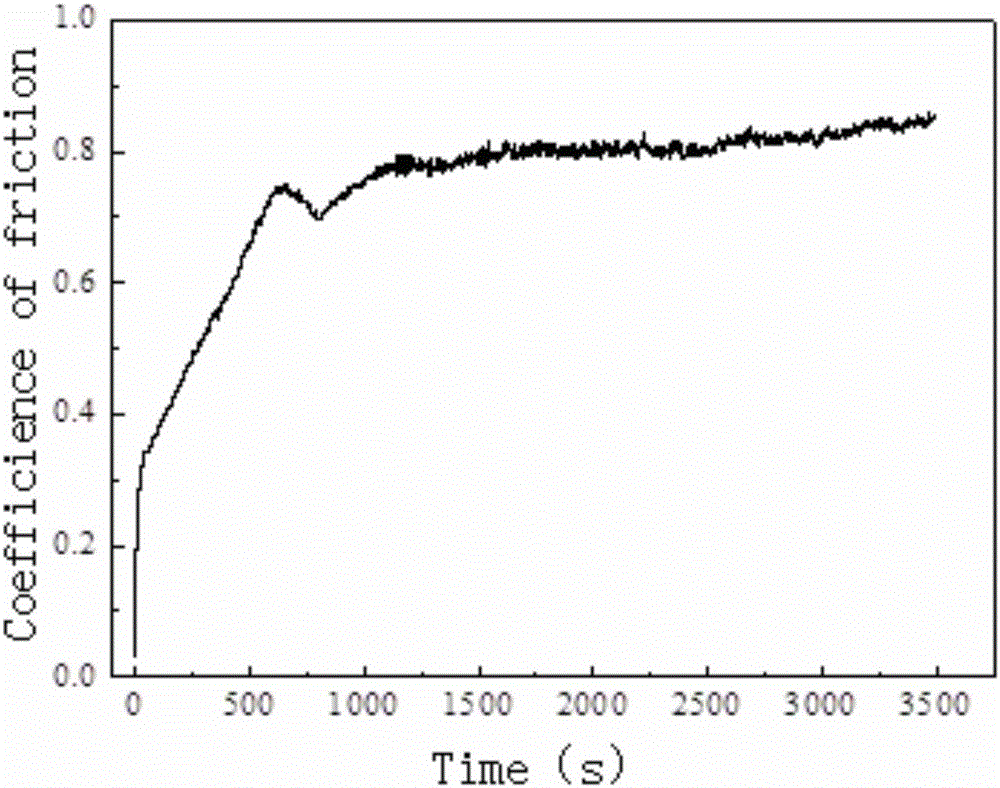

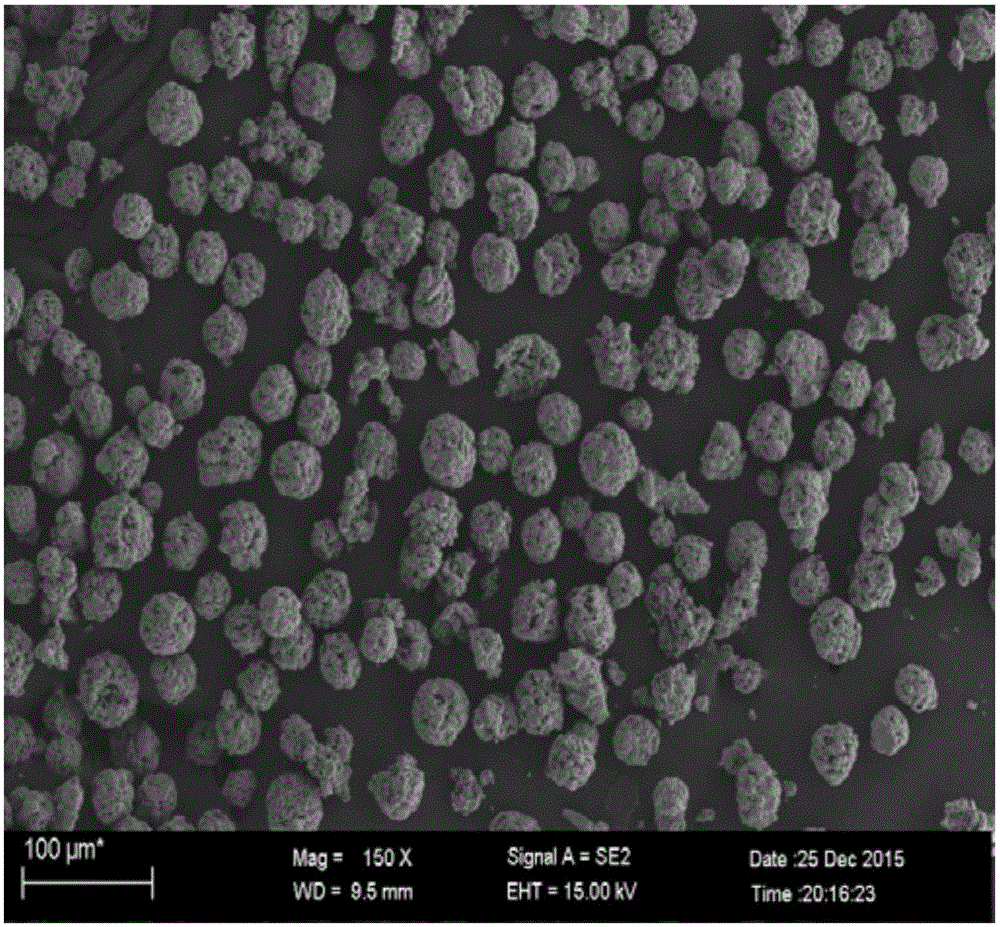

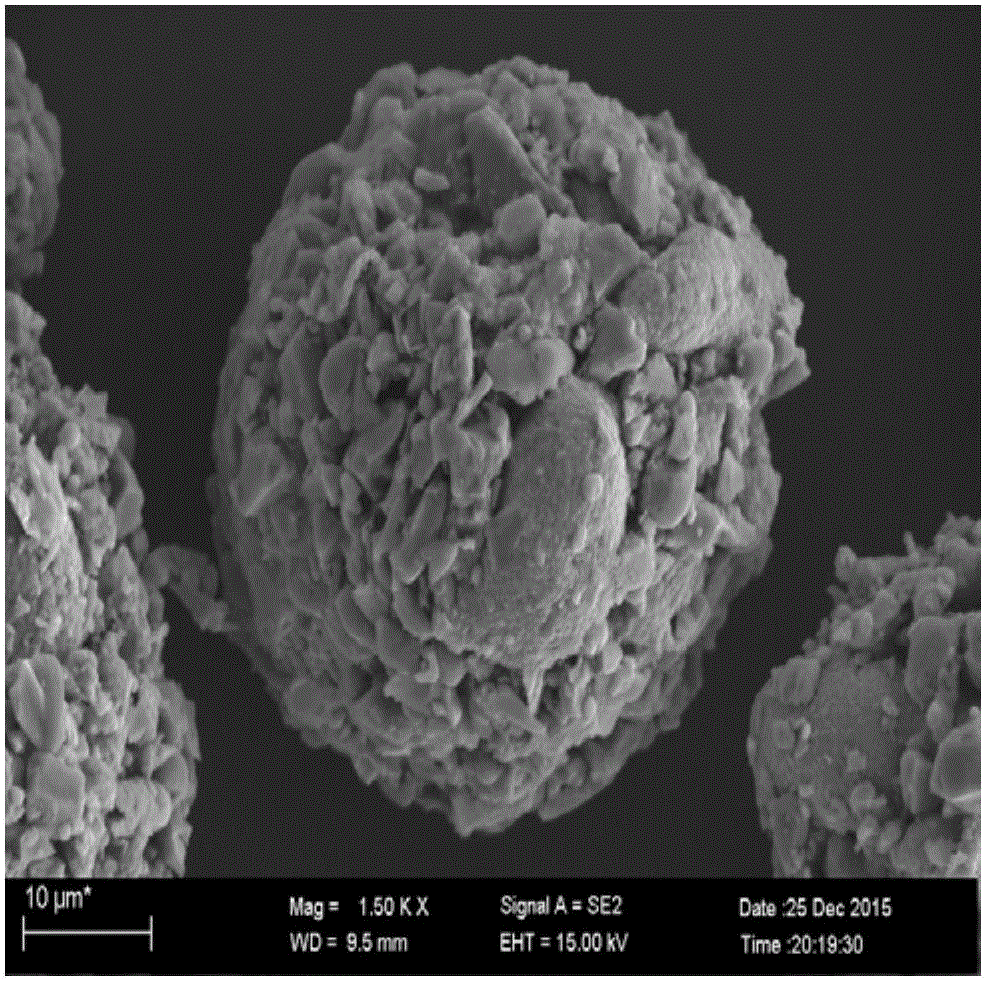

Boride metal ceramic coating material and preparation method

The invention discloses a boride metal ceramic coating material and a preparation method. According to the boride metal ceramic coating material and the preparation method, a centrifugal spraying and drying method is used for preparing boride metal ceramic powder which comprises, by mass, 60-80% of TiB2 powder, and 20-40% of Ni powder and Cr powder. The boride metal ceramic powder is made to have a certain bonding strength through a vacuum heat treatment method, and the surface of a metal substrate is coated with the boride metal ceramic powder through an HVOF method. A coating prepared according to the technical scheme is compact in structure, even in boride distribution, of a typical layered structure and excellent in mechanical property. Accordingly, the tribological property and the high-temperature oxidation resistance of the metal substrate are further improved.

Owner:TIANJIN SPECIAL EQUIP INSPECTION INST +1

Preparation method of molybdenum disulfide-tourmaline composite material

InactiveCN108554424ALow priceAbundant resourcesCell electrodesCatalyst activation/preparationHigh energyMolybdenum disulfide

The invention provides a preparation method of a molybdenum disulfide-tourmaline composite material and relates to a composite material. The molybdenum disulfide-tourmaline composite material is prepared by a microwave hydrothermal method. The preparation method comprises the following steps: treating tourmaline, preparing a reactant raw material mixed liquid of molybdate, sulfide and tourmaline;pouring the reactant raw material mixed liquid into a polytetrafluoroethylene reaction kettle, placing the polytetrafluoroethylene reaction kettle into microwave hydrothermal equipment and completingmicrowave hydrothermal effective composition of the reactants; and washing and drying the product obtained by the microwave hydrothermal method to prepare the molybdenum disulfide-tourmaline compositematerial. The defects in the prior art for preparing the molybdenum disulfide composite material that the molybdenum disulfide composite material is liable to gather or stack again in the drying or annealing process as well as the defects of complex preparation process, long reaction cycle, high energy consumption and high cost are overcome.

Owner:HEBEI UNIV OF TECH

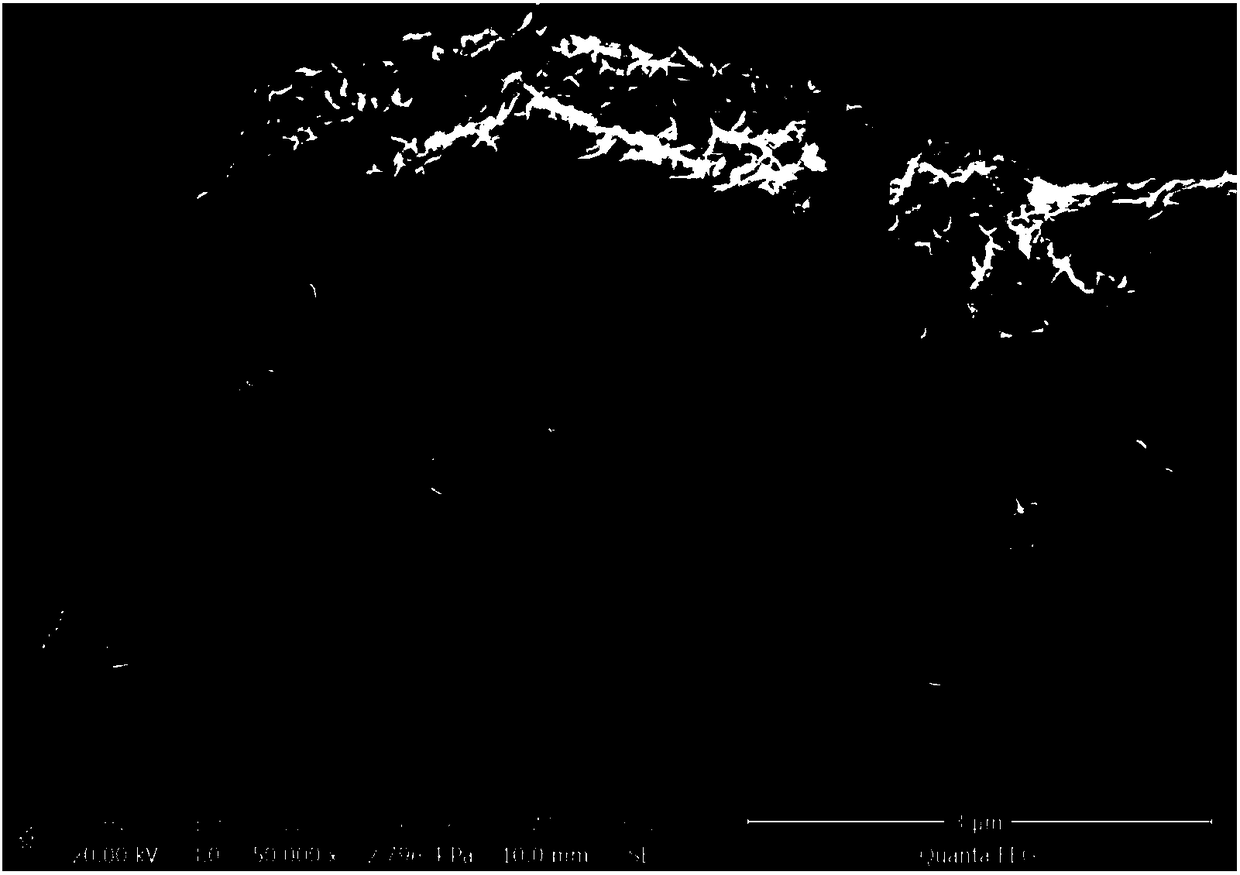

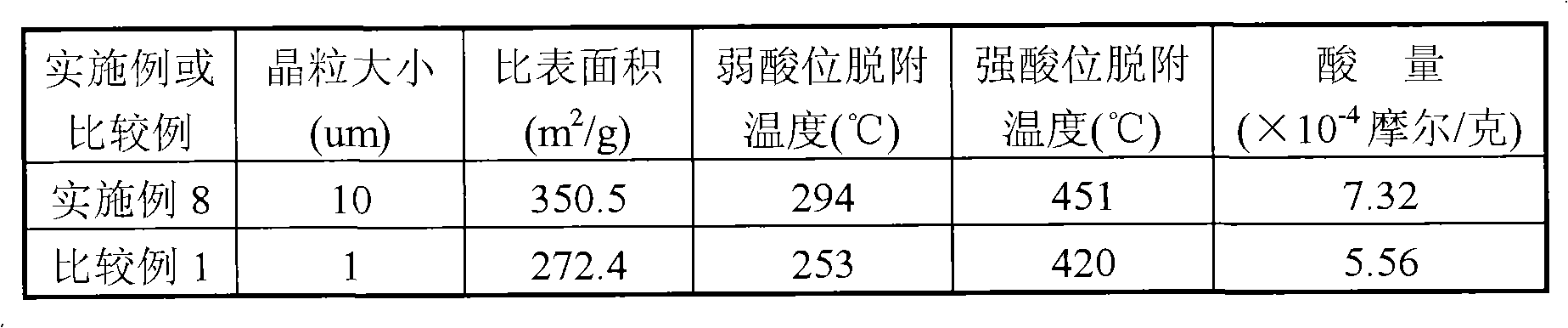

Method for preparing small crystal grain molecular sieve

ActiveCN102372276AHigh activityLarge specific surface areaCrystalline aluminosilicate zeolitesMolecular sieveHydrothermal synthesis

The invention relates to a method for preparing a small crystal grain molecular sieve, and mainly solves the problems that: by the conventional method for preparing the small crystal grain molecular sieve, the hydrothermal synthesis is required, the period is longer, the small crystal grain molecular sieve cannot be continuously produced, the separation is difficult after synthesis and the synthetic cost is high. The problems are better solved by adopting the technical scheme that the method for preparing the small crystal grain molecular sieve comprises the following steps of: feeding synthesized large crystal grain molecular sieve raw materials into crushing equipment and performing physical crushing, and classifying products to obtain the small crystal grain molecular sieve; and the method can be used for the production of small crystal grain molecular sieves.

Owner:CHINA PETROLEUM & CHEM CORP +1

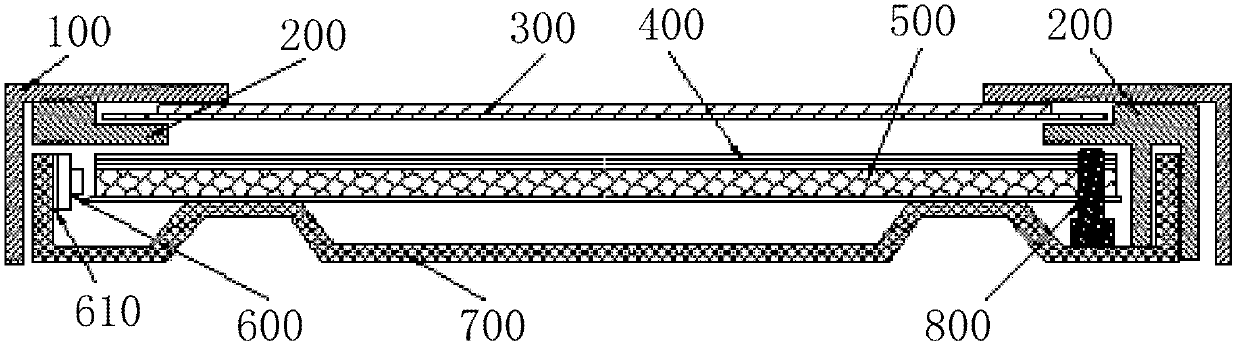

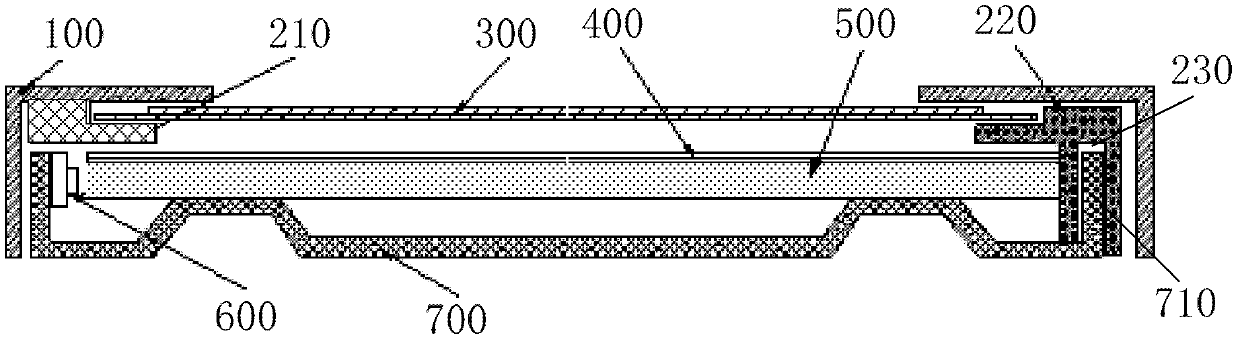

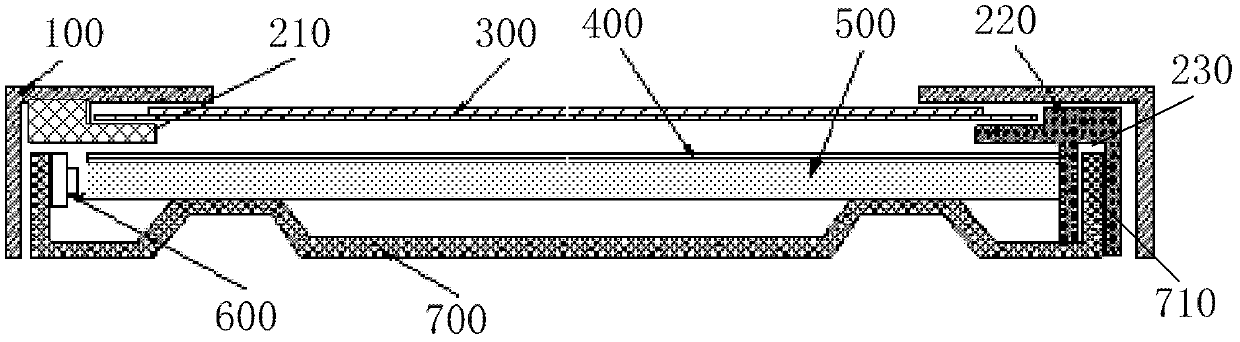

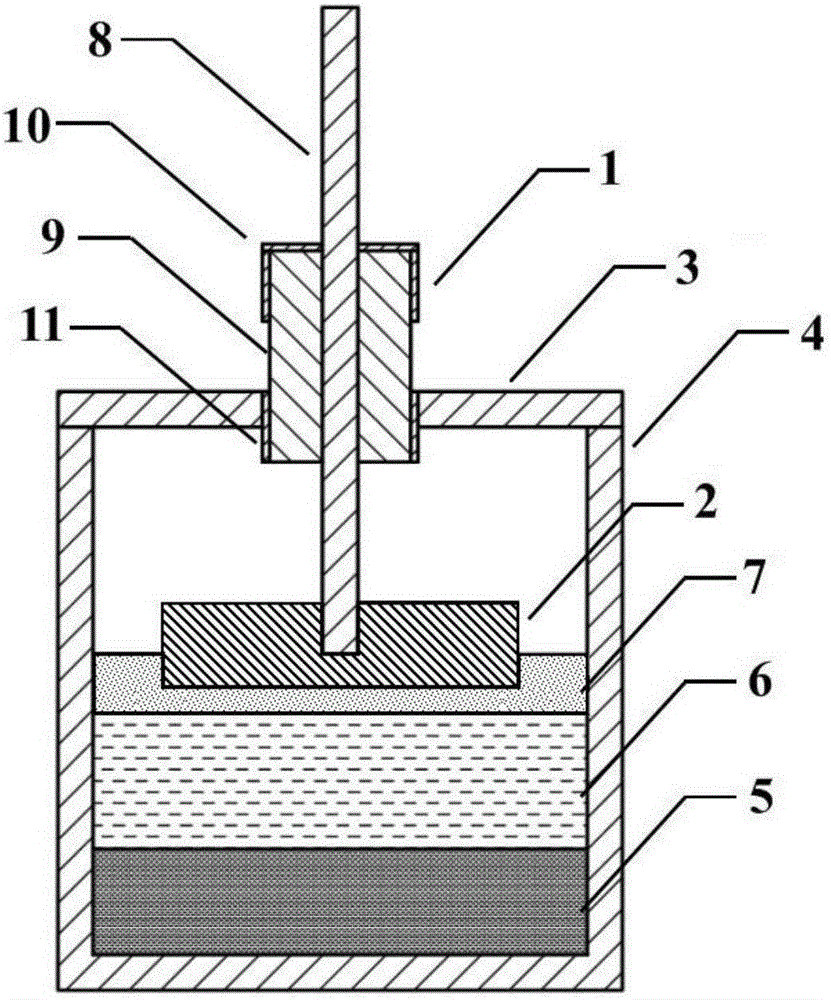

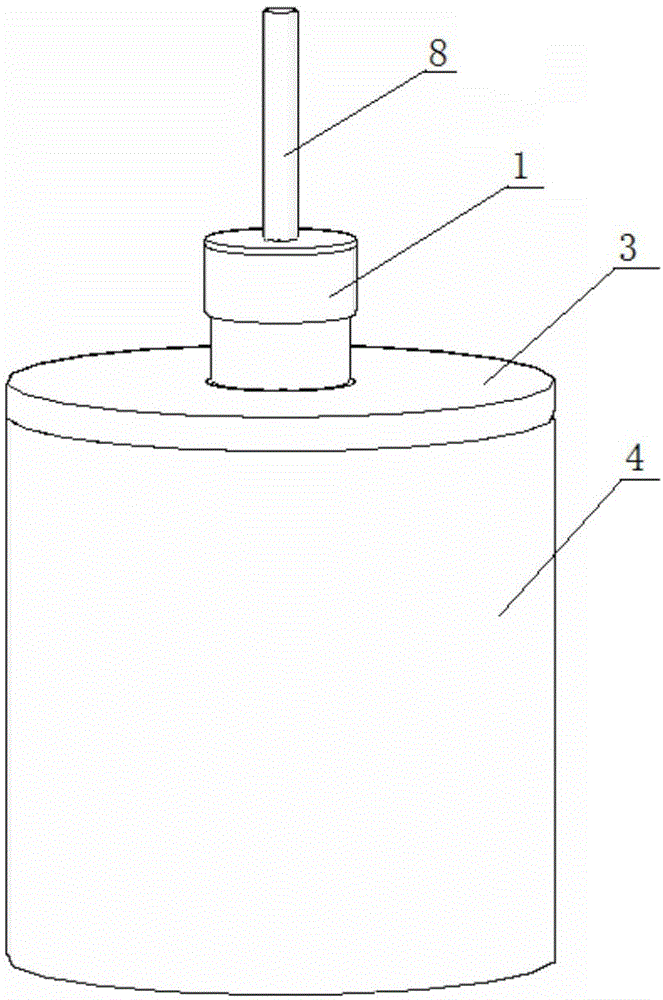

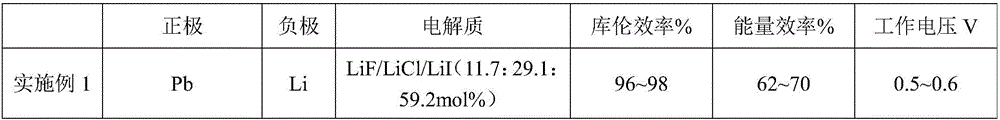

High-temperature fusant battery apparatus and preparation process thereof

ActiveCN106654072AGuaranteed uptimeEffective size controlFinal product manufactureSmall-sized cells cases/jacketsWorking lifeCarbide

The invention discloses a high-temperature fusant battery apparatus and a preparation process thereof. The high-temperature fusant battery apparatus comprises a ceramic sealing-in negative electrode column, a stainless steel negative electrode current collector, a stainless steel positive electrode cover plate and a stainless steel positive electrode shell, wherein the ceramic sealing-in negative electrode column is connected with the positive electrode cover plate to form a battery top cover; an electrode core is connected with the negative electrode current collector through screw threads to form a battery negative electrode; the battery top cover is tightly connected with the positive electrode shell to form a sealed battery cavity; a compact oxide insulating thin film and a carbide conductive thin film are formed on the inner wall and the bottom surface of the positive electrode shell through physical film-coating respectively; the ceramic sealing-in negative electrode column consists of the electrode core, a stainless steel coating layer, an insulating ceramic sleeve, and an upper transitional ring and a lower transitional ring, wherein the lower transitional ring is tightly welded with the battery shell to form the sealed battery cavity; and the lower end of the electrode core is connected with the negative electrode current collector to form the battery negative electrode. By adoption of the high-temperature fusant battery apparatus, problems existing in corrosion resistance and sealing of the battery at the high-temperature environment are solved; and meanwhile, the long-term cycling stability and working life of the battery are improved and prolonged.

Owner:CHINA XD ELECTRIC CO LTD

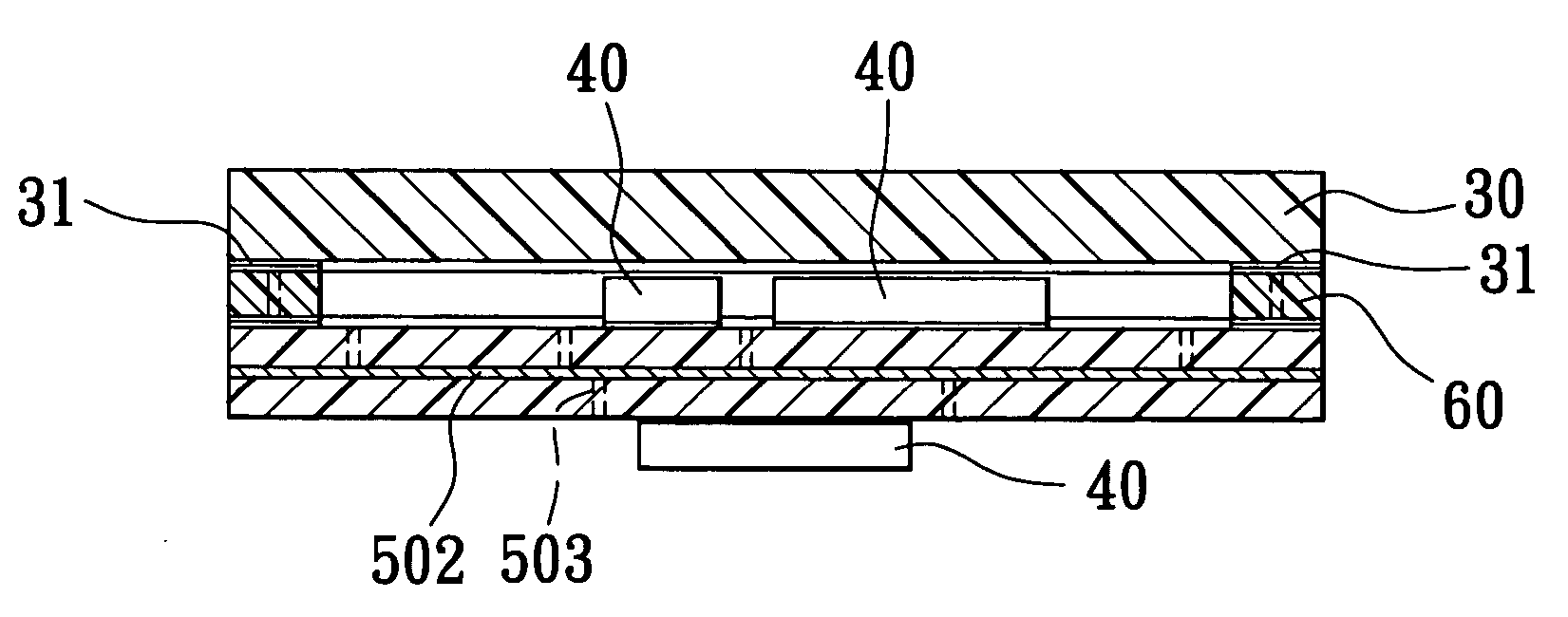

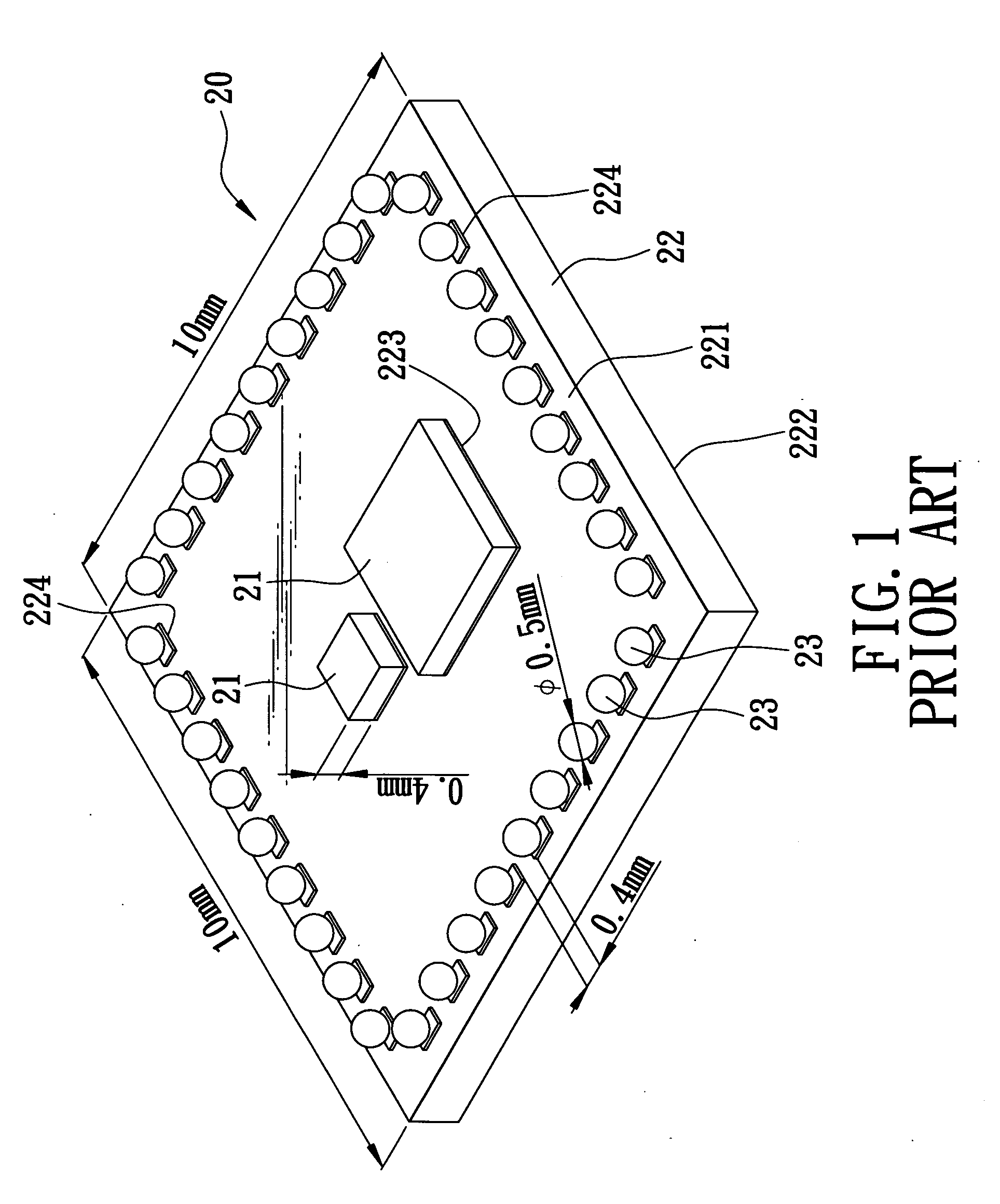

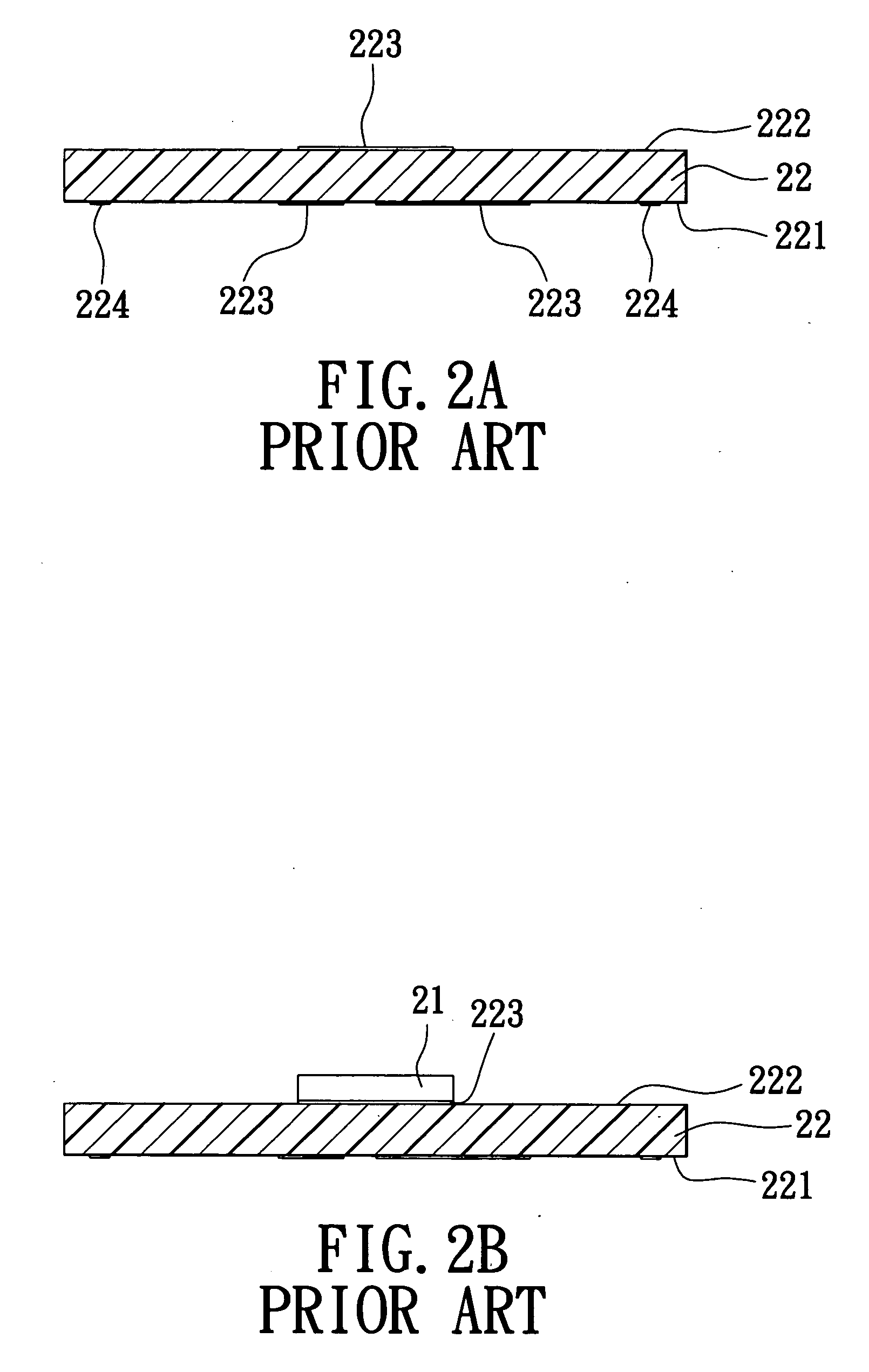

Miniaturized multi-chip module and method for manufacturing the same

ActiveUS20060249838A1High capital costLong production cycleSemiconductor/solid-state device detailsPrinted circuit aspectsIntegrated circuitElectrical connection

A miniaturized multi-chip module suitable for application to wireless transmission devices includes a substrate, integrated circuit chips mounted on and connected electrically to the substrate, and an interposer mounted on one surface of the substrate. The interposer cooperates with the substrate to confine a receiving space for receiving the integrated circuit chips on the surface of the substrate to which the interposer is attached, and is provided with conductors that are connected electrically to the substrate. Therefore, when the interposer is mounted on a circuit board, the conductors serve as external electrical connections for the integrated circuit chips. A method for manufacturing the miniaturized multi-chip module is also disclosed.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD

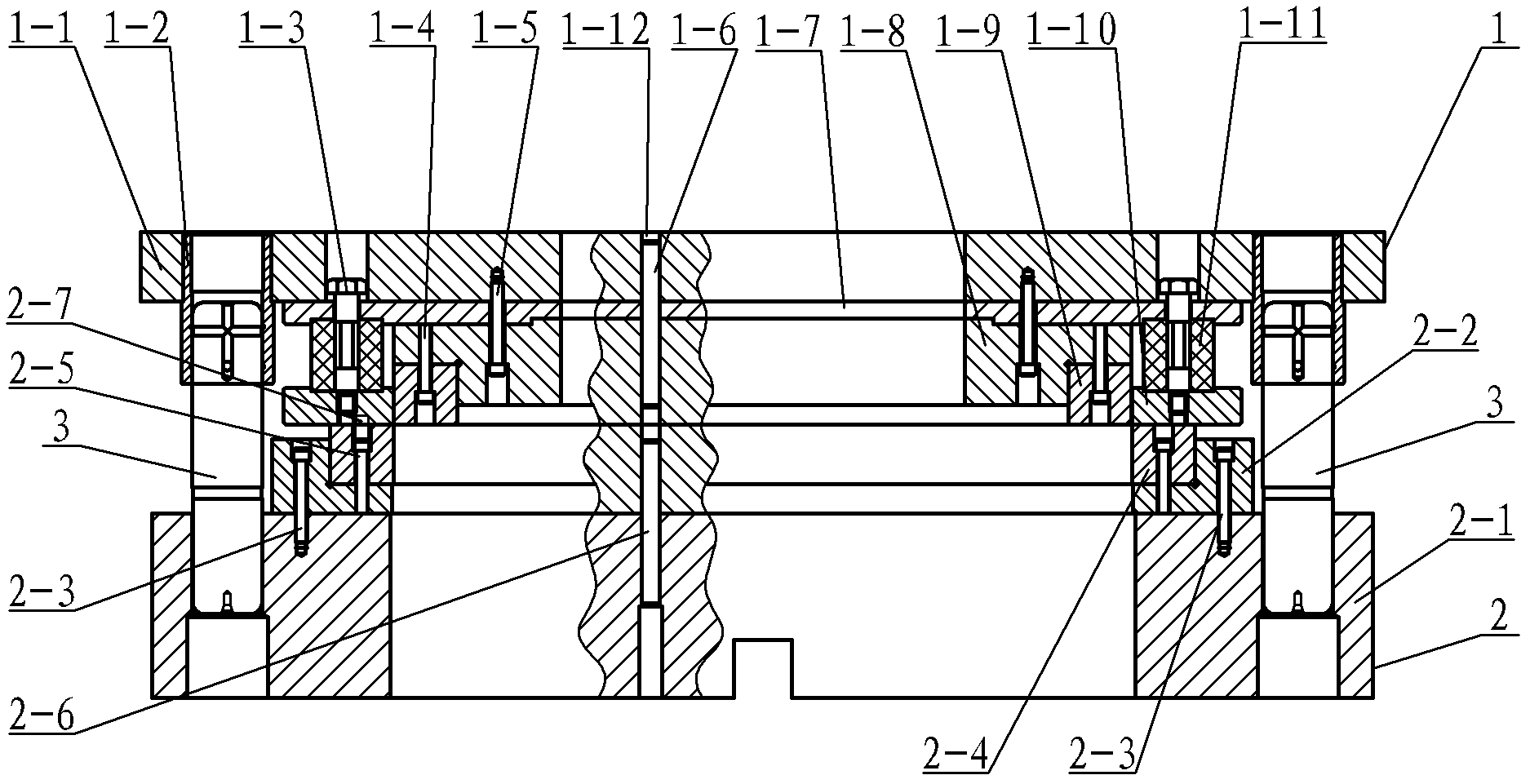

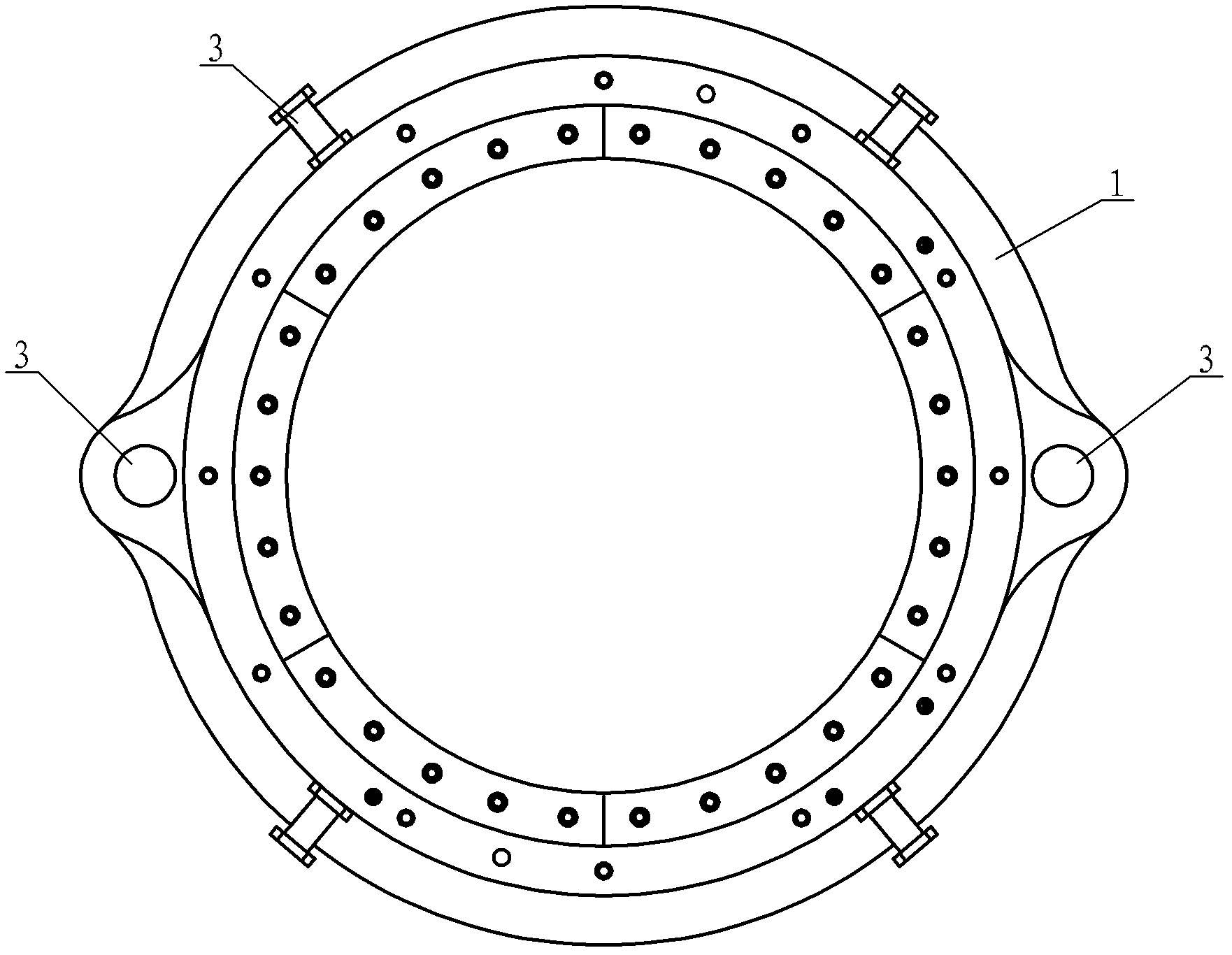

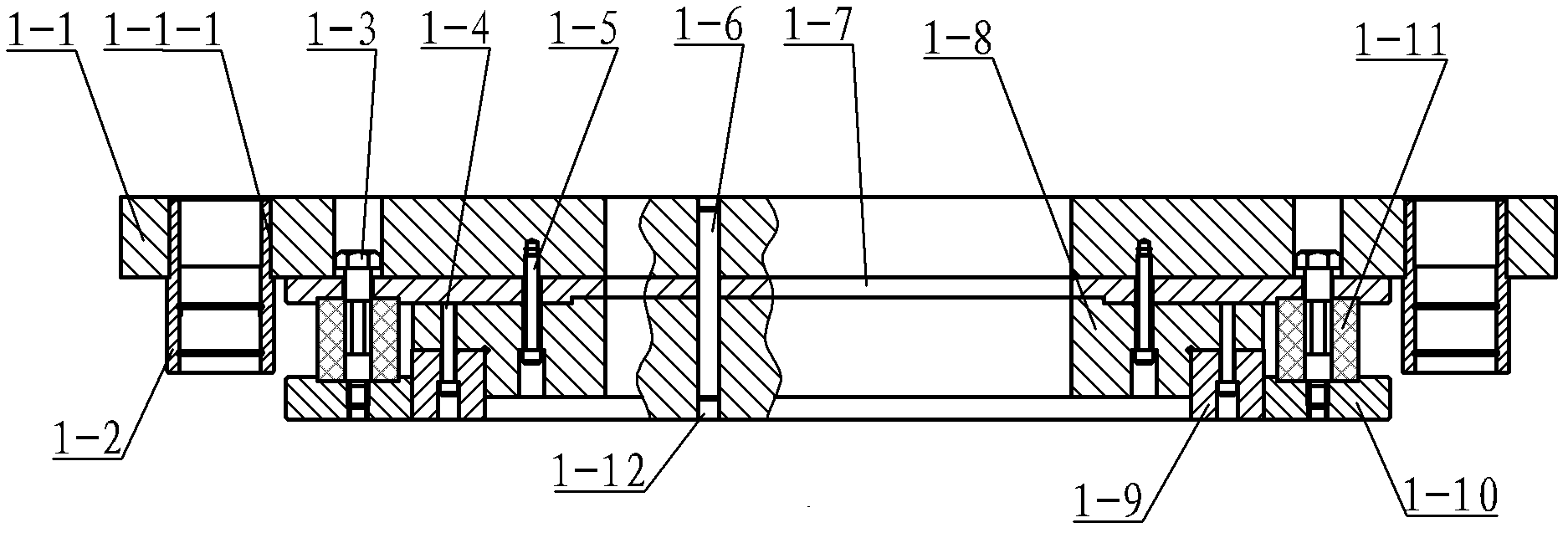

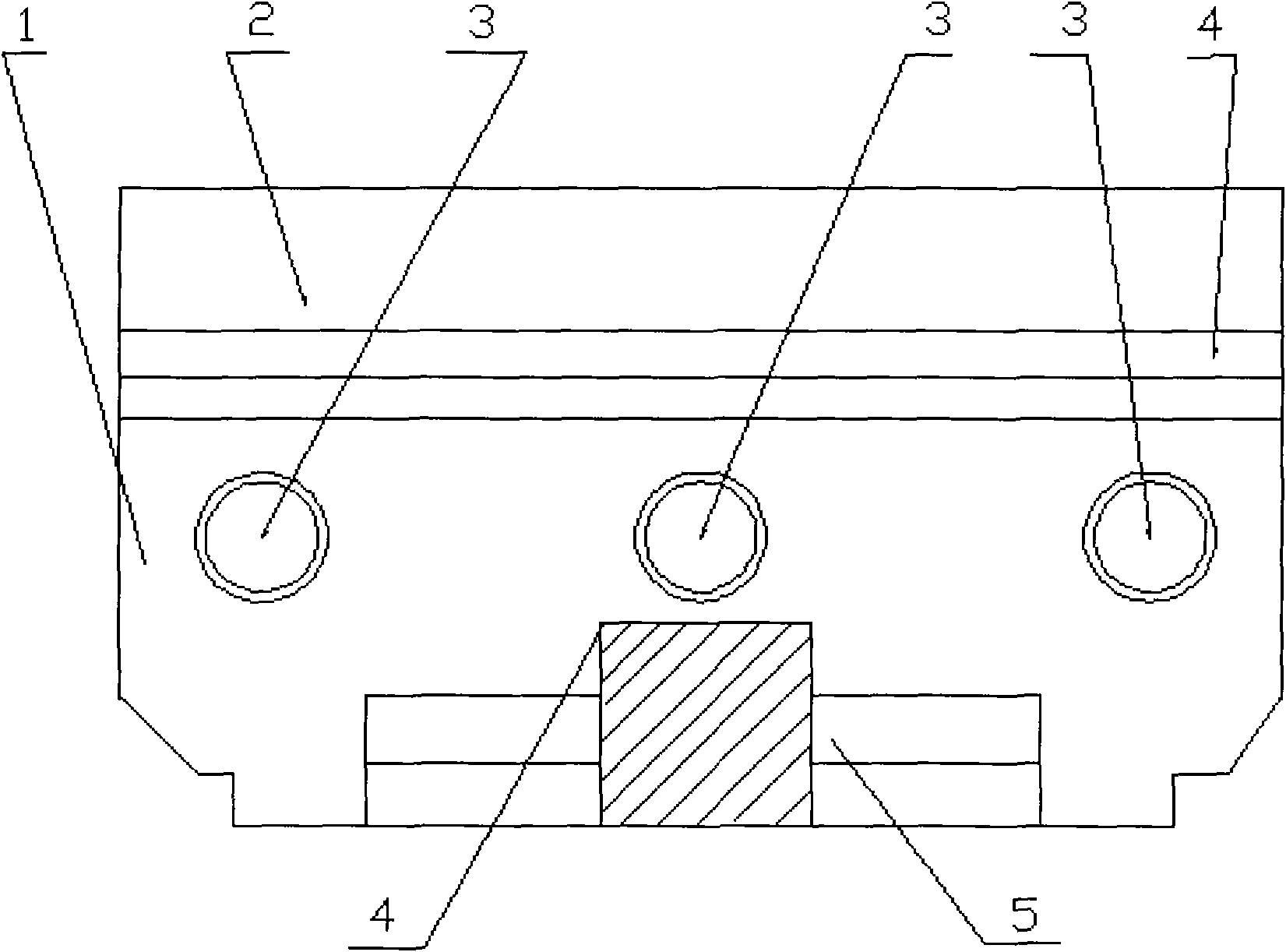

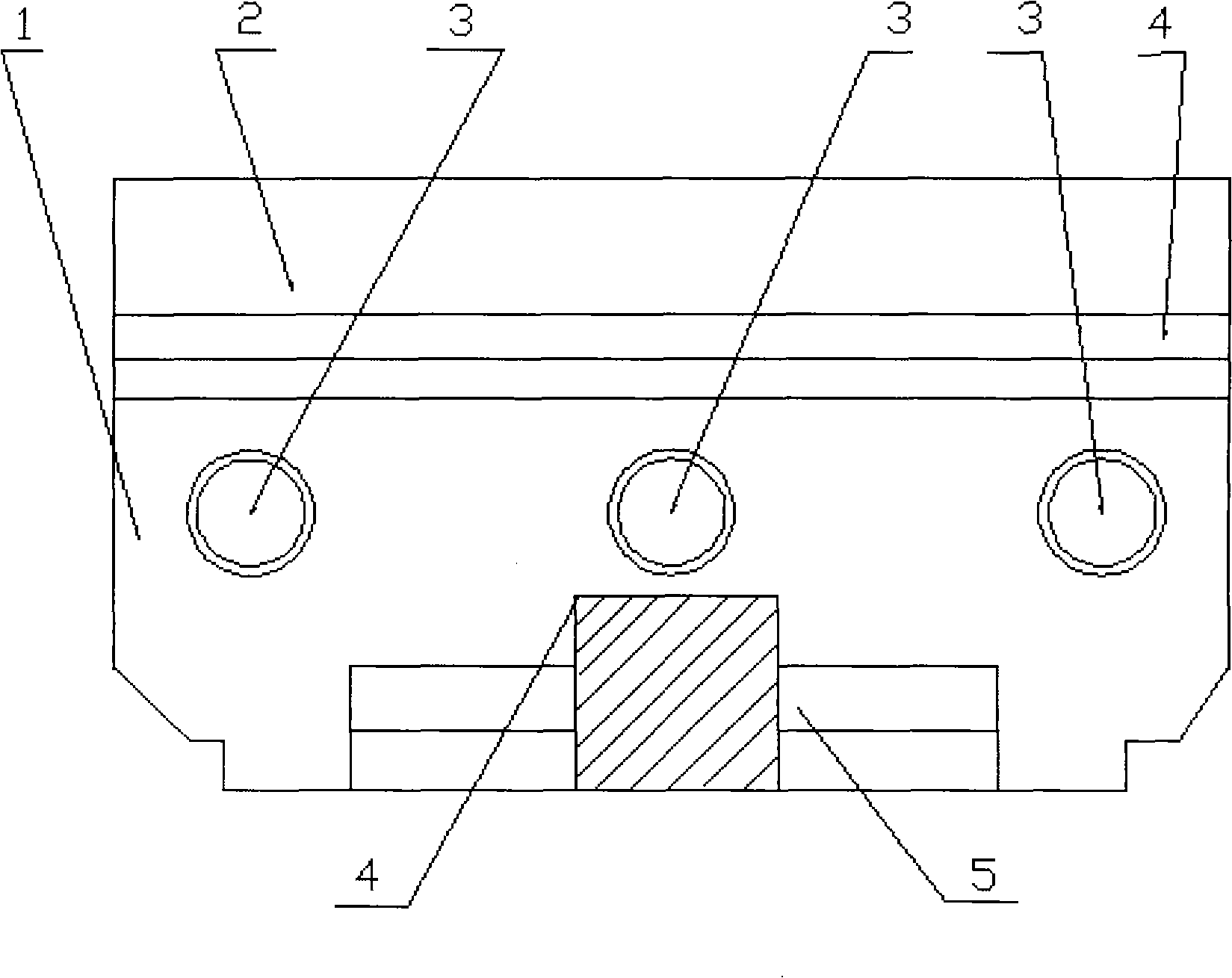

Large-scale embedded blanking mould

ActiveCN102962335ASolve the overall processing difficultiesSolve processing difficultiesShaping toolsEngineeringSharpening

The invention discloses a large-scale embedded blanking mould, and relates to a blanking mould, aiming to solve the problems of materials waste, difficult manufacture, short service life of a mould, difficulty in sharpening, maintenance, assembly and disassembly during integrally manufacturing a large-scale blanking mould and a punch die. The mould comprises an upper die component, a lower die component and at least two guide columns, wherein the upper die component comprises an upper die seat, a terrace die pad, a terrace die fixing board, an unloading ring, at least two guide sleeves, two terrace die positioning pins, at least four embedded terrace dies, eight unloading rubbers, a plurality of unloading screws, a plurality of terrace die fixing screws, and a plurality of fixing screws, the lower die component comprises a lower die seat, an embedded female die fixing seat, a plurality of fixing seat fixing screws, at least four embedded female dies, a plurality of female die fixing screws, two female die positioning pins and at least two material guiding and blocking pins, one end of each guide column is arranged in the guide sleeve corresponding to the upper die component, and the other end of each guide column is arranged in the guide column hole corresponding to the lower die component. The mould is applied in the blanking of a large batch of thick board materials.

Owner:HARBIN JIANCHENG GRP

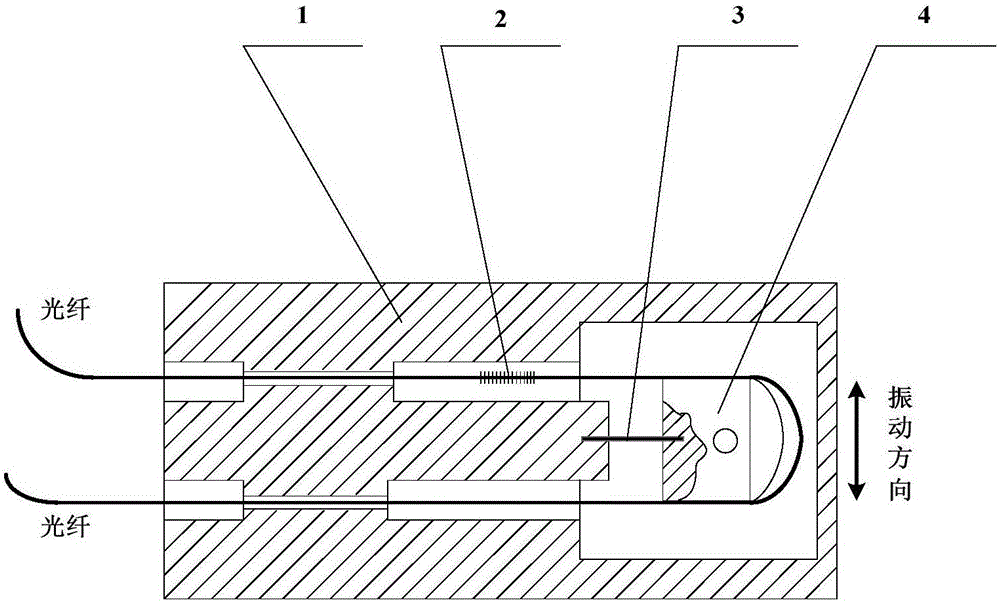

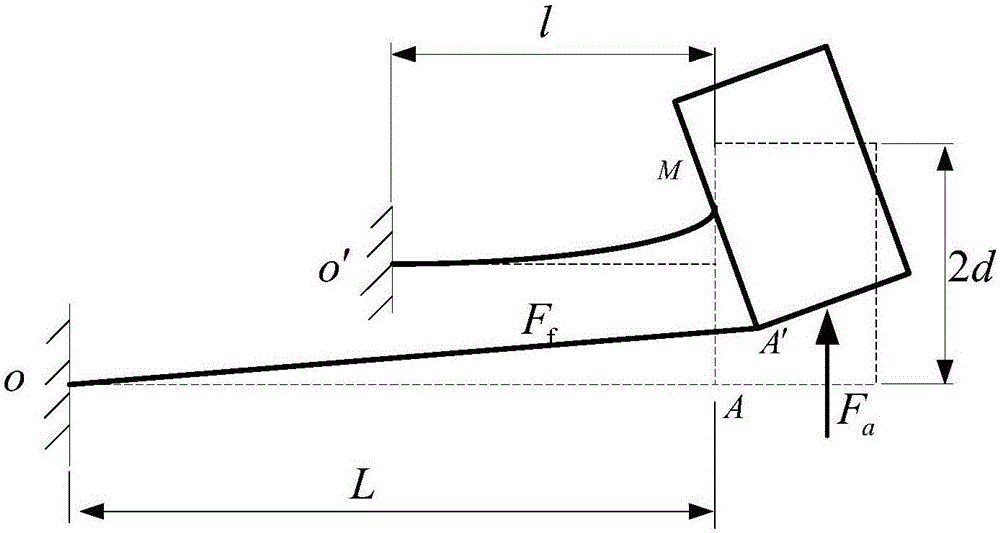

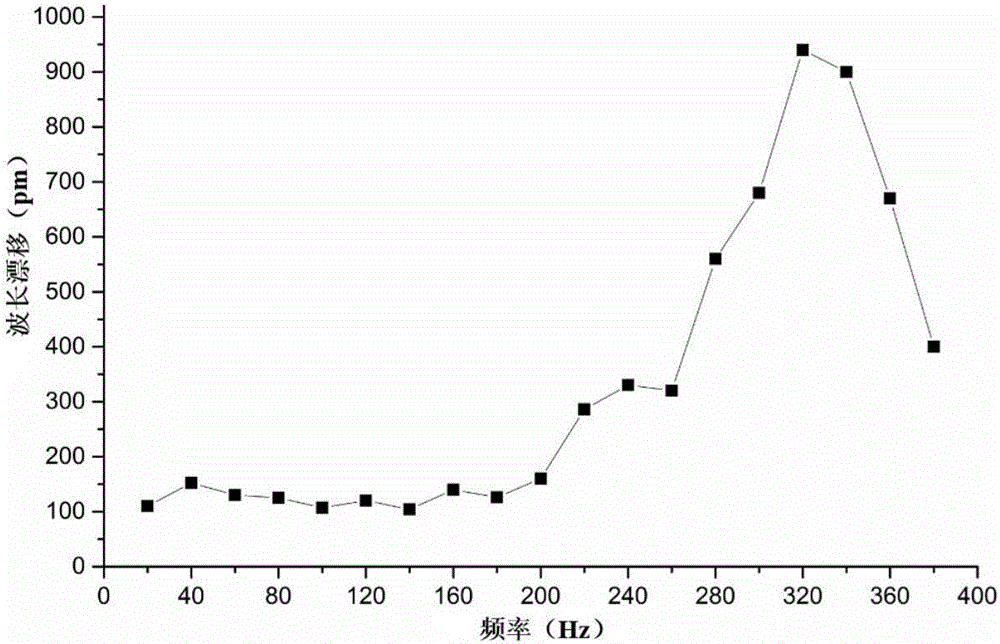

Manufacturing method of cantilever beam fiber grating accelerometer

The present invention provides a manufacturing method of a cantilever beam fiber grating accelerometer. The sensor comprises a substrate, a spring leaf, a quality block, a side cover and a fiber grating. The substrate, the spring leaf and the quality block are assembled through mechanical coordination and laser welding to form a cantilever structure. The fiber grating performs etching on the G.657 fiber, the fiber tension performance is improved through adoption of macromolecule ultrathin coating, and the epoxy resin dispensing is employed to fix the positions between the fiber grating and substrate and the quality block to assemble a fiber grating acceleration sensor. A balance weight hole is processed on the quality block in advance, the assembled sensor is calibrated, and the dispensing or machining is performed on the balance weight hole to flexibly regulate the sensitivity and the resonant frequency point of the sensor to optimize the performance index of the acceleration sensor. The manufacturing method of the cantilever beam fiber grating accelerometer simplifies the design and processing requirement of the acceleration sensor, simple in operation method and high in practicality, and the made sensor is high in sensitivity, small in insertion loss and excellent in performace.

Owner:湖北三峡物联网知识产权运营有限公司

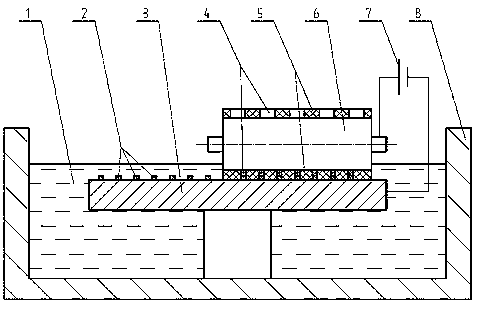

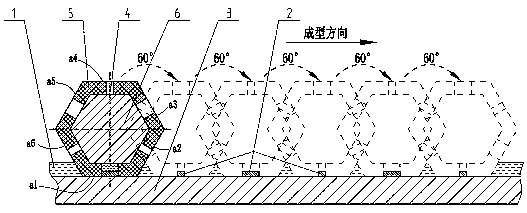

Regular polygonal cylinder anode and method for preparing large-area metal microstructure through electrodeposition

ActiveCN108893771AReduce size areaReduce manufacturing costElectrodesElectrochemistryMetal microstructure

The invention discloses a regular polygonal cylinder anode and a method for preparing a large-area metal microstructure through electrodeposition. The regular polygonal cylinder anode is composed of acylinder anode body with cross section being a regular polygon and an electric insulation mask with a hollow pattern array. The method for preparing the large-area metal microstructure through electrodeposition of the regular polygonal cylinder anode in tank liquid includes: closely fitting the regular polygonal cylinder anode above a conductive substrate to enable liquid level of electrolyte toonly immerse the mask hollow pattern array downmost below the regular polygonal cylinder anode; connecting an electrodeposition power source positive electrode with the regular polygonal cylinder anode and a negative electrode with the conductive substrate, and electrodepositing out a microstructure array copied to the mask hollow pattern array on the conductive substrate under action of electrochemistry; acquiring multiple columns of microstructure arrays copied to different mask surfaces at different positions by clockwise or anticlockwise rotating the polygonal cylinder anode so as to realize modular forming of the large-area metal microstructure.

Owner:HENAN POLYTECHNIC UNIV

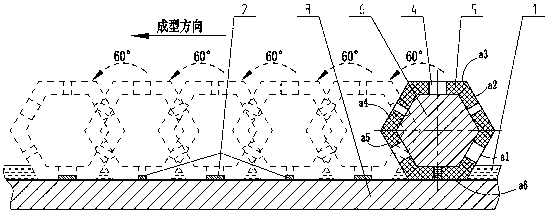

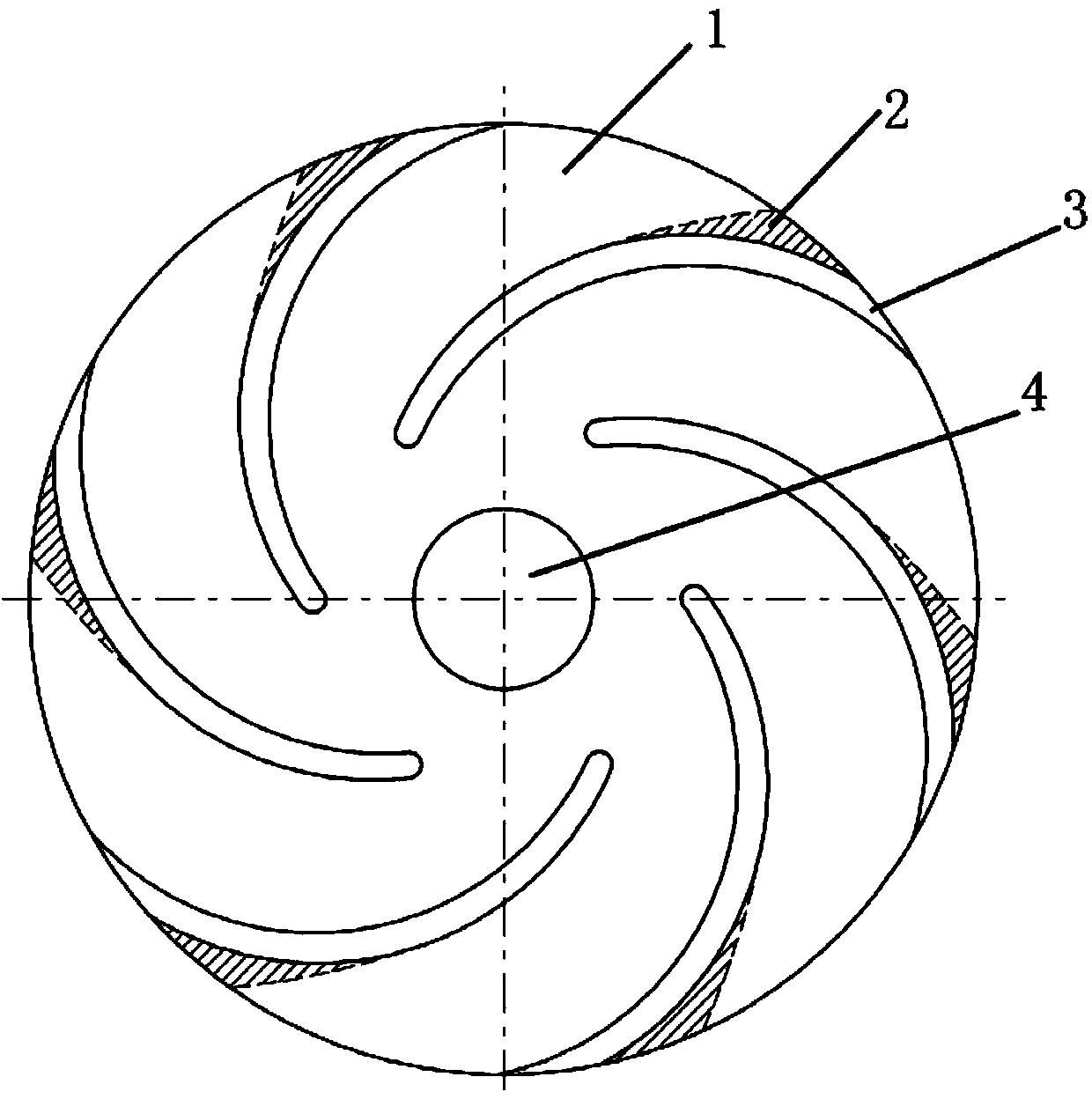

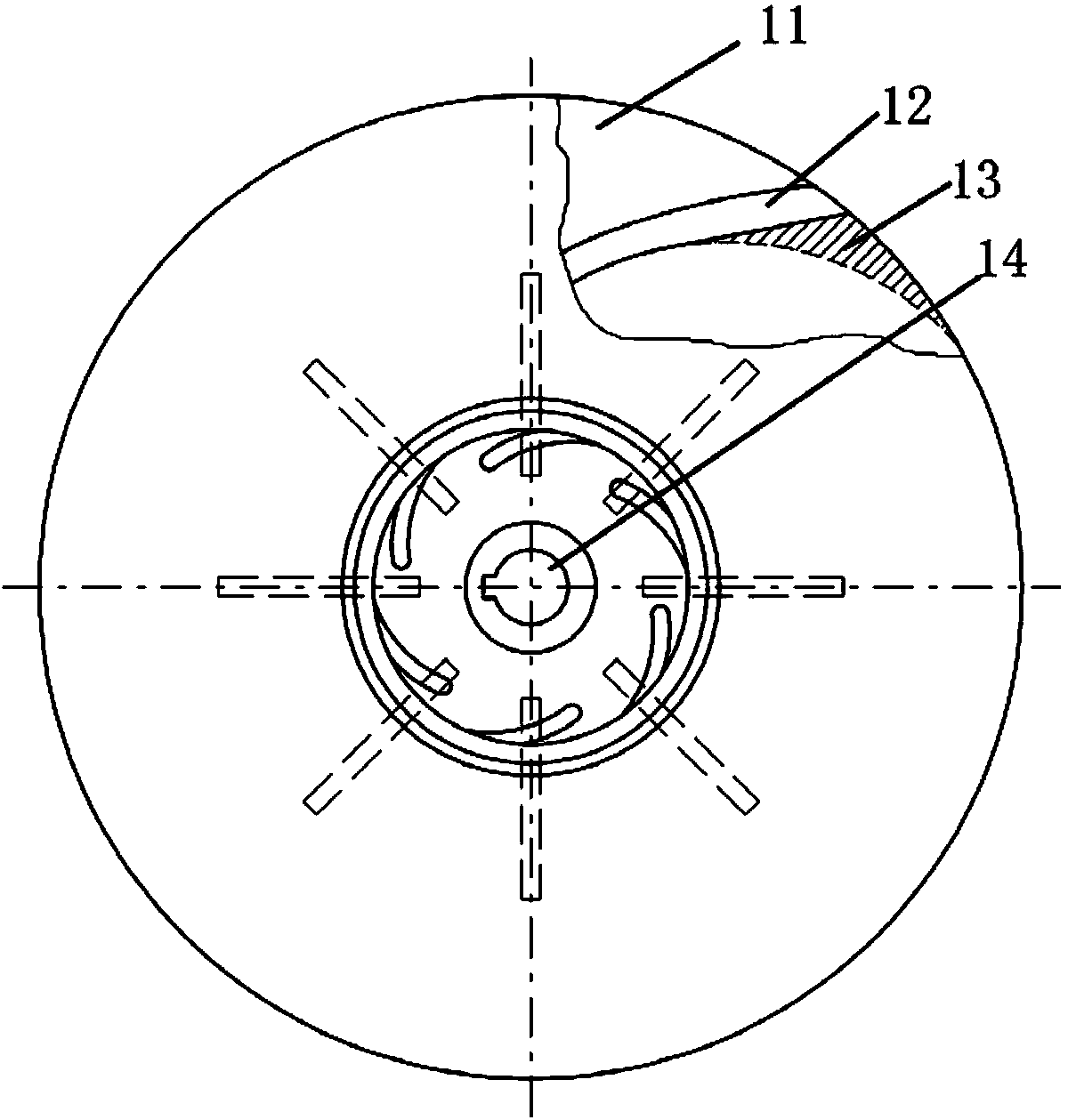

Production technology for impellers with different lifts by utilizing existed impeller mold

The invention relates to a production technology for impellers with different lifts by utilizing existed impeller mold. The main process flow comprises: preparing a movable block with certain thickness, and enabling the inner side of the movable block to be capable of fitting the working face of a blade of an impeller; fixedly connecting the edge position of each blade of the impeller mold with one movable block, so as to obtain a new impeller mold; putting molding sand into the new impeller mold for core preparation, and after core preparation is finished, taking out a new impeller sand core; putting the sand core into a molded core cavity and performing casting molding, so as to obtain an impeller blank; and performing turning processing on the impeller blank, and finally performing milling processing on the outlet end at the back side of each blade, so as to obtain different blade outlet angles according to self demands. The beneficial effects comprise that the technical scheme is short in impeller preparation period, and correspondingly low in production cost. The impeller outlet edges can be conveniently thickened, and further the lift of a pump is facilitated to be adjusted by employing a milling method to increase the blade outlet angle.

Owner:ANHUI LINE ELECTRIC PUMP

Method for preparing super-hydrophobic surface on silicon wafer based on laser interference nanometer lithography

ActiveCN103663358AHigh surface energyImprove hydrophilic abilityDecorative surface effectsPhotomechanical exposure apparatusLight intensityBeam splitting

The invention discloses a method for preparing a super-hydrophobic surface on a silicon wafer based on laser interference nanometer lithography. The method comprises the following steps: (1) simulating a four-beam interference pattern by using Matlab (Matrix Laboratory), setting parameters to simulate an ideal lattice model; building a laser interference optical system according to simulation parameters; emitting a beam of laser through a laser, splitting the beam of laser into four beams of laser through a beam splitting system, in which incidence angles Theta1, Theta2, Theta3 and Theta4 are equal to 15 degrees; phase angles which are polarization angles Psi1, Psi2, Psi3 and Psi4 are equal to 90 degrees; the light intensity energy density ratio of four beams of laser is 1:1:1:1; and etching a lattice structure on a silicon wafer through four beams of laser; (2) removing dust pollutants on the surface of the etched silicon wafer by using ultrasonic vibration; (3) processing the etched silicon wafer by using HF and removing SiO2 to obtain a micro-nano surface structure with a contact angle up to 150 degrees.

Owner:CHANGCHUN UNIV OF SCI & TECH

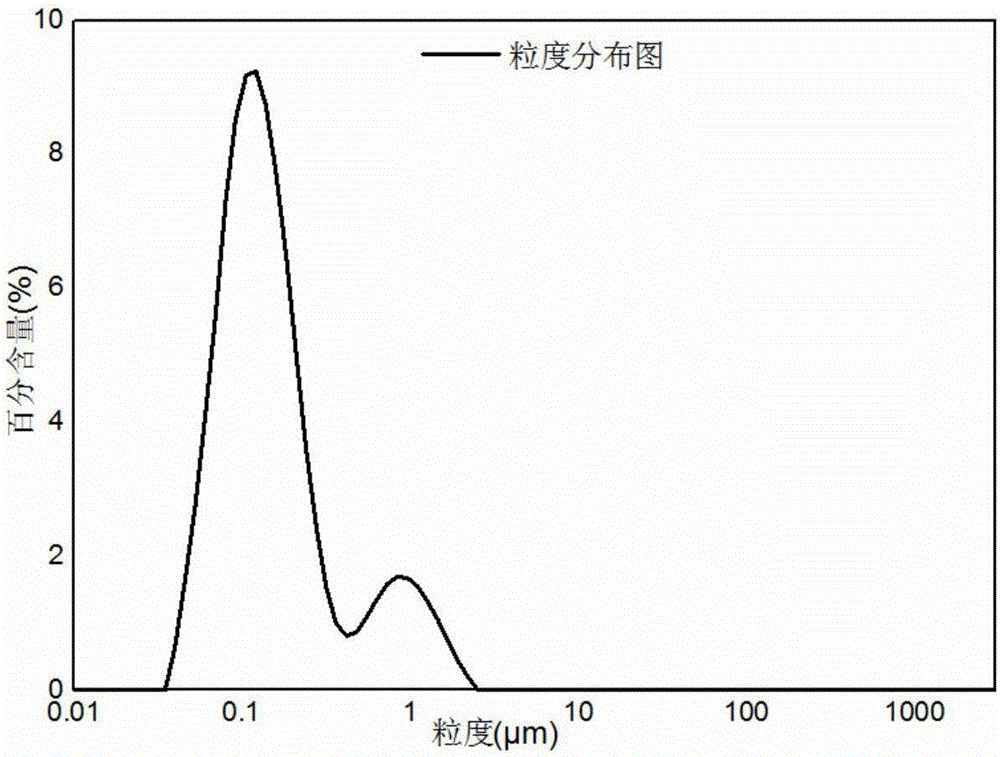

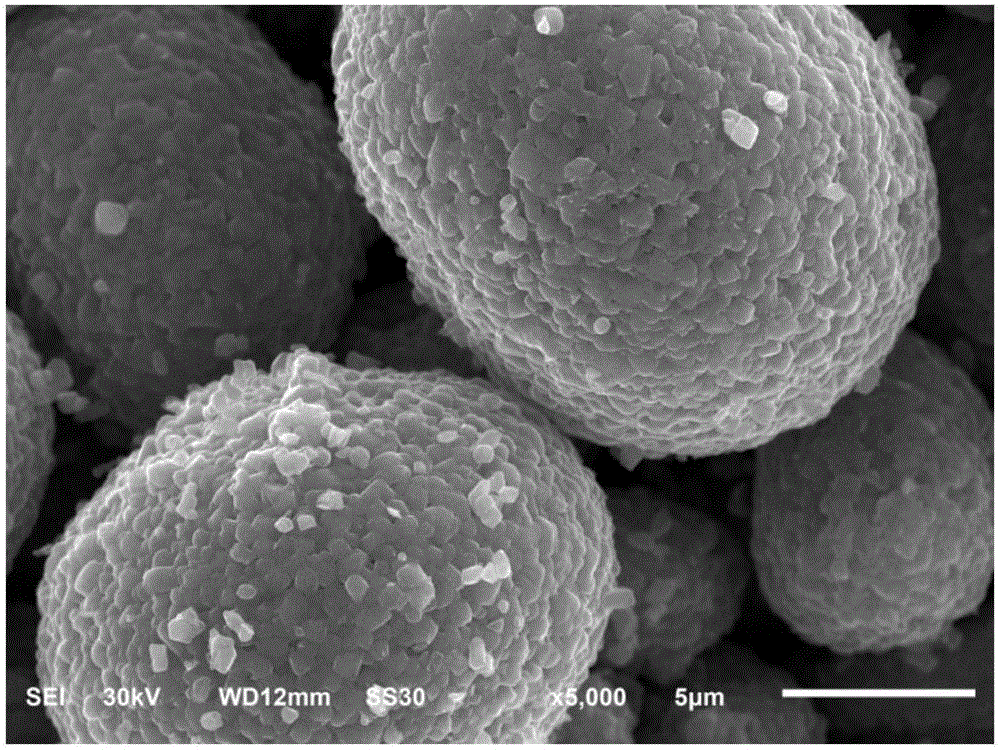

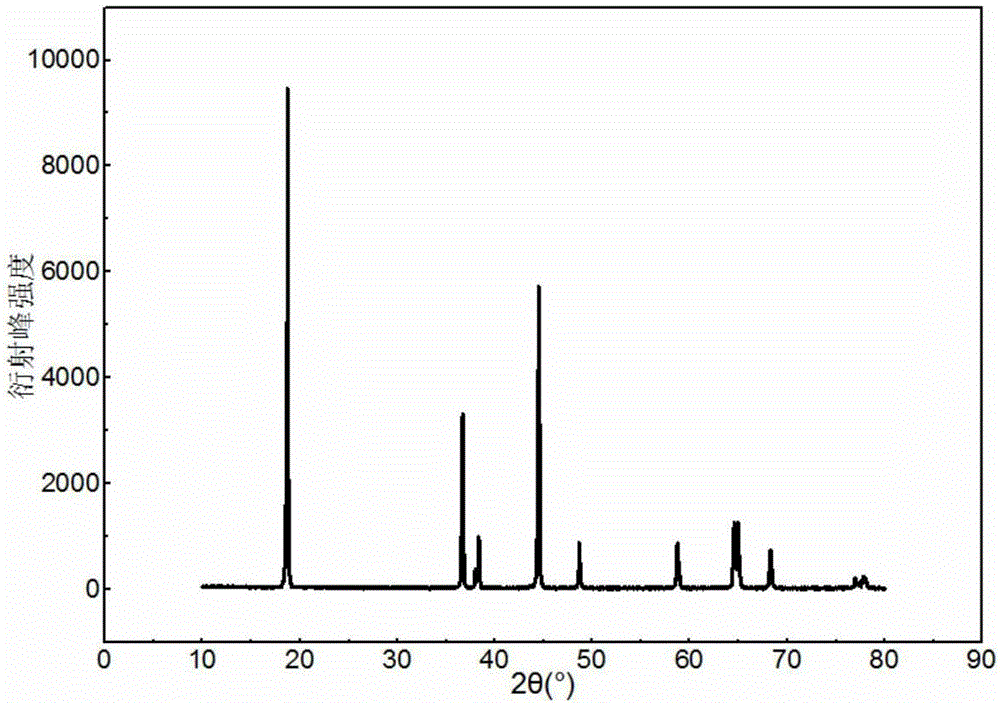

Method for preparing cathode material lithium nickel cobalt aluminate for lithium ion battery by spray drying

InactiveCN106025179ASimple processReduce manufacturing costsCell electrodesLithium compoundCobalt aluminate

The invention relates to a method for preparing a cathode material lithium nickel cobalt aluminate for lithium ion battery by spray drying. A chemical general formula of the material is LiNi1-x-yCoxAlyO2, wherein x is more than 0.1 and less than 0.3, y is more than 0.01 and less than 0.15 and 1-x-y is more than 0 and less than 1. The preparation method comprises the following steps: mixing and sanding an insoluble nickel compound, an insoluble cobalt compound, an insoluble aluminum compound and a lithium compound for 2 to 8h, performing spray drying to obtain a lithium nickel cobalt aluminate precursor, and performing roasting to prepare the cathode material lithium nickel cobalt aluminate under an oxygen airflow by adopting a two-stage method. According to the method, spray drying is performed to rapidly evaporate water to obtain the uniform and dense spherical lithium nickel cobalt aluminate precursor after nickel, cobalt and aluminum are mixed on a nanometer scale by adopting an efficient sander, and the cathode material lithium nickel cobalt aluminate with stable electrochemical performance is finally obtained by stagewise roasting. The method is easy to operate and short in preparation cycle, and the product is high in quality and consistency, and can be continuously and industrially produced.

Owner:HUNAN SOUNDDON NEW ENERGY

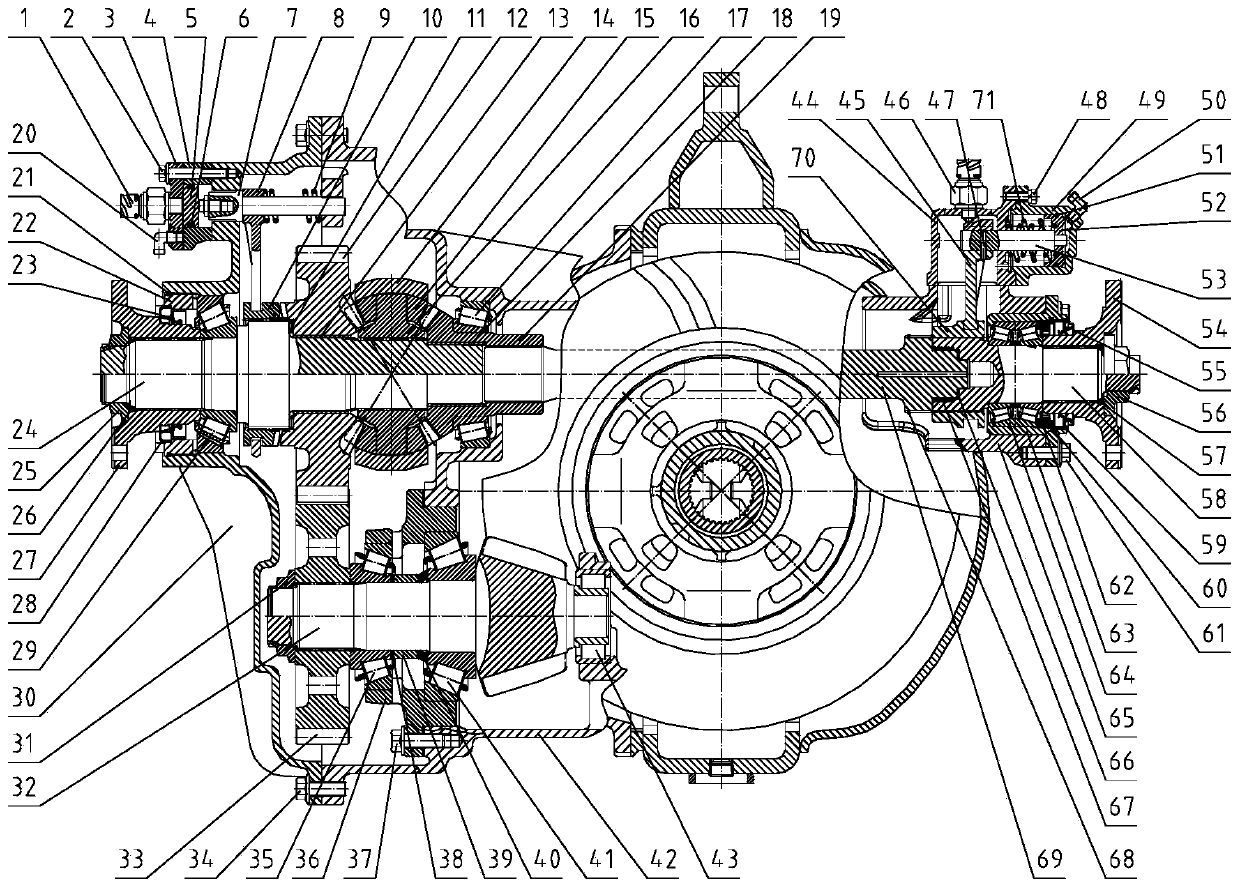

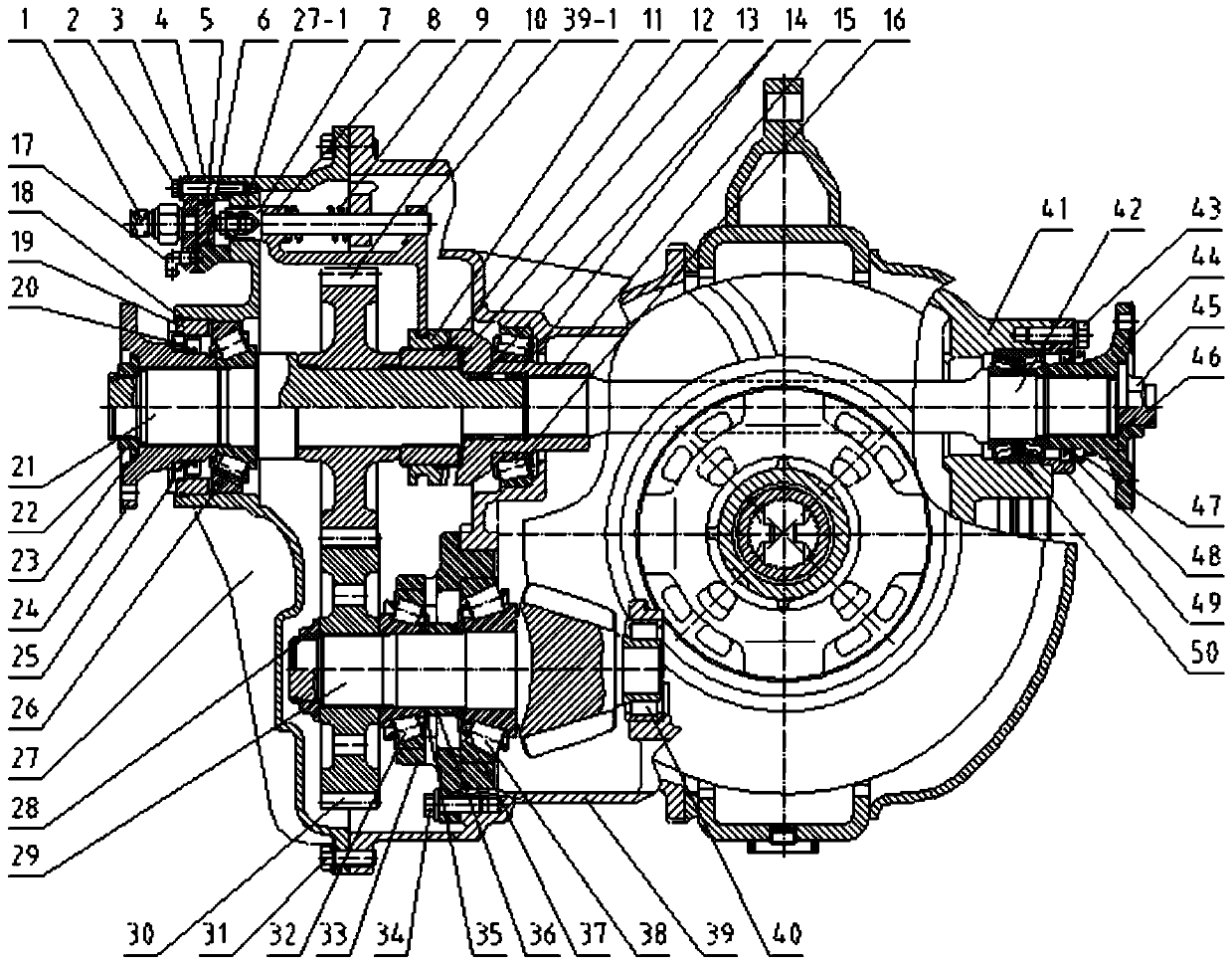

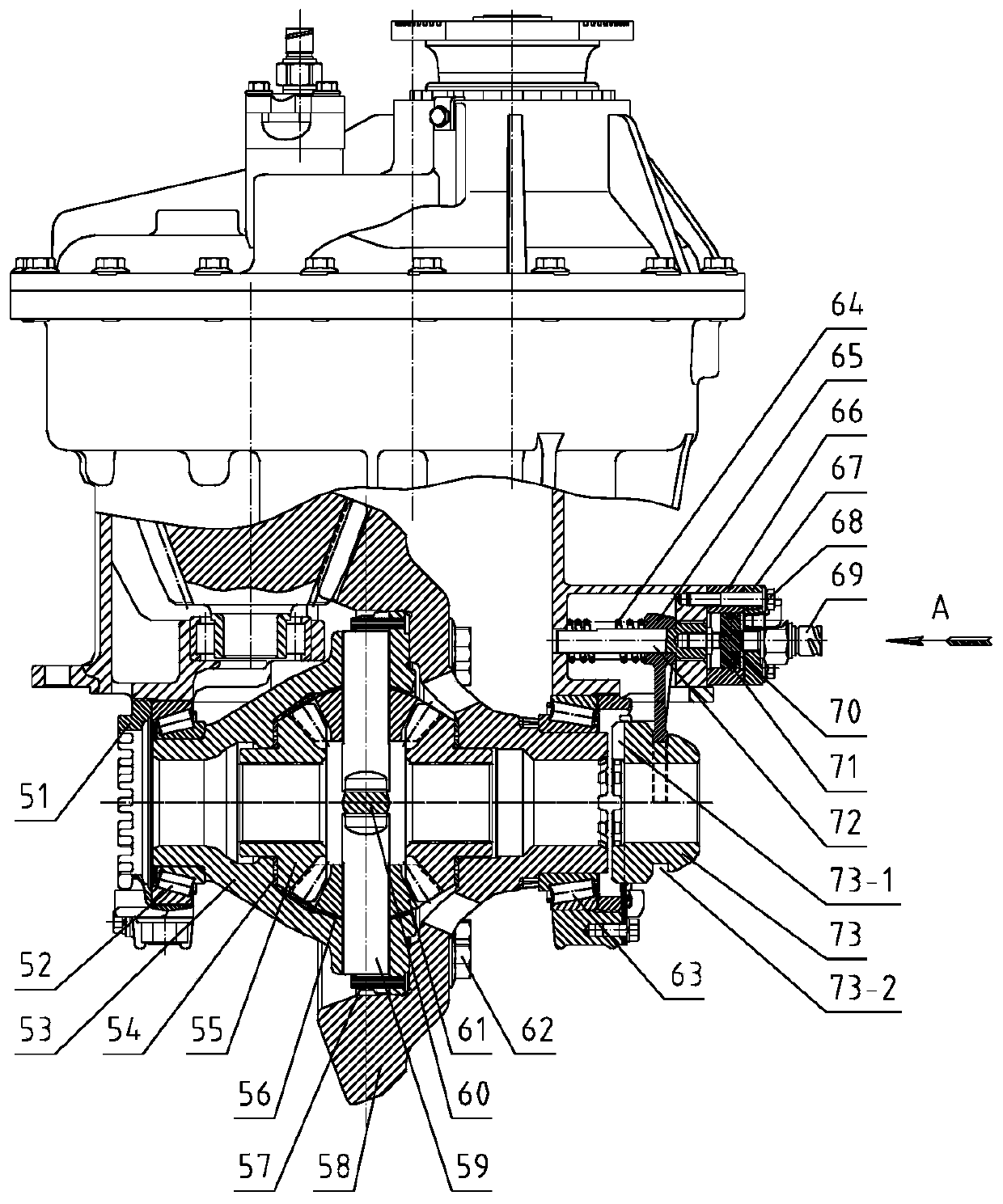

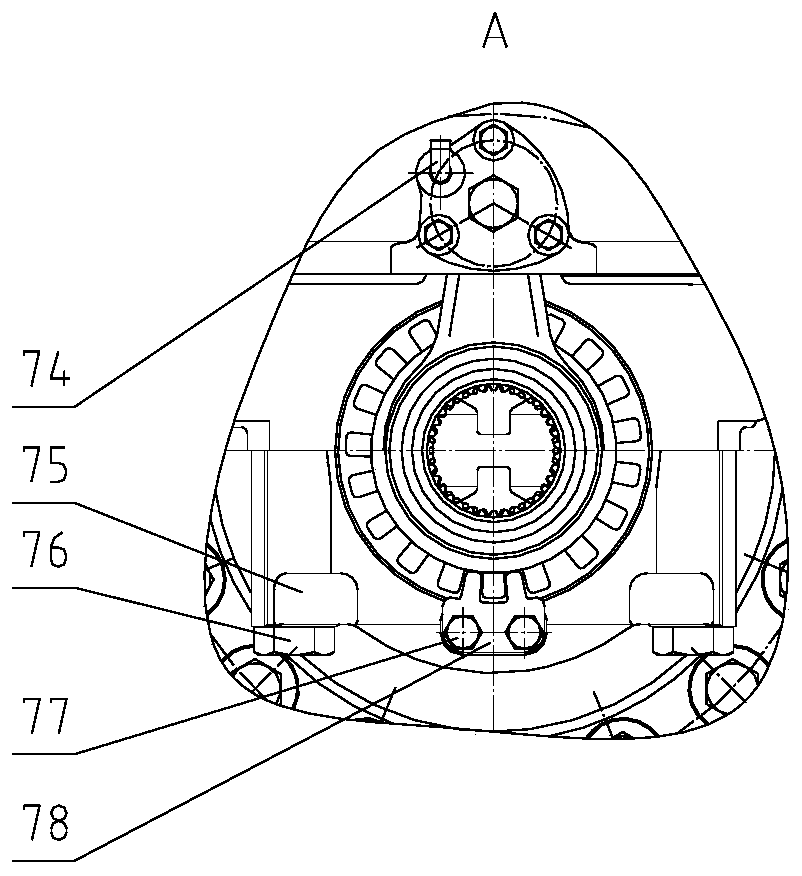

Medium bridge main speed reducer assembly with through shaft disengagement and engagement device

ActiveCN110792749AReduce consumptionIncrease incomeControlled membersGearing controlReduction driveCar manufacturing

The invention belongs to the technical field of automobile manufacturing, and discloses a medium bridge main speed reducer assembly with a through shaft disengagement and engagement device. The mediumbridge main speed reducer assembly is composed of an inter-axle differential and inter-axle differential lock assembly, a driving bevel gear assembly, the through shaft disengagement and engagement device and an inter-wheel differential and inter-wheel differential lock assembly. The through shaft disengagement and engagement device is additionally arranged at the position of a through shaft of amedium bridge main speed reducer, a drive axle is converted between a 6*4 drive manner and a 6*2 drive manner, a shell body of the medium bridge main speed reducer does not need to be changed, the invested cost is low, and the generalization performance is high. When a vehicle is under a non-load or non-full-load condition, the through shaft disengagement and engagement device is switched off, thus, the input torque of the rear drive axle is zero, the rear drive axle can be lifted, the turning radius of the whole vehicle can be improved, the requirement of vehicle operation for a site is reduced, abrasion of tires can be reduced, the expense of the tires is reduced, and higher economic benefits are brought for a user. The fuel consumption can be reduced by 3% or above for the user every year in the commercial vehicle with the device.

Owner:FAW JIEFANG AUTOMOTIVE CO

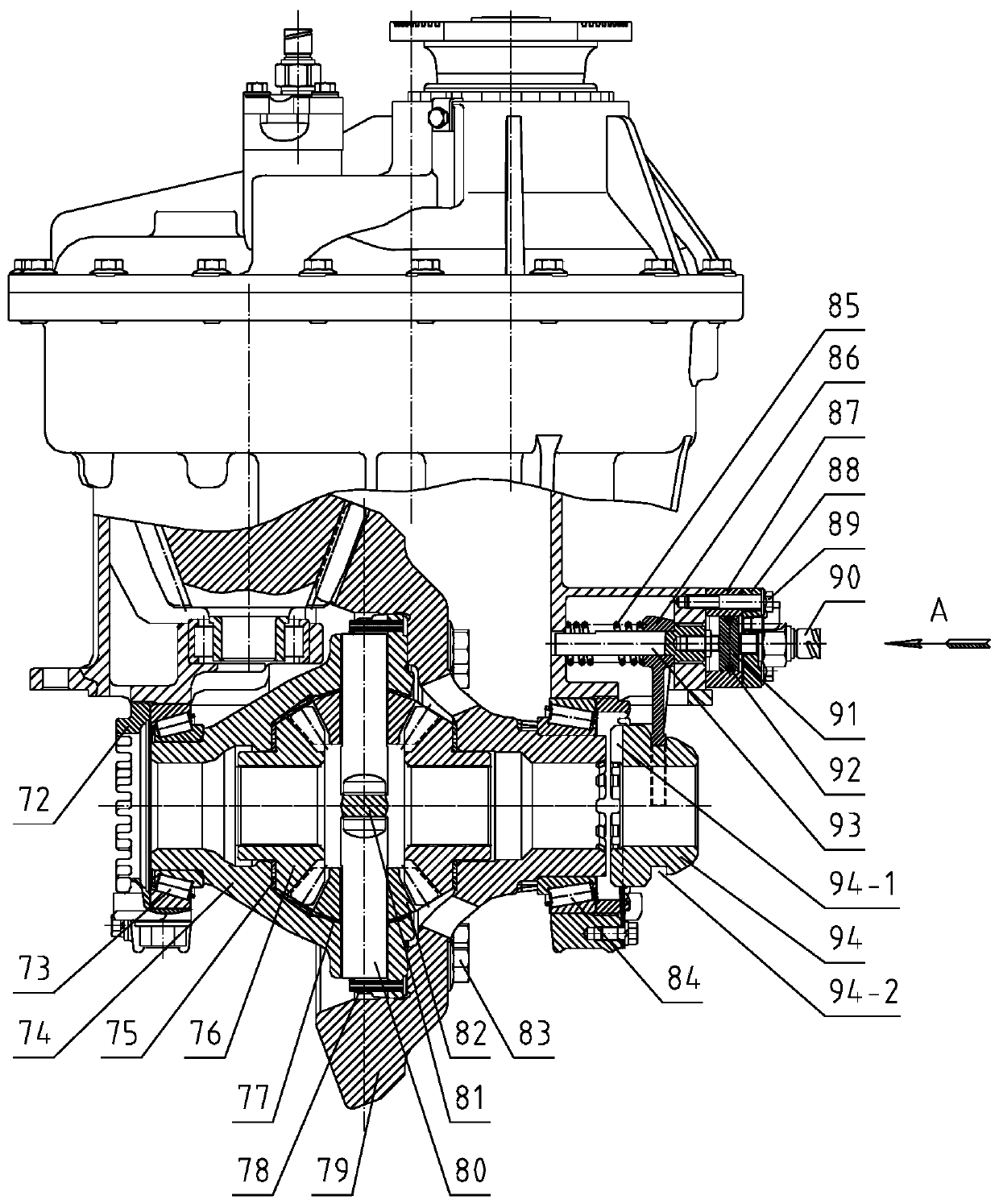

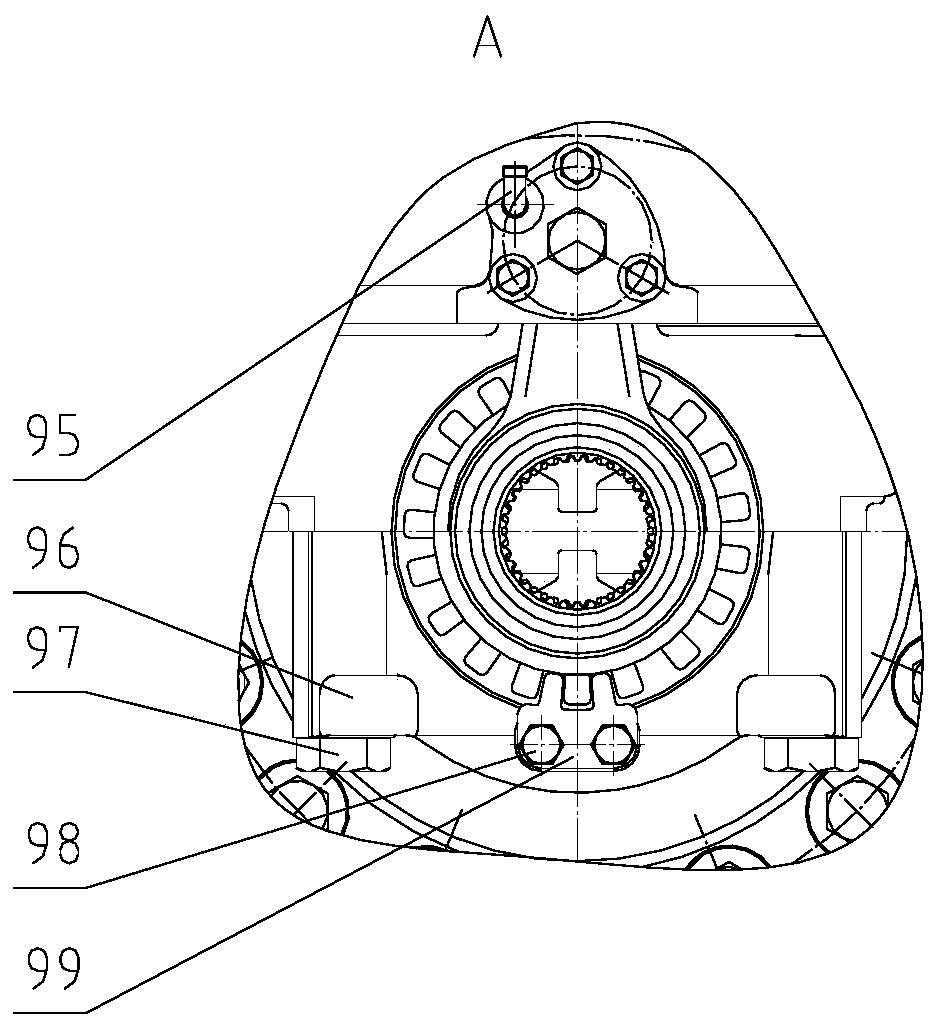

Intermediate axle main reducer assembly provided with rear bevel gear engaging and disengaging mechanism

ActiveCN110748622AReduce consumptionIncrease incomeGear lubrication/coolingDifferential gearingsFuel conservationReduction drive

The invention relates to an intermediate axle main reducer assembly provided with a rear bevel gear engaging and disengaging mechanism. The intermediate axle main reducer assembly is formed by a rearbevel gear engaging and disengaging mechanism assembly, an inter-gear differential mechanism and inter-gear differential lock assembly, a driving conic gear assembly and a through shaft assembly. Theintermediate axle main reducer assembly achieved the aims that transmission efficiency is improved, fuel consumption is saved, and additional incomes are increased for users. An inter-axle differential assembly only needs to be eliminated on the basis of producing the intermediate axle main reducer assembly at present, the rear bevel gear engaging and disengaging mechanism is adopted, the rear bevel gear engaging and disengaging mechanism is cut off, and therefore the torque transmitted to a rear drive axle can be cut off, conversion of 6*4 and 6*2 drive manners of a whole vehicle can be achieved, a reduction shell, an upper cover and a transmission shaft do not need to be modified, the assembly is suitable for a full-series through axle, the development cost is low, and transverse expansion and adaptability are high. The rear drive axle can be lifted, the turning radius of the whole vehicle can be improved, the requirements of vehicle running for sites can be reduced, tire wear can also be reduced, tire expenses are saved, and higher economic benefits are brought to users.

Owner:FAW JIEFANG AUTOMOTIVE CO

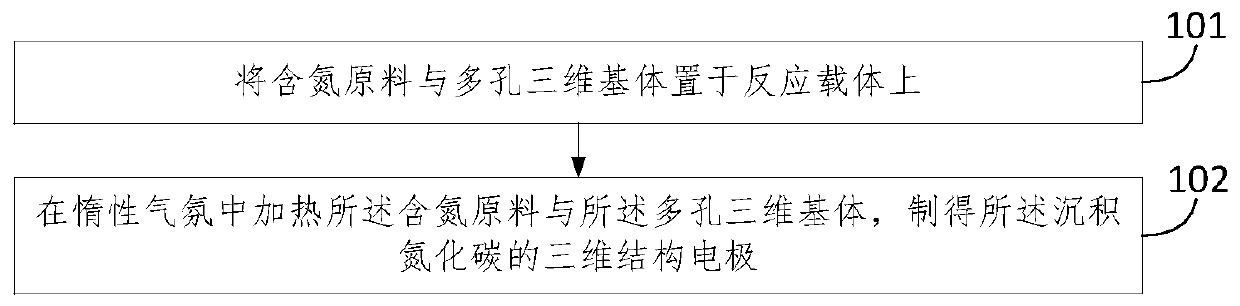

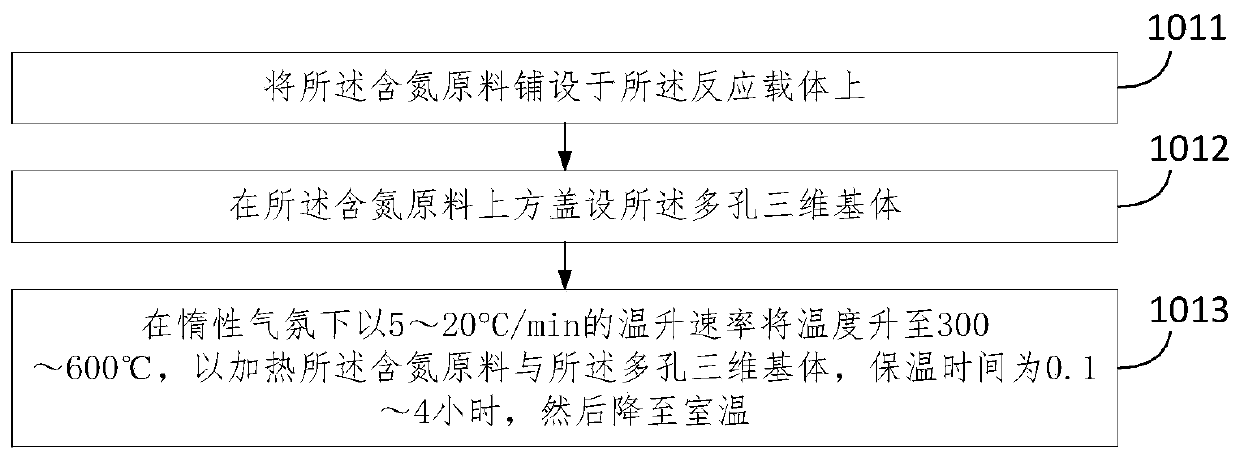

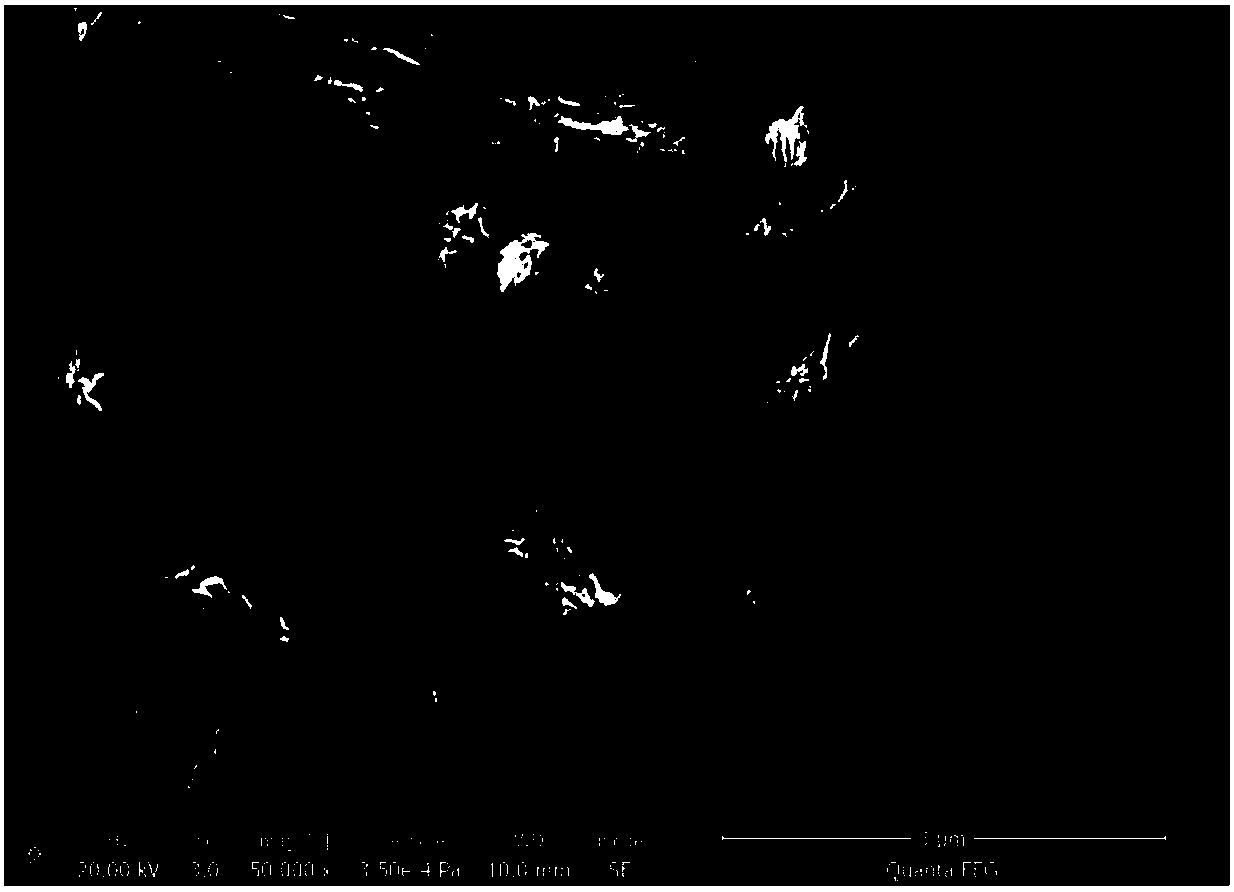

3D (Three-Dimensional) structure electrode and preparation method thereof

InactiveCN109809375AIncrease capacityHigh rate characteristicsNitrogen and non-metal compoundsPolyvinylidene fluorideIn situ reaction

The invention relates to the technical field of energy storage, provides a 3D (Three-Dimensional) structure electrode and a preparation method thereof, and aims to solve the problems that in an existing carbon nitride-containing electrode material, the binding force between carbon nitride and a matrix material is weak, the nitrogen loss rate is high, and the preparation technology is complicated.The preparation method comprises the following steps: putting a nitrogen-containing raw material and a porous 3D matrix on a reaction carrier; heating the nitrogen-containing raw material and the porous 3D matrix in inert atmosphere, thus obtaining the 3D structure electrode, wherein a binding agent and a solution are not required. The preparation method is different from a method of binding the carbon nitride and graphite felt by utilizing polyvinylidene fluoride as the binding agent in the prior art, and is characterized by heating and drying the nitrogen-containing raw material, sublimatingthe nitrogen-containing raw material to the surface or the inner part of the porous 3D matrix and generating the carbon nitride through in-situ reaction, thus forming the 3D structure electrode. Thebinding force between the carbon nitride and the porous 3D matrix is remarkably enhanced, the nitrogen loss rate is reduced, the preparation technology is simple, and the battery performance can be increased.

Owner:SICHUAN UNIV

Preparation method for molybdenum disulfide-sepiolite nanofiber composite materials

InactiveCN108525680AHighlight substantiveHighlight substantive featuresPhysical/chemical process catalystsOther chemical processesMolybdateMicrowave

The invention discloses a preparation method for molybdenum disulfide-sepiolite nanofiber composite materials, and relates to composite materials. The preparation method based on a microwave hydrothermal process includes preparing a reactant stock mixed liquor of molybdate, sulfides and sepiolite nanofibers; pouring the reactant stock mixed liquor into a polytetrafluoroethylene reaction kettle, and putting the reaction kettle in microwave hydrothermal equipment to complete microwave-hydrothermal-process based effective compounding of reactants; cleaning and drying products obtained by the microwave hydrothermal process to obtain the molybdenum disulfide-sepiolite nanofiber composite materials. The preparation method has the advantages that the defects of the prior art for preparing molybdenum disulfide composite materials, including proneness to re-gathering or stacking of the molybdenum disulfide composite materials during drying or annealing, complexity in preparation process, long reaction period, high energy consumption and high cost, are overcome.

Owner:HEBEI UNIV OF TECH

Industrial method for producing dispersion-strengthened iron-based materials at low cost and in large-scale

The invention provides an industrial method for producing dispersion-strengthened iron-based materials at low cost and in large-scale. The industrial acid pickling waste solution is treated by spray roasting process after yttrium chloride is added. During the spray roasting process, the solution is atomized into fine droplets, the droplets are contacted with gas and dried into powders, which are heated in air to form metal oxides. The mixed powders of the metal oxides are reduced in hydrogen stream to obtain yttria dispersion-strengthened iron powders. High performance dispersion-strengthened iron materials are obtained by densifying the yttria dispersion-strengthened iron powders. The method has simple process and low cost, and is suitable for large-scale production due to the direct use of acid pickling waste solution from steel factory.

Owner:UNIV OF SCI & TECH BEIJING

Novel oilstone base and grinding strip device

InactiveCN101844327AOvercome the defect that it is easy to fall off from the oilstone seatIncrease manufacturing costGrinding devicesHoning toolsEngineeringMechanical engineering

The invention discloses a novel oilstone base and grinding strip device. Due to the adoption of a grinding method, a groove is grinded on two side faces of a grinding strip in the full-length direction; a groove is respectively made on one side face of a press plate in the full-length direction by other proper methods; the grinding strip is placed on an L-shaped step of an oilstone base; rubber strips with a proper section shape are placed in the grooves on the two side faces; and the press plate is fastened on the side face of the oilstone base by a fastening screw. When the press plate is fixed on the oilstone base simultaneously, the proper amount of compression of the rubber strips on the two side faces of the grinding strip is guaranteed.

Owner:孟建波

Preparation method of molybdenum disulfide-halloysite nano-tube composite material

InactiveCN108557889AHighlight substantiveHighlight substantive featuresNanotechnologySilicon compoundsHalloysiteState of art

The invention provides a preparation method of a molybdenum disulfide-halloysite nano-tube composite material and relates to a composite material. The molybdenum disulfide-halloysite nano-tube composite material is prepared by a microwave hydrothermal method. The preparation method comprises the following steps: preparing a halloysite nano-tube; preparing a reactant raw material mixed liquid of molybdate, sulfide and the halloysite nano-tube; pouring the reactant raw material mixed liquid into a polytetrafluoroethylene reaction kettle, placing the polytetrafluoroethylene reaction kettle into microwave hydrothermal equipment and completing microwave hydrothermal effective composition of the reactants; and washing and drying the product obtained by the microwave hydrothermal method to prepare the molybdenum disulfide-halloysite nano-tube composite material. The defects in the prior art for preparing the molybdenum disulfide composite material that the molybdenum disulfide composite material is liable to gather or stack again in the drying or annealing process as well as the defects of complex preparation process, long reaction cycle, high energy consumption and high cost are overcome.

Owner:HEBEI UNIV OF TECH

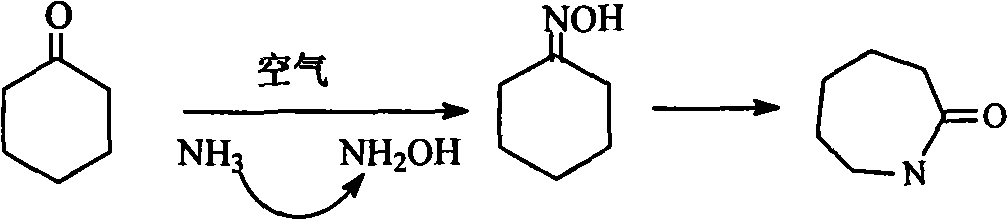

Catalyst for synthesizing caprolactam in one step by ammoxidation of cyclohexanone and preparation and application method thereof

InactiveCN101670291AEasy to prepareRaw materials are cheap and easy to getPhysical/chemical process catalystsOrganic chemistryCyclohexanonePhosphoric acid

The invention relates to a supported solid-acid catalyst for synthesizing caprolactam in one step by cyclohexanone as well as a preparation and an application method thereof. The catalyst is a supported dual-function type catalyst and comprises a carrier and active components, wherein the carrier is a composite oxide of silicon oxide and aluminum oxide, and the active component is phosphoric acid;the mol ratio between silicon and aluminum in the carrier is 0.73 to 1.13: 1, the load amount of the phosphoric acid is 10 percent to 40 percent, and the load amount is the mass percentage content ofthe phosphoric acid in the whole supported dual-functional type catalyst. The supported dual-functional type catalyst has the advantages of simple preparation method, low-price and easily-obtained raw materials and lower production cost, can be repeatedly used for more than three times and can recover the activity just by simple washing and roasting.

Owner:HEBEI UNIV OF TECH

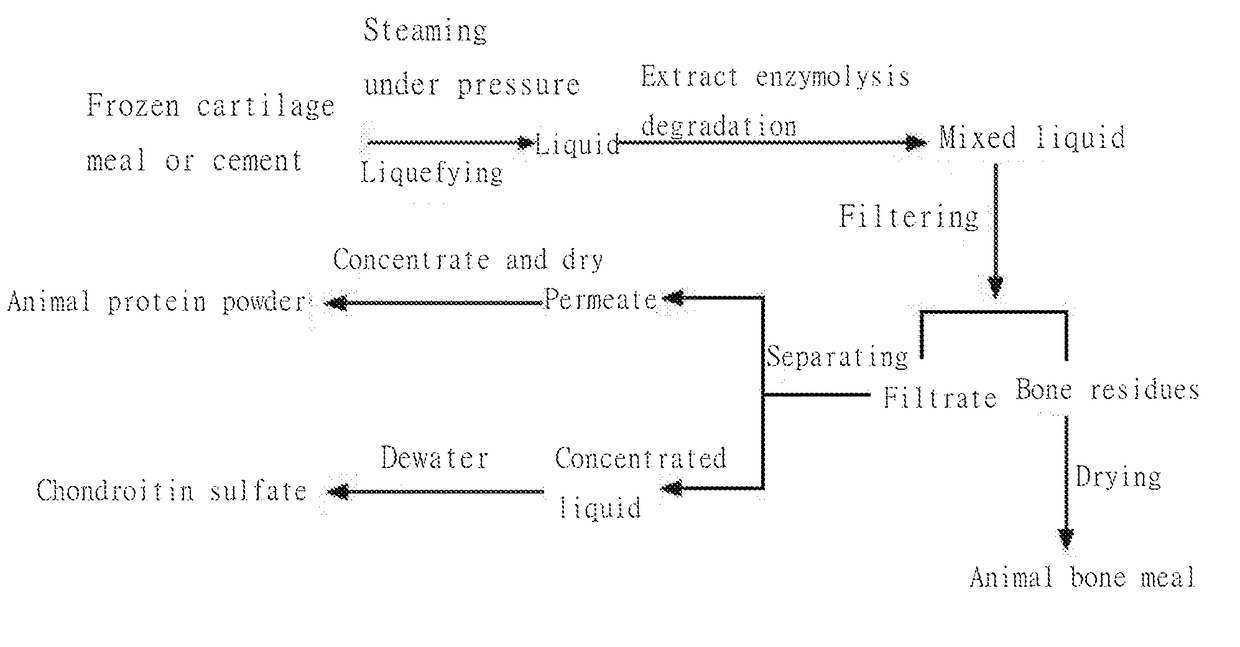

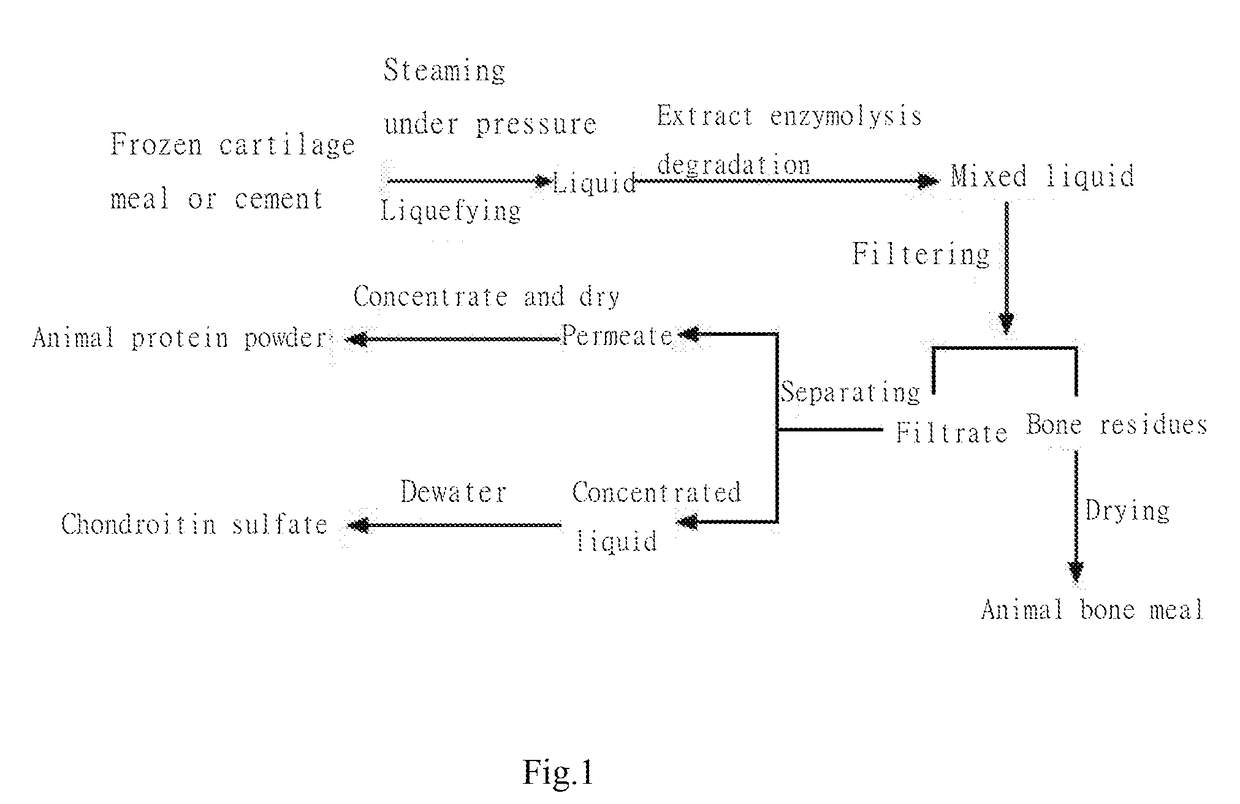

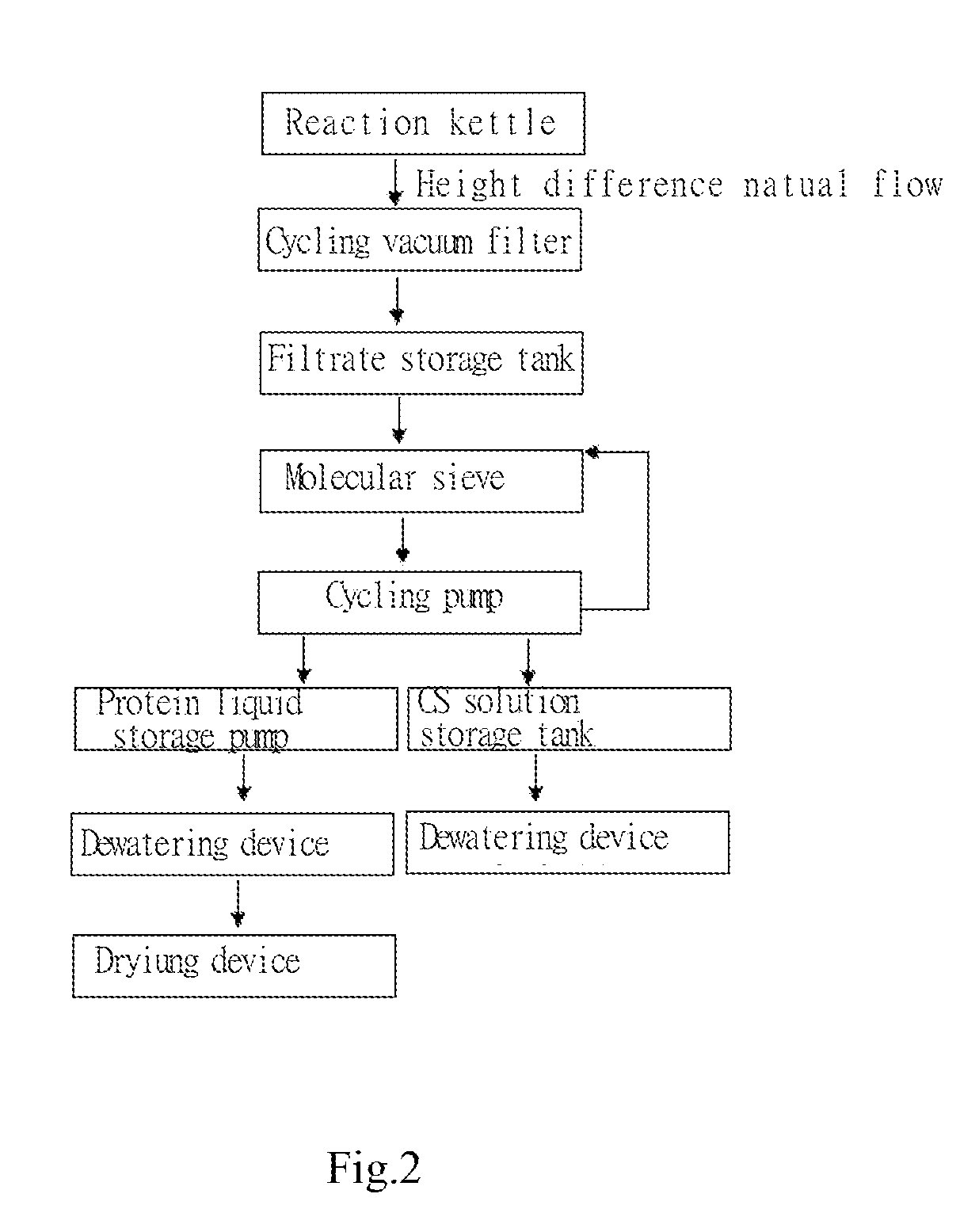

Chondroitin sulfate preparation process and equipment thereof

A chondroitin sulfate preparation process and device thereof and in particular a process for extracting ten thousand tons of chondroitin sulfate by means of a solvent-free process is disclosed. The process comprises steps such as liquefaction, extraction, enzymolysis and degradation, filtering, separation and after-treatment. The device comprises a reaction kettle. The reaction kettle is preferably a Teflon reaction kettle. The reaction kettle is in pipeline connection with a vacuum circulation filter, a filtrate storage tank and a molecular sieve in sequence. The molecular sieve is separately in pipeline connection with a protein fluid storage tank and a CS solution storage tank. The present invention has the advantages of low investment. Compared to the same production scale, the investment is cut by 80%. The larger the production scale is the more advantageous in investment. The production capacity is over million tons, which is unattainable by solvent-process technology. The production is automatic and continuous. The production quality is controllable. The CPC content is 60%-105% and other quality indexes meets or exceeds the current quality standard. The production is no pollution, zero discharge and environmentally friendly.

Owner:ZHANG MULIANG

Method for rapidly preparing black phosphorus by crystal nucleus assisted high temperature difference manner

The invention belongs to the technical field of nano two-dimensional material preparation, and particularly relates to a method for rapidly preparing black phosphorus by crystal nucleus assisted hightemperature difference manner. The method includes sealing red phosphorus, stannum powder, stannic iodide and black phosphorus microcrystals in a mass ratio of 100:1:1:1 in a quartz tube; putting thequartz tube in the middle of a dual-temperature-zone heating tubular furnace, with a loaded end of the quartz tube being in a high-temperature zone, and an unloaded end being in a low-temperature zone; and heating to 610 DEG C in a speed of 10 DEG C / min in the high-temperature zone and maintaining the temperature for 1 h, with heating being not performed in the low-temperature zone, and then blackphosphorus crystals can be obtained at the low-temperature end of the quartz tube. The method utilizes nucleation of the black phosphorus microcrystals and the mechanism of high temperature difference rapid crystallization to rapidly prepare the black phosphorus crystals, shortens the preparation time of the black phosphorus from 24 h or above to 2h, and reduces energy consumption of steps. The black phosphorus crystals prepared by the method have great potential application value in the fields of biomedicine, electronic film, lithium batteries, infrared photoelectron technology and catalysis.

Owner:MINJIANG UNIV

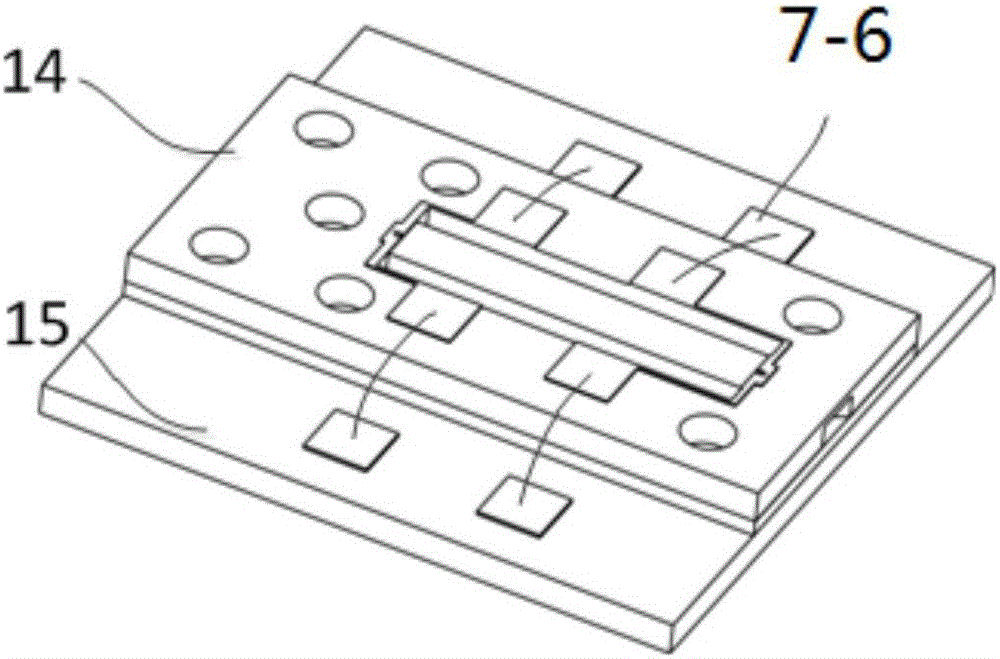

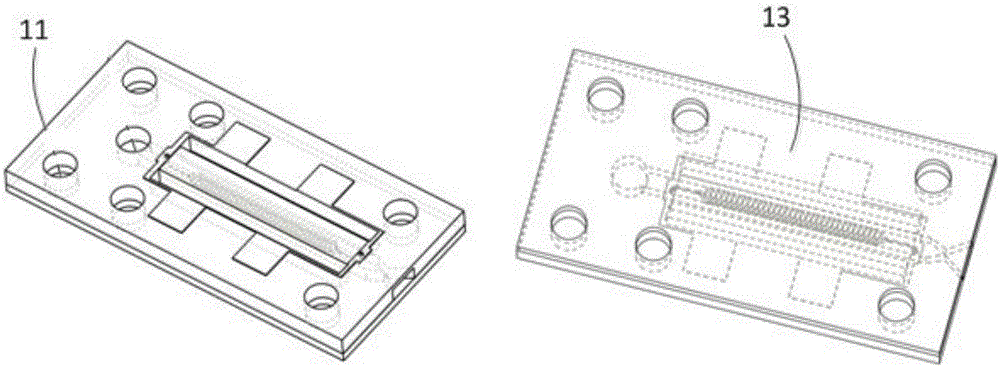

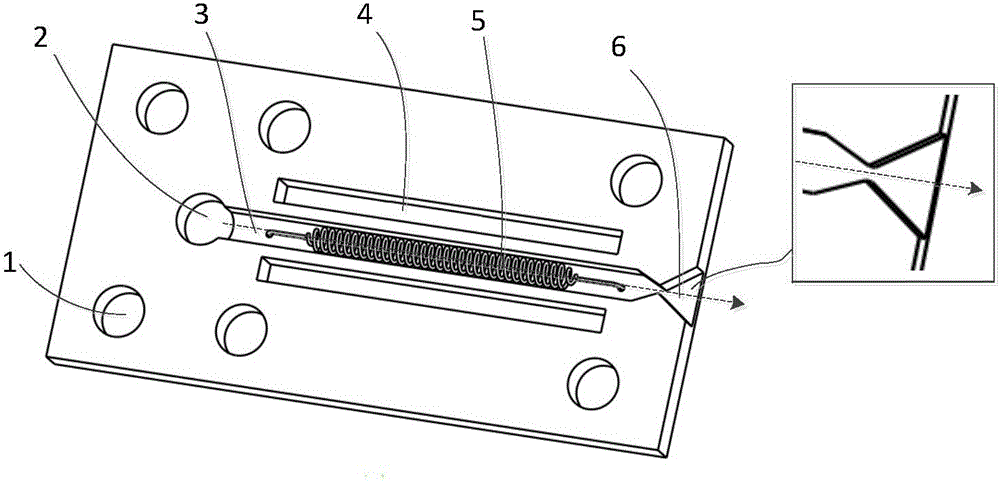

Microthruster chip of microsatellite

InactiveCN105888884AHigh melting pointHigh resistivityCosmonautic vehiclesCosmonautic propulsion system apparatusMicrosatelliteElectrical and Electronics engineering

The invention relates to a microthruster chip of a microsatellite. The microthruster chip comprises a heating cavity (3) and is characterized in that a heating wire (5) is arranged in the heating cavity (3), and lead-out holes (17) are formed in the wall of the heating cavity (3) so as to enable two ends of the heating wire (5) to be led out of the heating cavity (3) from the heating cavity (3).

Owner:SHANGHAI ENG CENT FOR MICROSATELLITES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com