3D (Three-Dimensional) structure electrode and preparation method thereof

A three-dimensional structure and electrode technology, applied in the field of energy storage, can solve the problems of high nitrogen loss rate, complicated preparation process, weak binding force, etc., and achieve the effects of pure quality, increased battery capacity, and low nitrogen loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

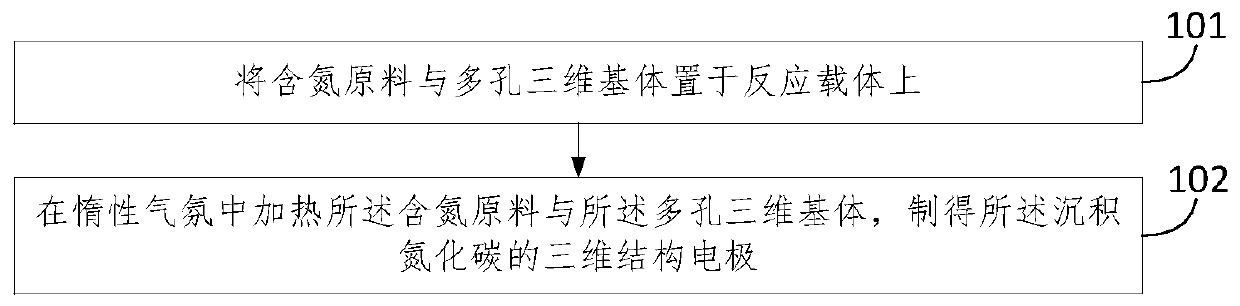

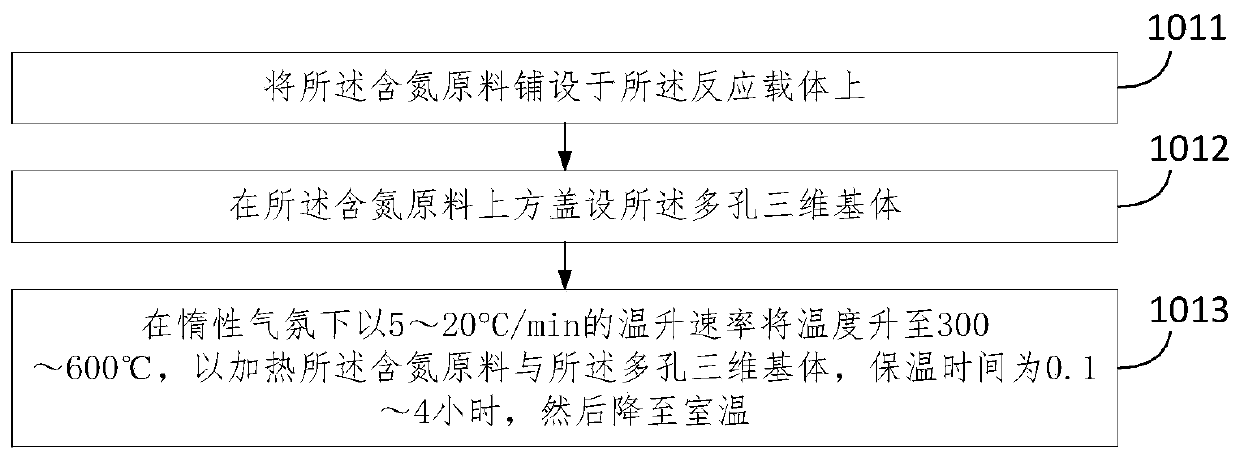

[0034] This embodiment provides a method for preparing a three-dimensional structure electrode, the preparation method comprising the following steps:

[0035] Step 101, placing the nitrogen-containing raw material and the porous three-dimensional matrix on the reaction carrier;

[0036] Step 102, heating the nitrogen-containing raw material and the porous three-dimensional matrix in an inert atmosphere to prepare the three-dimensional structure electrode.

[0037] In the above preparation method including step 101 and step 102, under an inert atmosphere, the nitrogen-containing raw material is used as the precursor of the target product, and after being sublimated by heat, it is deposited on the surface or inside of the porous three-dimensional structure matrix; and reacts in situ under a high temperature environment , and finally obtain a three-dimensional structure electrode without binder. Among them, the inert atmosphere environment can avoid the influence of oxygen, hyd...

specific Embodiment approach 1

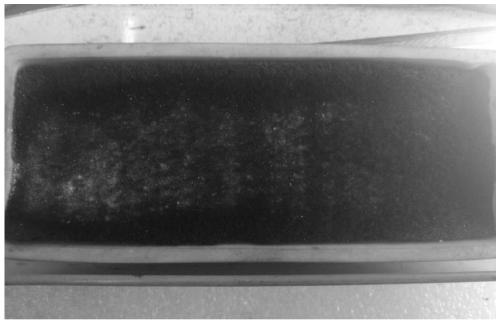

[0051] Get an appropriate amount of melamine and spread it on the corundum boat, wherein the specific quantity of melamine is determined according to the design amount of the target product carbon nitride; No contact, the present invention does not limit this; then put the corundum boat in the tube furnace, fill the tube furnace with argon to exclude air, and raise the temperature to 550 °C at a temperature rise rate of 10 °C / min , keep warm for 2 hours, and then take out the corundum boat when the temperature drops to room temperature. Melamine is sublimated to the surface or inside of the graphite felt, and carbon nitride is generated on the surface of the graphite felt or the surface of the internal pores to obtain a three-dimensional structure electrode. The macroscopic photo of the three-dimensional structure electrode as shown in image 3 Shown; The X-ray diffraction pattern of the three-dimensional structure electrode is shown as Figure 4 Shown, the diffraction peak ...

specific Embodiment approach 2

[0052] Get an appropriate amount of urea and lay it flat on the stainless steel boat, wherein the specific quantity of urea is determined according to the design amount of the target product carbon nitride; No contact, the present invention does not limit this; a layer of foamed copper has a specific surface area of 2000m 2 / g of activated carbon, and then put the corundum boat in the tube furnace, one end of the tube is closed, and the other end is sealed with water, and the CO formed by the reaction of the carbon and the air in the tube is used as an inert atmosphere, and the temperature rise rate is 5°C / min. The temperature was raised to 300°C, and kept for 0.1 hour, and then the corundum boat was taken out after the temperature dropped to room temperature. Urea generates carbon nitride on the surface of copper foam or the surface of internal pores to obtain a three-dimensional structure electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com