High-temperature fusant battery apparatus and preparation process thereof

A battery device and high-temperature melt technology, applied in secondary batteries, battery pack parts, battery boxes/jackets, etc., can solve problems such as corrosion of high-temperature insulating and sealed batteries, and achieve a reduction in production cycle, good performance, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

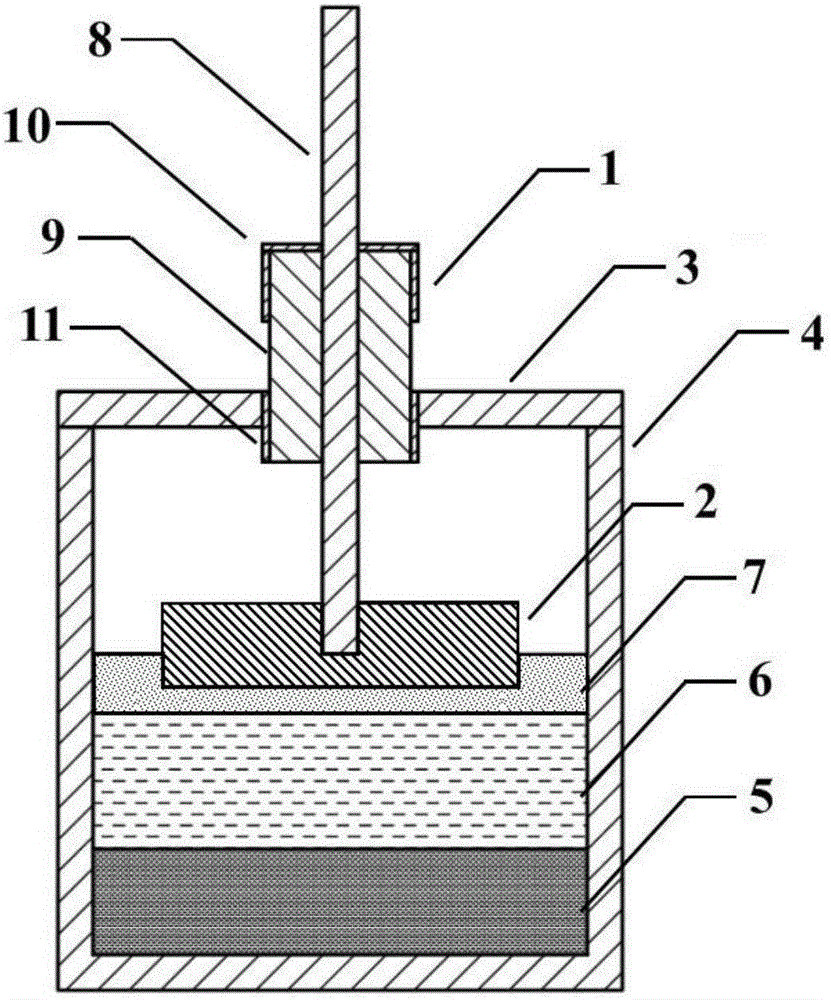

Method used

Image

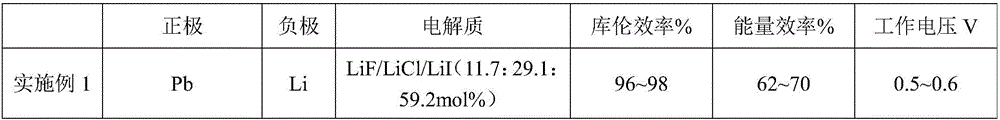

Examples

Embodiment 3

[0063] The preparation process of the liquid metal battery adopted in embodiment 3 is as follows:

[0064] 1) Put Sb pellets into a mold and heat to melt. The heating process is as follows: 5°C / min to 800°C, heat preservation for 10h, and then naturally cool to room temperature. The whole process is carried out in an absolute vacuum or high-purity argon environment less than 0.1Pa.

[0065] 2) the mixed MgCl 2 , NaCl and KCl electrolyte powders were put into a mold and heated and melted. The heating process was as follows: the temperature was raised to 450°C at a rate of 1°C / min, kept for 15 hours, and then naturally cooled to room temperature to obtain the battery electrolyte material. The whole process is carried out in an absolute vacuum or high-purity argon environment less than 0.1Pa.

[0066] 3) Put the metal Mg into the mold and heat and melt it. The heating process is as follows: the temperature is raised to 800° C. at 5° C. / min, and the temperature is kept for 3 to ...

Embodiment 6

[0073] The preparation process of the liquid metal battery adopted in embodiment 6 is as follows:

[0074] 1) Put the metal Te into the mold and heat and melt it. The heating process is as follows: the temperature is raised to 800°C at 5°C / min, kept for 20 hours, and then naturally cooled to room temperature. The whole process is carried out in an absolute vacuum of less than 0.1Pa or in high-purity argon.

[0075] 2) Put the mixed NaF, NaCl and NaI electrolyte powders into a mold and heat and melt them. The heating process is to raise the temperature to 600°C at 1°C / min, keep it warm for 20h, and then cool it down to room temperature naturally. The whole process is carried out in an absolute vacuum or high-purity argon environment less than 0.1Pa.

[0076] 3) Put the metal Na into the mold and heat and melt it. The heating process is as follows: the temperature is raised to 400° C. at 5° C. / min, and the temperature is kept for 3 to 5 hours. The anode current collector was s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com