Preparation method for molybdenum disulfide-sepiolite nanofiber composite materials

A technology of nanofibers and molybdenum disulfide, applied in chemical instruments and methods, alkali metal compounds, inorganic chemistry, etc., can solve the problems of complex preparation process, long reaction cycle, high cost, etc., achieve good dispersion, improve shape, Reduce the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

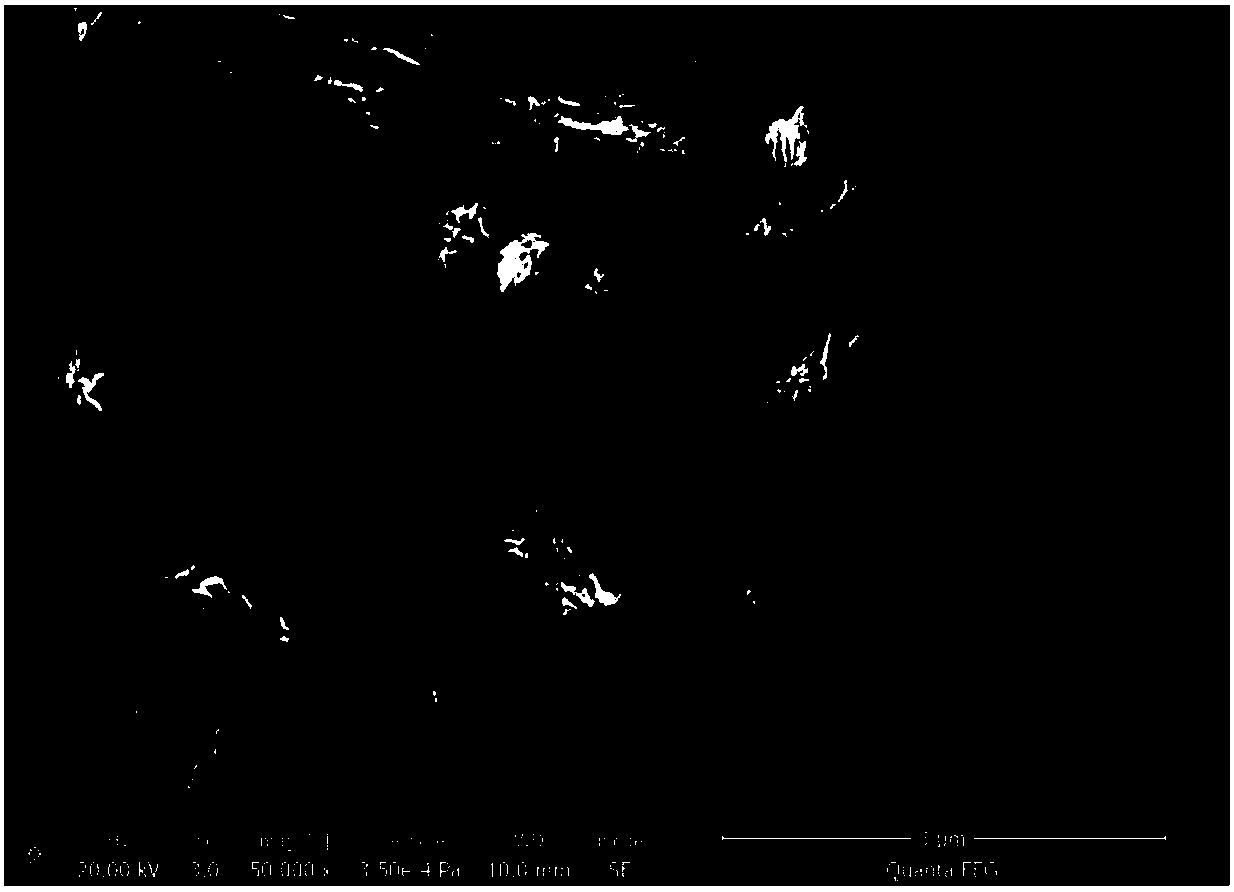

Image

Examples

Embodiment 1

[0044] The first step, the preparation of reactant raw material mixture:

[0045] Weigh 1mmol of ammonium molybdate, 10mmol of thioacetamide and 0.1g of sepiolite nanofibers, first dissolve the ammonium molybdate in 35mL of deionized water, stir until the ammonium molybdate is completely dissolved, and then dissolve the weighed Thioacetamide was dissolved in the above ammonium molybdate solution, stirred magnetically at room temperature for 20 minutes, and after the mixed solution was uniform and transparent, added the weighed sepiolite nanofibers, stirred magnetically at room temperature for 30 minutes, and then ultrasonicated 10min, complete the preparation of reactant raw material mixture;

[0046] In the second step, the microwave hydrothermal method of the reactants is effectively compounded:

[0047] Pour the reactant raw material mixture prepared in the first step above into a polytetrafluoroethylene reaction kettle with a volume of 50mL, and the filling degree is 50%,...

Embodiment 2

[0051] The first step, the preparation of reactant raw material mixture:

[0052] Weigh 10mmol of magnesium molybdate, 80mmol of thiourea, and 1.0g of sepiolite nanofibers, first dissolve the magnesium molybdate in 100mL of deionized water, stir until the magnesium molybdate is completely dissolved, and then dissolve the weighed thiourea Dissolve in the above-mentioned magnesium molybdate solution, stir magnetically at room temperature for 35 minutes, and when the mixed solution is uniform and transparent, add the weighed sepiolite nanofibers, stir magnetically at room temperature for 45 minutes, and then ultrasonicate for 20 minutes to complete the reaction Preparation of raw material mixture;

[0053] In the second step, the microwave hydrothermal method of the reactants is effectively compounded:

[0054] Pour the reactant raw material mixture prepared in the first step above into a polytetrafluoroethylene reactor with a volume of 150 mL, and the filling degree is 60%, and...

Embodiment 3

[0058] The first step, the preparation of reactant raw material mixture:

[0059] Weigh 20mmol of alkali metal molybdate, 150mmol of L-cysteine and 2.0g of sepiolite nanofibers, first dissolve the alkali metal molybdate in 175mL of deionized water, and stir until the alkali metal molybdate is completely dissolved , then dissolve the weighed L-cysteine in the above-mentioned alkali metal molybdate solution, and stir magnetically at room temperature for 50 minutes. After the mixed solution is uniform and transparent, the weighed sepiolite nanofiber Add, magnetically stir at room temperature for 60 minutes, and then ultrasonic for 30 minutes to complete the preparation of the reactant raw material mixture;

[0060] In the second step, the microwave hydrothermal method of the reactants is effectively compounded:

[0061] Pour the reactant raw material mixture prepared in the first step above into a polytetrafluoroethylene reactor with a volume of 250mL, and the filling degree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com