Preparation method of molybdenum disulfide-halloysite nano-tube composite material

A technology of halloysite nanotubes and molybdenum disulfide, which is applied in the field of composite materials, can solve the problems of complex preparation process, long reaction period and high energy consumption, and achieve the effects of good dispersion, improved morphology and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

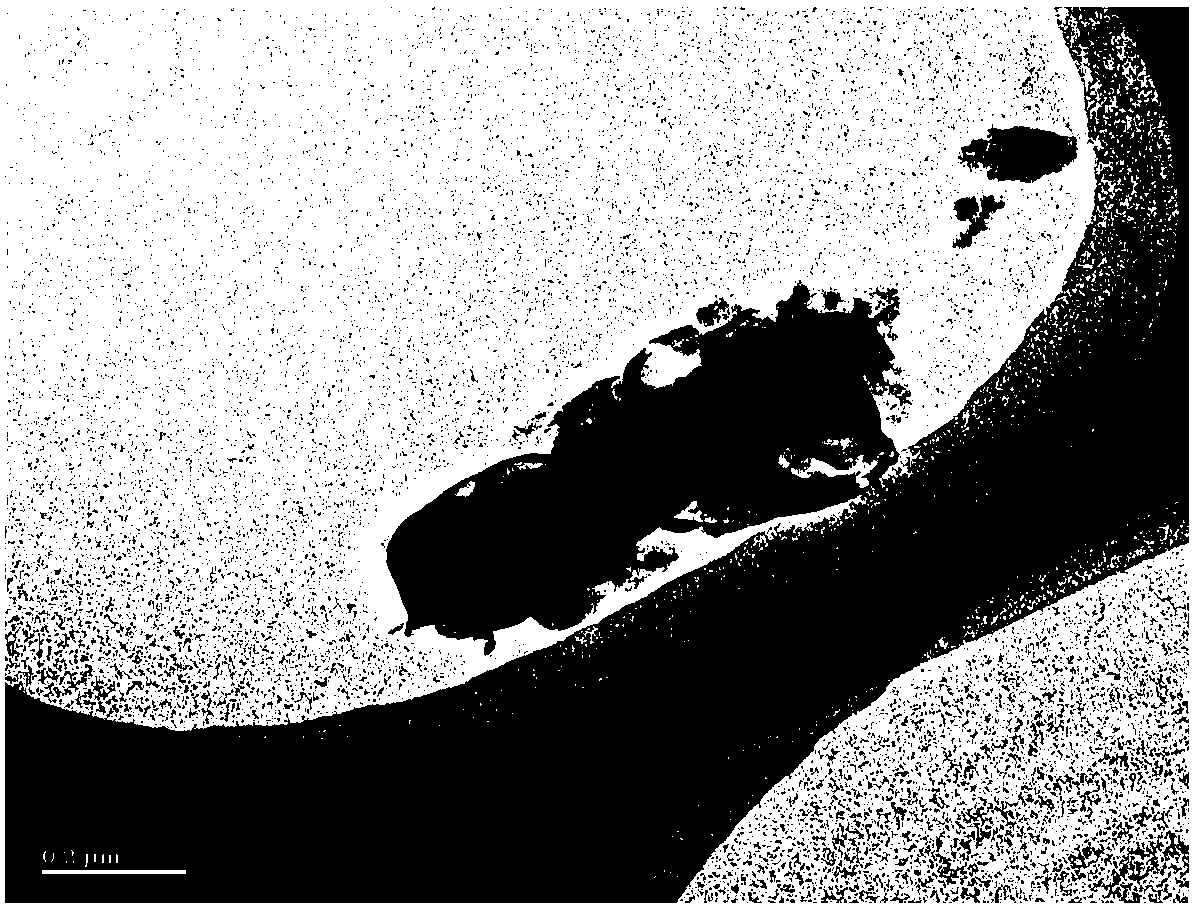

Image

Examples

Embodiment 1

[0045] The first step is to prepare halloysite nanotubes:

[0046] Weigh the required amount of halloysite and 0.3mol / L HCl solution in a container according to the solid-liquid mass ratio of 1:3, mix them in a container, heat them in water at 60°C for 3 hours, then suction filter and wash with deionized water for 5 hours. Secondary to neutral, put the filter cake in an oven at 60°C to dry, then grind and pass through a 200-mesh sieve to obtain purified halloysite powder, add 0.3mol / L NaOH solution to the purified angstromite obtained above In the rockite powder, the mass ratio of solid to liquid was 1:10, ultrasonic treatment was carried out at a temperature of 50°C for 1 hour, and then suction filtration and washing were performed for 5 times until the pH value was neutral, and the obtained filter cake was placed in 60 Dry in an oven at ℃ for 10 hours, take out and grind and pass through a 200-mesh sieve to obtain halloysite nanotubes, which are set aside;

[0047] The seco...

Embodiment 2

[0054] The first step is to prepare halloysite nanotubes:

[0055] Weigh the required amount of halloysite and 2.6mol / L HCl solution in a container according to the solid-liquid mass ratio of 1:4, mix them in a container, heat them in water for 4 hours at a temperature of 70°C, and then filter them with suction and wash them with deionized water for 6 hours. Secondary to neutral, put the filter cake in an oven at 70°C to dry, then grind and pass through a 200-mesh sieve to obtain purified halloysite powder, add 3mol / L NaOH solution to the purified halloysite obtained above In the stone powder, the mass ratio of solid to liquid was 1:30, ultrasonic treatment was carried out at 60°C for 1.5h, and then suction filtration and washing 6 times until the pH value was neutral, and the obtained filter cake was placed in 70 Dry in an oven at ℃ for 11 hours, take out and grind and pass through a 200-mesh sieve to obtain halloysite nanotubes, which are set aside;

[0056] The second step...

Embodiment 3

[0063] The first step is to prepare halloysite nanotubes:

[0064] Weigh the required amount of halloysite and 5mol / L HCl solution according to the solid-liquid mass ratio of 1:5, mix them in a container, heat them in water at 80°C for 6 hours, then suction filter and wash with deionized water for 7 times To neutrality, place the filter cake in an oven at 80°C to dry, then grind and pass through a 200-mesh sieve to obtain purified halloysite powder, add 6mol / L NaOH solution to the purified halloysite obtained above In the powder, the mass ratio of solid to liquid is 1:50, ultrasonic treatment is carried out at a temperature of 70°C for 2 hours, then suction filtration and washing are carried out 7 times until the pH value is neutral, and the obtained filter cake is placed in an oven at 80°C Dry in medium for 12h, take out and grind and pass through a 200 mesh sieve to obtain halloysite nanotubes for subsequent use;

[0065] The second step is to prepare the reactant raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com