Preparation method of molybdenum disulfide-tourmaline composite material

A molybdenum disulfide and composite material technology, applied in chemical instruments and methods, catalyst activation/preparation, electrical components, etc., can solve the problems of high cost, complex preparation process, long reaction period, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

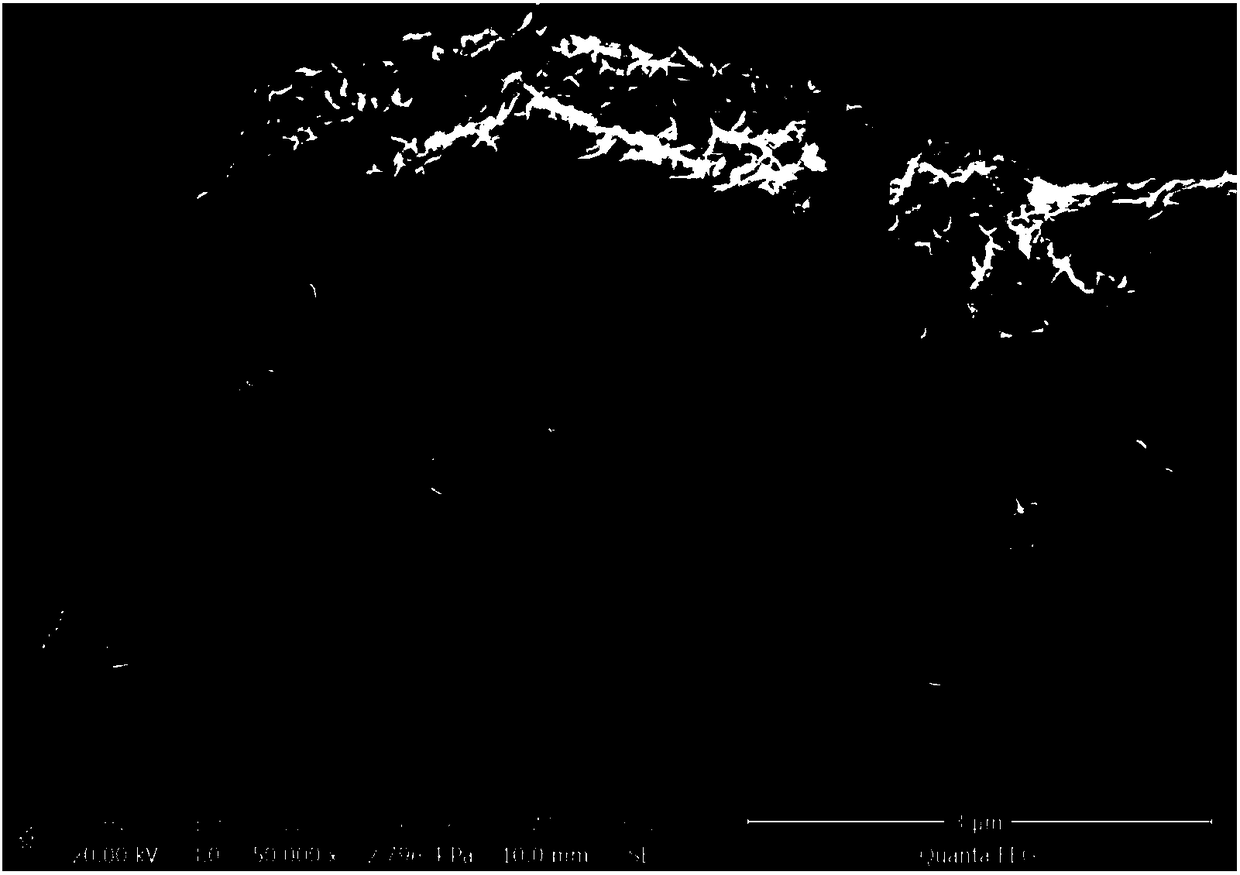

Image

Examples

Embodiment 1

[0048] The first step, the treatment of tourmaline:

[0049] According to the mass ratio of tourmaline: deionized water: polyacrylate grinding aid = 1: 2: 0.005, take the required amount of tourmaline, deionized water and polyethyl acrylate grinding aid in the ball mill Carry out wet ball milling at a speed of 700r / min for 1 hour, the ball-to-material ratio is 1:2, then wash the product of wet ball milling with deionized water, and dry it at 60°C for 12 hours to make powdered tourmaline. Roast the dried powdered tourmaline at a temperature of 500°C for 3 hours, cool to room temperature, complete the treatment of tourmaline, and set aside;

[0050] The second step, the preparation of reactant raw material mixture:

[0051] Weigh 1mmol of ammonium molybdate, 10mmol of thioacetamide and 0.1g of the tourmaline treated in the first step, first dissolve the weighed ammonium molybdate in 35mL of deionized water, and stir until the ammonium molybdate is completely Dissolve, then dis...

Embodiment 2

[0057] Except that grinding aid is polymethyl acrylate PMA, other are the same as embodiment 1.

Embodiment 3

[0059] The first step, the treatment of tourmaline:

[0060] Tourmaline by mass ratio: deionized water: polyacrylate grinding aid = 1: 11: 0.025, take the required amount of tourmaline, deionized water and sodium polyacrylate grinding aid, in the ball mill Wet ball milling was carried out at a speed of 1000r / min for 3 hours, the ball-to-material ratio was 1:4, and then the wet ball milled product was washed with deionized water, dried at 70°C for 18 hours, and powdered tourmaline was made. The above dried powdered tourmaline is roasted at a temperature of 700° C. for 6 hours, cooled to room temperature, and the treatment of the tourmaline is completed, ready for use;

[0061] The second step, the preparation of reactant raw material mixture:

[0062] Take by weighing 10mmol of magnesium molybdate, 80mmol of thiourea and 2.5g of tourmaline after the first step treatment, first dissolve the weighed magnesium molybdate in 100mL of deionized water, and stir until the magnesium moly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com