Novel oilstone base and grinding strip device

A technology of oilstone seat and grinding rod, which is applied in grinding devices, honing tools, grinding/polishing equipment, etc., can solve the problems of easy falling off of oilstone seat and grinding rod, high cost, quality accident, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

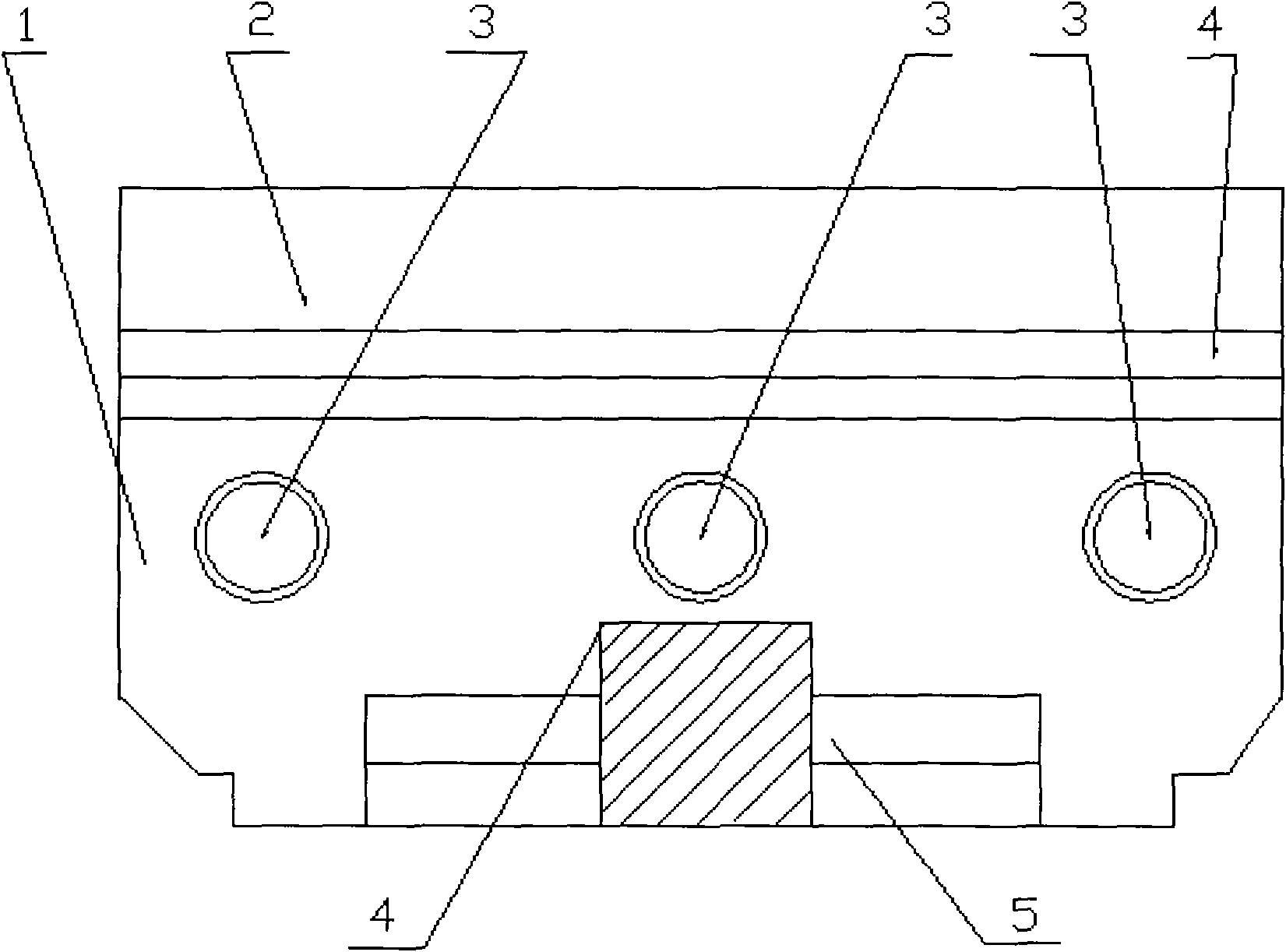

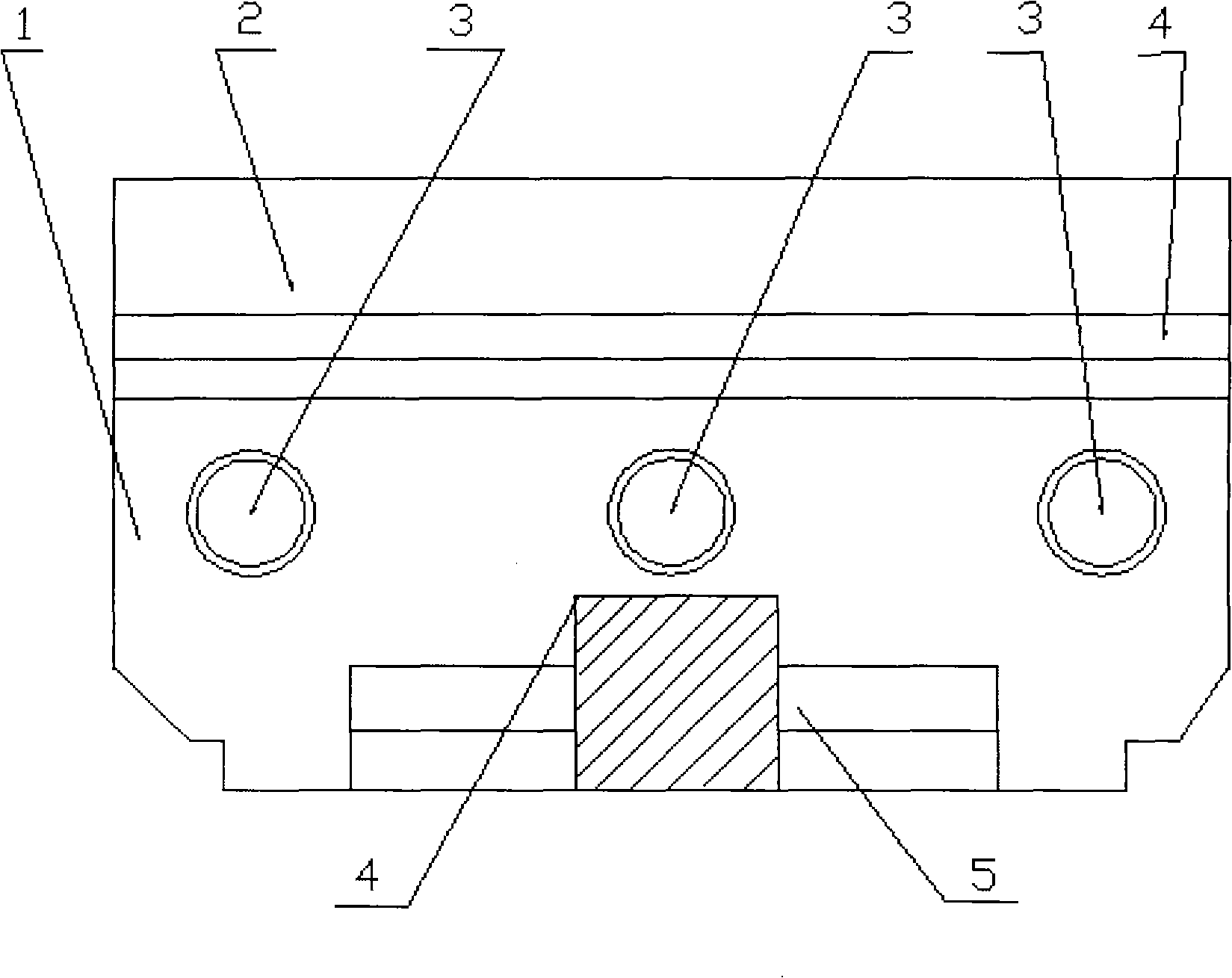

[0008] Adopt the method of grinding, grind grooves on the full length direction of both sides of the grinding bar (2), and use other appropriate methods to make grooves on the full length direction of one side of the pressure plate (5) respectively , place the grinding strip (2) on the L-shaped step of the oilstone seat (1), and put a rubber strip (4) of appropriate cross-sectional shape into the groove on both sides, and use the fastening screw (3) to fix the pressure plate Fasten it to the side of the oilstone seat (1). While fixing the pressure plate (5) on the oilstone seat (1), ensure that the rubber strips (4) on both sides of the grinding bar (2) have an appropriate amount of compression. Its working principle is: an L-shaped notch is formed on the top of the oilstone seat (1), an arc or rectangular groove is opened on one of the bars of the L-shaped notch, and an arc-shaped or rectangular groove is opened on one side of the pressure plate to match the oilstone seat (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com