Patents

Literature

100results about How to "Short maintenance cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

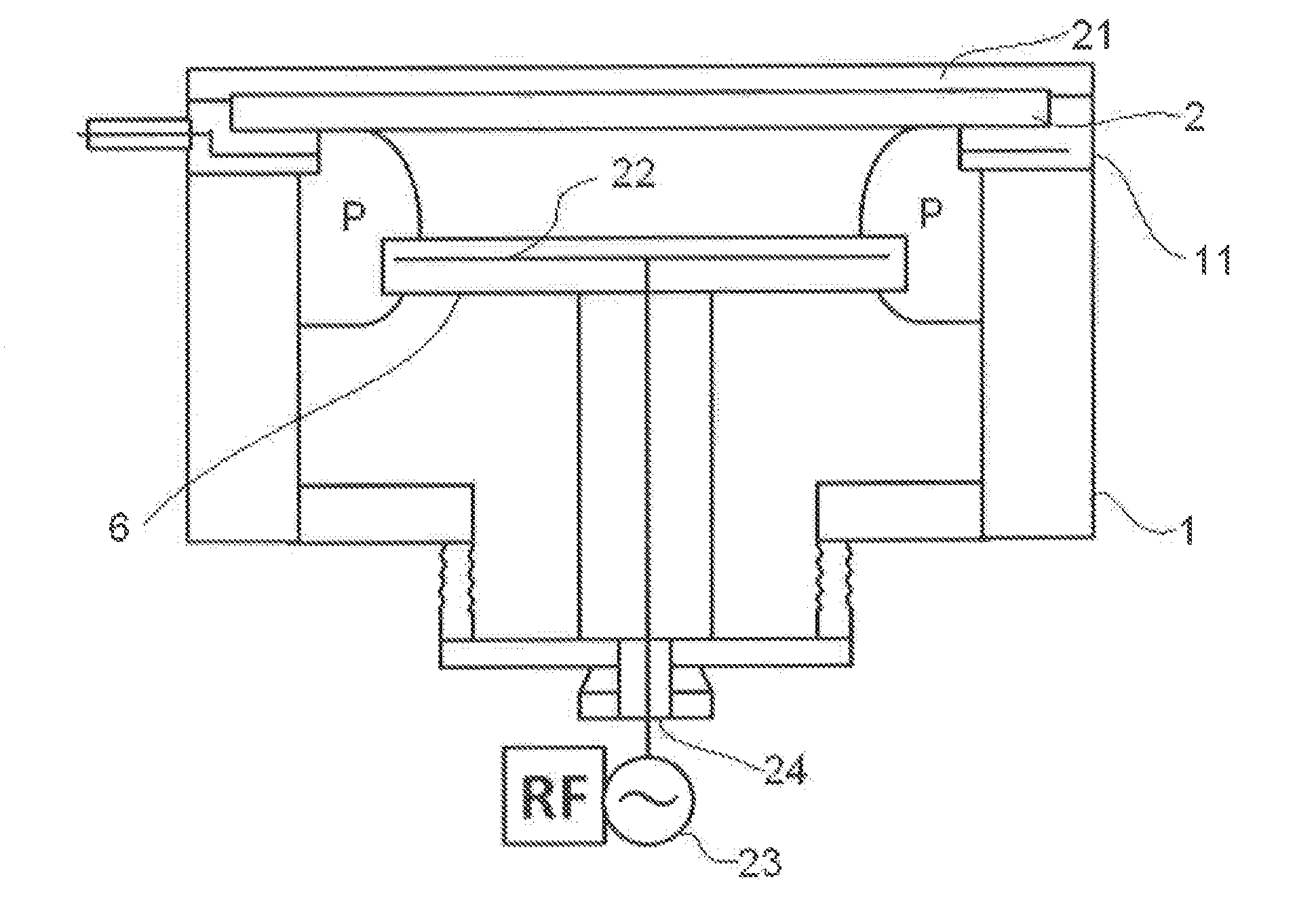

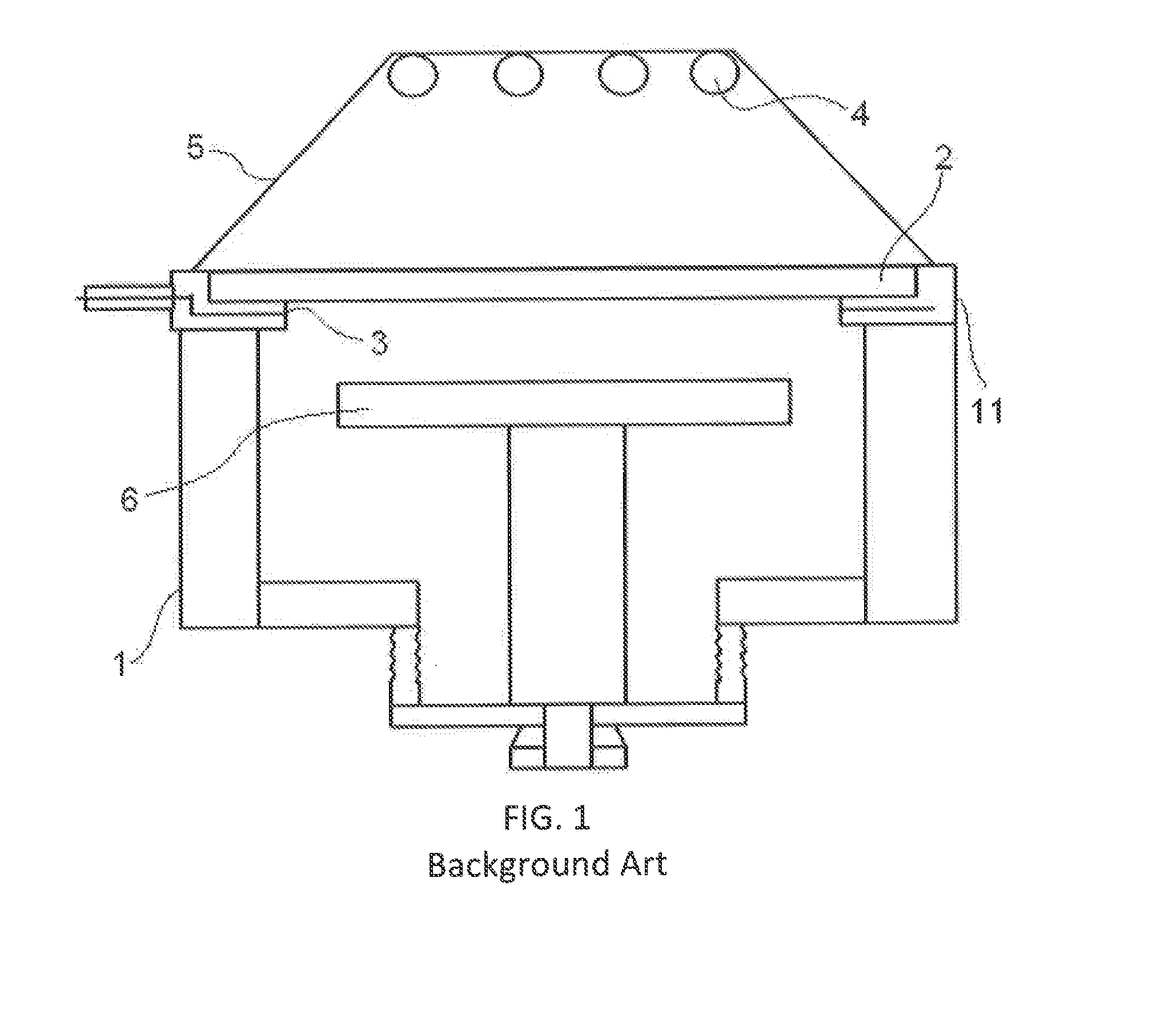

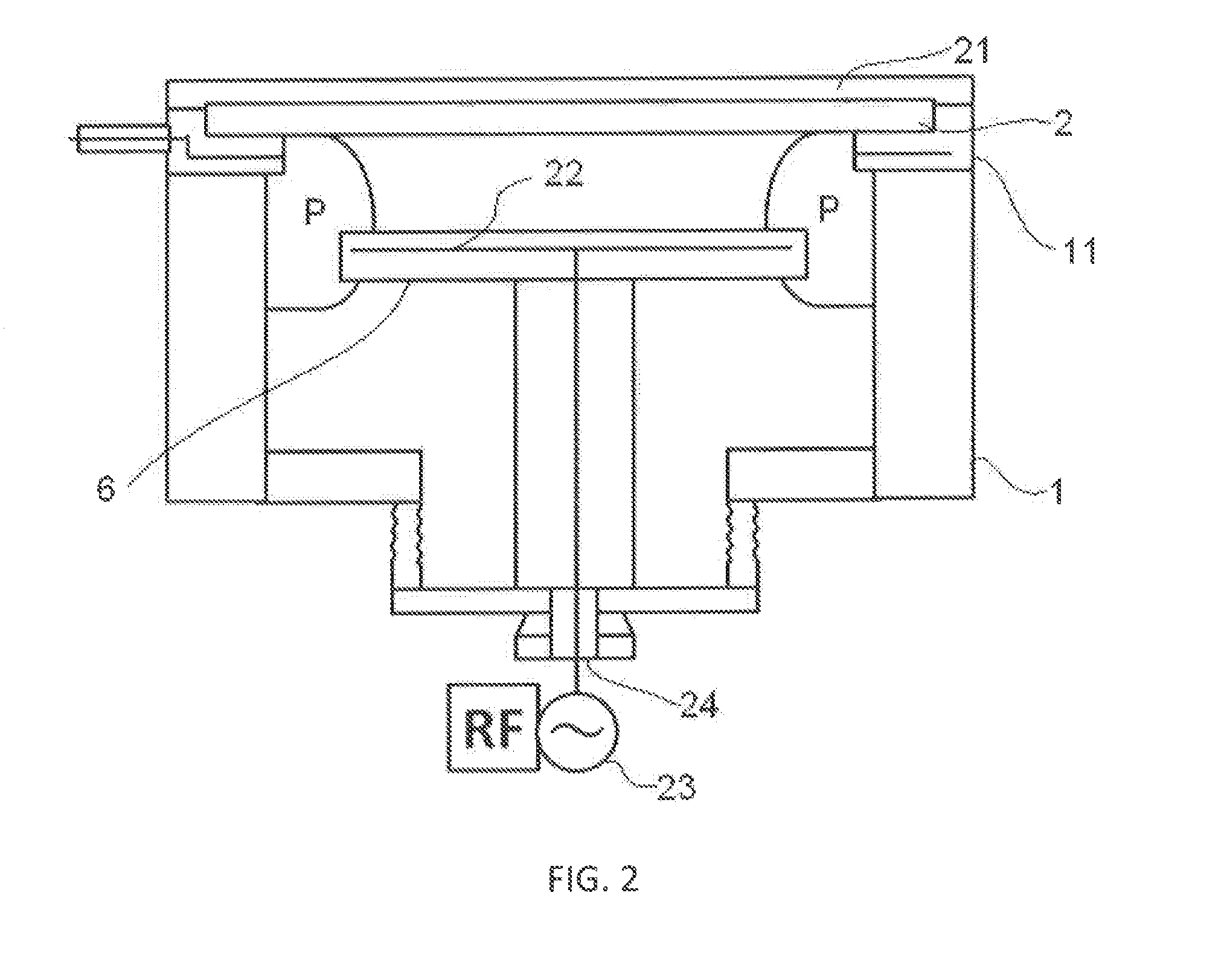

UV Irradiation Apparatus with Cleaning Mechanism and Method for Cleaning UV Irradiation Apparatus

InactiveUS20140116335A1Efficient implementationEfficient cleaning methodLiquid surface applicatorsElectric discharge tubesUltravioletEngineering

A UV irradiation apparatus for processing a semiconductor substrate includes: a UV lamp unit; a reaction chamber disposed under the UV lamp unit; a gas ring with nozzles serving as a first electrode between the UV lamp unit and the reaction chamber; a transmission window supported by the gas ring; an RF shield which covers a surface of the transmission window facing the UV lamp unit; a second electrode disposed in the reaction chamber for generating a plasma between the first and second electrodes; and an RF power source for supplying RF power to one of the first or second electrode.

Owner:ASM IP HLDG BV

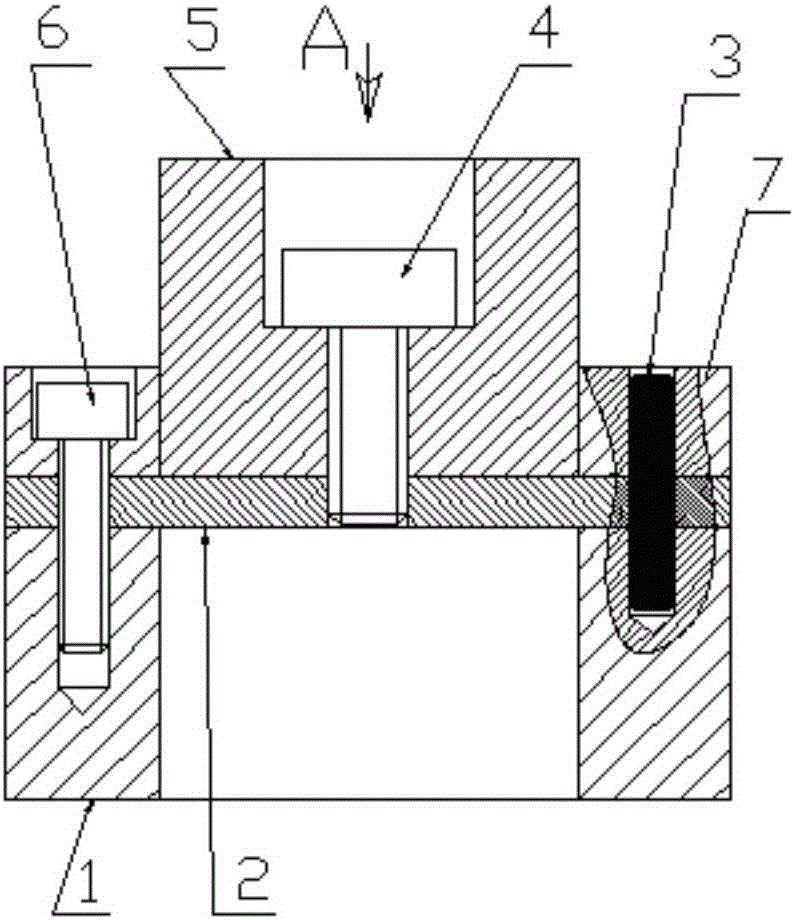

Field repairing method of welding cracks of feeding slip-ring body of large-sized slide mill

The invention provides a field repairing method of welding cracks of a feeding slip-ring body of a large-sized slide mill, wherein a field detection step comprises the following steps of coloring, detecting defects, drilling crack arrest holes and cleaning and polishing a surface; a repairing welding step comprises reinforcing plate repairing welding, repairing welding method and defect re-detection; in a machine processing step, a supporting frame arranged near a feeding slip-ring body is used for installing a turning machine for grinding and processing the surface of the maximum outside diameter of a slip ring; and finally, the field repairing is achieved by replacing a new bearing bush and commissioning and inspecting a cylinder body. The invention utilizes an installation base of the traditional device without disassembling the cylinder body of the traditional large-sized slide mill and has short repairing period, simple operation and safe and reliable running. The field repairing method of the welding cracks of the feeding slip-ring body is also suitable for the field reparation of welding cracks of a discharging slip-ring cone.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

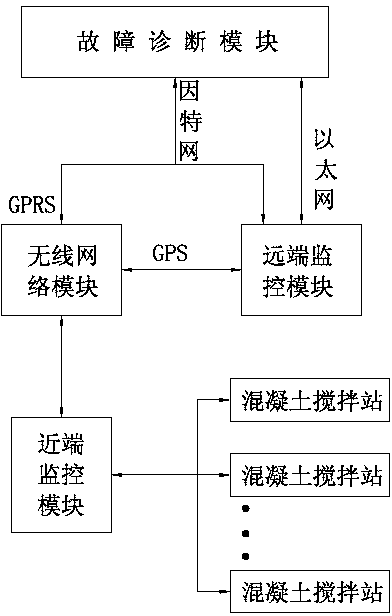

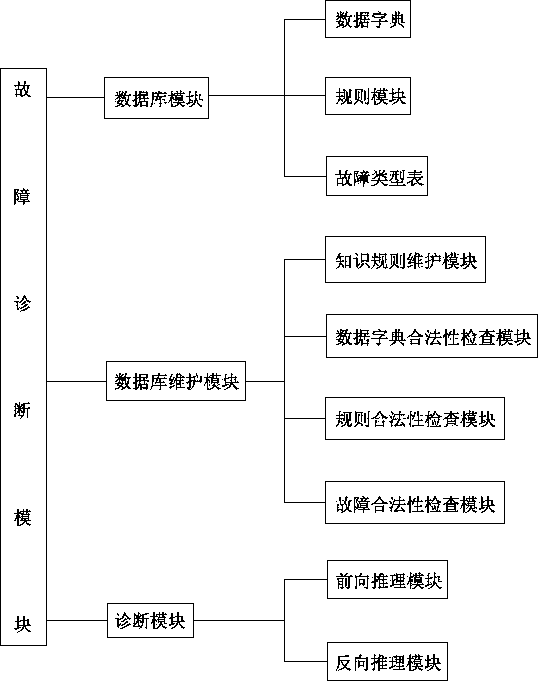

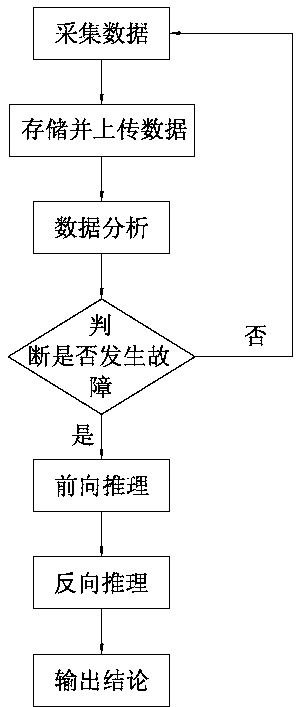

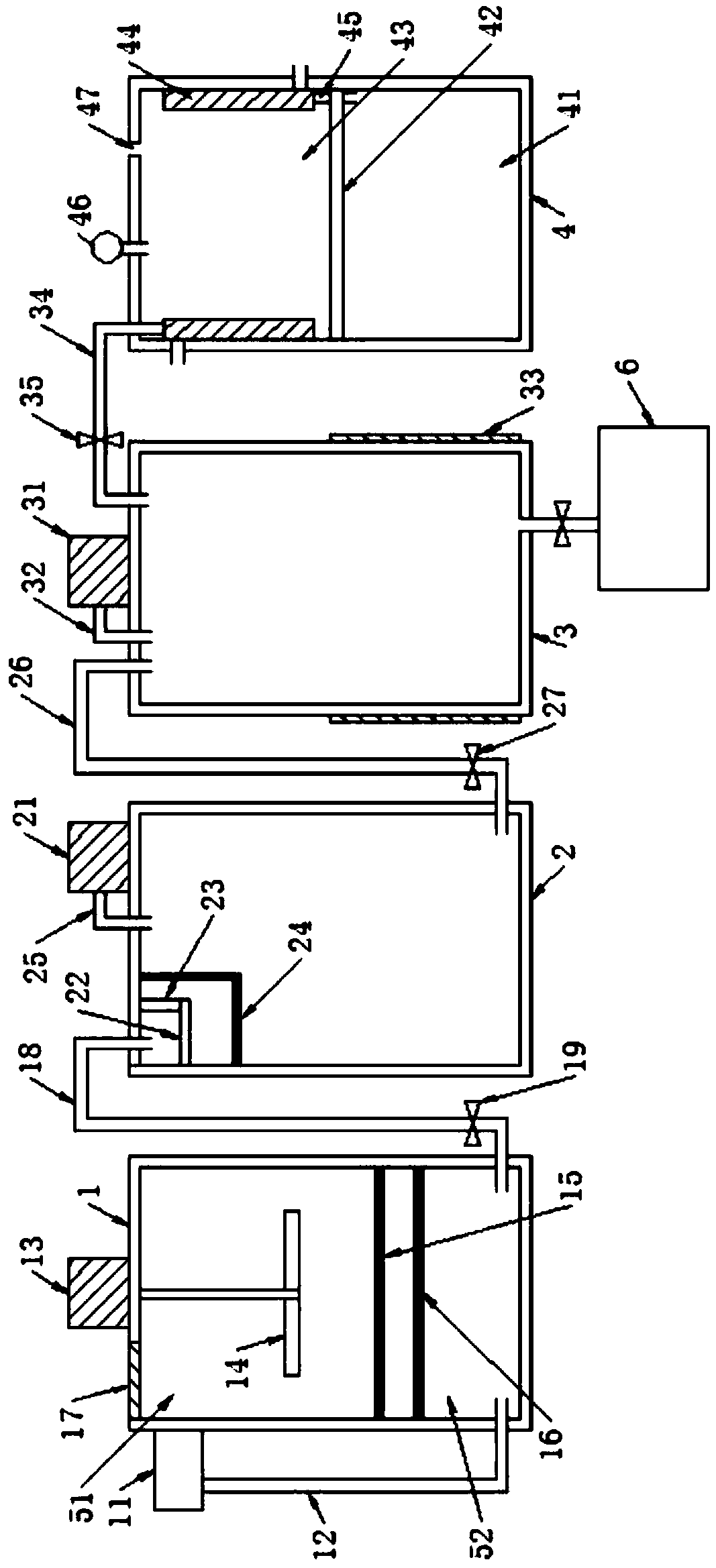

Remote fault diagnosis system and method for concrete batching plants

ActiveCN103901878ASolve the long maintenance cycleGood economic and social benefitsElectric testing/monitoringDatabase maintenanceGeolocation

The invention provides a remote fault diagnosis system and method for concrete batching plants. The system comprises at least one concrete batching plant, a near-end monitoring module, a wireless network module, a far-end monitoring module and a fault diagnosis module, wherein the wireless network module is connected with the fault diagnosis module through the GPRS and is connected with the far-end monitoring module through the GPS, the far-end monitoring module comprises a far-end monitoring computer and a portable far-end monitoring device, and the fault diagnosis module comprises a database module, a database maintenance module and a diagnosis module. The method comprises the steps of (1) acquiring data, (2) storing and uploading data, (3) analyzing data, (4) judging whether a fault occurs, (5) conducting forward reasoning, (6) conducting backward reasoning, and (7) outputting a conclusion. By means the system and method, geographical location positioning, remote information management, equipment state detection and remote fault diagnosis of the concrete batching plants can be achieved, and quick response to maintenance requirements of users is realized.

Owner:SHANTUI JANEOO MACHINERY

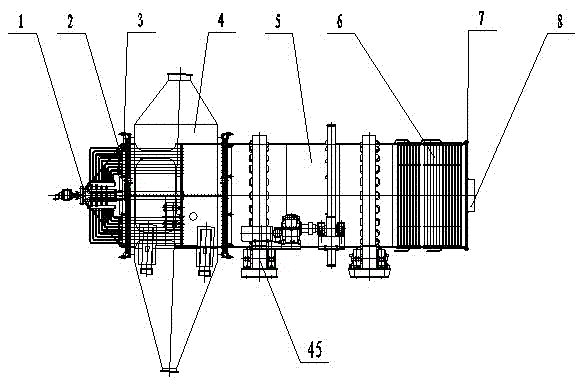

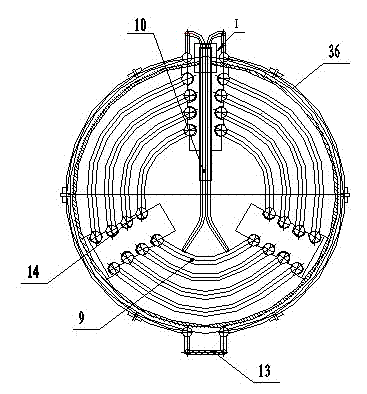

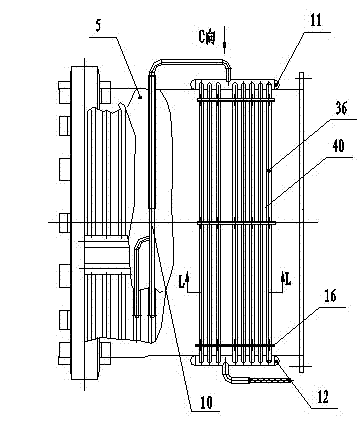

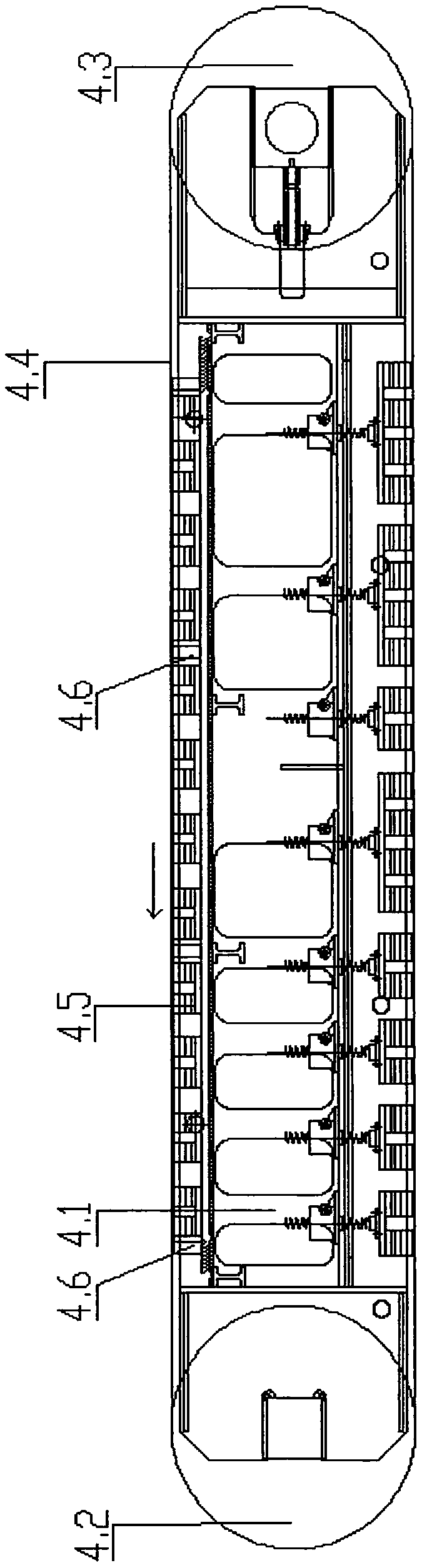

Auxiliary heating type steam rotary dryer

ActiveCN102393130AImprove liquidityReduce maintenance costsDrying solid materialsDrying machines with non-progressive movementsEvaporationEngineering

The invention provides an auxiliary heating type steam rotary dryer comprising a drum for containing a material to be dried and a rotary support device for supporting and driving the drum to rotate, wherein the drum is provided with a feed end and a discharge end, the feed end is constructed for receiving the material to be dried, the discharge end is constructed for discharging the dried material, the feed end is provided with a feed end plate, the discharge end is provided with a discharge sealing plate and a discharge cover, a plurality of heat exchange tube assemblies which rotate together with the drum are arranged in the drum, a drum heat tracing device connected with the heat exchange tube assemblies is arranged outside the drum near to the feed end area, and the drum heat tracing device rotates together with the drum. The invention adopts a drum heat tracing structural style, so that when the water content of the dried material is higher, the temperature of the drum wall can be improved to promote evaporation of water of the dried material and improve the flowing property of the material.

Owner:SHANDONG KEYUAN TIANLI ENERGY CONSERVATION ENG

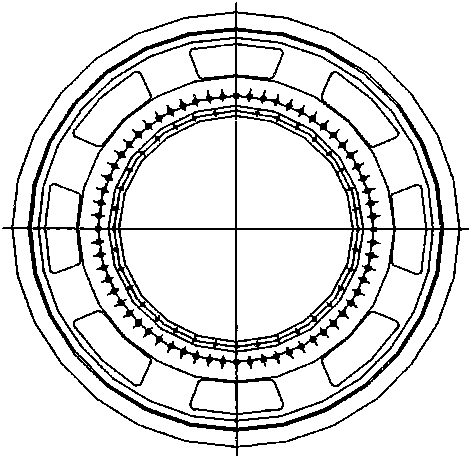

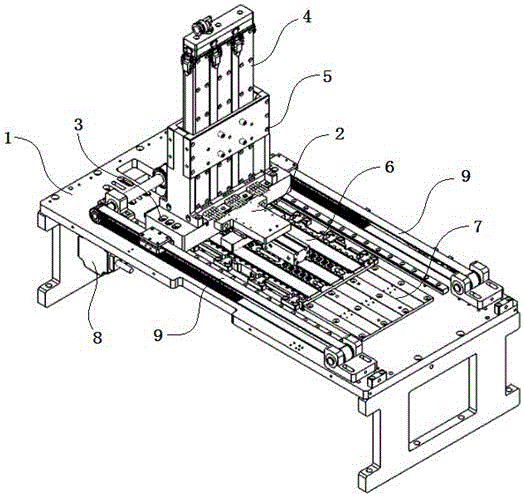

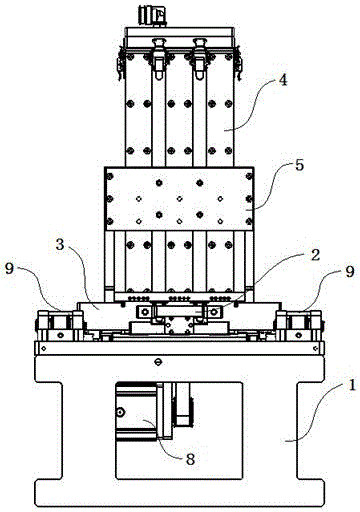

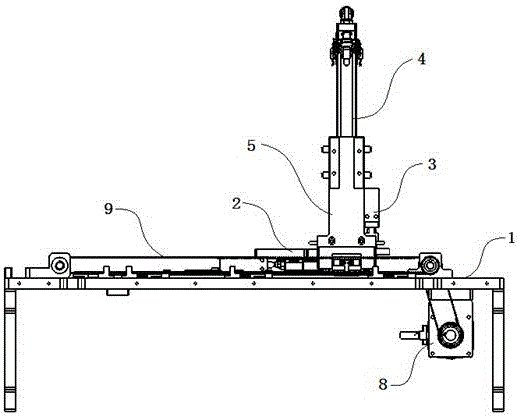

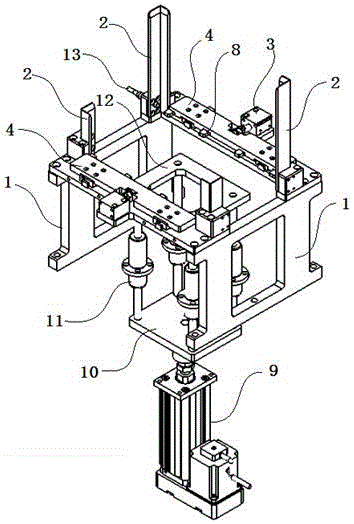

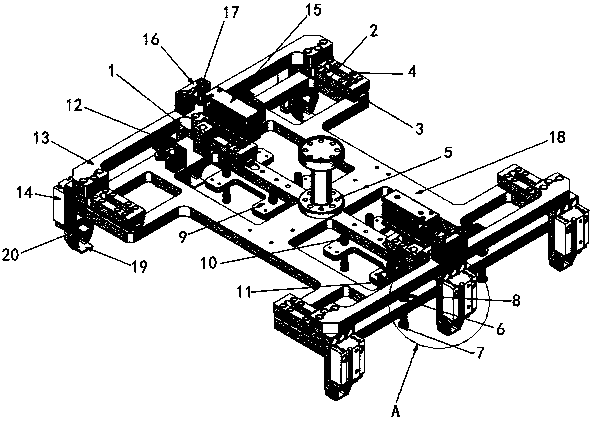

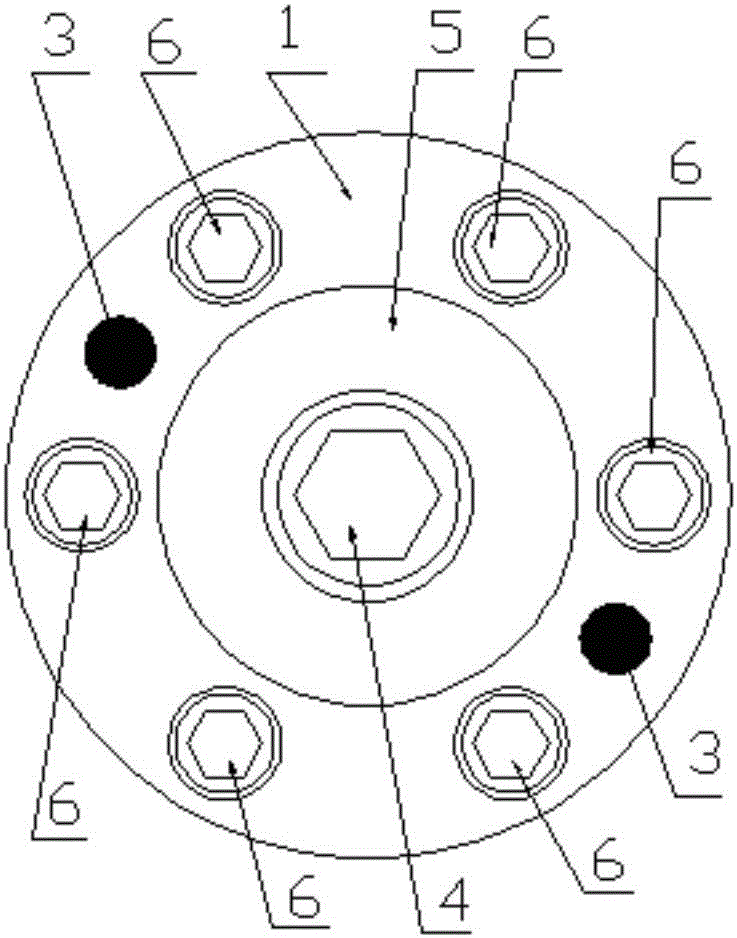

Magnet assembling mechanism

ActiveCN106041465AEasy to processEasy maintenanceMetal working apparatusProduction lineElectric machinery

The invention discloses a magnet assembling mechanism. The magnet assembling mechanism comprises an assembling working table, a conveying mechanism, a separating mechanism, a filling mechanism, a rapid disassembling magazine, a magazine holding mechanism and a tray, wherein a carrier plate used for placing the tray is arranged in the center of the table surface of the assembling working table; the conveying mechanism comprises two conveyor belts driven by a motor, and the two conveyor belts are separately arranged on the table surface, on the left and right sides of the carrier plate, of the assembling working table; and the filling mechanism is arranged on the two conveyor belts, the separating mechanism is arranged at the front part of the filling mechanism, the magazine holding mechanism is arranged at the upper part of the filling mechanism, and the rapid disassembling magazine is perpendicularly plugged on the magazine holding mechanism. The mechanism has the advantages of being simple to machine, simple to maintain, rapid to disassemble and assemble, low in cost, high in efficiency and the like, can be widely applied to various mobile phone production lines, and has advantages over the existing structures on the market in machining, assembly and later maintenance due to novel structural design and magnet assembling mode.

Owner:苏州茂特斯自动化设备有限公司

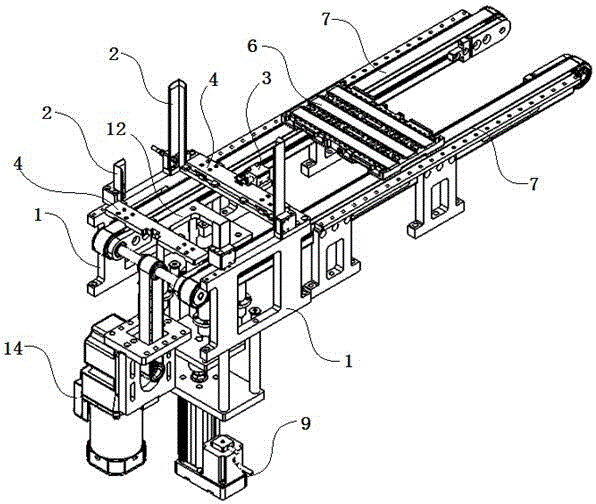

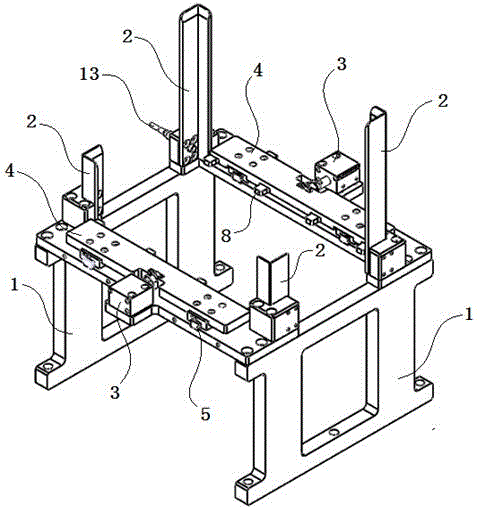

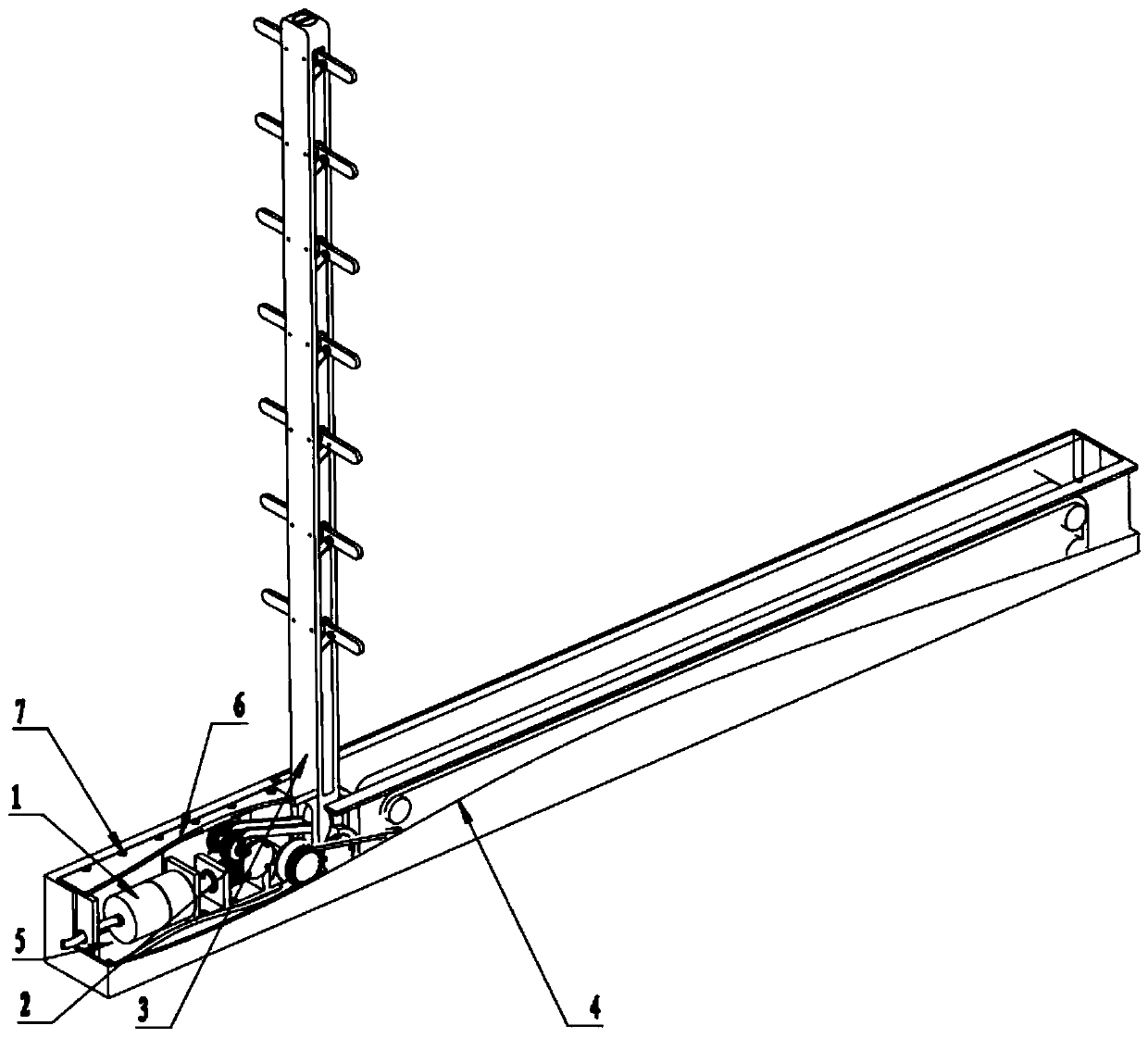

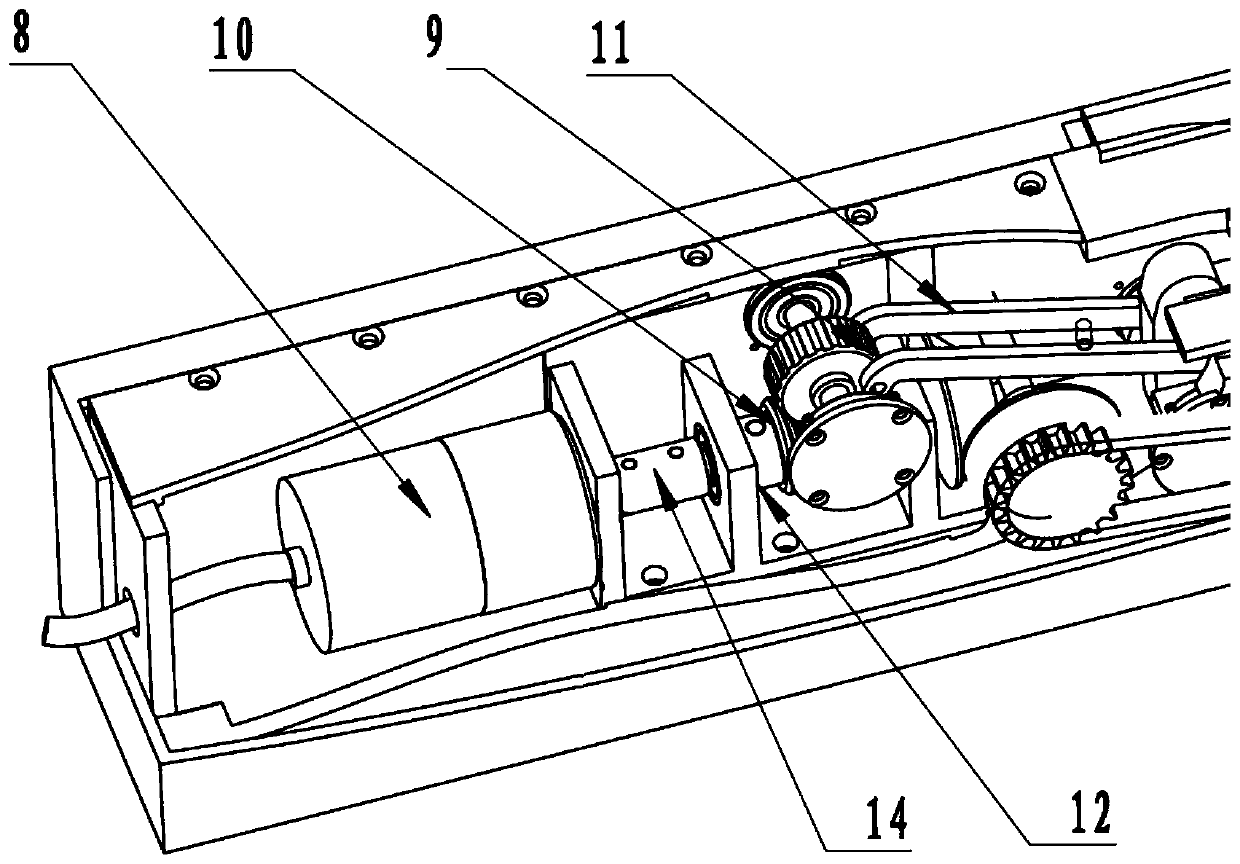

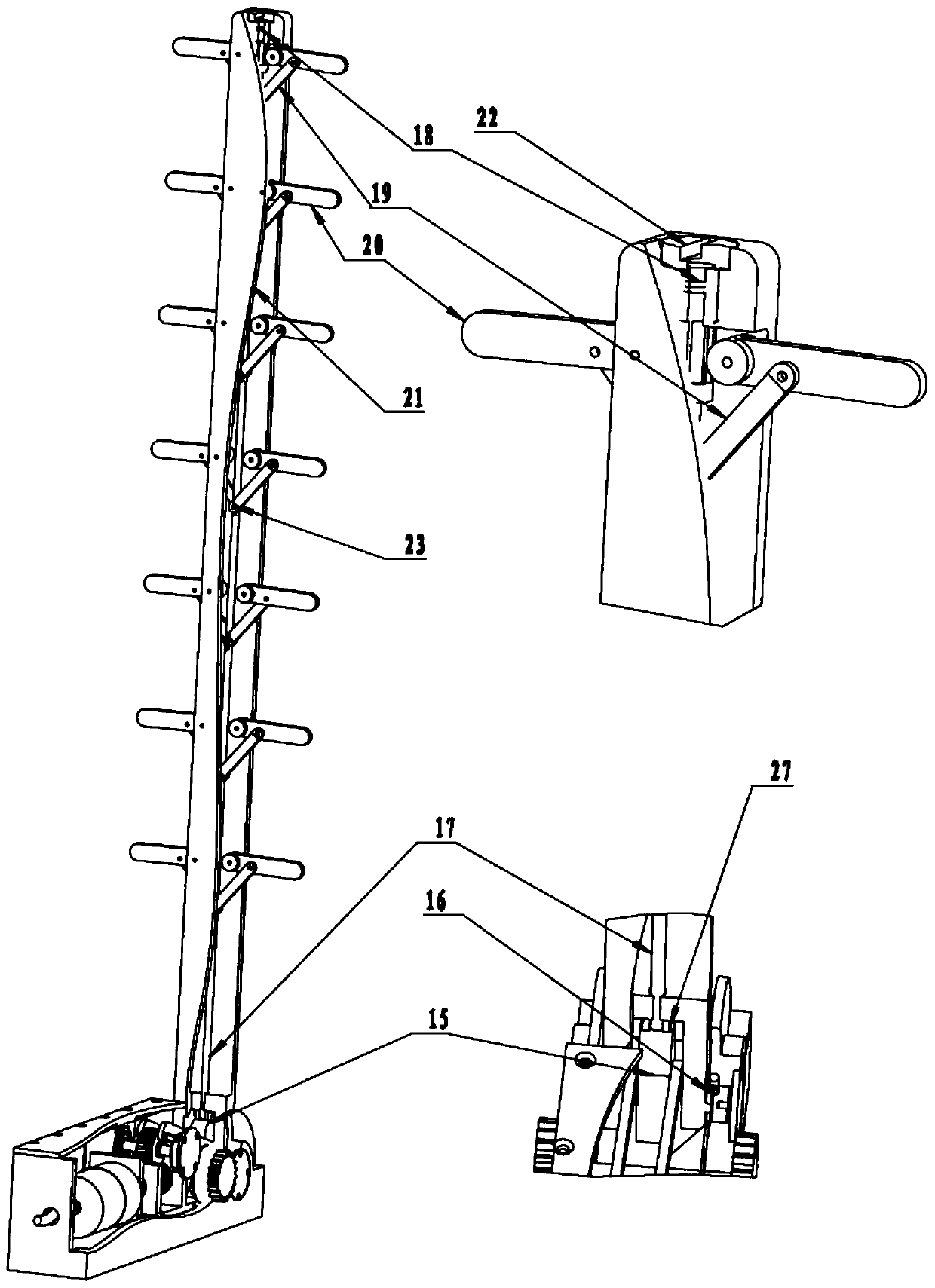

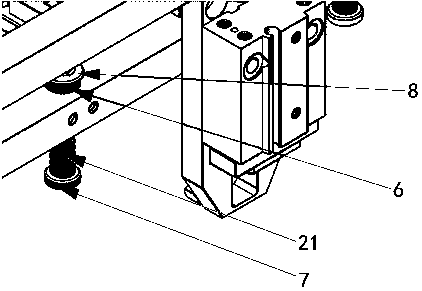

Automatic magnet assembly tray supply mechanism

InactiveCN106081643AHigh repeat positioning accuracyEasy to operateDe-stacking articlesElectric machineryMagnet

The invention discloses an automatic magnet assembly tray supply mechanism. The automatic magnet assembly tray supply mechanism comprises a storage mechanism, clamping mechanisms, a supporting mechanism and a transmission mechanism. The storage mechanism comprises a supporting frame and four retaining sides, and the four retaining sides are arranged on the upper end face of the supporting frame. The clamping mechanisms are arranged at left and right ends of the upper end face of the supporting frame respectively, clamping plates are arranged on the upper end face of the supporting frame through slide rails, and horizontal pushing air cylinders are arranged on outer sides of the clamping plates and connected with the clamping plates. The transmission mechanism is arranged below the supporting frame and comprises two conveying belts driven by a motor. The supporting mechanism is arranged below the supporting frame, a supporting air cylinder is connected with a supporting plate, four connecting rods are arranged on the upper end face of the supporting plate, and the supporting plate is fixed to the four connecting rods. The automatic magnet assembly tray supply mechanism has advantages of high repeated positioning accuracy, simplicity in operation, short maintenance period, high adaptability and the like, labor saving is achieved, action fusion with magnet assembly equipment can be realized, high reasonability in joint with the equipment is achieved, automation level is raised, and integral efficiency is improved.

Owner:苏州茂特斯自动化设备有限公司

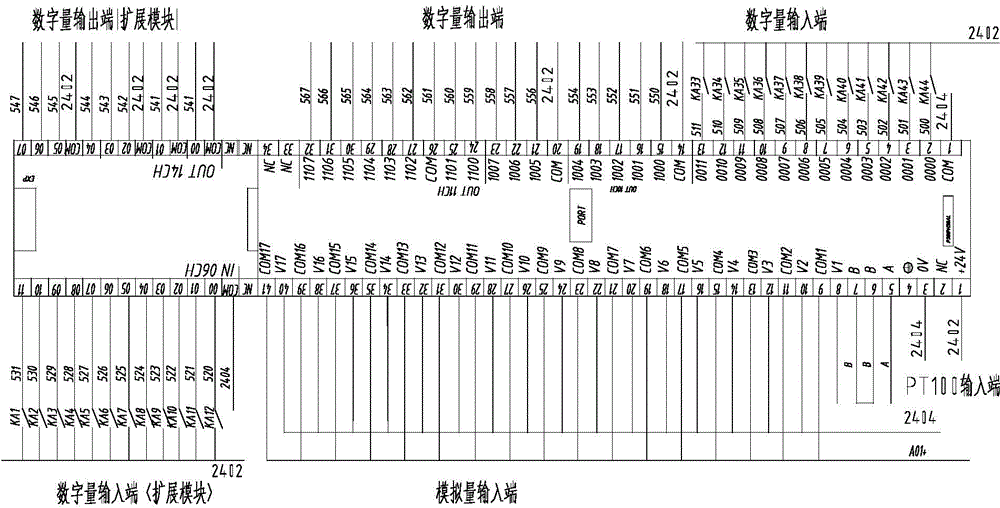

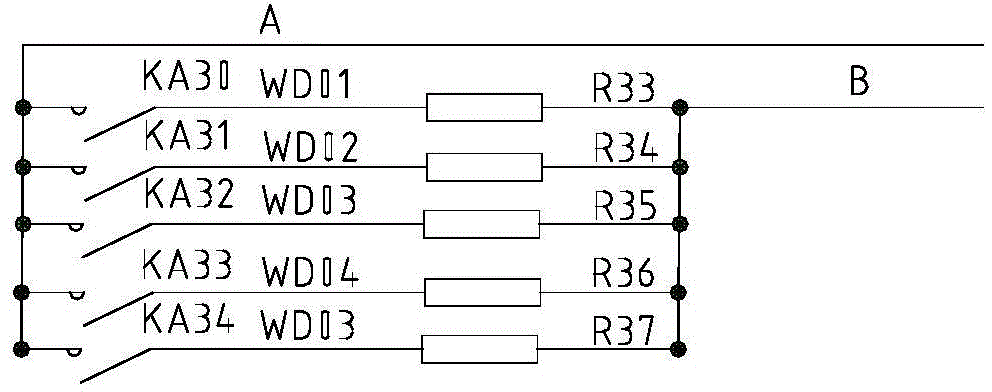

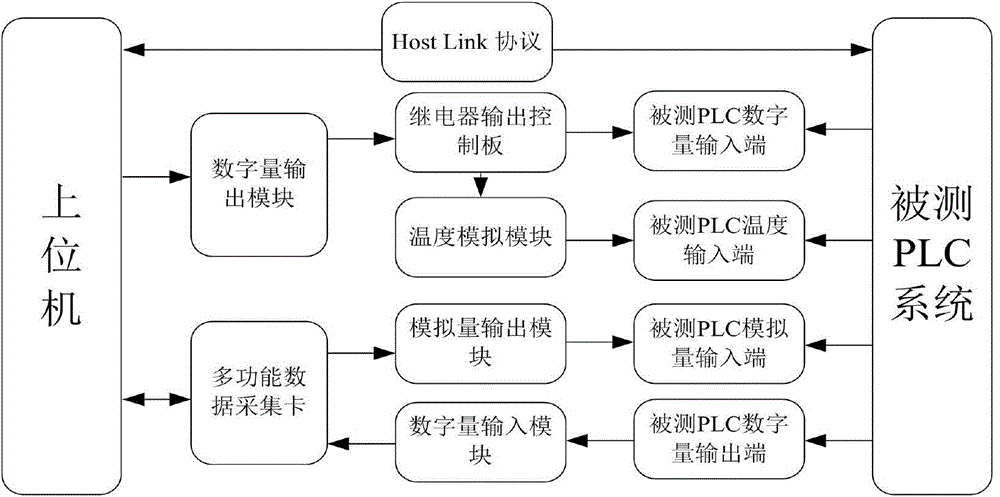

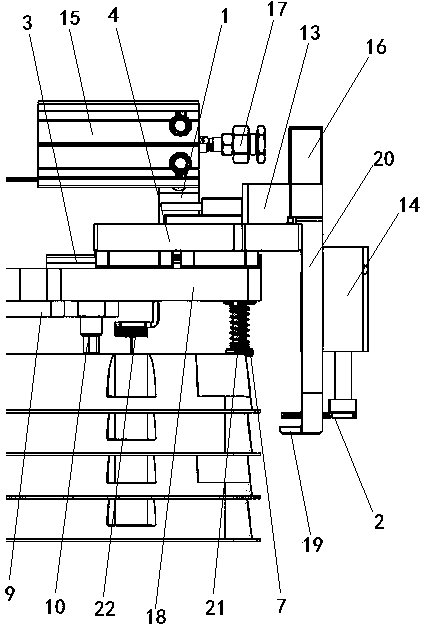

PLC detection system and method of Railway carriage control chamber

ActiveCN104834264AShort maintenance cycleReduce maintenance costsProgramme control in sequence/logic controllersElectrical controlControl room

The invention relates to a PLC detection system conducting performance detection on PLC system of an electrical control cabinet in railway carriage and a detection method. The PLC detection system comprises a host computer and a detected PLC system, wherein communication between the host computer and the detected PLC system is conducted. The PLC detection system also comprises a temperature signal detection unit, an analog input channel detection unit, a digital quantity output detection unit, and a digital quantity input detection unit, which can respectively achieve the automatic detection of the digital quantity input end, the temperature input end, the analog input end and the digital quantity output end of the detected PLC system. When the system of the invention is adopted for detection, the program of the PLC system is not required for updating, and no complicated work condition is required to be simulated, and thereby rapid, efficient and accurate detection can be realized.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST

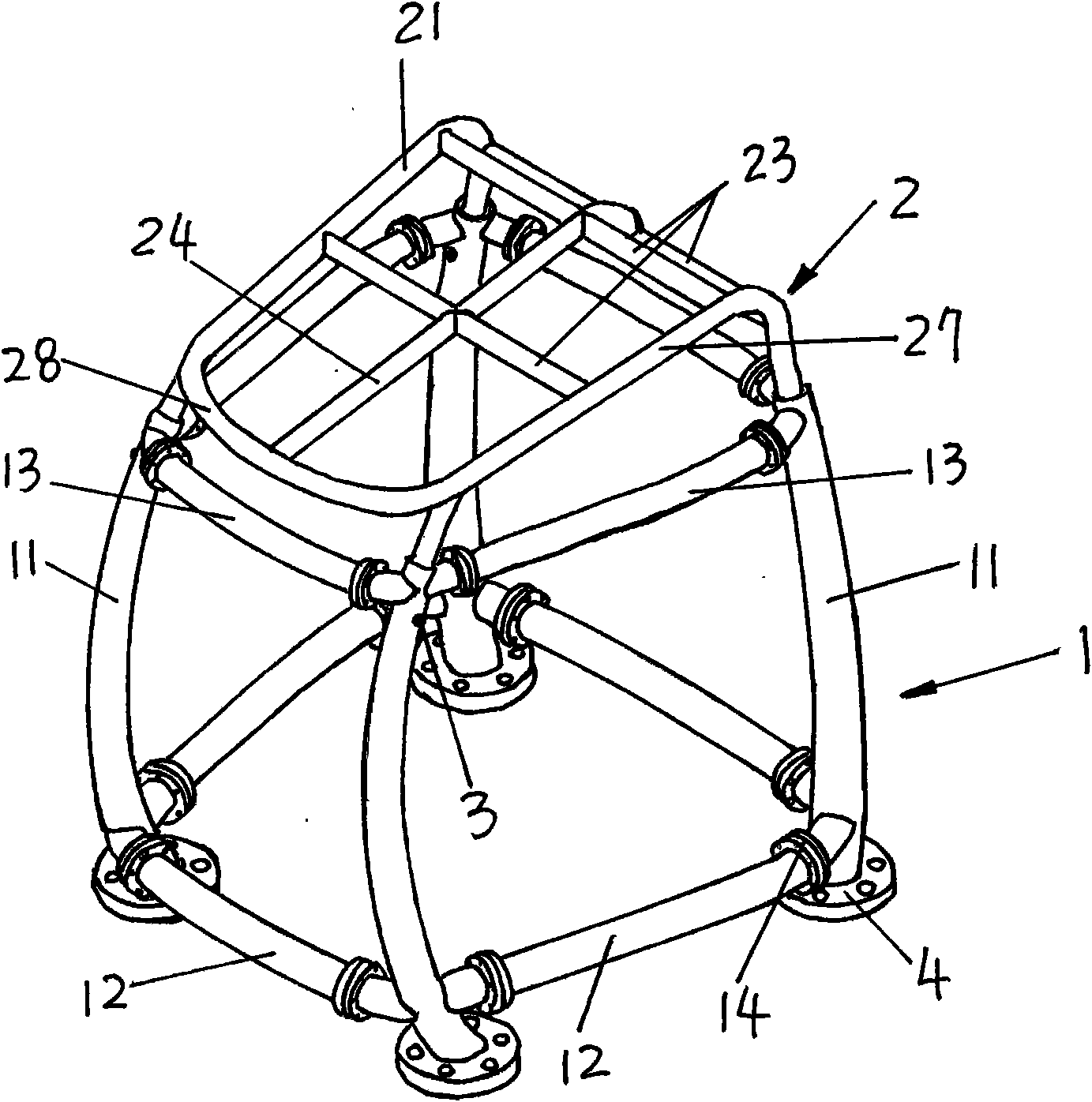

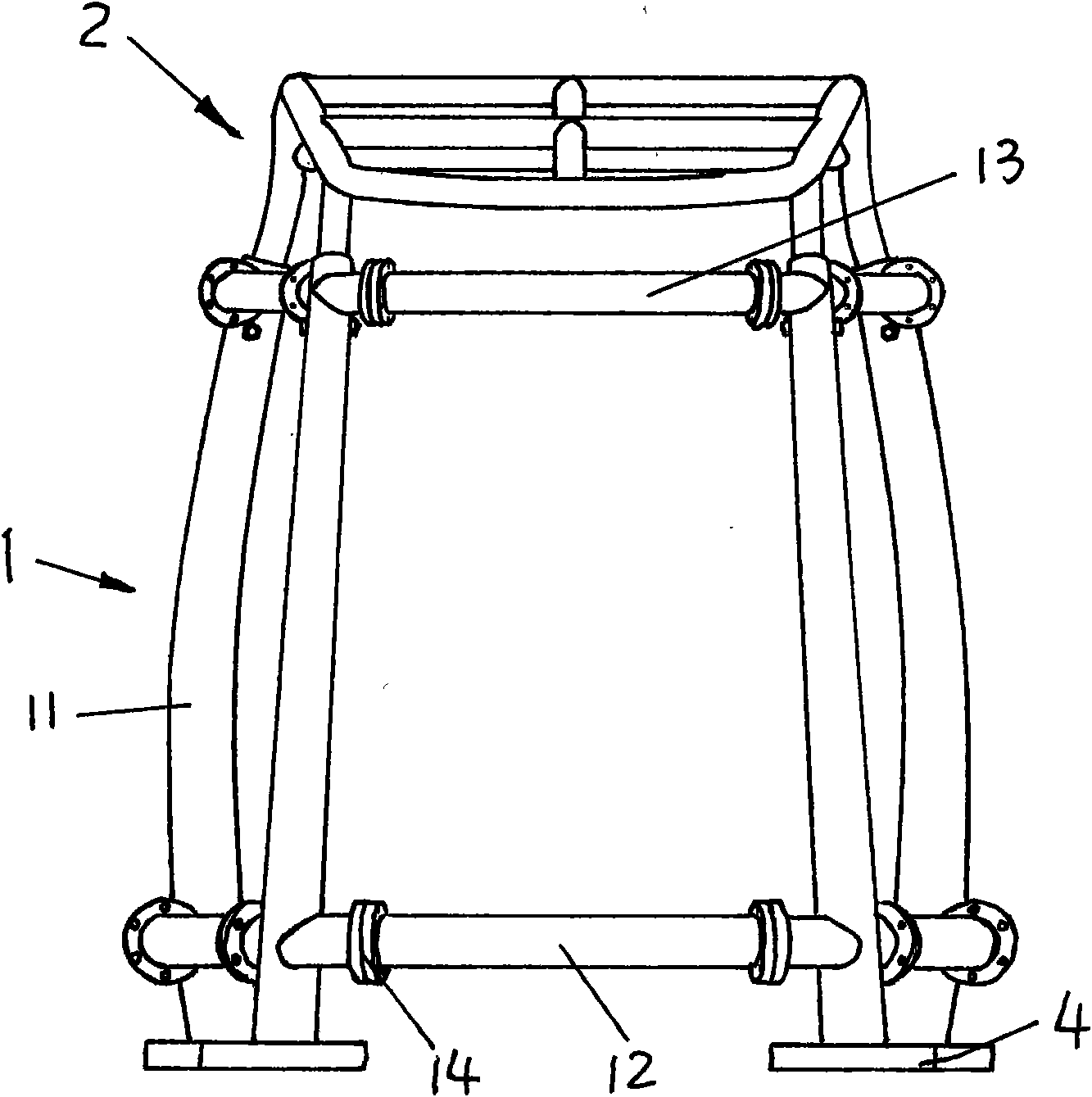

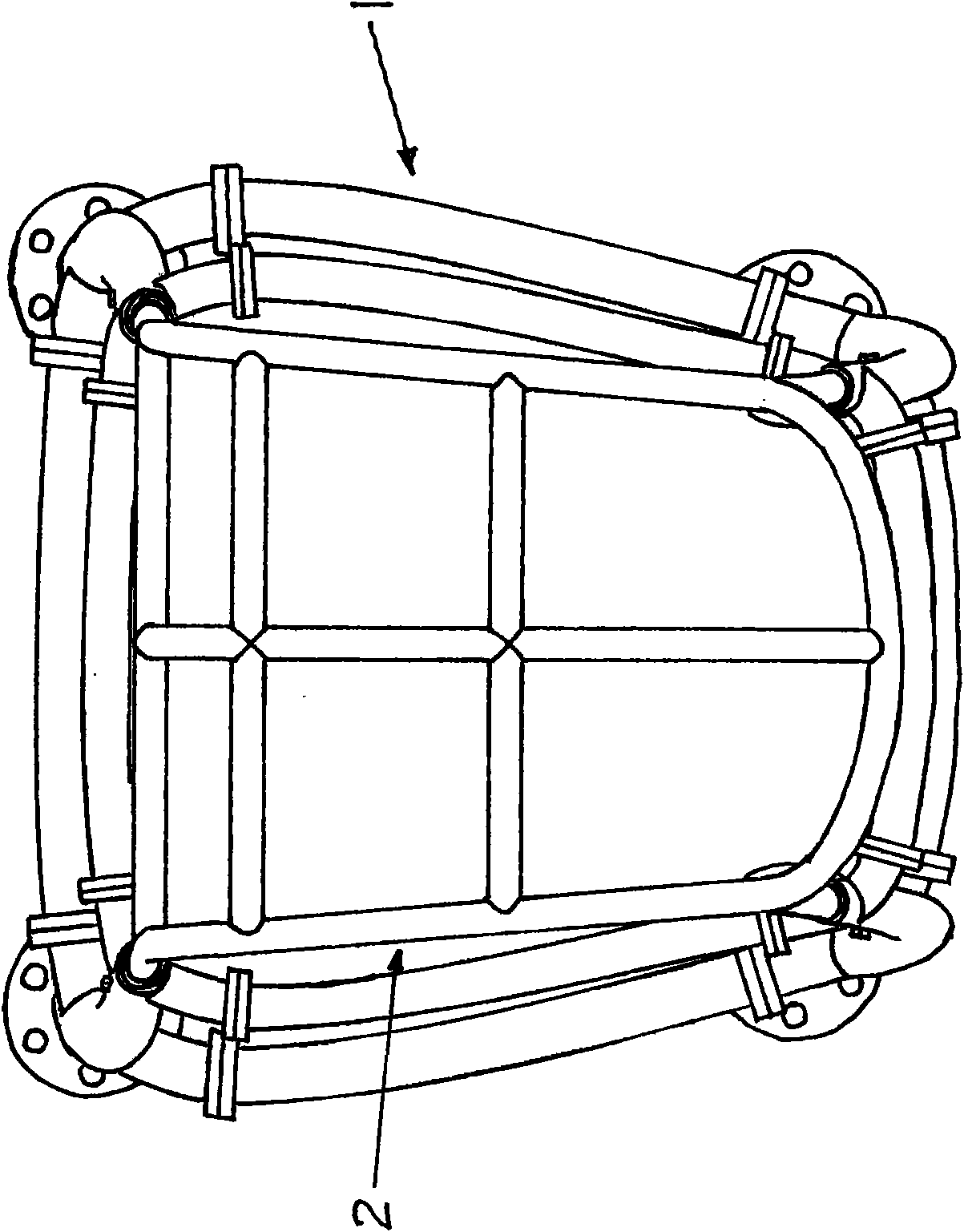

Buffer-induced independent combined-type roll-over protection structure

InactiveCN101559788AIncreased resistance to deformationLight weightPedestrian/occupant safety arrangementSuperstructure subunitsVehicle frameEngineering

The invention discloses a buffer-induced independent combined-type roll-over protection structure, which consists of a main-body bearing structure and a buffer-induced structure, wherein the main-body bearing structure is formed by connecting four upright columns with an upper beam and a lower beam through flanges; the main-body bearing structure is in a curved-edge trapezoidal shape in the left-right, front-back and upper-lower surfaces; the buffer-induced structure is in a trapezoidal shape; the buffer-induced structure is in the curved-edge trapezoidal shape in the left-right, front-back and upper surfaces; the upright column of the buffer-induced structure and the upright column of the main-body bearing structure are connected with bolts though transition fit; the lower end of the upright column of the buffer-induced structure is welded with a curved pipe; the curved pipe is inserted into the upright column of the main-body bearing structure and is fixed through the bolt throughout the two; and the main-body bearing structure and the buffer-induced structure are arranged outside a cab and are connected with a vehicle frame through the flanges. The protection structure has the advantages of taking the flanges for connection to ensure convenient replacement and maintenance, short maintenance cycle and lower maintenance cost, along with strong capability of resisting deformation and absorbing the kinetic energy of roll-over.

Owner:JILIN UNIV +1

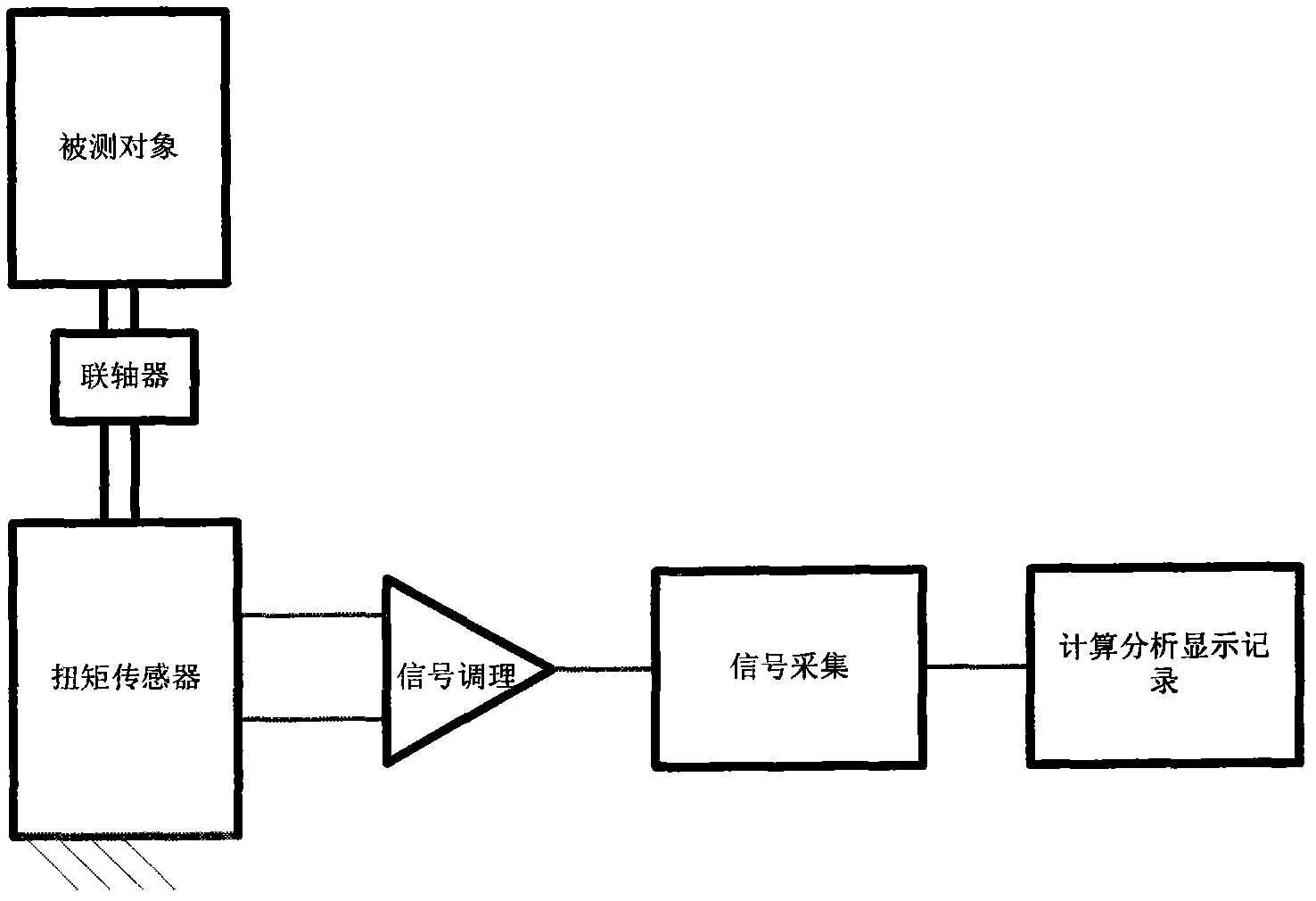

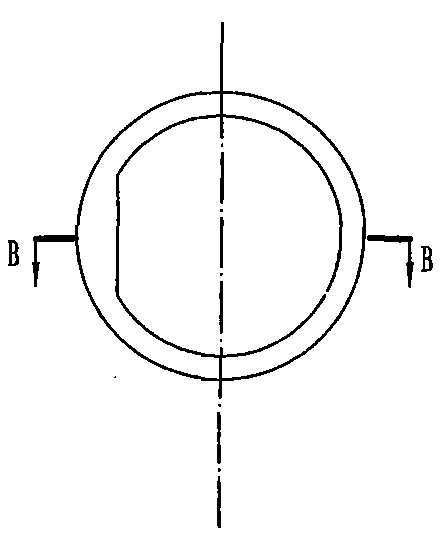

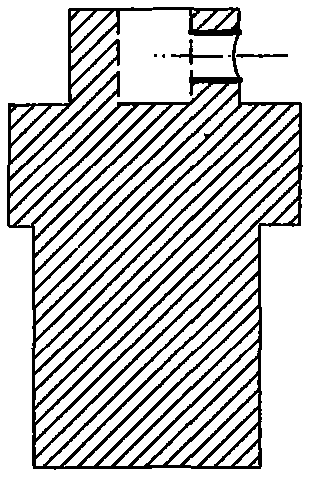

Reaction torque test method and tester

InactiveCN102095540ASimple structureLow costWork measurementTorque measurementFriction torqueLoad torque

The invention relates to a method for testing reaction torque. The method comprises the following steps of: fixing a stator shaft of a tested object on a static torque sensor through a coupler to acquire an electrical signal corresponding to the accurate micro torque value of the tested object; carrying out signal conditioning and data acquisition to the electric signal output by the sensor to accurately acquire torque data; and processing related data by a computer to acquire start torque, load torque and friction torque and calculating inertia time and synchronizing time. The reaction torque tester for realizing the method is provided with the static torque sensor, the coupler is fixed on the static torque sensor to acquire the accurate micro torque value of the tested object, and the accurate micro torque sensor is sequentially connected with signal conditioning and data acquisition systems and accessed in a computer processing system. By analyzing and researching tested characteristics and the test principle, the static torque sensor is selected to acquire the accurate micro torque value and accurately acquire the torque data through signal conditioning and data acquisition.

Owner:中国航天科技集团公司第九研究院七一〇七厂

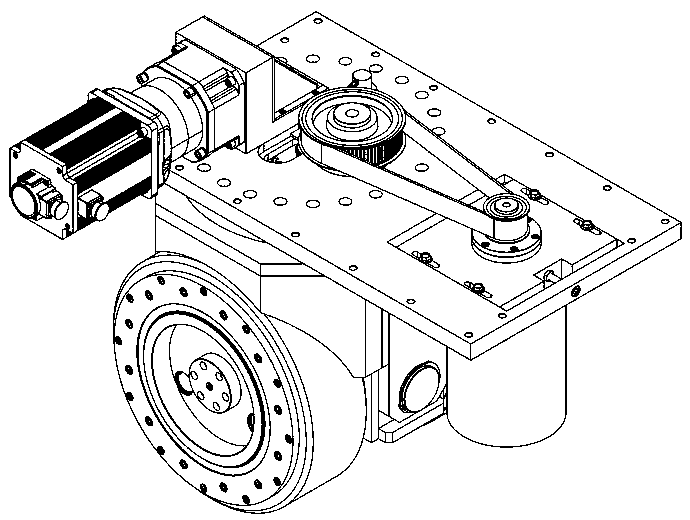

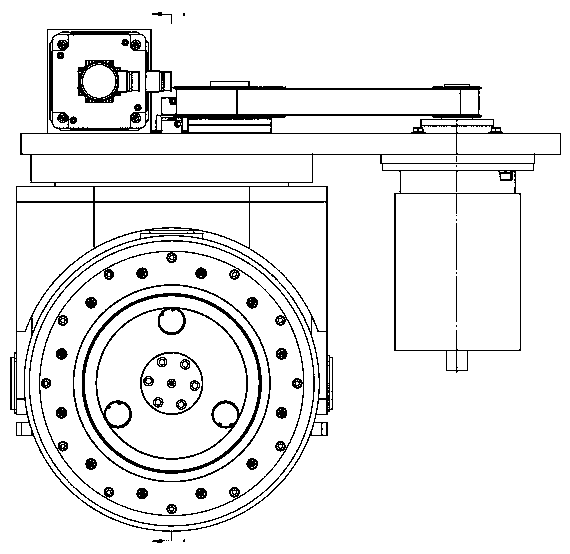

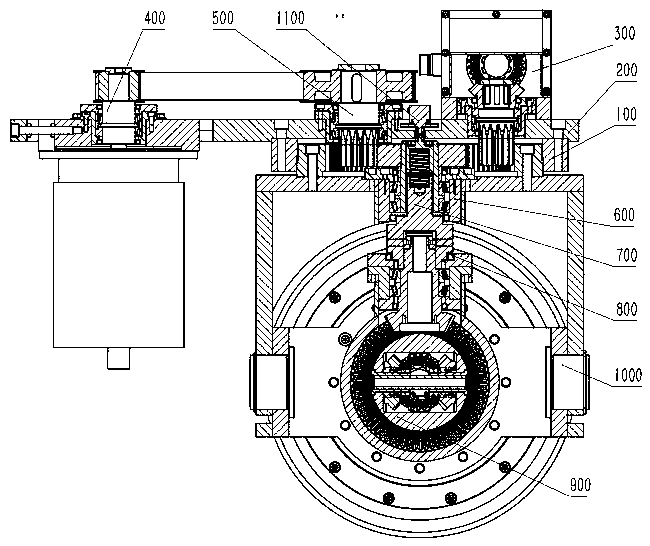

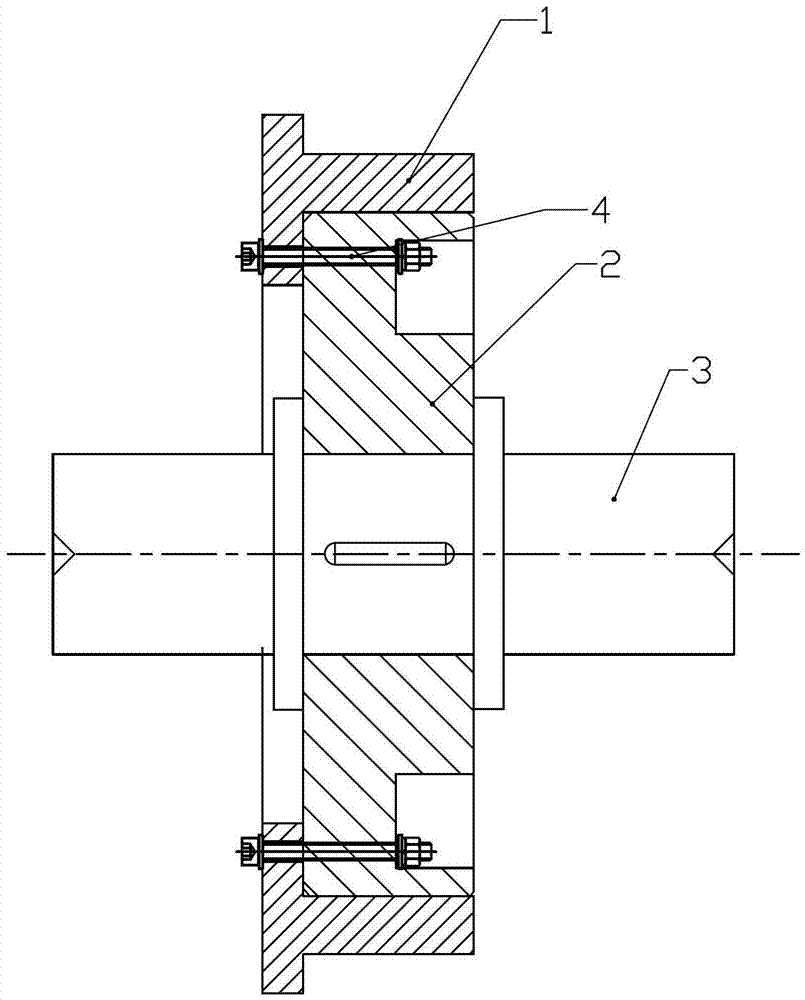

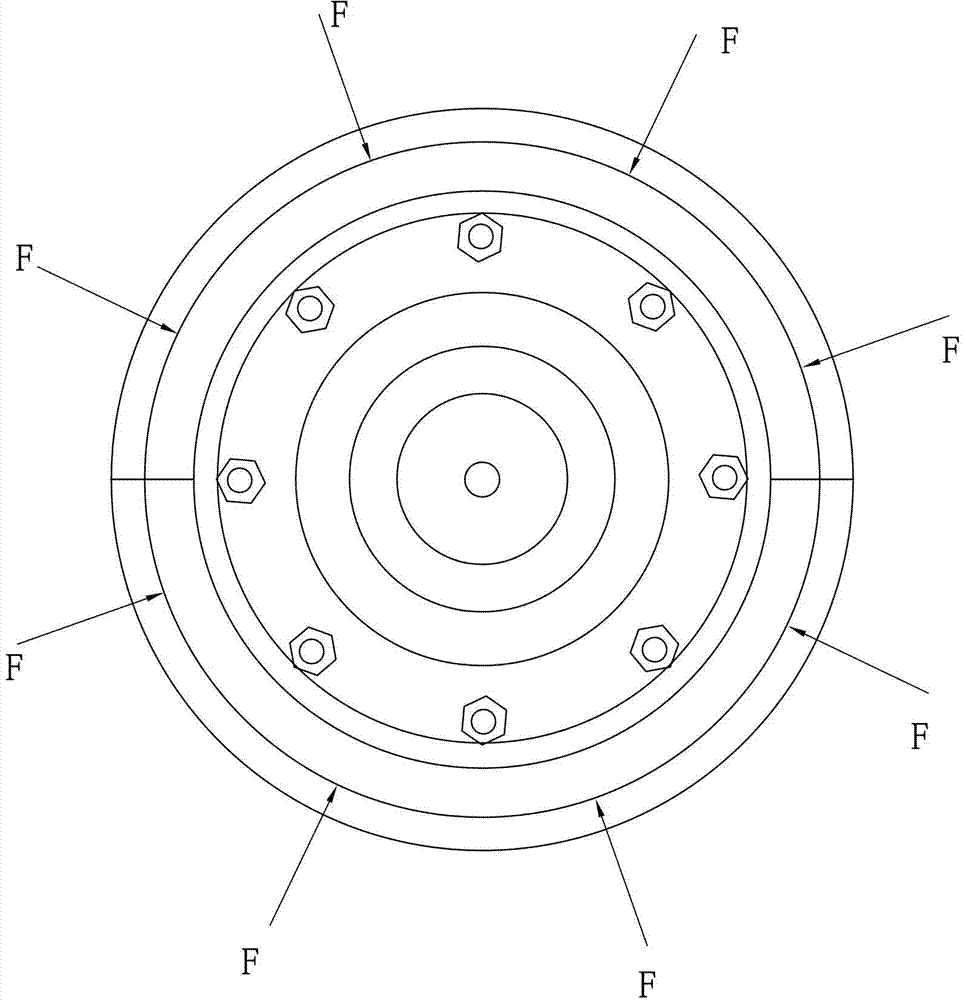

Double-wheel steering driving wheel

ActiveCN111152837ASmall turning radiusImprove carrying capacityMotor depositionElectrical steeringSupporting systemDrive wheel

The utility model relates to a double-wheel steering driving wheel, and belongs to a driving wheel for an electric loading vehicle, and the double-wheel steering driving wheel comprises a steering rotating support system and a walking system, the steering rotating supporting system comprises an internal tooth rotating supporting device, a rotating supporting mounting plate 200, a steering wheel steering driving device, a driving wheel steering encoder device, a connecting piece and a fastening piece. The walking system comprises a rotating support mounting plate, a steering wheel walking powerdriving device, a steering wheel walking power driving transition device, a third-stage transmission shaft device, a floating coupling power transmission device, a walking driving fourth-stage transmission shaft device, a walking power differential output device, a swing balance support assembly, a driving wheel walking position encoder device, a neutral gear clutch device, a rubber wheel, a built-in planetary reducer hub, a connecting piece and a fastening piece. The double-wheel steering driving wheel is suitable for application occasions with heavy loads and severe environment road conditions, and is safe and reliable.

Owner:上海鸣界机电科技有限公司

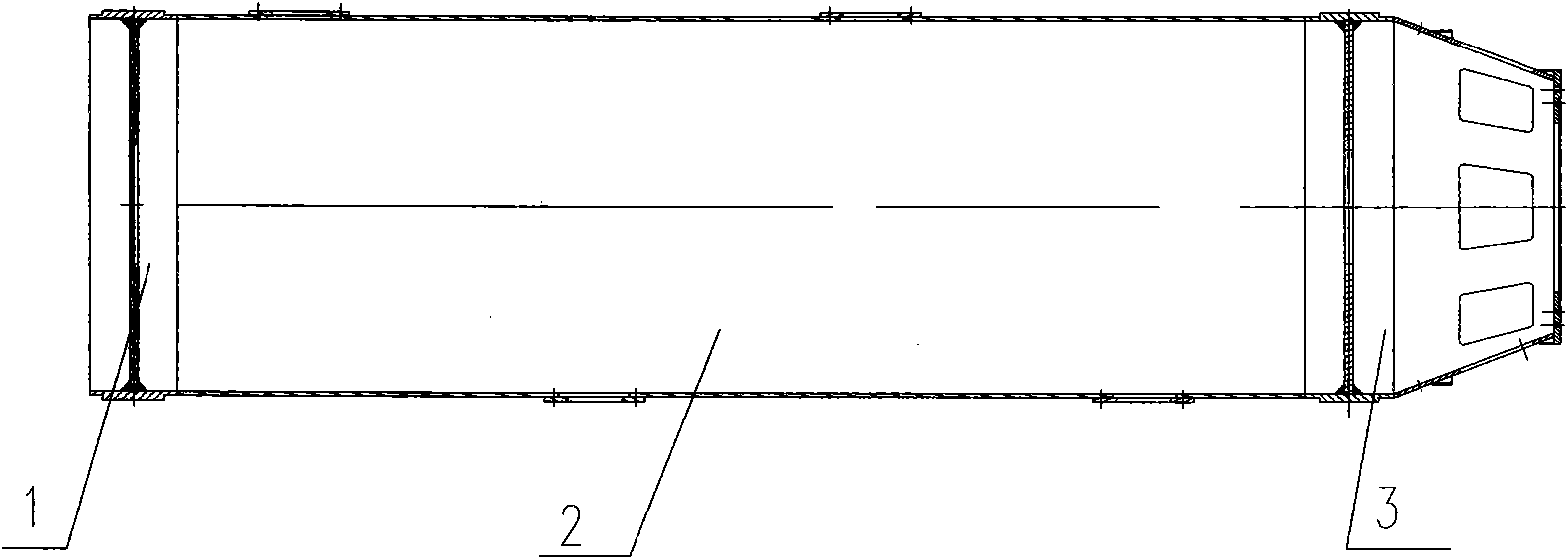

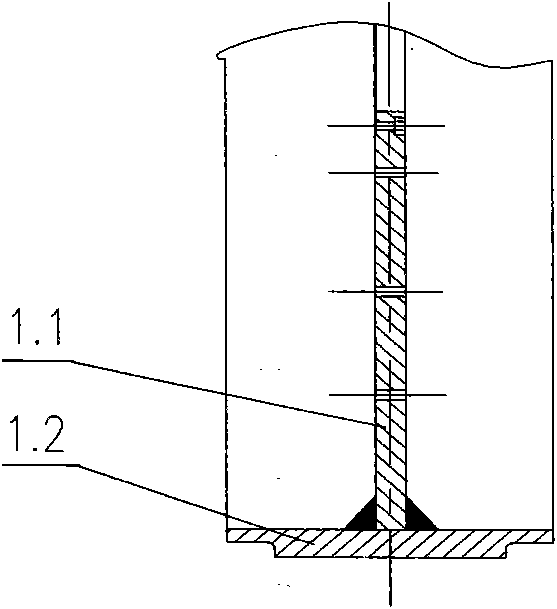

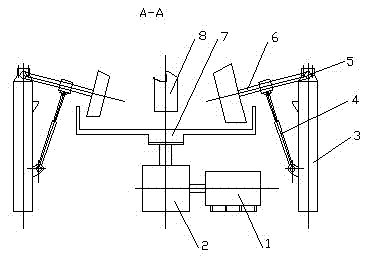

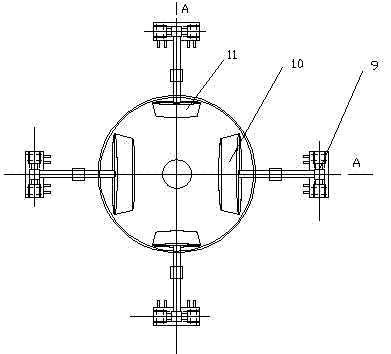

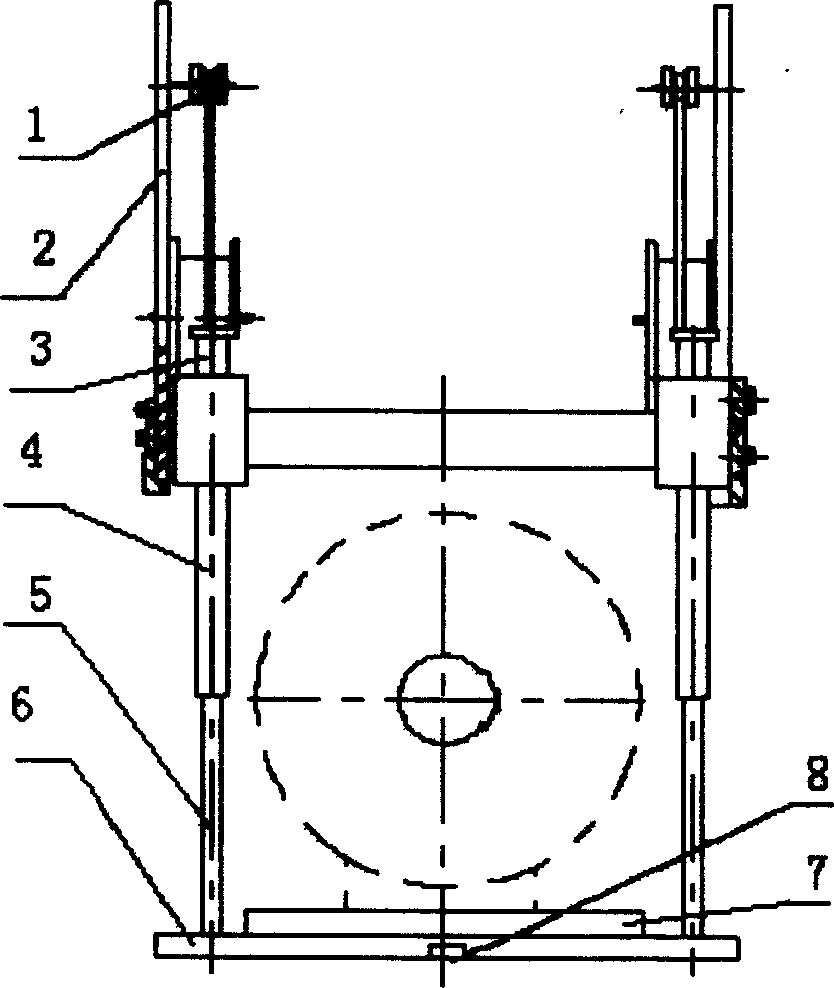

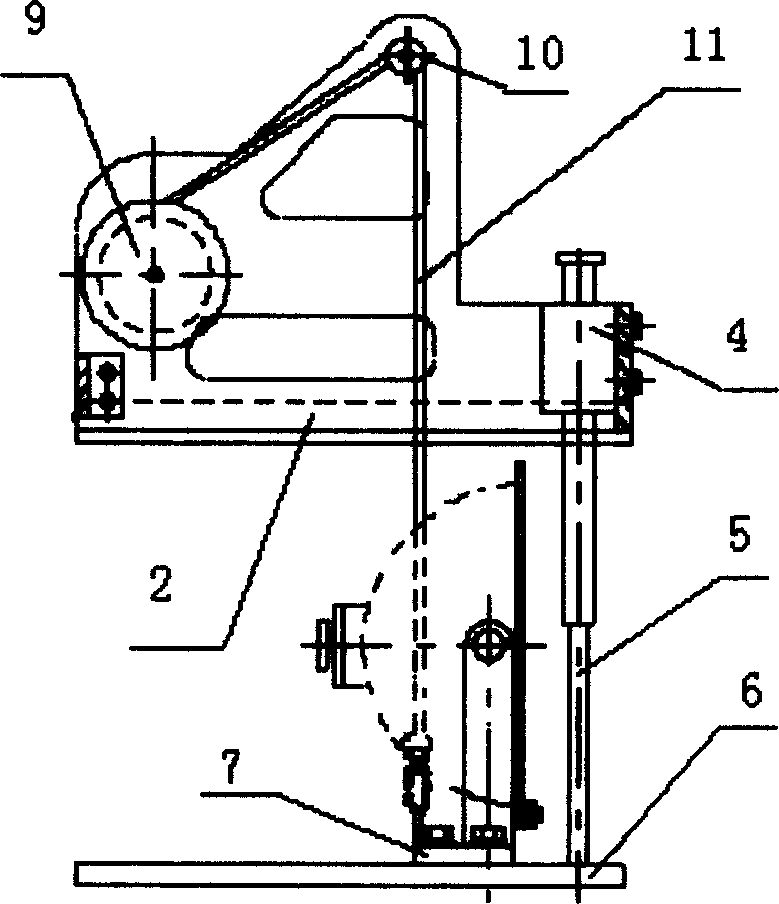

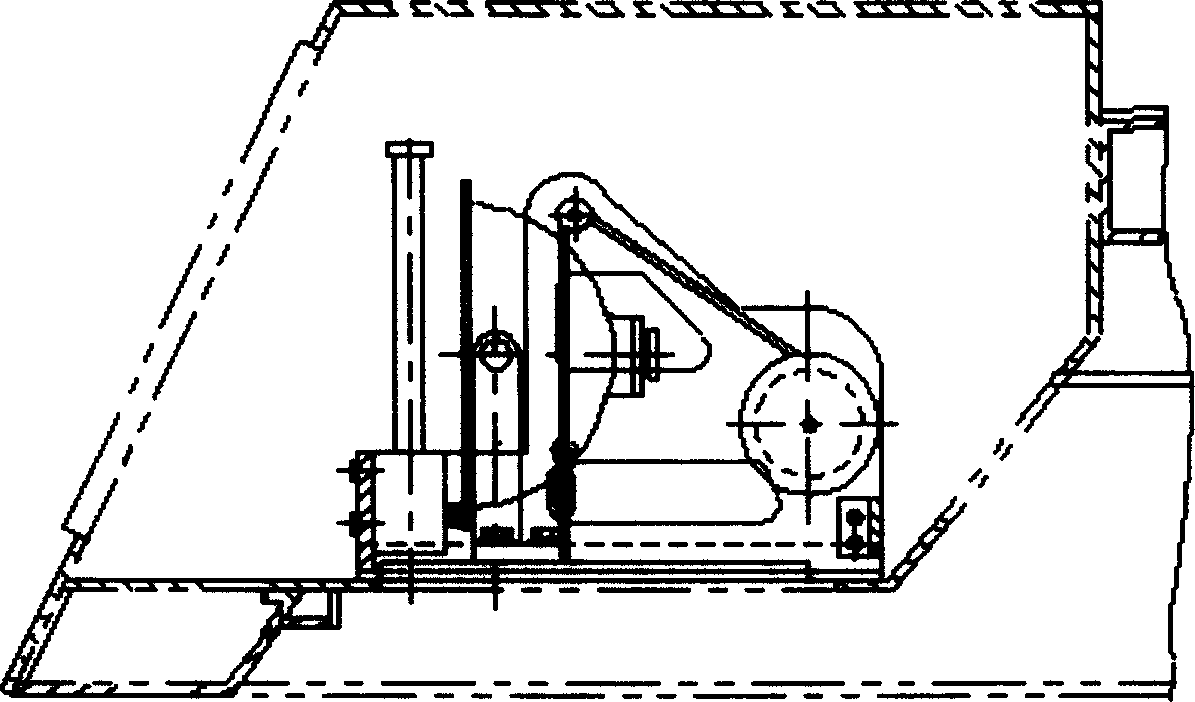

Field processing method for grinding surface of slip ring in feeding slip ring body

InactiveCN102059626AFix production issuesSolve shipping problemsGrinding machinesLow speedSurface roughness

The invention provides a field processing method for grinding the surface of a slip ring in a feeding slip ring body. A supporting frame is built beside the feeding slip ring body, a lathe is installed on the supporting frame, a grinding wheel is installed on a motor output shaft the rotation speed of which is 2800-3000rpm, a motor base is fastened to the bottom slide of a saddle which transversally shifts along a guide rail of the lathe, and a protective cover is assembled on the non-working side of the grinding wheel. The field processing method comprises the following steps: jacking the feeding slip ring body end of a cylinder through a high-pressure pump of a large slipper mill lubrication station; starting a low-speed motor of a driving device of a large slipper mill so that the cylinder rotates; and carrying out surface grinding processing on the position with the maximum outer diameter, of the slip ring, wherein the surface grinding processing is divided into coarse grinding and fine grinding; in coarse grinding, the roundness and straightness of the slip ring can be achieved by coarse grinding via a coarse grinding wheel; and after the roundness and straightness meet the technical requirements, the surface roughness of the slip ring can be achieved by fine grinding via a fine grinding wheel until the surface roughness meets the technical requirement. The field processing method has the characteristic of short maintenance period, is simple and feasible to operate, and is safe and reliable in performance.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

Centrifugal steel mould hub repairing process

InactiveCN103157951AImprove the new processing technologyImprove new processing technologyStress reliefEngineering

Provided is a centrifugal steel mould hub repairing process. In the process of long term contacting of a hub and a power wheel, the outer surface of the hub can generate tension force, namely, pressure stress, once the hub is taken down from a centrifugal steel mould, under the function of the tension force on the outer surface of the hub, the inner diameter of the hub is bound to reduce and deform, and is difficult to repair. The centrifugal steel mould hub repairing process comprises the following steps: manufacturing a positioning mould with a core shaft, a mould fixing plate and a basic flange plate on the centrifugal steel mould for fixing the hub are identical, the basic flange is imitated, the hub is fixed on the mould fixing plate, equivalently, a running wheel is moved to a lathe for processing, improvements relies in steps of increasing stress relief, diameter and shaft bi-directional pressing and fixing in the process of dismantling and positioning. Due to the fact that same order and same position in an integrated task is not restricted by sequencing and processing, single mode repair cycle is just 4.5 hours, general repairing of a 10 meters mode can be completed in 2 to 3 days, time saving effect is very obvious, and emergency repairing is benefited.

Owner:吕传水

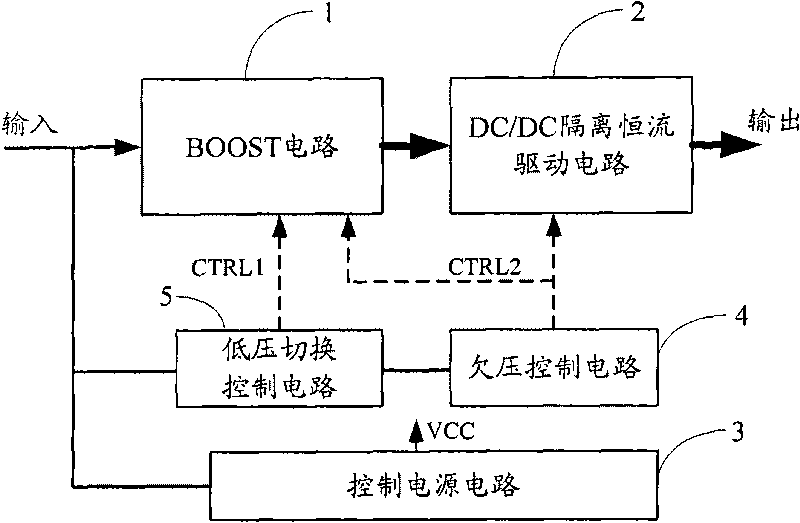

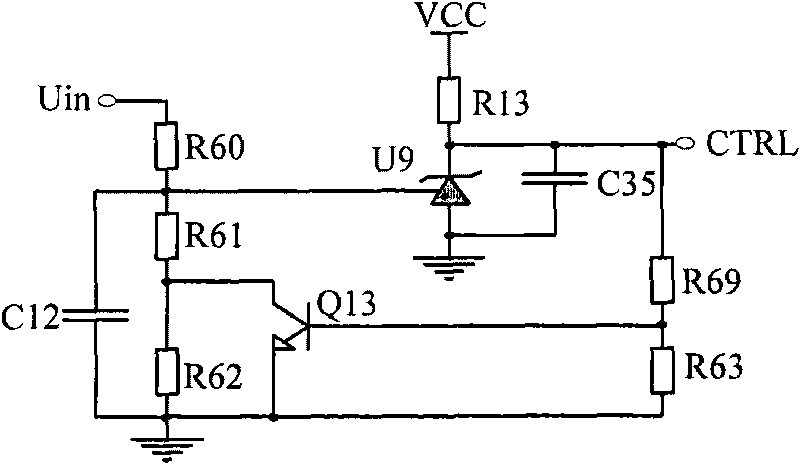

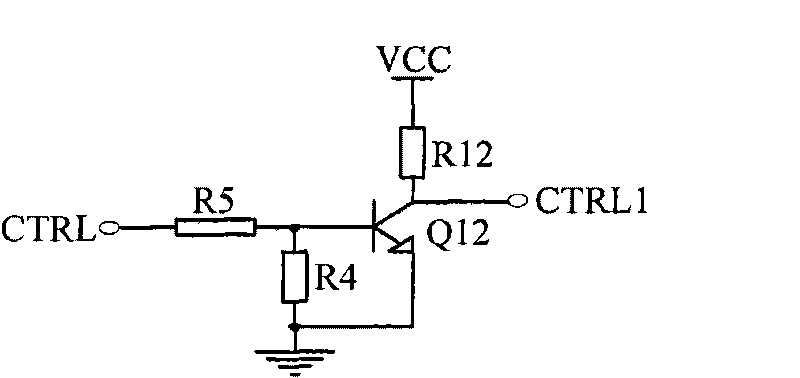

Constant current driving circuit, LED light source and locomotive light

ActiveCN101711072ALow light efficiencyShort maintenance cycleElectric light circuit arrangementEnergy saving control techniquesDriver circuitControl power

The invention is applicable to the field of illumination and provides a constant current driving circuit, an LED light source and a locomotive light. The circuit comprises a BOOST circuit, an isolating DC / DC constant current driving circuit, an under-voltage control circuit, a low-voltage switching control circuit and a control power supply circuit, can support direct current input with low voltage and wide range, can effectively solve the defects of narrow input voltage range, short service life of the light source, low light efficiency, poor vibration resistance, short maintenance cycle, insufficient protection functions and the like of a locomotive light used in a coal mine, and improves safety of mine operation.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD

Push layer type coin classifying machine

InactiveCN106097538AImprove efficiencyLow costCoin/currency accepting devicesCircular discMotor drive

The invention discloses a push layer type coin classifying machine comprising coin classifying slideways, coin classifying plates, classifying plate supports, a base, a fixed base, slide rails, a connecting rod shaft base, a connecting rod, a circular disc and a speed reducing motor. The coin classifying plates are installed from the top to the bottom in turn. The upper three coin classifying plates are respectively provided with one-yuan, five-jiao and one-jiao coin classifying holes. The upper ends of the coin classifying slideways are respectively connected with the end parts of the corresponding coin classifying plates, and the lower ends are respectively connected with the internal side plates of corresponding coin collecting boxes. Mixed paper currency and coins are put in, the speed reducing motor drives the circular disc to rotate to drive the connecting rod and the moving base vibrates, and coins falls through the coin classifying holes of the classifying plates and are classified along the slideways so that different values of coins and paper currency can be automatically sorted, the push layer type coin classifying machine is simple in structure, concentrated in arrangement and practical and convenient, and the coin sorting device is wide in range of application, high in efficiency, low in cost, safe in work and short in maintenance period.

Owner:CHANGCHUN UNIV OF SCI & TECH

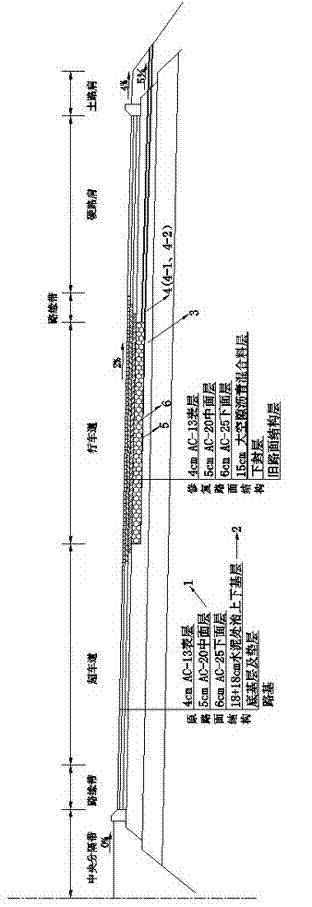

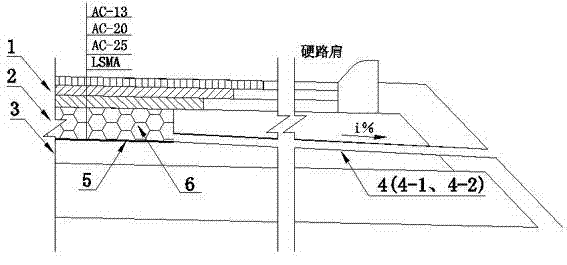

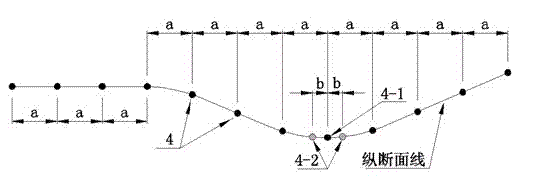

Repair method of structural water damage of asphalt pavement with cement-cured base layer

InactiveCN102900002AAvoid damageSolve drainage problemsIn situ pavingsGround-workEnvironmental resistanceStructural water

The invention discloses a repair method of a structural water damage of an asphalt pavement with a cement-cured base layer, belonging to the field of maintenance and repair of road works. The method comprises the following repair steps: a) milling damaged surface layer and base layer structure and arranging transverse drainpipe; b) arranging lower sealing layer; and c) paving macroporous asphalt mixture layer, dense-graded asphalt mixture surface layer, etc. Compared with prior art, the method provided by the invention is environmentally friendly and highly efficient, can maintain a long-term and continuous use of the pavement structure, and has a good application value.

Owner:山东省交通科学研究所

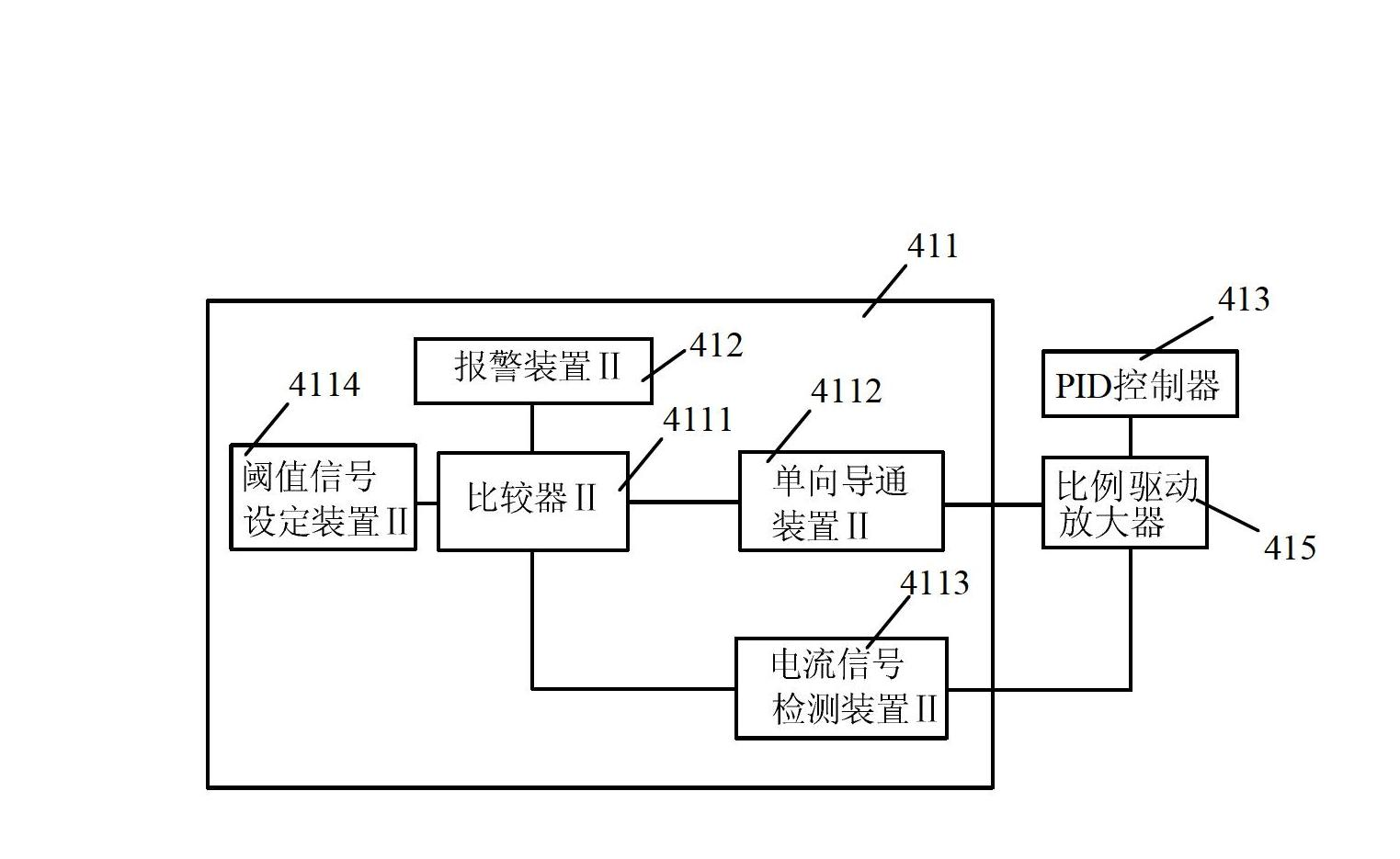

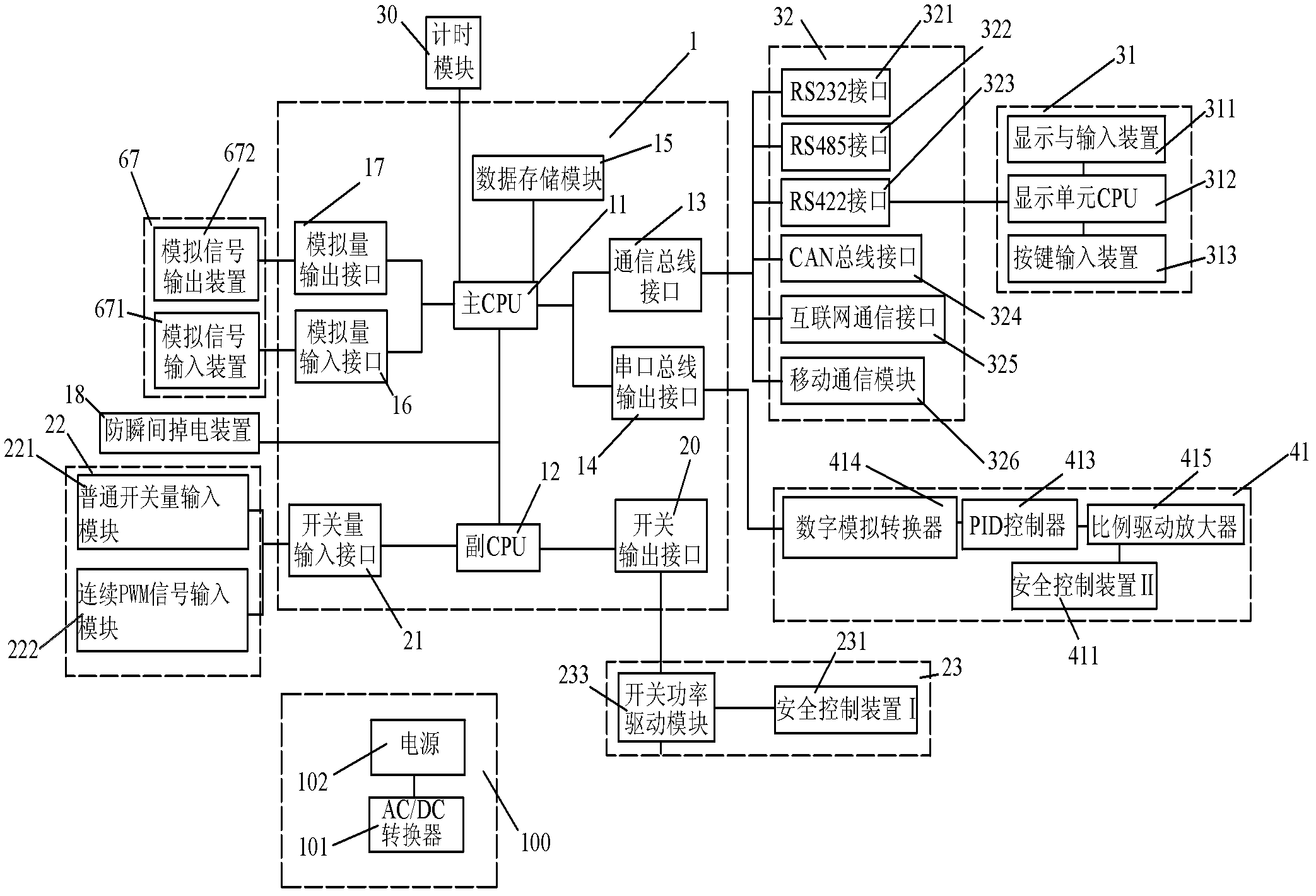

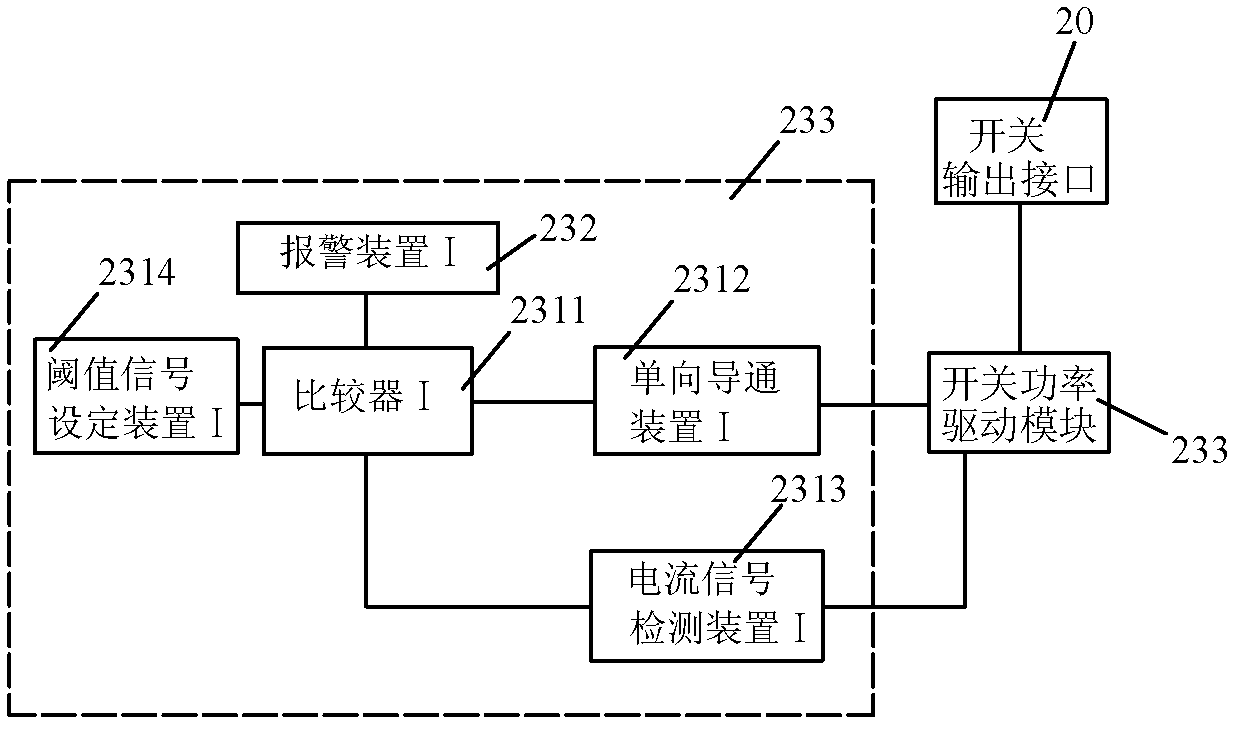

Integrated control device and control method for hydraulic system

InactiveCN102681557ASimple designShorten the development processLevel controlCommunication unitAnalog signal

The invention discloses an integrated control device and a control method for a hydraulic system. The integrated control device for the hydraulic system comprises a CPU (central processing unit), a power source unit, a switching and pulse input unit, a switch power drive unit, an analog signal input and output unit, a proportional driver unit, a communication unit and an interactive display unit. The switching and pulse input unit, the switch power drive unit, the analog signal input and output unit, the proportional driver unit, the communication unit and the interactive display unit are all connected with the CPU. The CPU, the switching and pulse input unit, the switch power drive unit, the analog signal input and output unit, the proportional driver unit, the communication unit and the interactive display unit are all connected with the power source unit and powered by the power source unit.

Owner:ZHEJIANG UNIV

Production method of ferritic stainless steel welded tube

ActiveCN105537875AHigh dimensional accuracyImprove corrosion resistanceConveyorsThermal treatmentSteel belt

The invention relates to the field of production of stainless steel welded tubes, in particular to a production method of a ferritic stainless steel welded tube. The method comprises the following steps: selecting a stainless steel strip with thickness of 2-3mm, wherein the stainless steel strip is prepared from the following components in mass percent: 0.01-0.03% of C, 0.20-1.00% of Si, 1.00-2.50% of Mn, less than or equal to 0.040% of P, less than or equal to 0.015% of S, 11.00-13.00% of Cr, 0.50-1.00% of Ni, 0.2-1.00% of Cu, 0.10-0.25% of N, 0.10-0.35% of Ti, less than or equal to 0.002% of O, and the balance of Fe and unavoidable impurities; and then uncoiling and flattening the steel strip, arranging rollers for forming, removing burrs inside and outside the welded tube, carrying out thermal treatment, and carrying out cold correction on the welded tube. The welded tube prepared by adopting the method disclosed by the invention is high in dimension precision, and can meet the requirements of tubes for carrier rollers used in long-distance, large-volume and high-speed belt conveyer conveying environments.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Falling type roadblocks, road resource allocation systems using falling type roadblocks and ground locking devices

PendingCN110080133AResource optimizationImprove traffic capacityTraffic restrictionsRoadway safety arrangementsTraffic capacityAutomatic control

The invention relates to falling type roadblocks, road resource allocation systems using the falling type roadblocks and ground locking devices. The falling type roadblocks are mainly used on tidal lanes, between lanes, in complex intersections and in car parks, buried under ground and flush with the ground, used for diverting, guiding or stopping vehicles, so that the effect of warning and lanesisolation can be played, road resources are optimized fully, traffic capacity of roads is improved, the pressure of traffic congestion is eased, and at the same time, the falling type roadblocks are used in car parks and other places that need maneuverable isolation or block the roads; furthermore, the falling type roadblocks are used as the ground locking devices of shopping malls and parking lots of residence, installed on the ground or buried under the ground and flush with the ground, lifting or falling of falling assemblies can be controlled manually or automatically, and traditional scaffolding type ground lock does not need to be operated manually. The falling type roadblocks have the characteristics of being simple in structure, small in volume, high in reliability, convenient to construct and maintain, and wide in applicability.

Owner:北京智辅特科技有限公司

Combined electrolytic cathode plate

InactiveCN101358360AImprove the effective area of electrolysisImprove loading and unloading efficiencyPhotography auxillary processesElectrodesElectrolysisEngineering

The invention discloses a combined electrolysis cathode plate which comprises an electrolysis cathode plate and a conductive connecting piece, and is characterized in that the electrolysis cathode plate comprises an electrolysis mother plate, a plurality of electrolysis unit plates and connecting mechanisms thereof, wherein, the electrolysis mother plate is in a plane structure, and the upper end of the mother plate is connected with a conductive connecting structure; the connecting mechanism is arranged on the surface of the electrolysis mother plate; the electrolysis unit plates are frame plates which are applicable to paste application and removing devices with surface area smaller than that of the electrolysis mother plate; the electrolysis unit plates are movably arranged on the electrolysis mother plate by the connecting mechanisms, to form a large removable combined electrolysis cathode plate. The combined electrolysis cathode plate of the invention can not only meet the requirements for the mechanical operation during paste application and removing processes, but also realize wet electrolysis mass industrialized production, improve production efficiency, improve current efficiency and reduce power consumption.

Owner:DONGGUAN SONGSHAN TECH GROUP

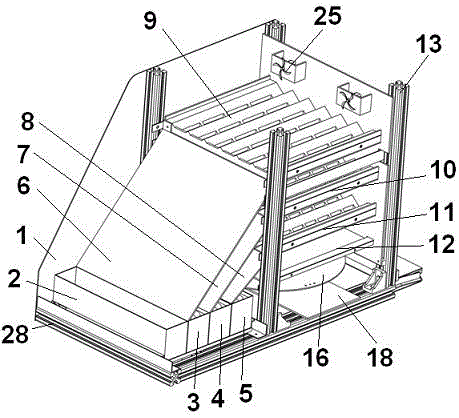

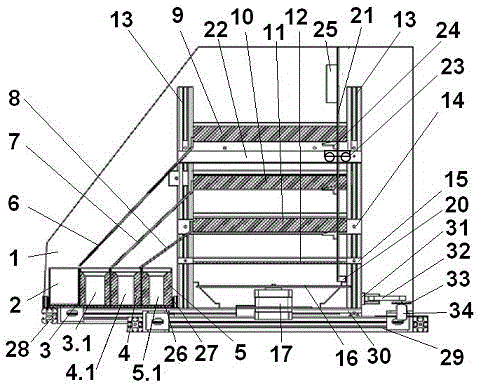

Multi-stage dry magnetic separator

PendingCN108787161AImprove magnetic separation efficiencyMeet magnetic separation requirementsConveyorsHigh gradient magnetic separatorsMagnetic separatorEngineering

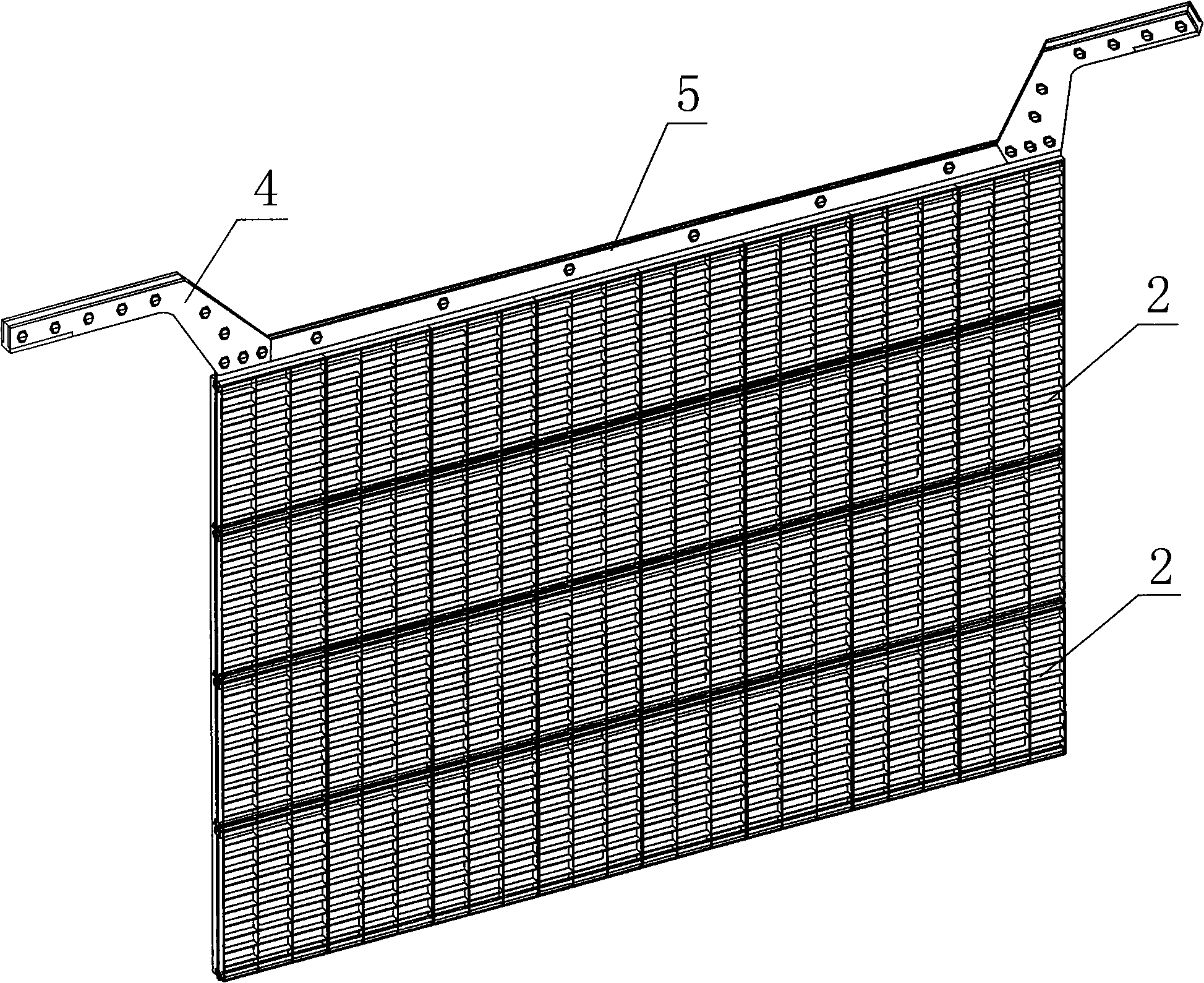

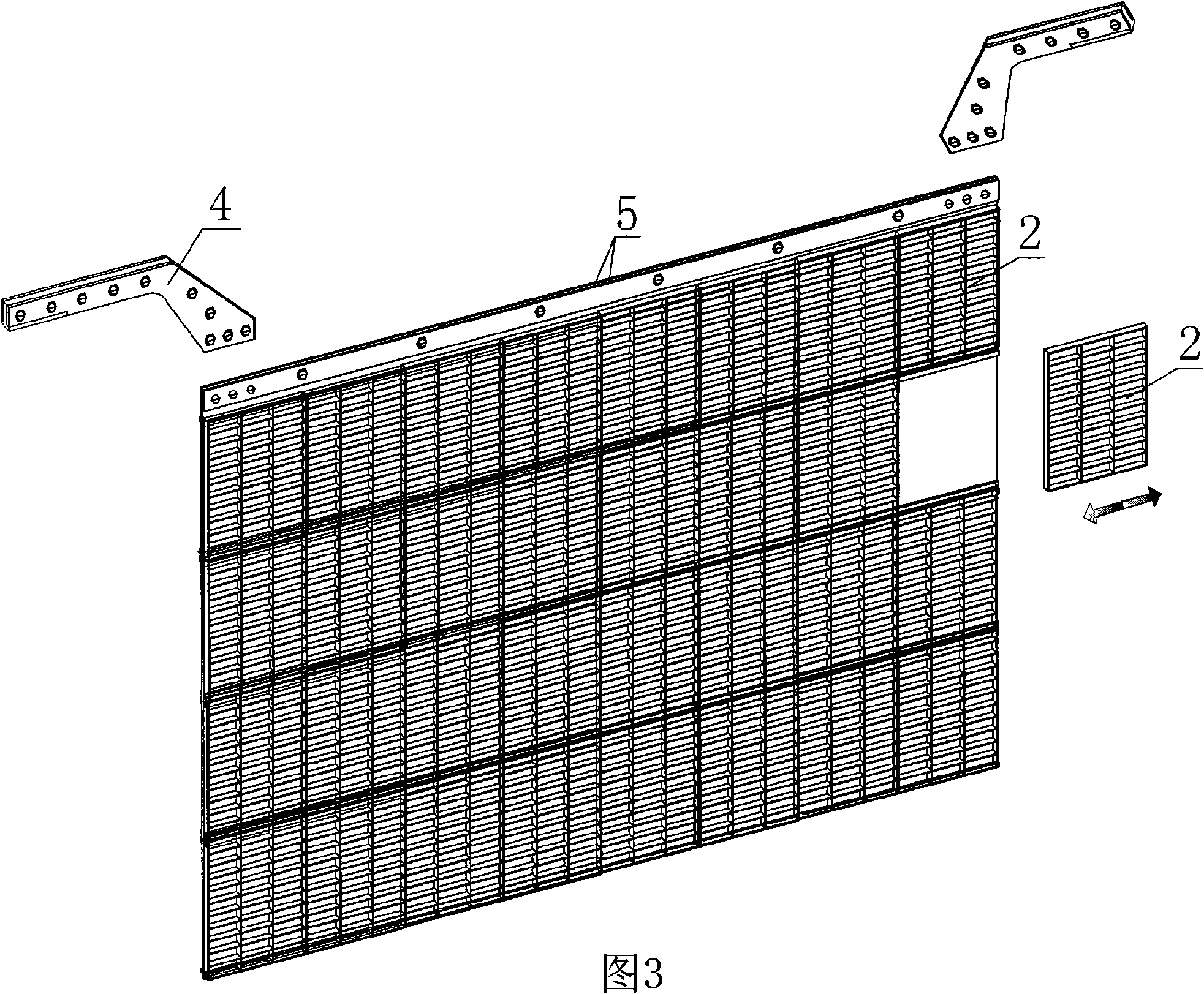

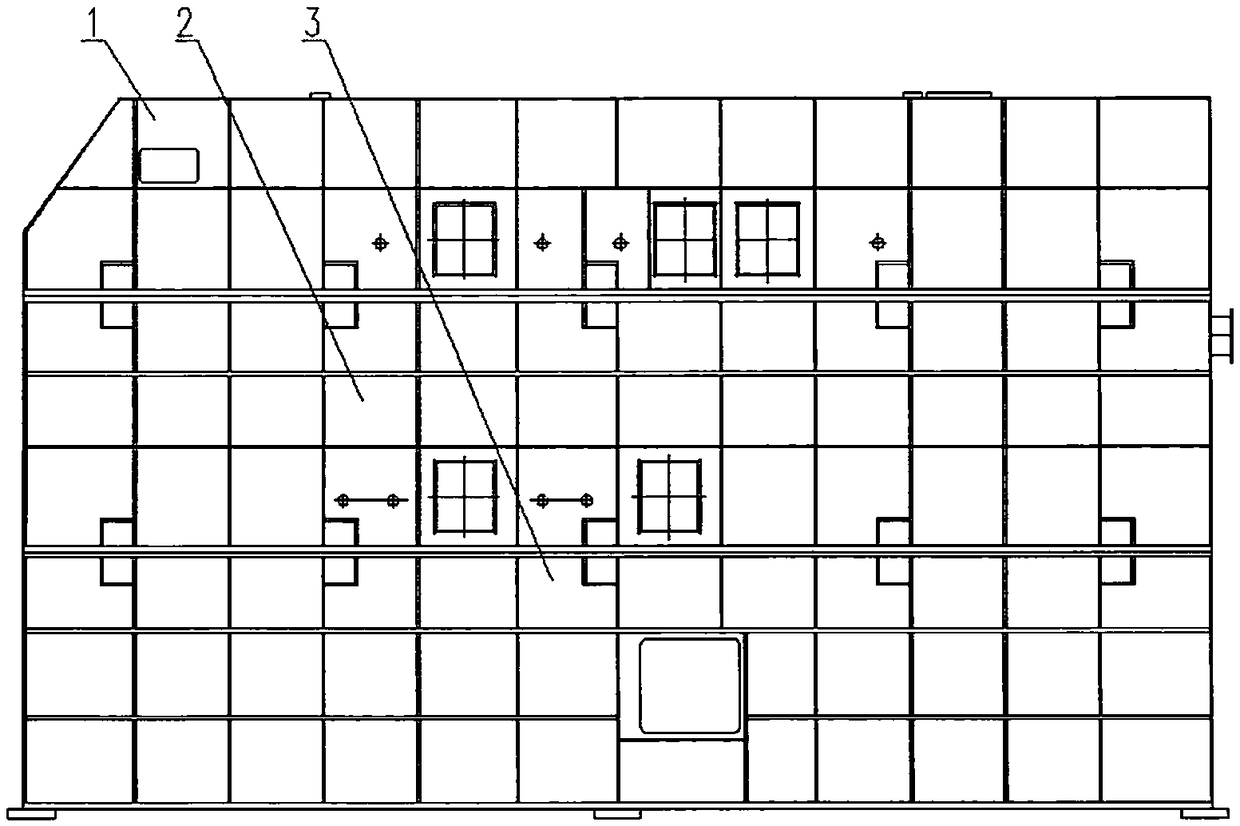

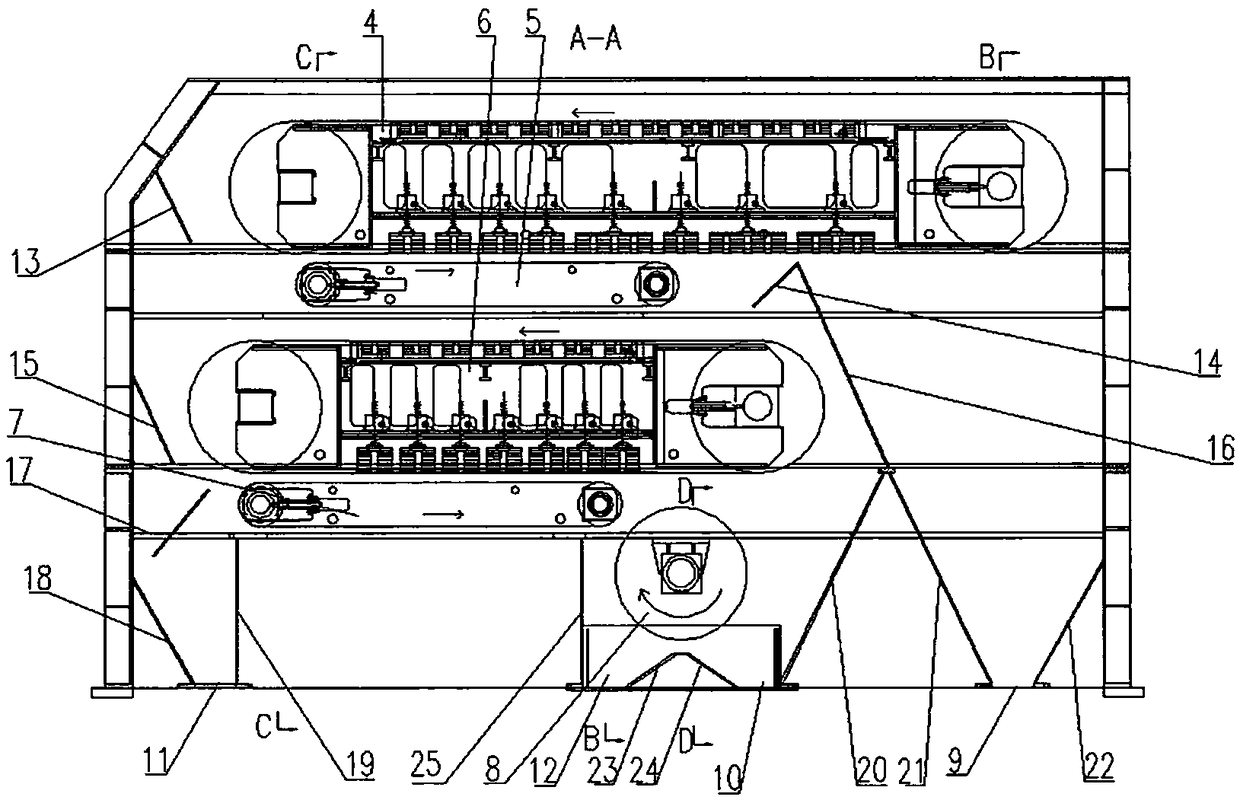

The invention relates to a multi-stage dry magnetic separator which is characterized by comprising four layers of conveying mechanisms sequentially arranged from top to bottom, wherein from top to bottom, the four layers of conveying mechanisms sequentially comprise a first-stage magnetic separation main conveyor (4) at the first layer, a first-stage auxiliary conveyor (5) at the second layer, a second-stage magnetic separation main conveyor (6) at the third layer and a second-stage auxiliary conveyor (7) at the fourth layer. The multi-stage dry magnetic separator can pick out concentrate withhigher iron content, middlings with medium iron content and tailings with lower iron content; the concentrate is picked out from the right section of the bottom of the multi-stage dry magnetic separator; a concentrate discharging hole (9) is formed in the right section of a corresponding lower frame (3); the middlings are picked out from the middle section of the bottom of the multi-stage dry magnetic separator; and a middlings discharging hole (10) is formed in the middle section of the corresponding lower frame (3). The multi-stage dry magnetic separator has the advantages of being high inmagnetic separation efficiency, adaptability and using stability and convenient to maintain.

Owner:江阴市尚时环境工程有限公司

Manipulator clamping jaw mechanism used for blow molding disc

The invention discloses a manipulator clamping jaw mechanism used for blow molding disc, which comprises a substrate, wherein a manipulator flange connector is arranged at the central point of the substrate, the middle of the lower surface of the substrate is provided with two suction nozzle mounting plates with product suction nozzles; the left and right ends of the upper surface of the substrateare respectively provided with three linear sliding rails which are provided with clamping jaw mounting plates through sliding rail connecting blocks, holes are formed in the lower parts of the clamping jaw mounting plates, anti-adhesion clamping jaws are arranged at the bottoms of the clamping jaw mounting plates, the end surfaces of the outer sides of the clamping jaw mounting plates are provided with upper and lower separated clamping jaw cylinders, telescopic rods of the upper and lower separated clamping jaw cylinders are connected with a separated clamping jaw in the hole; the sliding rail connecting blocks at the same end are commonly provided with a clamping jaw connecting arm controlled by a clamping jaw translation cylinder. According to the manipulator clamping jaw mechanism, ablow molding disc clamping jaw and the product suction nozzles are combined into one, and the manipulator clamping jaw mechanism has the advantages of low design cost, small occupying space, easinessin guaranteeing of processing precision, convenience in operation, short maintenance period and the like, and is provided with an anti-adhesion mechanism so as to better adapt to the characteristicsof the blow molding disc.

Owner:苏州茂特斯自动化设备有限公司

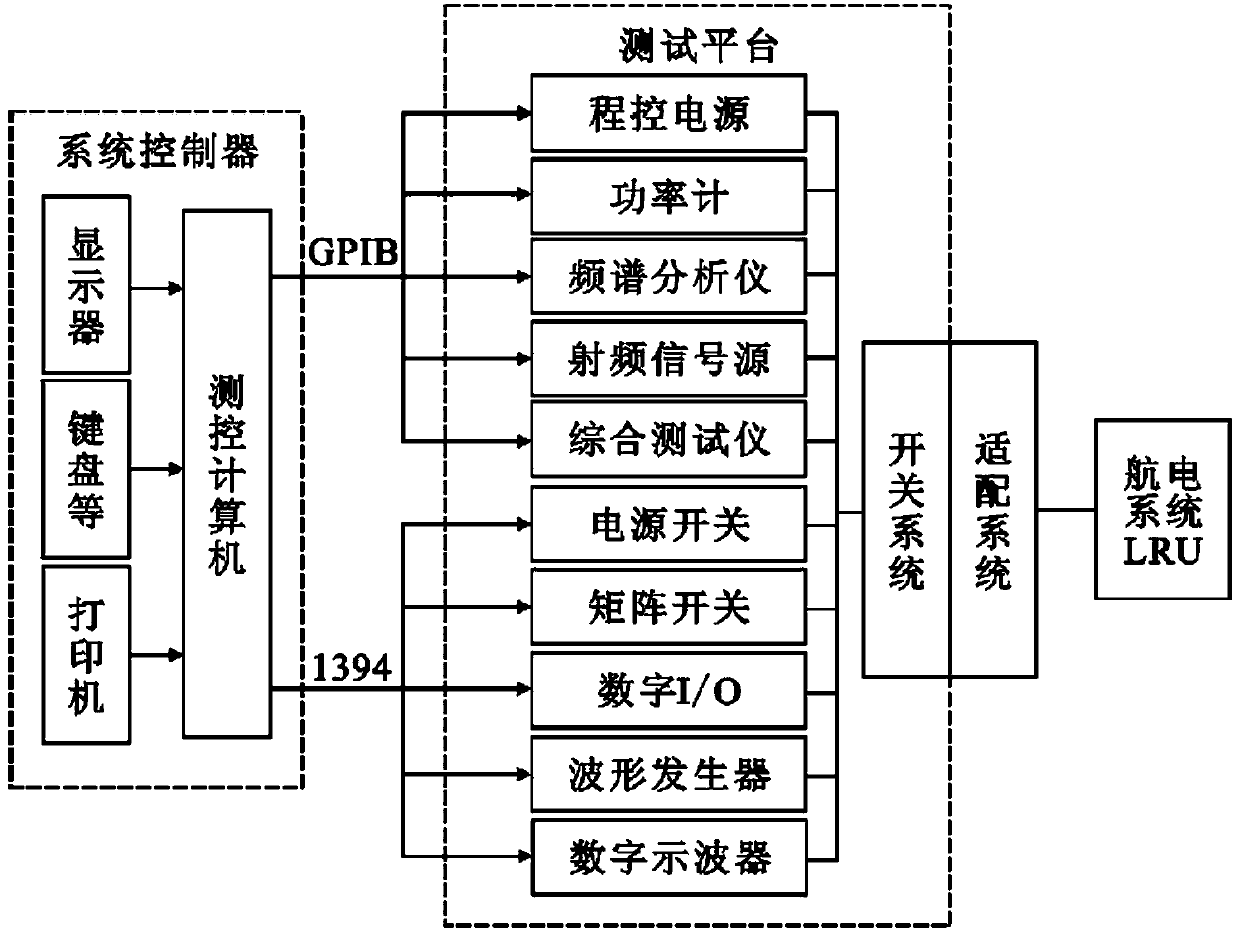

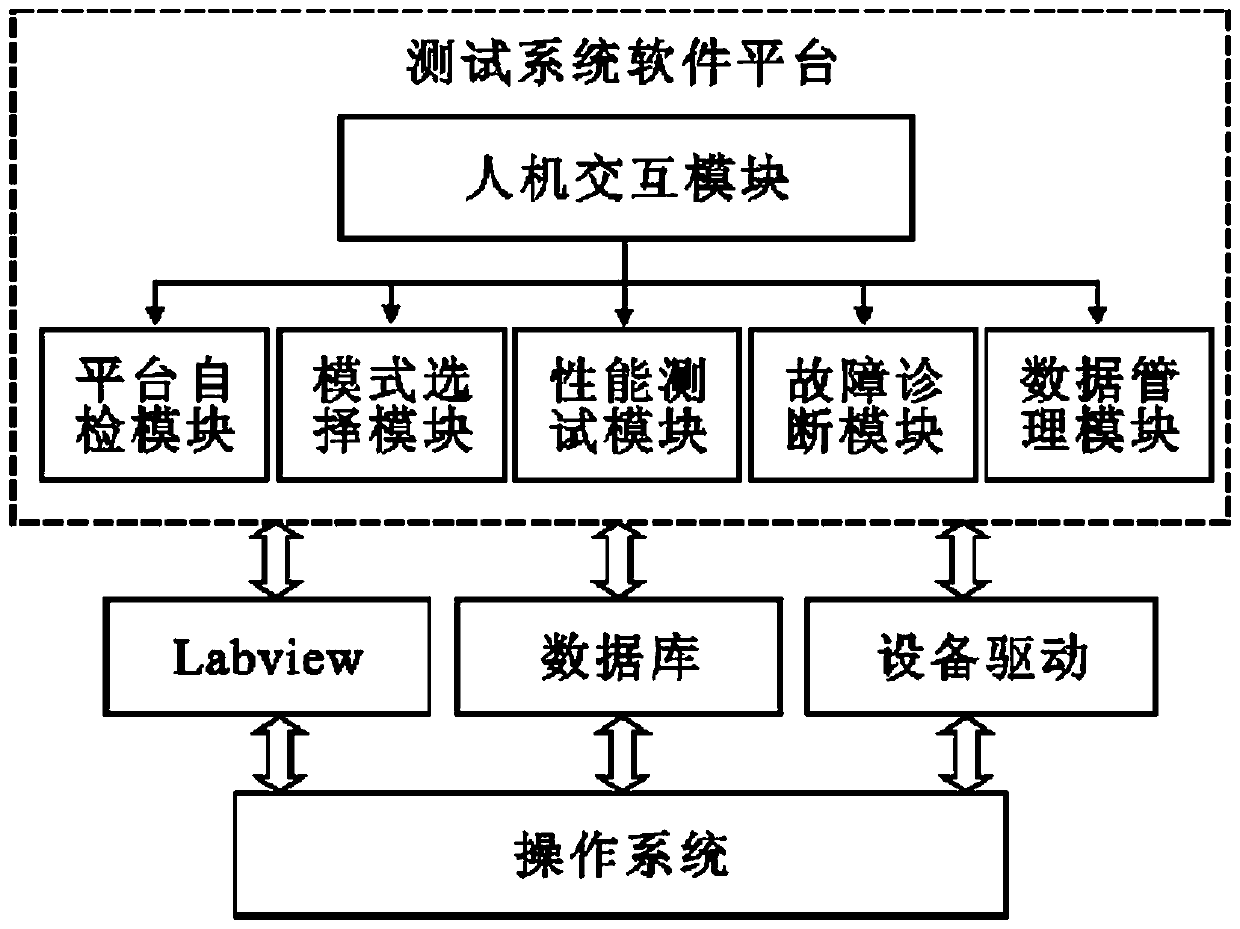

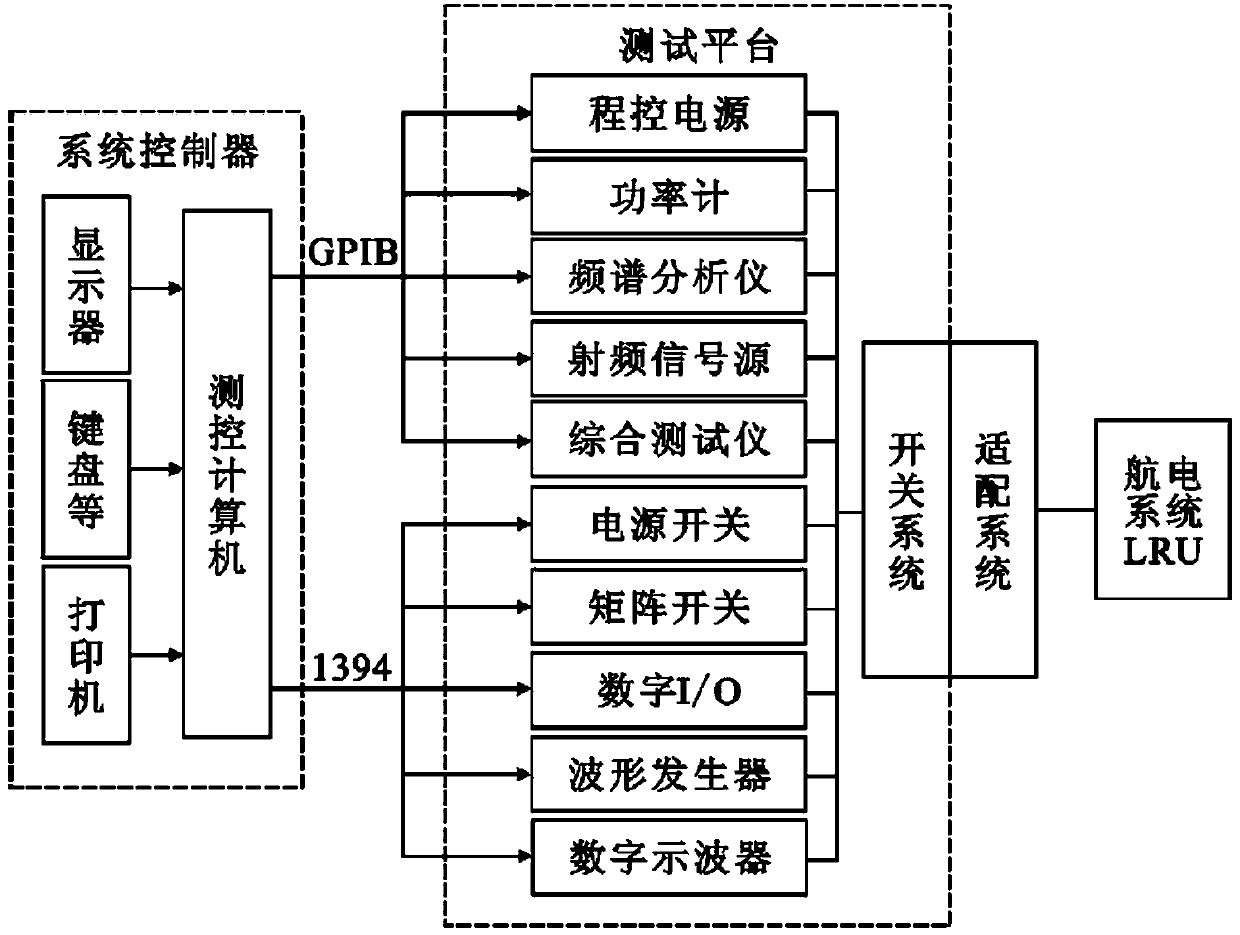

Electronic communication system monitoring device

InactiveCN109842532AShort maintenance cycleReduce maintenance costsBus networksElectronic communicationSystem monitor

An electronic communication system monitoring device belongs to the technical field of monitoring devices, and particularly relates to an electronic communication system monitoring device. The invention provides an electronic communication system monitoring device which can reduce the maintenance cost and improve the maintenance quality. The monitoring device comprises an industrial personal computer, a GPIB bus instrument, a VXI bus instrument and a power supply system, and is structurally characterized in that the VXI bus instrument is of a clamping type case structure, an IEEE1394 bus is adopted in the bus control mode, and PCI-1394 interface card is loaded in a main control computer to finish the control of the VXI bus instrument; The industrial personal computer comprises a bottom layer driving module, a database, an equipment driving module, an upper layer function module and a man-machine interaction module. And the bottom layer driving module establishes a complex virtual interface and completes flight parameter simulation display transmitted by the complete machine avionics system.

Owner:辽宁神孚网络集团有限公司

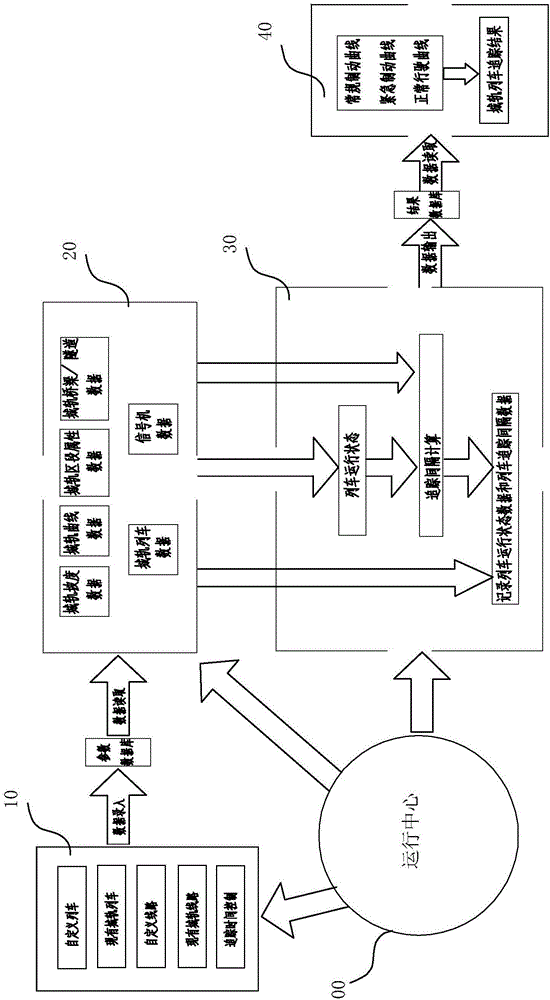

Tracking simulation method for moving closed urban rail train

InactiveCN106250629ARealize Tracking SimulationTracking simulation is easy to implementGeometric CADRailway signalling and safetyControl signalComputer module

The invention relates to a tracking simulation method for a moving closed urban rail train. The tracking simulation method comprises the following steps of: S1, performing classification treatment of entities, such as an urban rail line, a control signal and an urban rail simulation train, and establishing a basic data module; S2, establishing a simulation parameter definition module; S3, establishing a system operation module; S4, according to requirements, setting and calling basic data required when all kinds of trains operate simulation; S5, inputting simulation parameters, and performing embodiment and digitization of an environment needing to be simulated; S6, entering system simulation operation; S7, outputting tracking result data; and S8, drawing a tracking result curve, and determining a tracking result. A simulation system adopted in the simulation method is low in cost, short in maintenance period, simple and convenient to operate, reliable to operate, good in humanization and high in pertinence, and can be tightly combined with practical teaching requirements.

Owner:LIUZHOU RAILWAY VOCATIONAL TECHN COLLEGE

Efficient grinding mechanism for vertical roller mill

The present invention relates to an efficient grinding mechanism for a vertical roller mill. The efficient grinding mechanism comprises a drive mechanism, wherein the drive mechanism is connected with a grinding table, the upper part of the grinding table is provided with a feeding tube, a plurality of grinding rollers are arranged on the circumferential edge of the grinding table, the grinding rollers are divided into large grinding rollers and small grinding rollers, and the large grinding rollers and the small grinding rollers are arranged on the circumferential edge of the grinding table in a staggered manner. The present invention provides an efficient grinding mechanism for a vertical roller mill, wherein the efficient grinding mechanism has characteristics of high grinding efficiency, simple structure and easy maintenance.

Owner:扬州中材机器制造有限公司

Equipment for rising and falling headlamp on locomotive

InactiveCN1562684AEasy to operateShort maintenance cycleRailway lightingSignalling indicators on vehicleHeadlampEngineering

A vertically moving unit for the headlight of locomotive is composed of a lifting mechanism which may be pulley one, rack bar one, or hydraulic one, fixed supporting frame, guide mechanism and movable supporting frame connected to said fixed one via guide mechanism.

Owner:顾群

Drill padding maintaining method for steel ladle working lining

InactiveCN104043815ADrilling filling maintenance method is convenient and practicalLow costMelt-holding vesselsCarbide siliconSlag

The invention discloses a drill padding maintaining method for a steel ladle working lining. A steel ladle is cooled, the impurities on the inner wall are cleaned thoroughly, bricks are drilled out through a cylindrical hollow drill bit, the hole diameter ranges from 30 mm to 80 mm, the drilling depth ranges from 5 cm to 10 cm, the interior is cleaned thoroughly, the interior is filled with cylindrical bricks with the same diameter and length until an original working plane is flush with the stacked brick level, the surrounding gap is filled with fire clay, the cement water is evaporated through the waste heat of an original working lining or the high temperature at which the molten steel is contained again, and the padding is combined with the original working lining. The maintaining method is convenient to carry out, practical, simple, low in cost and suitable for maintaining steel ladles with the wrapped wall or the slag line working line as magnesia carbon bricks or aluminum magnesium carbon bricks and maintaining the steel ladles of aluminum silicon carbide carbon bricks.

Owner:河南竹林耐材有限公司

Heat-insulating and wear-resistant pipe coating

The invention discloses a heat-insulating and wear-resistant pipe coating. The heat-insulating and wear-resistant pipe coating is prepared from the following raw materials in certain proportions: floating beads, nanometer hollow ceramic microbeads, waste electroceramic particles, expanded vermiculite, Guangxi white mud, activated aluminum oxide powder, silicon powder, carboxymethyl cellulose, epoxy resin, a T series curing agent and polypropylene explosion-proof fiber. The heat-insulating and wear-resistant pipe coating has relatively good wear resistance and washing resistance, and is applicable to lining coating of a factory hot air pipe; excellent heat insulation and volume stability reduce the heat loss of the hot air pipe, and good suspension is more conducive to coating during construction, so that the heat-insulating and wear-resistant pipe coating can be better attached to the surface of a construction body; meanwhile, the heat-insulating and wear-resistant pipe coating is convenient to construct and short in maintenance period, the heat insulation and the wear resistance thereof meet production needs, and the heat-insulating and wear-resistant pipe coating is high in comprehensive cost performance, prolongs the service life of the pipe and lowers the production cost; moreover, the heat-insulating and wear-resistant pipe coating has excellent fire-proof and heat-insulating effects, so that the heat-insulating and wear-resistant pipe coating can be also applied to outer-surface treatment of some firefighting pipes.

Owner:REWELL REFRACTORY ZHENGZHOU CO LTD

Split type rigid protecting device

Owner:SUZHOU BLUE KING MACHINE TOOL TECH CO LTD

Solid-liquid separation device for hydrometallurgy

ActiveCN109055741AFast separationEasy to separateProcess efficiency improvementFractionationHydrometallurgy

The invention discloses a solid-liquid separation device for hydrometallurgy. The solid-liquid separation device for hydrometallurgy comprises a primary filter box, a secondary filter box, a fractionation box and a condensation box which all sequentially communicate. The fractionation box is connected with an electrodeposition system. The interior of the primary filter box is divided into a dissolution chamber and a primary leaching chamber through a rigid mesh sieve and a filter net. The second filter box is internally provided with a suction filter net and a retarding plate. The second filter box is provided with a first vacuum pump. The fractionation box is provided with a second vacuum pump and a heating coil, and the fractionation box communicates with the condensation box through a third communicating pipe. The solid-liquid separation device for hydrometallurgy is high in separation speed, good in separation effect, capable of recovering a great number of recyclable matter, in the whole working process, conveying is carried out through pressure difference generated between two adjacent containers by the vacuum pump, the operational use time is long, and the part maintaining period is short.

Owner:GUIZHOU ZIJIN MINING

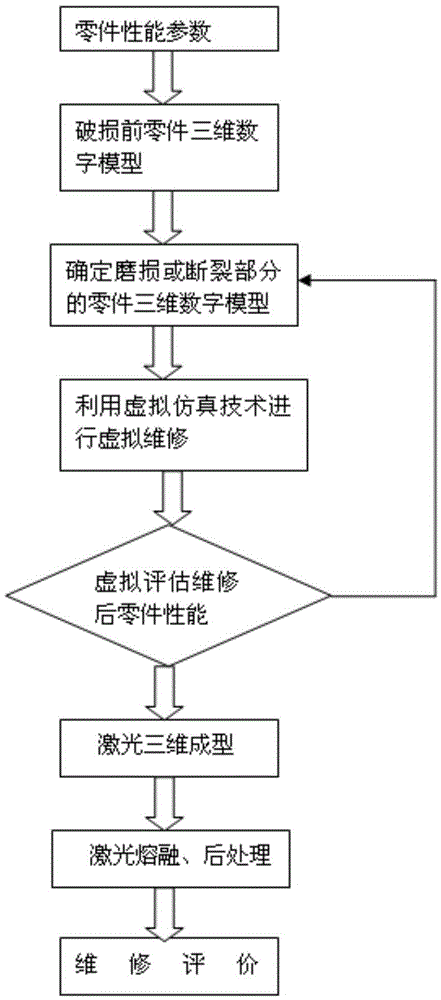

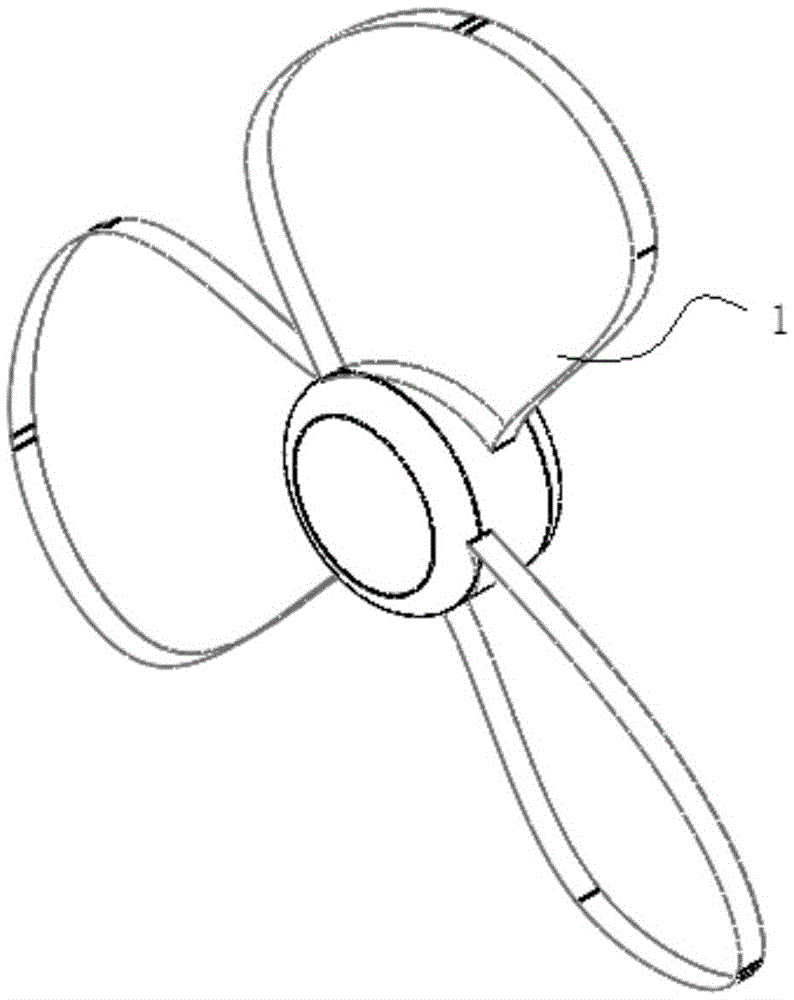

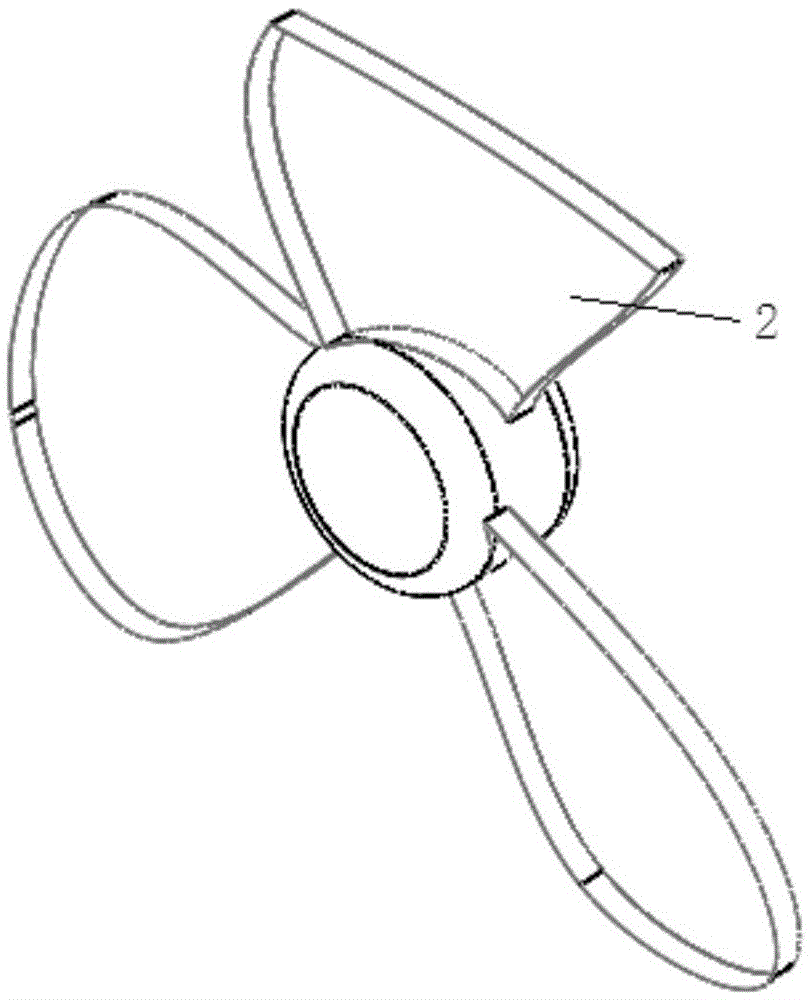

Special-shaped part forming maintenance method

InactiveCN106166659AImprove maintainabilityReduce maintenance costsLaser beam welding apparatusManufacturing technologyMaterial resources

The invention discloses a special-shaped part forming maintenance method which includes the steps: forming a sub-material model of a special-shaped part by a model before breakage and a base material model of the special-shaped part; virtually and integrally melting the sub-material model and the base material model of the special-shaped part in a virtual laser melting environment to obtain virtual laser melting parameters when the performance of a virtual welding seam formed in the virtual melting process meets a standard; integrally melting sub-materials and base materials of the special-shaped part by the aid of a laser melting treatment method and the laser melting parameters. According to the forming maintenance method, a virtual maintenance technology and a laser material increase manufacturing technology are combined, the structure and the performance of the special-shaped part after maintenance are as same as those of the special-shaped part before breakage, the performance of the special-shaped part after maintenance is improved, the service cycle of the special-shaped part is prolonged, and a large quantity of manpower, material resources and financial resources are saved, so that the special-shaped part is high in recycling rate, short in maintenance cycle and good in maintenance effect.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com