Integrated control device and control method for hydraulic system

A hydraulic system, integrated control technology, applied in liquid level control, non-electric variable control, control/regulation system, etc., can solve the problem of inability to meet the requirements of industrial hydraulic systems, limited input and output channels, and difficulty in system-level expansion, etc. problems, to achieve the effect of simple function expansion and deformation design, simplifying design and improving development efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

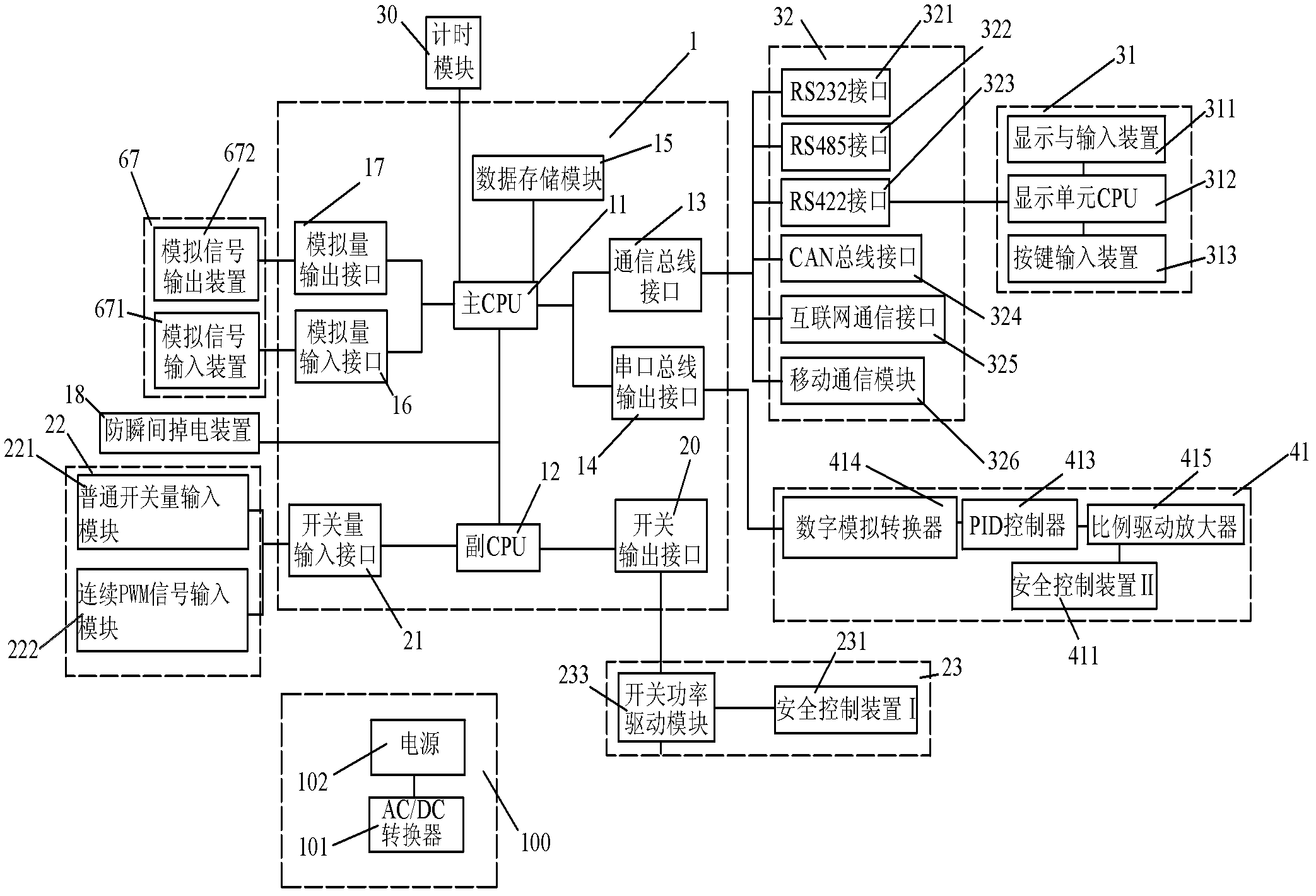

[0020] A hydraulic system integrated control device and control method are given, including a CPU unit 1, a power supply unit 100, a switch value and pulse input unit 22, a switch power drive unit 23, an analog signal input and output unit 67, a proportional drive unit 41, a communication unit 32 and interactive display unit 31.

[0021] The CPU unit 1 described above includes a main CPU11, a secondary CPU12, a communication bus interface 13, a serial bus output interface 14, a data storage module 15, an analog input interface 16, an analog output interface 17, a switch output interface 20, and a switch input Interface 21, anti-instantaneous power failure device 18 and timing module 30; Timing module 30, communication bus interface 13, serial port bus output interface 14, data storage module 15, analog quantity input interface 16 and analog quantity output interface 17 are all connected with main CPU11 Connection, both the switch value output interface 20 and the switch value ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com