Auxiliary heating type steam rotary dryer

A rotary dryer and auxiliary heating technology, applied in non-progressive dryers, dryers, heating devices, etc., can solve the problem of the inner wall of the cylinder and the heat exchange tube components sticking to the wall, high processing and maintenance costs, and roller materials. Problems such as poor fluidity, to achieve the effect of long maintenance time, high processing cost and maintenance cost, no return material leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below with reference to the accompanying drawings and embodiments, but it is not intended to limit the present invention.

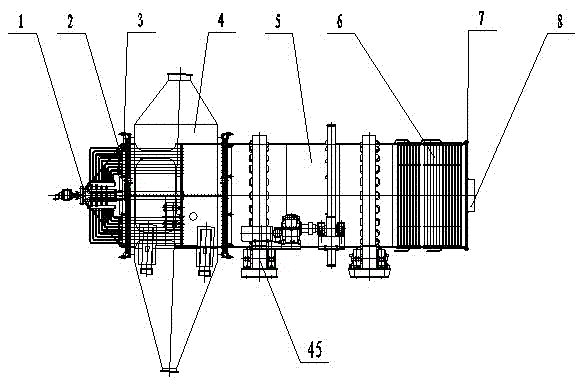

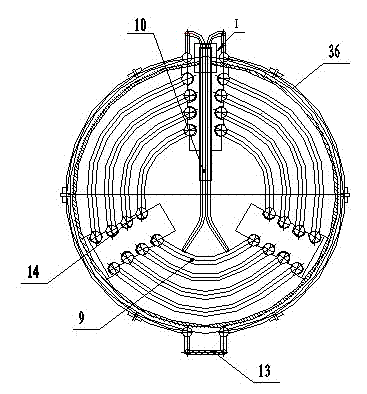

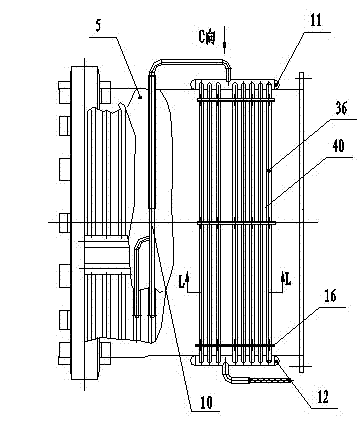

[0042] See figure 1 , Figure 14 , Auxiliary heating steam rotary dryer, including a cylindrical drum 5, a rotating support device 45 that supports and drives the drum 5 to rotate, the support mechanism of the rotating support device 45 is a set of supporting wheels that lift the drum 5, which The rotating mechanism is an external power unit and a large gear on the outer wall of the drum 5 driven by it. The main steam distribution chamber 1 is arranged outside the discharge sealing plate 3 of the drum 5 and is coaxial with the drum 5, used for the main steam distribution chamber 1. It supplies steam to the heat exchange tube assembly 24 in the drum and simultaneously discharges the condensate formed in the steam tube assembly 24. As the supporting and rotating mechanism of the drum 5, and as the mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com