Patents

Literature

80 results about "Virtual maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Virtual Maintenance Training is a type of training method that includes computer-based interactive 3D simulations of virtual equipment that replicates the actual real life vehicle or device. It safely teaches vehicle and device crewmembers the procedures to properly service, repair, and maintain equipment.

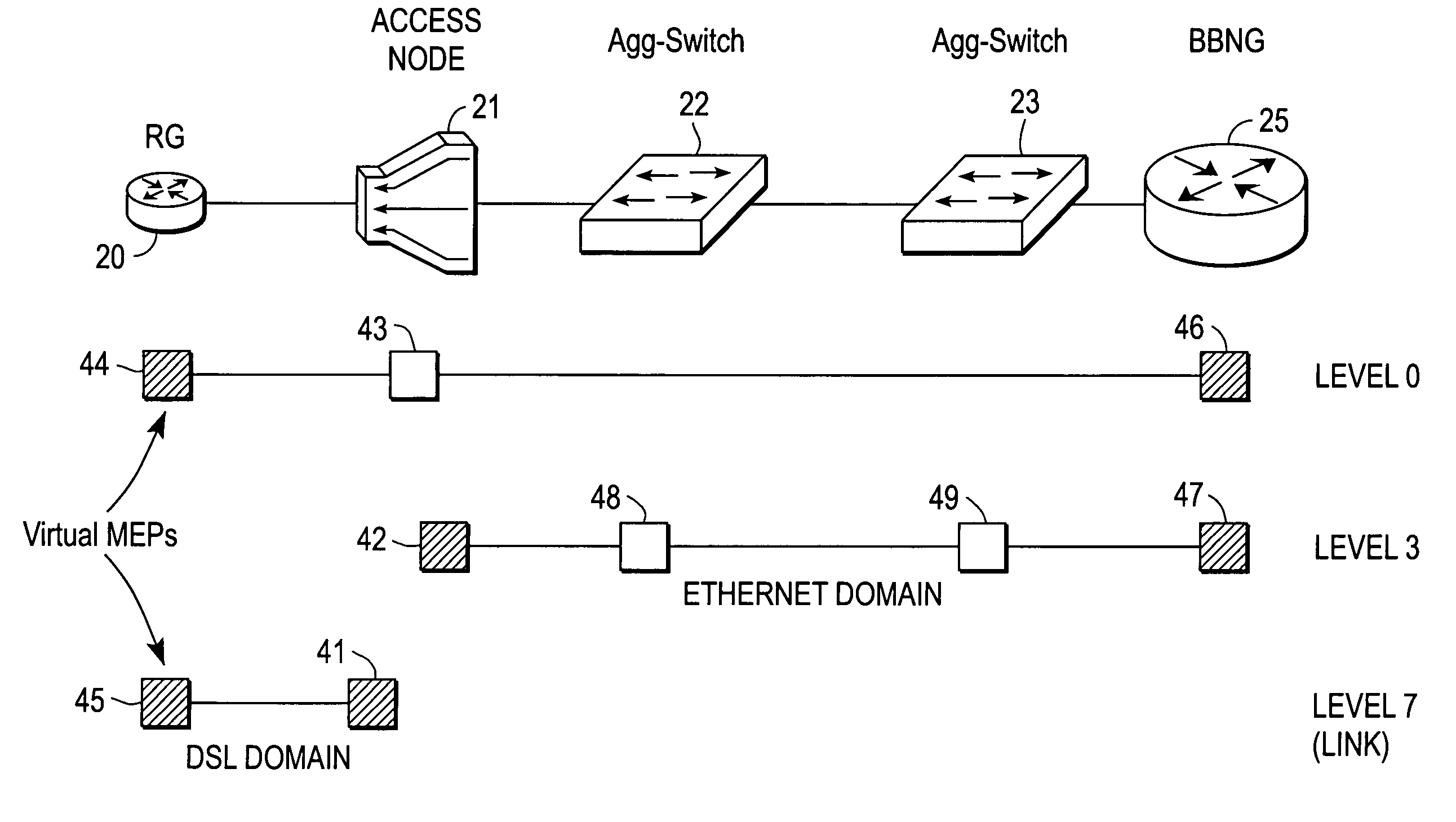

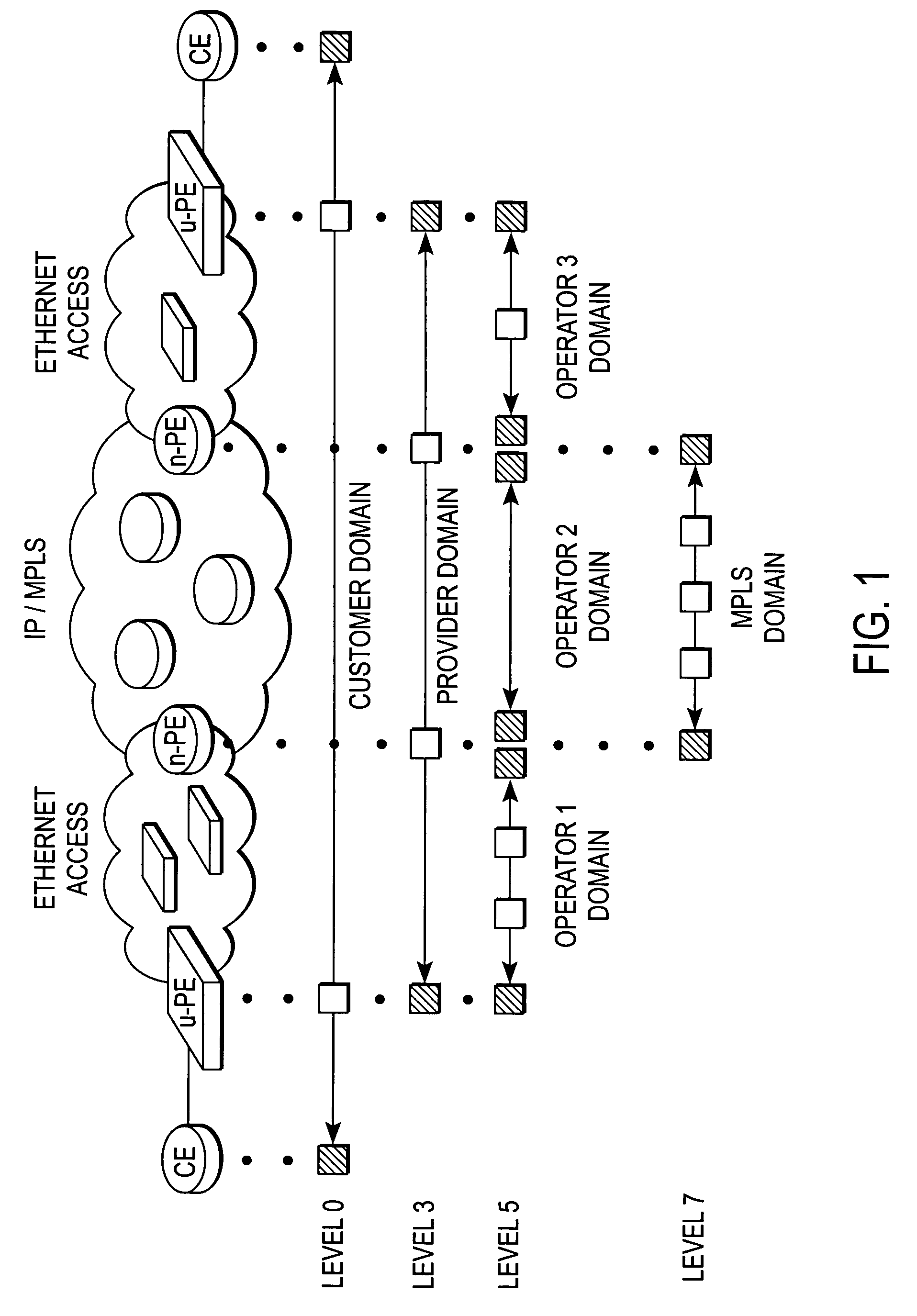

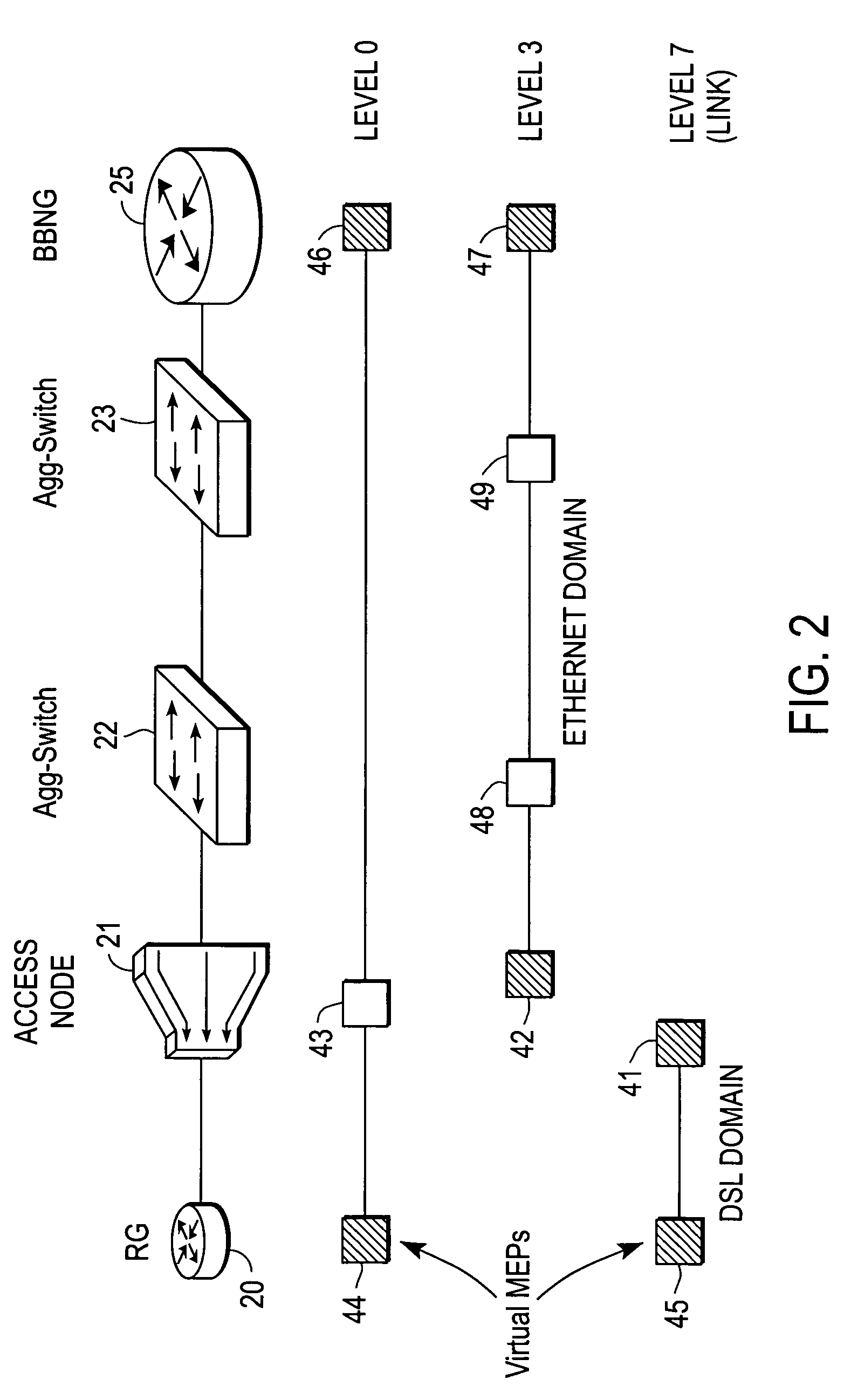

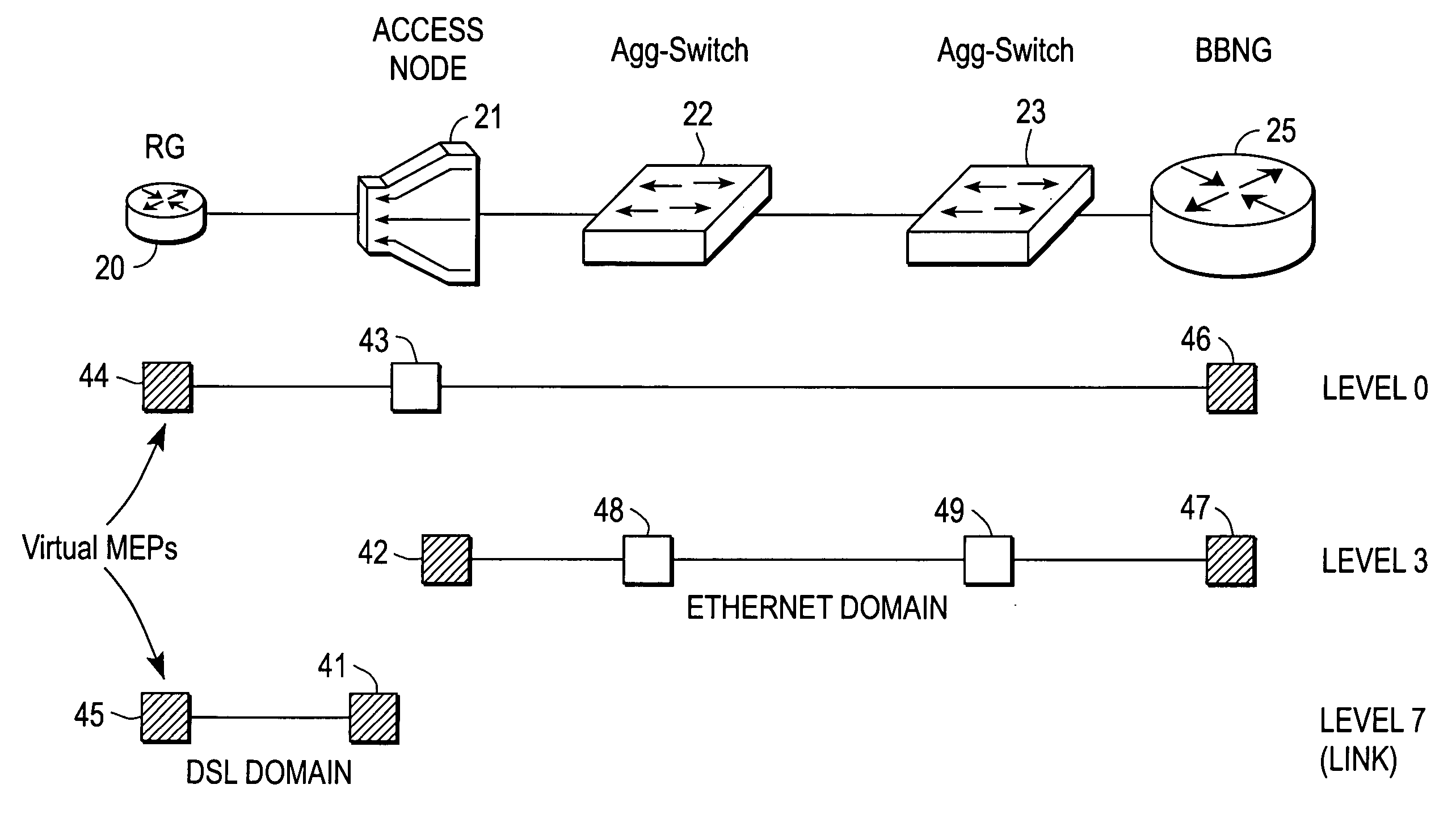

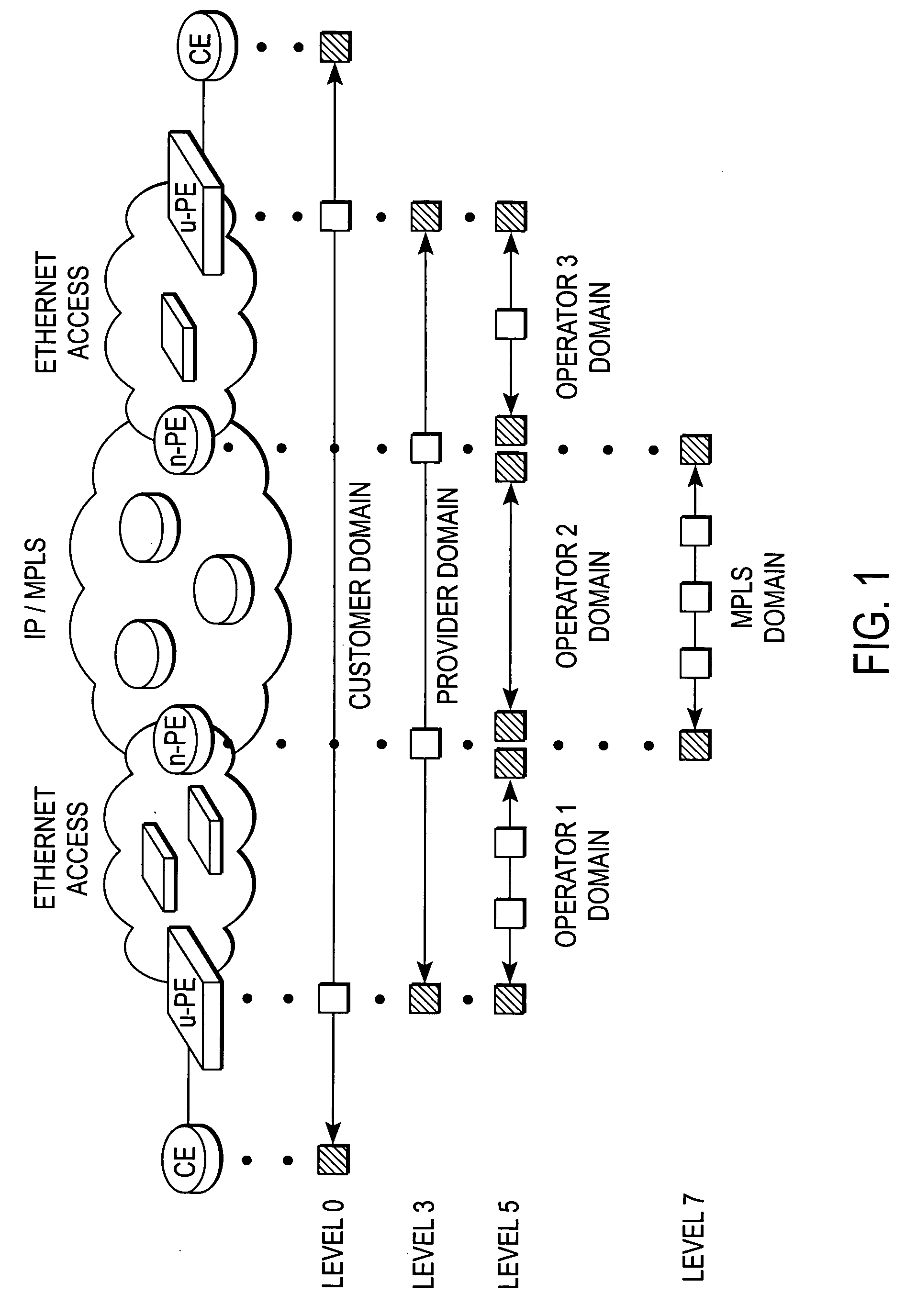

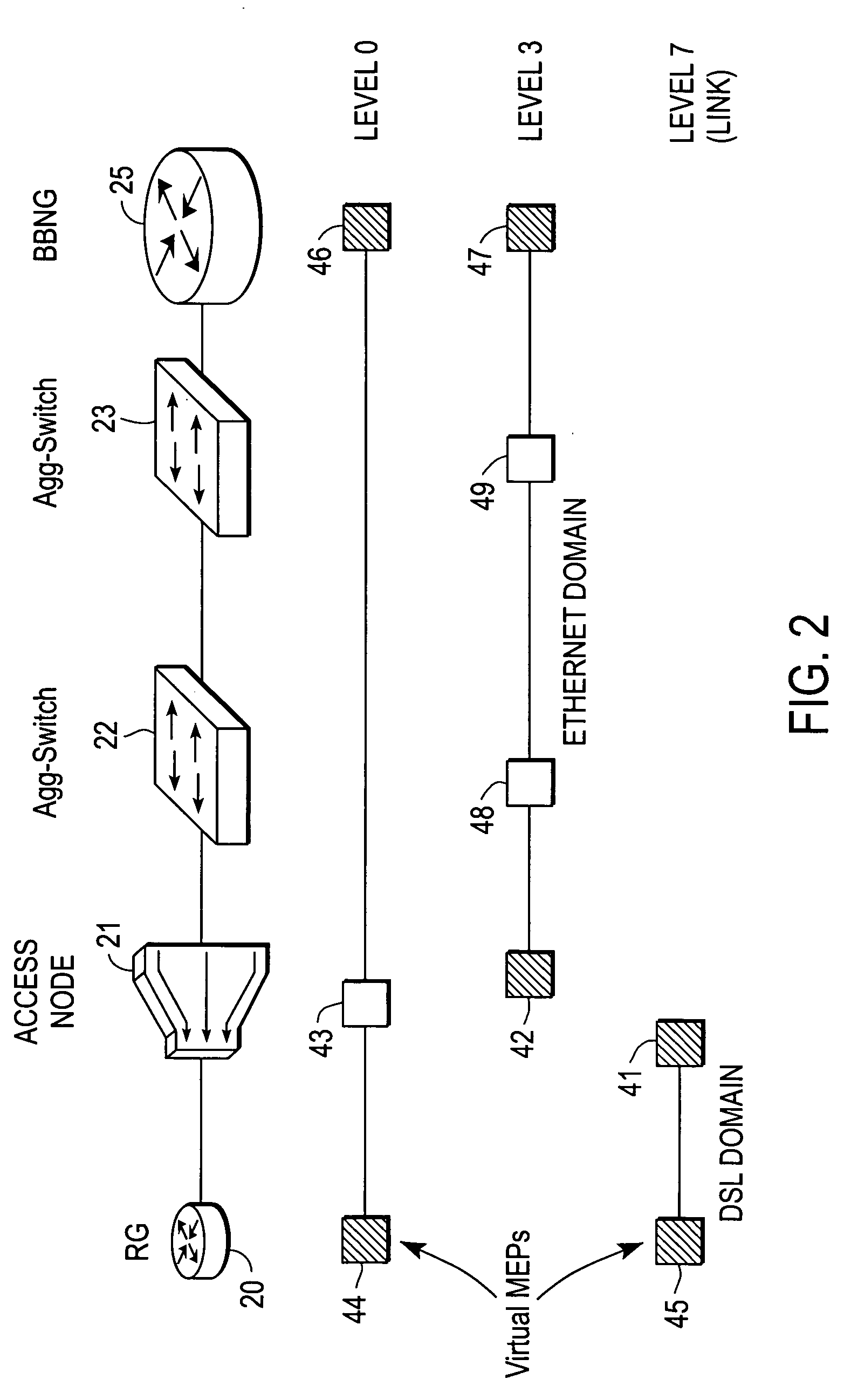

Broadband access note with a virtual maintenance end point

A broadband access node includes a port for connection with a Digital Subscriber Line and a processor to run code that implements a virtual maintenance end point (vMEP). The vMEP translates an IEEE 802.1ag Loopback Message (LBM) received from a device on an Ethernet access network into a legacy operations and maintenance (OAM) message that is transmitted to a residential gateway (RG) device. The legacy OAM message determines a link-level connectivity status between broadband access node and the RG device. The vMEP also transmits a reply message back to the device on an Ethernet access network in compliance with the IEEE 802.1ag specification. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:CISCO TECH INC

Broadband access node with a virtual maintenance end point

A broadband access node includes a port for connection with a Digital Subscriber Line and a processor to run code that implements a virtual maintenance end point (vMEP). The vMEP translates an IEEE 802.1ag Loopback Message (LBM) received from a device on an Ethernet access network into a legacy operations and maintenance (OAM) message that is transmitted to a residential gateway (RG) device. The legacy OAM message determines a link-level connectivity status between broadband access node and the RG device. The vMEP also transmits a reply message back to the device on an Ethernet access network in compliance with the IEEE 802.1ag specification. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims. 37 CFR 1.72(b).

Owner:CISCO TECH INC

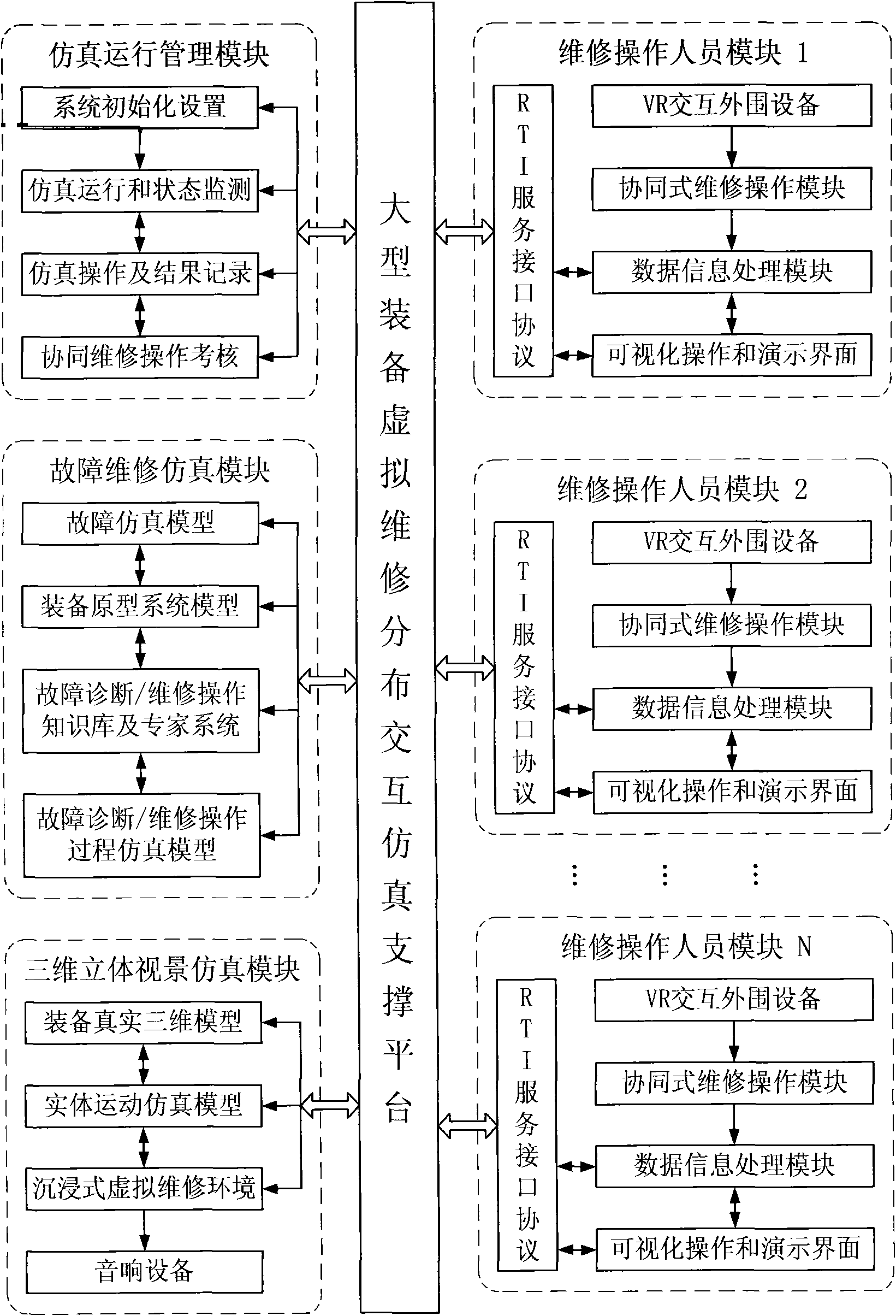

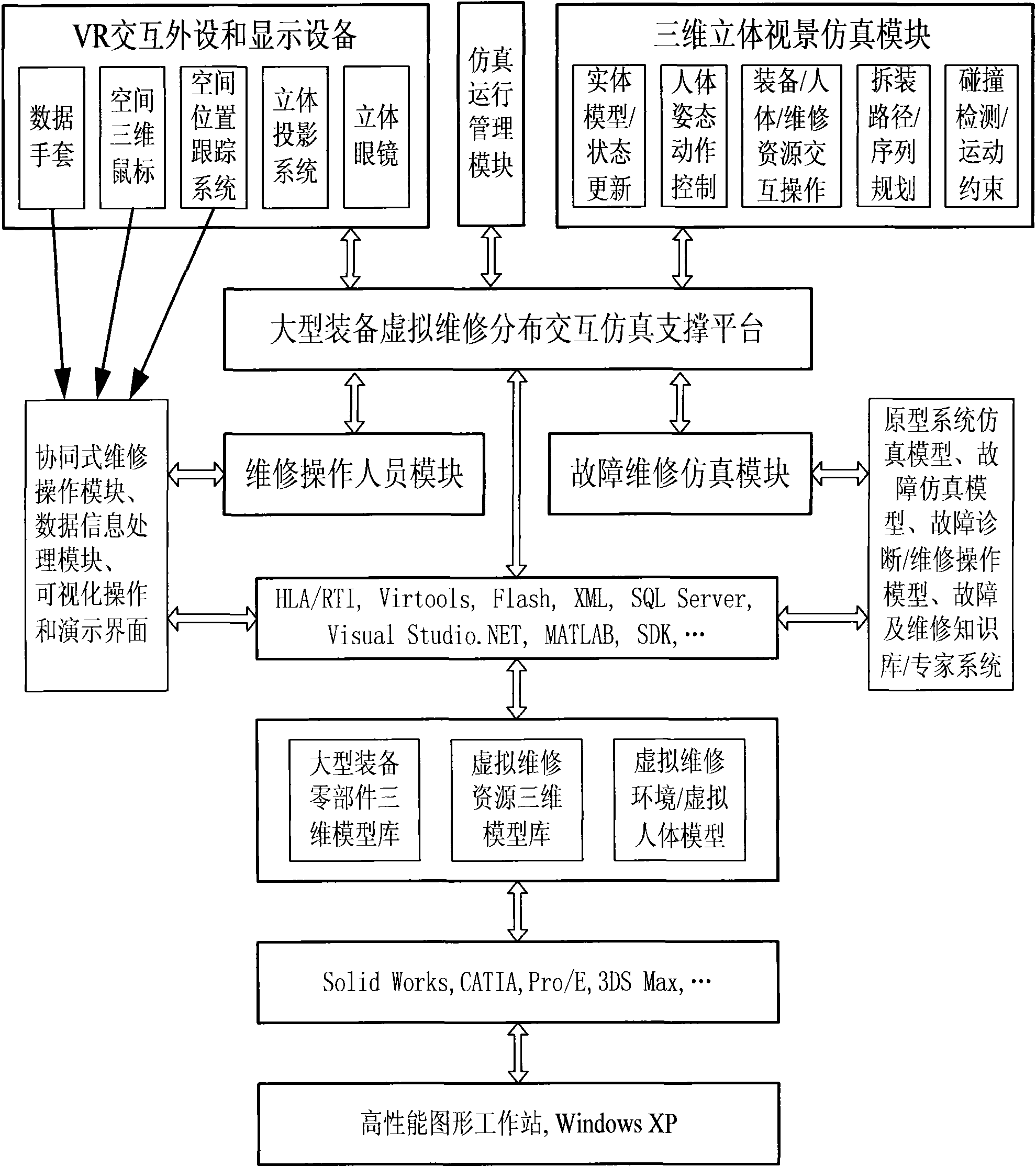

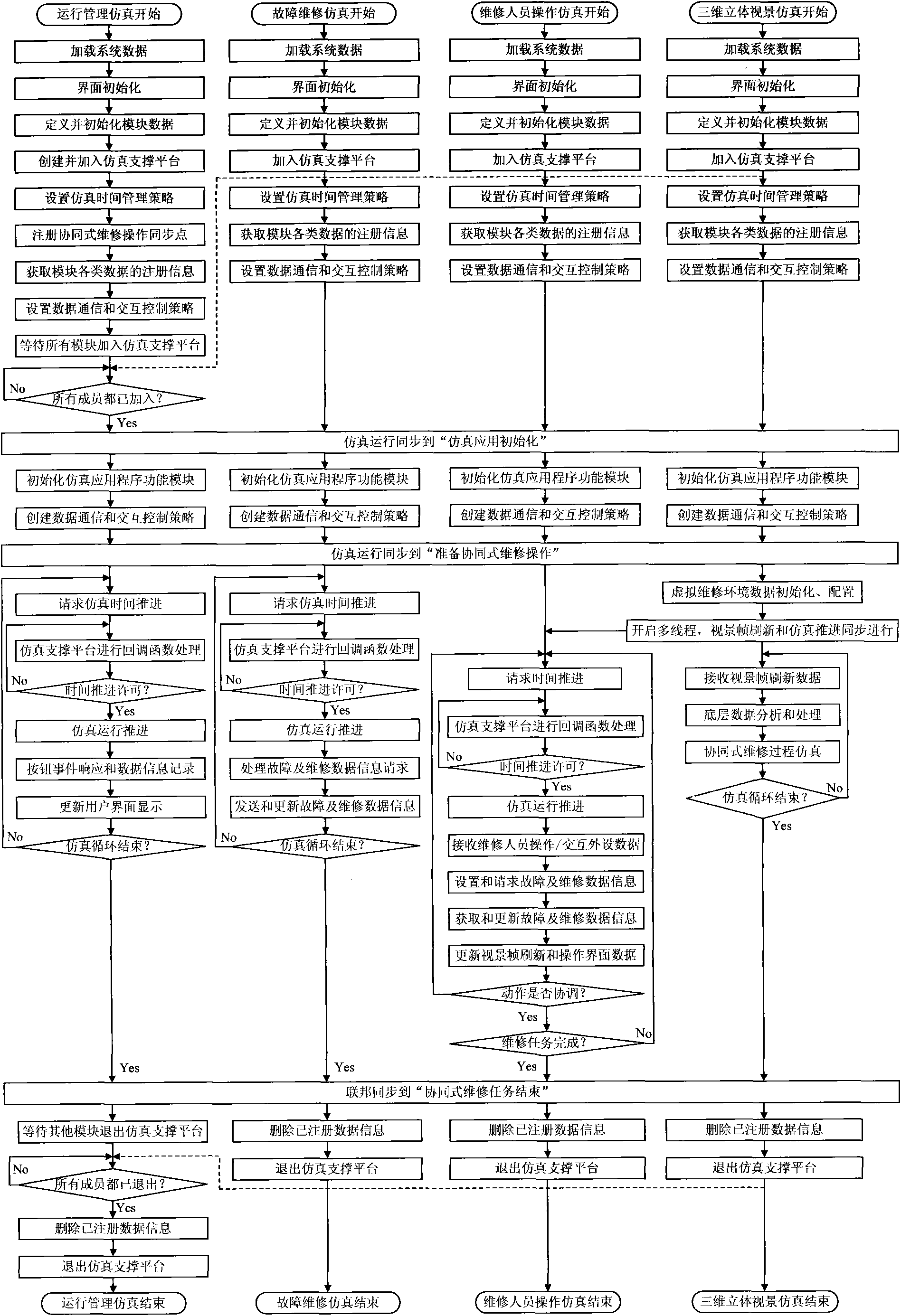

Virtual maintenance distribution interactive simulation support platform of large equipment and collaborative maintenance method

InactiveCN102136204AImprove versatilityImprove good performanceCosmonautic condition simulationsSpecific program execution arrangementsData informationCombinatorial hierarchy

The invention relates to a virtual maintenance distribution interactive simulation support platform of large equipment and a collaborative maintenance method. Combined hierarchical structure and modular design are adopted, a general service program is provided for various types of simulation application by a bottom-layer standardized communication protocol to realize data communication and interaction control among different software and hardware function modules; the virtual maintenance distribution interactive simulation support platform is composed of a simulation operation management module, a fault maintenance simulation module, a maintenance operation module and a basic function module for visual scene simulation; the platform captures the operation input, the body gesture and the hand space action data information of each training person by standard peripheral equipment and VR (Virtual Reality) interactive equipment; different collaborative maintenance modes are set, and various three-dimensional solid models in the virtual maintenance environment are driven; and collaborative interactive simulation and state information are updated in real time to realize the operation cooperation and the motor coordination in the collaborative maintenance process. The virtual maintenance distribution interactive simulation support platform has the advantages of good popularity, expansibility, instantaneity and illusion of immersion, and can support the simulation training of collaborative maintenance tasks of multiple maintenance personnel on different stations of large equipment.

Owner:PLA SECOND ARTILLERY ENGINEERING UNIVERSITY

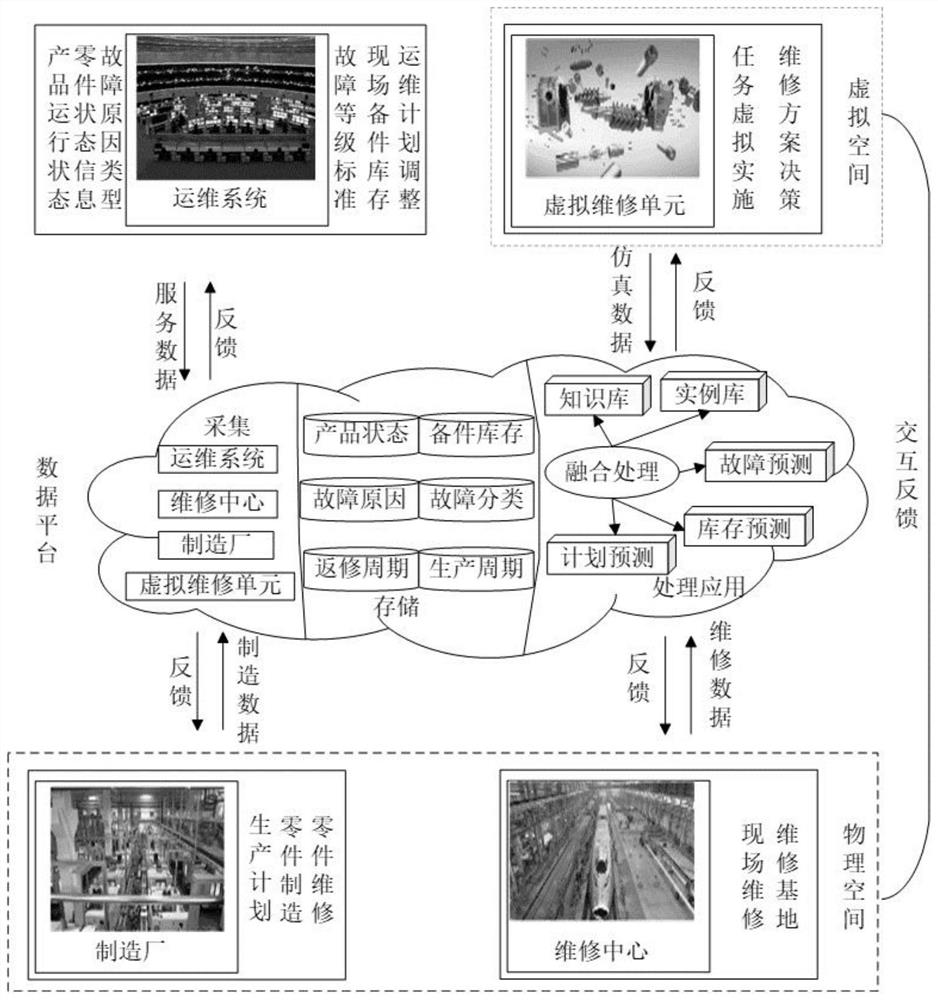

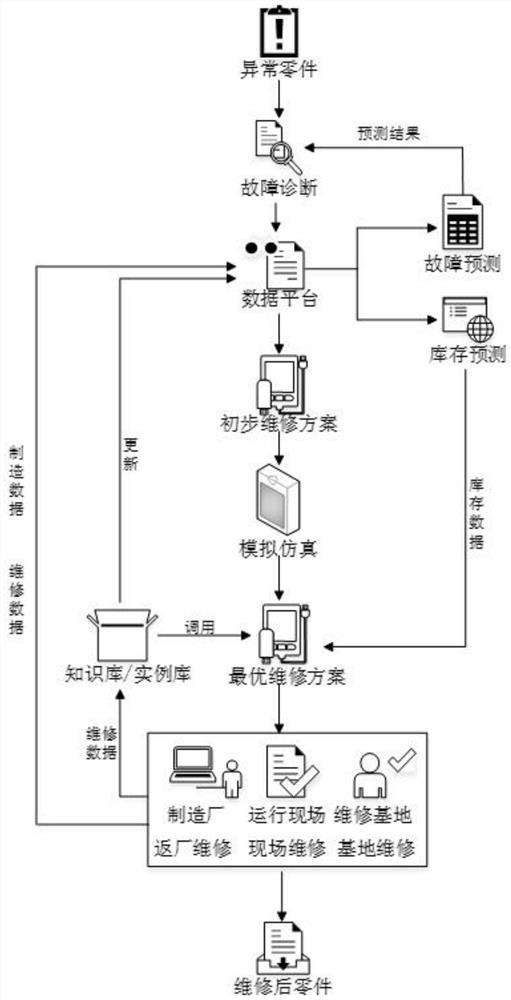

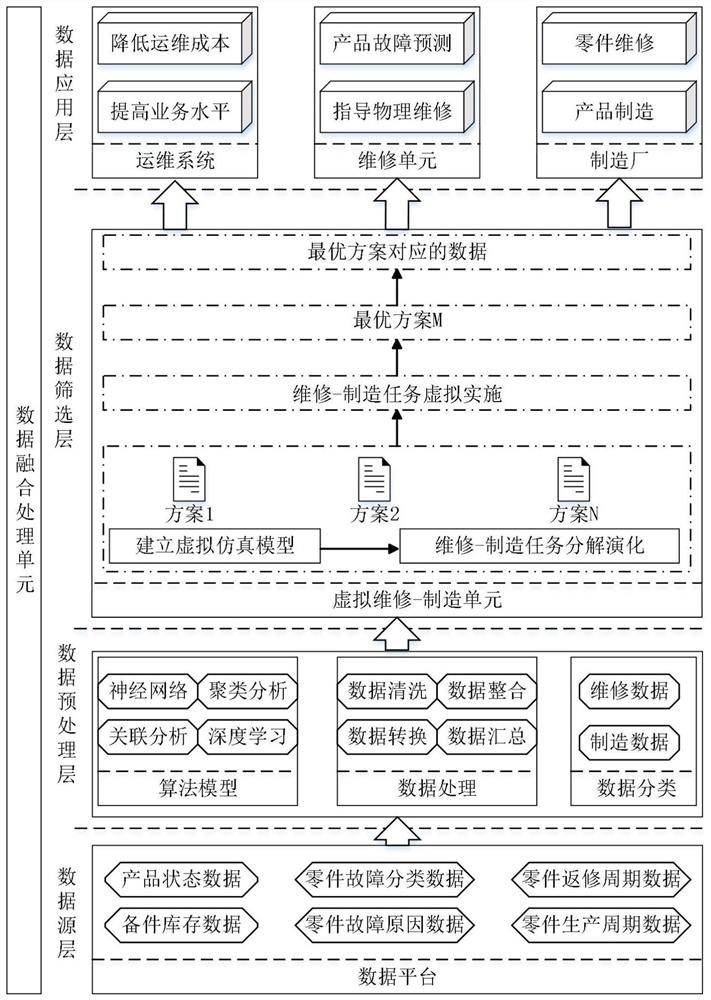

Complex product operation, maintenance and manufacturing integrated general model based on digital twinning

PendingCN112800668AData processing applicationsDesign optimisation/simulationData platformManufacturing data

The invention provides a complex product operation, maintenance and manufacturing integrated general model based on digital twinning. The complex product operation, maintenance and manufacturing integrated general model comprises an operation and maintenance system module, a virtual maintenance unit module, a maintenance center module, a manufacturing plant module and a data platform module. The invention also provides a digital twinning-based operation, maintenance and manufacturing integrated process operation mode, modeling simulation, data fusion processing and other solutions, and discusses digital twinning-based key technologies such as intelligent diagnosis, fault prediction, data comprehensive perception, knowledge base / instance library construction and the like. Complex product operation and maintenance and manufacturing information are deeply fused, operation and maintenance and manufacturing data are interactively fed back, virtual and real combination of complex product operation and maintenance and manufacturing is realized through digital twinning, and more real-time, efficient and intelligent integrated services are provided. According to the operation mode of the complex product operation, maintenance and manufacturing model based on digital twinning, deep integration of the complex product operation, maintenance and manufacturing process is achieved, and the information island phenomenon generated in the operation, maintenance and manufacturing links is eliminated.

Owner:XIAN UNIV OF SCI & TECH

Intelligent virtual maintenance training system for large equipment

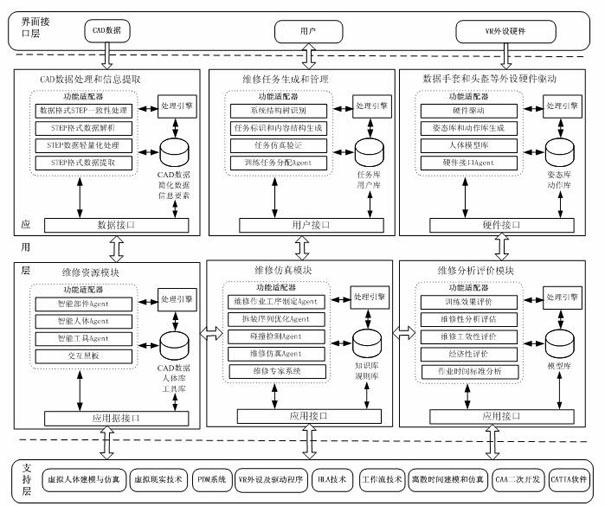

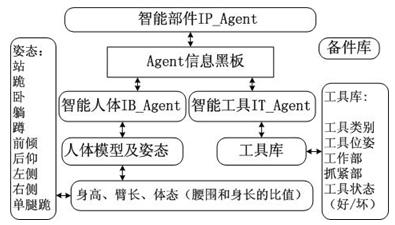

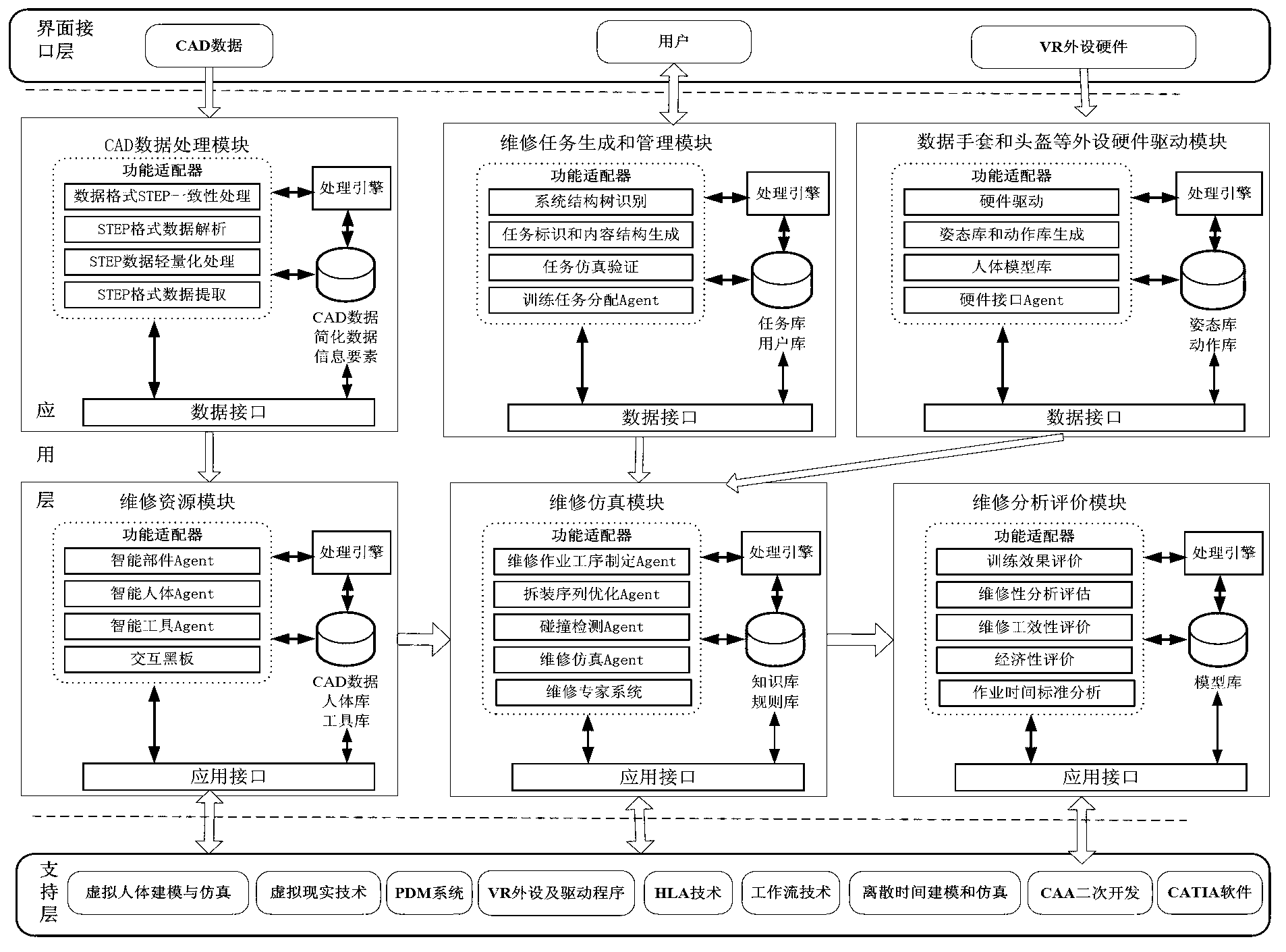

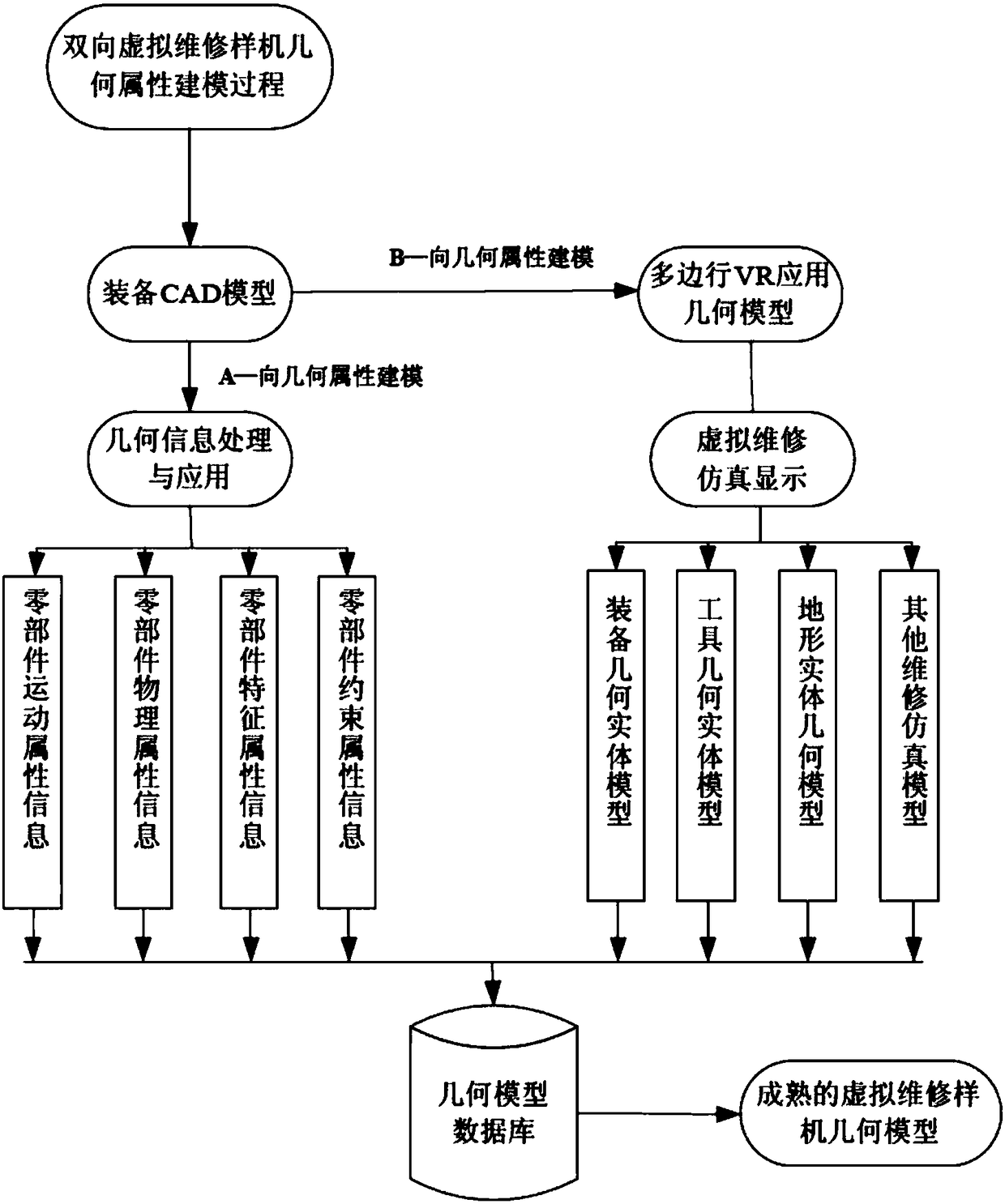

InactiveCN102663182AImprove training effectDoes not consume resourcesSpecial data processing applicationsComputer Aided DesignInterface layer

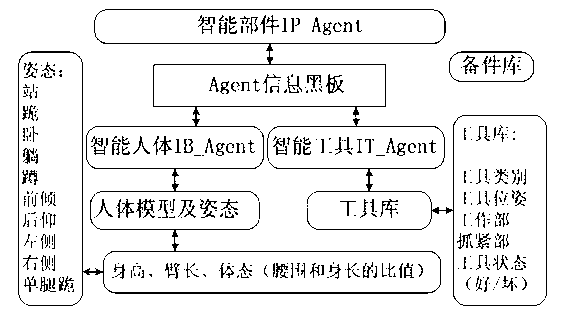

The invention discloses an intelligent virtual maintenance training system for large equipment. The system comprises an interface layer, an application layer and a technical support layer, wherein the application layer comprises a CAD (computer aided design) data processing module, a maintenance task library generating and managing module, an external hardware driver module, a maintenance resource module, a maintenance simulating module and a maintenance analyzing and assessing module; the maintenance resource module builds an intelligent module based on the data achieved by the CAD data processing module; and the intelligent module interacts with an external hardware to simulate gestures and actions of trainees and tools and further prepares for maintenance simulation tasks. The intelligent virtual maintenance training system for large equipment employs the training manner combined with a plurality of interaction manners and does not waste real resources and energy, shortens the training time, reduces the training cost, enhances the effect of simulation operational training and has significance to promotion of civil aircraft digital maintenance and development of maintenance training technique.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

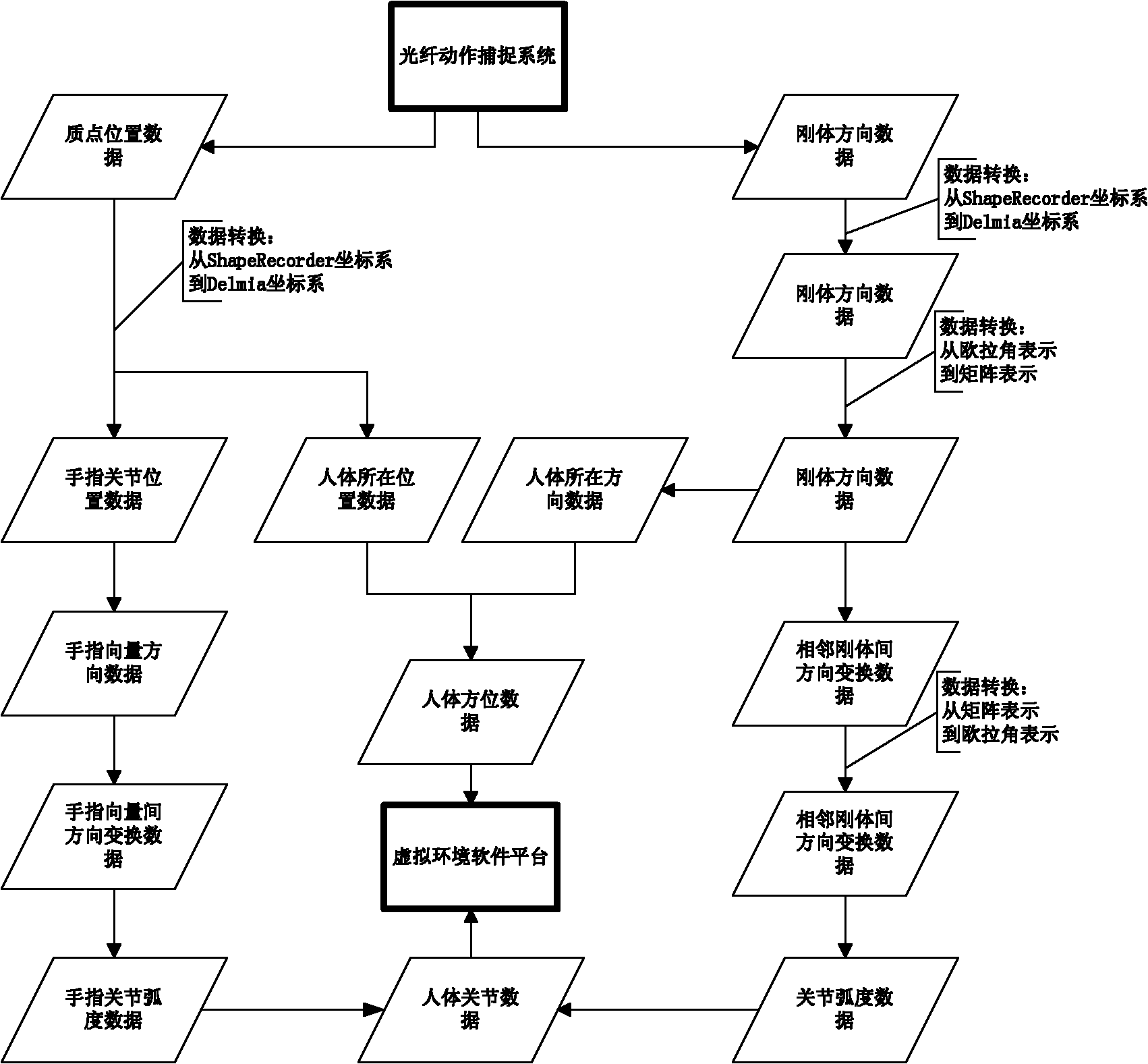

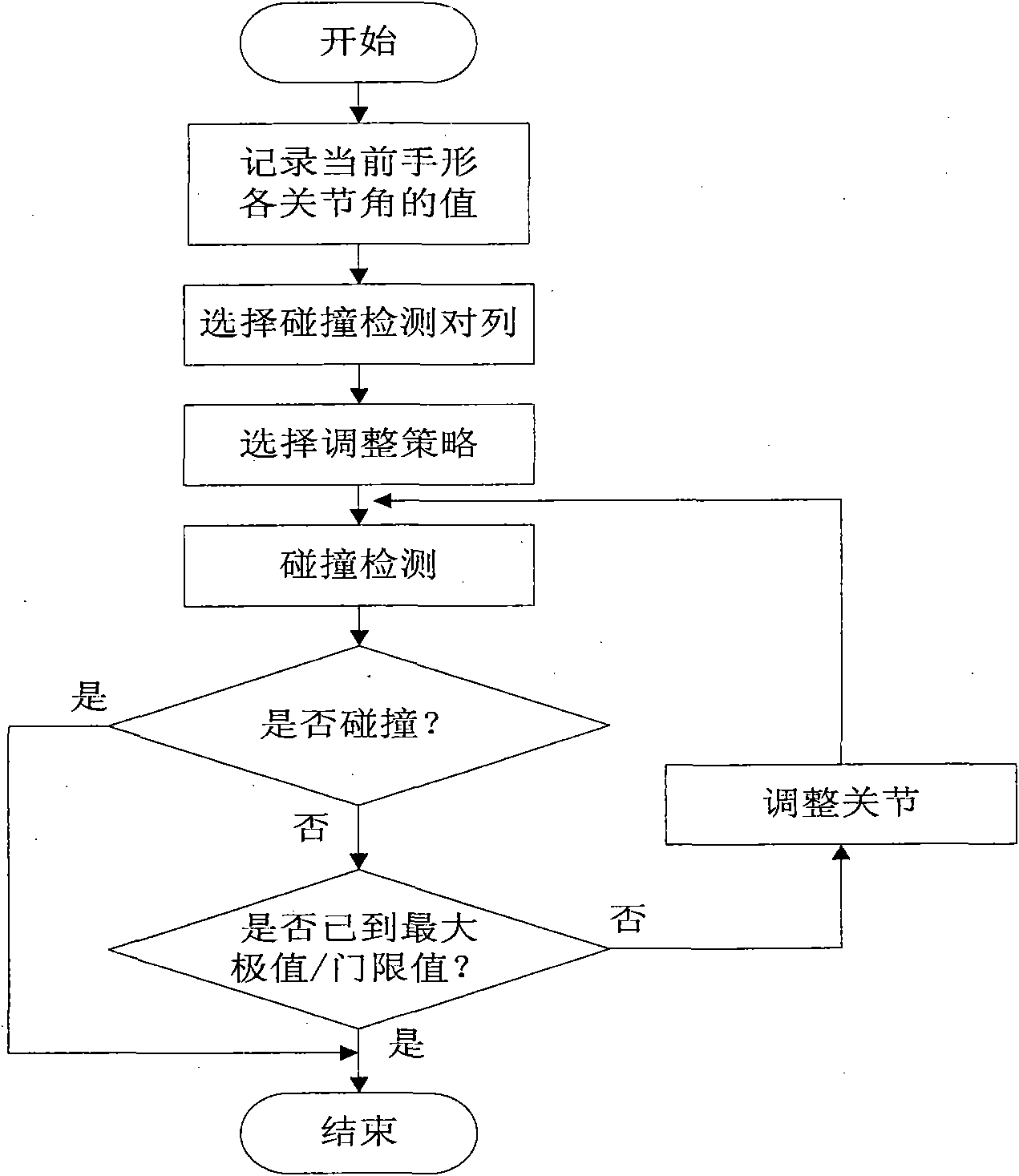

Digital enterprise lean manufacturing interactive application (DELMIA)-environment-based virtual human control method for immersive virtual maintenance simulation system

InactiveCN102521464AScalableSpecial data processing applicationsInterface designApplication programming interface

The invention discloses a digital enterprise lean manufacturing interactive application (DELMIA)-environment-based virtual human control method for an immersive virtual maintenance simulation system. The method comprises the following six main steps of: 1, setting the data output of motion capture software; (2) performing motion capture, and transmitting data in real time by using the software ofmotion capture equipment; 3, receiving and temporarily storing motion data output by the motion capture software; (4) calculating the motion data; 5, endowing DELMIA virtual simulation software with the converted motion data in an Automation application programming interface (API) way; and 6, repeating the steps 2 to 5. The immersive virtual maintenance simulation system is constructed by the DELMIA virtual simulation software and a wireless optical fiber motion capture system adopting ShapeWarp, corresponding researches on interface design algorithms for the DELMIA virtual simulation software and the wireless optical fiber motion capture system adopting the ShapeWarp by utilizing an Automation secondary development technology provided by the DELMIA virtual simulation software are made torealize the motion control of real maintenance data acquired by the motion capture system over virtual humans in the virtual simulation software DELMIA, and a new scheme for controlling the virtual humans under a DELMIA environment is provided to realize the fusion of a user and a virtual environment.

Owner:BEIHANG UNIV

Intelligent virtual maintenance training system for civil aircraft

InactiveCN103020332AImprove training effectDoes not consume resourcesCosmonautic condition simulationsSpecial data processing applicationsDigitizationTraining effect

The invention discloses an intelligent virtual maintenance training system for a civil aircraft. The intelligent virtual maintenance training system comprises an interface port layer, an application layer and a technical support layer. The application layer comprises a computer-aided design (CAD) data processing module, a maintenance task generation and management module, a peripheral hardware drive module, a maintenance resource module, a maintenance simulation module and a maintenance analysis evaluation module. The system builds an Agent intelligent object of the maintenance resource module according to the data which is obtained through the CAD data processing module, and a task generated by the maintenance task generation and management module, a motion database and a gesture database which are generated by the hardware drive module, and the pose simulation of virtual human maintenance motions and tools are combined to simulate and analyze the maintenance operation. The system adopts a training mode which adopts the combination of maintenance element intelligent interaction and knowledge database decision optimization, practical resources and energy are not consumed, the training time is shortened, the training cost is lowered, a maintenance training effect is enhanced, and the development of a digital maintenance training technology is greatly promoted.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

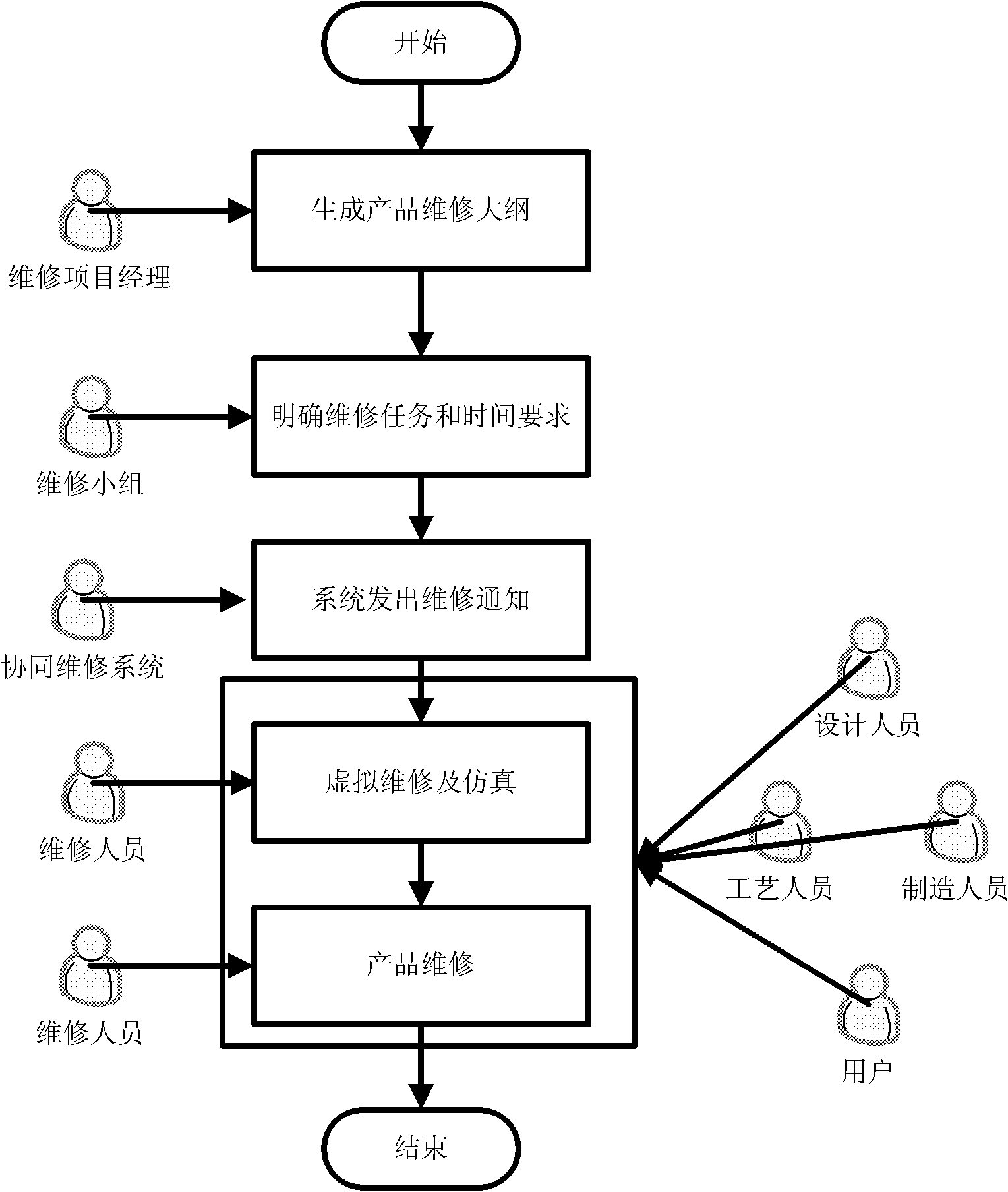

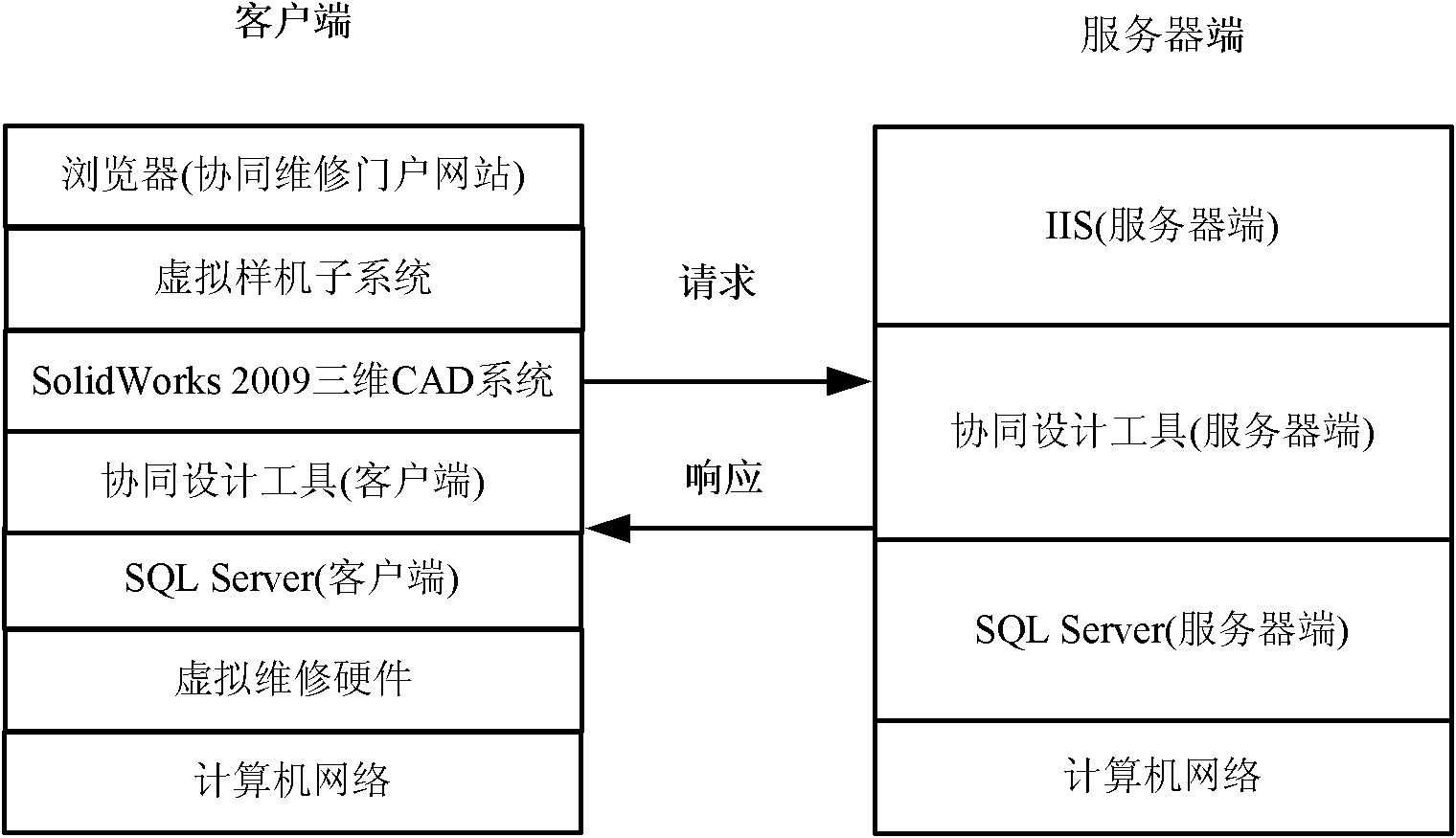

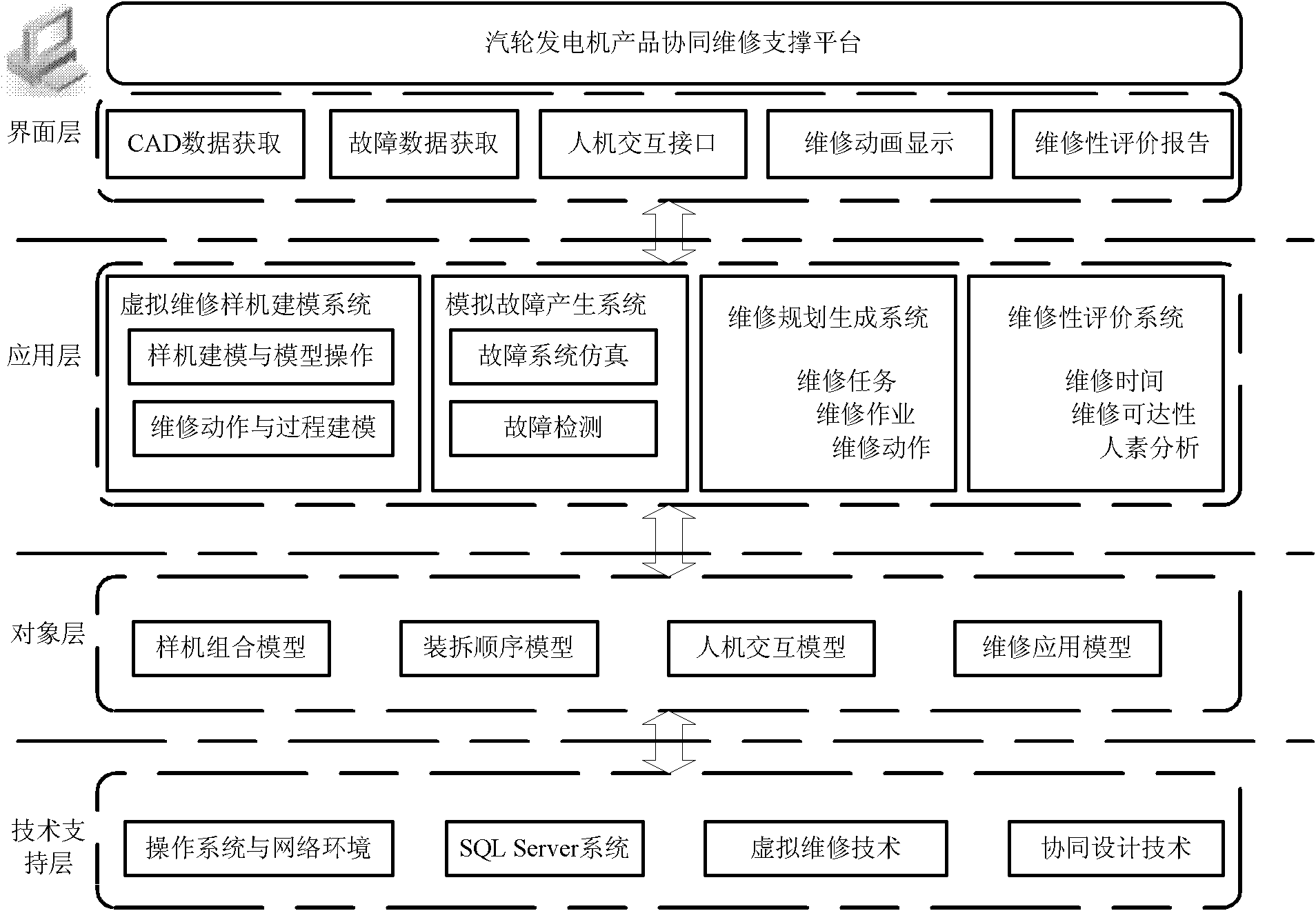

Supporting platform for product collaborative maintenance and maintenance method

The invention provides a supporting platform for product collaborative maintenance and a maintenance method. The supporting platform sequentially comprises a technical support layer, an object layer, an application layer and an interface layer from the bottom layer to the top layer; the technical support layer comprises an operating system and network environment, an SQL (Structured Query Language) Server system, a virtual maintenance technology set and a collaborative design technology set; and the object layer comprises a virtual prototype combination model, an assembly and disassembly sequence model, a human-computer interaction model and a maintenance application model. The maintenance method comprises the following steps of: (S1) generating a product maintenance outline; (S2) defining maintenance tasks and time requirements; (S3) sending a maintenance notice by a supporting platform system; (S4) carrying out virtual maintenance and simulation; and (S5) carrying out collaborative maintenance on the product. The invention can conveniently support collaboration and maintenance of members at different areas and accelerate the maintenance progress.

Owner:WUHAN UNIV OF TECH

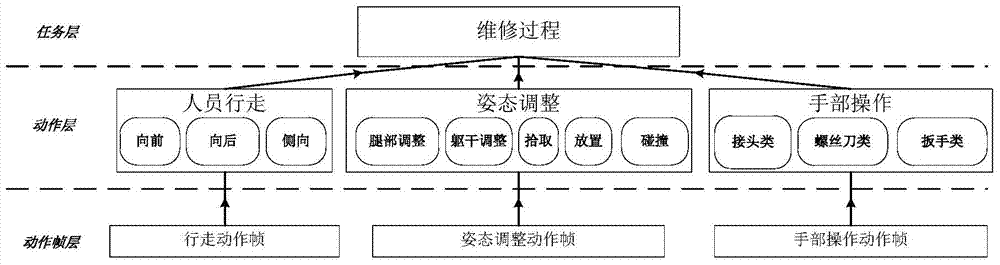

Method for establishing maintenance therblig set supporting virtual maintenance simulation

InactiveCN101853319AReduce workloadLower requirementSpecial data processing applicationsAction functionMaintenance actions

The invention discloses a method for establishing a maintenance therblig set supporting virtual maintenance simulation. The method comprises the following steps of: encapsulating a control function for a low-level movement and an action of a person so as to form a plurality of maintenance therbligs which can simulate a basic action unit of a maintenance action; and establishing a corresponding basic action function library based on the maintenance therbligs. In the method, the maintenance action is divided into moving actions and operating actions, wherein the moving actions comprise two therbligs of human movement and posture adjustment; the operating actions comprise two types of unarmed operation and tool using operation; the unarmed operation comprises three therbligs of grasping, disassembly and assembly operation, and releasing; and the tool using operation comprises four therbligs of tool using, positioning, placing an object and holding. Due to the adoption of the method, work load of a user can be reduced; requirements on the user are reduced; and virtual maintenance simulation efficiency is greatly improved.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

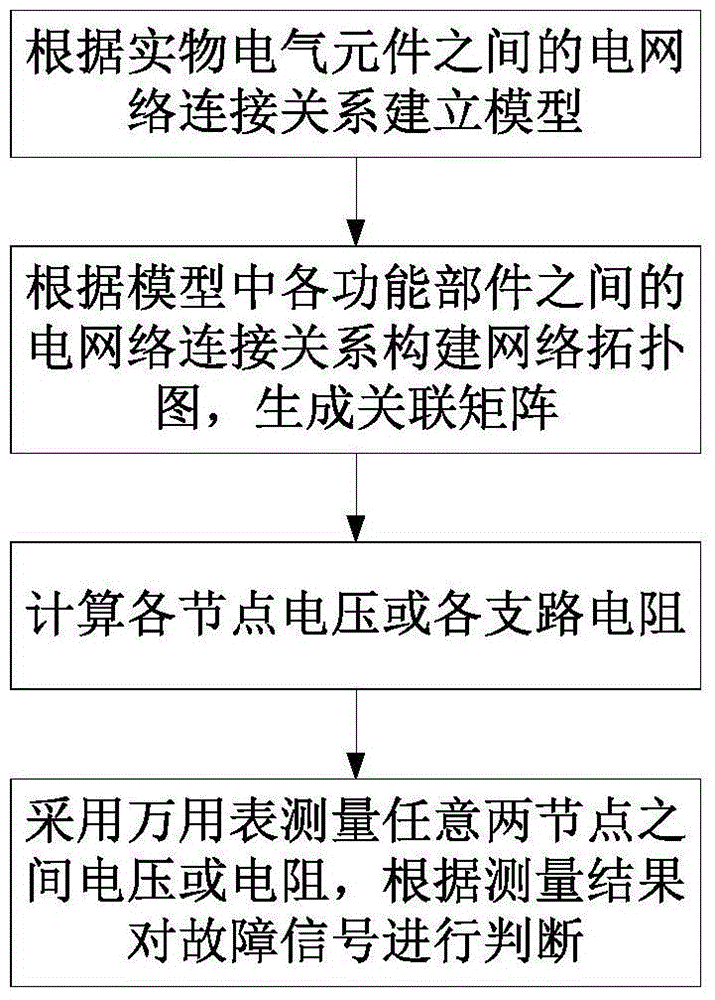

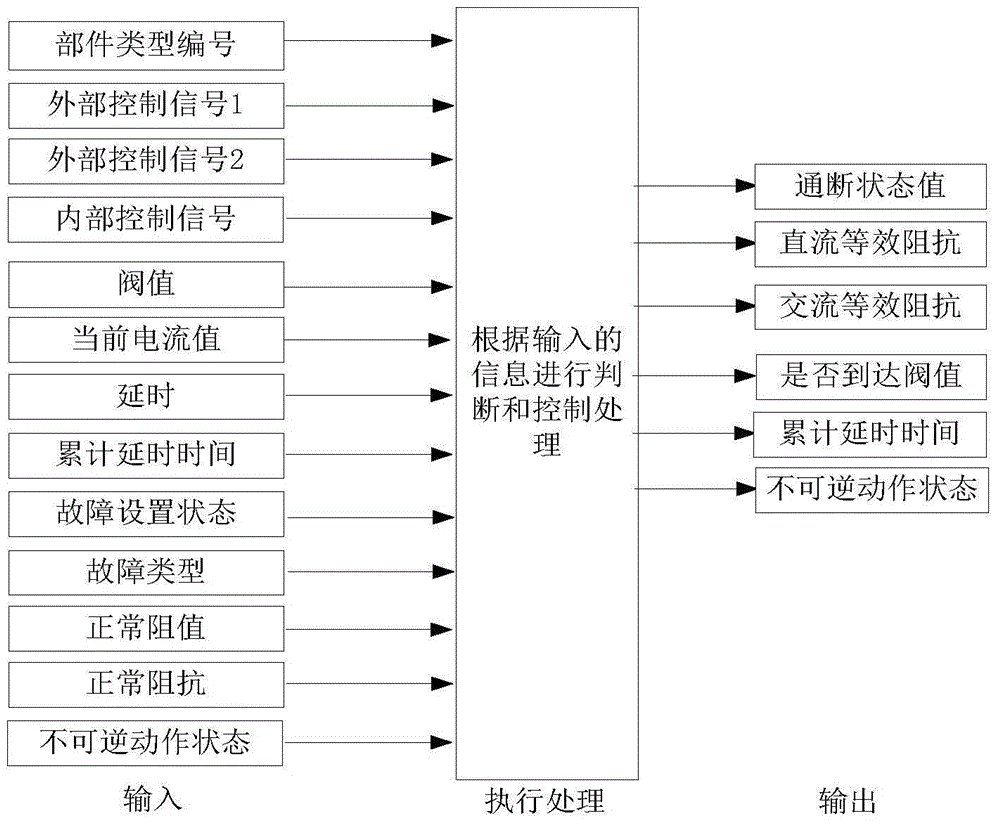

Electrical equipment virtual maintenance training system simulation method

ActiveCN105096694AStrengthen maintenance skills trainingAvoid designTeaching apparatusElectric networkNetwork topology

The invention discloses an electrical equipment virtual maintenance training system simulation method. The method comprises the steps that all the physical electrical elements in electrical equipment are disassembled into functional parts respectively, and a model is established with all the functional parts acting as basic objects; then a network topological diagram is constructed according to the electric network connection relationship among all the functional parts in the model, and an incidence matrix is generated by the network topological diagram; and then voltage of all nodes or resistance of all branches is calculated according to the parameters of the incidence matrix and the model, a maintenance man uses a virtual multimeter to measure voltage or resistance between any two nodes in the model, a fault signal is judged according to the measurement result and electrical equipment virtual maintenance training simulation is realized. Detection judgment of the fault signal is performed by using the multimeter so that simulation of the fault of different combinations of node signals and accurate simulation of current of each branch of the circuit under the normal and fault state and voltage and resistance between any two nodes can be realized, and maintenance skill training of operating personnel can be effectively enhanced.

Owner:NAVAL UNIV OF ENG PLA

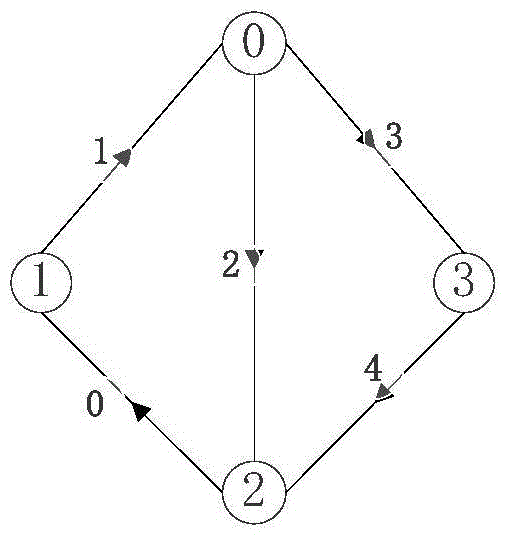

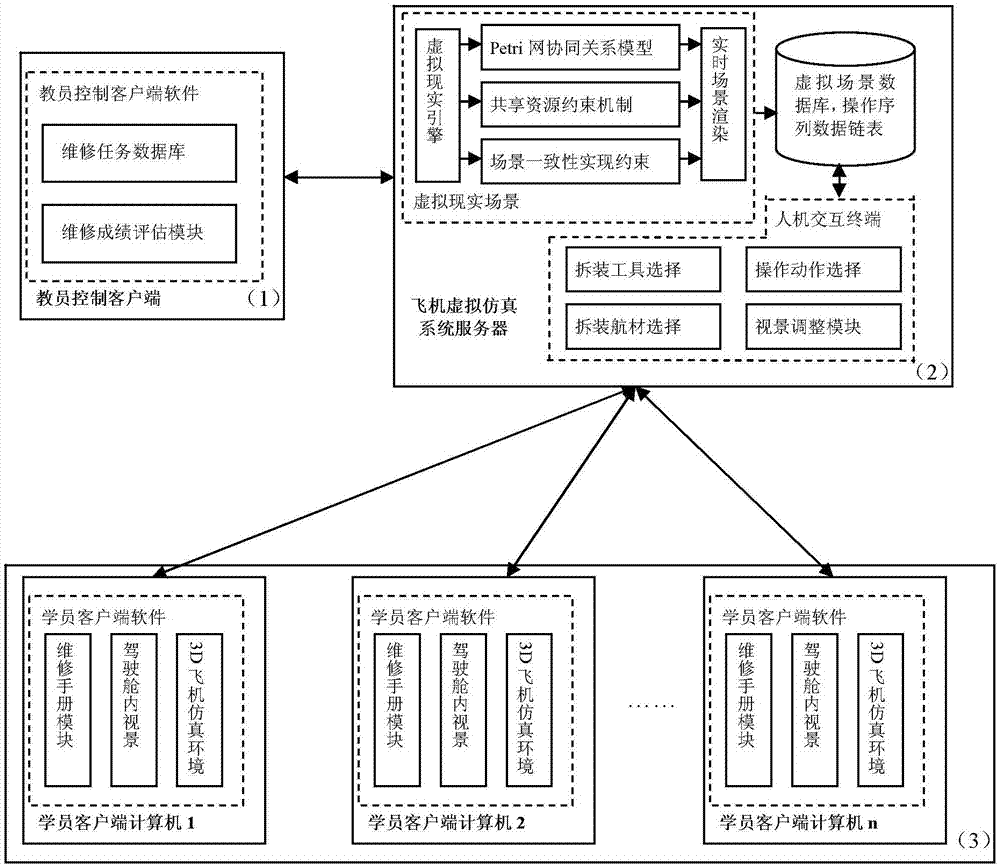

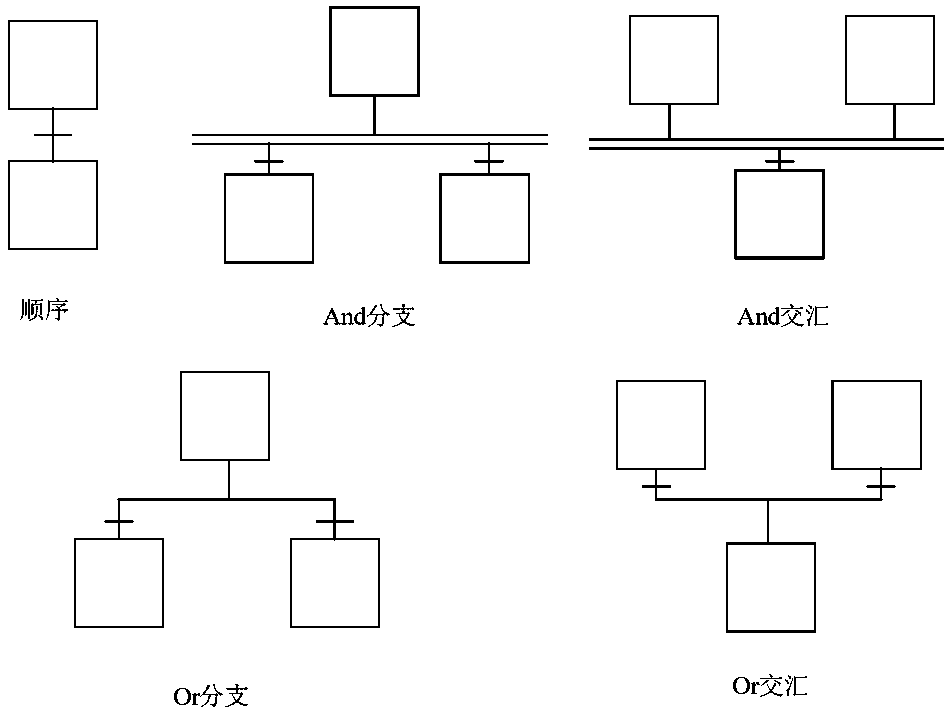

Airplane digitalized coordination virtual maintenance training device and coordination maintenance method

InactiveCN104504958AImprove standard operationImprove the ability of multi-person collaborationCosmonautic condition simulationsSimulatorsJet aeroplaneComputer module

The invention discloses an airplane digitalized coordination virtual maintenance training device and a coordination maintenance method. The training device comprises a teacher control client-side, an airplane virtual simulation system server and a plurality of student client-sides, wherein the teacher control client-side is connected with the airplane virtual simulation system server; the airplane virtual simulation system server is connected with the student client-sides; a teacher control client-side program, a maintenance task database and a maintenance result evaluation module are arranged in the teacher control client-side; the airplane virtual simulation system server mainly comprises a virtual scene database, a shared resource restriction mechanism, a Petri network coordination relation model and a scene consistency realizing restriction; each student client-side comprises a maintenance handbook module, a 3D (three-dimensional) airplane simulation environment and a flight deck inner viewing scene. The airplane digitalized coordination virtual maintenance training device and the coordination maintenance method have the beneficial effects that the training of multi-person coordination maintenance on large complex equipment can be finished, and the ability of standard operation and multi-person coordination of maintenance men is improved.

Owner:CIVIL AVIATION UNIV OF CHINA

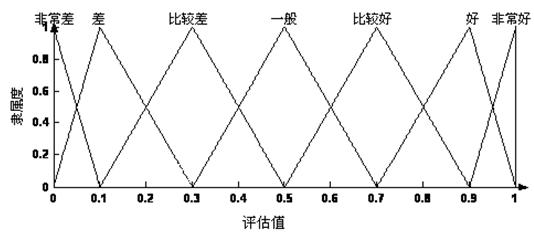

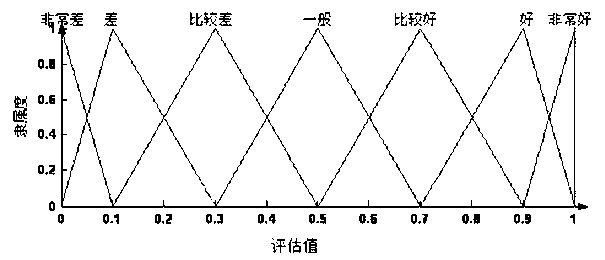

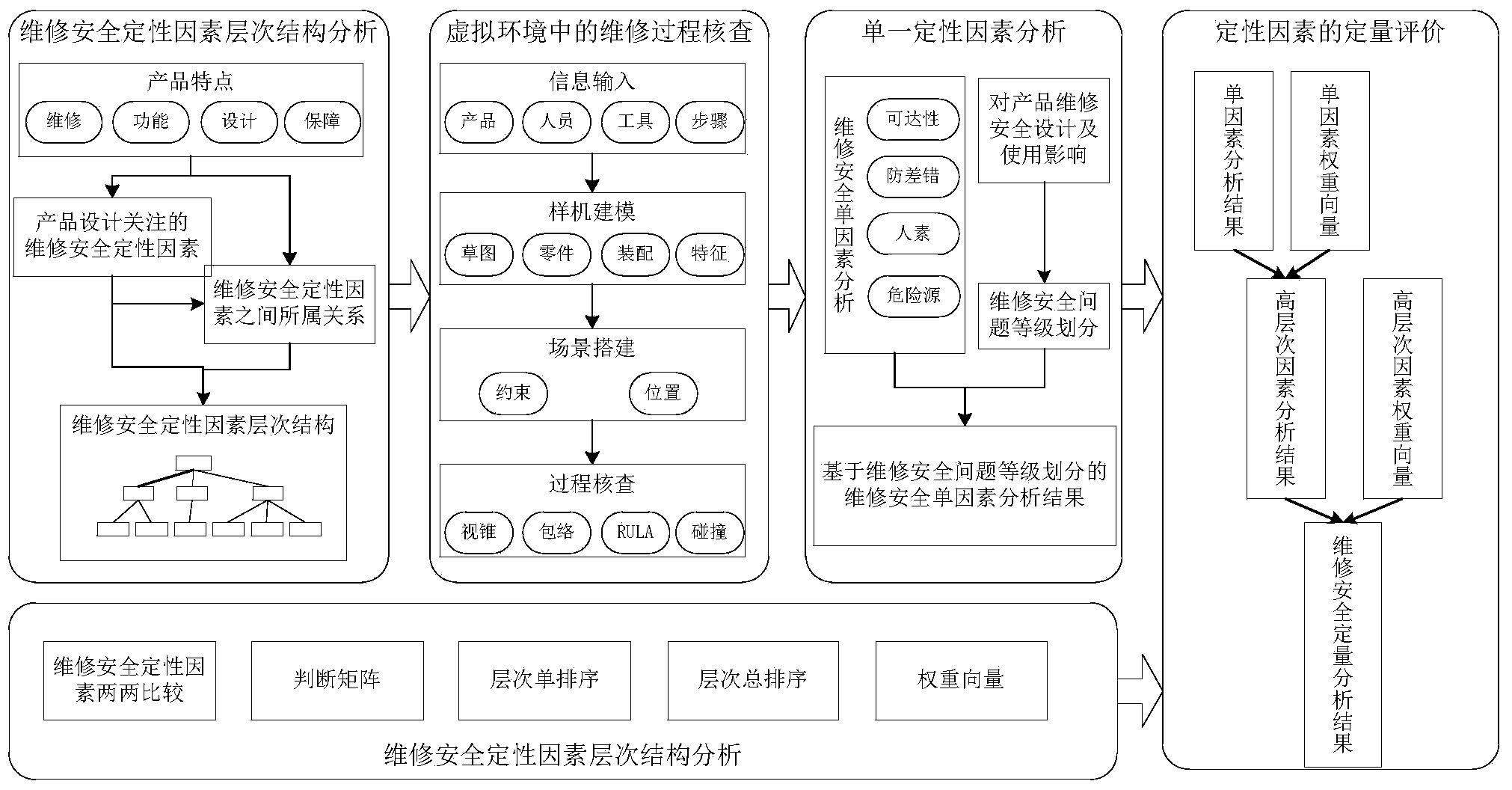

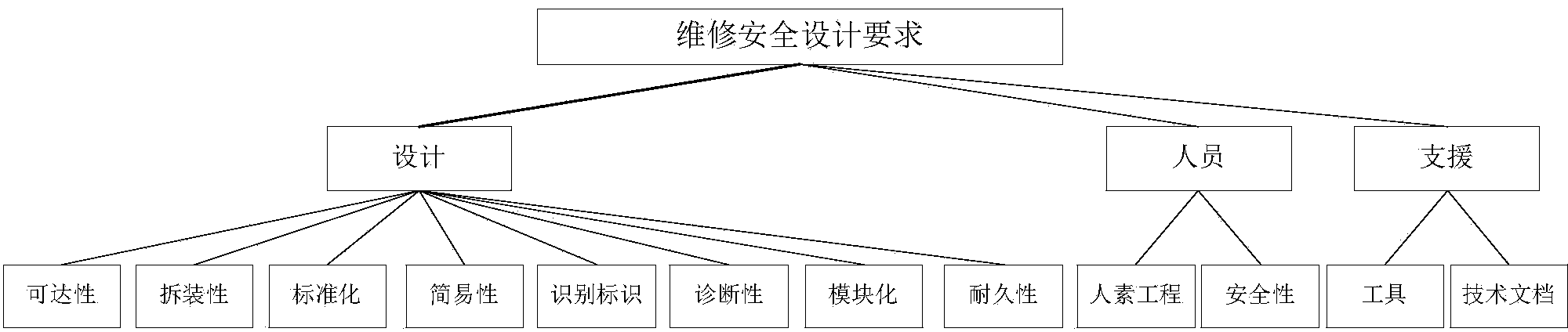

Virtual maintenance-based quantitative evaluation method for maintenance safety qualitative factors

InactiveCN103823939AImprove maintenance safety design and improve implementationSpecial data processing applicationsEvaluation resultSafety design

The invention relates to a virtual maintenance-based quantitative evaluation method for maintenance safety qualitative factors and belongs to the technical fields of virtual reality technology and mathematical science-aided product design. The virtual maintenance-based quantitative evaluation method comprises the following steps: firstly, determining the maintenance safety qualitative factors in specific product maintenance safety design; performing hierarchical division on the maintenance safety qualitative factors; performing ranking weight definition on the maintenance safety qualitative factors of a hierarchical structure by applying an analytic hierarchy process to finish product virtual prototype-oriented maintenance procedure inspection and factor analysis in a virtual environment; performing evaluation on question grades of all factors of a bottom layer in the hierarchical structure by combining analysis results of the factors and maintenance safety question classification, and performing quantitative evaluation on all the factors by combining evaluated values and ranking weight. According to the virtual maintenance-based quantitative evaluation method provided by the invention, by fully utilizing single-factor evaluation results, provided by virtual maintenance, of the maintenance safety qualitative factors, the quantitative evaluation is provided for the maintenance safety qualitative factors; at the initial stage of the product design, an ancillary support is objectively and systematically provided for the product maintenance safety qualitative factors.

Owner:BEIHANG UNIV

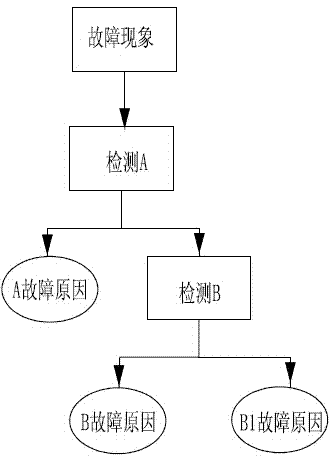

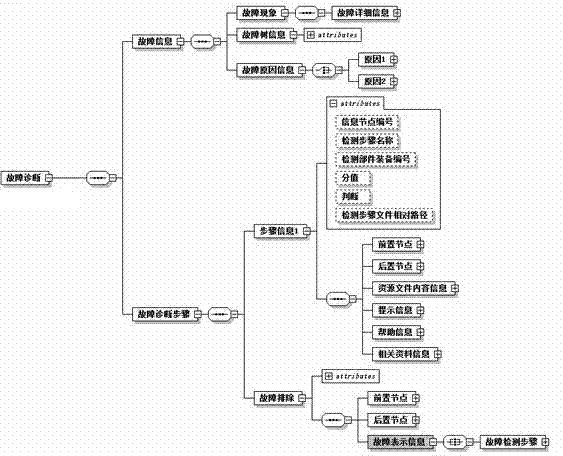

Fault diagnosis training method for ordnance equipment

ActiveCN104503442AAddress training effectsAddress training qualityElectric testing/monitoringControl systemSimulation

The invention discloses a fault diagnosis training method for ordnance equipment, and relates to the technical field of a process control system. The fault diagnosis training method comprises the following steps of (1) establishing a virtual maintenance training model machine; (2) setting fault diagnosis training processes of the virtual maintenance training model machine; (3) packaging the fault diagnosis training processes according to a subject system; (4) issuing packaged fault diagnosis training processes; (5) carrying out fault diagnosis training through a virtual maintenance training environment. According to the fault diagnosis training method disclosed by the invention, the problem that the training effect and the training quality during fault diagnosis training of the ordnance equipment are low can be solved, the difficult problem facing current fault diagnosis can be overcome, the training effect and the training quality are increased, the training cost is reduced, the training safety is ensured, and the defect of a current maintenance training means is relived.

Owner:PEOPLES LIBERATION ARMY ORDNANCE ENG COLLEGE

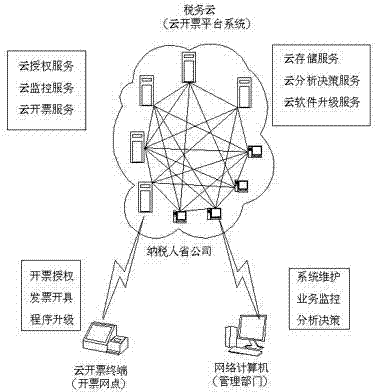

Industry billing system based on cloud computing technology

The invention discloses an industry billing system based on a cloud computing technology. The system can maximize the utilization effectiveness of a server and other computing equipment through optimizing the configuration of performance resources of the server by utilizing a virtual server technology, realize the centralized construction and centralized management of billing terminal equipment by combining with a virtual maintenance technology of a billing terminal, and truly realize a construction mode of a centralized management and distributed billing system of billing transactions, thus effectively solving the problems of high cost, low efficiency, difficult management and the like of the traditional billing system. The industry billing system is mainly applied to billing network nodes of tax payers in petrochemistry, electric power, telecommunication, gas and other industries sp as to realize machine-printed invoice businesses by utilizing cloud billing terminals.

Owner:INSPUR SOFTWARE TECH CO LTD

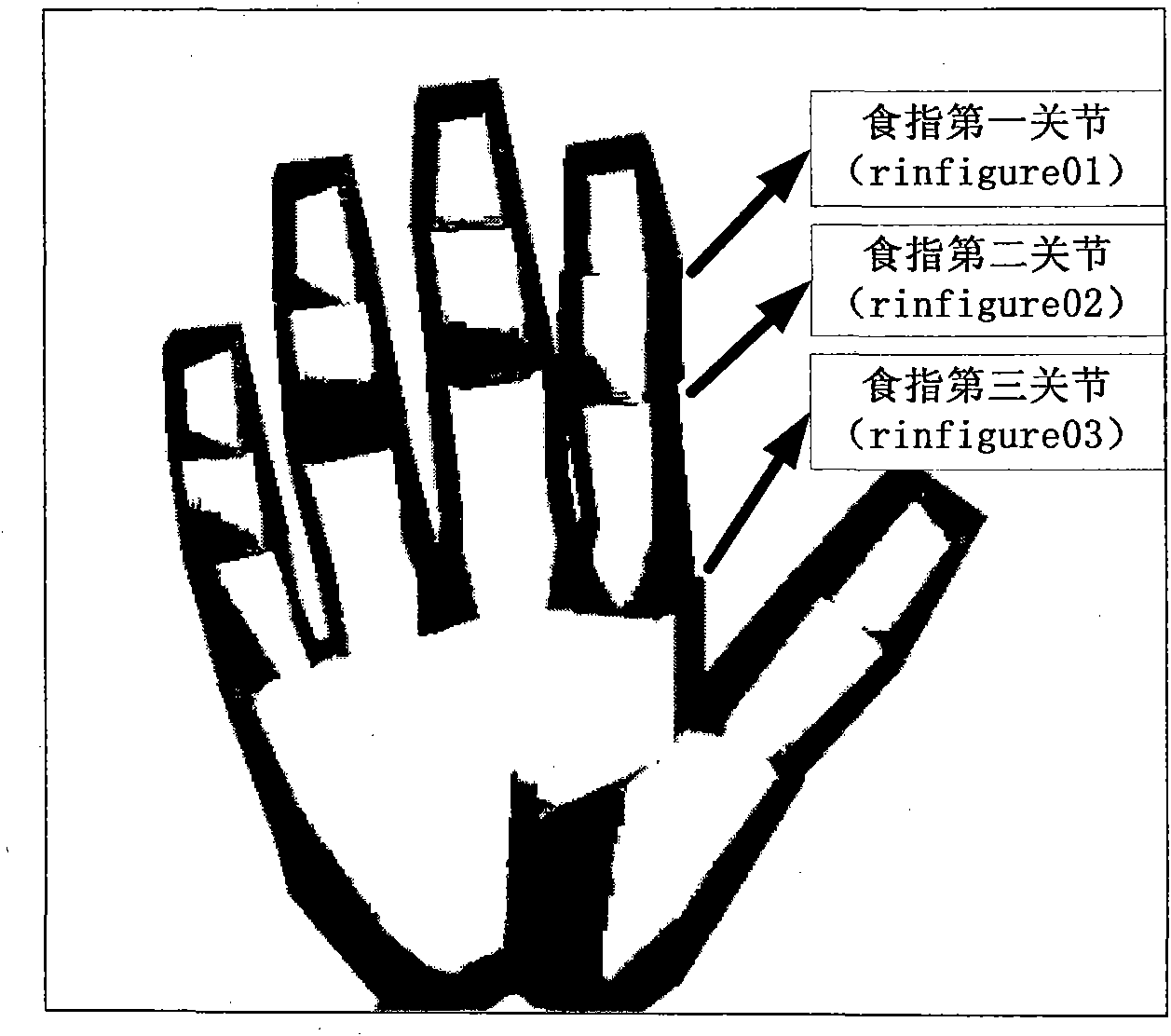

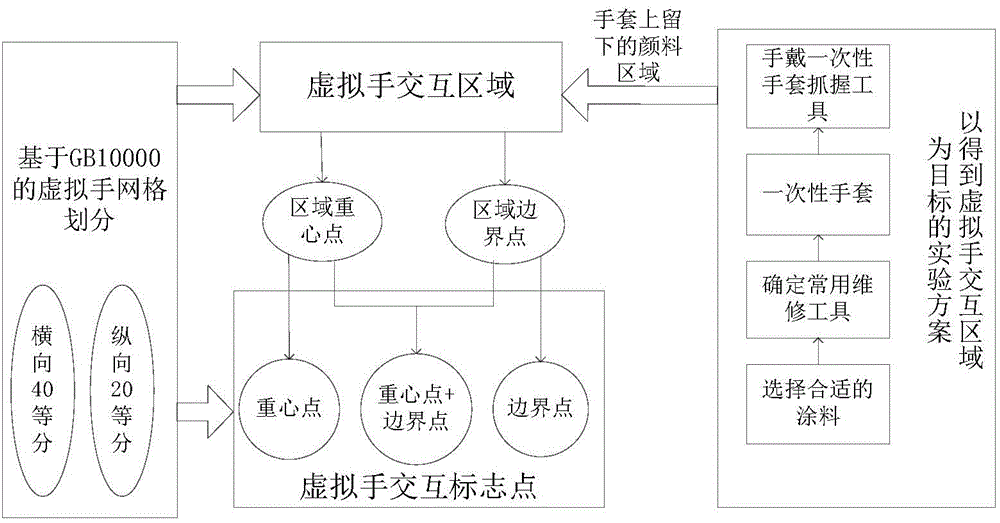

Virtual maintenance interaction operation method based on virtual hand interaction feature layer model

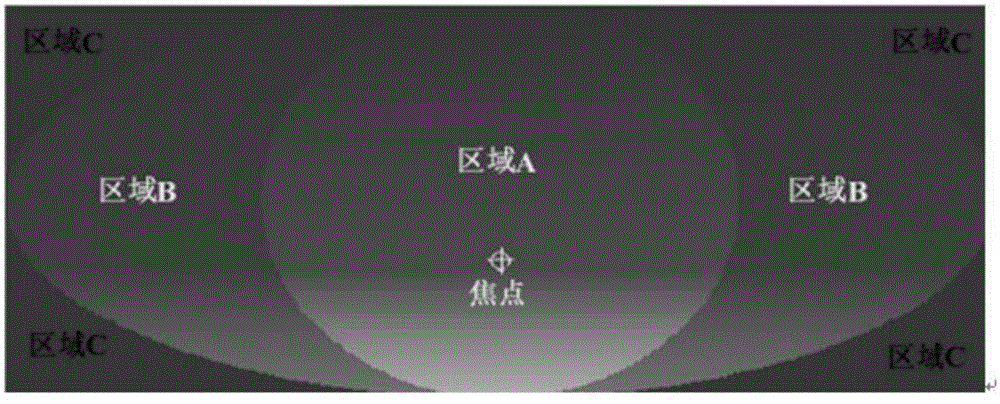

ActiveCN104156068AAchieve interactionImprove immersionInput/output for user-computer interactionGraph readingMaintenance actionsVirtual maintenance

The invention provides a virtual maintenance interaction operation method based on a virtual hand interaction feature layer model, and belongs to the technical field of virtual maintenance in maintenance design. The method includes the steps that an interaction area of a virtual hand and a maintenance tool is determined through experiments; the obtained interaction area is simplified, and virtual hand interaction feature point identification is carried out in virtual environments; virtual hand interaction is achieved through a data glove; the point where the virtual hand and the virtual maintenance tool is in contact is obtained, the obtained contact point is matched with a corresponding interaction feature point, and a coordinate system of the maintenance tool clings to a coordinate system of the virtual hand for virtual maintenance when matching is successful. By means of the method, interaction of maintenance actions in immersion virtual maintenance environments is achieved, and accordingly accuracy of virtual interaction and immersion sensing of user operations are improved.

Owner:BEIHANG UNIV

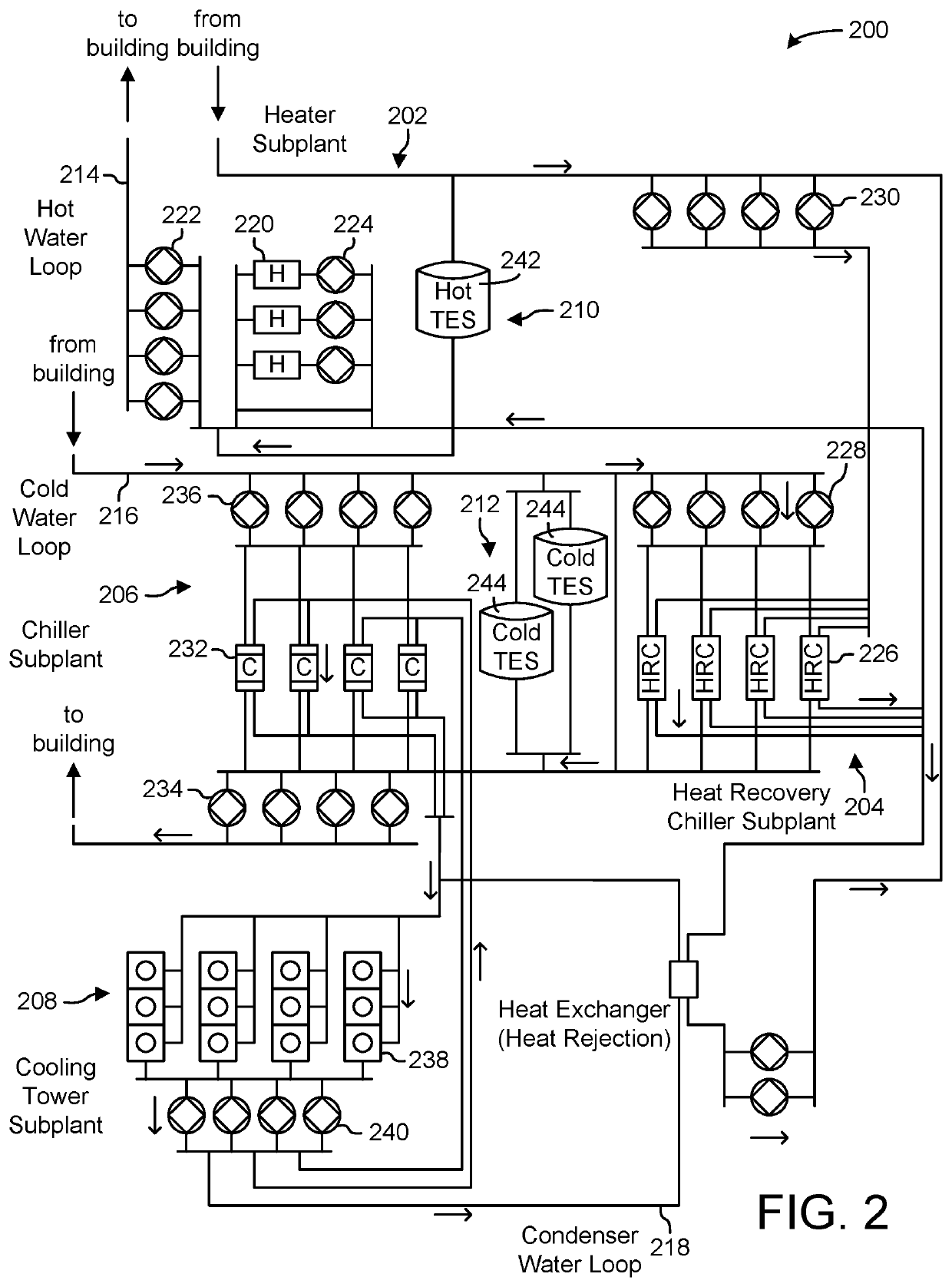

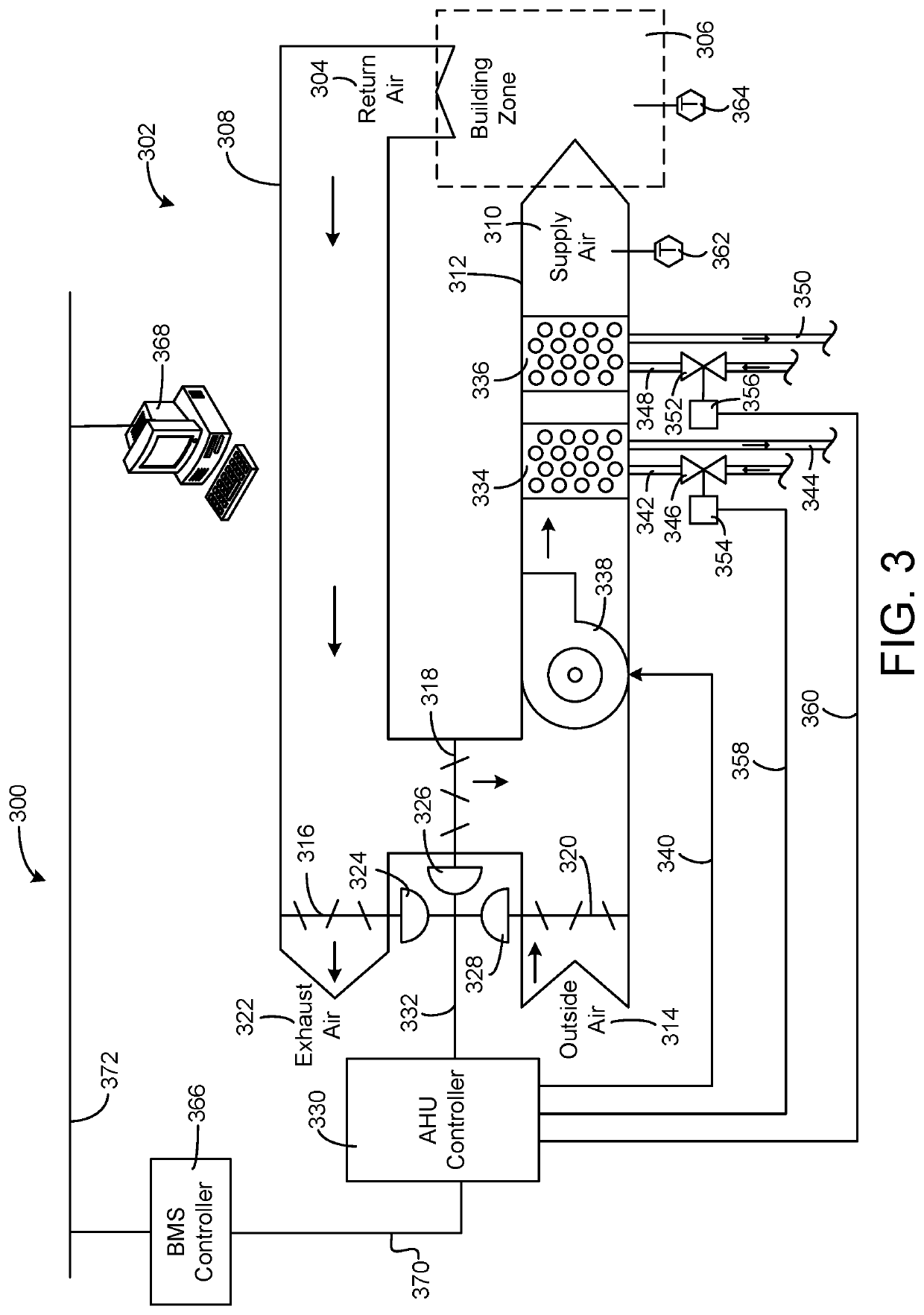

Virtual maintenance manager

A user interface for a security system includes a processing circuit, the processing circuit including a processor and memory coupled to the processor, the memory having instructions stored thereon that, when executed by the processor, cause the processing circuit to receive, from a user via a user device, a user request for information relating to the security system, determine, using natural language processing, an intent and one or more entities associated with the user request, the intent describing a purpose of the user request and the one or more entities describing a type or source of security system data, generate a response to the user request based on the intent and the one or more entities, wherein the response is a graphical display of security system data, and send the response to the user device.

Owner:JOHNSON CONTROLS TECH CO

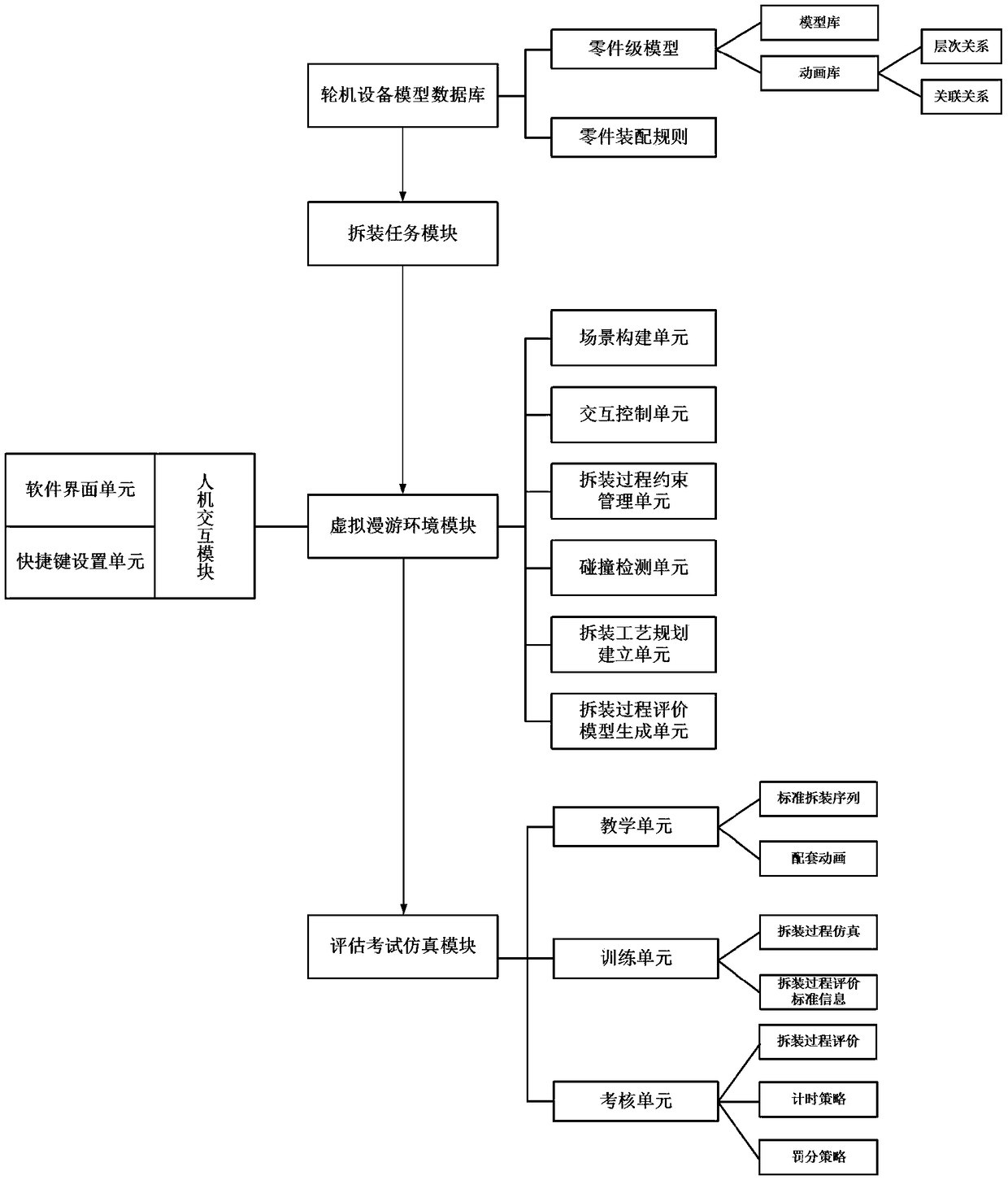

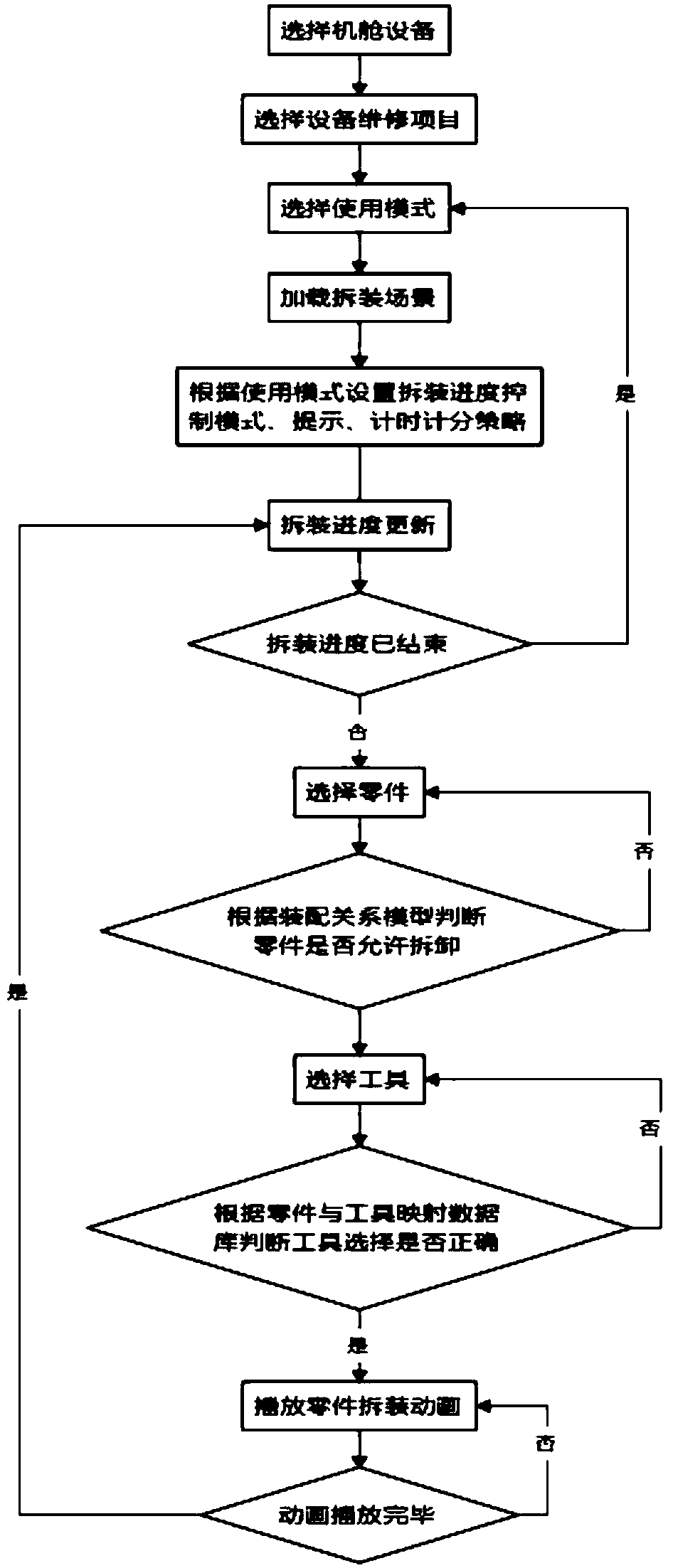

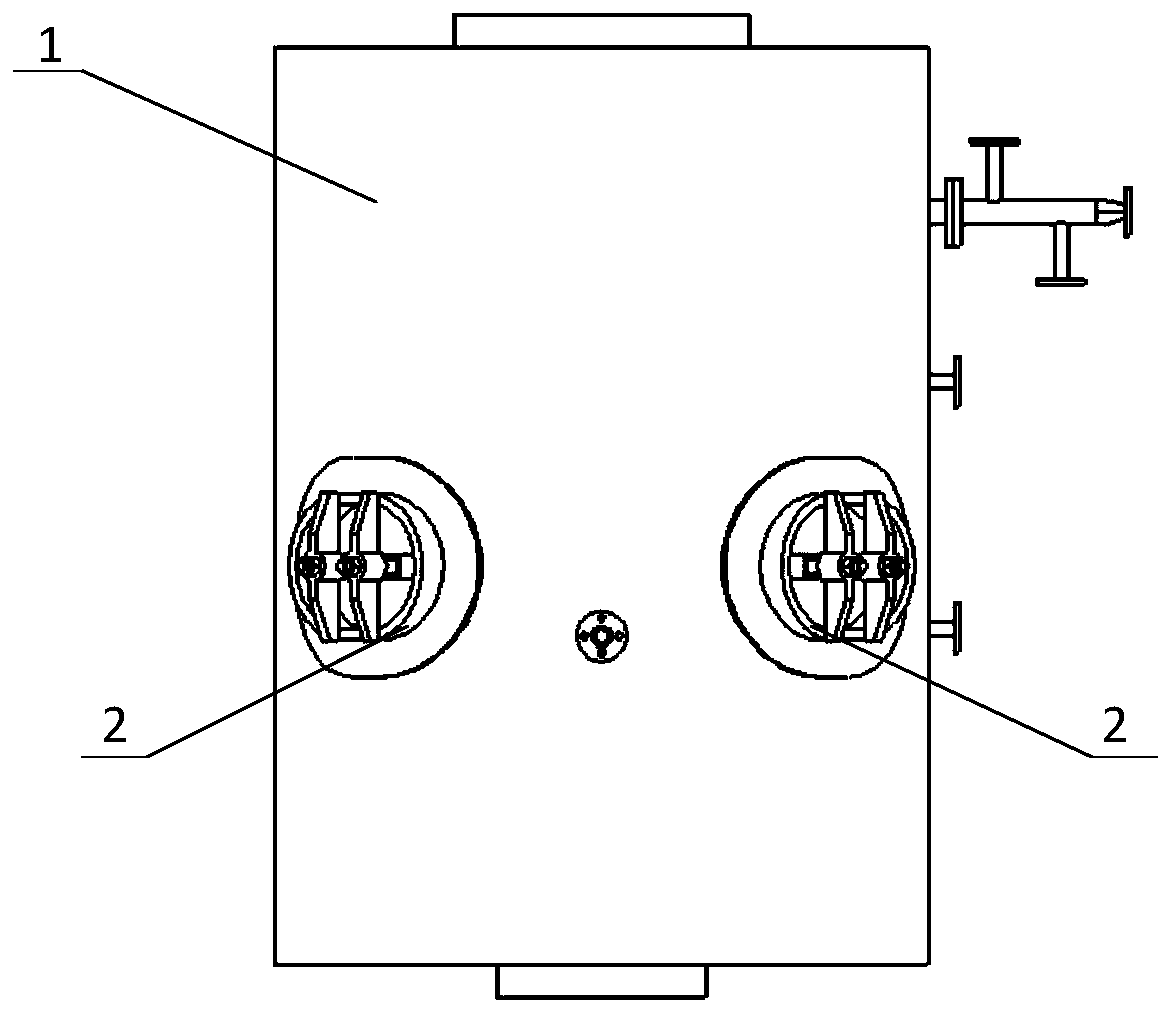

High-sense-of-reality marine engine room equipment three-dimensional virtual evaluation and training system

ActiveCN109118869ASolve the problem that it is impossible to conduct a large number of ship maintenance and disassembly trainingAccurate modelingCosmonautic condition simulationsElectrical appliancesComputer moduleHuman–robot interaction

The invention provides a high-sense-of-reality marine engine room equipment three-dimensional virtual evaluation and training system comprising a man-machine interaction module, a disassembly and assembly task module, a virtual roaming environment module, an evaluation test simulation module and a marine engine equipment model database. The disassembly and assembly task module is sequentially communicated with the virtual roaming environment module and the evaluation test simulation module. The virtual roaming environment module can be operated by an operator through a shortcut key to input the instruction. The software interface unit performs three-dimensional dynamic display of the operation training. The high-sense-of-reality highlight and light-shade effect is realized by using the off-line baking and on-line shader programming. The student performs engine room equipment virtual maintenance training according to the set virtual environment. The multi-functional virtual simulation system which can be used for teaching and examination can be realized. The training cost is low and the training efficiency is high.

Owner:大连海大智船科技有限责任公司

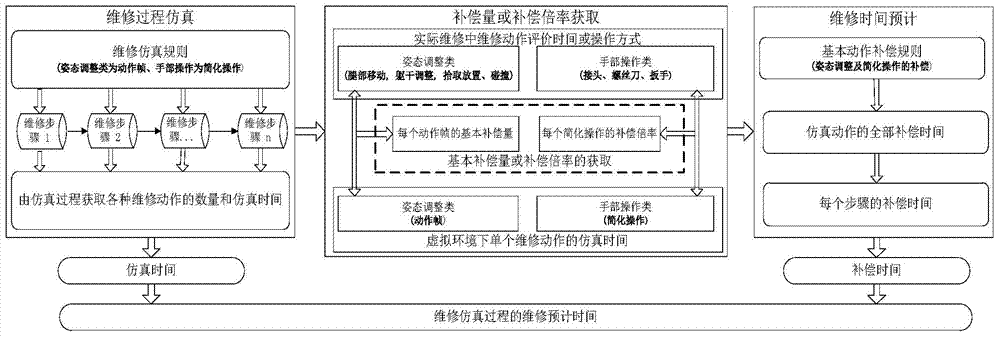

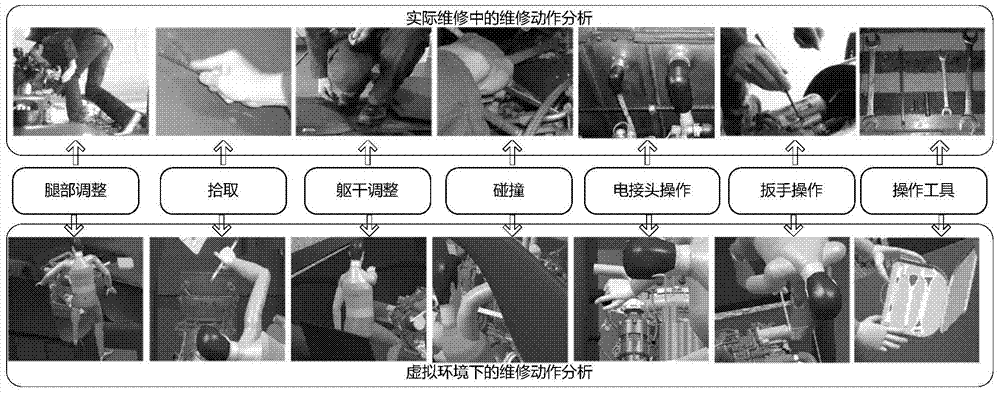

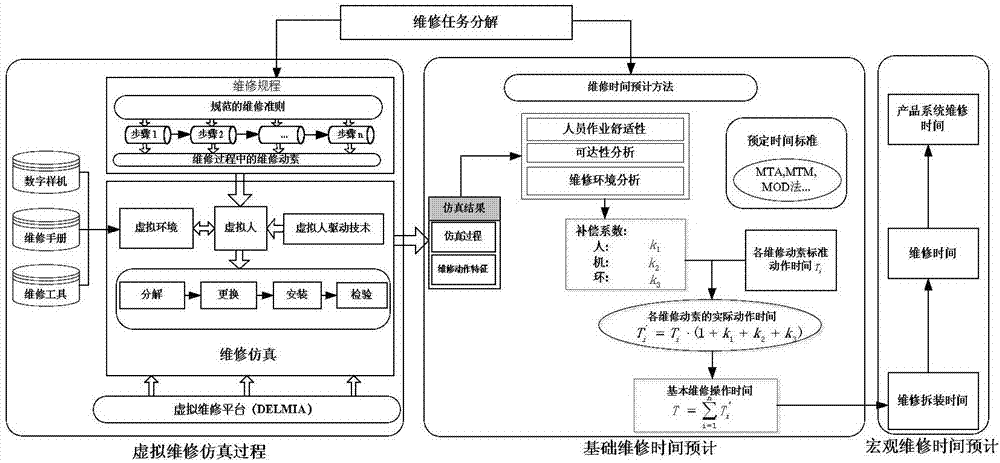

Maintenance time prediction method based on virtual maintenance simulation process

InactiveCN103678821AImprove general performanceGet rid of hysteresisSpecial data processing applicationsMultiplication rateRepair time

The invention relates to a maintenance time prediction method based on a virtual maintenance simulation process and belongs to the technical field of design of auxiliary products of the virtual reality technology. To overcome the defects that a traditional maintenance time prediction method is tedious in calculation and low in visualization degree and manpower and materials are wasted, statistics is performed on maintenance action design simulation rules with the method to determine the compensation time of each maintenance action, then, the maintenance process is simulated through the virtual reality technology, after the simulation, statistics is performed on the number of the maintenance actions in the simulation process, and the maintenance time is predicted according to the compensation time. According to the compensation time, corresponding compensation is performed on the differential value or the multiplication rate between a single actual maintenance action and the virtual operation. The method avoids tediousness and uncertainty of a traditional method in the calculation process, the maintenance time of a new product is predicted objectively and systematically in the early stage of product design through a product model machine, and auxiliary support is provided for the design scheme of the maintenance time of the product.

Owner:BEIHANG UNIV

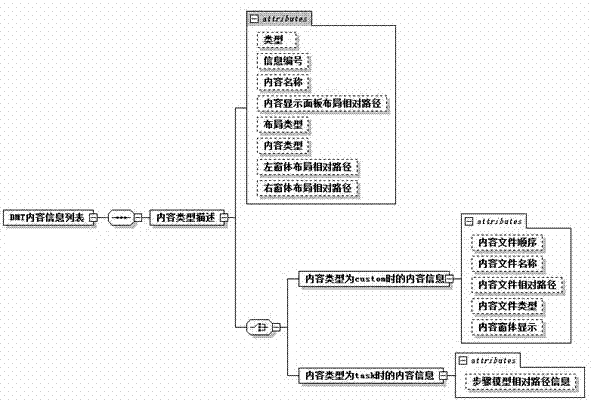

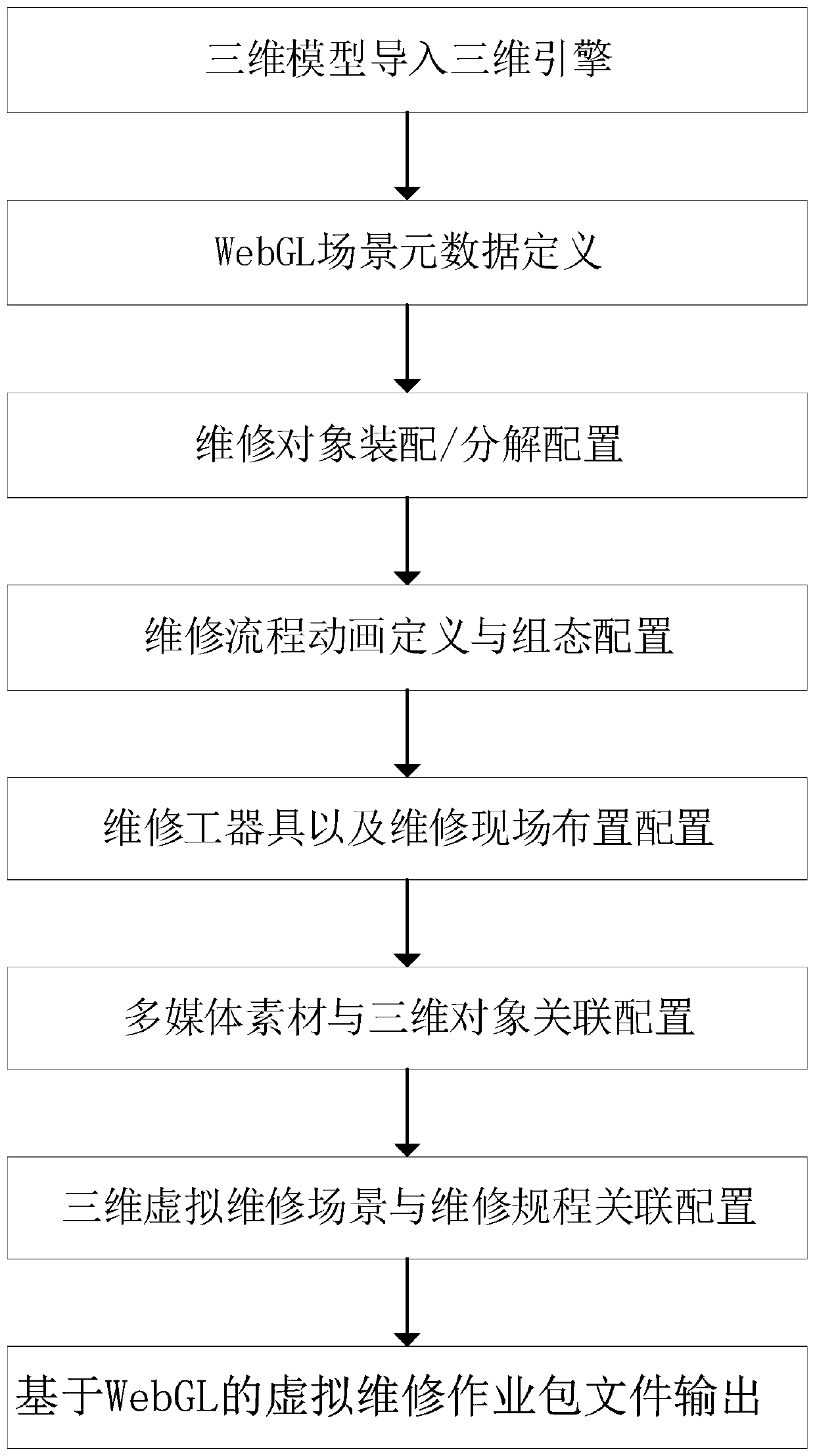

Three-dimensional virtual maintenance scene configuration method based on WebGL

The invention discloses a three-dimensional virtual maintenance scene configuration method based on WebGL. The method comprises the steps of importing a three-dimensional model into a three-dimensional engine; carrying out metadata definition on the three-dimensional scene based on WebGL; assembling / disassembling the maintenance object in the three-dimensional scene; establishing maintenance process animation definition and configuration configuration for the maintenance object; arranging and configuring the maintenance tools and instruments and the maintenance site environment in a three-dimensional scene; performing associated configuration on the multimedia file material and the corresponding maintenance object; performing associated configuration on the three-dimensional scene and thecorresponding equipment maintenance regulation file; and forming a virtual maintenance operation package file from the configured three-dimensional virtual maintenance configuration data and the equipment maintenance procedure and outputting the virtual maintenance operation package file. According to the technical scheme, the WYSIWYG visual configuration mode is adopted in the whole configurationprocess, a user can master compiling and learning of the three-dimensional virtual maintenance scene without programming basis, and dependence of virtual maintenance application on the bottom layer technology is reduced.

Owner:武汉方拓数字科技有限公司

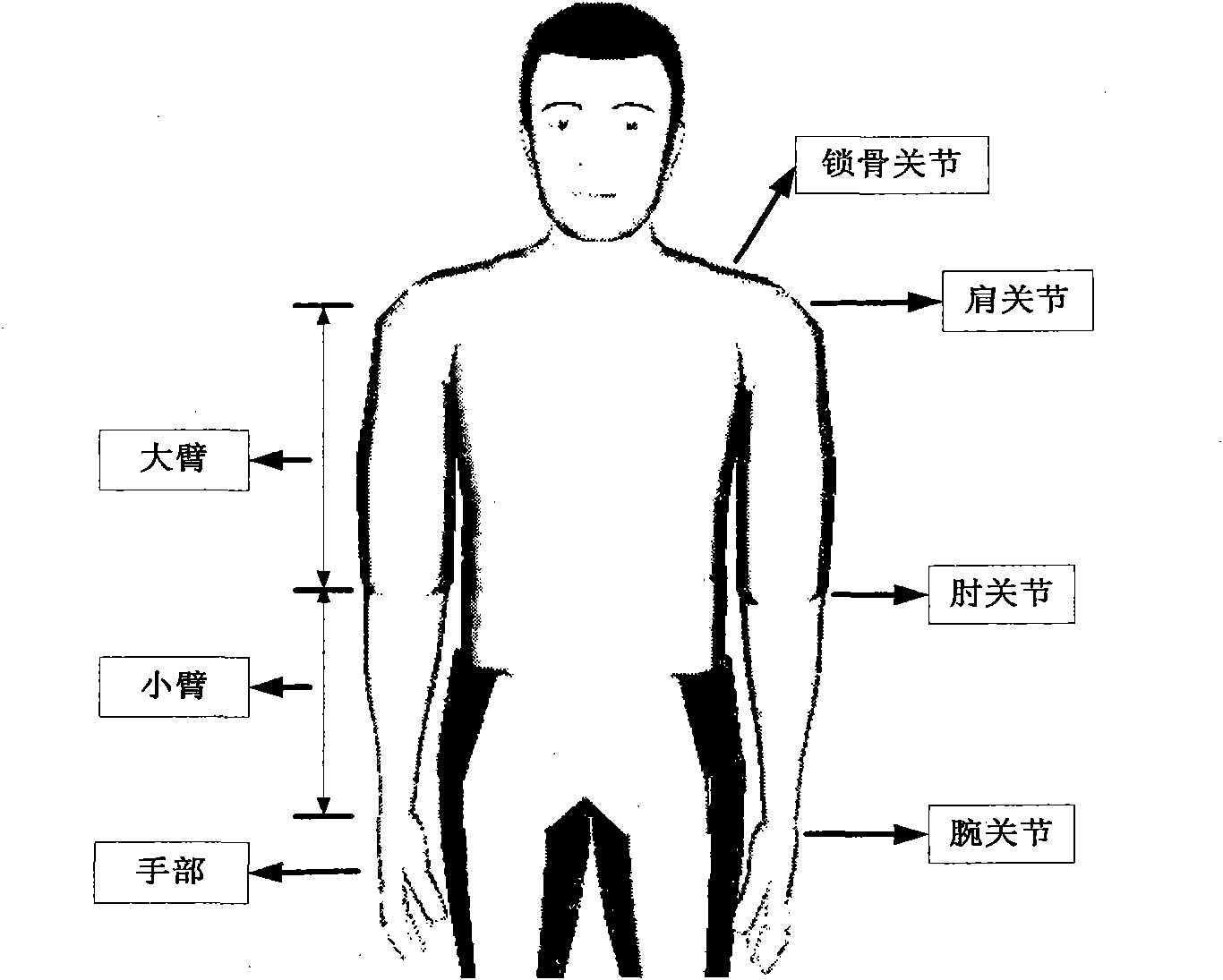

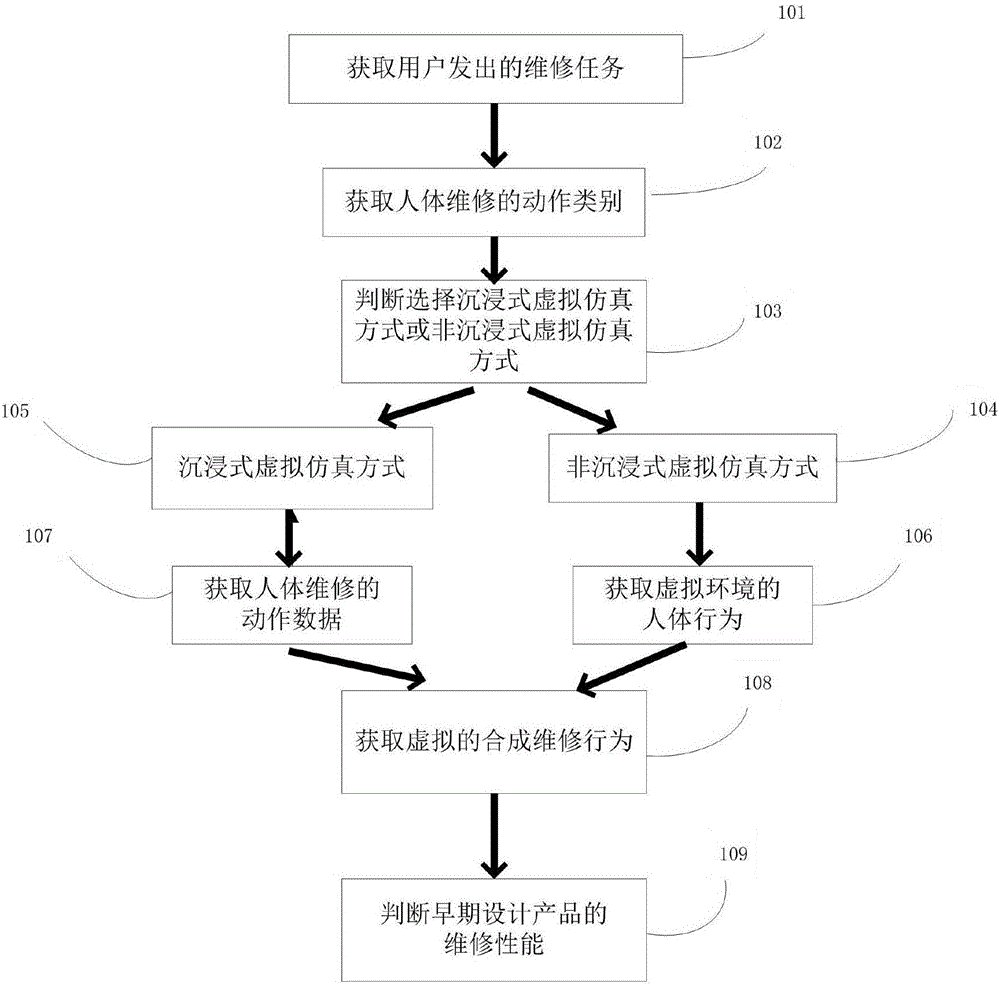

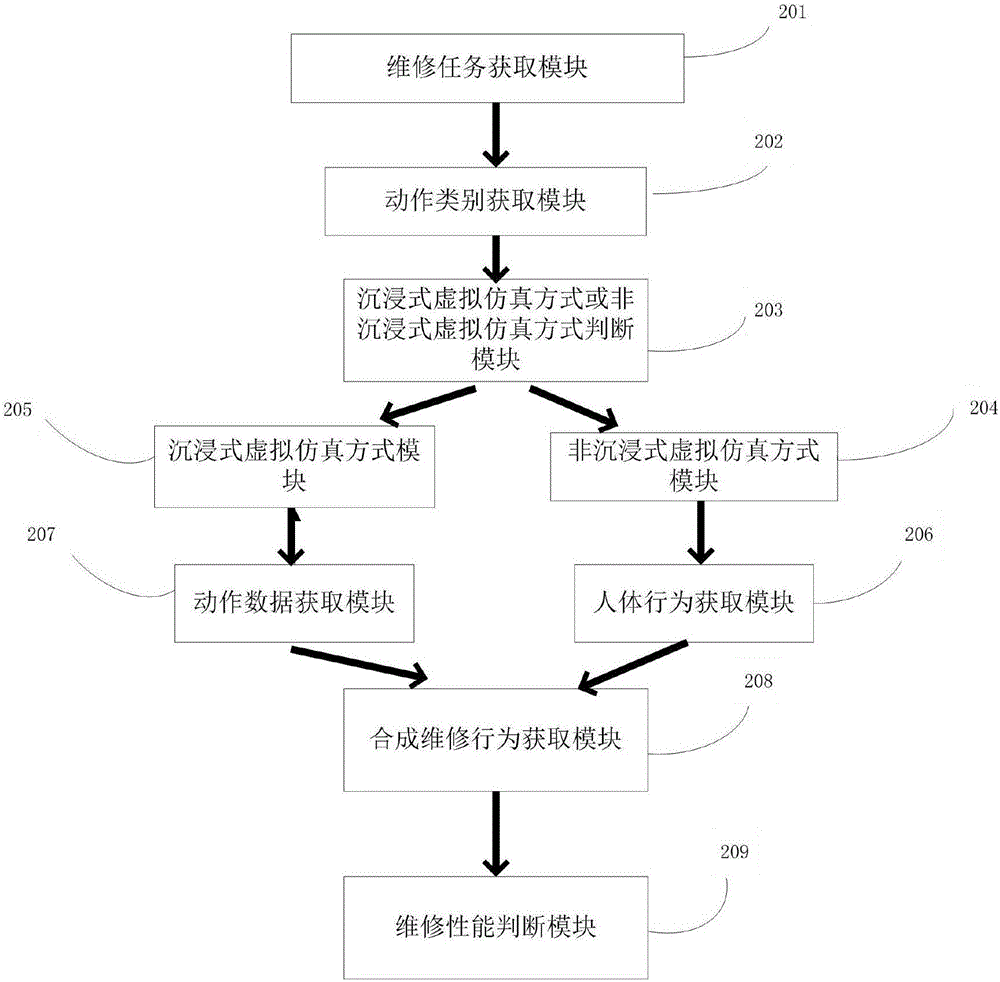

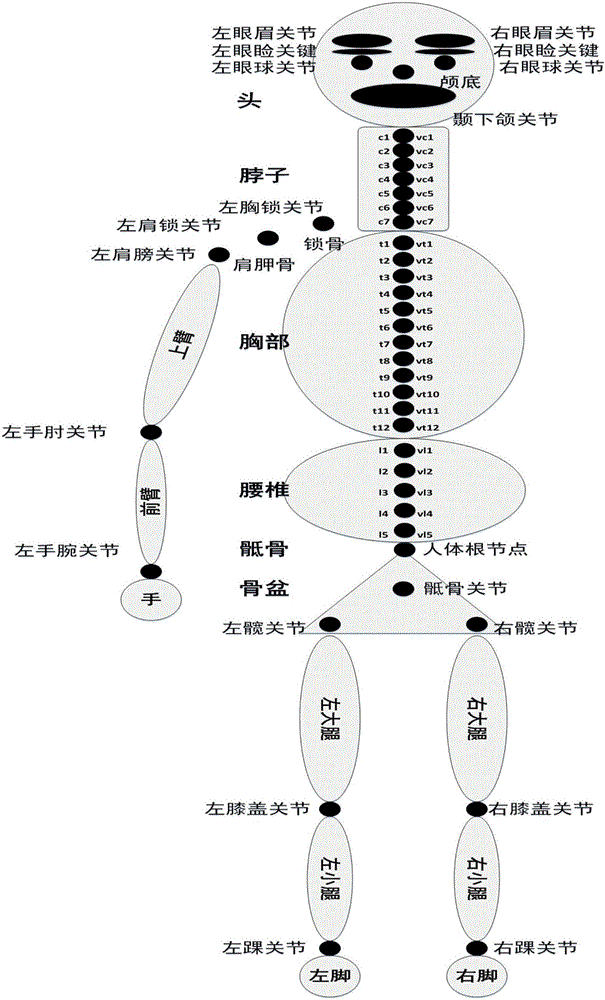

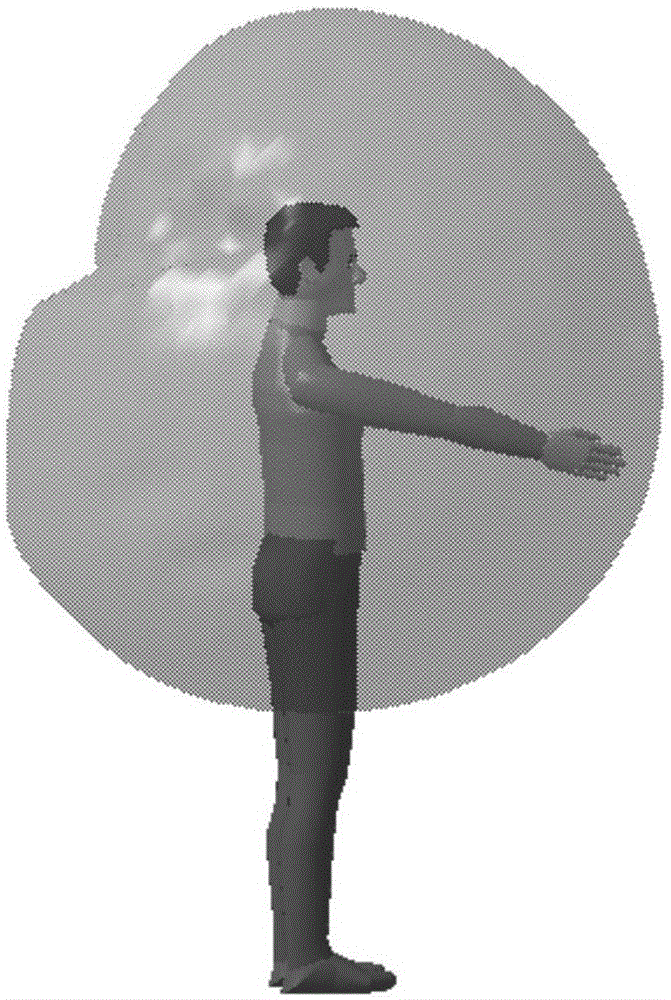

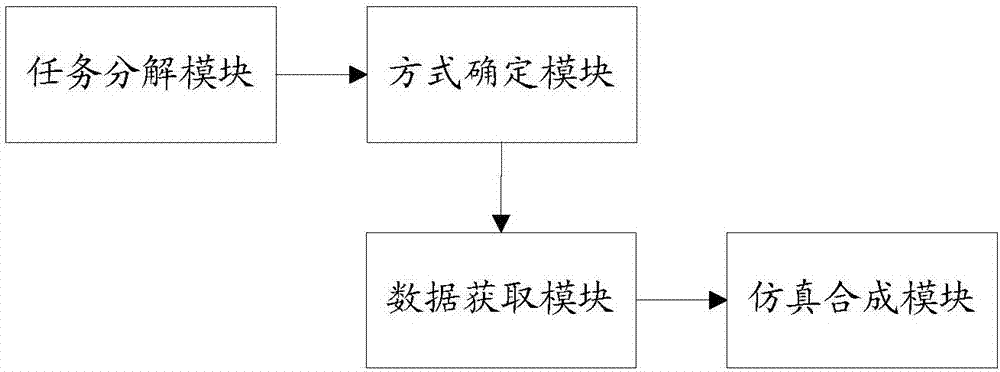

Virtual maintenance behavior synthetic method and system based on human body function parts

InactiveCN106469467AMake up for the roughness of the simulationAccurate virtual maintenance simulation technologyDetails involving processing stepsAnimationHuman bodyMaintainability

The invention discloses a virtual maintenance behavior synthetic method and system based on human body function parts. The method includes: firstly, obtaining a maintenance task emitted by a user, obtaining the human body maintenance motion category with the combination of a maintainability design requirement, and determining and selecting an immerse type virtual simulation mode or a non-immerse type virtual simulation mode; obtaining human body maintenance motion data according to the selected immerse type virtual simulation mode, and obtaining a virtual environment human body behavior according to the selected non-immerse type virtual simulation mode; and finally obtaining a virtual maintenance synthesis behavior with the combination of the obtained human body maintenance motion data and the virtual environment human body behavior, and determining the maintenance performance of an early-stage design product according to the synthesis behavior. According to the method and system, the problem of failure of simulation development due to space limitation in immerse simulation is solved, the defect of rough simulation of complicated operation behaviors in non-immerse simulation is overcome, and virtual maintenance rapid simulation with high efficiency and accuracy is realized.

Owner:BEIHANG UNIV

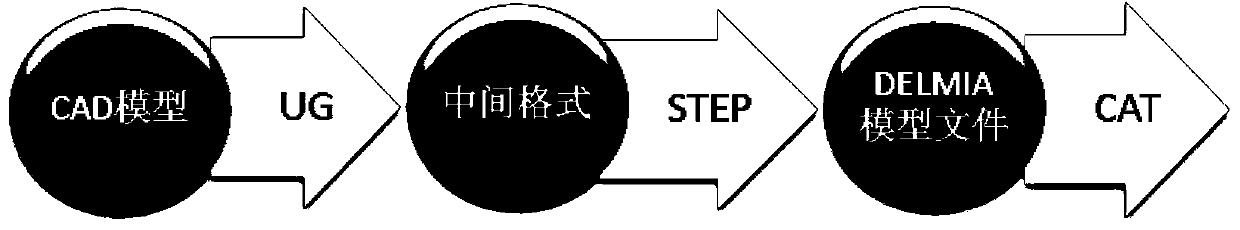

DELMIA-based emulational engineering practice method of cable maintenance

ActiveCN104008256ARealize flexible activitiesImproved maintainability designSpecial data processing applications3D modellingHuman bodyHuman-body model

The invention provides a DELMIA-based emulational engineering practice method of cable maintenance. The method includes the steps that cable information and space relation are determined; a virtual maintenance environment is built on a DELMIA-based emulational platform; a disassembly path of a cable connector is designed, and movement actions of the cable connector are built; different control points are set on a cable module along the disassembly path of the cable connector to achieve flexible movement of a cable; the movement locus that a hand grabs the connector is planed, and maintenance actions of the hand of the human body are built; emulation is processed by segments to achieve space-time synchronization of the cable connector, the cable and a human body model. According to the DELMIA-based emulational engineering practice method of cable maintenance, the limitation that in a traditional virtual assembly process, a flexible part is considered as a rigid body, the flexible body of the cable cannot be showed up, and the interactive operation emulation of the flexible body can not be conducted is broken through, simulation of complex movement of the cable is achieved, the problems existing in the cable in the maintenance process can be found, and improvement of the maintenance design of the cable is facilitated.

Owner:BEIJING ZHIZHEN ZHIZAO TECH CO LTD

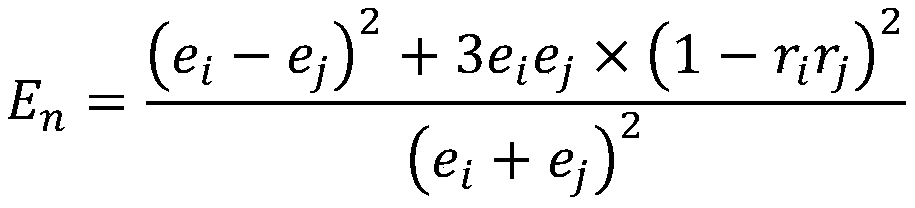

Virtual maintenance based maintainability analysis method for aircraft part

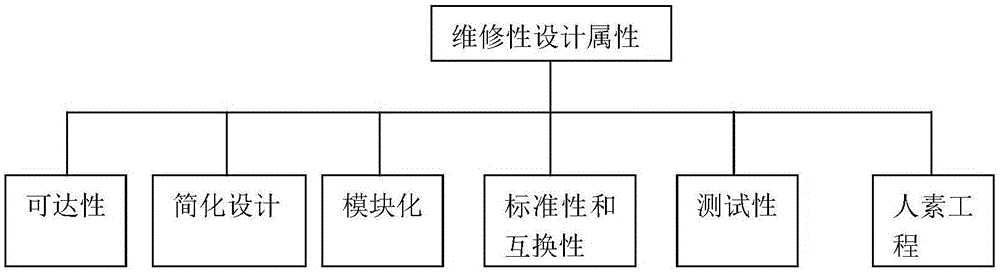

InactiveCN105045989AFind design flaws in timeMaintainability Design ImprovementsSpecial data processing applicationsStandardizationQualitative property

The invention discloses a virtual maintenance based maintainability analysis method for an aircraft part. Firstly, a maintenance attribute value of the to-be-analyzed aircraft part is quantitatively determined, wherein the maintenance attribute value comprises human factor engineering, reachability, simplified design, modularization, standardization and interchangeability, and testability; secondly, a natural language is quantitatively processed; thirdly, according to the obtained attribute value, performing weighted calculation on a comprehensive maintainability attribute value of the to-be-analyzed aircraft part; and finally, according to the comprehensive maintainability attribute value, calculating degree of membership, and obtaining comprehensive maintainability evaluation and partial evaluation of the to-be-analyzed aircraft part. According to the method, on the basis of determining maintainability influence attributes, each maintainability influence attribute is analyzed and inspected, an evaluation method for maintainability quantitative requirements is proposed, and parallel design-oriented maintainability qualitative analysis and evaluation are realized, so that design defects can be discovered in time and the improvement on maintainability design is facilitated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

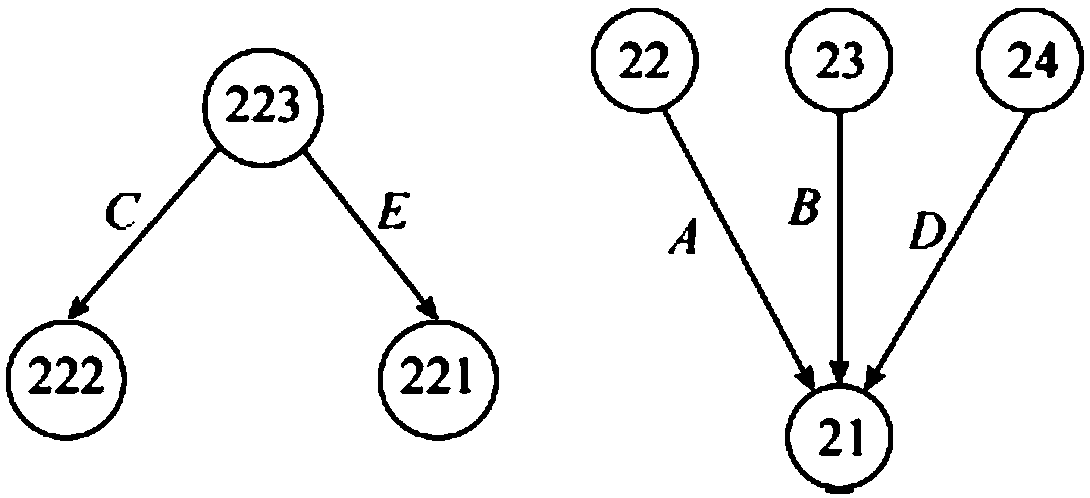

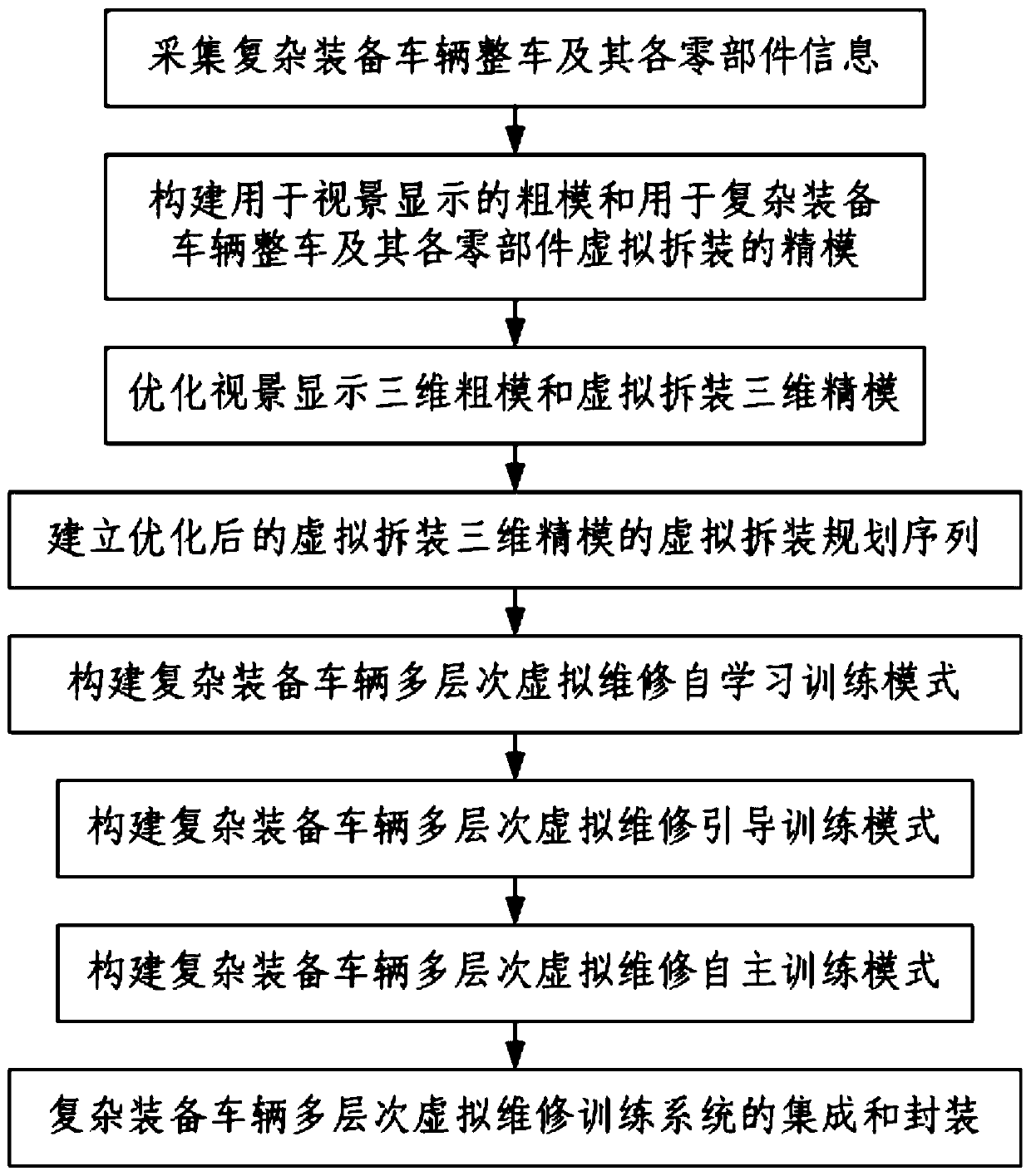

Method for establishing multi-level virtual maintenance training system of complex equipment vehicle

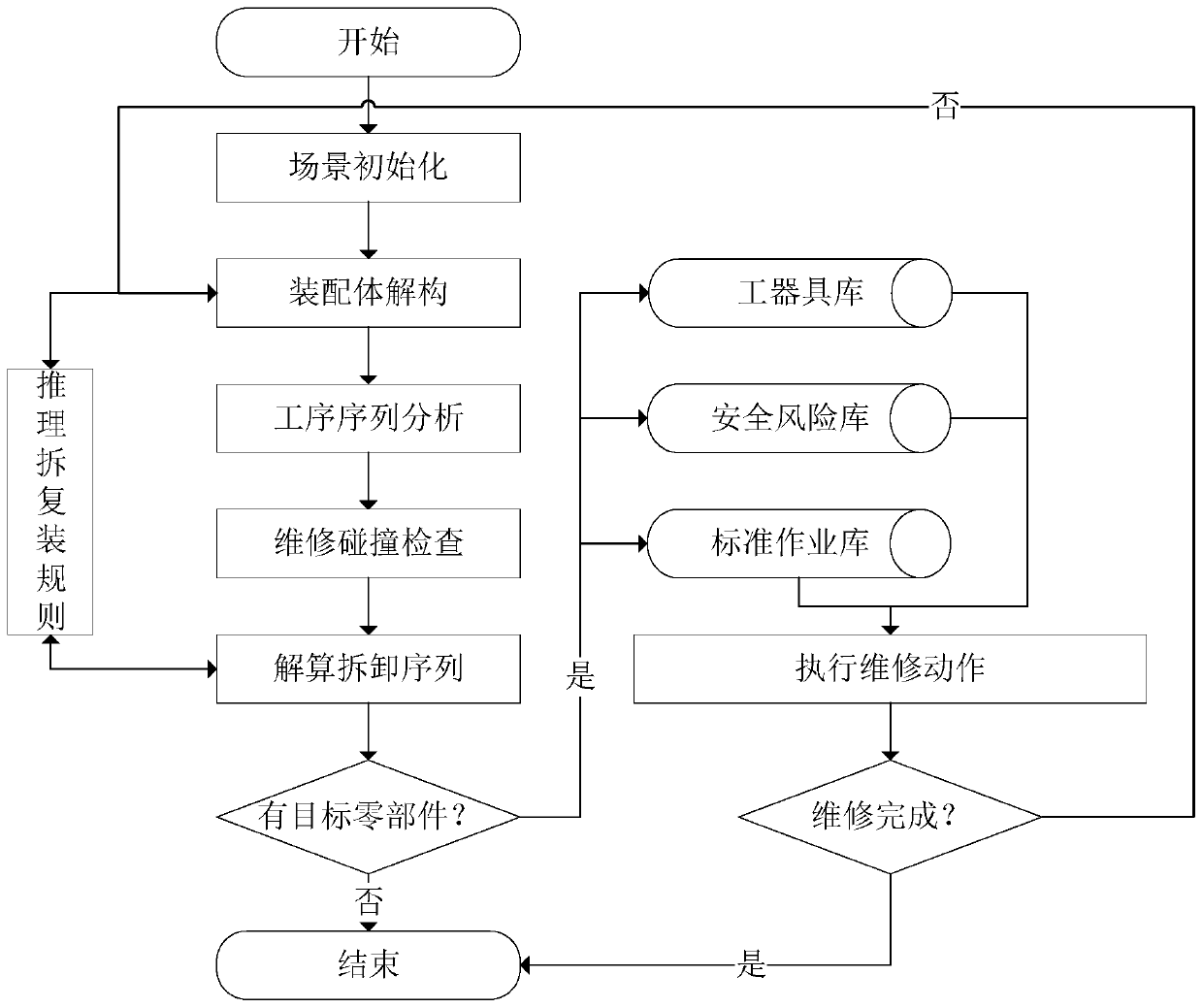

ActiveCN110502868AAvoid running out of memoryIncrease real-time interactionCosmonautic condition simulationsCharacter and pattern recognitionDecompositionSimulation

The invention discloses a method for establishing a multi-level virtual maintenance training system of a complex equipment vehicle. The method comprises the following steps: 1, acquiring the information of the whole complex equipment vehicle and each part thereof; 2, constructing a rough mold for visual display and a fine mold for virtual disassembly and assembly of the whole complex equipment vehicle and all parts thereof; 3, optimizing a visual display three-dimensional coarse mold and virtually disassembling and assembling a three-dimensional fine mold; 4, establishing a virtual disassemblyand assembly planning sequence of the optimized virtual disassembly and assembly three-dimensional precision mold; 5, constructing a multi-level virtual maintenance self-learning training mode of thecomplex equipment vehicle; 6, constructing a multi-level virtual maintenance guide training mode of the complex equipment vehicle; 7, constructing a multi-level virtual maintenance autonomous training mode of the complex equipment vehicle; and 8, integrating and packaging the multi-level virtual maintenance training system of the complex equipment vehicle. According to the method, the rough modeland the fine model are established, training is smooth, the truth and immersion are good, the virtual decomposition and assembly object model and the hierarchical relationship thereof are established, and later virtual maintenance training is facilitated.

Owner:中国人民解放军火箭军工程大学

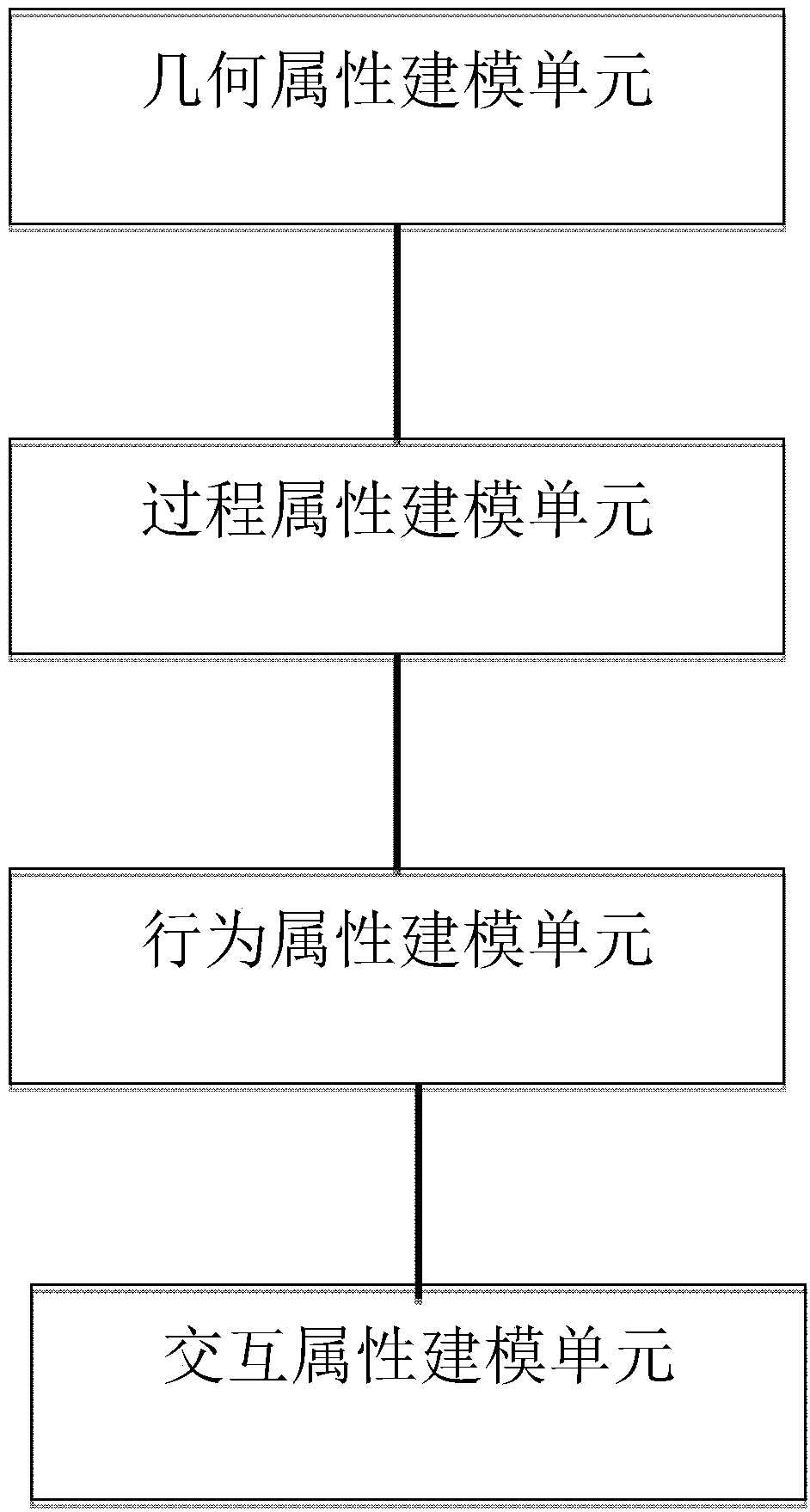

Modeling system of desktop type three-dimensional virtual maintenance model

ActiveCN108153932AShorten the timeQuality improvementDesign optimisation/simulationSpecial data processing applicationsModel systemSimulation

The invention provides a modeling system of a desktop type three-dimensional virtual maintenance model. The system includes a geometric attribute modeling unit, a process attribute modeling unit, a behavior attribute modeling unit and an interaction attribute modeling unit; the geometric attribute modeling unit is used for drawing an appearance structure of a virtual maintenance object, a constrained relationship is built, the process attribute modeling unit is used for serialization and standardization of the maintenance process of a maintained object, the behavior attribute modeling unit isused for setting a virtual tool and achieving real-time following of the virtual tool, and the interaction attribute modeling unit is used for building an interaction mode with a user in the virtual maintenance process. The interaction mode includes a virtual maintenance demonstration mode and a virtual maintenance training mode. According to the provided modeling system of the desktop type three-dimensional virtual maintenance model, a computer can be used for combining related equipment hardware with virtual software, the three-dimensional virtual maintenance model is built for the maintained object, and the analogue simulation of the maintained object is achieved in the virtual environment.

Owner:SHANGHAI PRECISION METROLOGY & TEST RES INST +1

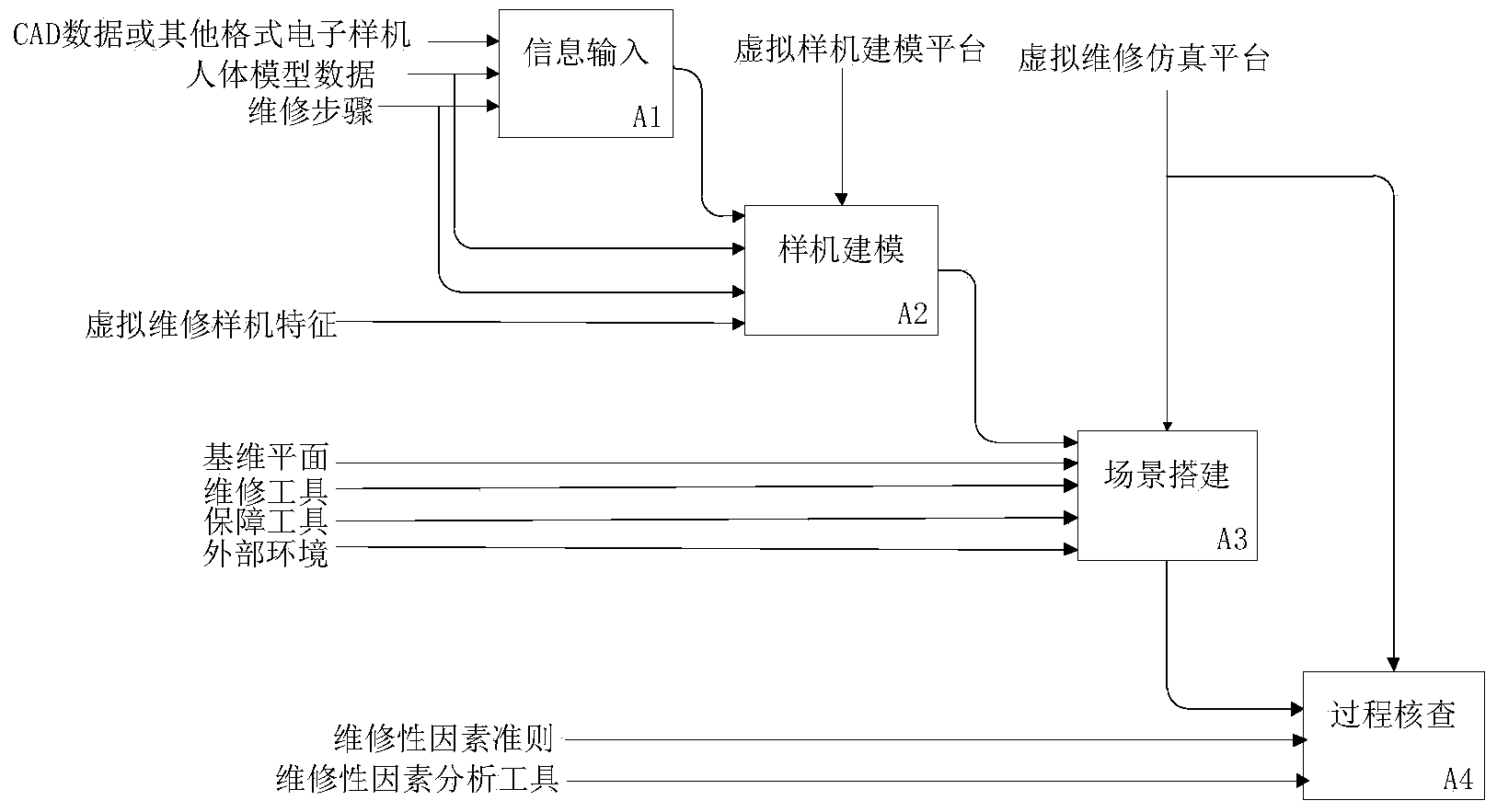

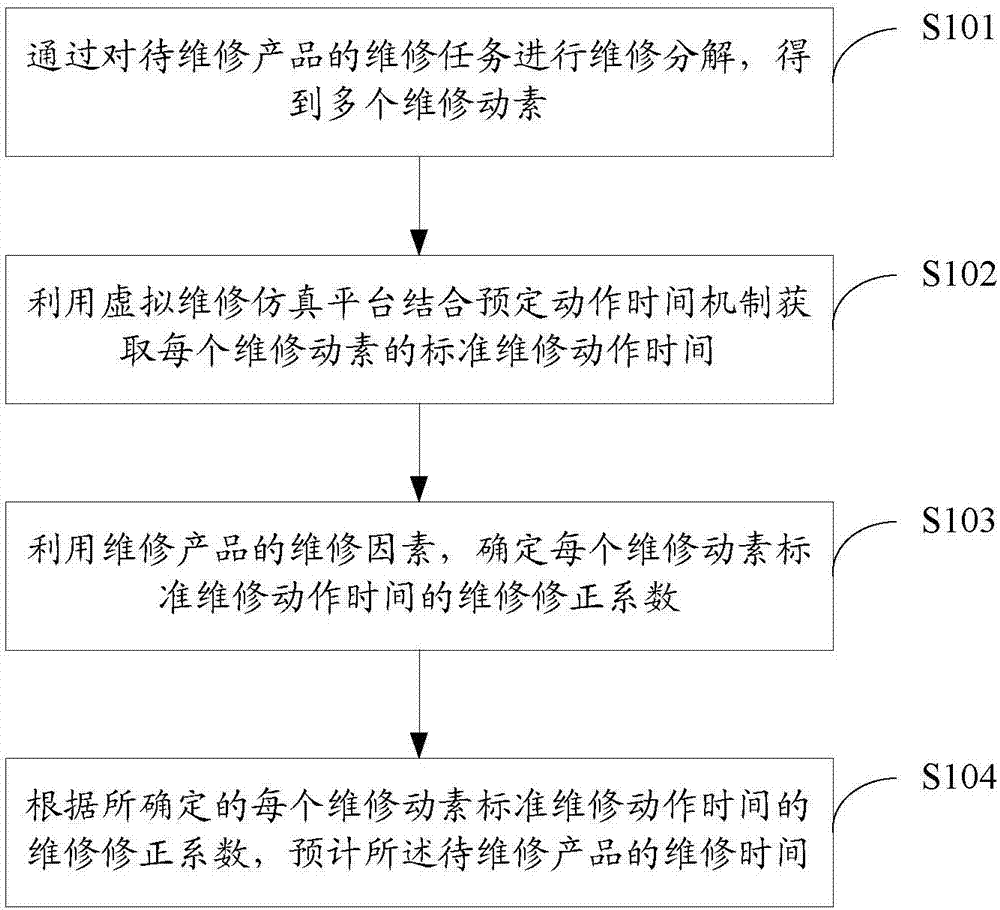

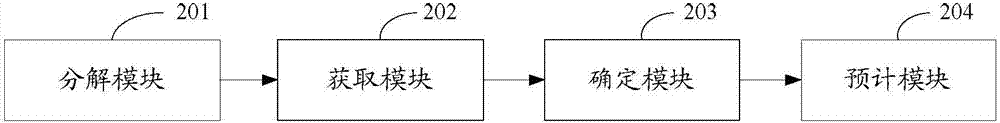

Method and device for prediction of maintenance time

The present invention discloses a method and device for prediction of maintenance time, and relates to the maintenance time prediction technology field. The method comprises: performing maintenance decomposition of maintenance tasks of products to be maintained, obtaining a plurality of maintenance therbligs; employing a virtual maintenance simulation platform to combine a preset motion time mechanism to obtain the standard maintenance motion time of each maintenance therblig; employing the maintenance factor of a maintenance product, and determining the maintenance correction coefficient of the standard maintenance motion time of each maintenance therblig; and predicting the maintenance time of the products to be maintained according to the maintenance correction coefficient of the standard maintenance motion time of each maintenance therblig.

Owner:BEIHANG UNIV

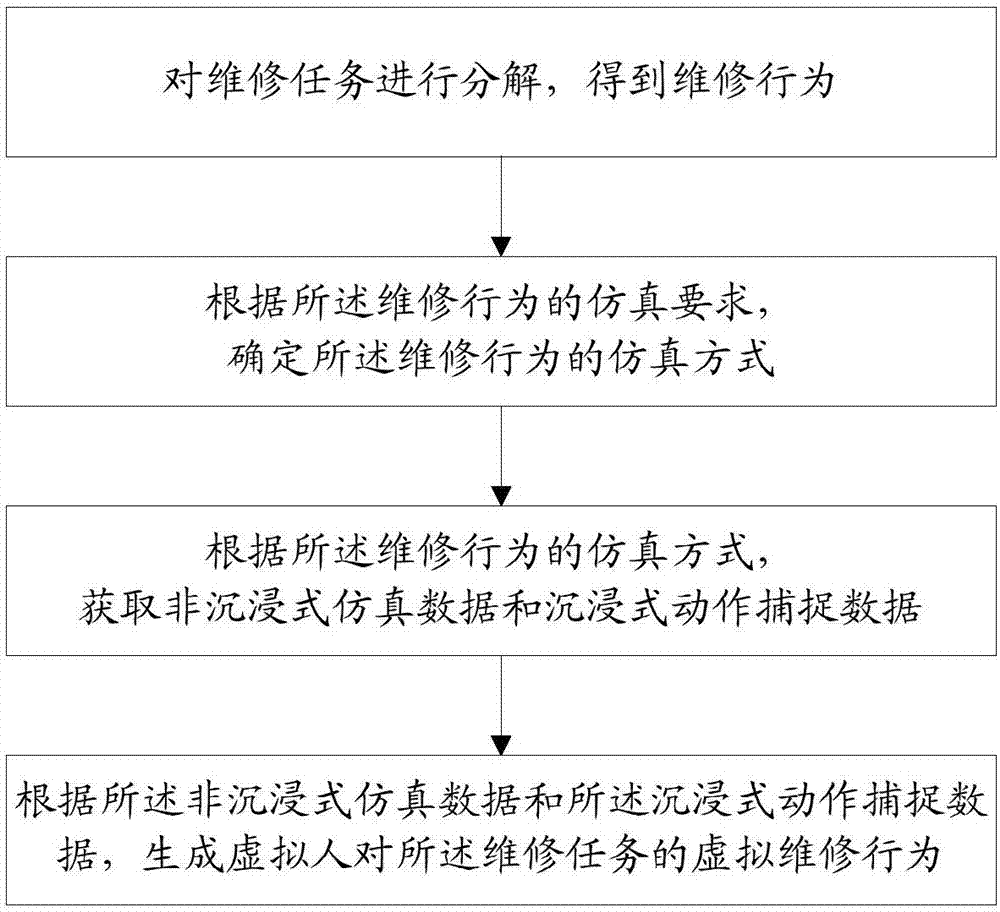

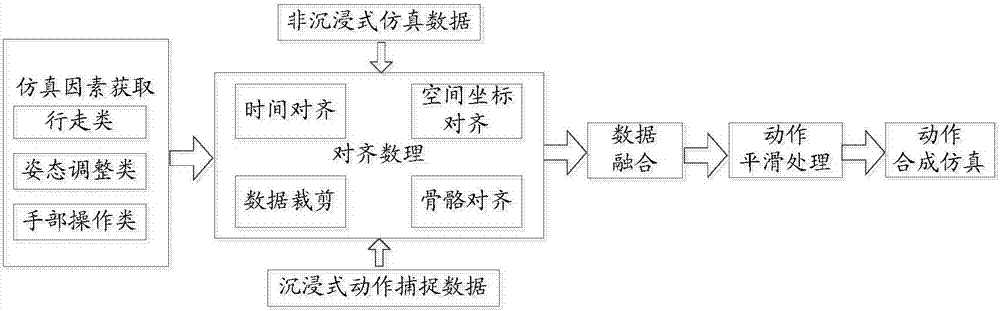

Virtual maintenance simulation method and device based on data fusion

InactiveCN107424207AQuick buildDesign optimisation/simulationSpecial data processing applicationsData sourceSimulation

The invention discloses a virtual maintenance simulation method and device based on data fusion, relating to the field of data fusion assisted virtual simulation. The method comprises a step of decomposing a maintenance task and obtaining a maintenance behavior, a step of determining a simulation mode of the maintenance behavior according to the simulation requirement of the maintenance behavior, a step of obtaining non-immersive simulation data and immersive motion capture data according to the simulation mode of the maintenance behavior, and a step of generating a virtual maintenance behavior for the maintenance task by virtual people according to the non-immersive simulation data and immersive motion capture data. According to the embodiment of the invention, the two kinds of data sources are cooperatively controlled and synthesized to form the virtual maintenance behavior, and a purpose of fast and realistic simulation can be achieved.

Owner:BEIHANG UNIV

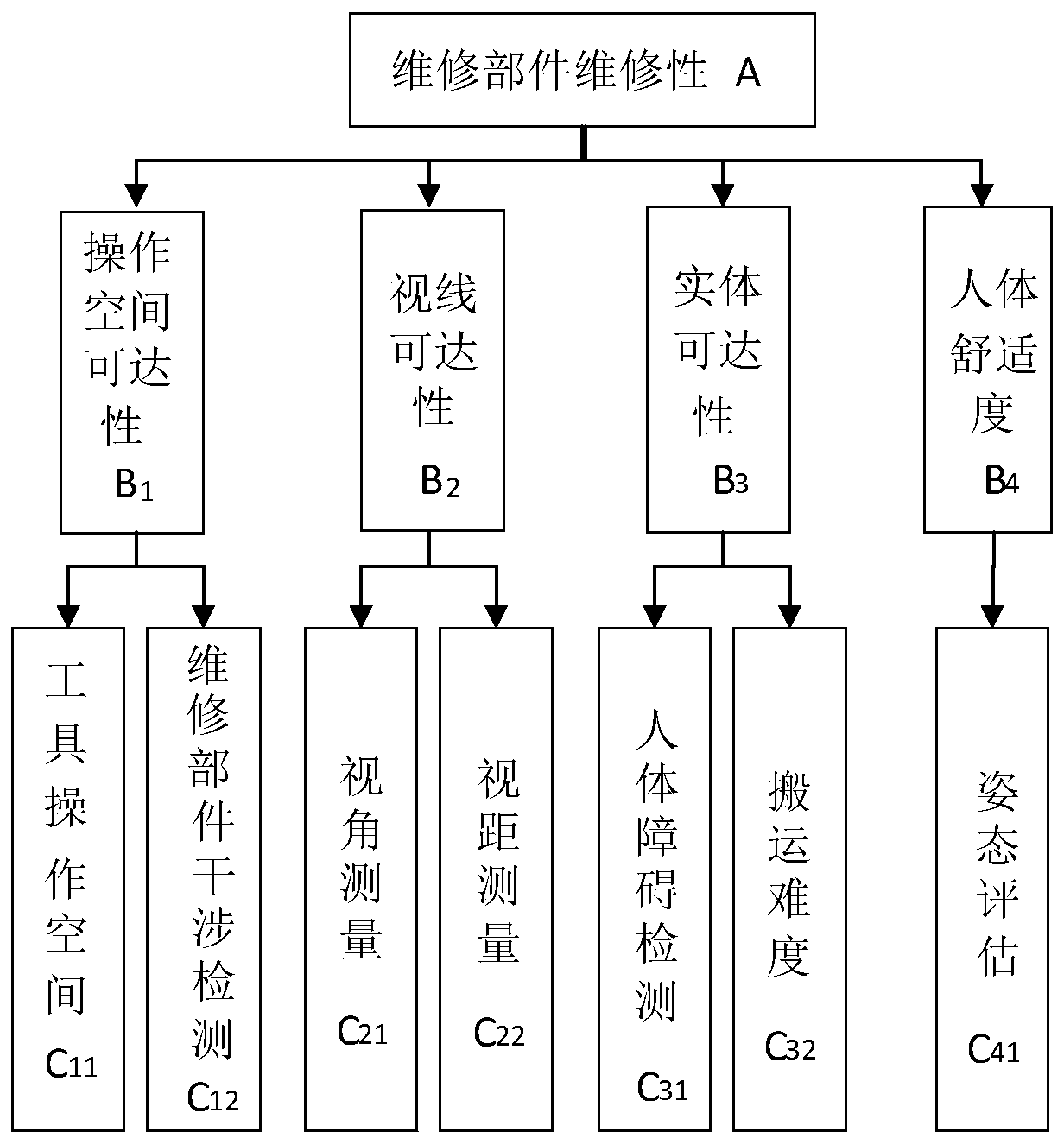

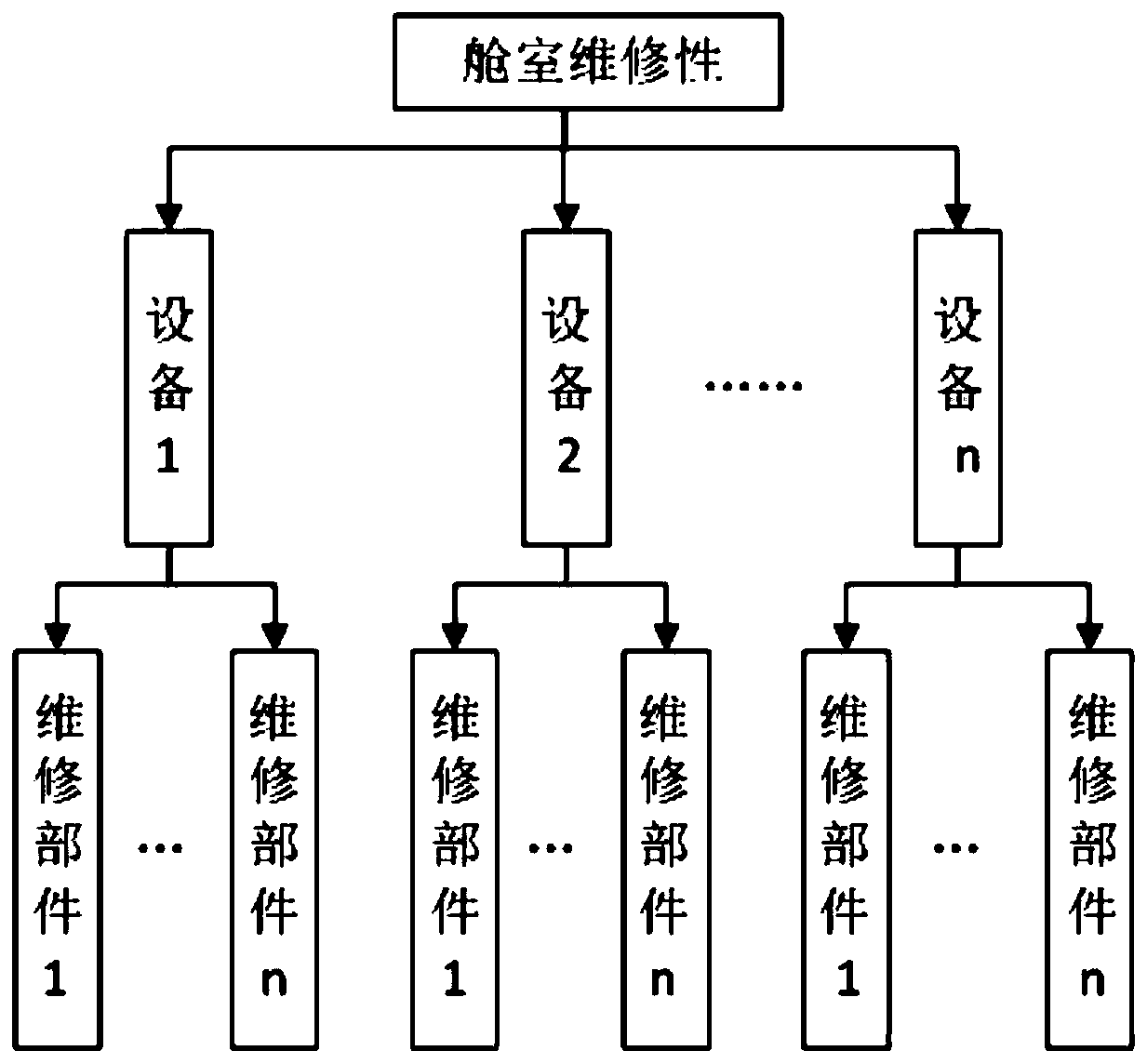

Ship cabin maintenance accessibility comprehensive evaluation method

PendingCN109978321AEnables maintenance accessibility analysisRealization of maintenance accessibility evaluationResourcesAccessibilityReliability engineering

The invention discloses a ship cabin maintenance accessibility comprehensive evaluation method. The method comprises the following steps: 1) evaluating the maintenance accessibility of each maintenance part; 2) determining an index weight, and establishing a fuzzy evaluation matrix; 3) evaluating the maintenance accessibility of the equipment according to the maintenance accessibility of each maintenance part; 4) evaluating the maintenance accessibility of the cabin according to the maintenance accessibility of each device; and 5) taking a total score as a maintenance accessibility comprehensive evaluation score of the cabin. The invention provides a ship cabin maintenance accessibility comprehensive evaluation method based on virtual maintenance. Through virtual simulation of the maintenance process, the quantitative score of each influence factor influencing the cabin maintenance accessibility is determined, the quantitative evaluation of the ship cabin maintenance accessibility is performed, and the design of the ship cabin maintenance accessibility is guided.

Owner:CHINA SHIP DEV & DESIGN CENT

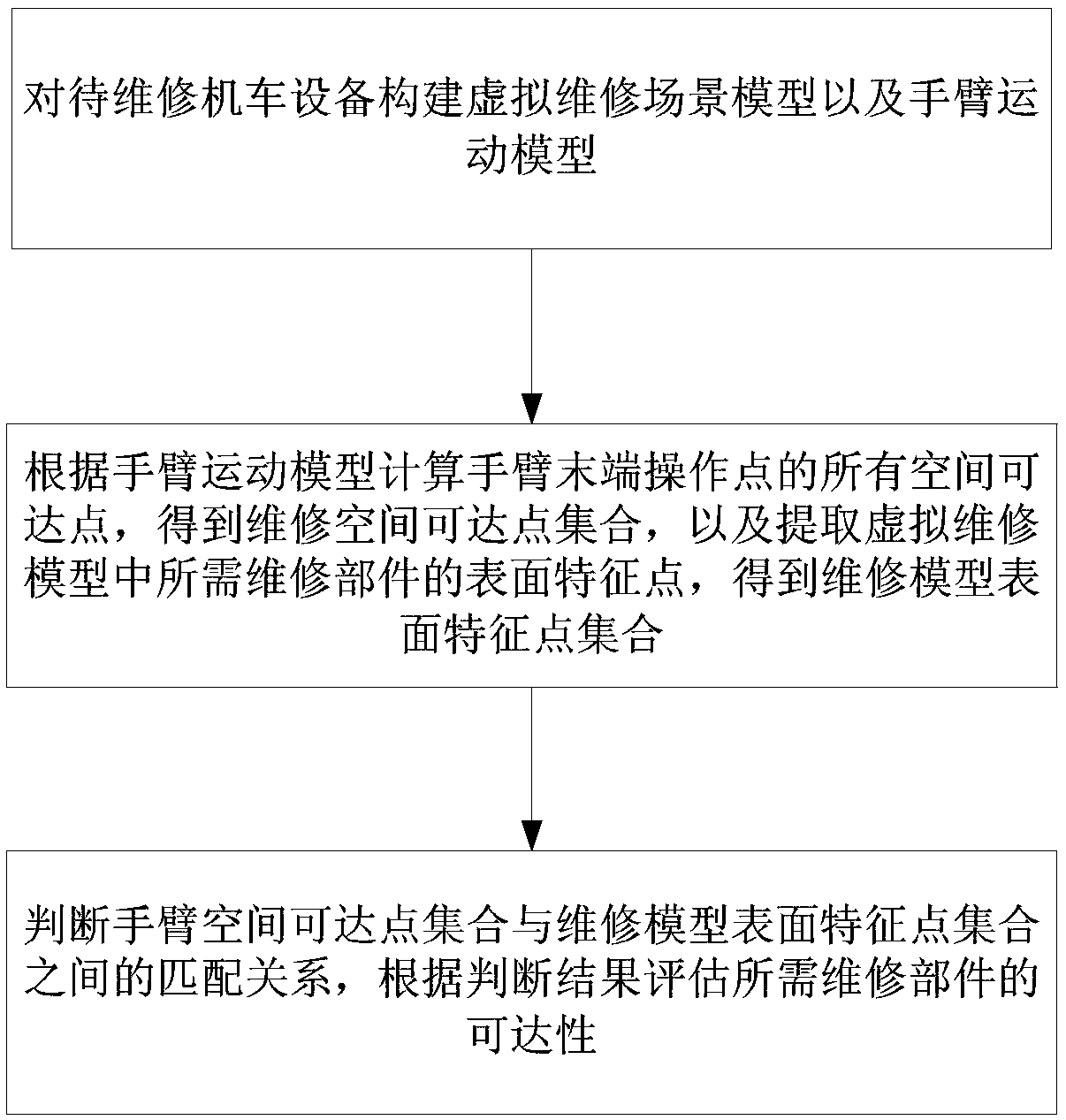

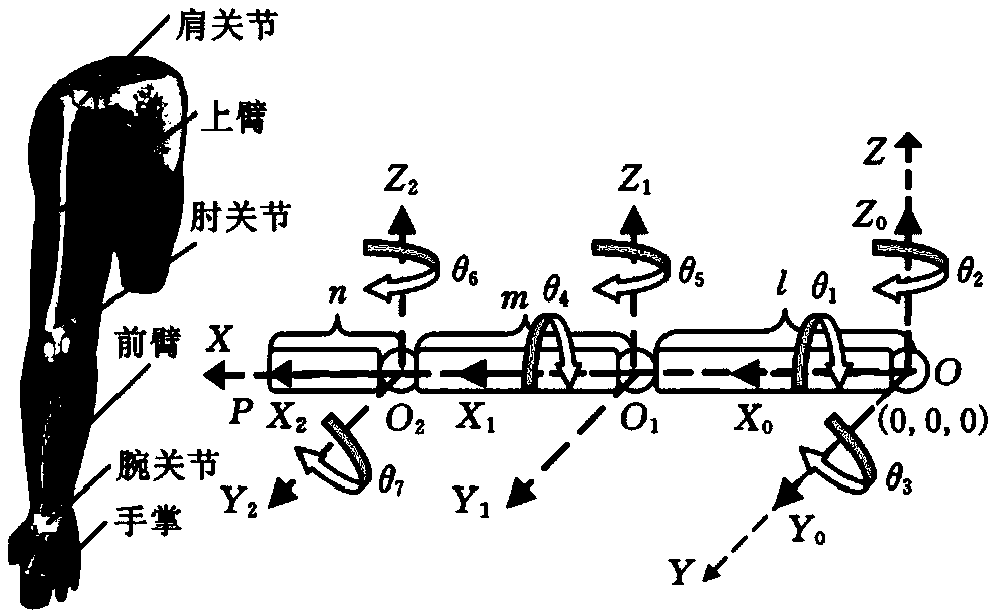

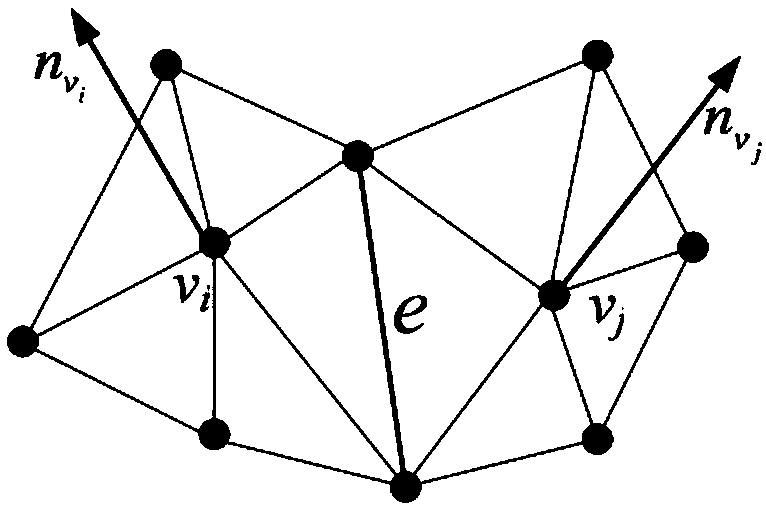

Equipment maintenance accessibility evaluation method and device based on virtual environment

PendingCN111179431ALow costHigh precisionResourcesComplex mathematical operationsControl engineeringComputer science

The invention discloses an equipment maintenance accessibility evaluation method and device based on a virtual environment. The method comprises the following steps: S1, constructing a virtual maintenance scene model and an arm motion model for locomotive equipment to be maintained; s2, calculating all spatial reachable points of an arm tail end operation point according to the arm motion model toobtain a maintenance personnel arm spatial reachable point set, and extracting surface feature points of a to-be-maintained part in the virtual maintenance model to obtain a model surface feature point set of the maintained part; s3, judging the matching relationship between the arm space reachable point set and the maintenance model surface feature point set, and evaluating the reachability of the part to be maintained according to the judgment result. The device comprises a model construction module, a model feature point extraction module and an accessibility evaluation module. The equipment maintenance accessibility evaluation method based on the virtual environment can realize equipment maintenance accessibility evaluation based on the virtual environment, and is simple in realization operation, low in cost and high in evaluation precision and efficiency.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

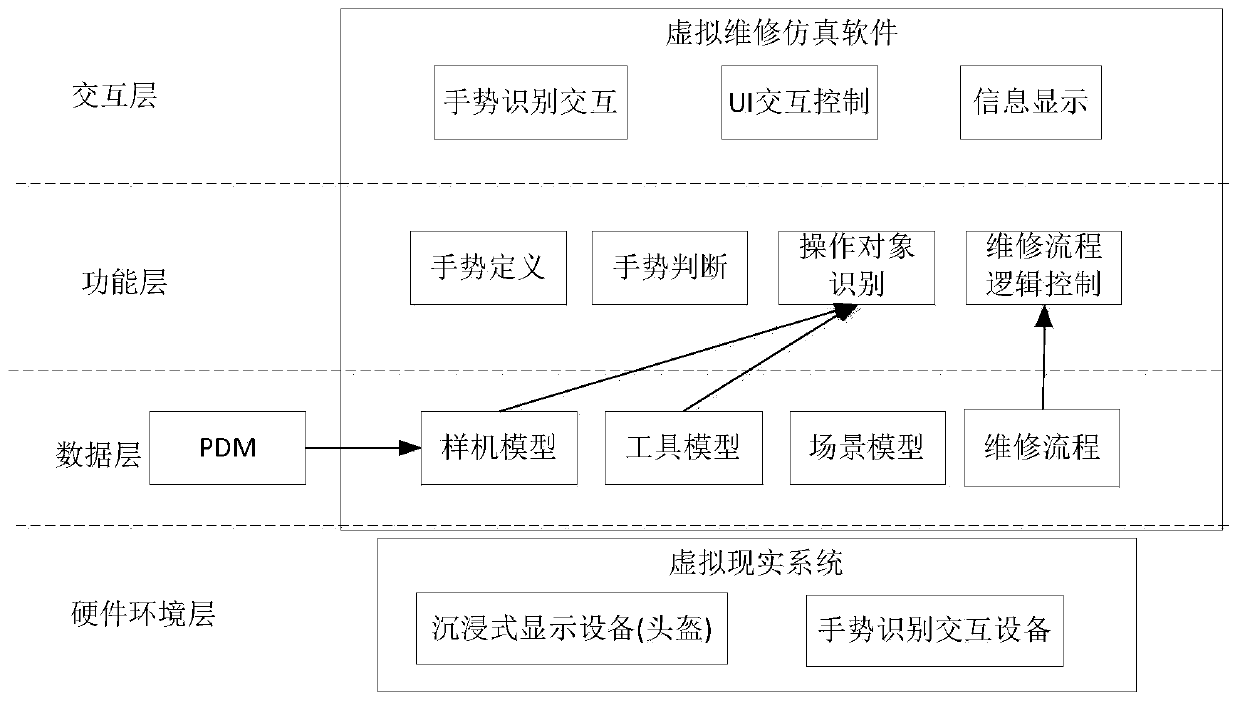

Virtual maintainability simulation method based on depth perception gesture recognition

ActiveCN111191322AEnhance the sense of natureImprove accuracyGeometric CADDesign optimisation/simulationHuman-in-the-loopMaintainability

The invention relates to a virtual maintainability simulation method based on depth perception gesture recognition. The method comprises the following steps: 1) building of a hardware environment; 2)data preparation; 3) realization of a functional layer; and 4) realization of an interactive layer. The method adopts non-wearable deep perception gesture recognition interaction equipment, so that auser can perform natural, visual and high-precision gesture interaction according with natural use habits of a human body, and the method can be used for more people without difference. In the aircraft design stage, maintainability simulation is conducted on all shipping spaces of an aircraft through the method, simulation operation can be directly conducted on a design digital model in a human-in-loop mode in the virtual reality environment, the maintainability simulation process is greatly simplified, and efficiency is improved; and by defining operation steps and operation gestures, the problems of high interaction randomness and low interaction precision of real-time maintainability simulation of the human in the loop are solved, and the practicability and accuracy of the real-time maintainability simulation of the human in the loop are improved.

Owner:CHENGDU AIRCRAFT DESIGN INST OF AVIATION IND CORP OF CHINA

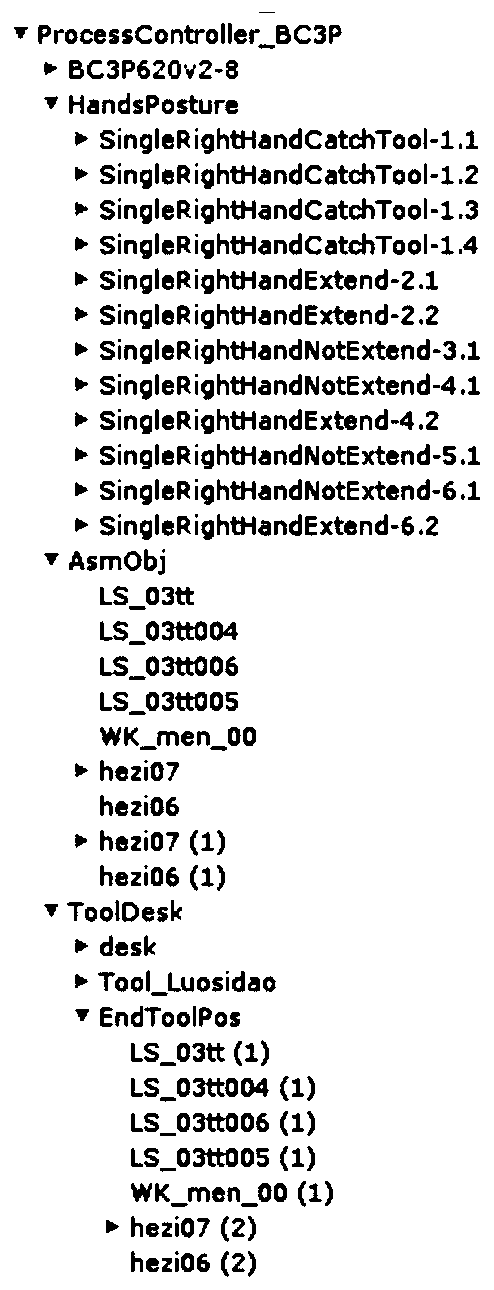

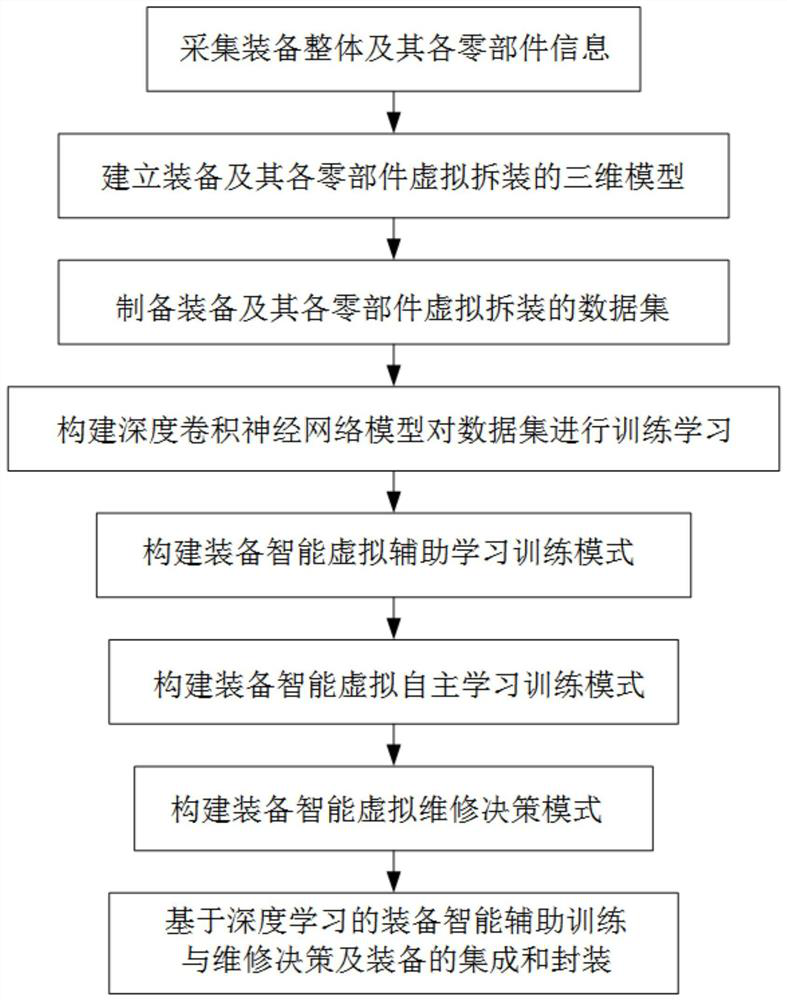

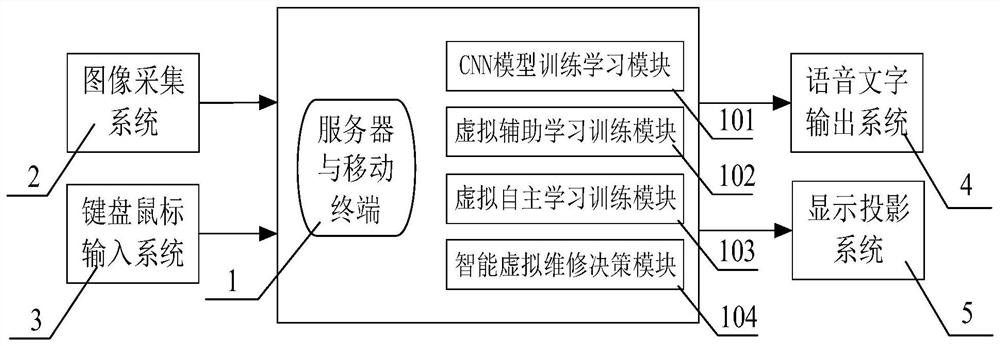

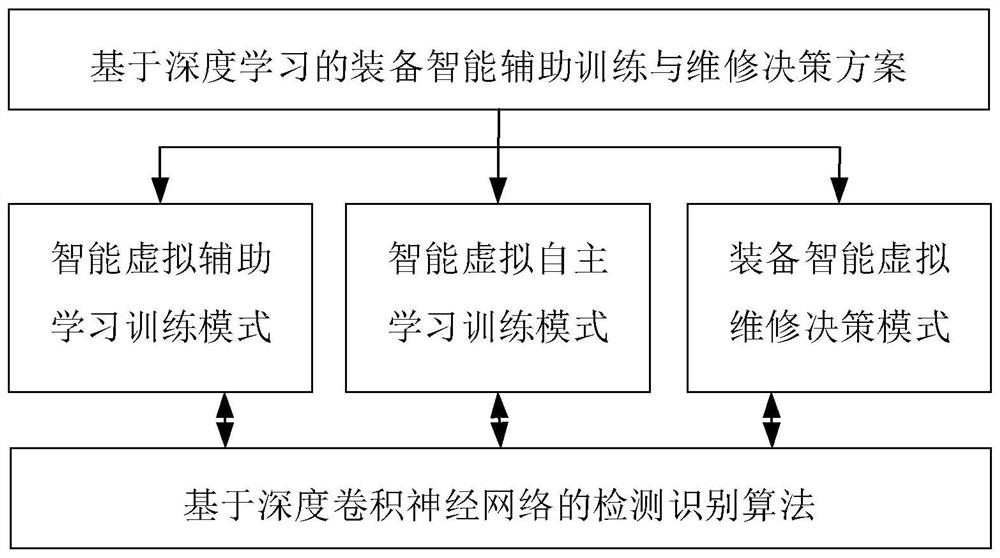

Intelligent auxiliary training and maintenance decision-making method and device for equipment based on deep learning

ActiveCN113780525AAccelerated trainingImprove the level of intelligenceCosmonautic condition simulationsNeural architecturesVirtual trainingData set

The invention discloses an intelligent auxiliary training and maintenance decision-making method and device for equipment based on deep learning, and the method comprises the steps: collecting the overall and local information of equipment, building a three-dimensional model of the equipment for visual display and the virtual disassembly and assembly of all parts of the equipment, preparing a data set of the equipment and the virtual disassembly and assembly of all parts of the equipment, training and learning the data set by using a deep convolutional neural network model, and respectively constructing an equipment intelligent virtual maintenance decision mode, an equipment intelligent virtual auxiliary learning training mode and an equipment intelligent virtual autonomous learning training mode; and finally, integrating and packaging the equipment intelligent auxiliary training and maintenance decision based on deep learning and the equipment. A visual, efficient and intelligent technical means is provided for virtual training maintenance of large-scale complex equipment and training examination of operators.

Owner:ROCKET FORCE UNIV OF ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com