Maintenance time prediction method based on virtual maintenance simulation process

A technology of virtual maintenance and maintenance time, applied in computing, special data processing applications, instruments, etc., can solve the problems of low degree of visualization and complex computing, and achieve the effect of strong versatility and getting rid of hysteresis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

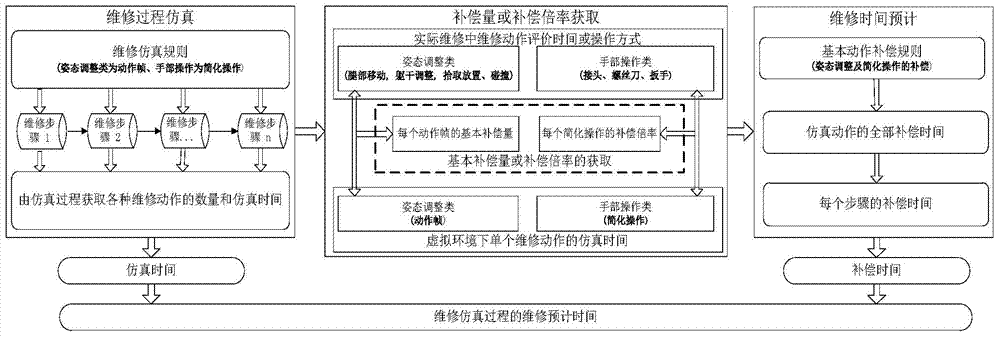

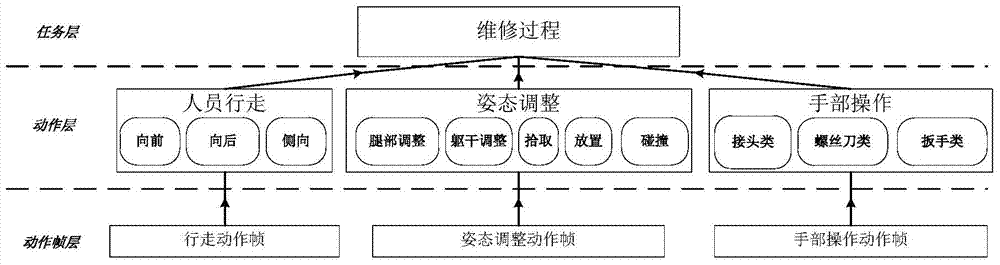

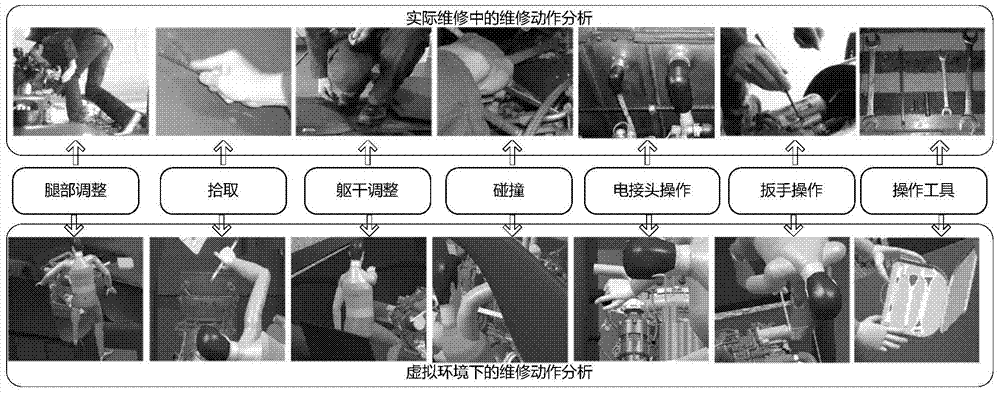

Method used

Image

Examples

Embodiment

[0108] Taking the dismantling process of an electronic control device of an object as an example, according to the simulation rules in step 2 and its actual maintenance procedures, the simulation of the maintenance process in the virtual environment is completed, as shown in Figure 4 As shown, the main disassembly steps of the electronic control unit are as follows.

[0109] A. The virtual maintenance personnel walk to the maintenance object and stand on the workbench of the support equipment;

[0110] B. The virtual maintenance personnel pick up the screwdriver and stand on the pedal of the support equipment to remove the maintenance port cover;

[0111] C. The virtual maintenance personnel disconnect the electrical plugs connected to the electronic control device and peripheral equipment;

[0112] D. Virtual maintenance personnel remove the fixing bolts of the electronic control device;

[0113] E. Virtual maintenance personnel open the cover on the side of the electronic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com