Special-shaped part forming maintenance method

A technology for special-shaped parts, which is applied in the field of forming and maintenance of special-shaped parts, can solve the problems of long repair time, accuracy cannot be guaranteed, and parts cannot be repaired, etc., and achieve the effect of improving reuse rate, short maintenance cycle and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

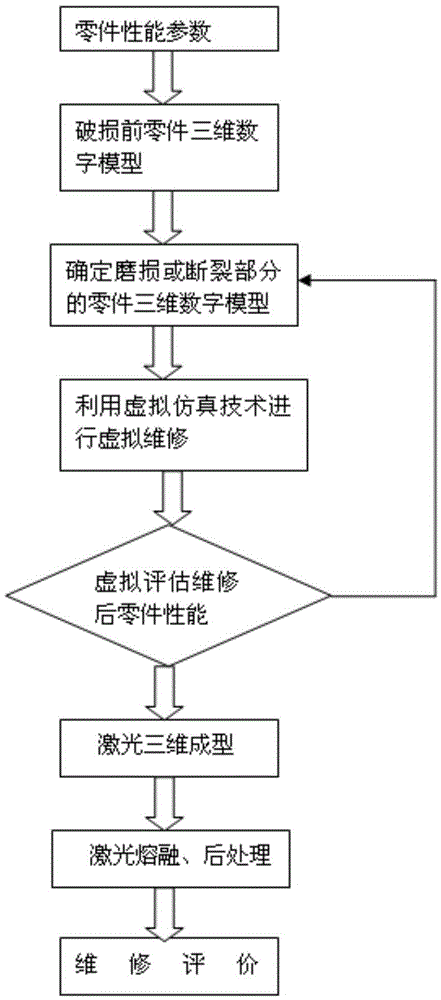

[0044] The invention provides a method for forming and repairing the damaged base metal after the special-shaped parts are damaged, such as figure 1 Shown, forming maintenance method of the present invention comprises the steps:

[0045] Establish the model of the special-shaped parts before damage and the model of the base material after damage;

[0046] Obtain the sub-material model of the special-shaped part by using the pre-damage model and the parent material model of the special-shaped part;

[0047] In the virtual laser melting environment, the sub-material model and the base metal model of the special-shaped parts are virtual fused together, and the virtual laser melting parameters when the performance of the virtual weld formed during the virtual melting process meets the standard are obtained;

[0048] Use the sub-material model of special-shaped parts to obtain the sub-materials of special-shaped parts;

[0049] Using the laser melting treatment method and virtual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com