Buffer-induced independent combined-type roll-over protection structure

A technology of protective structure and cushioning structure, which is applied to the upper structure, upper structure, and upper structure subassembly of trucks, and can solve the problem of prolonging the interaction time between the ROPS and the ground, reducing the peak impact force of the ROPS, and maintenance and high replacement costs, to achieve light weight, improve the ability to absorb the kinetic energy of overturning, and ensure the integrity of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

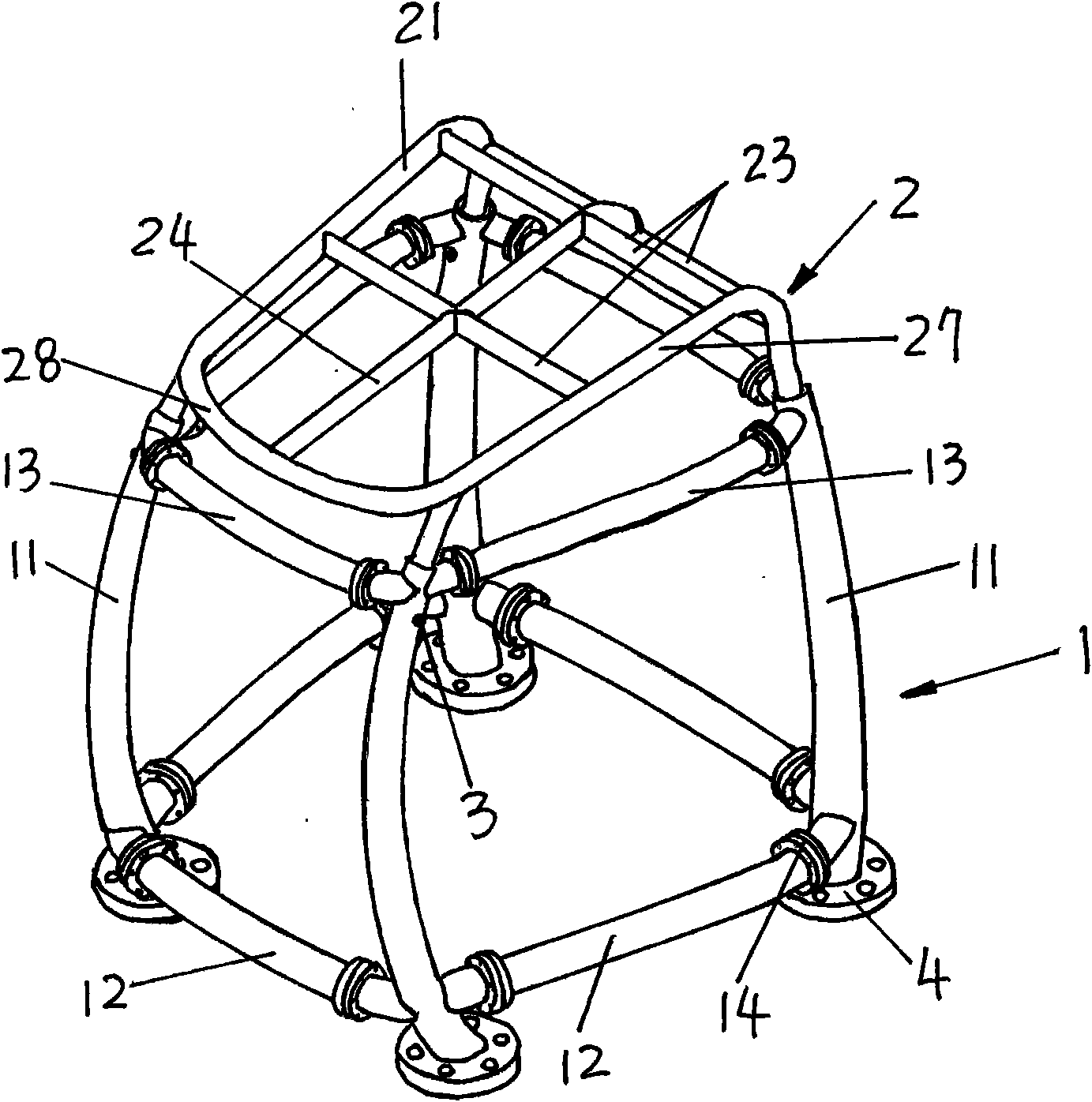

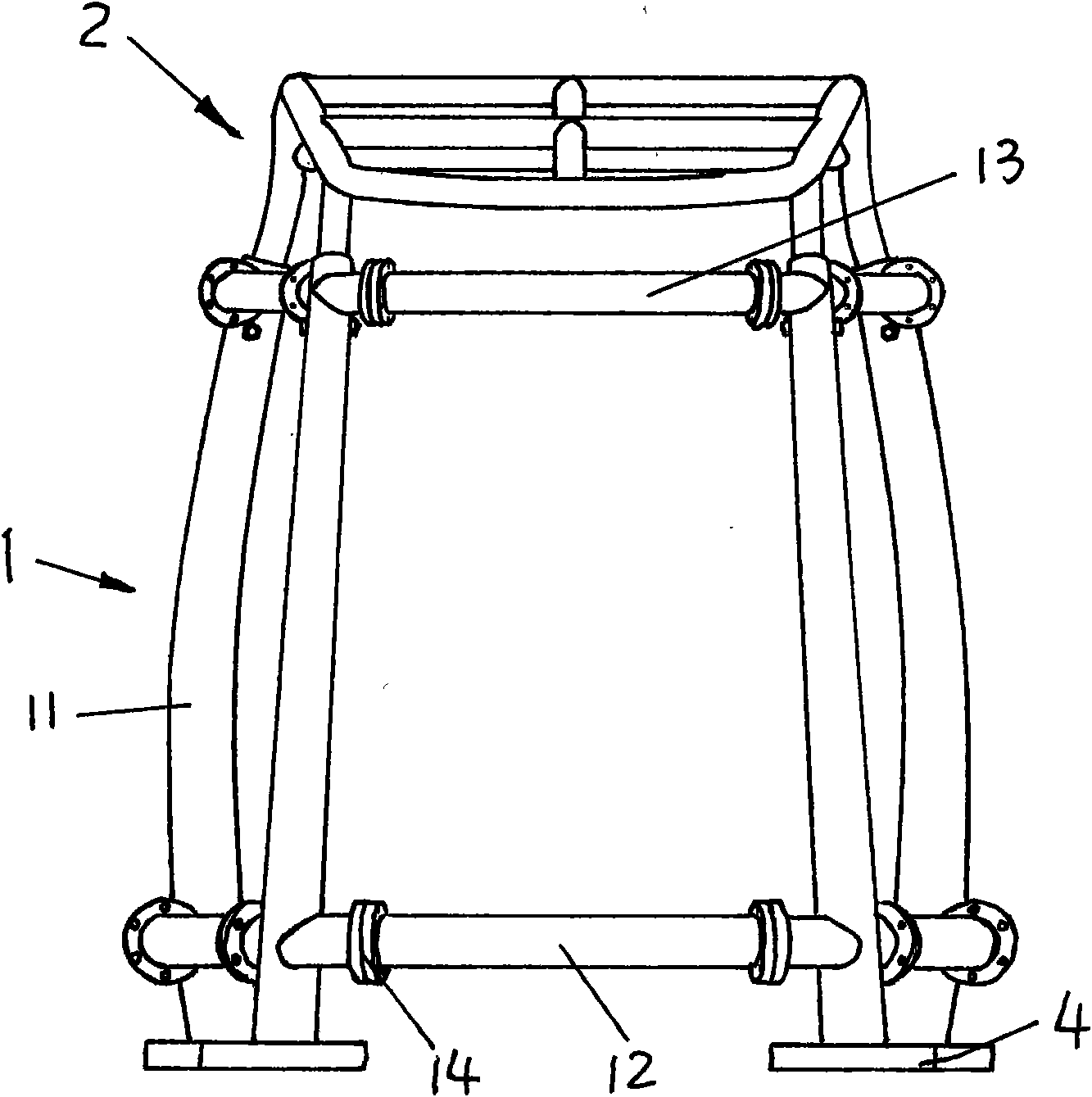

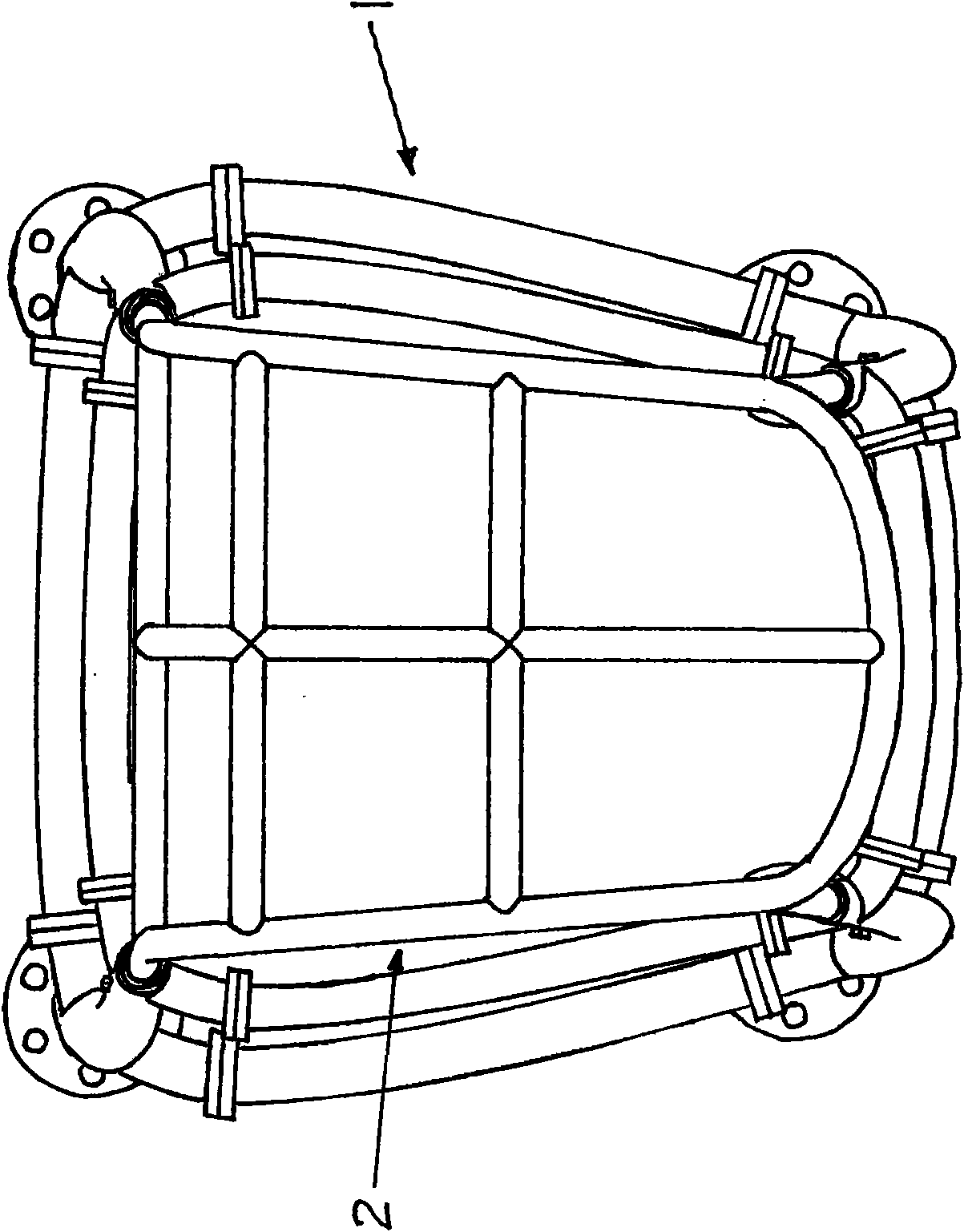

[0019] see Figure 1 to Figure 8 As shown, this embodiment is composed of a main body load-bearing structure 1 and an induced buffer structure 2. The main body load-bearing structure 1 is formed by connecting four columns 11 with upper and lower beams 12, 13 through flanges 14. The main body load-bearing structure 1 The left and right sides, the front and the back, and the upper and lower sides are all in the shape of a curved trapezoid. The four columns 11 are equal-strength columns, and their axes are curved. into; the left and right sides, the front, the back and the top of the induced buffer structure 2 are all in the shape of a curved trapezoid. The front column 25 is respectively welded at the intersection of the left and right crossbeams 21, 27 and the front crossbeam 28 to form the frame of the induced buffer structure. In the trapezoidal frame, several longitudinally curved round steel pipes 24 and several transverse round steel pipes 23 are cross-welded together, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com