Field repairing method of welding cracks of feeding slip-ring body of large-sized slide mill

A technology for welding cracks and repair methods, which is applied in the field of on-site repair of welding cracks in the feed slip ring body of large-scale sliding shoe mills, can solve problems affecting the dimensional accuracy of slip rings, surface roughness of shape and position tolerances, unsatisfactory repair welding, slip rings, etc. Ring deformation and other problems, to achieve the effect of long manufacturing cycle, avoid replacement and reinstallation, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

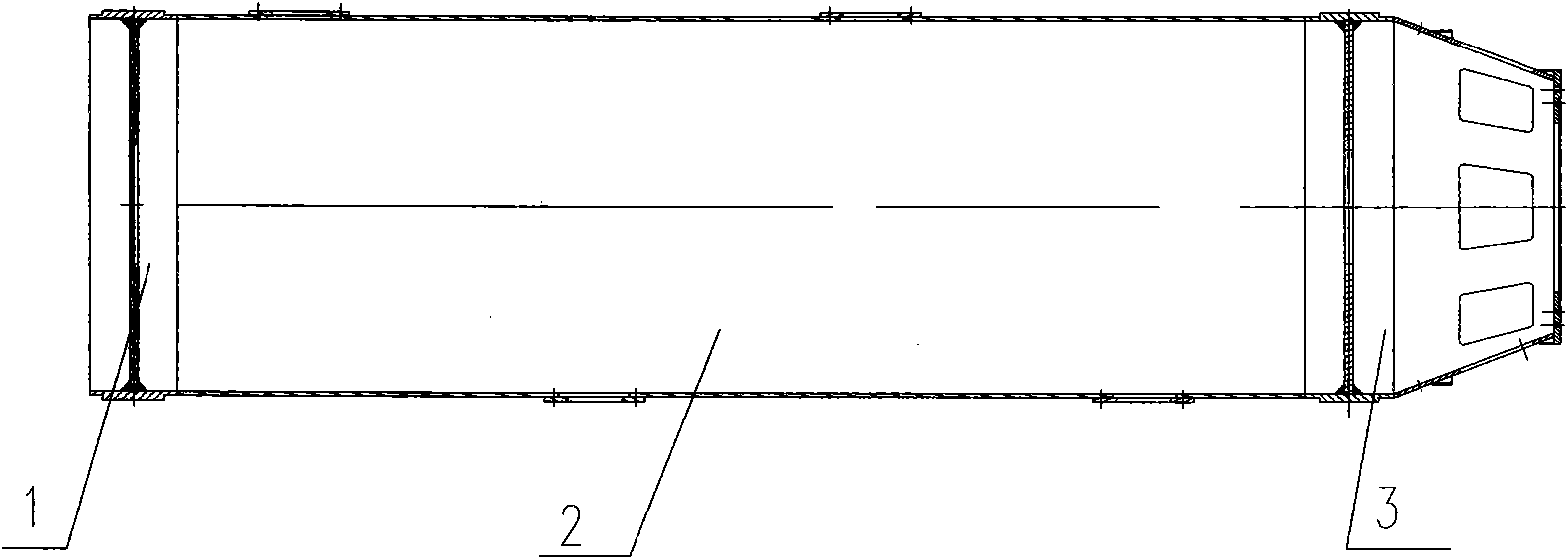

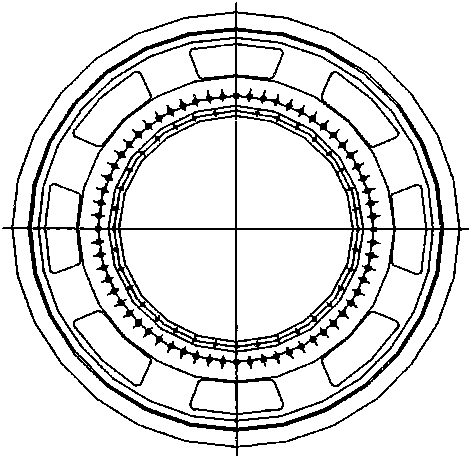

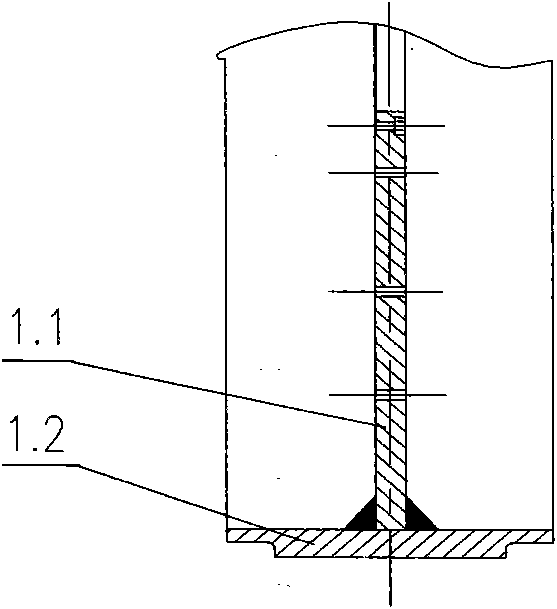

[0037] combine Figure 1-3 , such as a large sliding shoe mill with an outer diameter of 5m in the middle cylinder 2, the maximum outer diameter of the slip ring 1.2 in the feed slip ring body 1 is 5.23m, and the largest outer diameter of the slip ring 1.2 is matched with the sliding shoe bearing pad , the width at the maximum outer diameter of the slip ring 1.2 is 0.74m, if the slip ring 1.2 and the web 1.1 in the feed slip ring body 1 with a T-shaped cross-section have cracks, the method according to the present invention needs to go through the following process:

[0038] (1) On-site inspection

[0039] ①When the feed slip ring body 1 produces welding cracks, in order to prevent the continuous extension of the welding cracks, first use coloring and flaw detection to find out the depth, width and length of each crack, and find out the two parts of each welding crack. At the end points, a Φ20mm crack stop hole should be drilled at 50mm outside the extension line of the two e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com