Equipment for rising and falling headlamp on locomotive

A lifting device and headlight technology, which is applied to railway vehicle lighting devices, signal devices, vehicle parts, etc., can solve the problems of damage to interior decoration components, difficulty in repairing headlight lamps and lanterns, and inability to reach the headlight box with hands, and achieves convenient operation. , the effect of short maintenance cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

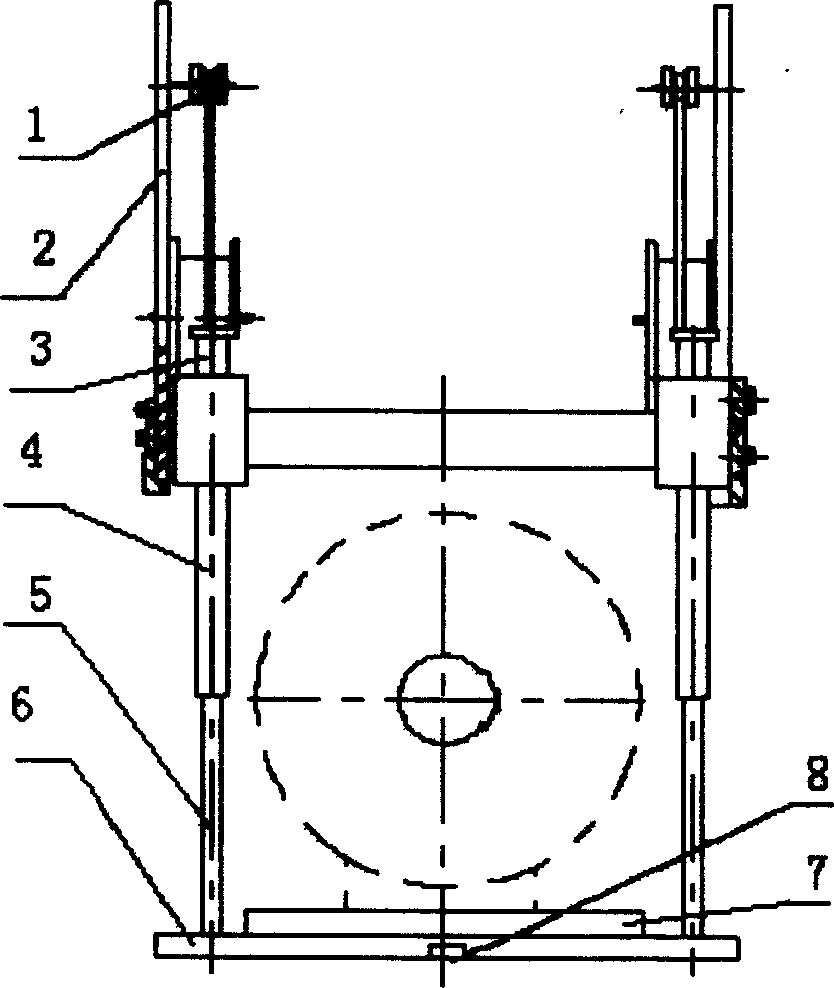

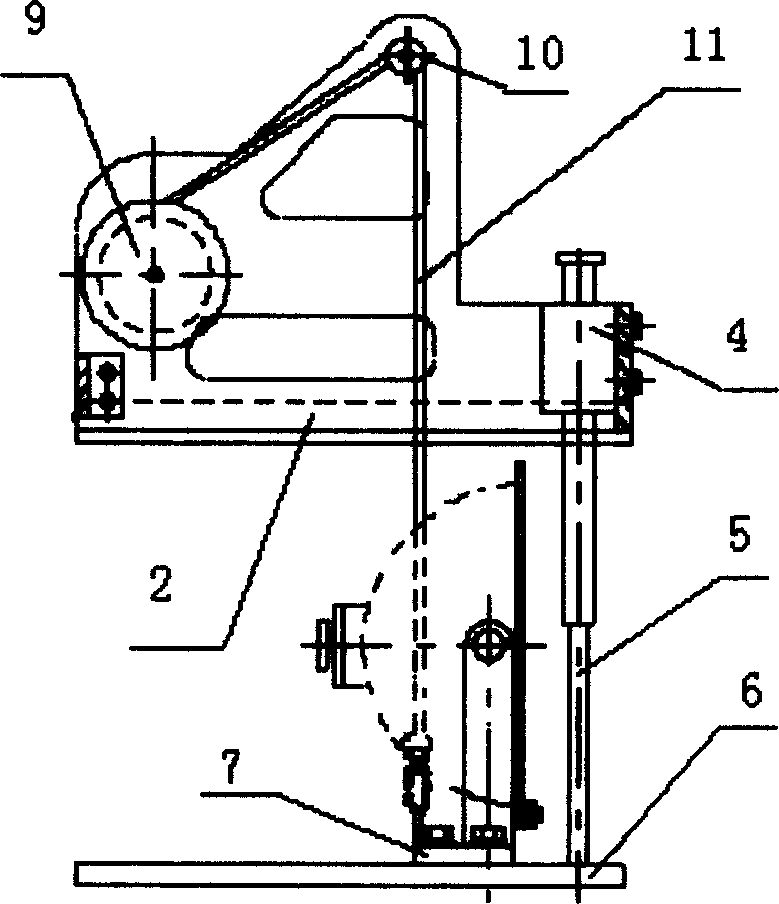

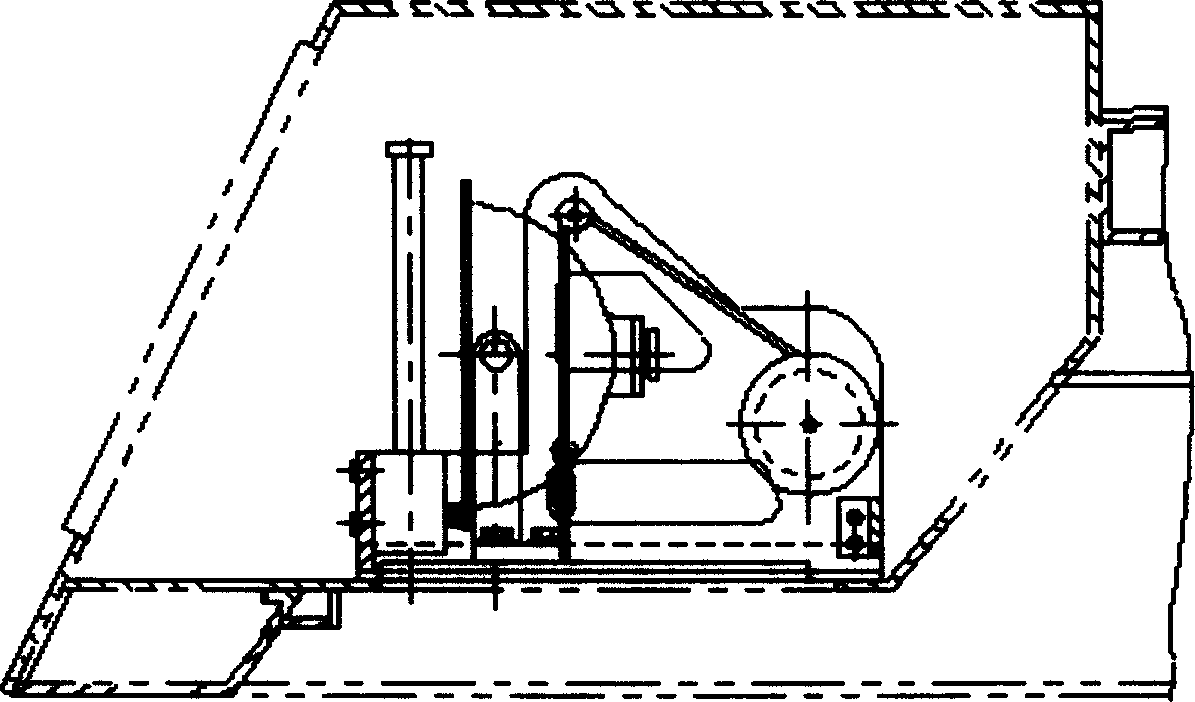

[0013] Such as figure 1 , 2 As shown, the locomotive headlight lifting device is composed of four parts: a lifting mechanism 1, a fixed support 2, a guide mechanism 4, and a movable support 6.

[0014] Described lifting mechanism 1 is to comprise spring wheel 9, pulley 10, wire rope 11. Spring wheel 9 and pulley 10 are installed on the fixed support 2, and one end of wire rope 11 is fixed on the spring wheel 9 and after winding around pulley 1 more than 2 circles again, its end is fixed on the movable support 6. Due to the effect of spring wheel 9 internal springs, wire rope 10 is in tension state all the time, and movable support 6 is subjected to upward pulling force all the time by pulley 10, has balanced the gravity of movable support 6 together with guide mechanism 4. Due to the effect of the guide mechanism 4, the movable support 6 can move up and down along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com