Patents

Literature

82results about How to "Improve magnetic separation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

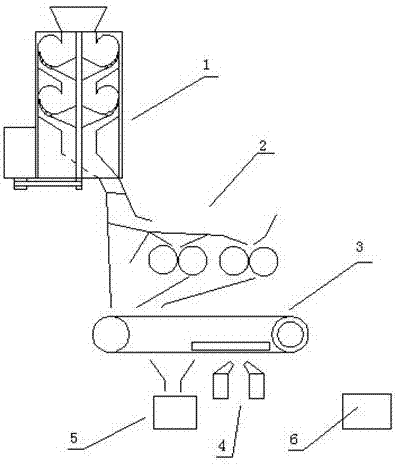

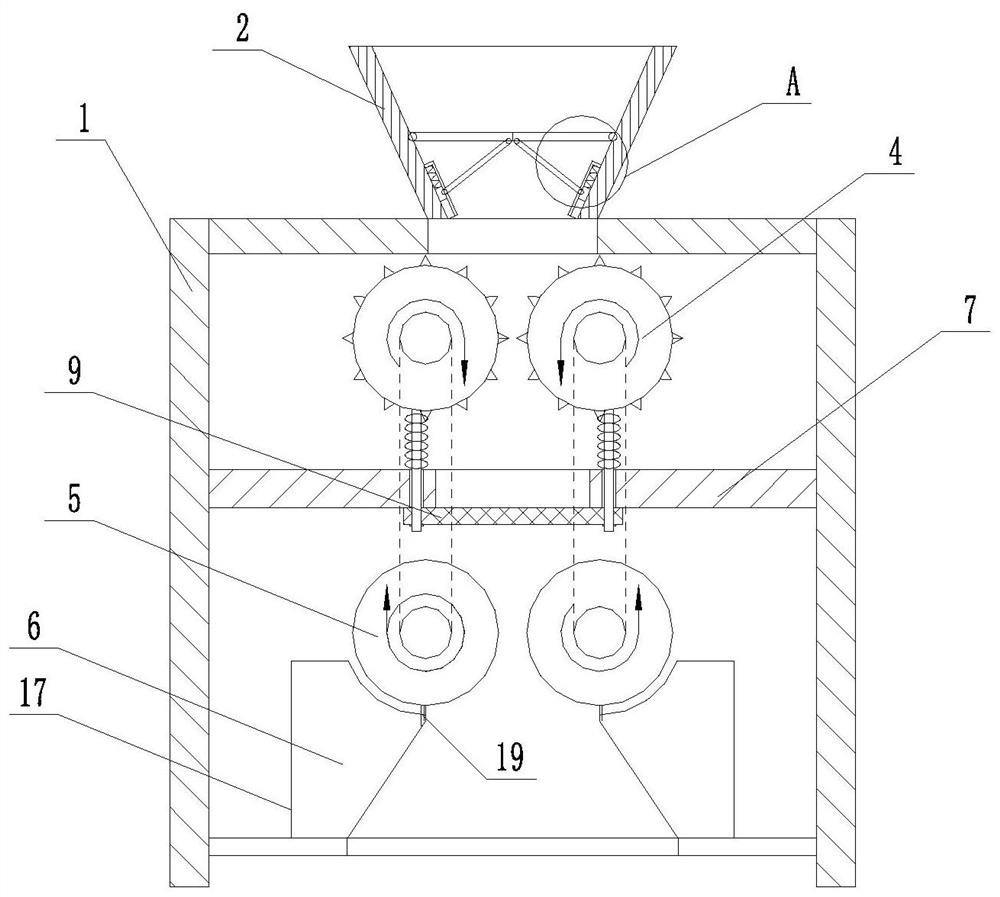

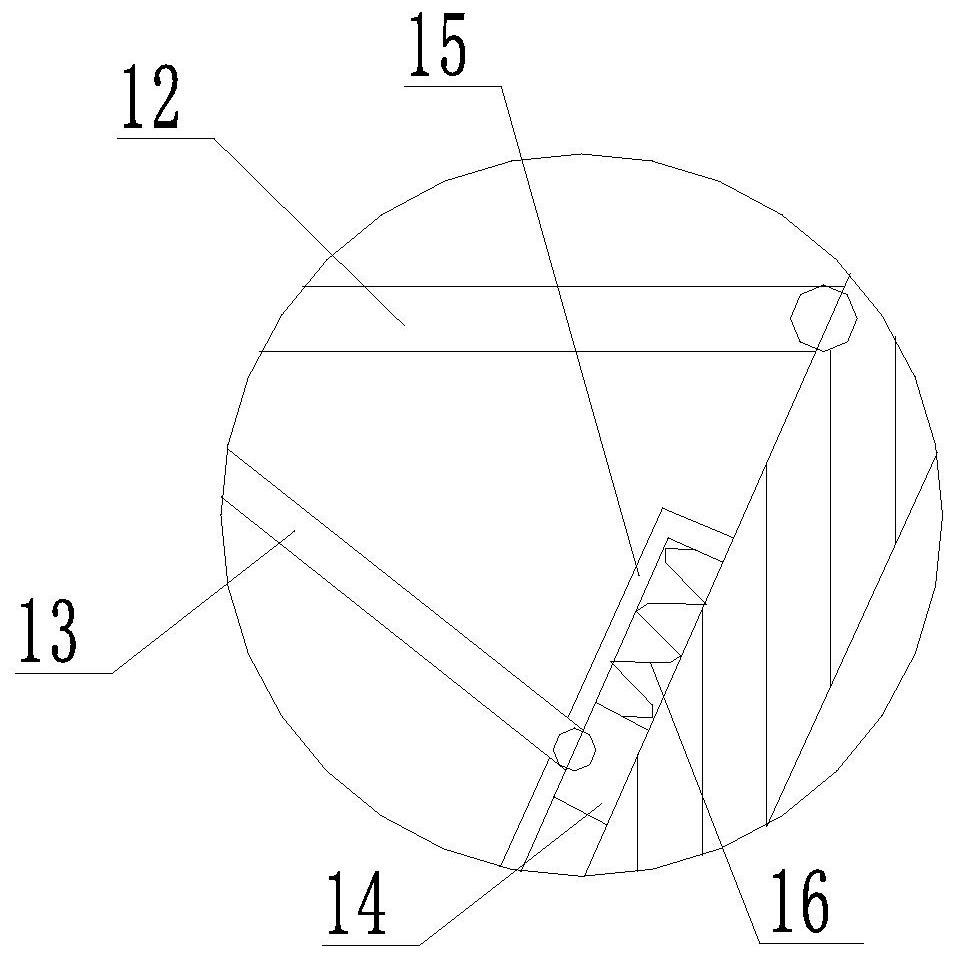

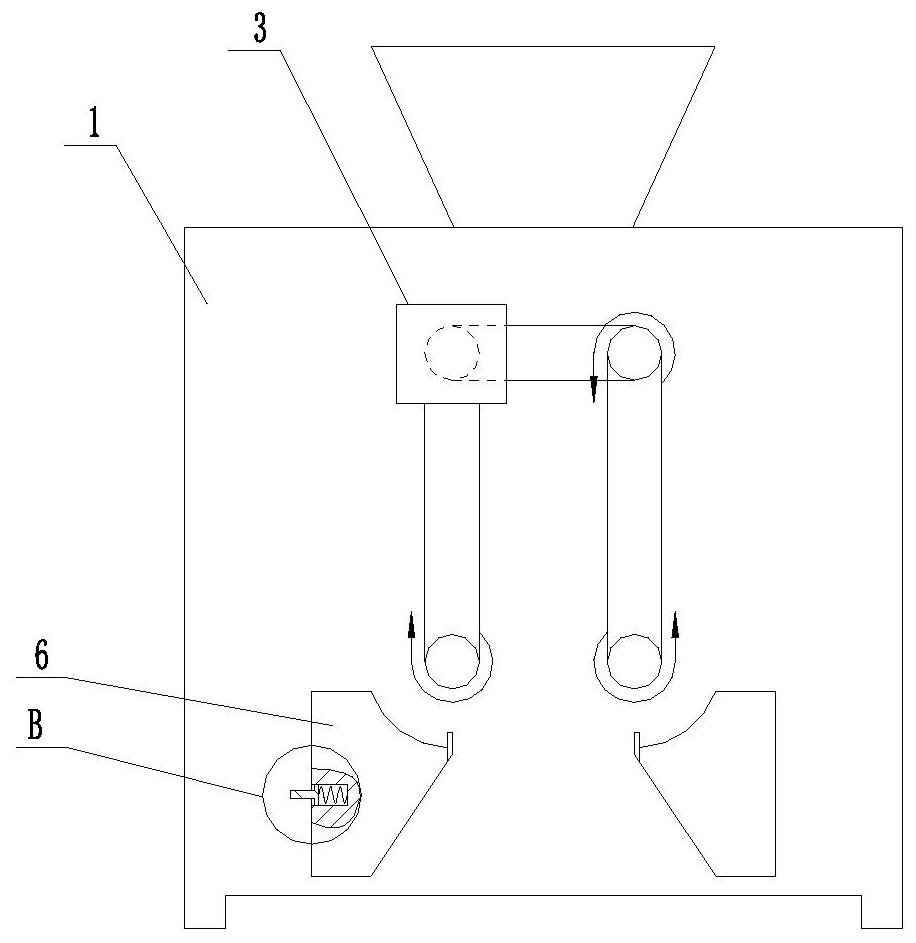

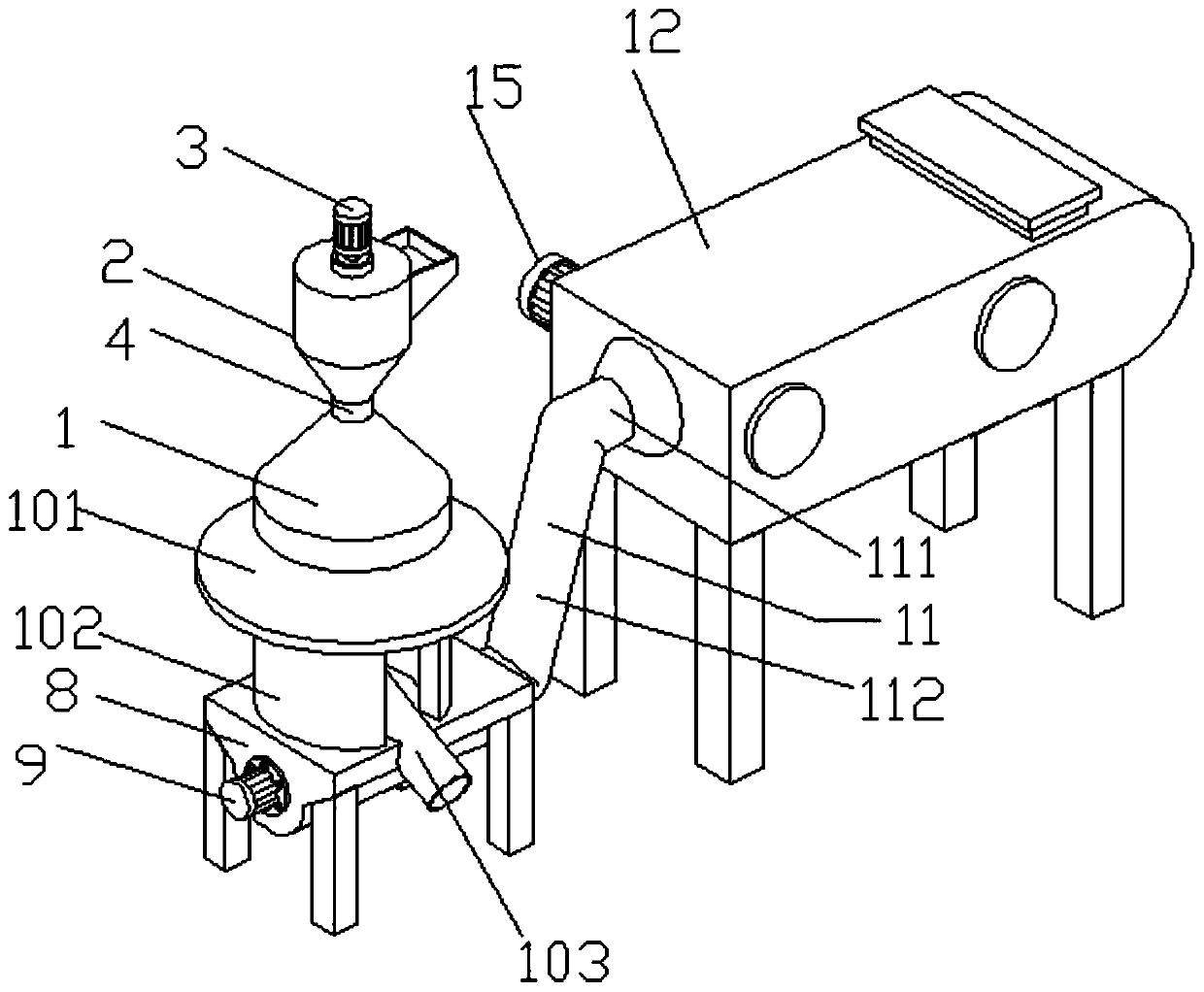

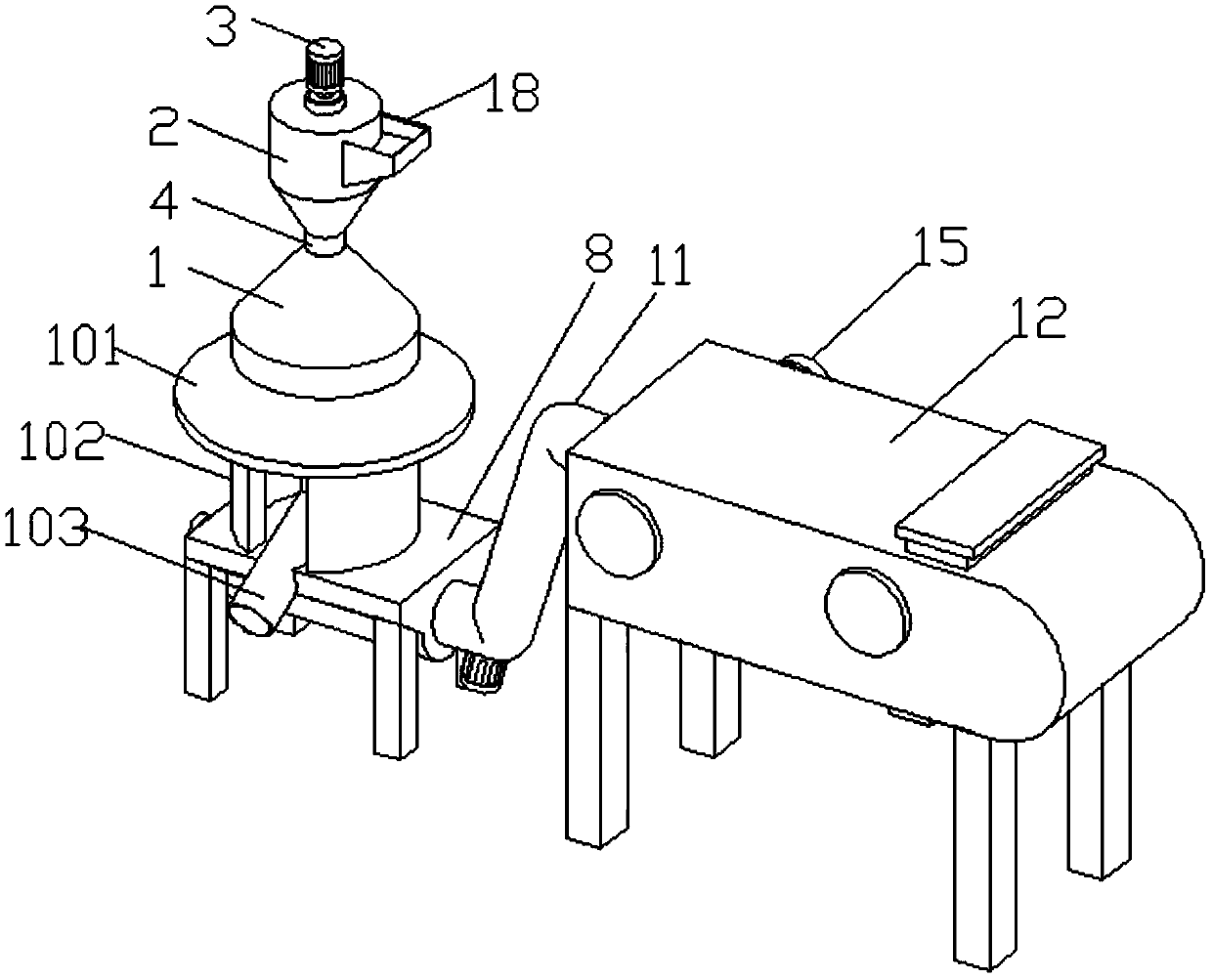

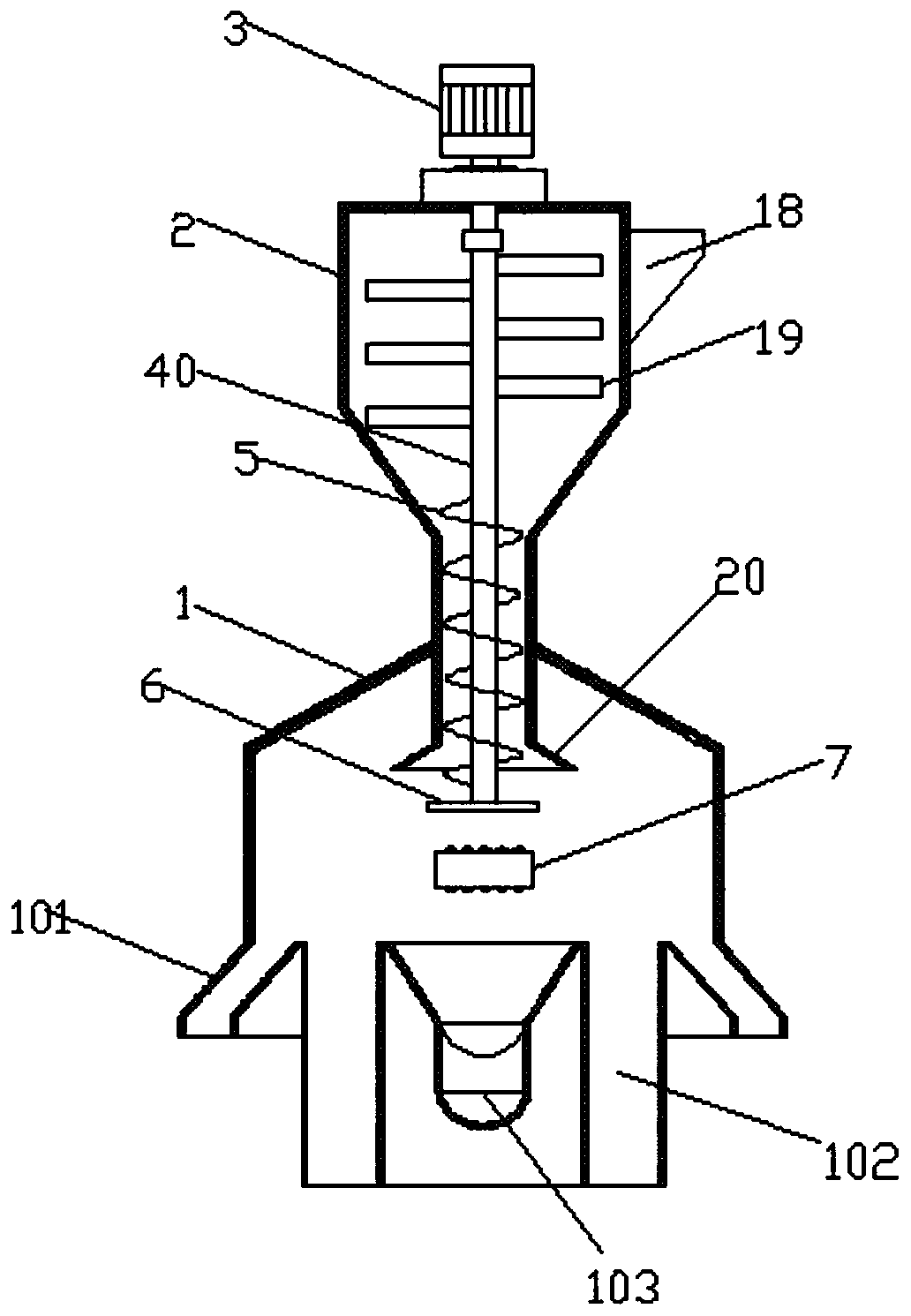

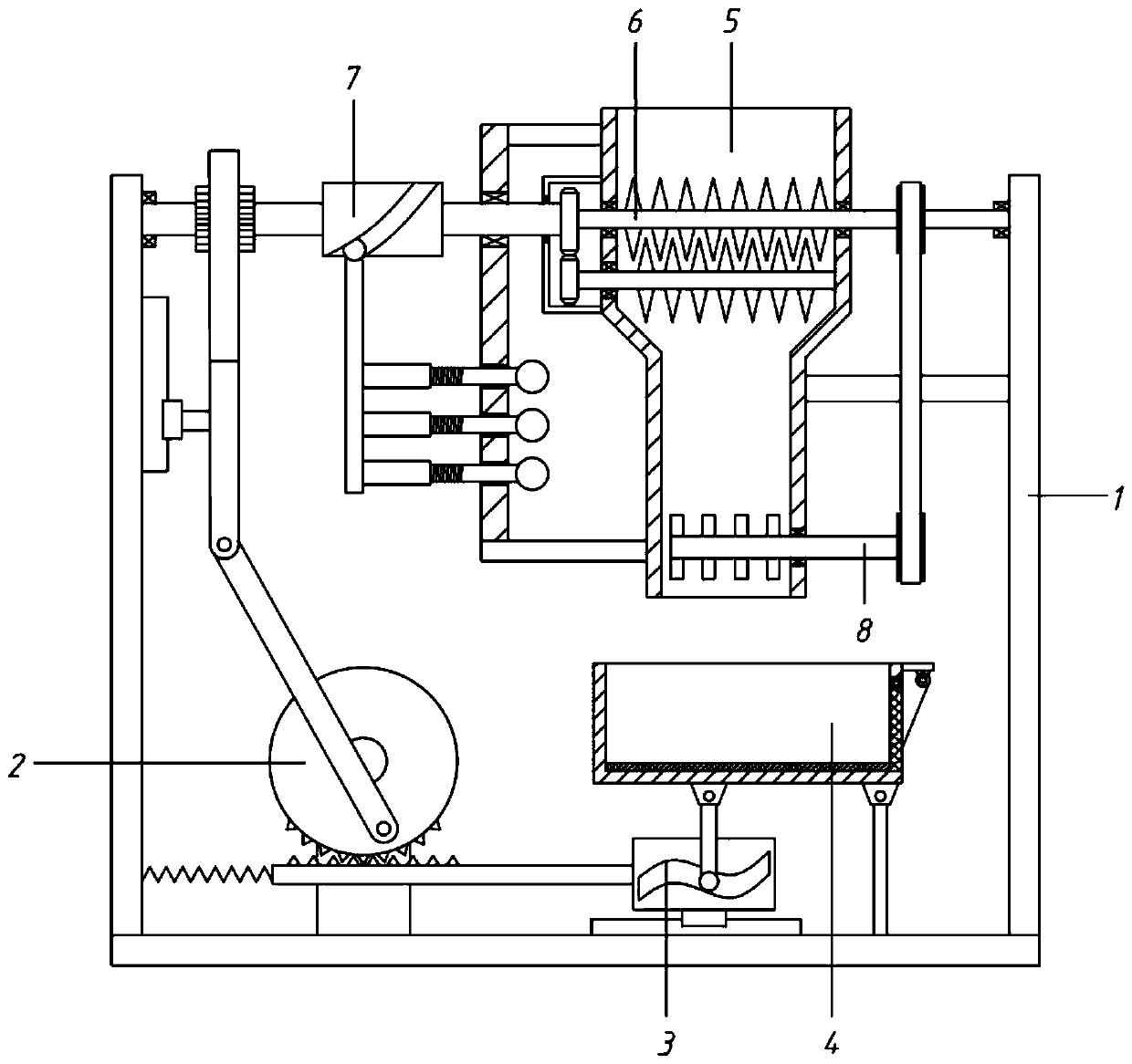

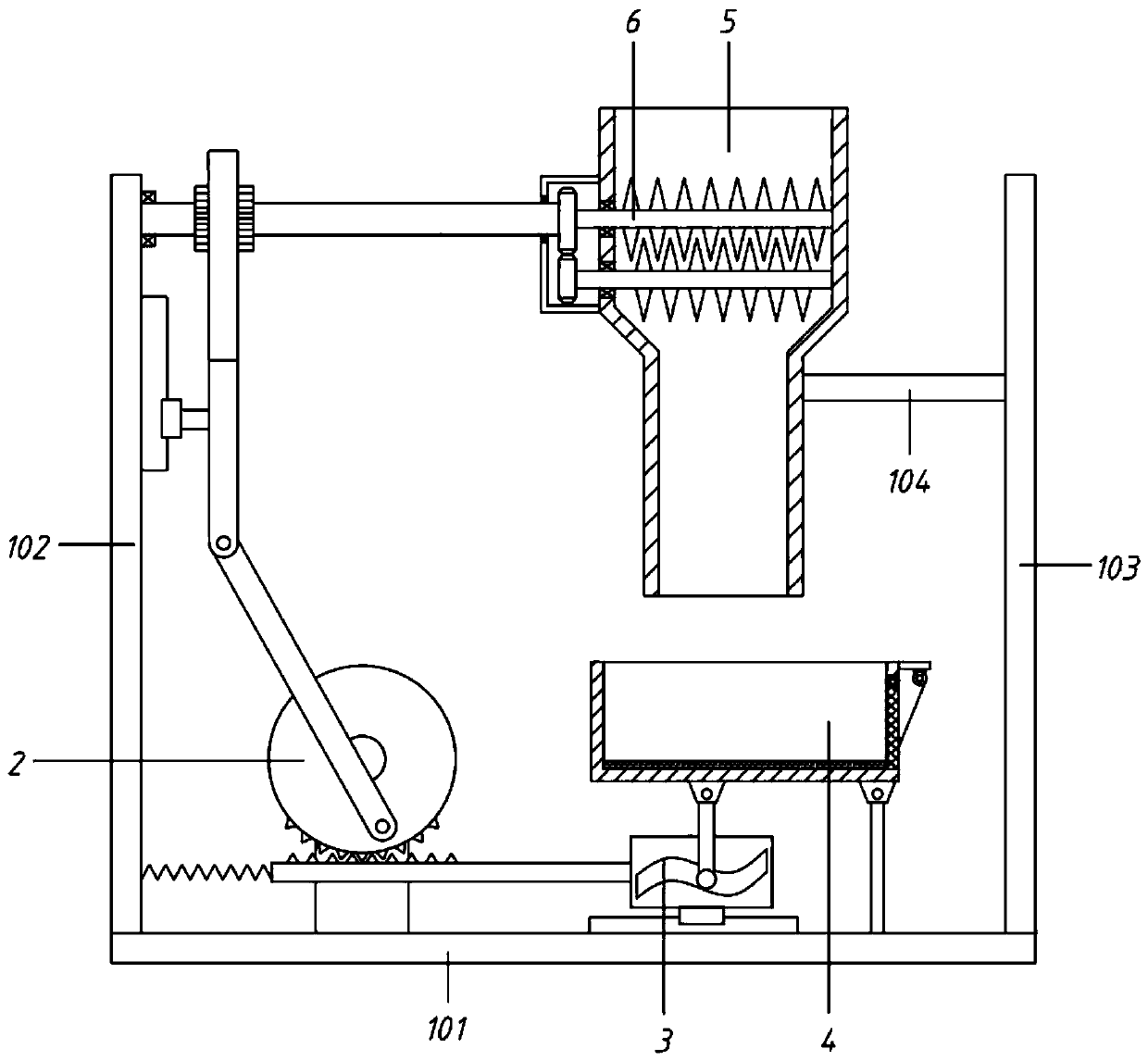

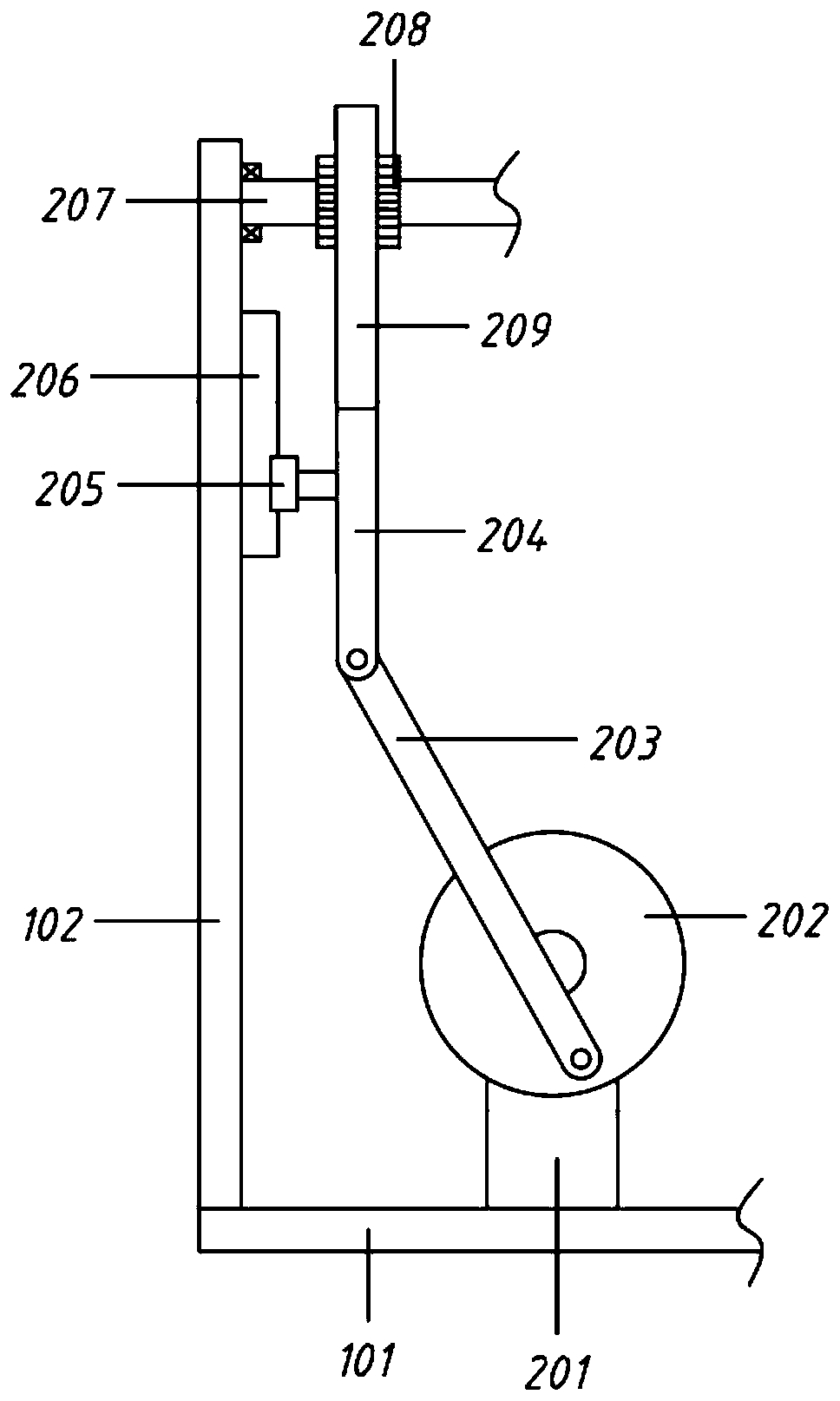

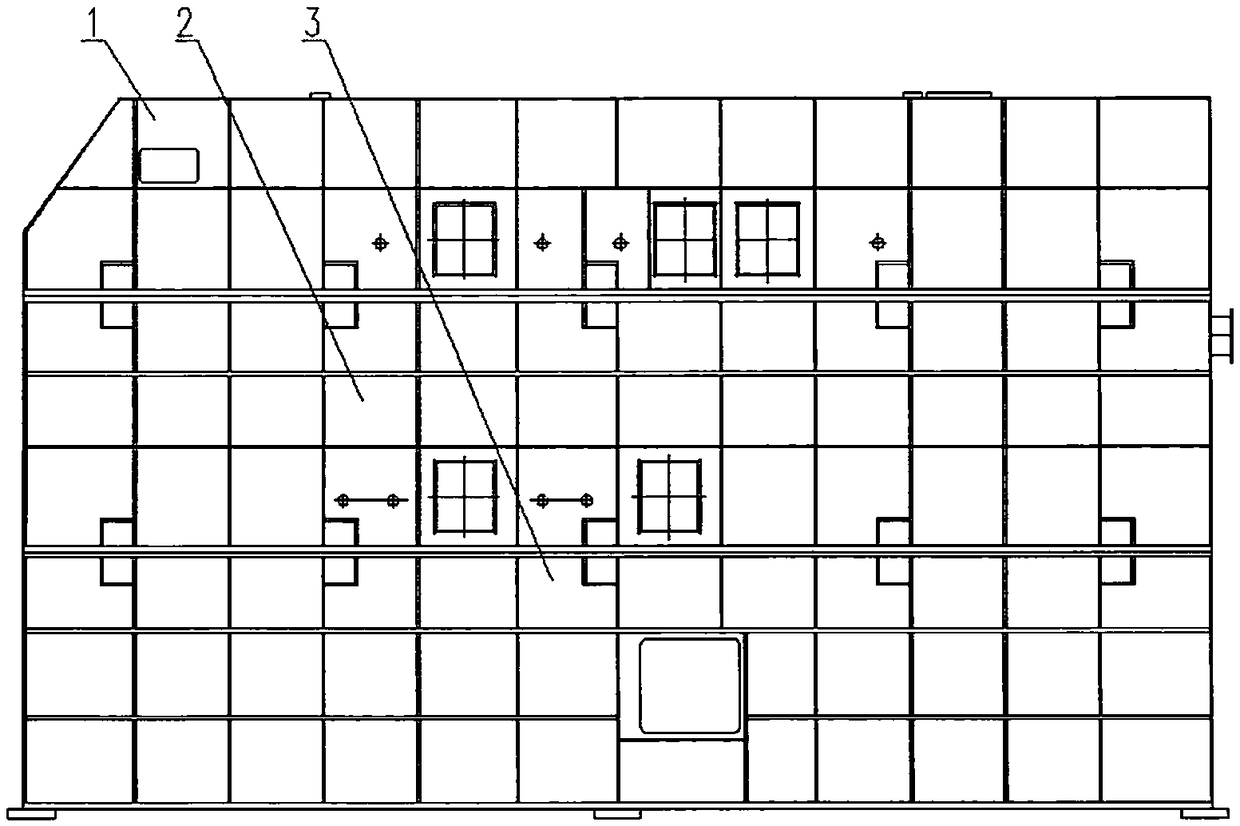

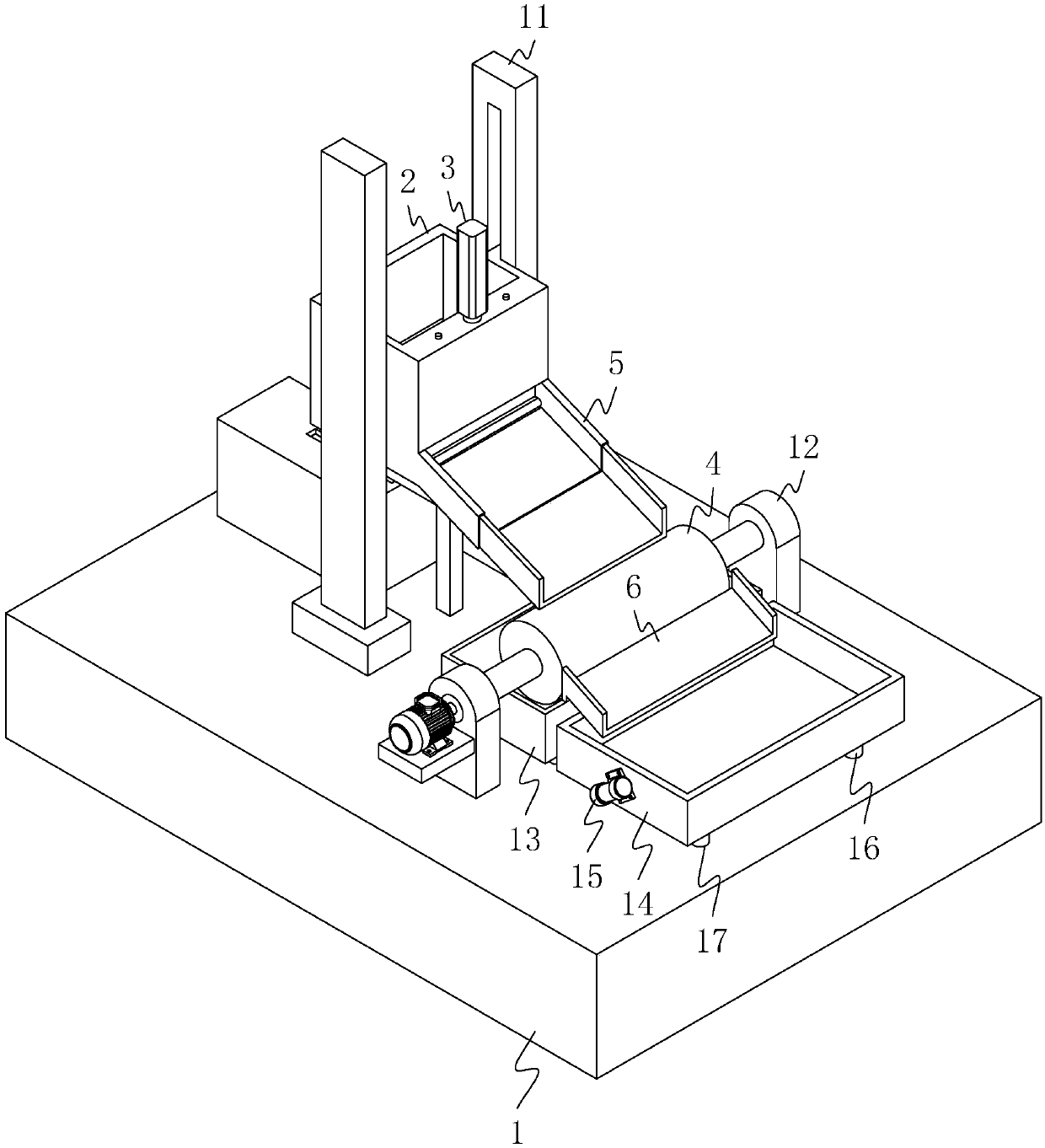

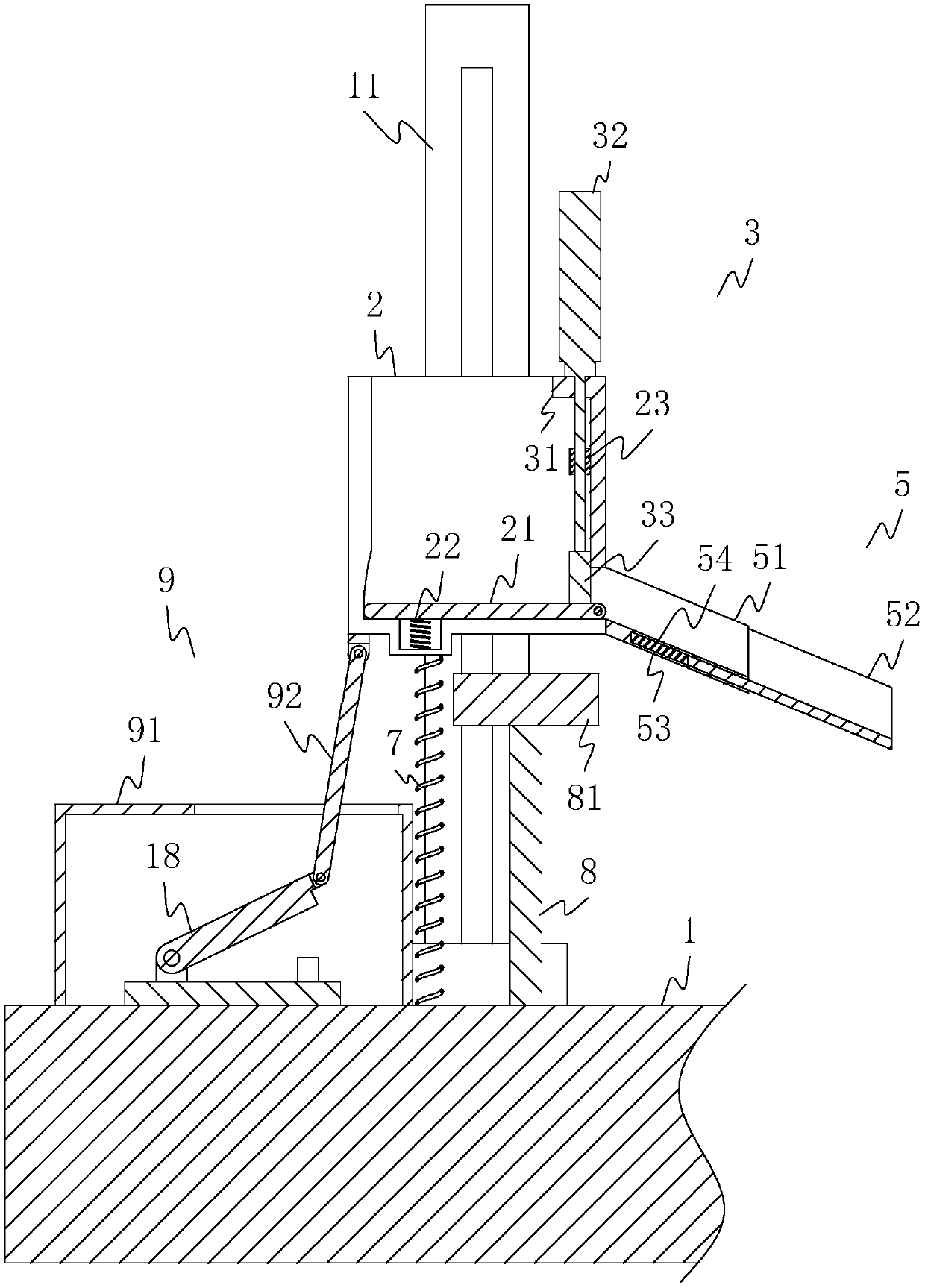

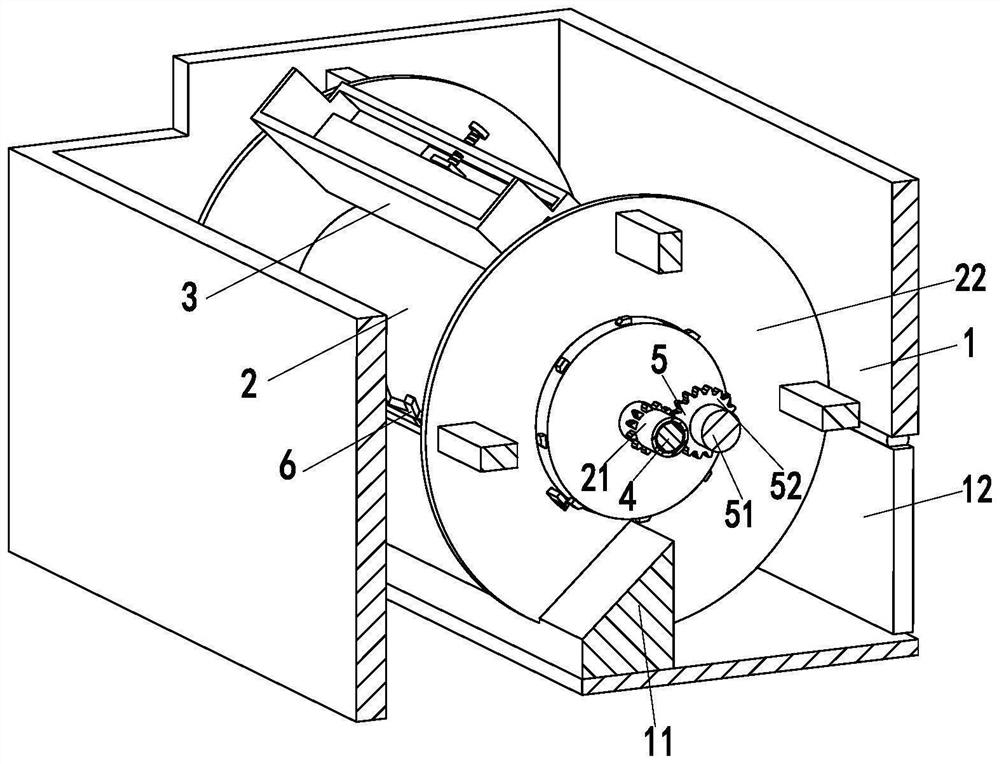

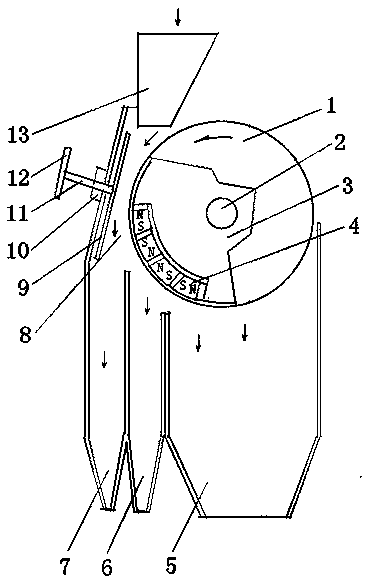

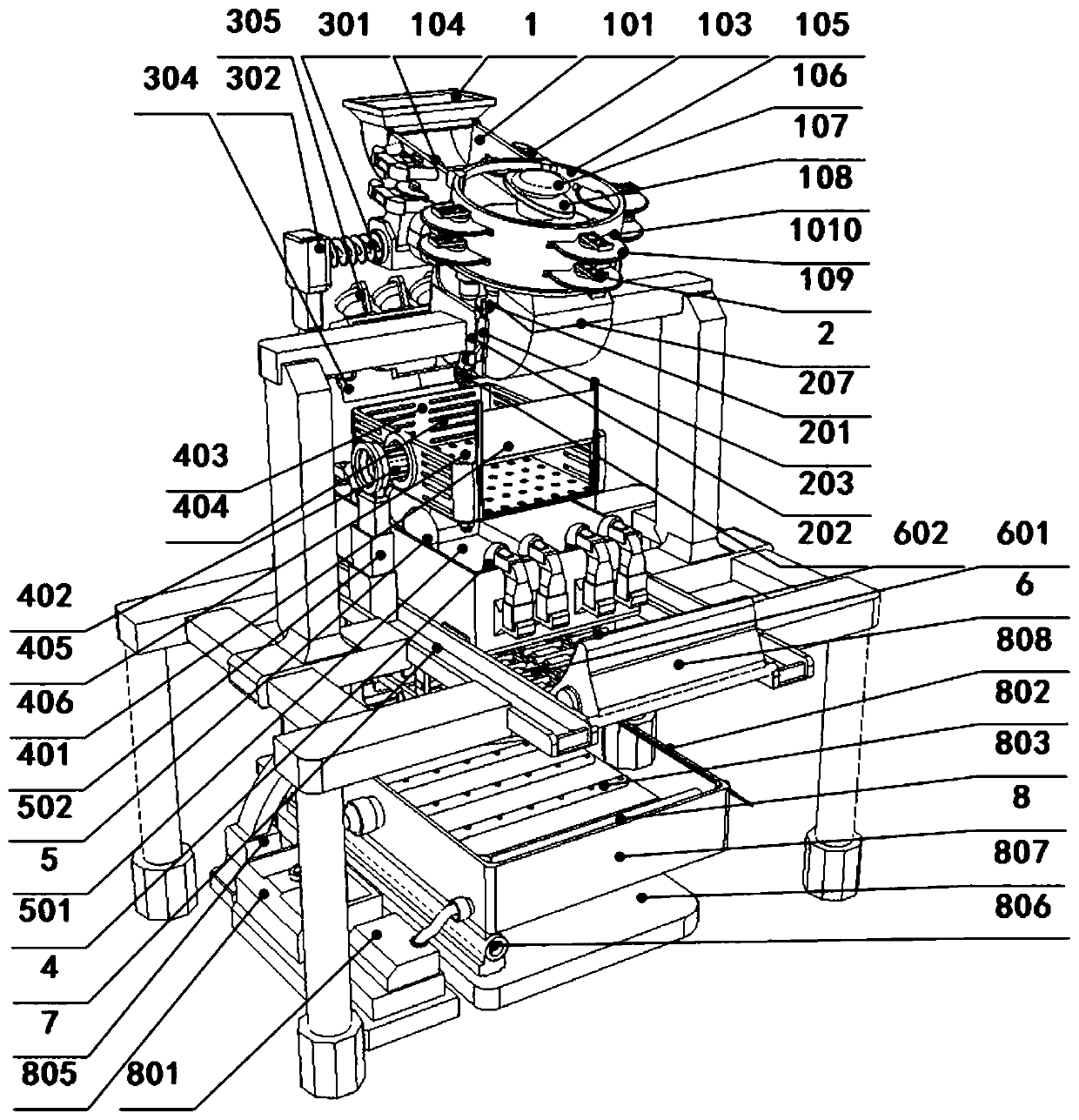

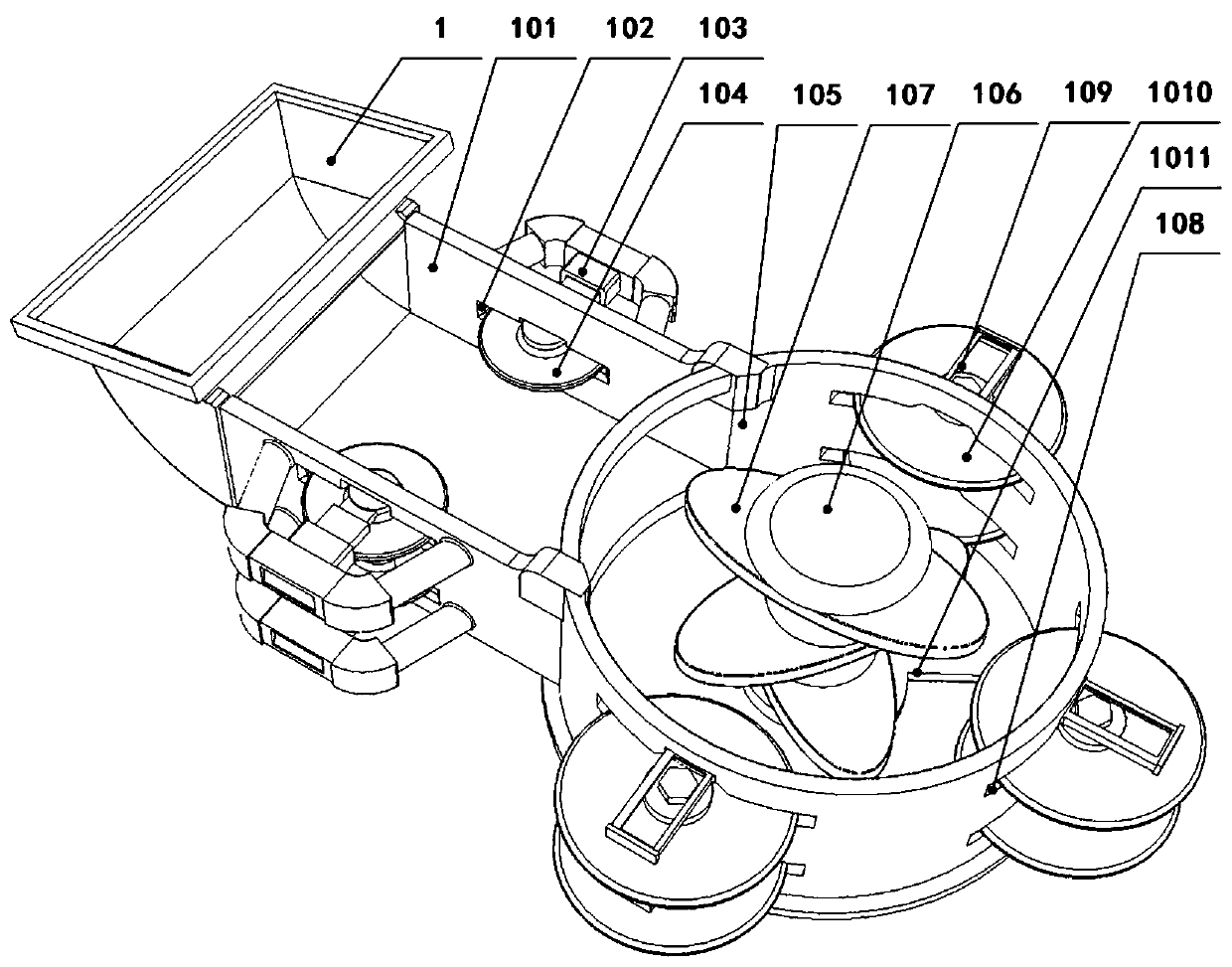

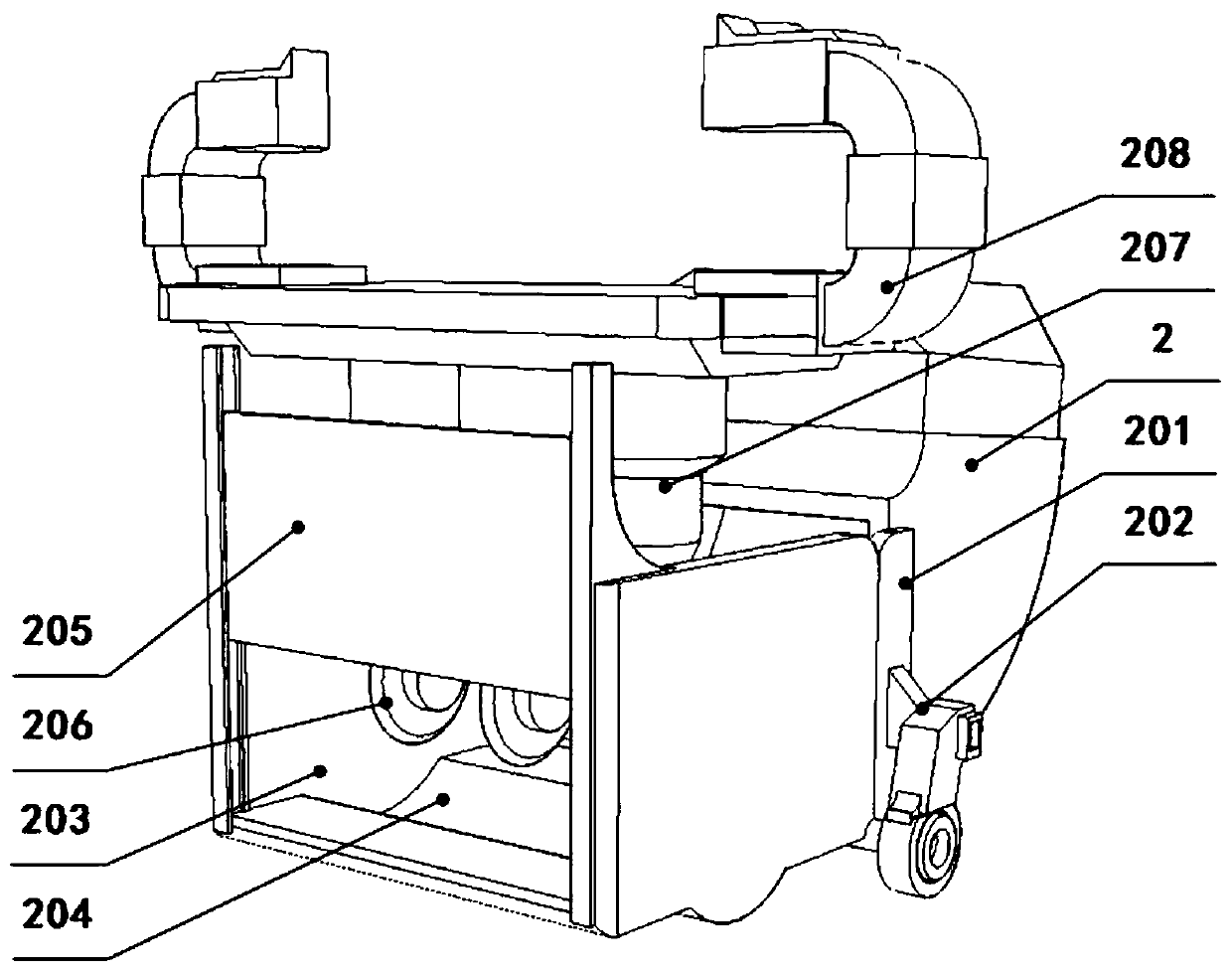

Mine magnetic separator

The invention relates to the field of mine magnetic separation, in particular to a mine magnetic separator. The mine magnetic separator comprises a crushing mechanism, a feeding mechanism, a conveying mechanism and a magnetic separation mechanism. The conveying mechanism is used for conveying magnetic ore output by the crushing mechanism into the feeding mechanism. An output port of the feeding mechanism is opposite to an inlet of the magnetic separation mechanism. The structure is suitable for magnetic ore screening of mines, in-situ magnetic separation is facilitated, and the magnetic separation cost of the ore is reduced. In addition, magnetic separation of the magnetic ore crushed by the crushing mechanism is more facilitated, the magnetic ore is evenly distributed conveniently through the feeding mechanism, production and application of the equipment are convenient, and the magnetic separation efficiency and the recovery rate of the magnetic ore are improved. Crushing is conducted by sufficiently utilizing the characteristics of ore grains, the crushing precision is higher, and safety and effectiveness of equipment application can be guaranteed through the structure. More specific collision is conducted on the magnetic ore through characteristics of the magnetic ore and non-magnetic ore, the service life of the equipment is prolonged, and the feeding mechanism has re-screening and crushing functions.

Owner:浙江国正安全技术有限公司

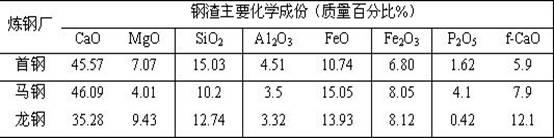

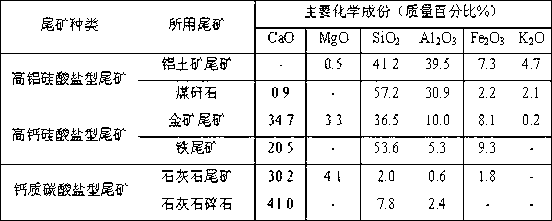

Method for modifying high-temperature steel slag by using compound materials of tailings

ActiveCN102605113AChange compositionChange physical stateIncreasing energy efficiencyCalcium in biologySteelmaking

The invention relates to method for modifying steel slag, in particular to a method for modifying high-temperature steel slag discharged in the final steelmaking stage by using a large amount of mining tailings with low cost, comprising the following steps: mixing 15-30 parts by weight of high alumina silicate tailings, 60-80 parts by weight of high calcium silicate tailings and 5-15 parts by weight of calcium carbonate tailings to obtain compound materials of the tailings; granulating to prepare agglomerated blocks of 3-5cm; adding the compound materials of the tailings into steel slag pot or disc by batches according to the proportion of (70-80%):(20-30%) of the discharged steel slag and the compound materials of the tailings; carrying out steel slag splashing for furnace maintenance, wherein the left steel slag is not poured into the steel slag pot or disc for modifying the steel slag; preserving the temperature of the steel slag at 1,200-1,400 DEG C for 30-60min; quenching by using water, applying heat or covering by heat when the temperature is below 1,200-1,400 DEG C; breaking; and carrying out magnetic separation. Due to the adoption of the method, the separation effect of the steel slag can be improved significantly, the grindability of the separated steel slag can be improved, the total recovery rate of the scrap steel can be up to 95-100%, the components of the separated steel slag are controllable and have high activity, and the separated steel slag contain less than 1.5% by weight of the free calcium oxide, has the grinding work index of 14-17kw.h / t and can replace the portland cement clinker.

Owner:迁安金隅首钢环保科技有限公司

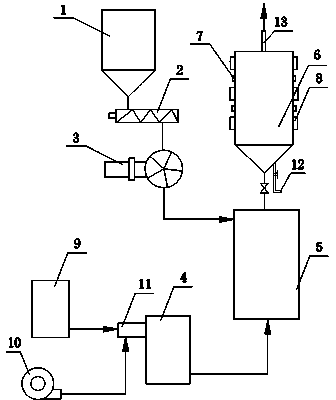

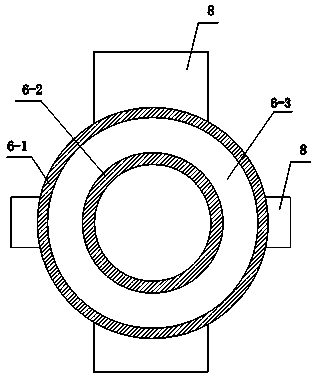

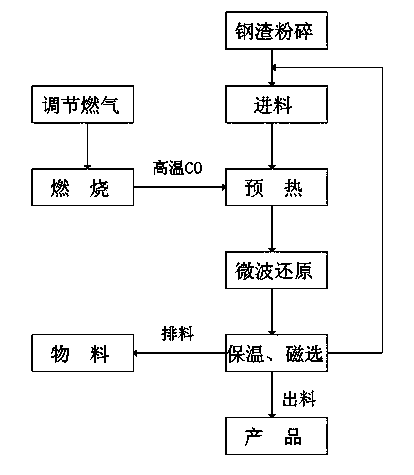

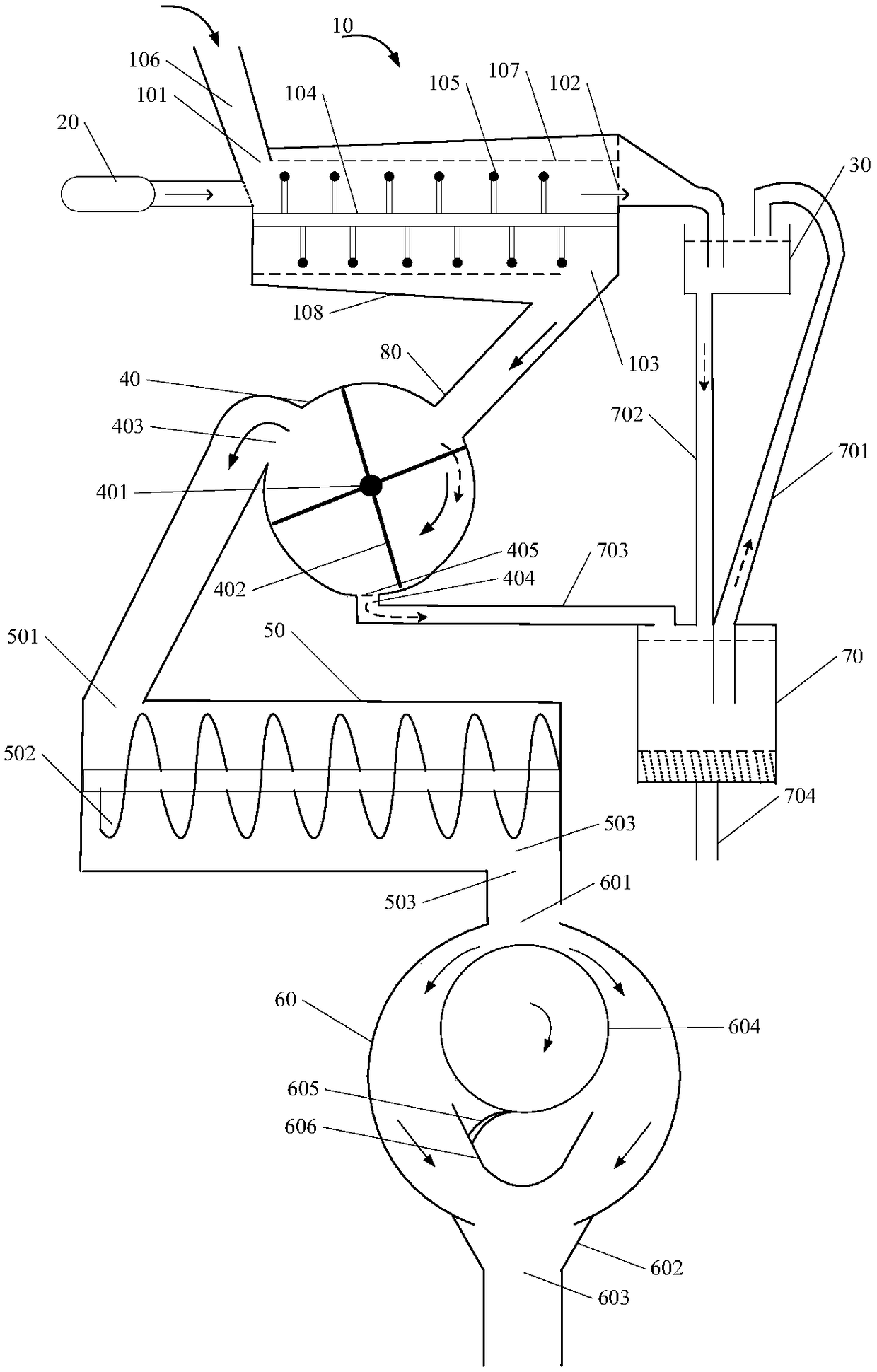

Magnetic separation device and method for reducing hematite-containing material by utilizing microwave

The invention relates to a device and a method for reducing hematite-containing materials by utilizing microwave heat treatment and carrying out magnetic separation. The device comprises a material bin, a screw feeder, a star type feeding machine, a preheating reacting furnace and a microwave magnetic separator. When the magnetic separation is carried out, the materials are crushed and then added to the material bin, powdery materials enter the preheating reacting furnace through the screw feeder and the star type feeding machine for preheating, and the preheated powdery materials enter the microwave magnetic separator through an air inlet pipe for the microwave heat treatment and the magnetic separation; products subjected to the magnetic separation are discharged through an ore discharge pipe from a discharge port, and other materials are discharged through an outlet pipe from the discharge port. The device disclosed by the invention can be used for reducing the weak magnetic Fe2O3 contained in the materials into strong magnetic Fe3O4 through the microwave heating and separating the iron ore concentrates through the magnetic separation, integrally and simultaneously carries out the reduction and the magnetic separation, has the advantages of small investment, low energy consumption, large treatment quantity, water saving, no air pollution, wide application range and relatively popularization prospect, is simple in equipment, and can be used for treating multiple hematite-containing materials which include ores, such as steel slag, low-grade limonite and iron ores.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

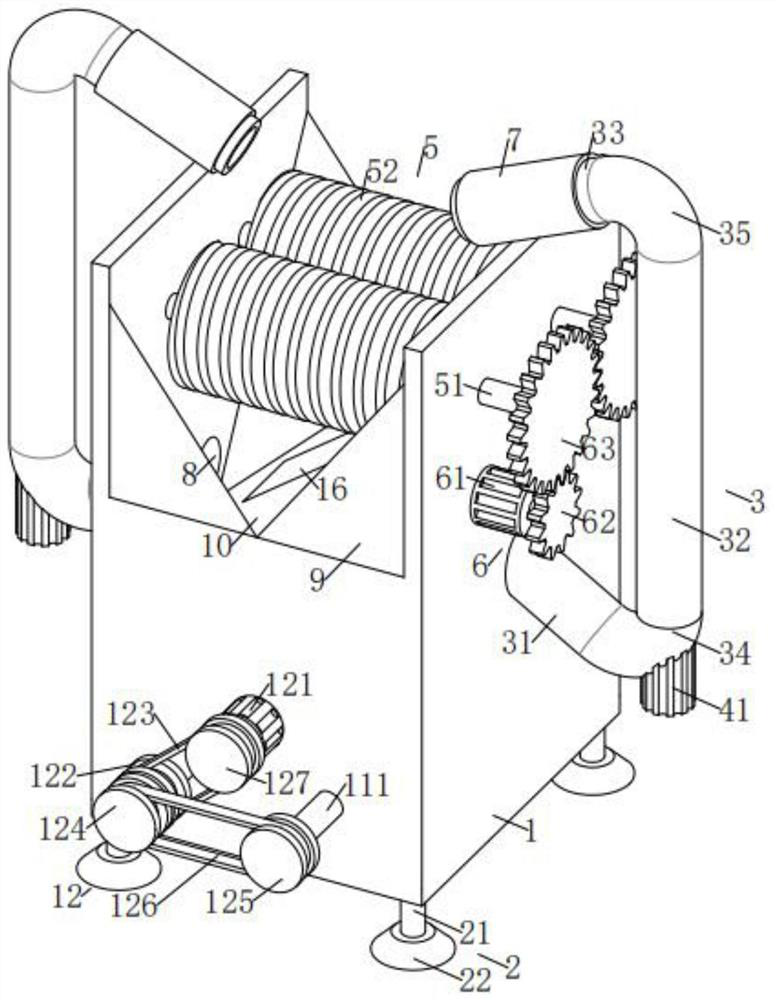

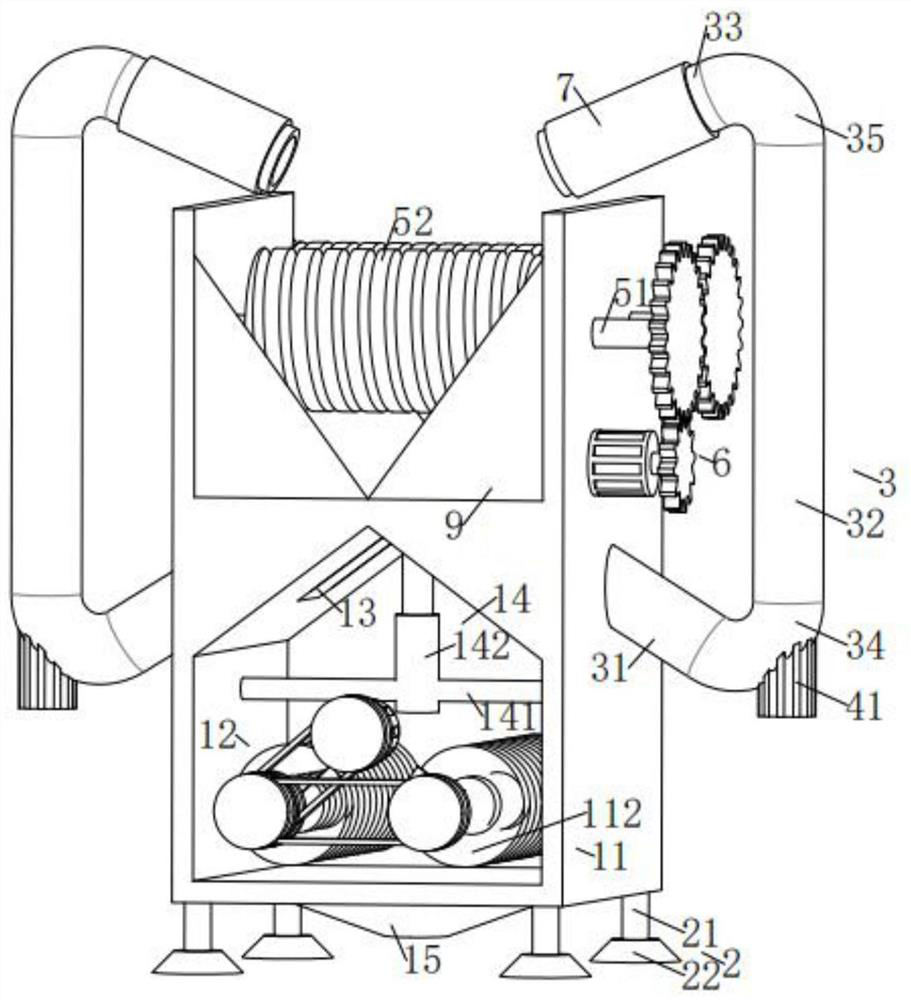

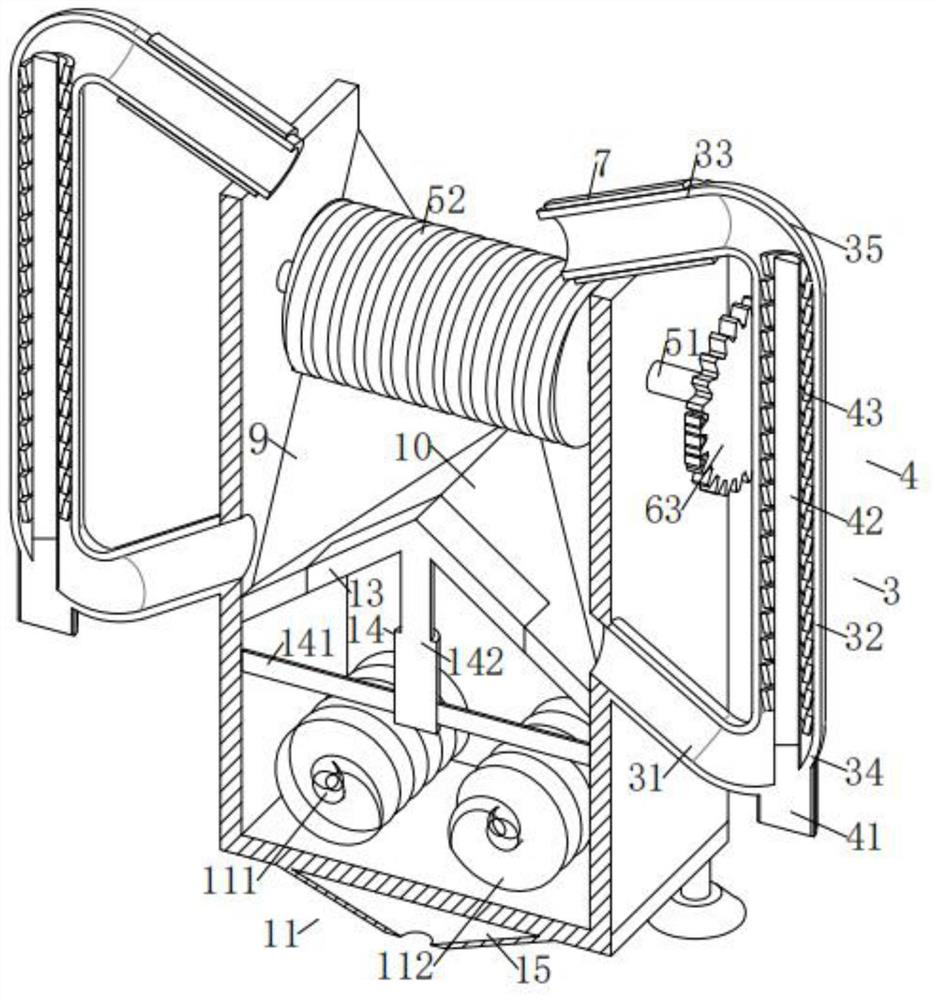

Efficient rubber crushing and recycling device and crushing and recycling method thereof

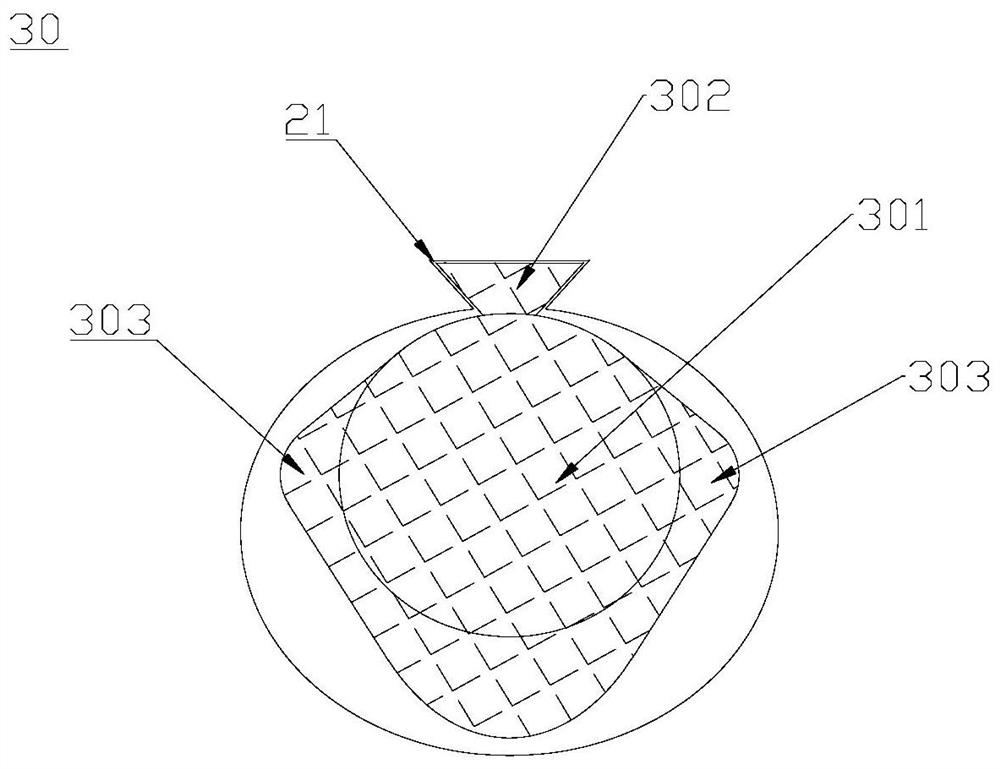

ActiveCN111688069AConvenient for magnetic separationImprove crushing efficiencyPlastic recyclingMagnetic separationGear driveGear wheel

The invention discloses an efficient rubber crushing and recycling device and a crushing and recycling method thereof, and belongs to the technical field of rubber crushing. The efficient rubber crushing and recycling device comprises a U-shaped outer frame, a herringbone blanking plate, two sets of triangular pyramid guide stop blocks, discharging holes, a crushing mechanism and a gear transmission mechanism, the lower side parts of the front end and the rear end of the U-shaped outer frame are closed, and the U-shaped outer frame is hollow and has a thickness; the herringbone blanking plateis arranged between the left inner wall and the right inner wall of the U-shaped outer frame; the two sets of triangular pyramid guide stop blocks are arranged at the top of the herringbone blanking plate, the number of each set of triangular pyramid guide stop blocks is two, and the outer sides of the triangular pyramid guide stop blocks are flush with the U-shaped outer frame; the two discharging holes are formed in the left end and the right end of the U-shaped outer frame correspondingly and located in the bottoms of the left side and the right side of the herringbone blanking plate correspondingly; the crushing mechanism is arranged on the U-shaped outer frame and located on the upper side of the herringbone blanking plate; and the gear transmission mechanism is arranged on the U-shaped outer frame. According to the efficient rubber crushing and recycling device, efficient crushing is facilitated, meanwhile, good magnetic separation is carried out, and the crushing and magnetic separation efficiency is effectively improved.

Owner:益阳市朝阳三鑫环保科技有限公司

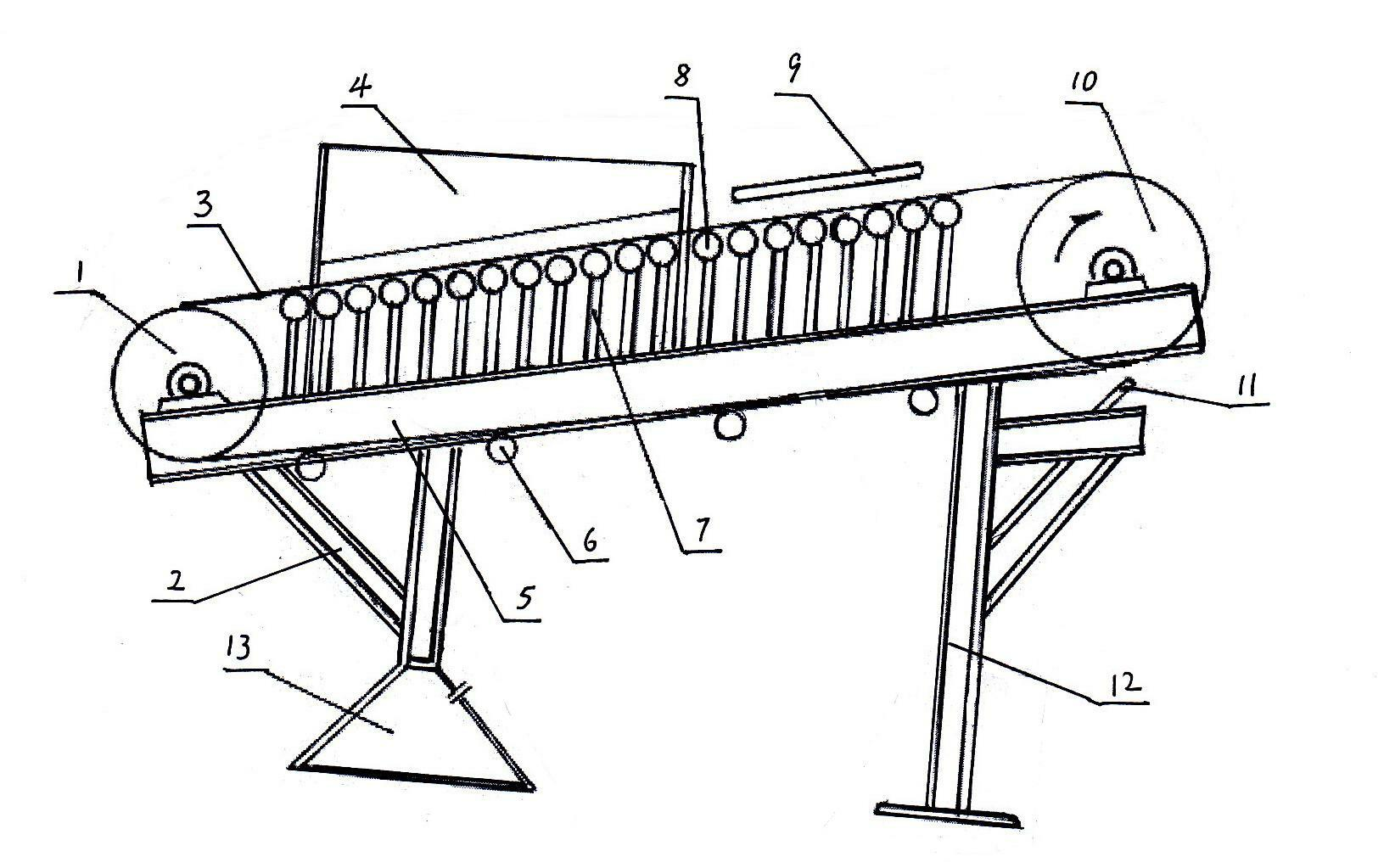

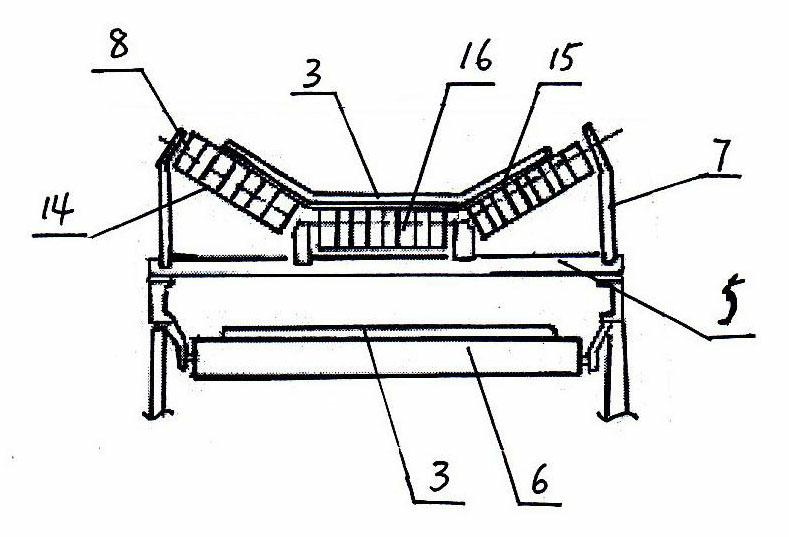

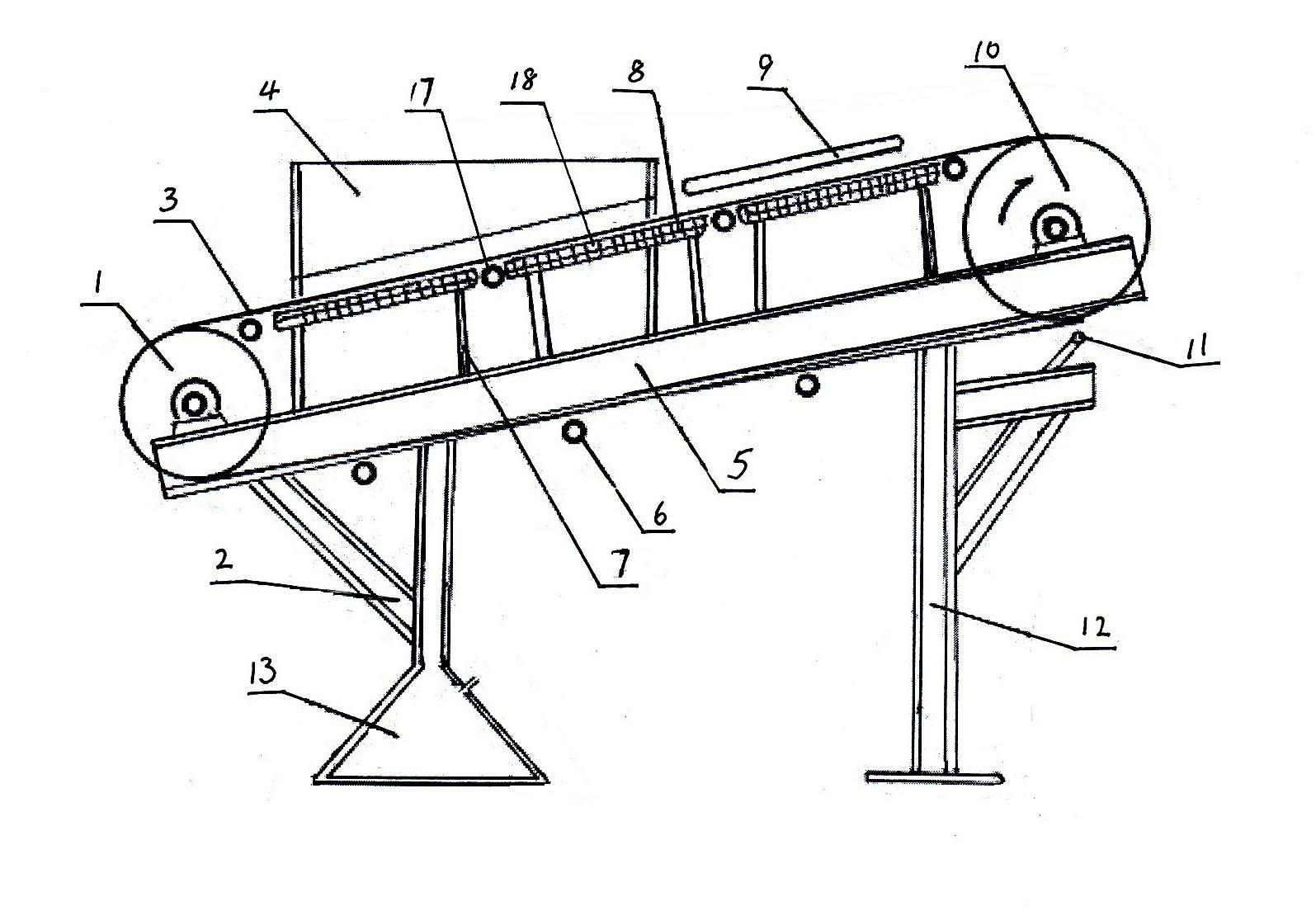

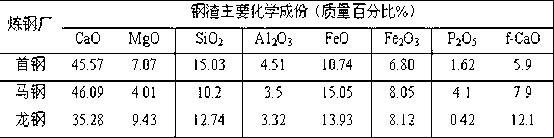

Belt type roller magnetic separator

InactiveCN102553714ALess flushingEasy to rinseMagnetic separationWet separationIron powderMagnetic separator

The invention discloses a belt type roller magnetic separator. The belt type roller magnetic separator comprises a redirecting roller, a left machine frame, a conveying belt, a rain spraying gradient slurry dispersing sieve, a belt conveying bracket, a conveying belt lower carrier roller, an upper flusher, an electric roller and a right bracket and is characterized in that: a plurality of groove-shaped high-strength magnet carrier roller devices are arranged below the conveying belt on the upper layer. The high-strength magnet carrier roller devices can magnetize patterned belts completely above the devices, and iron powder in the slurry is sucked by the magnetized patterned belts and falls into pits of the patterned belts. After the patterned belts upstream enters a non-magnetic region, all the iron concentrate powder falls into an iron concentrate powder bank and are collected, so that the magnetic separation efficiency is greatly improved. The belt type roller magnetic separator has the advantages of large conveying quantity, high collecting capacity, capacity of reducing washing of slurry on the adsorbed iron powder, high magnetic separation efficiency, high yield, high iron powder adsorption capacity, resource saving, simple structure and easiness in assembly, and is ideal equipment for extracting iron concentrate powder through iron ore magnetic separation and tailings treatment.

Owner:周国发

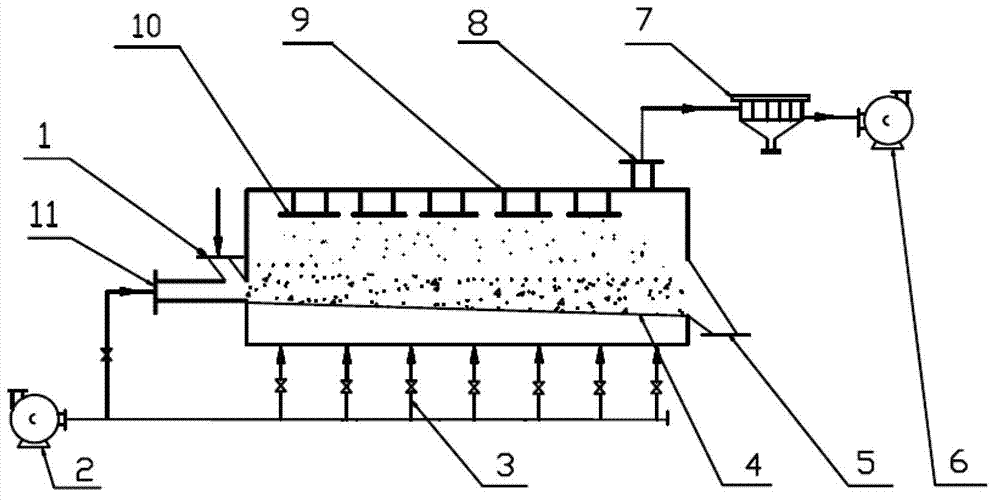

Iron removing method during process of extracting aluminum from coal gangue

ActiveCN103204552AWide application range of particle sizeLower iron levelsIron halidesMagnetic separationAluminium chlorideChloride

The invention provides an iron removing method during the process of extracting aluminum from coal gangue, and is used for solving the problems that the iron content in the coal gangue is high while the conventional magnetic separation method cannot meet the requirement of the aluminum extracting process. The method comprises the following steps of: firstly pretreating the coal gangue by using a horizontal-type fluidized magnetic separation device; calcining and activating the pretreated coal gangue; and removing residual iron by adopting an acid leaching process at a low temperature and in short time as well as under the action of an concentrated acid. After the two-step iron removing method is performed, the obtained material is leached in the acid to extract the aluminum, so that the mass ratio of Al / Fe being above 25 in a filtrate can be obtained; and thus the preparation of subsequent crystallized aluminum chloride or alumina is not influenced. According to the method, the high iron removing efficiency is achieved; the filtrate obtained by the acid soluble iron removing process can serve as a building material additive after being treated; the simple equipment is required; and the secondary pollution is avoided.

Owner:SHANXI UNIV

Construction waste sorting device and use method

InactiveCN111672567AIncrease profitImprove economySievingScreeningMagnetic separatorElectric machinery

The invention discloses a construction waste sorting device and a use method, and belongs to the technical field of construction waste sorting. The construction waste sorting device is provided with adriving motor, a crushing roller wheel and a magnetic separation mechanism below. The driving motor drives the crushing roller to carry out crushing treatment on construction waste, and the treated debris is separated and screened by the magnetic separation mechanism, so that the utilization rate and economical efficiency of garbage are improved greatly, and the screened muck can be sold at the same time.

Owner:CHINA MCC17 GRP

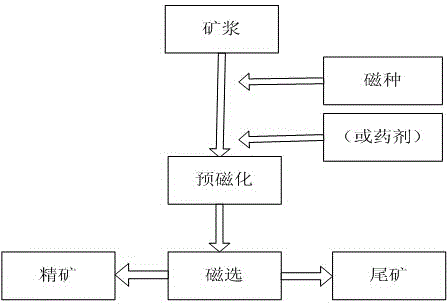

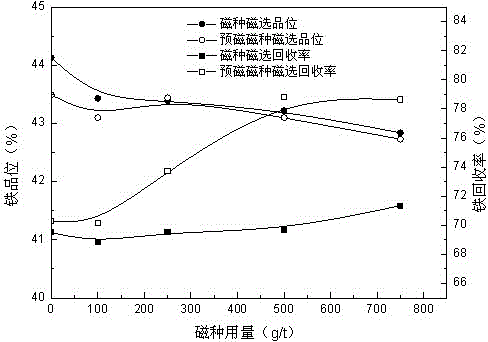

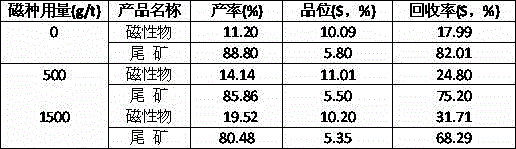

Pre-magnetization magnetic seed magnetic separation method

InactiveCN104624364AEnhanced magnetic forceReduce magnetic field strengthMagnetic separationMagnetiteMagnetization

The invention discloses a pre-magnetization magnetic seed magnetic separation method, belonging to the field of magnetic separation. The method comprises the steps of selecting fine grinded natural magnetic iron ore, reduced magnetic iron ore or synthetic magnetic ferrite or other ferromagnetic materials as the magnetic; directly adding water into to-be-magnetically-separated fine particles to form pulp, or according to ore embedding particle size, crushing ores, fine grinding with water until useful ore monomer is separated, obtaining ore pulp, finally carrying out magnetic separation in magnetic separation equipment. The magnetic seed and pre-magnetization operation are added during the magnetic separation pulping process. By magnetization of the magnetic seed to the surface of a target ore, the magnetism of the ore is enhanced; with the pre-magnetization in low magnetic field, the magnetic action force of the magnetic seed and the ore is enhanced, and therefore the magnetic separation efficiency is improved.

Owner:CENT SOUTH UNIV

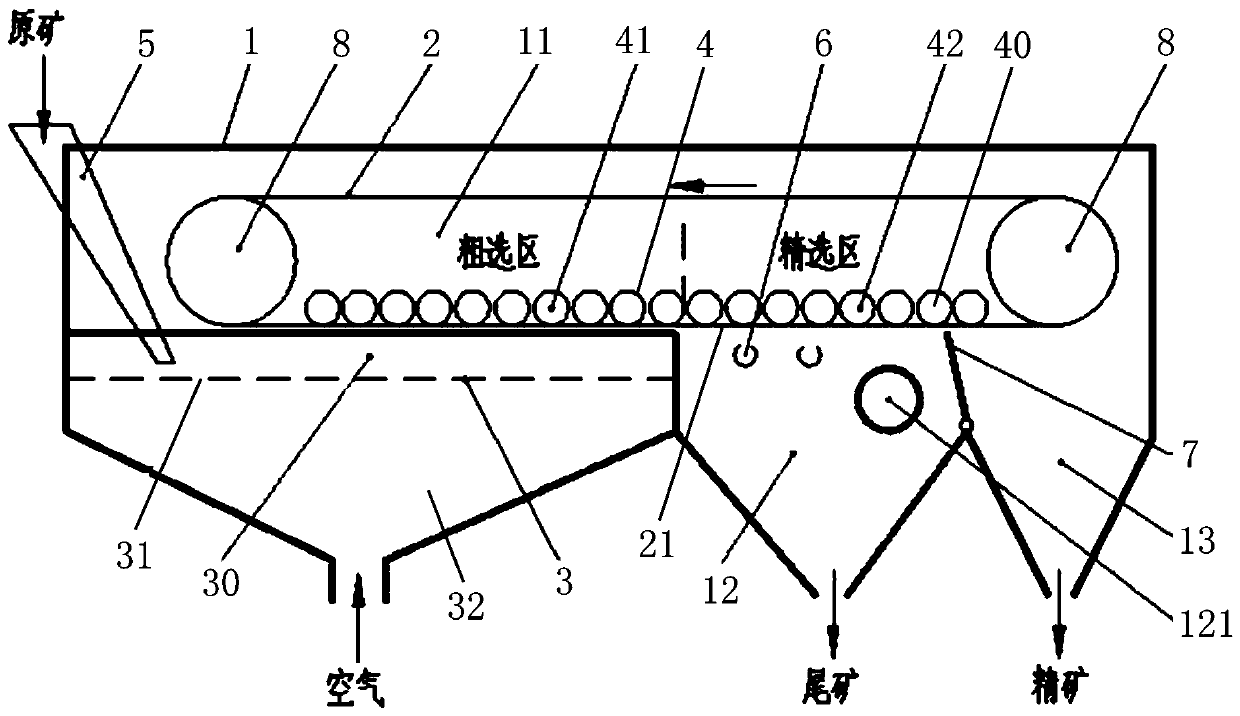

Air-suspending dispersion dry separation belt magnetic separator

PendingCN107716099AReduce self-adhesionReduce inclusionsMagnetic separationMagnetic separatorNon magnetic

An air-suspending dispersion dry separation belt magnetic separator comprises a shell with a closed inner cavity. A non-magnetic-conduction annular belt is installed in the closed inner cavity. One section on the lower portion of the non-magnetic-conduction annular belt is a magnetic separation section. A conveying tank, a non-magnetic product receiving hopper and a magnetic product receiving hopper which are located below the magnetic separation section and sequentially arranged in the operation direction of the magnetic separation section are arranged in the closed inner cavity. A conveyingpassageway for conveying materials to the non-magnetic product receiving hopper is defined by the conveying tank and the magnetic separation section. A magnetic separation magnetic system is arrangedabove the magnetic separation section and extends to the portion above the magnetic product receiving hopper from the portion above the conveying tank. A material distribution device is installed on the shell. The air-suspending dispersion dry separation belt magnetic separator further comprises an air-suspending dispersion device used for conveying the materials to the non-magnetic product receiving hopper in a dispersion and suspension state in the conveying passageway. By means of the magnetic separator, the powder dry magnetic separation efficiency, the magnetic separation effect and the product taste can be greatly improved, and the air-suspending dispersion dry separation belt magnetic separator is simple and compact in structure, stable and reliable in work, high in processing capacity and convenient to operate and control.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

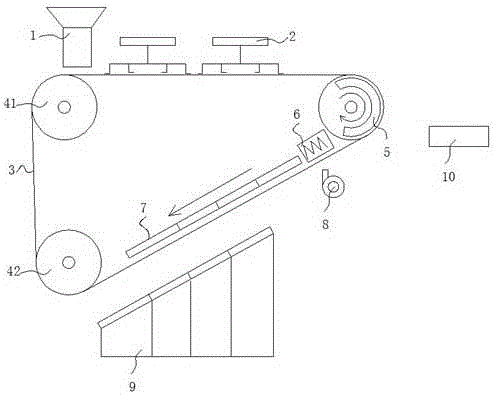

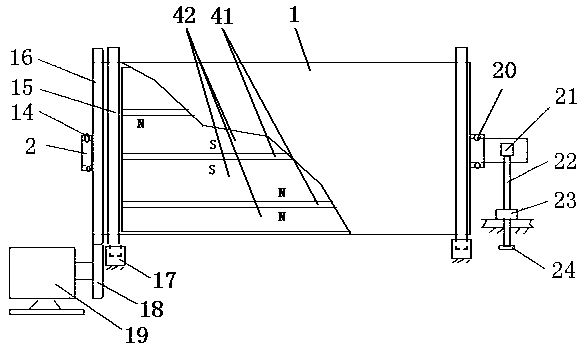

Oblique grading and magnetic separation device

ActiveCN105855040AAvoid gatheringControl thicknessMagnetic separationMagnetic tension forceEngineering

The invention relates to a magnetic separation device and particularly relates to an oblique grading and magnetic separation device. The oblique grading and magnetic separation device comprises a magnetic separation belt and wheels which support the magnetic separation to form a triangle, wherein the magnetic separation belt comprises a horizontal segment and an oblique segment, and a wheel at the intersection of the horizontal segment and the oblique segment is a magnetic roller; a separating magnetic system is arranged inside the oblique segment, a strong magnetic device is arranged between the separating magnetic system and the magnetic roller, and magnetic forces of the magnetic roller, the strong magnetic device and the separating magnetic system are continuous; and a strong fan is arranged below the strong magnetic device, the magnetic field intensity of the strong magnetic device is stronger than that of the separating magnetic system or the magnetic roller, and strong fan cannot blow magnetic minerals at the strong magnetic device down. According to the oblique grading and magnetic separation device, the problems of magnetic inclusion and magnetic packaging are solved; by virtue of the design, the magnetic separation efficiency of the device can be improved, and the grade of concentrates can be improved; and by virtue of continuous magnetic forces of the magnetic roller, the strong magnetic device and the separating magnetic system, the situation the magnetic minerals fall at the oblique segment is prevented. Compared with existing magnetic separation devices, the oblique grading and magnetic separation device has the advantages that the quantity of magnetically included and packaged dust is reduced by 20%-50%, and the grade of the concentrates is improved by 10%-15%.

Owner:山东金玺泰矿业有限公司

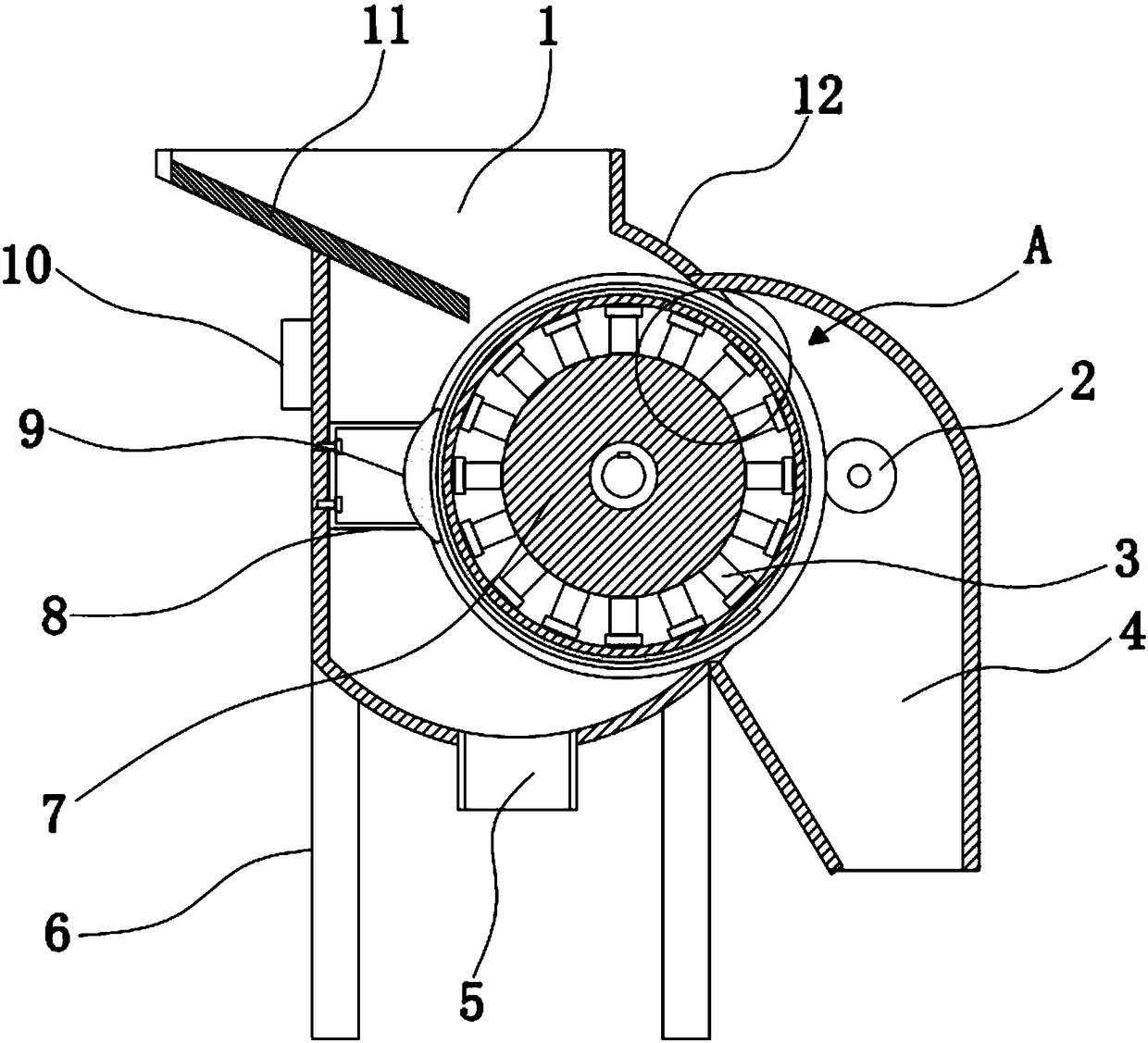

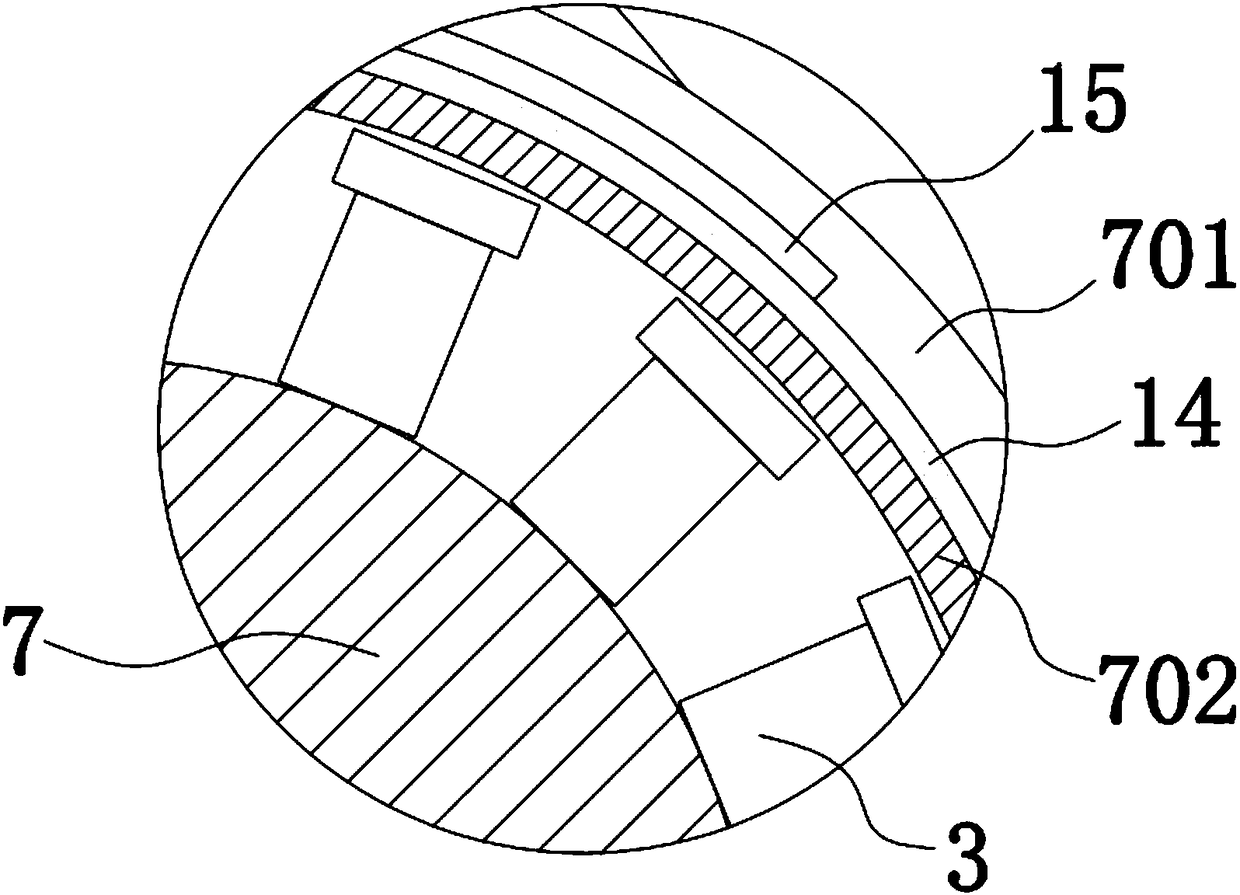

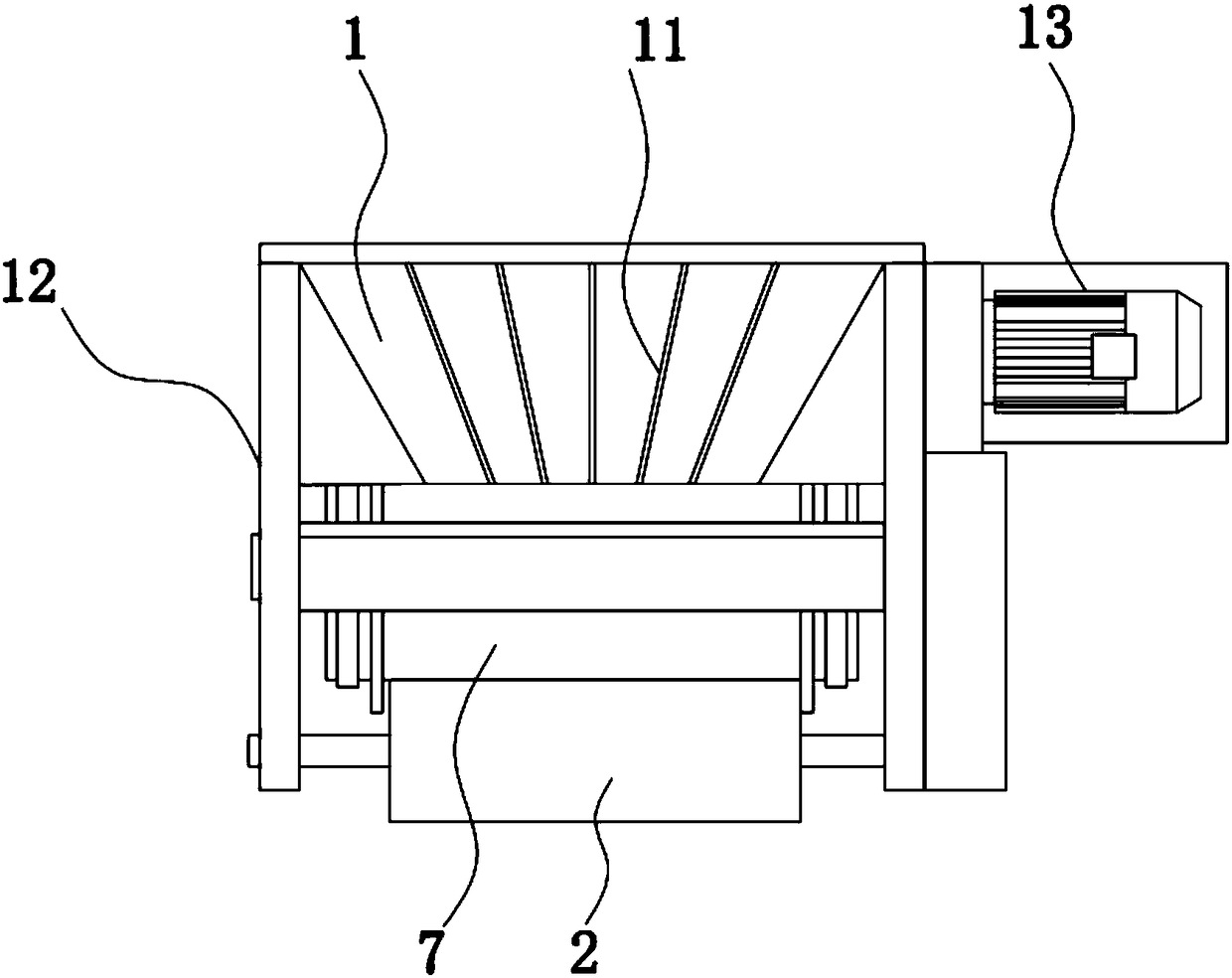

Magnetic separator convenient to feed

InactiveCN108554625AEvenly dispersedImprove magnetic separation efficiencyMagnetic separationDischarge efficiencyMagnetic separator

The invention discloses a magnetic separator convenient to feed. The magnetic separator comprises a magnetic separation roller, wherein the magnetic separation roller is installed in a machine shell,a rotating shaft of the magnetic separation roller is connected to the output end of a motor at one side of the machine shell, the machine shell is fixed on a machine frame, and a discharging brush roller is furhter installed in the machine shell; a protective layer is arranged on the outer part of the magnetic separation roller, conductive strips are fixed at both ends of the protective layer, the conductive strips are slidably connected with conductive clamps, the conductive clamps are fixed on a fixed seat, the fixed seat is fixed on the machine shell through a fixed frame, and electromagnets are fixed on the inner side of the protective layer. According to the magnetic separator, materials can be uniformly guided to the surface of the magnetic separation roller through a guide plate, magnetic separation efficiency is improved; with the rotation of the magnetic separation roller, the magnetism of the position, passing the direction of the openings of the conductive clamps, on the magnetic separation roller disappears periodically, and adsorbed concentrate falls down automatically; and with the aid of the discharge brush roller, the residual concentrate on the surface of the magnetic separation roller can be effectively cleaned and the discharge efficiency can be improved.

Owner:伍文谦

Magnetic separator

InactiveCN106238205AReduce labor intensityImprove magnetic separation efficiencyMagnetic separationMagnetic separatorEngineering

The invention provides a magnetic separator. A feeding mechanism is composed of a feeding funnel; a first magnetic separation mechanism is composed of an auxiliary roll, a magnetic roll and a first drive device; the magnetic roll is far away from the feeding funnel relative to the auxiliary roll and is in transmission connection with the auxiliary roll through a conveyor belt; the first drive device can drive the auxiliary roll or the magnetic roll to rotate; a material evening mechanism is composed of a vibration plate and a second drive device; the two ends of the vibration plate are close to the feeding funnel and the auxiliary roll respectively; the second drive device can drive the vibration plate to vibrate; a second magnetic separation mechanism is composed of a slide rail, a sliding block, a third drive device, a permanent magnet and a fourth drive device; the sliding block is installed on the slide rail in a sliding manner; the third drive device can drive the sliding block to move along the slide rail; the permanent magnet is arranged in the sliding block; and the fourth drive device can drive the permanent magnet to move up and down. The magnetic separator provided by the invention is environmentally friendly and is low in labor intensity, high in magnetic separation efficiency and good in separation effect; and scrap iron obtained by magnetic separation can be directly recycled and utilized.

Owner:宿州市威菱耐火材料有限责任公司

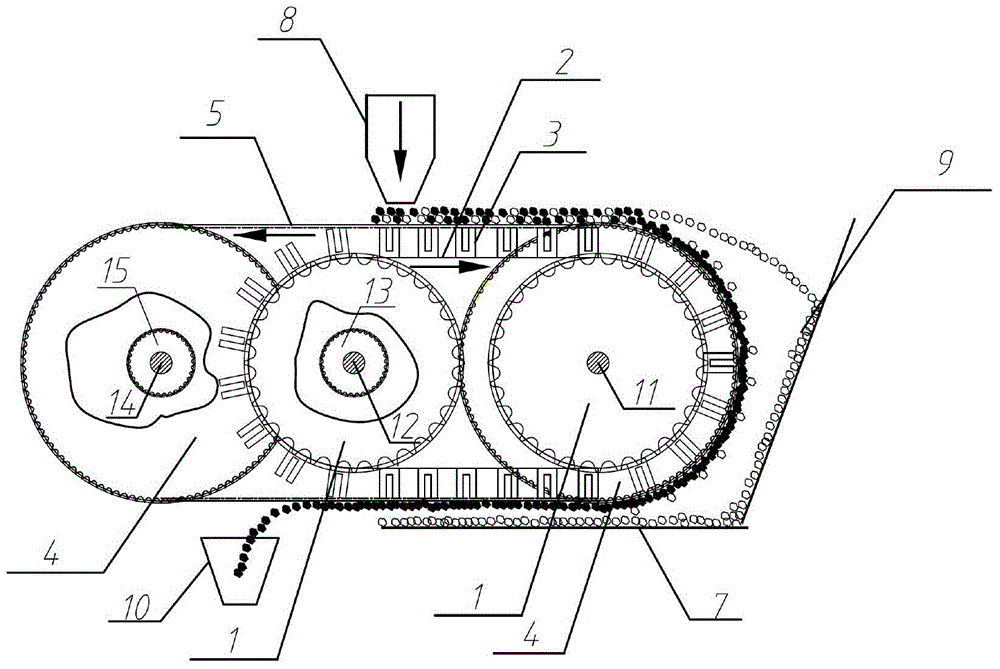

Dry type fine powder magnetic separator with annular mobile magnetic system

A dry type fine powder magnetic separator with an annular mobile magnetic system comprises a magnetic separation main working portion, a magnetic separation auxiliary working portion and a mechanical motion transmission portion, wherein the magnetic separation main working portion comprises the annular motion magnetic system, an annular motion magnetic separation belt which is arranged outside the magnetic system in a sleeving manner and is opposite to the magnetic system in motion direction, and a tailing discharging belt located below the annular motion magnetic separation belt. The magnetic separation auxiliary working portion comprises a discharging hopper arranged above the annular motion magnetic separation belt, a non-magnetic material blocking plate which receives materials thrown by the rotating portion of the annular magnetic, and a magnetic material collecting groove. The annular moving magnetic system and the tailing discharging belt are arranged in a crossing manner, and moving magnets arranged at intervals drag powder on the belt surface to move in a rolling manner, so that the effects of enrichment, tailing discarding and fine separation (scavenging) of the materials which are magnetically classified are sequentially achieved; the separation work area is large, and the unit yield is high; and a plurality of magnetic separators can be arranged on the tailing discharging belt in parallel, and the separation production scale and efficiency are improved.

Owner:北京中科领向环保研究院有限公司

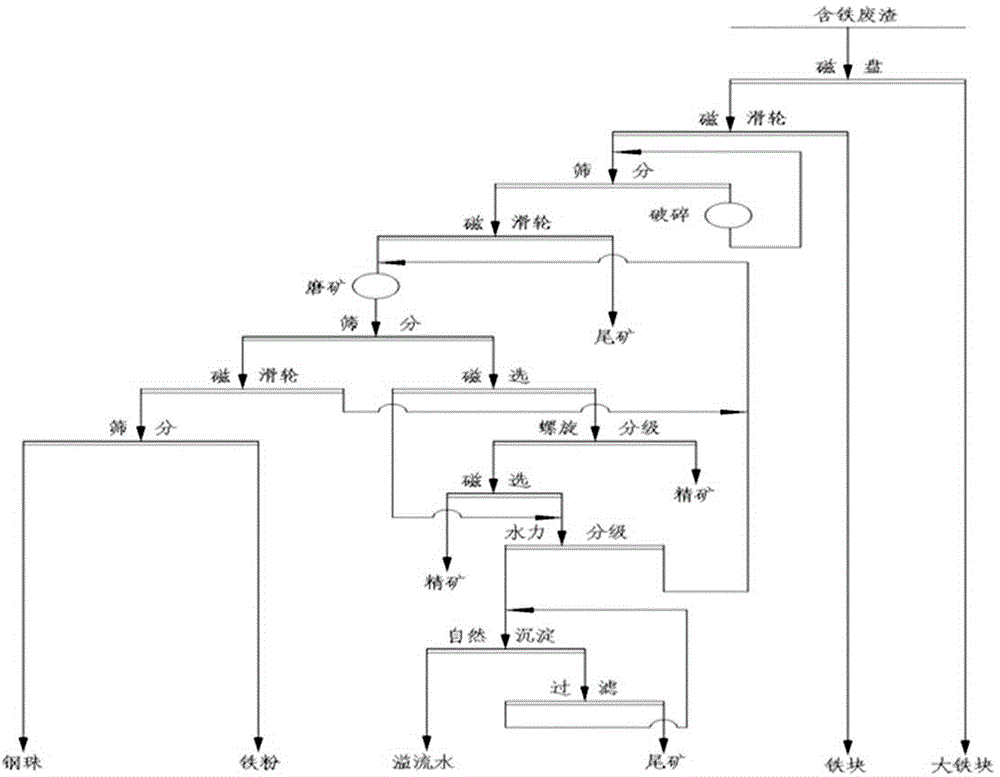

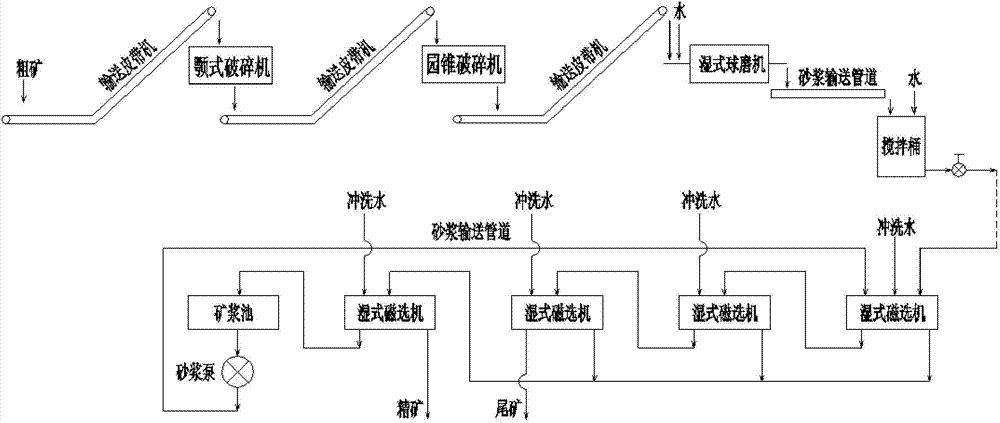

Wet magnetic separation process for recycling iron in iron-containing waste

The invention discloses a wet magnetic separation process for recycling iron in iron-containing waste. The wet magnetic separation process comprises the followings steps: magnetic disc magnetic separation, magnetic pulley magnetic separation, screening and grinding, magnetic pulley magnetic separation, ball-milling and screening, magnetic separation and screening, magnetic separation, helical classification, hydraulic classification, natural precipitation and filtering. Desulfurized slag and cast residue produced in steelmaking procedure or sow iron and slag iron produced in the ironmaking process are taken as raw materials, the total iron grade of the separated iron ore can achieve 90% and more, the total iron grade of washed iron shot and iron powder can achieve 60% and more, the total iron grade of the magnetically separated concentrate can achieve 55% and more, the total iron grade of the magnetic separation powder can achieve 40-50%, the total iron grade of tailings powder can achieve 15-20%, and the metal iron content is 0.5-0.8%, the tailings powder can be used as grinding raw material of cement admixture or concrete additive. The wet magnetic separation process is simple, the hydroelectric resource consumption is slow and the magnetic separation efficiency is high, and high economic benefit and environment benefit are realized.

Owner:WUKUN STEEL +1

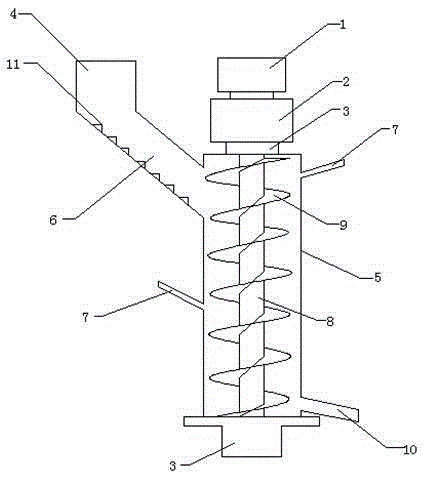

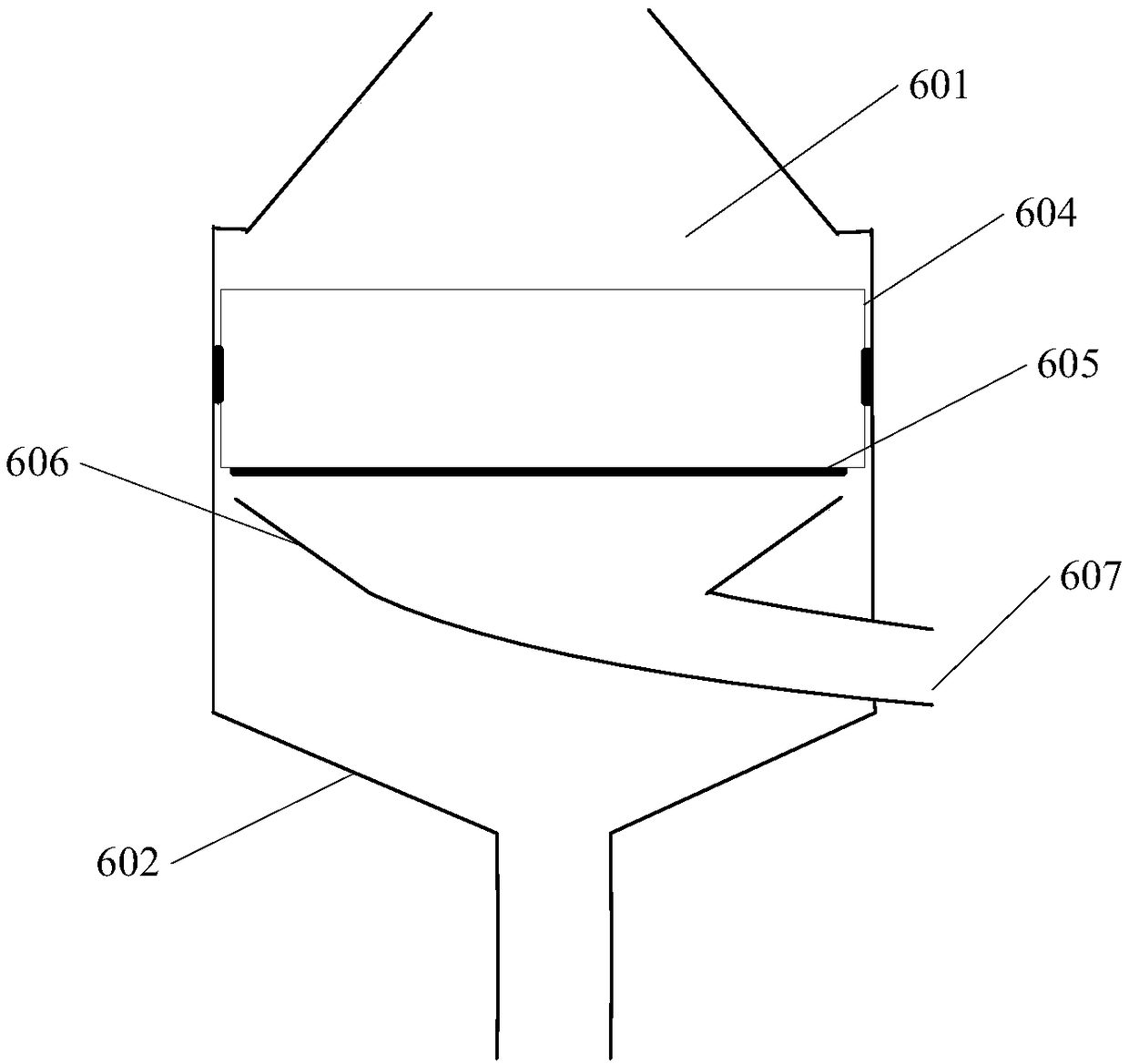

Spiral magnetic separator

InactiveCN105327774ACompact structureSmall footprintMagnetic separationMagnetic separatorSmall footprint

The invention discloses a spiral magnetic separator. The spiral magnetic separator comprises a machine base, a feed inlet, a mineral separation cavity and a tailing outlet pipe. The top end of the mineral separation cavity is connected with the machine base. The feed inlet is formed in one side of the upper portion of the mineral separation cavity. A flushing device is arranged on the other side of the upper portion of the mineral separation cavity. A flushing device is arranged on one side of the middle lower portion of the mineral separation cavity. The tailing outlet pipe is arranged on one side of the lower portion of the mineral separation cavity. The lower end of the mineral separation cavity is connected to the machine base. A rotary shaft is arranged inside the mineral separation cavity. The upper end of the rotary shaft is fixedly connected to a bearing seat of the machine base. A U-shaped groove is wound on the rotary shaft. The spiral magnetic separator is simple and compact in structure and small in occupied area; the problems that when an existing magnetic separator is used for separating certain weakly-magnetic mineral grains, the recovery rate is low, and the concentrate grade is low are mainly solved; the mineral separation efficiency is improved; the problem that a non-magnetic part of the magnetic separator is magnetized is also solved; the adaptive capacity of the magnetic separator is improved, and the corrosion resistance of the magnetic separator is also improved.

Owner:谢福星

Magnetic separation equipment used in process of recycling copper and nickel salt from waste ABS electroplated parts

InactiveCN110898988AEfficient screeningImprove magnetic separation efficiencyMagnetic separationNickel saltCopper

The invention belongs to the technical field of waste electroplated part magnetic separation, and specifically relates to magnetic separation equipment used in the process of recycling copper and nickel salt from waste ABS electroplated parts. The magnetic separation equipment comprises a magnetic drum. A feeding bin is arranged above the magnetic separation cylinder. A feeding motor is fixed to the upper surface of the feeding bin, a material guiding pipe inserted into the magnetic separation barrel is arranged at the lower end of the feeding bin, an output shaft of the feeding motor extendsinto the lower end of the feeding bin to be connected with a rotating rod, a spiral blade penetrating through the material guiding pipe is arranged on the rotating rod, and a circular material throwing plate is connected to the lower end of the rotating rod. According to the magnetic separation equipment, ABS crushed materials are subjected to primary magnetic separation through centrifugal force,the crushed materials are divided into three types, then ABS inclusions are subjected to magnetic separation through secondary magnetic separation, the magnetic separation efficiency is high, and themagnetic separation effect is excellent.

Owner:怀化恒安石化有限公司

Linkage type magnetic separation device for rare earth permanent magnet material

InactiveCN110976018ASmall unit volumeEasy magnetic separation workMagnetic separationGrain treatmentsGear wheelEngineering

The invention relates to the technical field of magnetic separation equipment for rare earth permanent magnet materials, in particular to a linkage type magnetic separation device for a rare earth permanent magnet material. A servo motor is adopted for driving a rotary table to rotate, a first rod rotates along with the rotary table to drive a second rod to move up and down, and a first rack movesrelative to a first gear and drives the first gear to rotate, so that a first rotary shaft rotates to serve as power input of a smashing assembly to smash materials fed from the top. In addition, intermittent cooperation of the gear and a second rack is not completed while rotation of the rotary table, deformation of a spring is matched to drive a moving block to move left and right, a connectingrod is moved up and down through the action of an S-shaped hole and a sliding shaft, so that the left part of a magnetic separation box ascends and descends, and finally, the magnetic separation boxshakes to make materials shake and make full contact with an electromagnetic chuck, and therefore, the magnetic separation effect is guaranteed, and the magnetic separation efficiency is improved.

Owner:安徽延创通讯科技有限公司

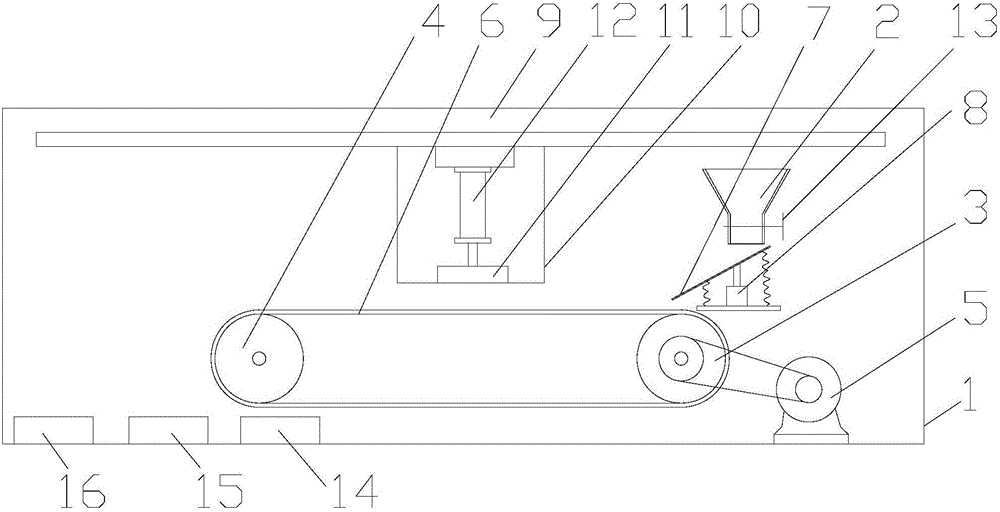

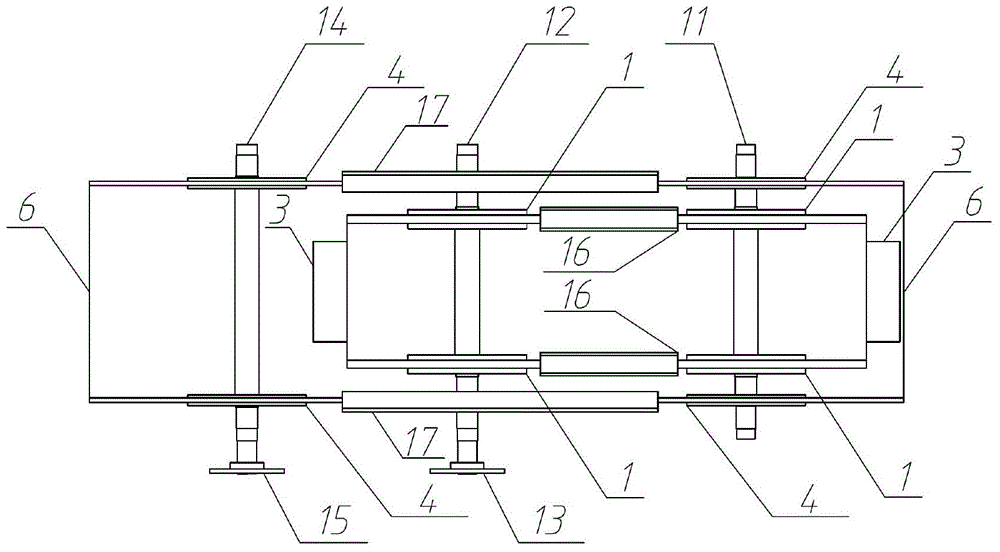

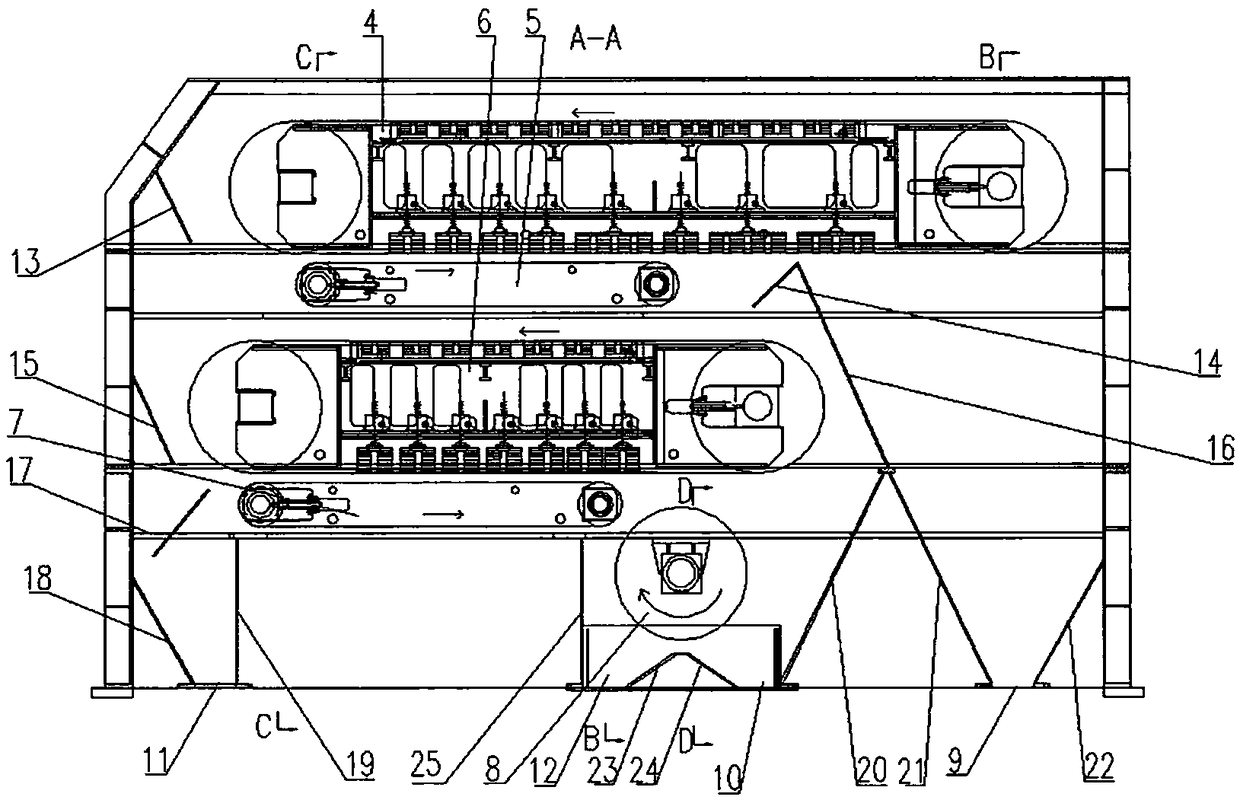

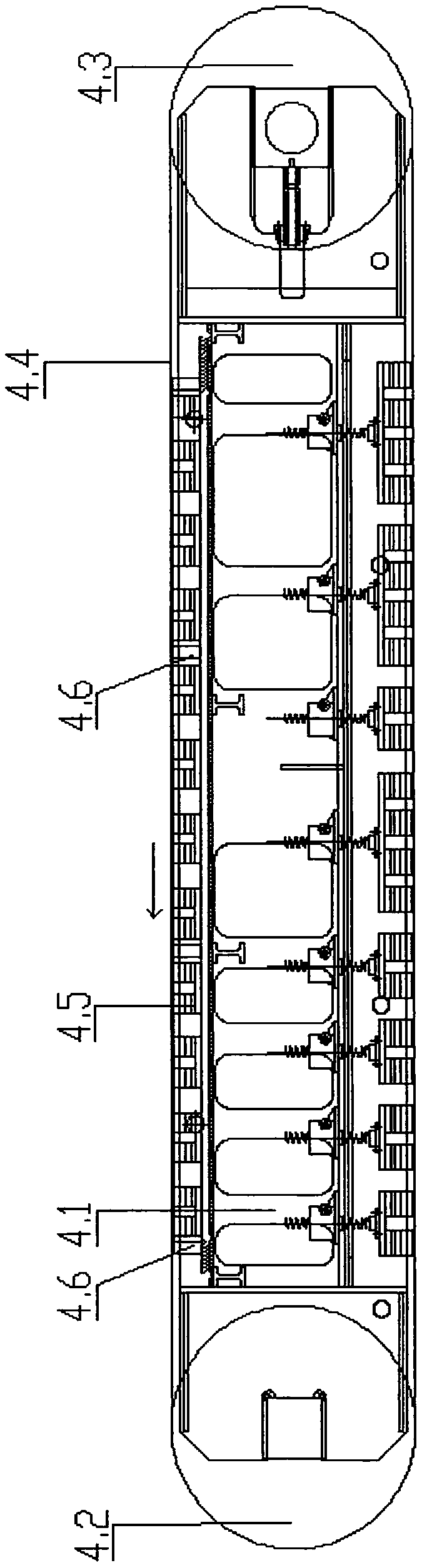

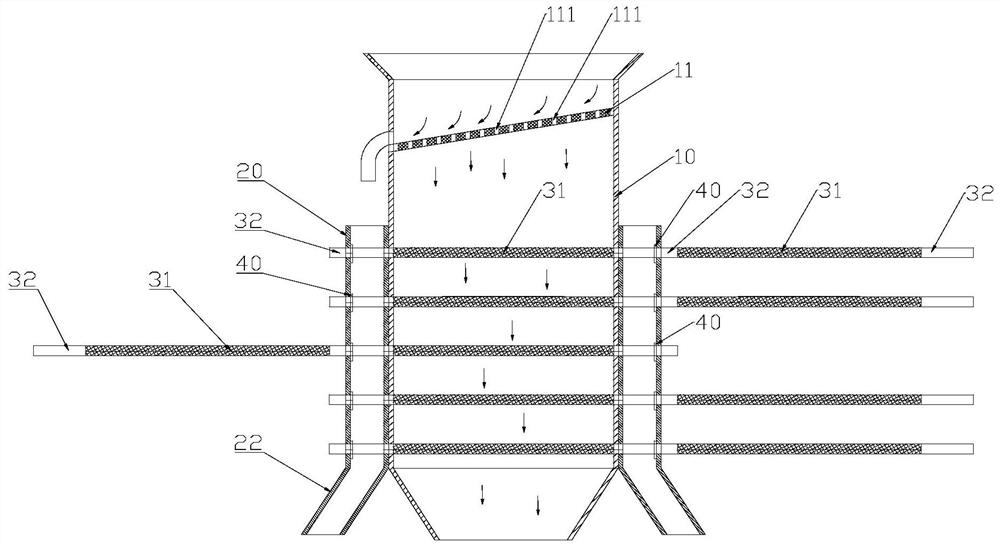

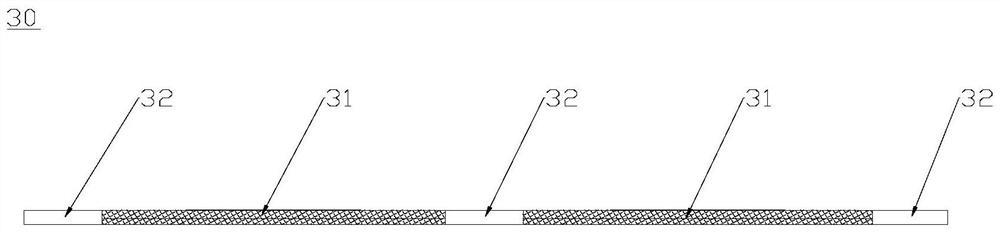

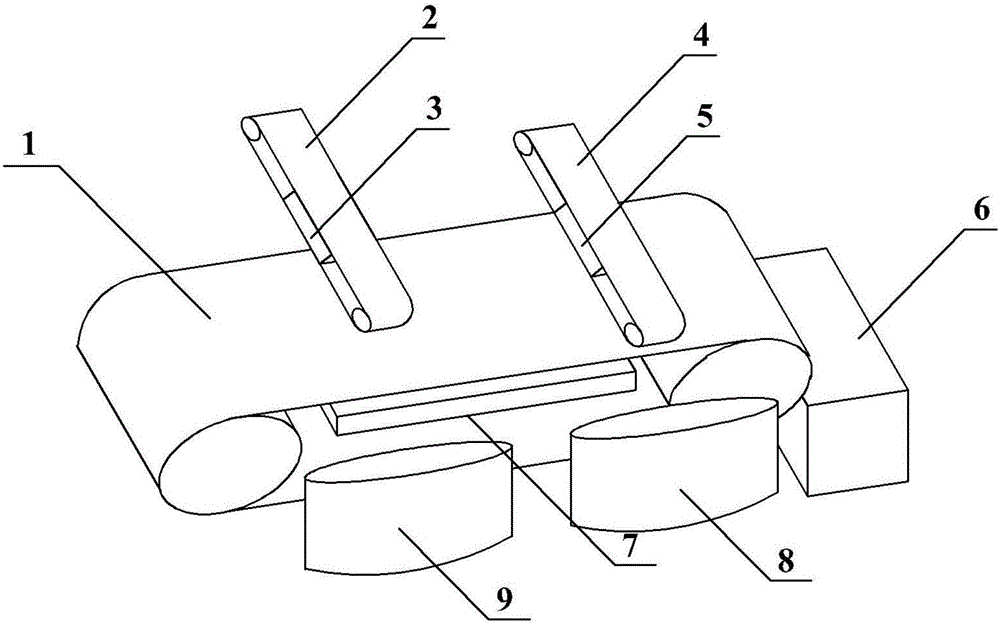

Multi-stage dry magnetic separator

PendingCN108787161AImprove magnetic separation efficiencyMeet magnetic separation requirementsConveyorsHigh gradient magnetic separatorsMagnetic separatorEngineering

The invention relates to a multi-stage dry magnetic separator which is characterized by comprising four layers of conveying mechanisms sequentially arranged from top to bottom, wherein from top to bottom, the four layers of conveying mechanisms sequentially comprise a first-stage magnetic separation main conveyor (4) at the first layer, a first-stage auxiliary conveyor (5) at the second layer, a second-stage magnetic separation main conveyor (6) at the third layer and a second-stage auxiliary conveyor (7) at the fourth layer. The multi-stage dry magnetic separator can pick out concentrate withhigher iron content, middlings with medium iron content and tailings with lower iron content; the concentrate is picked out from the right section of the bottom of the multi-stage dry magnetic separator; a concentrate discharging hole (9) is formed in the right section of a corresponding lower frame (3); the middlings are picked out from the middle section of the bottom of the multi-stage dry magnetic separator; and a middlings discharging hole (10) is formed in the middle section of the corresponding lower frame (3). The multi-stage dry magnetic separator has the advantages of being high inmagnetic separation efficiency, adaptability and using stability and convenient to maintain.

Owner:江阴市尚时环境工程有限公司

Magnetic separator

ActiveCN110893378AThe stripping process is thoroughIncrease the magnetic separation rateMagnetic separationMagnetic separatorEngineering

The invention discloses a magnetic separator, and relates to the field of copper rod production and processing. The magnetic separator comprises a base and a support frame. A material box is slidablyconnected to the supporting frame. A reset spring is arranged between the base and the material box; a switch part for controlling the discharge of the material box is arranged at the discharge end ofthe material box; the base is provided with a supporting base located below the discharging end of the material box, the supporting base is rotationally connected with an electromagnetic roller, thebase is provided with a scrap iron box and a copper material box which are located below the electromagnetic roller, the base is provided with a disconnecting link for controlling opening and closingof the switch part and on-off of the electromagnetic roller, and the material box is provided with a driving part for driving the disconnecting link to be opened and closed. The magnetic material stripping device has the following advantages and effects that the electromagnetic roller is arranged to replace a traditional permanent magnet roller, so that the magnetic material stripping process is more thorough; and the copper powder is screened through a full-automatic magnetic separator, and an electromagnetic roller for automatic power-off stripping is arranged, so that the magnetic separation rate of the copper powder is greatly increased, and the effects of improving the magnetic separation effect and the magnetic separation efficiency are further achieved.

Owner:台州鑫宇铜业股份有限公司

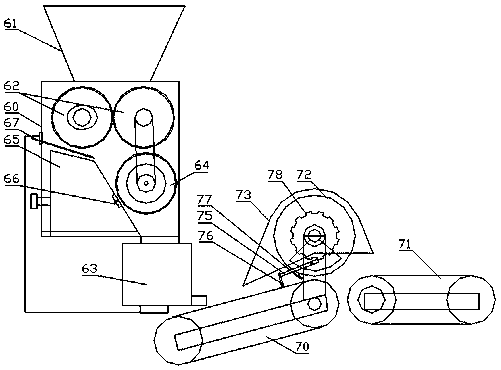

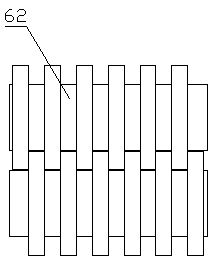

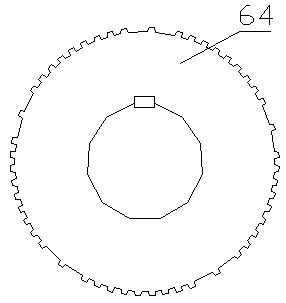

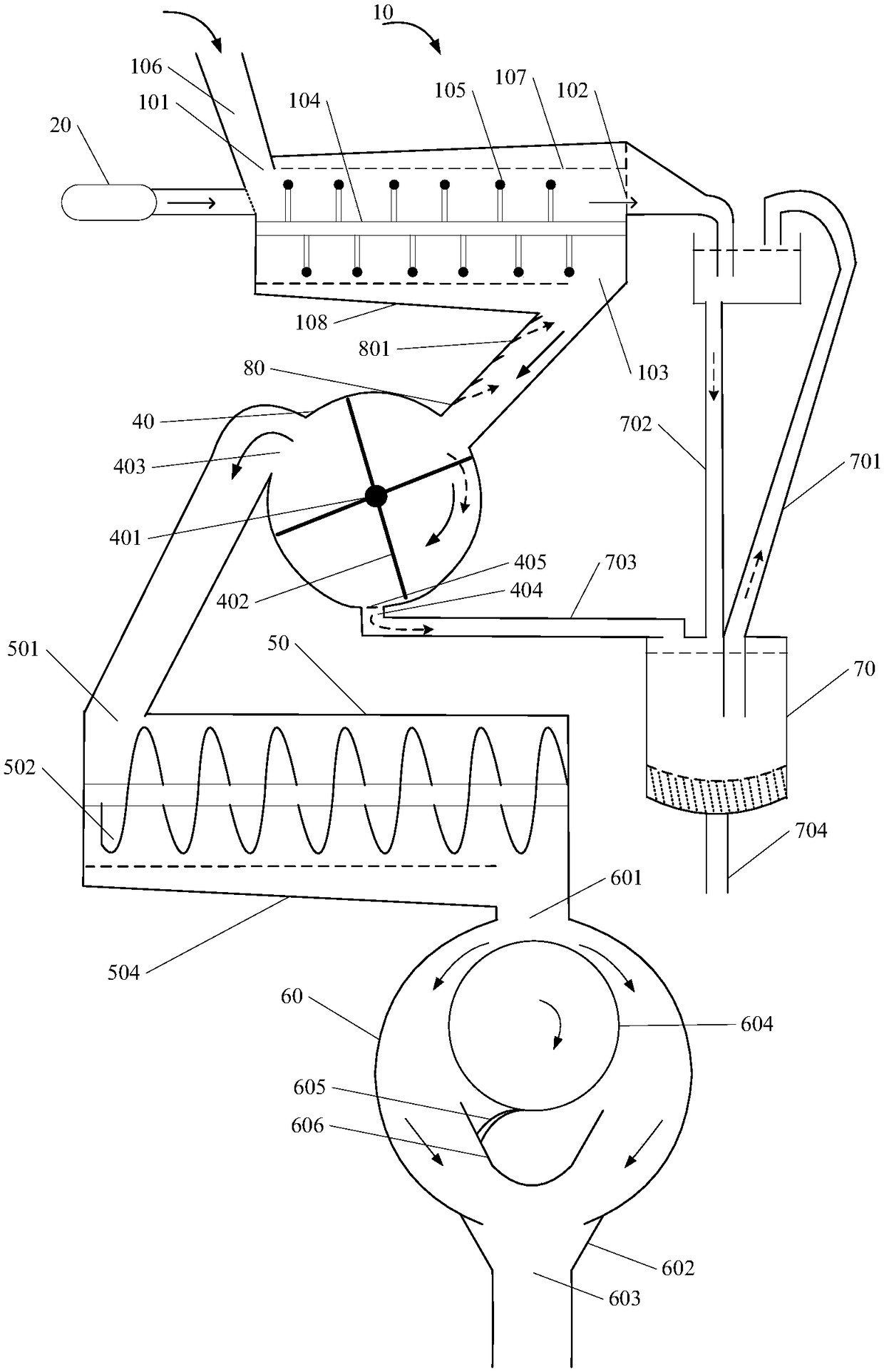

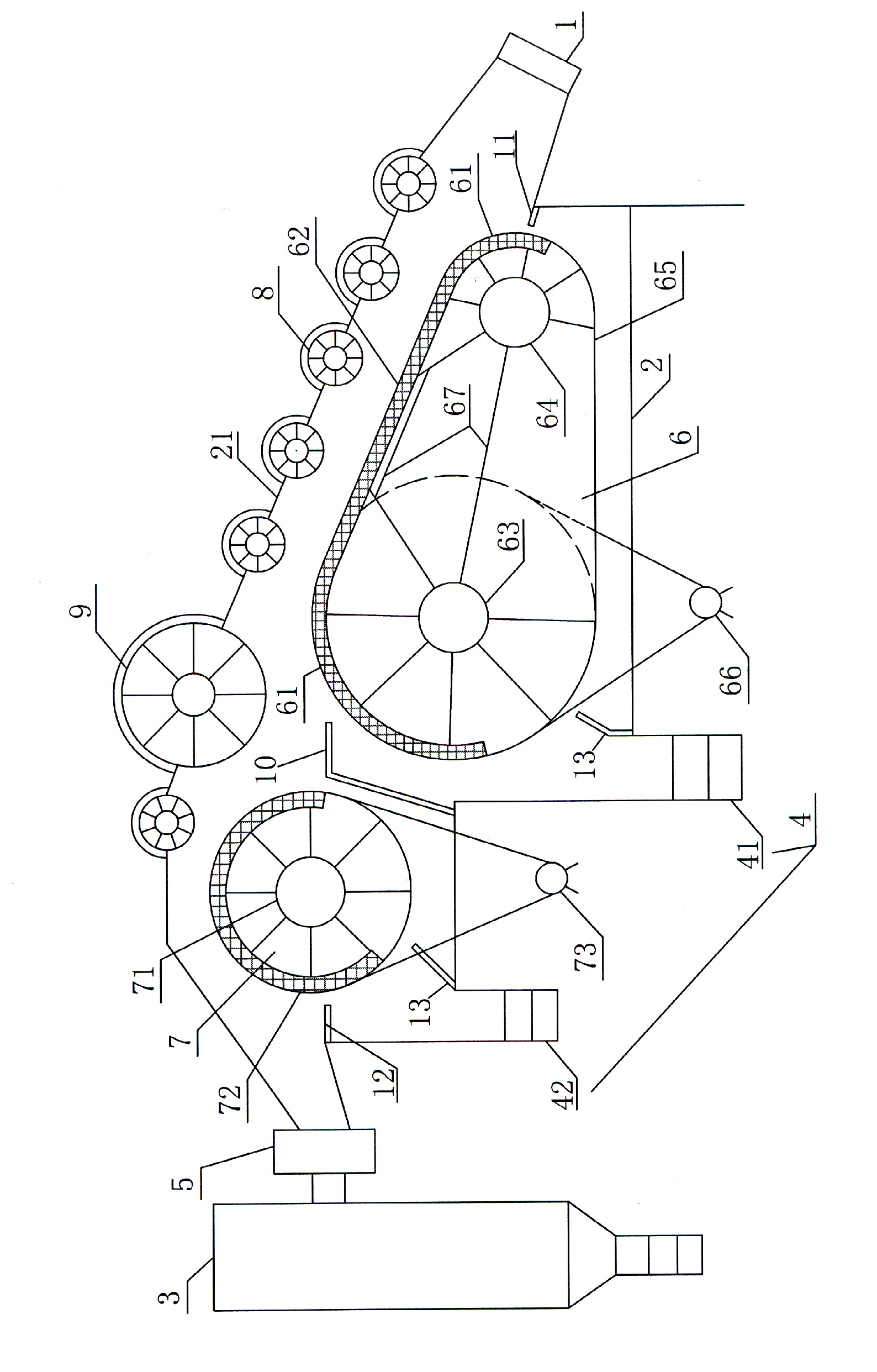

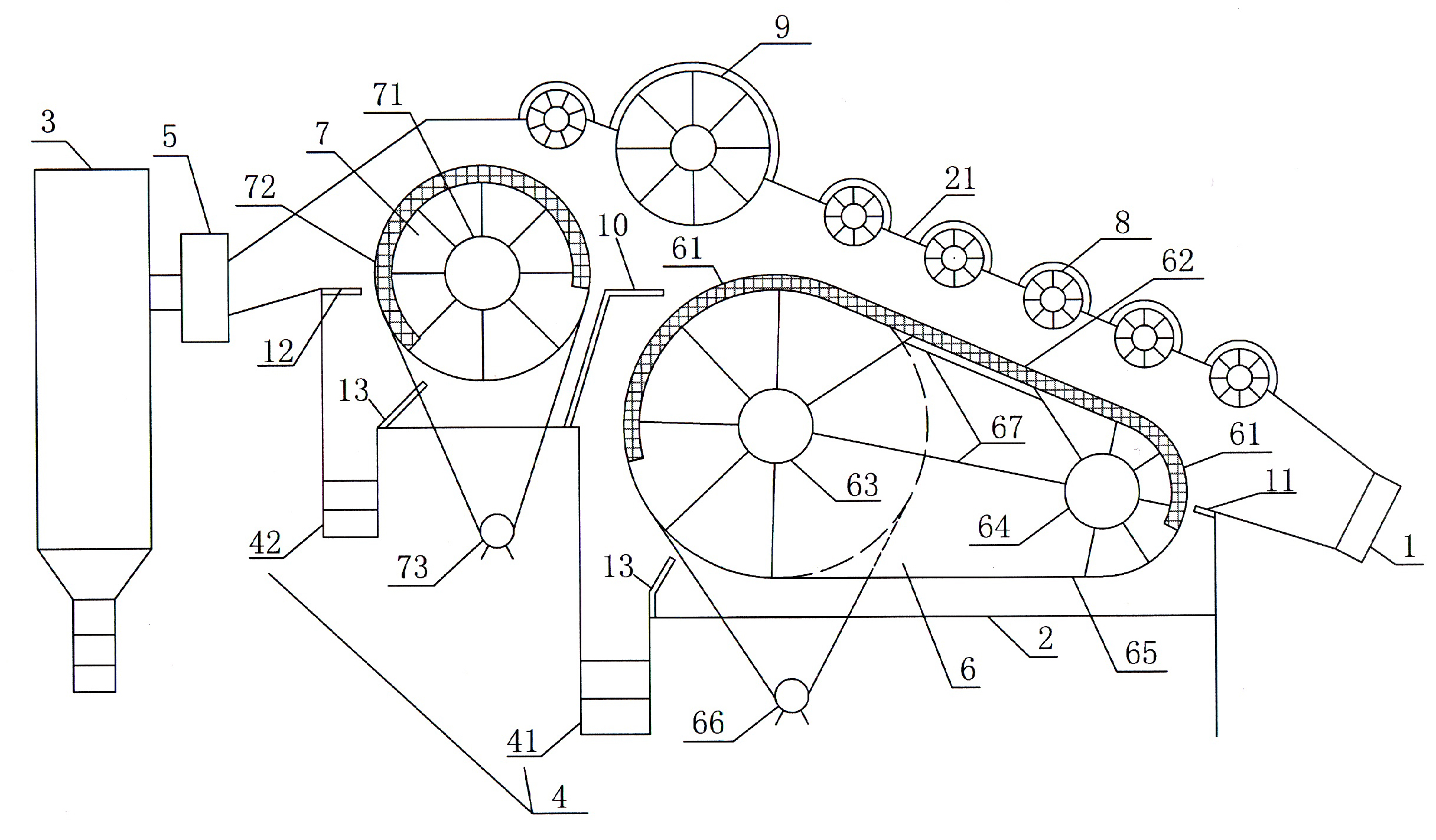

Reclaimed tire grinding and sorting system

InactiveCN110919917AQuick smashImprove magnetic separation efficiencyPlastic recyclingMechanical material recoveryMagnetic separatorBelt conveyor

The invention discloses a reclaimed tire grinding and sorting system. The system comprises a rubber block crusher and a magnetic separator. The rubber block crusher comprises a machine body (60), a primary crushing device, a secondary crushing device and a vibrating screen (63). The magnetic separator comprises a rubber powder belt conveyor (70), a metal filing belt conveyor (71), a magnetic separation roll (72), a cover body (73) and a rubber powder tiling device. The system has advantages that a tire rubber block can be quickly crushed after being sheared by the primary crushing device and ground by the secondary crushing device in sequence so that crushing efficiency and a tire recycling rate are improved; and the rubber powder on the rubber powder belt conveyor is flattened through a material uniformizing plate, secondary magnetic separation is performed on the rubber powder by a magnetic roller on the metal filing belt conveyor when the rubber powder falls down from a dischargingend of the rubber powder belt conveyor, and magnetic separation efficiency of the magnetic separation roll is improved.

Owner:湖北耐特胶业有限公司

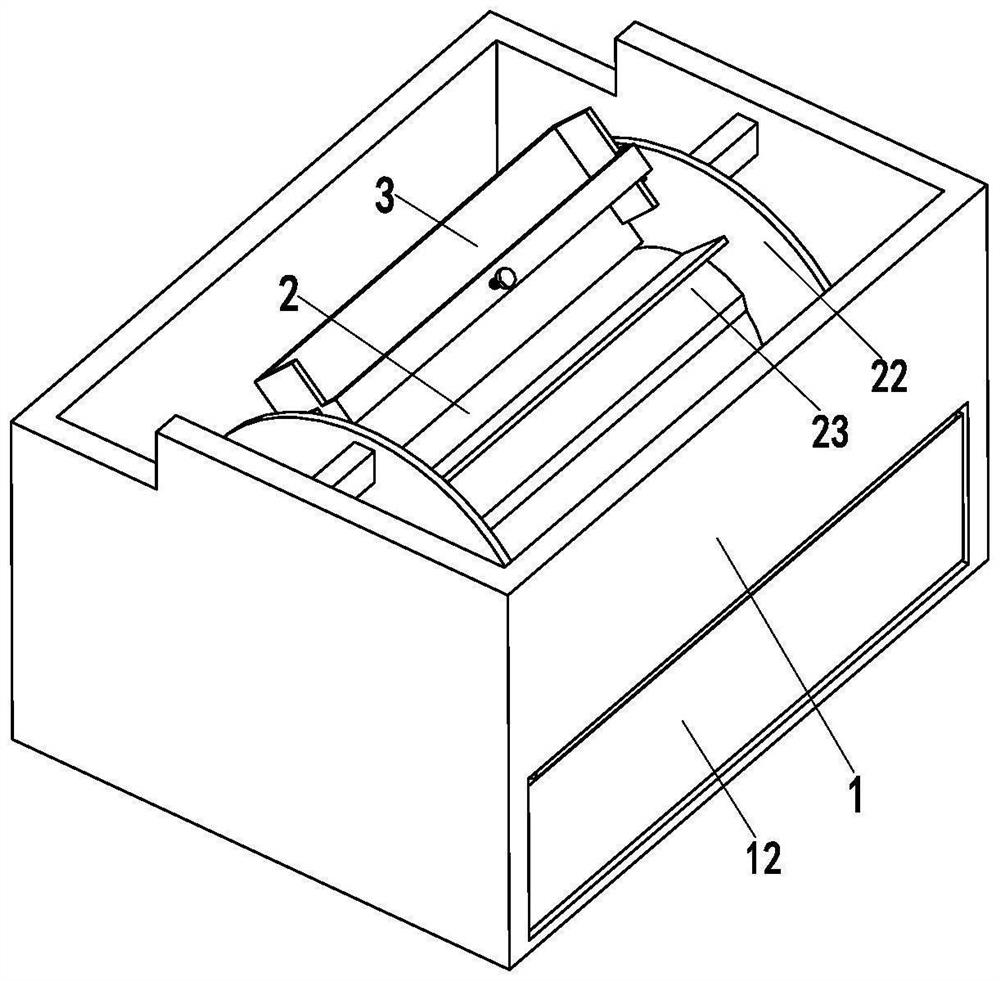

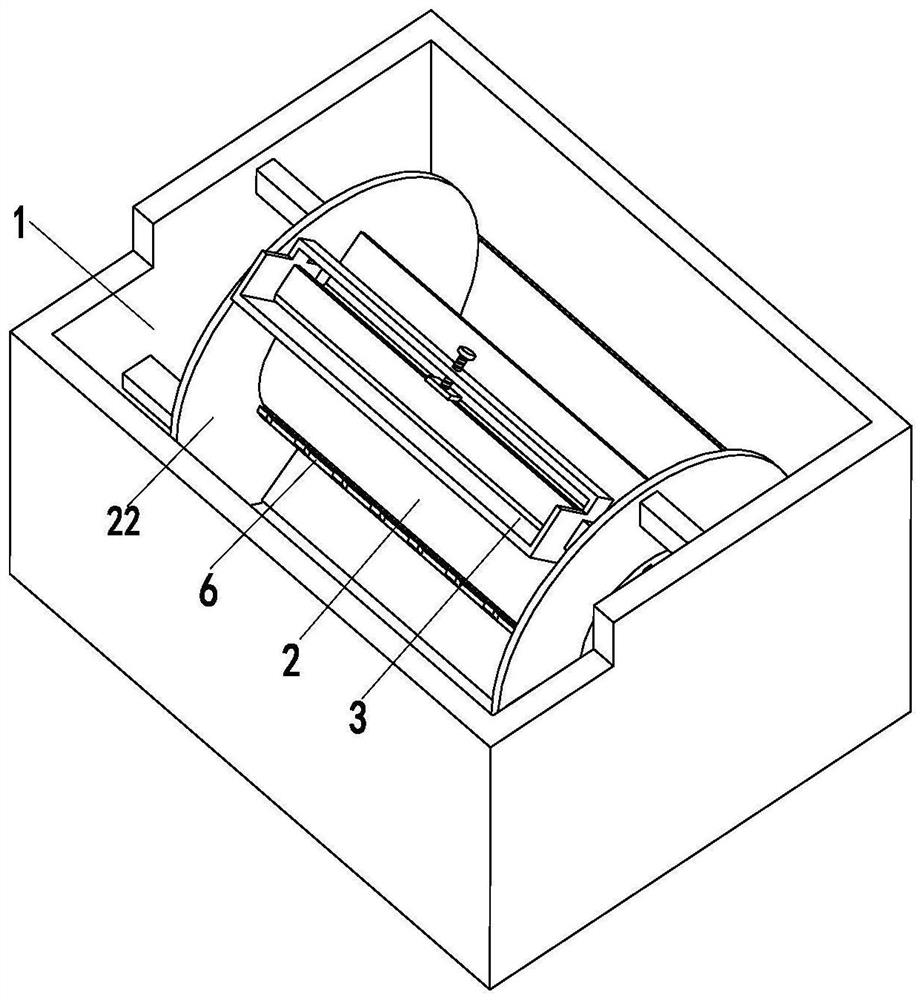

Multi-stage crushing and dust-removing toner cartridge recycling and processing system

ActiveCN109226199APromote recoveryAvoid it happening againSolid waste disposalPlastic recyclingWater circulationEngineering

The invention discloses a multi-stage crushing and dust-removing toner cartridge recycling and processing system, which comprises a sequentially connected mashing bin, which comprises an inner cylinder body and an outer cylinder body that are mutually sleeved, the inner cylinder body is horizontally arranged, and the cross section of the inner cylinder body is round, and the outer cylinder body iselliptical; an air blower that has an air outlet end connected to the end surface of one end of the crushing bin; a waste powder recycling bin; a water washing bin in which a shaft II is one or morestirring net and one or more pair of brush strips are disposed; a crushing bin in which a spiral breaking knife is horizontally extended; a magnetic sorting bin in which a magnetic selecting roller, acollecting bucket I and a collecting bucket II are arranged; and a water circulation barrel. The multi-stage crushing and dust-removing toner cartridge recycling processing system provided by the invention can be separated and effectively recovered by the steps of hammer crushing, dry dust collecting, and dust collecting with water washing, cutting and pulverizing and magnetic separation and thelike, The toner cartridge and the dust in the toner cartridge can be quickly separated and effectively recovered to avoid flying dust and protect the environment.

Owner:北海市天硌打印耗材有限公司

Method for preparing and processing high-purity quartz

ActiveCN114210438AAvoid dischargeImprove magnetic separation efficiencyMagnetic separationGrain treatmentsPhysical chemistryRotation control

The invention relates to the field of quartz processing, in particular to a high-purity quartz preparation processing method which comprises the following specific steps: S1, ore processing treatment; s2, ore magnetic separation; s3, purification treatment; s4, quartz forming; a magnetic separation screening machine in the high-purity quartz preparation and processing method comprises a magnetic separation frame, a magnetic separation roller, a discharging frame, an inner supporting rod and a rotation control assembly. The magnetic separation device can solve the problems that when existing ore particles are subjected to magnetic separation, particles obtained after ore is crushed are in irregular shapes, so that when iron impurities in the ore are subjected to magnetic separation, the iron impurities are adsorbed on a magnetic separation roller, non-iron impurities can be clamped between the iron impurities, the ore is mixed in the iron impurities, and the magnetic separation effect is poor. And when more iron impurities exist in the ore, the impurities can be accumulated on the magnetic separation roller, so that normal falling of ore particles is influenced, and the like.

Owner:中国建筑材料工业地质勘查中心四川总队

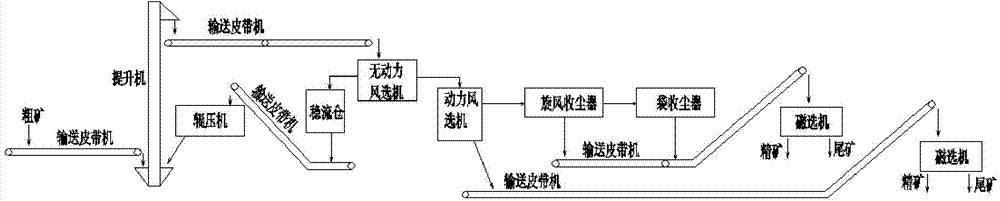

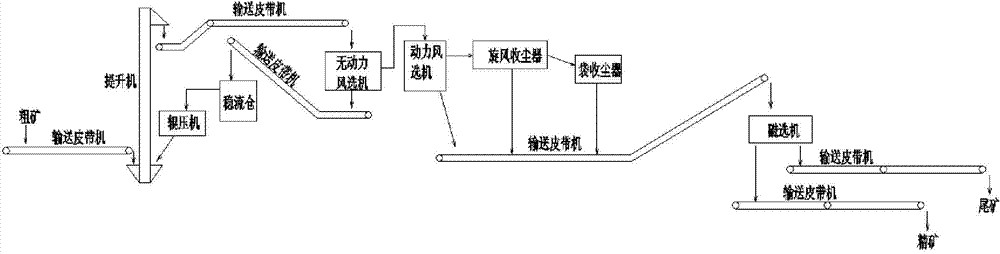

Separation system

InactiveCN104772212AImprove efficiencySpeed up the flowGas current separationMagnetic separationWater useWater resources

The invention provides a separation system, which comprises a roller press, a flow stabilizing bin, a wind grading system, a powered screening system and dry type magnetic separation systems, and the separation system is characterized in that the separation system is arranged longitudinally. Occupied floor area is saved by the separation system, a belt conveyer does not need to be used for conveying when material flows, and thereby enormous cost and energy consumption are reduced; moreover, because water is not needed in the process of separation, water resource is saved, and the separation system can be applied to places short of water resource.

Owner:胡沿东 +2

Air-suction type permanent magnet ore concentrating machine

ActiveCN102631986ASave waterImprove magnetic separation efficiencyMagnetic separationMagnetic separatorOre concentrate

The invention discloses an air-suction type permanent magnet ore concentrating machine comprising a material inlet, a dry magnetic separator, a tailings bin and a material bin, wherein the inner top wall of the cavity of the dry magnetic separator is arranged slantly and an air suction device is arranged at the outlet end of the dry magnetic separator; and a first magnetic roller set and a second magnetic roller set are sequentially arranged along the material inlet direction inside the cavity of the dry magnetic separator. The air-suction type permanent magnet ore concentrating machine increases the flowing accuracy of powder and enhances the precision of magnetic separation by the improvement on an air suction mode, a disturbance device, the magnetic separator and the like.

Owner:嘉善创越知识产权服务有限公司

Device for removing metal elements in regenerated plastic bottle flakes

InactiveCN112844830AImprove magnetic separation efficiencyMagnetic separationPolymer sciencePolymer chemistry

The invention belongs to the technical field of regenerated plastics, and particularly relates to a device for removing metal elements in regenerated plastic bottle flakes, which comprises a magnetic separation cylinder. An impurity material bin sleeves the magnetic separation cylinder, and a magnetic separation rod is horizontally inserted in a cylinder cavity of the magnetic separation cylinder; the magnetic separation rod consists of two sections of magnetic separation parts and a connecting part which is arranged between the two sections of magnetic separation parts and overhangs the end part; one section of magnetic separation part is located in a cylinder cavity of the magnetic separation cylinder, the adjacent connecting part is located in a cavity of the impurity material bin, the other section of magnetic separation part is located outside the cylinder cavity of the magnetic separation cylinder, and when the magnetic separation part located in the cylinder cavity of the magnetic separation cylinder moves outwards, the magnetic separation part located outside the cylinder cavity of the magnetic separation cylinder moves inwards. A scraping sleeve is arranged on the bin wall of the inner side of the impurity material bin and used for scraping away impurity chippings adsorbed to the magnetic separation part. According to the device for removing the metal elements in the regenerated plastic bottle flakes, the ferromagnetic metal chippings on the magnetic separation rod do not need to be cleared away without shutdown, and the magnetic separation efficiency is improved.

Owner:界首市成铭塑业有限公司

Method for modifying high-temperature steel slag by using compound materials of tailings

ActiveCN102605113BEasy to separateComponent controllableIncreasing energy efficiencyCalcium in biologySteelmaking

Provided is a method for modifying steel slag. High-temperature steel slag discharged in the final steelmaking stage is modified by using a large amount of mining tailings with low cost. 15-30 parts by weight of high alumina silicate tailings, 60-80 parts by weight of high calcium silicate tailings and 5-15 parts by weight of calcium carbonate tailings are mixed to obtain compound materials of the tailings; granulating is performed to prepare agglomerated blocks; the compound materials of the tailings are added into a steel slag pot or disc by batches according to the proportion of (70-80%):(20-30%) of the discharged steel slag and the compound materials of the tailings; the temperature of the steel slag is kept at 1200-1400°C for 30-60 min; water quenching, heat applying or heat covering is performed when the temperature is below 1200°C; breaking is performed; magnetic separation is performed. By means of the method, the separation effect of the iron slag is improved, the grindability of the steel slag is improved, the total recovery rate of the scrap steel is up to 95-100%, the components of the separated scrap slag are controllable and have high activity, and the separated scrap slag contains less than 1.5% by weight of the free calcium oxide, has the grinding work index of 14-17kw.h / t and is used to replace the silicate cement clinker.

Owner:迁安金隅首钢环保科技有限公司

Refractory material magnetic separation and conveying device

ActiveCN106238204AReduce labor intensityImprove magnetic separation efficiencyMagnetic separationRefractoryMagnetic separation

The invention provides a refractory material magnetic separation and conveying device. A first magnetic separation mechanism is composed of an auxiliary roll, a magnetic roll and a first drive device; the auxiliary roll is arranged under a feeding funnel; the auxiliary roll is in transmission connection with the magnetic roll through a conveyor belt; the first drive device is in driving connection with the auxiliary roll or the magnetic roll to enable the auxiliary roll or the magnetic roll to rotate; a second magnetic separation mechanism is composed of a slide rail, a sliding block, a second drive device, an electromagnetic sucker and a third drive device; the length direction of the slide rail is parallel to the conveying direction of the conveyor belt; the sliding block is installed in the slide rail in a sliding manner; the second drive device can drive the sliding block to move along the slide rail; the electromagnetic sucker is installed on the sliding block; and the third drive device can drive the electromagnetic sucker to move up and down. The refractory material magnetic separation and conveying device provided by the invention is environmentally friendly and is low in labor intensity, high in magnetic separation efficiency and good in separation effect; and scrap iron obtained by magnetic separation can be directly recycled and utilized.

Owner:宿州市威菱耐火材料有限责任公司

Magnetic separator for efficiently separating magnetic materials

PendingCN110075998AImprove magnetic separation efficiencyThorough magnetic separationMagnetic separationMagnetic separatorEngineering

The invention provides a magnetic separator for efficiently separating magnetic materials. The magnetic separator comprises a box, a rotating drum arranged on the box, a magnetic component which is arranged in the rotating drum and does not rotate with the rotating drum, a feed port which is arranged on the box and located above the rotating drum and a discharge port which is located below the rotating drum. The magnetic separator is characterized in that the magnetic component comprises a fixed roller, axial magnetic conducting stripes which are arranged at intervals on the surface of the fixed roller, and permanent magnets of which each is arranged between the two axial magnetic conducting stripes, wherein the magnetic poles of the permanent magnets are arranged in the same polar direction on both sides of the axial magnetic conducting stripes so that the magnetic materials can be separated more easily, and the problems that the magnetic separation effect and the recovery rate are difficult to improve due to the magnetic clamp and the mechanical inclusion can be completely solved, the magnetic separation efficiency is high, the magnetic separation is thorough and environment protection and energy conservation are realized. The concentrate with the metal grade of more than 66% and the metal recovery rate of more than 85% can be obtained by only using the magnetic separator.

Owner:云南焠金时代科技有限公司

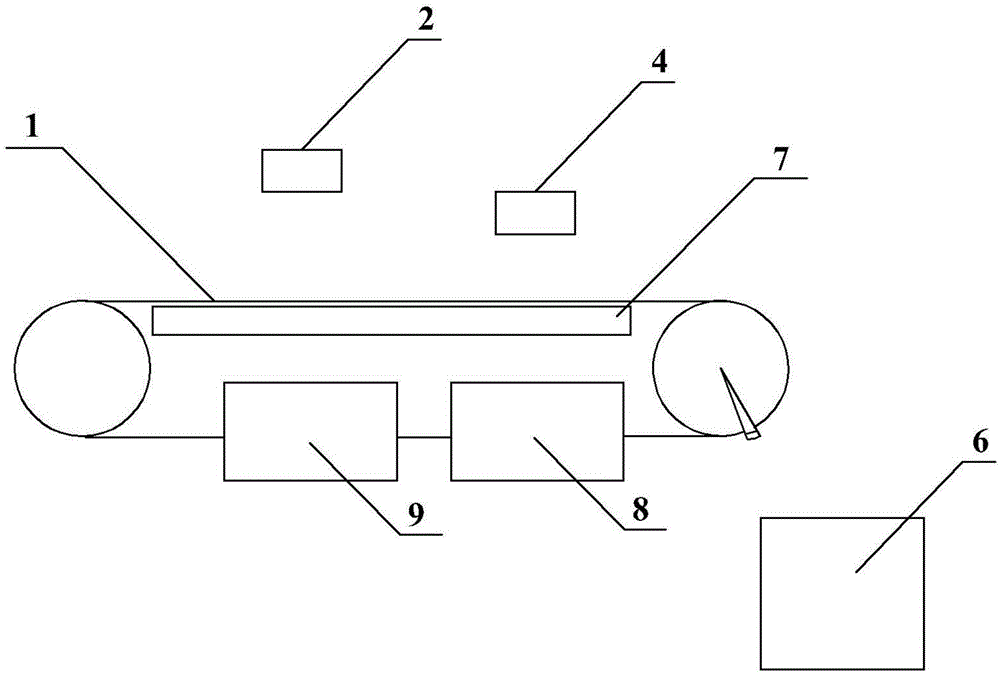

Magnetic separator

InactiveCN105107625ASimple structureEasy to assembleMagnetic separationMagnetic separatorUltrasonic vibration

The invention discloses a multi-stage magnetic separator which comprises a first roller conveyor belt, a second roller conveyor belt, a third roller conveyor belt, a first magnet, a second magnet, a first collecting barrel, a second collecting barrel, a third collecting barrel, and an ultrasonic vibration plate. The multi-stage magnetic separator is simple in structure and high in magnetic separation efficiency. According to the magnetic separator, after powder enters the magnetic separator, the feeding speed does not rely on a feeding plate and can be completely adjusted through a motor; the powder and the magnet make full contact, so that the missing rate is effectively lowered, and the magnetic separation efficiency is improved. The magnetic separator is simple in structure, convenient to assemble and easy to maintain.

Owner:TIANJIN FUZHAO ALLOY MATERIAL

Magnetite pretreatment device

ActiveCN110523626AUniform size and qualityUniform processing surfaceSievingGas current separationMagnetiteEngineering

A magnetite pretreatment device comprises a cutting system, a screening system, a washing system, a magnetic separation system and a flotation system which are sequentially arranged from top to bottom. According to the cutting system, the ore raw materials are cut three times in sequence, the cutting effect is good, the efficiency is high, and the situation that during the follow-up machining process, the ore size is too large, so that a machine gets stuck, can be effectively prevented. Meanwhile, the cutting system can adjust the number of the parts, extending into the corresponding working grooves, of the rotary cutters according to the size of ore raw materials and the cutting requirements, so that the cutting efficiency is changed, and the work scheduling is flexible. According to thescreening system, the mineral aggregate is screened through the vibration and the wind power, so that the screening efficiency is effectively improved. According to the magnetic separation system, through the design of the two layers of conveying crawler belts and the shifting plates, more magnetic separation heads can be used for magnetic separation at the same time, the magnetic separation efficiency is improved, and themetallic magnetite can be rapidly and effectively separated out.

Owner:肖春槐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com