Air-suction type permanent magnet ore concentrating machine

A dry magnetic separation and permanent magnet technology, which is applied in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of safety risks, low magnetic separation precision, and low magnetic separation efficiency, and meet the small requirements for sealing performance , Avoid pollution, reduce processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

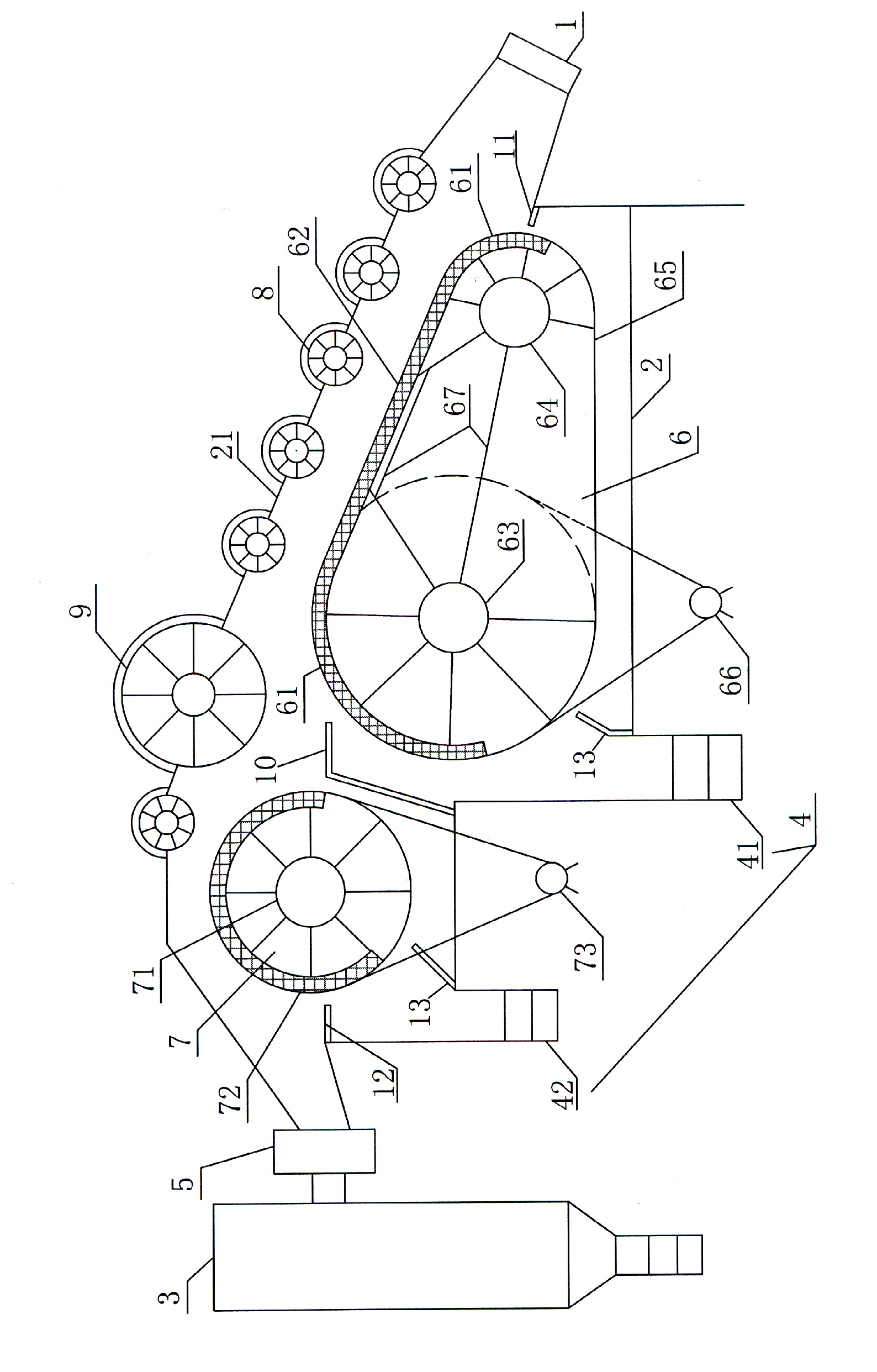

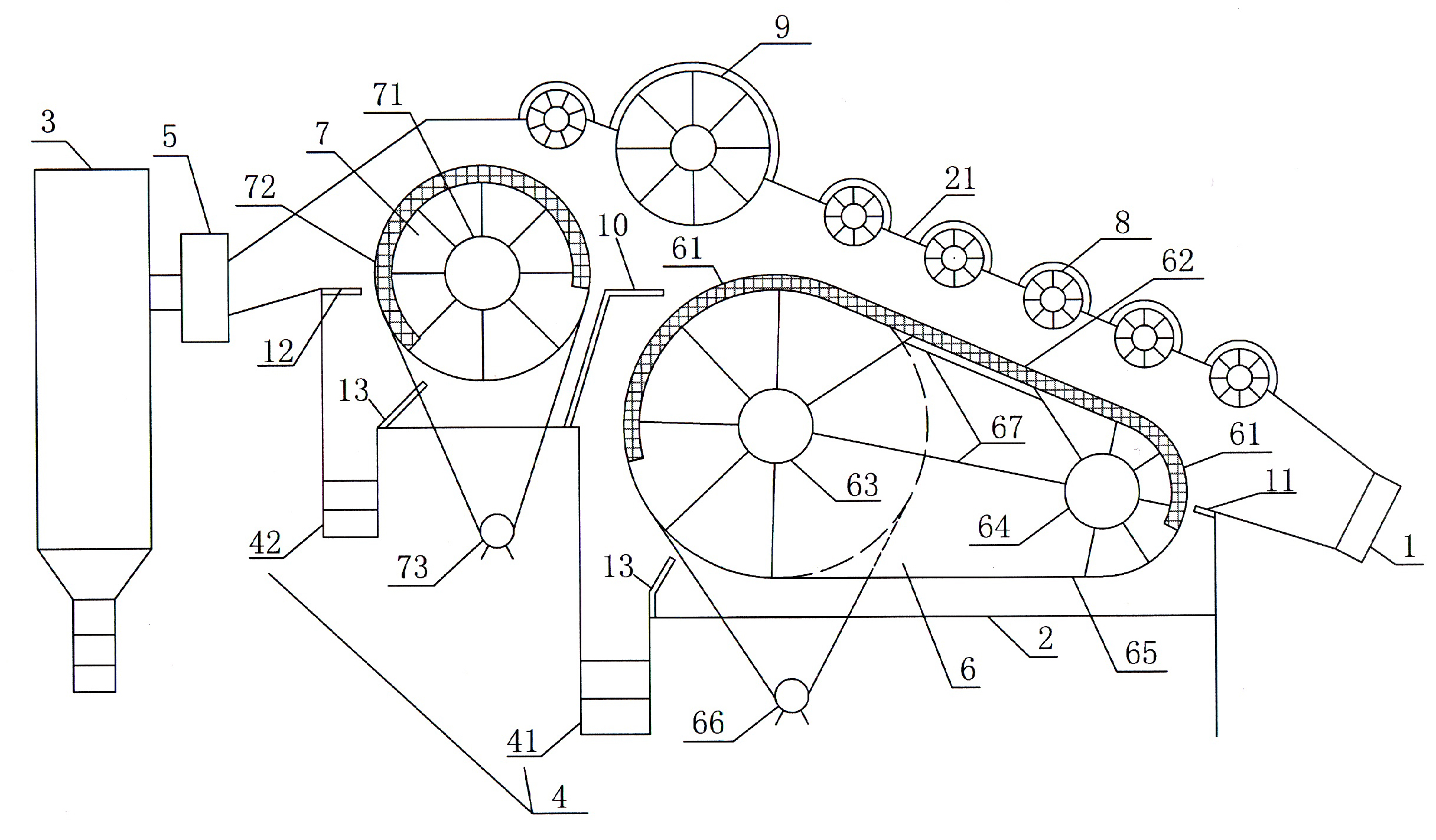

[0028] Such as figure 1 The embodiment shown is a wind-suction permanent magnet concentrator, which includes a feed port 1, a dry magnetic separation device 2, a tailing bin 3 and a feed bin 4, and the feed port 1 is installed on the dry magnetic The inlet end of the separation device 2 is used to transport ore powder to the magnetic separation chamber; the tailings bin 3 is installed at the outlet end of the dry magnetic separation device 2, and the combination of an ordinary tailings bin and a dust recovery bin is preferably used to classify and recover the tailings; The silo 4 is arranged at the bottom of the dry magnetic separation device 2 for collecting the magnetically separated metals; the top wall 21 in the cavity of the dry magnetic separation device 2 is arranged obliquely, that is, it is arranged along the direction of the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com