Oblique grading and magnetic separation device

A magnetic separation device, inclined technology, applied in the field of inclined classification magnetic separation device, can solve the problems of large material handling capacity, inconvenient material movement, no way to achieve, etc., to ensure the quality of magnetic separation, reduce floor space, reduce The effect of magnetic separation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

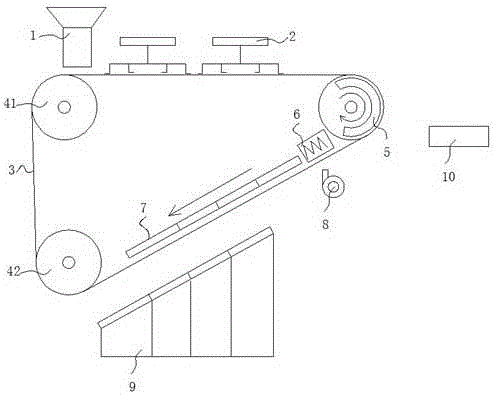

[0038] Such as figure 1 Shown, a kind of oblique classification magnetic separation device of the present invention. Comprise magnetic separation belt 3, and magnetic separation belt 3 is supported as triangular wheel, comprise magnetic roller 5, transmission roller one 41, transmission roller two 42; Magnetic separation belt 3 comprises horizontal section and inclined section, and horizontal section intersects with inclined section The wheel at the position is a magnetic roller 5; a sorting magnetic system 7 is arranged on the inner side of the inclined section, and a strong magnetic device 6 is arranged between the sorting magnetic system 7 and the magnetic roller 5, and the magnetic roller 5, the strong magnetic device 6 and the separation The magnetic force of the magnetic separation system 7 is continuous; a strong fan 8 is arranged under the strong magnetic device 6, and the magnetic field strength of the strong magnetic device 6 is stronger than that of the sorting magn...

Embodiment 2

[0050] Based on the magnetic separation device of embodiment 1, its magnetic separation system includes a magnetic separation device, a flat material device, a strong fan, a feeding device, a spray device, an ore-discharging device, and a controller;

[0051] Both the strong magnetic device and the sorting magnetic system of the magnetic separation device are electromagnets, the number of coil turns in the electromagnet of the sorting magnetic system decreases along the magnetic separation direction, and the coil turns ratio of the sorting magnetic system is 10:6:3; The magnetic separation belt of the magnetic separation device is driven by a drive motor;

[0052] The flat feeding device is arranged above the horizontal section of the magnetic separation belt, including a rotating shaft and a flat feeding claw connected to one end of the rotating shaft. The other end of the rotating shaft is connected to a driver. The horizontal bar is fixedly connected, and the claws are L-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com