Magnetic separation equipment used in process of recycling copper and nickel salt from waste ABS electroplated parts

A magnetic separation equipment and copper recovery technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve problems such as ineffective magnetic separation, achieve excellent magnetic separation effect, high magnetic separation efficiency, and improve utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

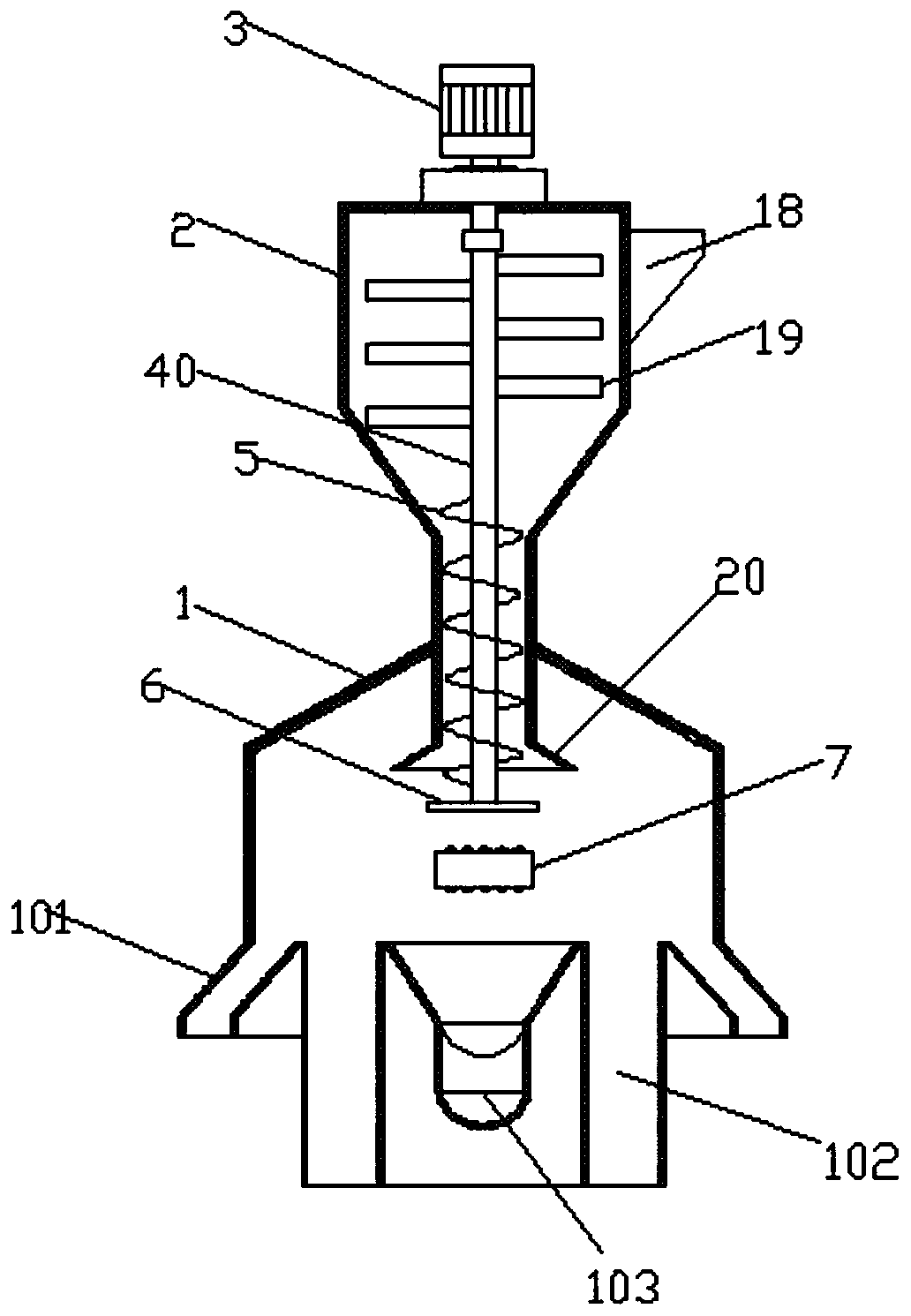

[0028] This embodiment 1 specifically introduces a magnetic separation device used in the process of reclaiming copper and nickel salts from waste ABS electroplating parts. A feeding port 18 is provided at the side upper end of the upper feed bin 2 for replenishing ABS waste in time. A feeding motor 3 is fixedly installed on the upper surface of the upper bin 2, and a feeding pipe 4 is arranged at the lower end of the upper bin 2. The feeding pipe 4 is inserted into the inside of the magnetic separation cylinder 1, and the output of the feeding motor 3 The shaft extends into the inside of the upper feed bin 2, and is connected with a rotating rod 40 at its lower end. The circular material throwing plate 6 is also provided with a crushing rod 19 on the turning 40 bar at the level of the feeding port 18, which can crush the added pulverized material again. An electromagnet 7 is arranged inside the magnetic separation cylinder 1 below the circular throwing plate 6. The electroma...

Embodiment 2

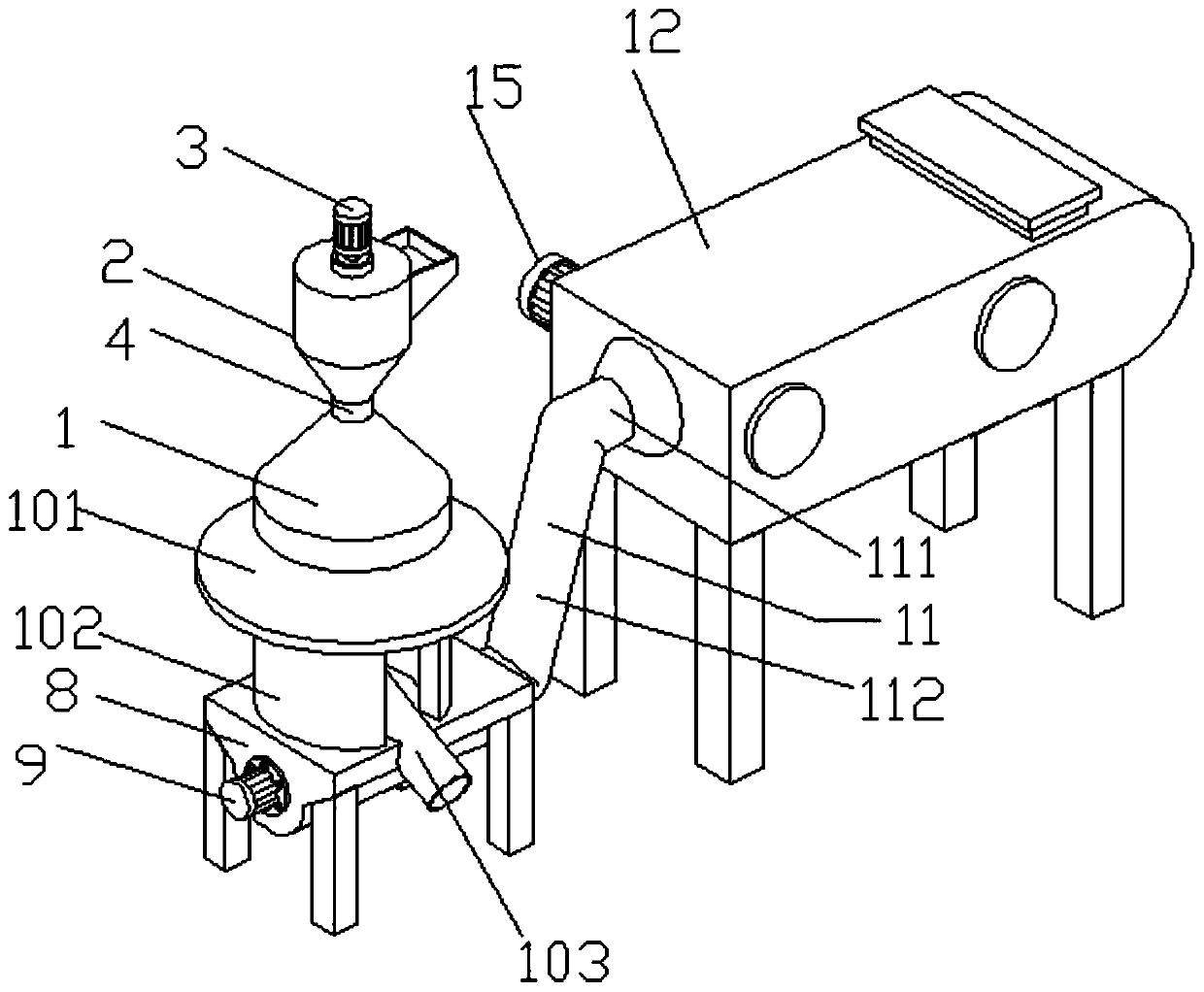

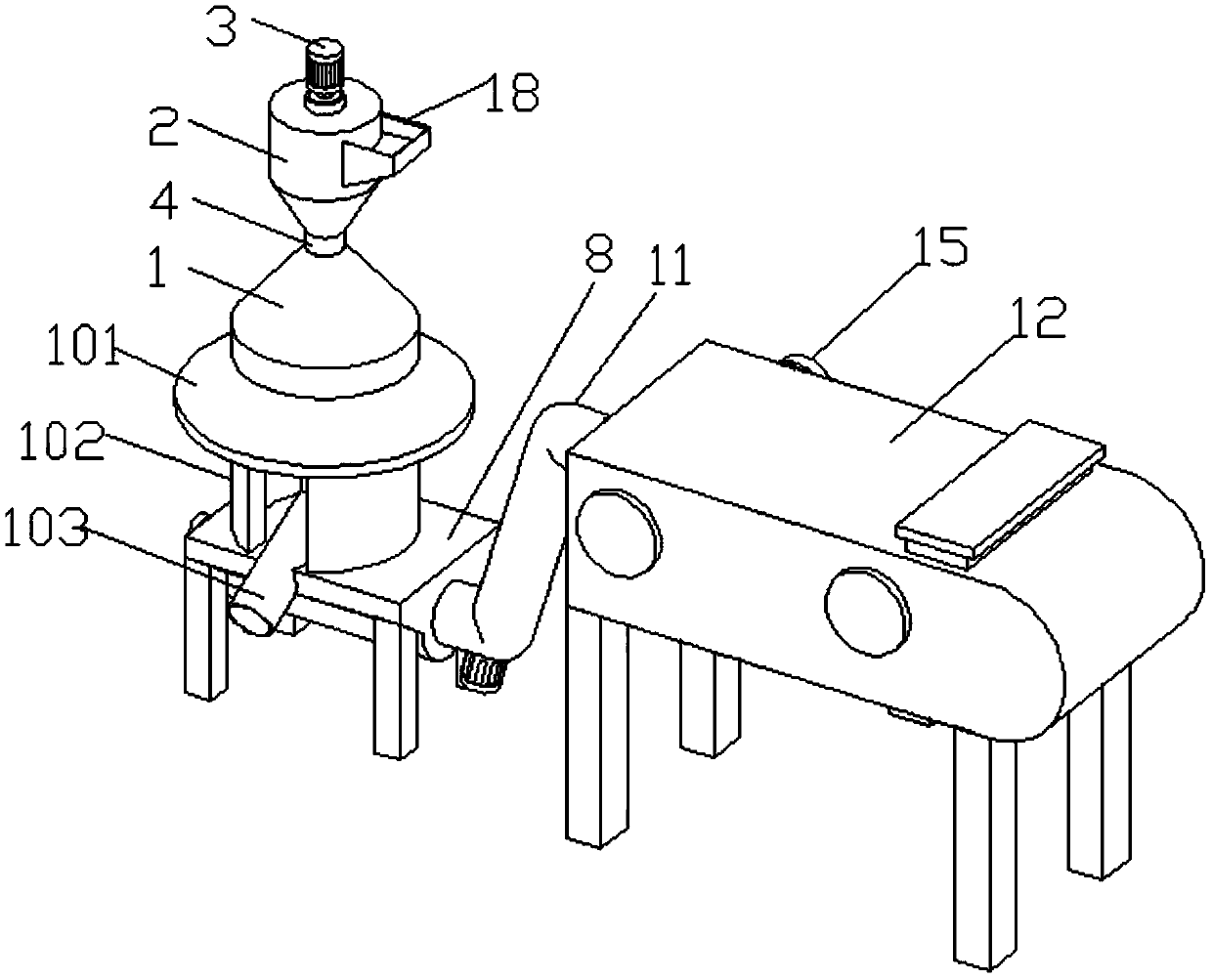

[0032]Embodiment 2 is to carry out secondary magnetic separation on the ABS inclusion material falling in the ABS inclusion material discharge ring mouth 102 on the basis of embodiment 1, and its specific improvement step structure is as follows: at the lower end of the ABS inclusion material discharge ring mouth 102 It is connected with the transition bin 8, wherein the discharge ring 102 of the ABS inclusion material is connected with the interior of the transition bin 8, and the falling ABS inclusion material can all fall into it, and a transport motor 9 is arranged on the side wall of the transition bin 8, And the output end of the transport motor 9 stretches into the end of the transition storehouse 8 and is connected with an auger transport leaf 10. Through the action of the auger transport leaf 10, the ABS can be clamped on the material and transported to its right end, and at the other end of the transition storehouse 8 A feeding pipe 11 is connected to the side wall, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com