Pre-magnetization magnetic seed magnetic separation method

A magnetic seed and pre-magnetization technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of magnetic mineral attachment and accumulation, high power consumption, etc., and achieve the effect of improving the recovery rate of magnetic separation and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

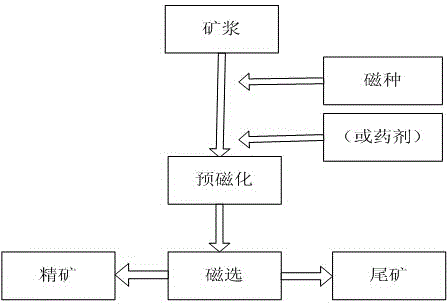

Method used

Image

Examples

Embodiment 1

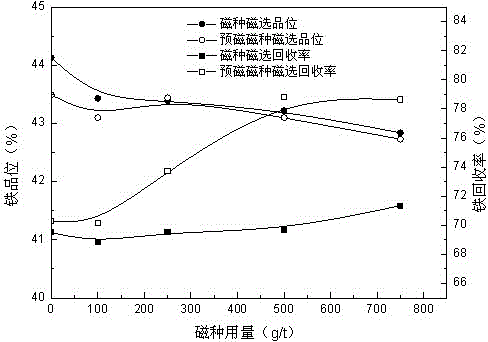

[0025] Example 1 Oxidized ore pre-magnetic magnetic seed magnetic separation, with weak magnetic iron oxide ore as test sample: magnetic seed is synthetic Fe 3 o 4 Particles, average particle size 2μm. Take finely ground 100g of a certain weak magnetic iron oxide ore in a beaker, add 200ml of water to adjust the slurry, add magnetic seeds (amount variable 0 g / t-750 g / t), pre-magnetic stirring or direct stirring for 3 minutes, Enter the strong magnetic separator (1.5T) to carry out two sets of series comparison tests of magnetic seed magnetic separation and pre-magnetic magnetic seed magnetic separation with the amount of magnetic seed as a variable. The so-called pre-magnetization is the pre-magnetization effect of stirring in a magnetic field with a field strength of 0.2T before the strong magnetic separation. Test results such as figure 2 shown. It can be seen that with the increase of the amount of magnetic seeds, at the same amount of magnetic seeds, the concentrate g...

Embodiment 2

[0026] Embodiment 2 Oxidized ore pre-magnetic magnetic seed magnetic separation, the impact of pre-magnetic field strength: sample and test method are the same as the above example 1, but the fixed magnetic seed consumption is 500g / t, and the effect of pre-magnetic magnetic seed magnetic separation on the pre-magnetic magnetic seed is investigated Influence, the results are shown in Table 1, from which we can see the effect of the pre-magnetic field.

[0027] Table 1 Pre-magnetization magnetic seed magnetic separation (magnetic seed dosage 500g / t, pre-magnetization time 5min, strong magnetic separation field strength 1.5T)

[0028] Pre-magnetic field strength (T) Magnetic concentrate yield (%) Concentrate grade (Fe,%) Recovery rate (Fe,%) 0.0 53.16 43.22 69.67 0.05 61.79 / / 0.1 62.05 42.23 79.45 0.2 60.32 43.10 78.83

Embodiment 3

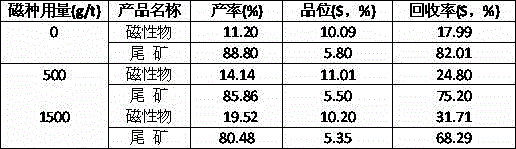

[0029] Embodiment 3 The pre-magnetic magnetic seed magnetic separation of weak magnetic iron oxide tailings, the interaction of magnetic seed, medicament and pre-magnetic: the sample is the tailings (containing 25.96% iron) produced through iron ore strong magnetic separation, and the test The method is the same as the above example 1, except that in one of the tests, the drug starch is added at the same time as the magnetic seed is added, and the pre-magnetic field strength is fixed at 0.2T. The test results are shown in Table 2 below. It can be seen that the recovery rate of pre-magnetic magnetic seed magnetic separation is higher than that of direct strong magnetic separation, and the recovery rate of pre-magnetic magnetic seed magnetic separation with medicament starch is higher.

[0030] Table 2 Pre-magnetic magnetic seed magnetic separation (pre-magnetic field strength 0.2T, pre-magnetic time 5min, strong magnetic field strength 1.5T)

[0031] Magnetic seed do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com