Method for preparing and processing high-purity quartz

A processing method, quartz technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of poor magnetic separation effect of magnetic separation drum, accumulation on magnetic separation drum, affecting the normal falling of ore particles, etc. The effect of increasing the magnetic separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

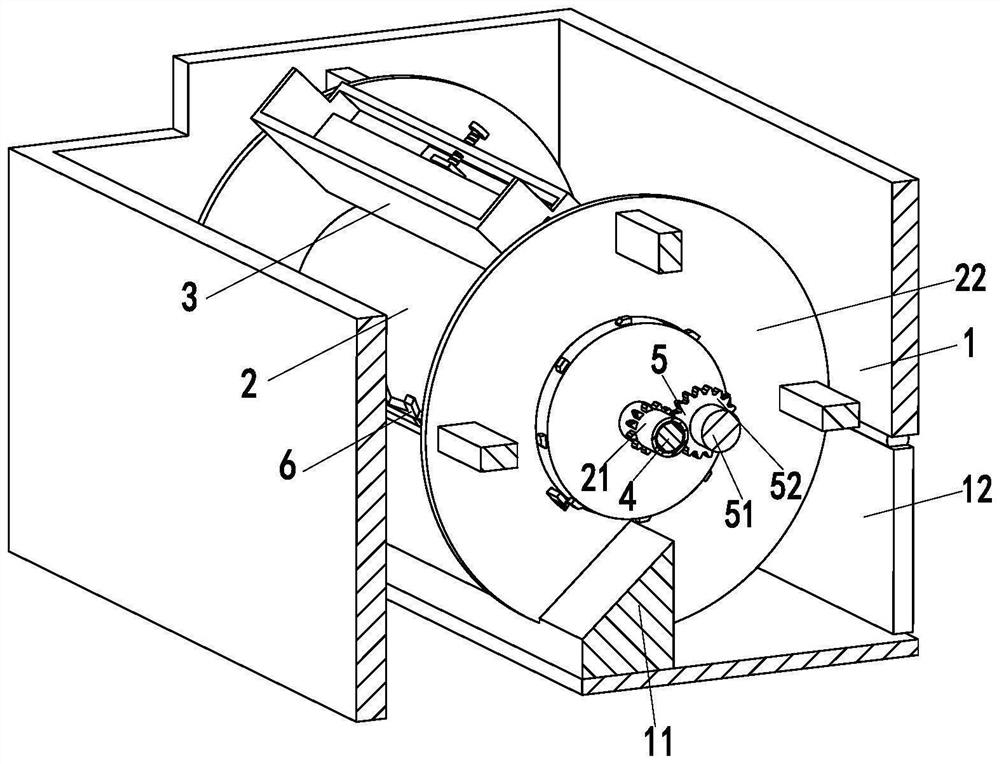

[0038] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0039] refer to Figure 9 , a method for preparing and processing high-purity quartz, the method for preparing and processing high-purity quartz includes specific steps as follows: S1, ore processing: first select vein quartz-type rock or granite-type rock to perform primary and secondary crushing treatment, Break the ore into small particles;

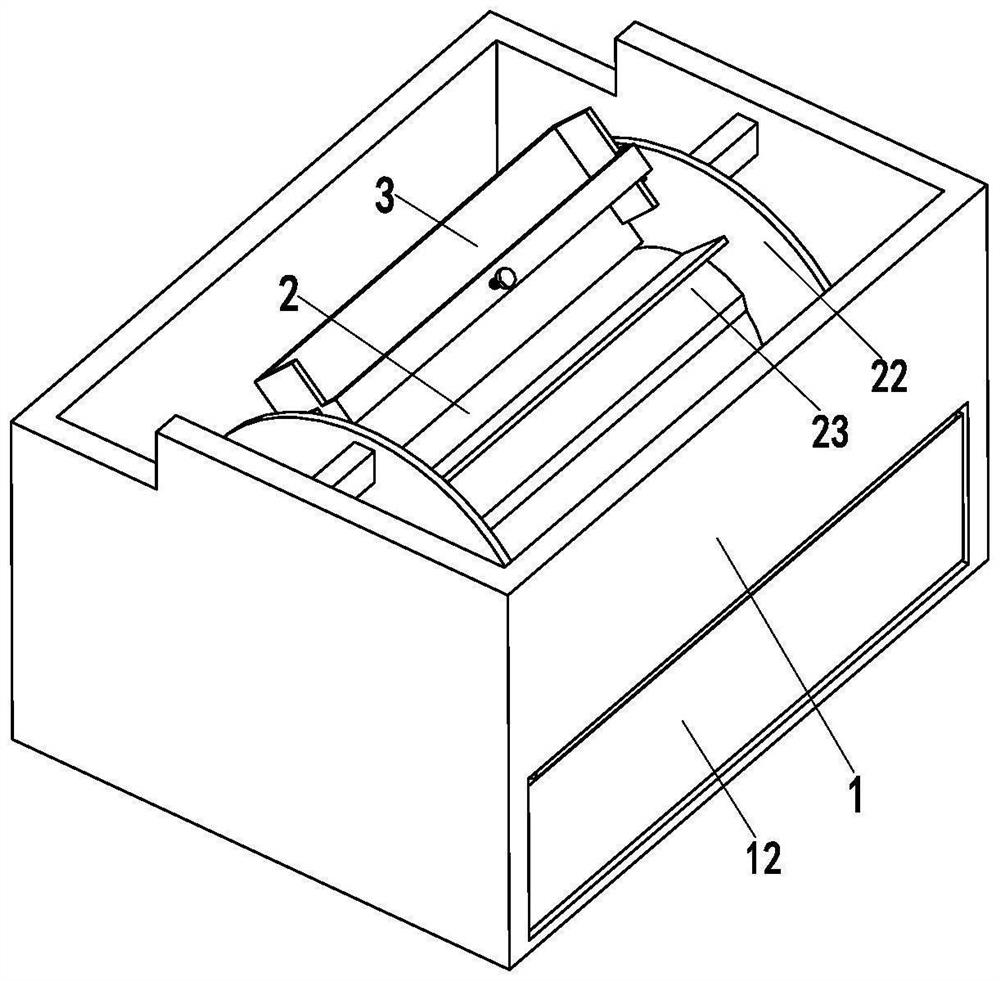

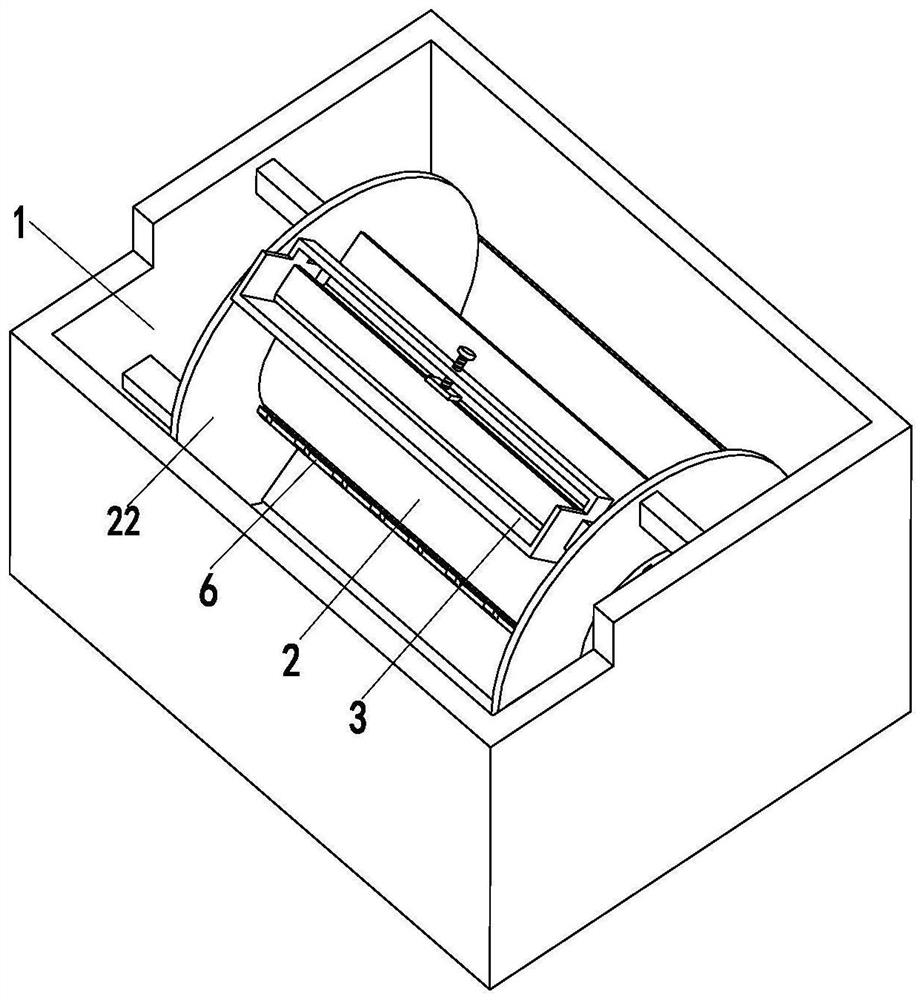

[0040] S2, ore magnetic separation: the ore broken into small particles is placed in a magnetic separation screening machine for magnetic separation treatment in order to remove iron impurities in the ore particles, and the magnetically separated ore particles are placed in a grinder with an agate bowl Grinding into powder inside, using a grinder with an agate bowl can avoid mixing metal debris after the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com