Efficient rubber crushing and recycling device and crushing and recycling method thereof

A recovery device and rubber technology, which is applied in the field of rubber crushing, can solve the problems of reducing iron powder content, increasing rubber processing efficiency, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

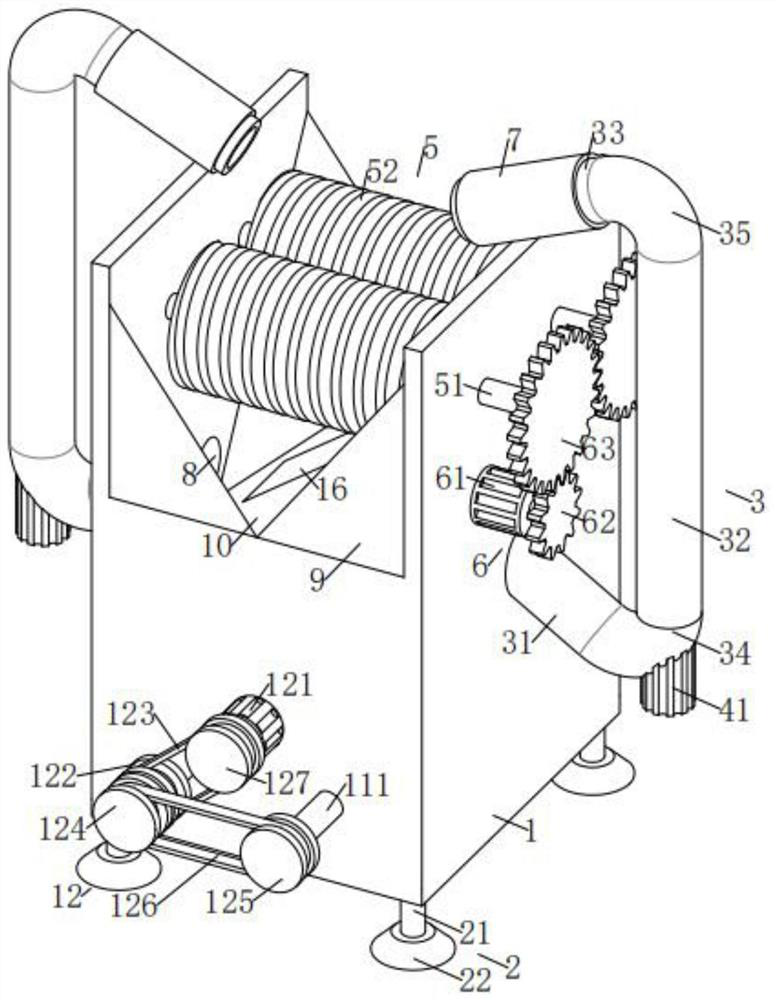

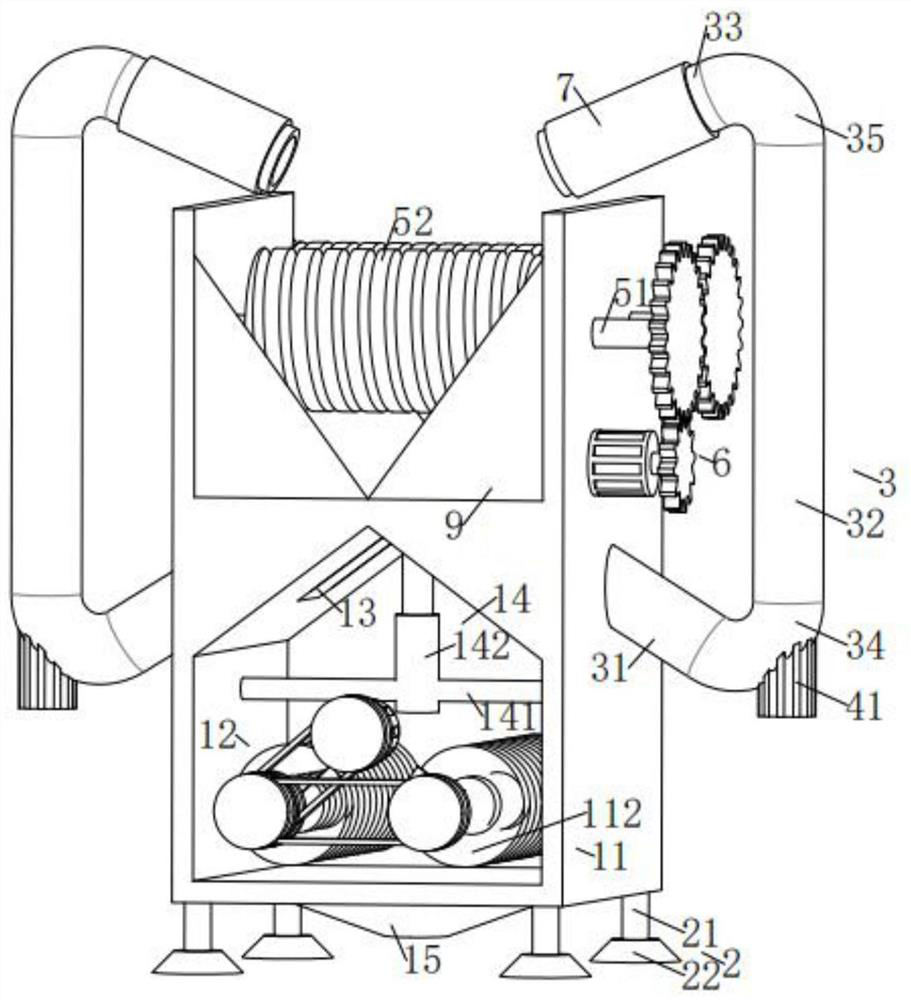

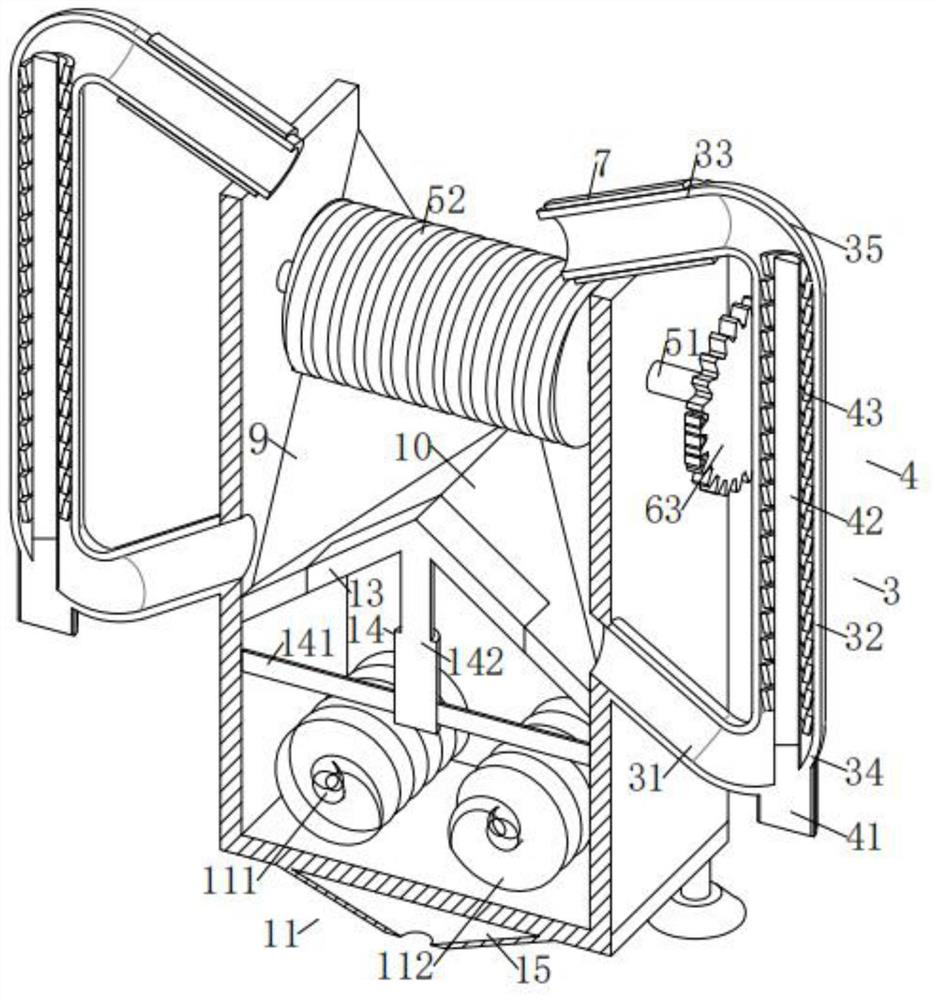

[0051] see Figure 1-3 , a high-efficiency rubber crushing and recycling device, including:

[0052] The lower parts of the front and rear ends are closed U-shaped outer frames 1, and the U-shaped outer frame 1 is hollowed out and has a thickness;

[0053] A herringbone-shaped blanking plate 10 fixedly arranged between the left and right inner walls of the U-shaped outer frame 1, the herringbone-shaped blanking plate 10 is used to realize the blanking of the pulverized rubber particles, and makes them slide to both sides by gravity;

[0054] Two groups of triangular pyramid guide blocks 9 fixedly arranged on the top of the herringbone blanking plate 10, each group of triangular pyramid guide blocks 9 are provided with two, and the outside of the triangular pyramid guide blocks 9 is flat with the U-shaped outer frame 1, Through the function of two sets of triangular pyramid guide blocks 9, it not only blocks them from falling to the outside of the U-shaped outer frame 1, but a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com