Solid waste material regeneration method and solid waste material regeneration device

A solid waste and regeneration device technology, applied in the direction of solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as natural environmental pollution, 100% treatment, secondary pollution of groundwater, air, and soil, and achieve The effect of solving the pollution problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

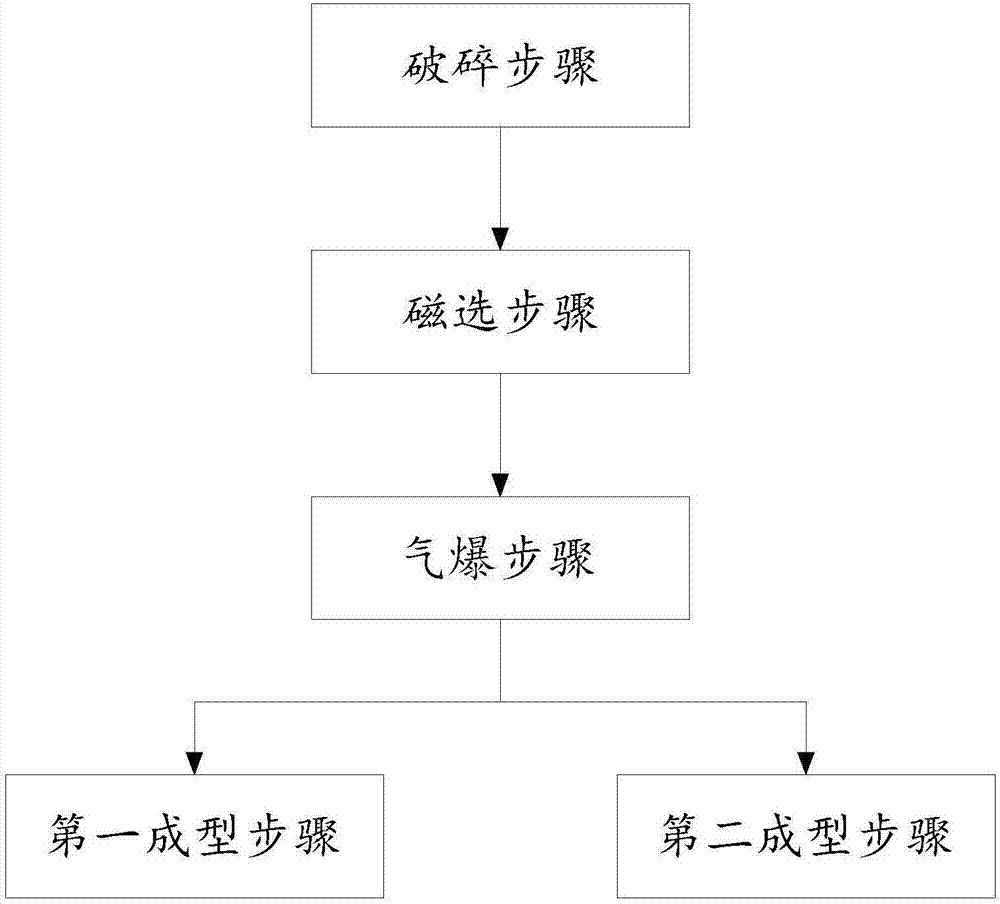

[0045] This embodiment provides a solid waste recycling method, please refer to figure 1 , this solid waste regeneration method comprises the steps:

[0046]Crushing step: crushing solid waste to obtain crushed materials;

[0047] Magnetic separation step: separating the crushed material into magnetic material and demagnetized material;

[0048] Gas explosion step: separating the demagnetized material into a solid mixture and a muddy mixture;

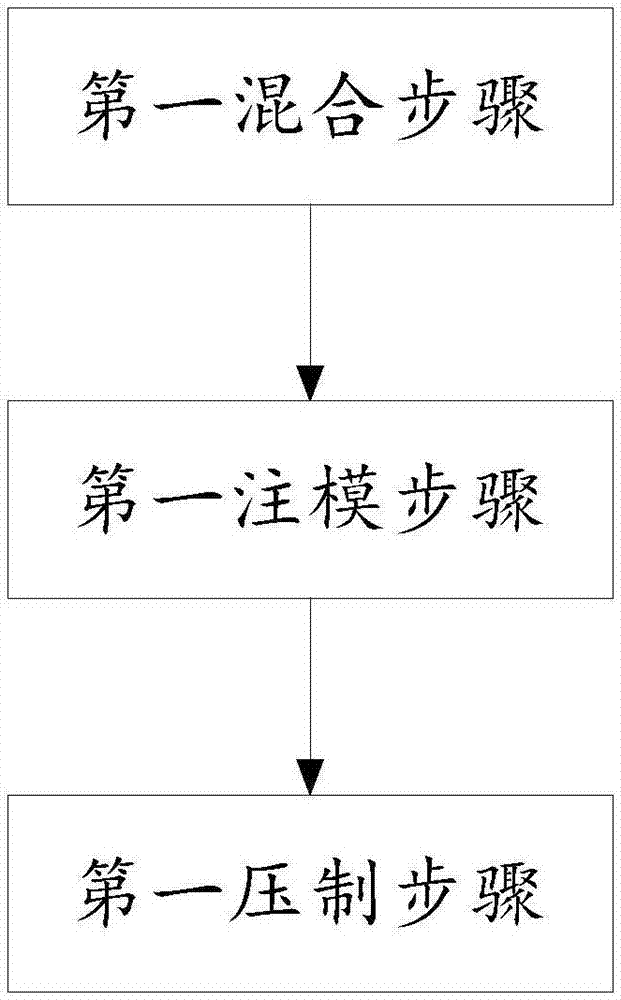

[0049] The first molding step: combining the solid mixture with a first adhesive material to form a first material;

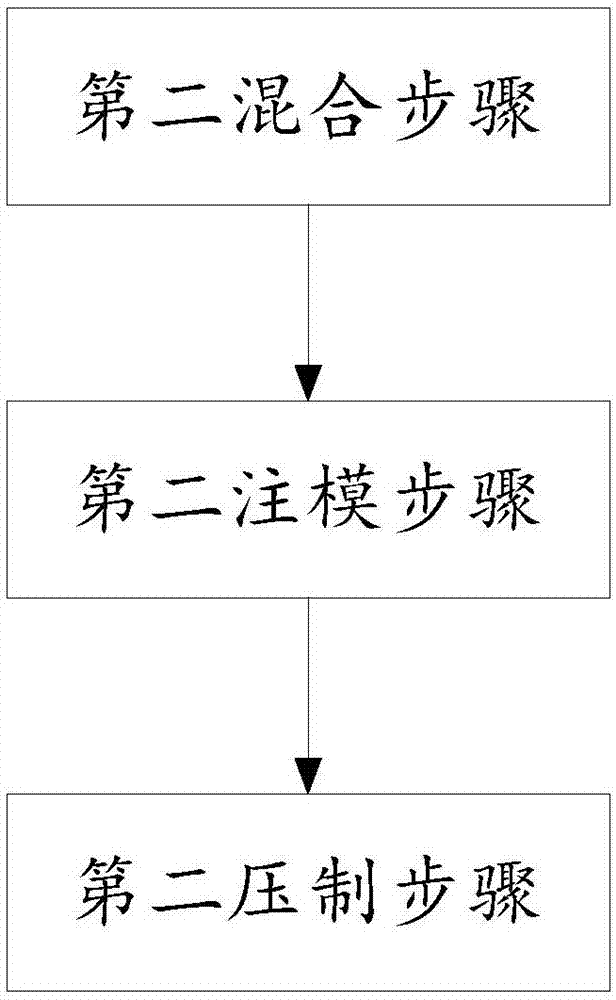

[0050] The second forming step: combining the mud-like mixture with a second bonding material to form a second material.

[0051] In this embodiment, the solid waste is industrial waste produced by paper mills.

[0052] Of course, in other embodiments, the solid waste may also be waste generated in other ways.

[0053] In this embodiment, the crushing step is to use a crusher to crush the solid waste to obtain crush...

Embodiment 2

[0080] This embodiment provides a solid waste regeneration device 100, which is used in the solid waste regeneration method provided in Embodiment 1. Please refer to Figure 4 and Figure 5 , this solid waste recycling device 100 includes a crushing device 110 for the crushing step, a magnetic separation device 120 for the magnetic separation step, a gas explosion generating device 130 for the gas explosion step, a first forming step and a second a forming device 140 for the forming step and a pressing device 150 for the first forming step and the second forming step;

[0081] The crushing device 110 has a first feed port 111 and a first discharge port 112, the magnetic separation device 120 has a second feed port 121 and a second discharge port 122, and the gas explosion generating device 130 has a third feed port. Port 131, the third discharge port 132 and the fourth discharge port 133, the molding device 140 includes a molding die 141, and the pressing device 150 has a wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com