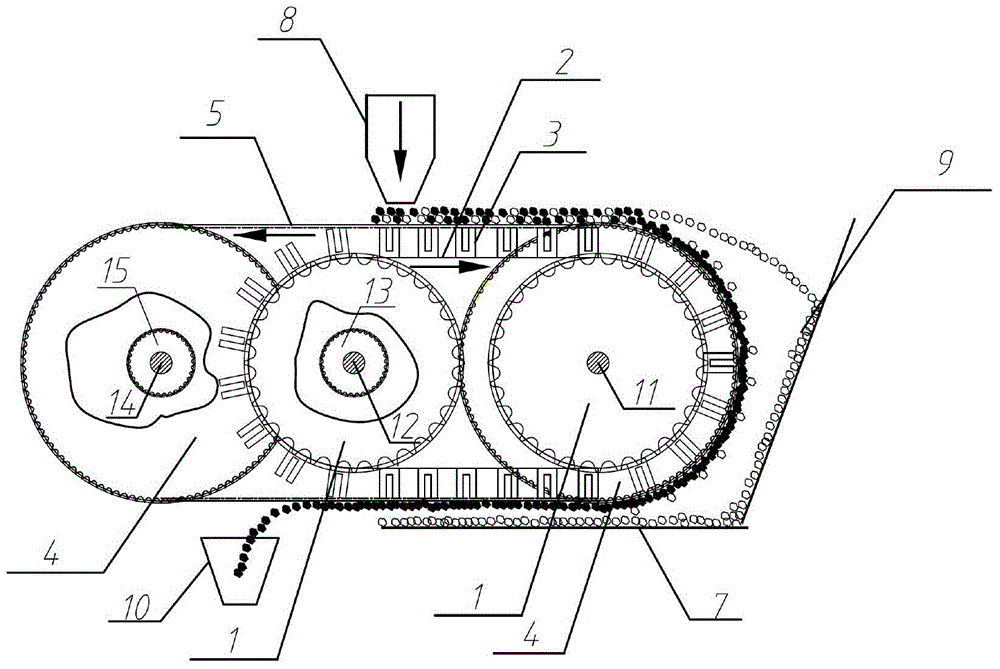

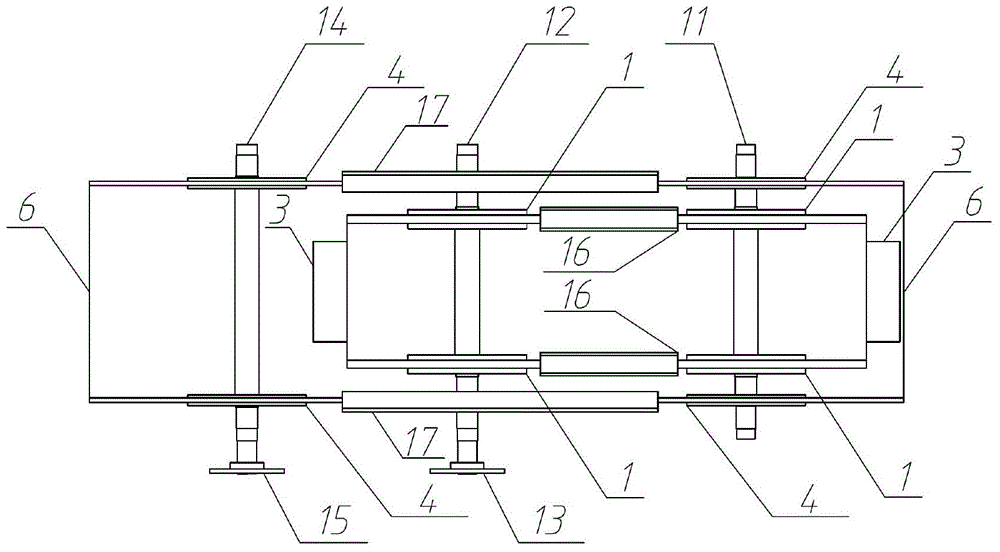

Dry type fine powder magnetic separator with annular mobile magnetic system

A technology of fine powder and magnetic separator, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of large particle size sorting characteristics, limited material flow thickness, poor sorting efficiency, etc., to improve magnetic The effect of selection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0056] (1) Using steel slag powder produced by a steelmaking plant, magnetic minerals (RO phase, Fe 3 o 4 , Fe) the total amount is about 30%, and the average particle size of steel slag powder is about 20 μm. After sorting with this equipment, the total amount of magnetic minerals in magnetic products increases to more than 60%, and the total amount of magnetic minerals in steel slag powder after sorting decreases to less than 5.0%, and the processing capacity of steel slag powder with a single machine can reach 10t / h.

[0057] (2) About 0.3t of magnetic products can be separated from 1 ton of steel slag raw material. After further processing and purification, the total amount of magnetic minerals can reach 96%, which can be used as raw material for ironmaking or heavy medium powder for coal preparation.

[0058] (3) The 3d, 7d, and 28d activity indices of the steel slag powder before sorting were 74.2%, 78.3%, and 82.9% respectively; 88.3%, 91.4%, become a high-quality ste...

example 2

[0060] The steel slag powder produced by a steelmaking plant is used, and the ultrafine particles are removed from the steel slag powder after the previous pneumatic separation process to obtain the steel slag coarse powder. Magnetic minerals (RO phase, Fe 3 o 4 , Fe) The total amount is about 40%, and the average particle size is about 40 μm. After using this equipment to magnetically separate steel slag coarse powder, the total content of magnetic minerals in the magnetic products increases to more than 80%. After these materials are further processed and purified, the total magnetic minerals can reach 96%. They can be used as raw materials for ironmaking or coal preparation. medium powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com